Numerical Simulation of Multi-Cluster Fracture Propagation in Marine Natural Gas Hydrate Reservoirs

Abstract

1. Introduction

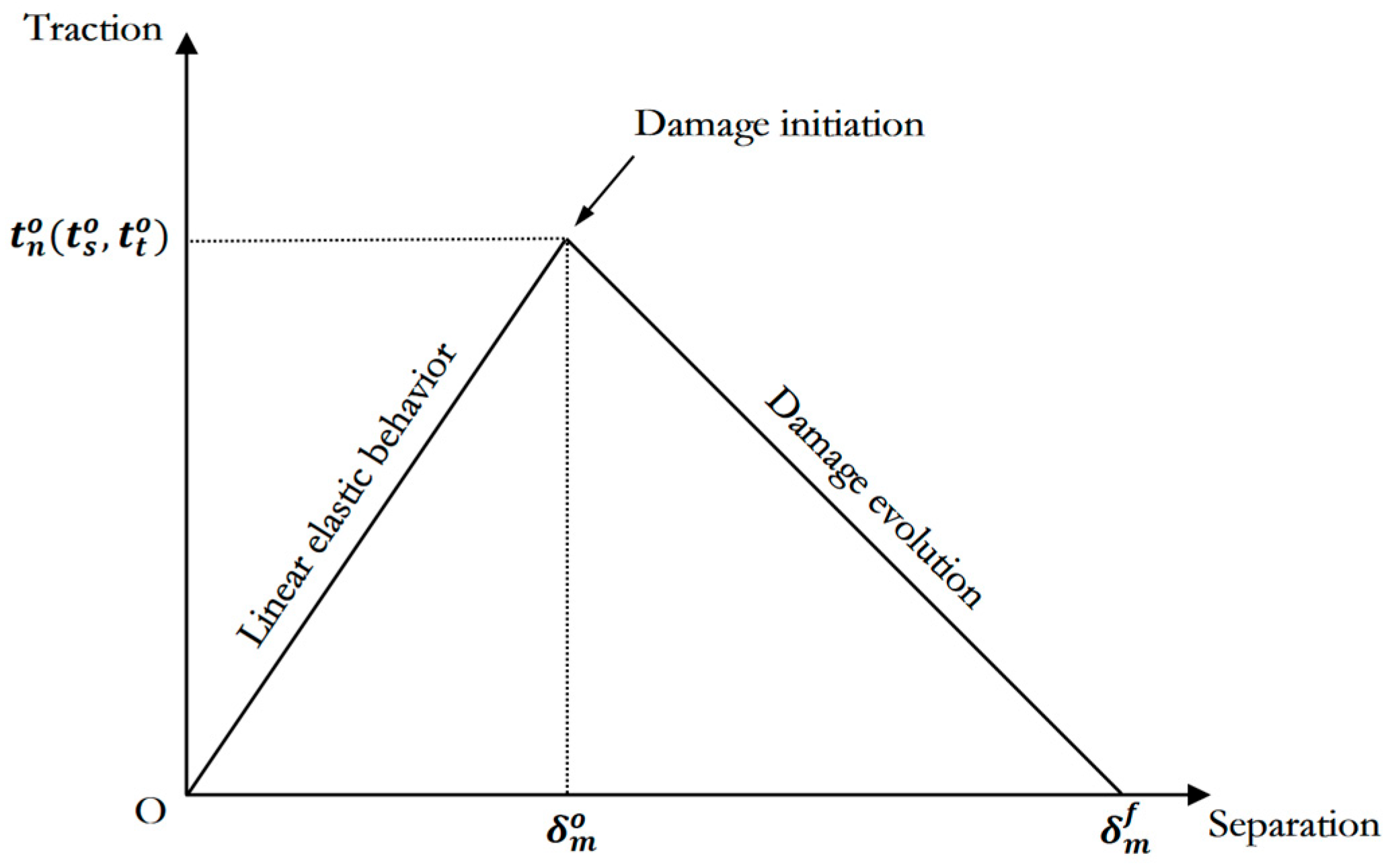

2. Hydraulic Fracturing Theory Based on Cohesive Method

2.1. Cohesive Element Method Introduction

2.2. Analysis of Fracture Process

2.3. Flow Equation in Fracture

3. Numerical Simulation

3.1. Model Assumptions

3.2. Model Construction

3.3. Model Parameters

3.3.1. Tensile Strength

3.3.2. Elastic Modulus

3.3.3. Permeability

3.3.4. Void Ratio

3.4. Initial and Boundary Conditions

4. Results

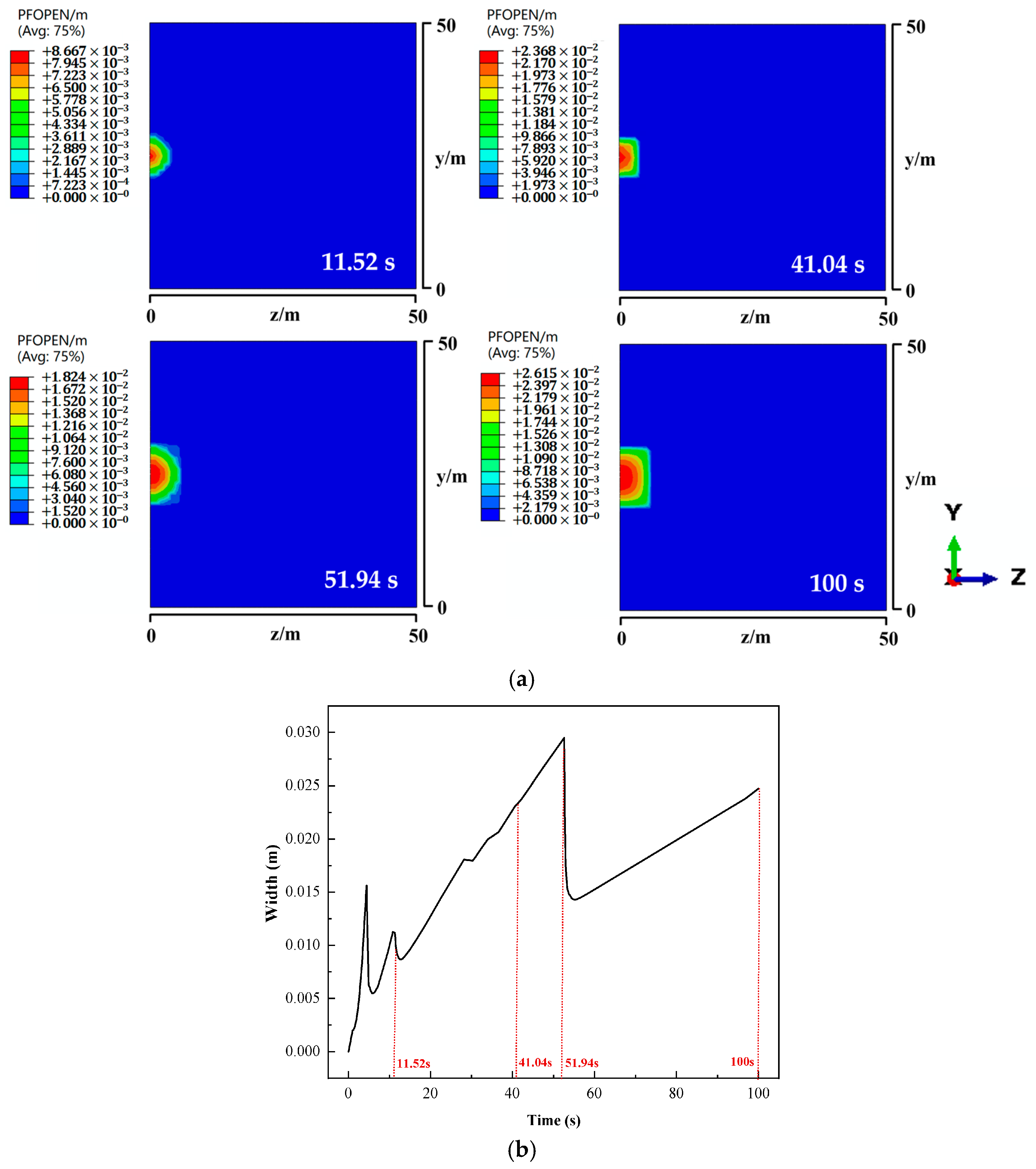

4.1. Reservoir Property and Fracturing Parameters Influence Analysis

4.1.1. Plasticity of Sediment

4.1.2. Hydrate Saturation

4.1.3. Viscosity of Fracturing Fluid

4.1.4. Injection Rate of Fracturing Fluid

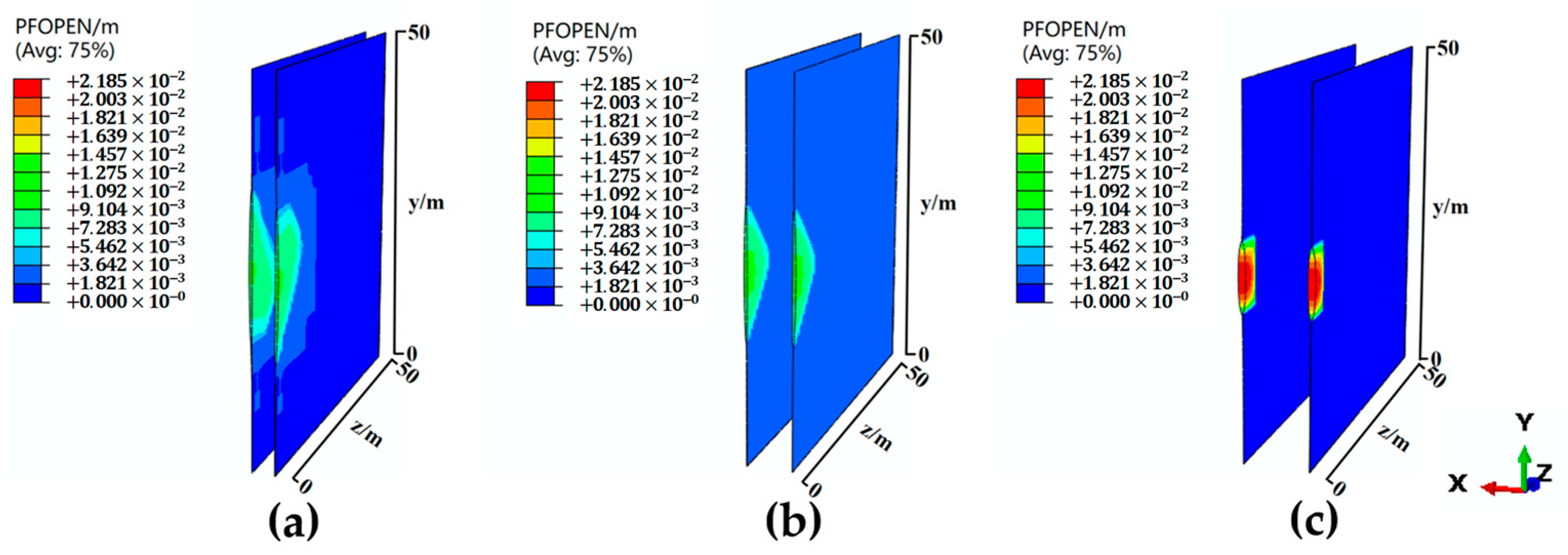

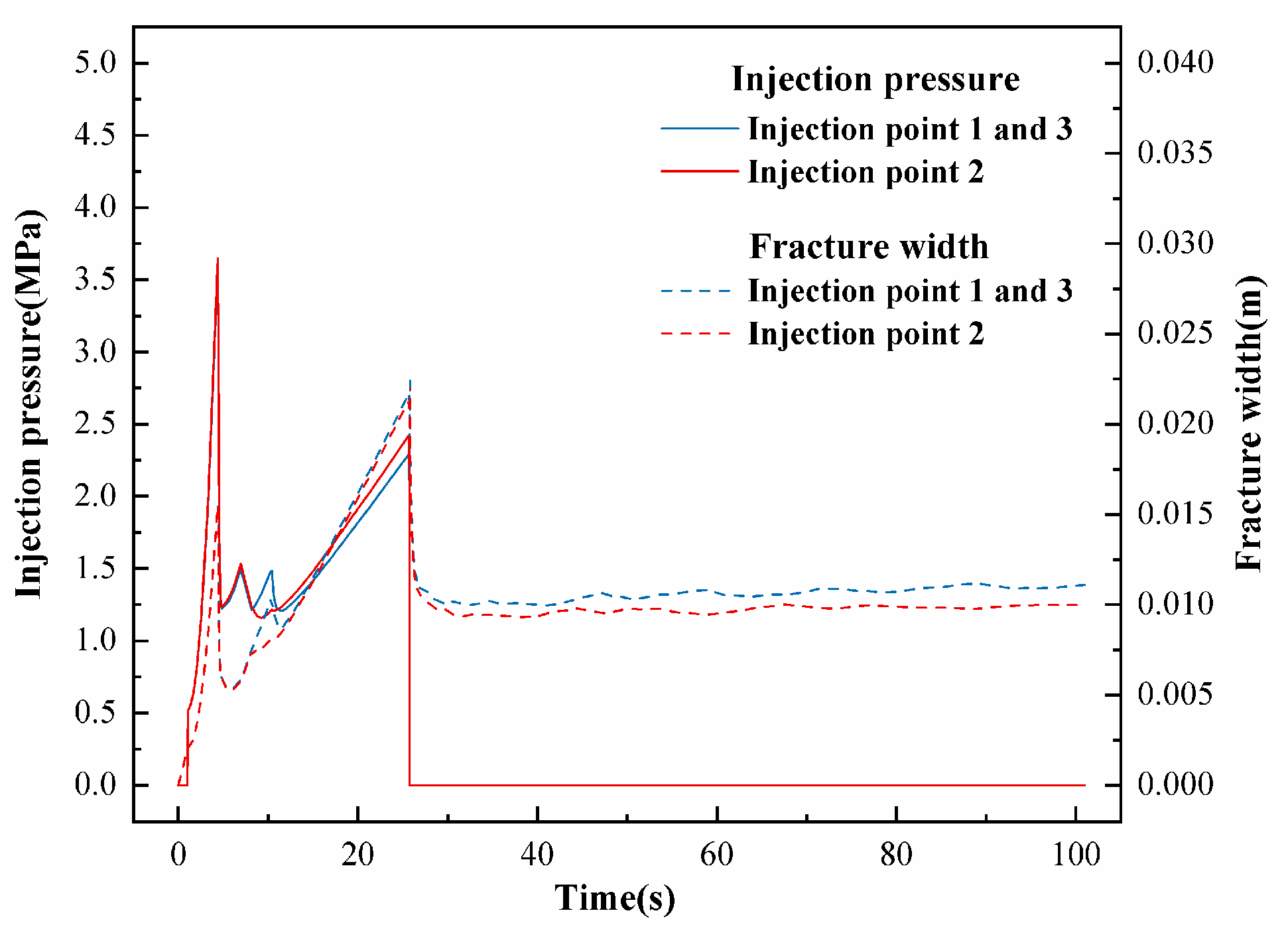

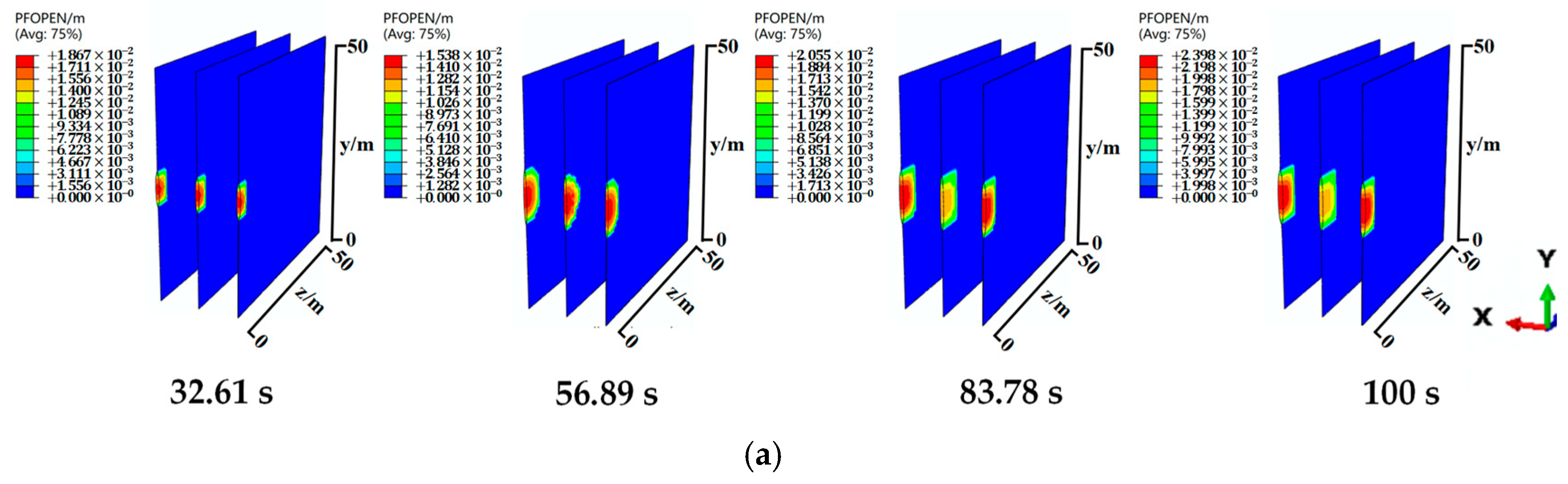

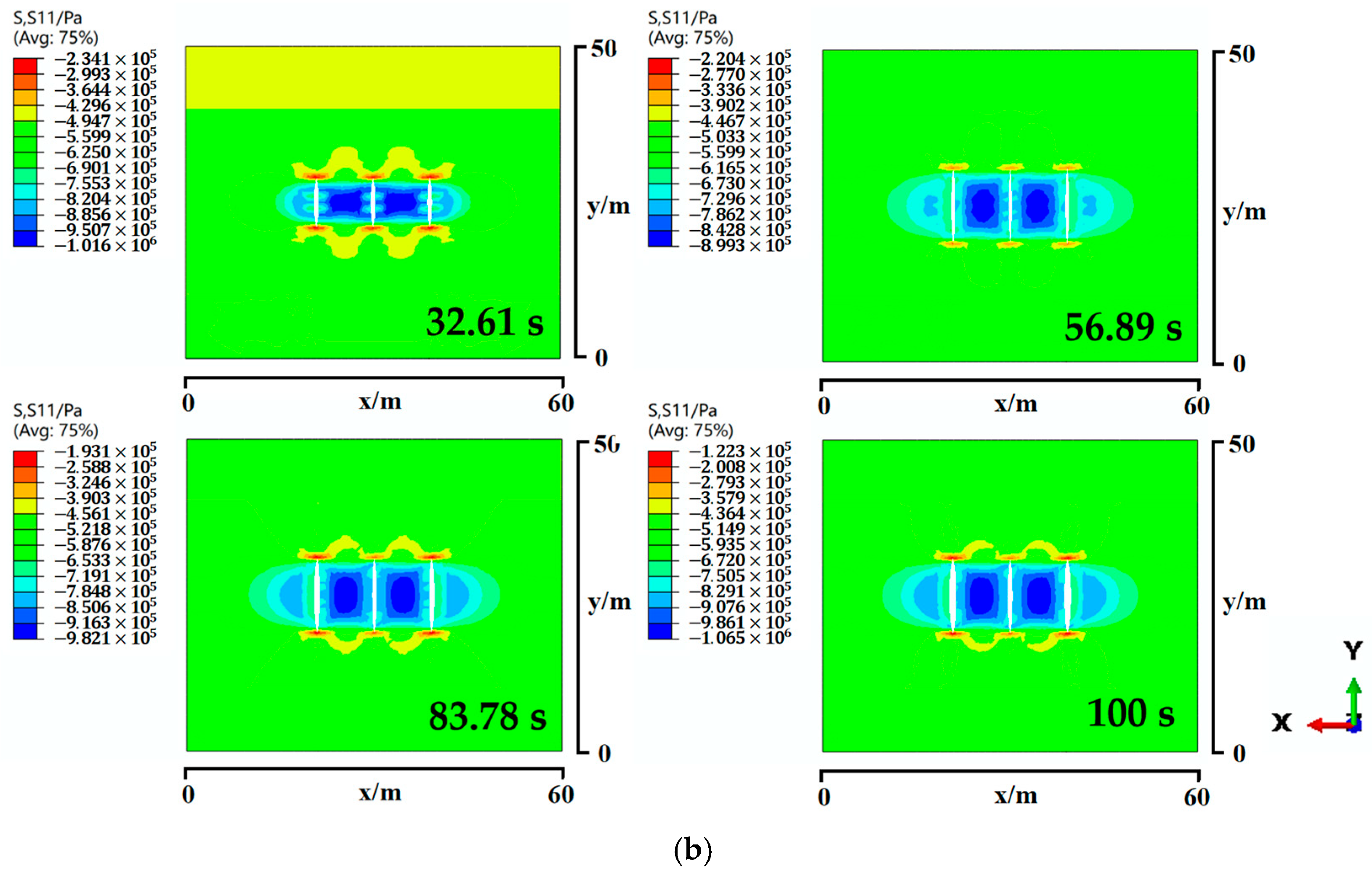

4.2. Multi-Cluster Fracturing Analysis

4.2.1. Effect of Cluster Spacing on Double-Cluster Simultaneous Fracturing

4.2.2. Effect of Cluster Spacing on Three-Cluster Simultaneous Fracturing

5. Conclusions

- The established model effectively characterizes the mechanical responses of fractures in NGH reservoirs during hydraulic fracturing. Cohesive elements successfully simulate the fracture morphology and dynamic propagation behavior, with the reservoir parameters of the model assigned using data from hydrate production tests at Site SH2 in the Shenhu Area, South China Sea.

- Hydrate-bearing sediments with low plasticity exhibit higher hydraulic fracture propagation efficiency and reduced plastic deformation dissipation. Increasing hydrate saturation enhances the mechanical properties and reduces fluid filtration, driving fracture morphology from slender to short. The low-plastic reservoir with high hydrate saturation (SH > 50%) is identified as the optimal reservoir condition in this paper.

- The fracturing fluid with a viscosity of 10 mPa∙s and an injection rate of 0.6 m3/min is the optimal combination for balancing fracture SRV and cross-layer risks.

- In multi-cluster fracturing, inter-fracture stress interference significantly affects the fracture propagation behavior. It reduces the fracture width by 33–63% (3 m cluster spacing) and 57–62% (6 m cluster spacing) while increasing the fracture length and height, among which the middle fracture of three-cluster fracturing exhibits pronounced interference effect. The inter-fracture stress interference nearly vanishes till 9m cluster spacing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Makogon, Y.F.; Holditch, S.A.; Makogon, T.Y. Natural gas-hydrates—A potential energy source for the 21st Century. J. Pet. Sci. Eng. 2007, 56, 14–31. [Google Scholar] [CrossRef]

- Kvenvolden, K.A. Methane hydrate—A major reservoir of carbon in the shallow geosphere? Chem. Geol. 1988, 71, 41–51. [Google Scholar] [CrossRef]

- Buffett, B.A. Clathrate Hydrates. Annu. Rev. Earth Planet. Sci. 2000, 28, 477–507. [Google Scholar] [CrossRef]

- Boswell, R.; Hancock, S.; Yamamoto, K.; Collett, T.; Pratap, M.; Lee, S.-R. Natural Gas Hydrates: Status of Potential as an Energy Resource. In Future Energy, 3rd ed.; Letcher, T.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 111–131. [Google Scholar]

- Misyura, S.Y.; Manakov, A.Y.; Nyashina, G.S.; Gaidukova, O.S.; Morozov, V.S.; Skiba, S.S. Gas Hydrate Combustion in Five Method of Combustion Organization. Entropy 2020, 22, 710. [Google Scholar] [CrossRef]

- Antonov, D.V.; Donskoy, I.G.; Gaidukova, O.S.; Misyura, S.Y.; Morozov, V.S.; Nyashina, G.S.; Strizhak, P.A. Dissociation characteristics and anthropogenic emissions from the combustion of double gas hydrates. Environ. Res. 2022, 214, 113990. [Google Scholar] [CrossRef]

- Sloan, E.D., Jr.; Koh, C.A. Clathrate Hydrates of Natural Gases; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Sun, C.; Li, W.; Yang, X.; Li, F.; Yuan, Q.; Mu, L.; Chen, J.; Liu, B.; Chen, G. Progress in research of gas hydrate. Chin. J. Chem. Eng. 2011, 19, 151–162. [Google Scholar] [CrossRef]

- Kou, X.; Wang, Y.; Li, X.-S.; Zhang, Y.; Chen, Z.-Y. Influence of heat conduction and heat convection on hydrate dissociation by depressurization in a pilot-scale hydrate simulator. Appl. Energy 2019, 251, 113405. [Google Scholar] [CrossRef]

- Feng, J.-C.; Wang, Y.; Li, X.-S. Hydrate dissociation induced by depressurization in conjunction with warm brine stimulation in cubic hydrate simulator with silica sand. Appl. Energy 2016, 174, 181–191. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, J.-C.; Li, X.-S.; Zhang, Y. Experimental investigation of optimization of well spacing for gas recovery from methane hydrate reservoir in sandy sediment by heat stimulation. Appl. Energy 2017, 207, 562–572. [Google Scholar] [CrossRef]

- Tupsakhare, S.S.; Castaldi, M.J. Efficiency enhancements in methane recovery from natural gas hydrates using injection of CO2/N2 gas mixture simulating in-situ combustion. Appl. Energy 2019, 236, 825–836. [Google Scholar] [CrossRef]

- Giovannetti, R.; Gambelli, A.M.; Rossi, A.; Castellani, B.; Minicucci, M.; Zannotti, M.; Nicolini, A.; Rossi, F. Thermodynamic assessment and microscale Raman spectroscopy of binary CO2/CH4 hydrates produced during replacement applications in natural reservoirs. J. Mol. Liq. 2022, 368, 120739. [Google Scholar] [CrossRef]

- Gambelli, A.M.; Rossi, F. Natural gas hydrates: Comparison between two different applications of thermal stimulation for performing CO2 replacement. Energy 2019, 172, 423–434. [Google Scholar] [CrossRef]

- Collett, T.S.; Kuuskraa, V.A. Hydrates contain vast store of world gas resources. Oil Gas J. 1998, 96, 90–95. [Google Scholar]

- Collett, T.S.; Ginsburg, G.D. Gas hydrates in the Messoyakha gas field of the West Siberian Basin-a re-examination of the geologic evidence. Int. J. Offshore Polar Eng. 1998, 8, 22–29. [Google Scholar]

- Chen, Z.-Y.; Li, Q.-P.; Yan, Z.-Y.; Yan, K.-F.; Zeng, Z.-Y.; Li, X.-S. Phase equilibrium and dissociation enthalpies for cyclopentane+ methane hydrates in NaCl aqueous solutions. J. Chem. Eng. Data 2010, 55, 4444–4449. [Google Scholar] [CrossRef]

- Tupsakhare, S.S.; Kattekola, S.; Castaldi, M.J. An application of the results from the large-scale thermal stimulation method of methane hydrate dissociation to the field tests. Ind. Eng. Chem. Res. 2017, 56, 4588–4599. [Google Scholar] [CrossRef]

- Gambelli, A.M.; Tinivella, U.; Giovannetti, R.; Castellani, B.; Giustiniani, M.; Rossi, A.; Zannotti, M.; Rossi, F. Observation of the main natural parameters influencing the formation of gas hydrates. Energies 2021, 14, 1803. [Google Scholar] [CrossRef]

- Hassanpouryouzband, A.; Joonaki, E.; Farahani, M.V.; Takeya, S.; Ruppel, C.; Yang, J.; English, N.J.; Schicks, J.M.; Edlmann, K.; Mehrabian, H. Gas hydrates in sustainable chemistry. Chem. Soc. Rev. 2020, 49, 5225–5309. [Google Scholar]

- Merey, S.; Chen, L. Worldwide regulations and policy trends on gas production from gas hydrates. Sci. Technol. Energy Transit. 2023, 78, 23. [Google Scholar] [CrossRef]

- Ye, J.; Qin, X.; Xie, W.; Lu, H.; Ma, B.; Qiu, H.; Liang, J.; Lu, J.; Kuang, Z.; Lu, C.; et al. Main progress of the second gas hydrate trial production in the South China Sea. Geol. China 2020, 47, 557–568. [Google Scholar]

- Zhou, S.; Li, Q.; Lv, X.; Fu, Q.; Zhu, J. Key issues in development of offshore natural gas hydrate. Front. Energy 2020, 14, 433–442. [Google Scholar] [CrossRef]

- Noguchi, S.; Shimoda, N.; Takano, O.; Oikawa, N.; Inamori, T.; Saeki, T.; Fujii, T. 3-D internal architecture of methane hydrate-bearing turbidite channels in the eastern Nankai Trough, Japan. Mar. Pet. Geol. 2011, 28, 1817–1828. [Google Scholar] [CrossRef]

- Saeki, T.; Fujii, T.; Inamori, T.; Kobayashi, T.; Hayashi, M.; Nagakubo, S.; Takano, O. Extraction of methane hydrate concentrated zone for resource assessment in the eastern Nankai Trough, Japan. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2008. OTC–19311–MS. [Google Scholar] [CrossRef]

- Yoneda, J.; Masui, A.; Konno, Y.; Jin, Y.; Egawa, K.; Kida, M.; Ito, T.; Nagao, J.; Tenma, N. Mechanical properties of hydrate-bearing turbidite reservoir in the first gas production test site of the Eastern Nankai Trough. Mar. Pet. Geol. 2015, 66, 471–486. [Google Scholar] [CrossRef]

- Wei, J.; Liang, J.; Lu, J.; Zhang, W.; He, Y. Characteristics and dynamics of gas hydrate systems in the northwestern South China Sea-results of the fifth gas hydrate drilling expedition. Mar. Pet. Geol. 2019, 110, 287–298. [Google Scholar] [CrossRef]

- Li, J.-F.; Ye, J.-L.; Qin, X.-W.; Qiu, H.-J.; Wu, N.-Y.; Lu, H.-L.; Xie, W.-W.; Lu, J.-A.; Peng, F.; Xu, Z.-Q.; et al. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Yan, J.; Yan, K.; Huang, T.; Mao, M.; Li, X.; Chen, Z.; Pang, W.; Qin, R.; Ruan, X. Research Progress on Characteristics of Marine Natural Gas Hydrate Reservoirs. Energies 2024, 17, 4431. [Google Scholar] [CrossRef]

- Gong, G.; Zhao, G.; Pang, W.; Yang, M.; Chen, B.; Zheng, J.-N. Review of hydrate-bearing sediment permeability for natural gas hydrate exploitation: Measurement and application development. J. Pet. Sci. Eng. 2023, 220, 111217. [Google Scholar] [CrossRef]

- Wang, J.; He, J.; Dong, H.; Ge, K. Association between multiphase seepage and exploitation of natural gas hydrate based on the Shenhu area of South China Sea. J. Pet. Sci. Eng. 2022, 209, 109855. [Google Scholar] [CrossRef]

- Ma, K.; Li, D.; Liang, D. Reservoir stimulation technologies for natural gas hydrate: Research progress, challenges, and perspectives. Energy Fuels 2023, 37, 10112–10133. [Google Scholar] [CrossRef]

- Konno, Y.; Jin, Y.; Yoneda, J.; Uchiumi, T.; Shinjou, K.; Nagao, J. Hydraulic fracturing in methane-hydrate-bearing sand. RSC Adv. 2016, 6, 73148–73155. [Google Scholar] [CrossRef]

- Zhang, W.; Shi, X.; Jiang, S.; Cao, Q.; Wang, F.; Wang, Z.; Ge, Y.; Du, Y. Experimental study of hydraulic fracture initiation and propagation in highly saturated methane-hydrate-bearing sands. J. Nat. Gas Sci. Eng. 2020, 79, 103338. [Google Scholar] [CrossRef]

- Wang, X.; Sun, Y.; Chen, H.; Peng, S.; Jiang, S.; Ma, X. Experimental study on the depressurization of methane hydrate in the clayey silt sediments via hydraulic fracturing. Energy Fuels 2023, 37, 4377–4390. [Google Scholar] [CrossRef]

- Lu, H.; Shang, S.; Chen, X.; Qin, X.; Gu, L.; Qiu, H. Research progress and development direction of numerical simulator for natural gas hydrate development. Acta Petrol. Sin. 2021, 42, 1516. [Google Scholar]

- Liu, X.; Sun, Y.; Guo, T.; Rabiei, M.; Qu, Z.; Hou, J. Numerical simulations of hydraulic fracturing in methane hydrate reservoirs based on the coupled thermo-hydrologic-mechanical-damage (THMD) model. Energy 2022, 238, 122054. [Google Scholar] [CrossRef]

- Ma, X.; Cheng, J.; Sun, Y.; Li, S. 2D numerical simulation of hydraulic fracturing in hydrate-bearing sediments based on the cohesive element. Energy Fuels 2021, 35, 3825–3840. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Hui, C.; Ren, Y.; Cui, X.; Jiang, Y.; An, Y.; Huang, H. Numerical research of fracture initiation in hydrate reservoirs based on XFEM. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Golden, CO, USA, 23–26 June 2024. D022S024R011. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, T.; Wang, R.; Wang, H.; Lu, X.; Zhang, X. Numerical simulation of hydraulic fracture characteristics in gas hydrate bearing-sediments by using CDEM. Acta Mech. Sin. 2024, 40, 322273. [Google Scholar] [CrossRef]

- Liang, X.; Zhao, H.; Dang, Y.; Lei, Q.; Wang, S.; Wang, X.; Chai, H.; Jia, J.; Wang, Y. Numerical Investigation on Mesoscale Evolution of Hydraulic Fractures in Hydrate-Bearing Sediments. Energies 2023, 16, 7502. [Google Scholar] [CrossRef]

- Chuprakov, D.A.; Akulich, A.V.; Siebrits, E.; Thiercelin, M. Hydraulic-fracture propagation in a naturally fractured reservoir. SPE Prod. Oper. 2011, 26, 88–97. [Google Scholar] [CrossRef]

- Xie, L.; Min, K.-B.; Shen, B. Simulation of hydraulic fracturing and its interactions with a pre-existing fracture using displacement discontinuity method. J. Nat. Gas Sci. Eng. 2016, 36, 1284–1294. [Google Scholar] [CrossRef]

- Fatahi, H.; Hossain, M.M.; Sarmadivaleh, M. Numerical and experimental investigation of the interaction of natural and propagated hydraulic fracture. J. Nat. Gas Sci. Eng. 2017, 37, 409–424. [Google Scholar] [CrossRef]

- Jing, L.; Ma, Y.; Fang, Z. Modeling of fluid flow and solid deformation for fractured rocks with discontinuous deformation analysis (DDA) method. Int. J. Rock Mech. Min. Sci. 2001, 38, 343–355. [Google Scholar] [CrossRef]

- Belytschko, T.; Black, T. Elastic crack growth in finite elements with minimal remeshing. Int. J. Numer. Methods Eng. 1999, 45, 601–620. [Google Scholar] [CrossRef]

- Taleghani, A.D.; Gonzalez, M.; Shojaei, A. Overview of numerical models for interactions between hydraulic fractures and natural fractures: Challenges and limitations. Comput. Geotech. 2016, 71, 361–368. [Google Scholar] [CrossRef]

- Guo, J.; Luo, B.; Lu, C.; Lai, J.; Ren, J. Numerical investigation of hydraulic fracture propagation in a layered reservoir using the cohesive zone method. Eng. Fract. Mech. 2017, 186, 195–207. [Google Scholar] [CrossRef]

- Zhai, L.; Zhang, H.; Pan, D.; Zhu, Y.; Zhu, J.; Zhang, Y.; Chen, C. Optimisation of hydraulic fracturing parameters based on cohesive zone method in oil shale reservoir with random distribution of weak planes. J. Nat. Gas Sci. Eng. 2020, 75, 103130. [Google Scholar] [CrossRef]

- Chen, Z. Finite element modelling of viscosity-dominated hydraulic fractures. J. Pet. Sci. Eng. 2012, 88, 136–144. [Google Scholar] [CrossRef]

- Gao, Q.; Cheng, Y.; Han, S.; Yan, C.; Jiang, L. Numerical modeling of hydraulic fracture propagation behaviors influenced by pre-existing injection and production wells. J. Pet. Sci. Eng. 2019, 172, 976–987. [Google Scholar] [CrossRef]

- Wang, S.; Li, D.; Mitri, H.; Li, H. Numerical simulation of hydraulic fracture deflection influenced by slotted directional boreholes using XFEM with a modified rock fracture energy model. J. Pet. Sci. Eng. 2020, 193, 107375. [Google Scholar] [CrossRef]

- Ma, X.; Jiang, D.; Fang, X.; Wang, X. Numerical simulation of single-cluster and multi-cluster fracturing of hydrate reservoir based on cohesive element. Eng. Fract. Mech. 2022, 265, 108365. [Google Scholar] [CrossRef]

- Lu, J.; Lin, D.; Li, D.; Liang, D.; Wen, L.; Wu, S.; Zhang, Y.; He, Y.; Shi, L.; Xiong, Y. Microcosmic Characteristics of Hydrate Formation and Decomposition in the Different Particle Size Sediments Captured by Cryo-SEM. J. Mar. Sci. Eng. 2022, 10, 769. [Google Scholar] [CrossRef]

- Luo, T.; Li, Y.; Madhusudhan, B.; Zhao, J.; Song, Y. Comparative analysis of the consolidation and shear behaviors of CH4 and CO2 hydrate-bearing silty sediments. J. Nat. Gas Sci. Eng. 2020, 75, 103157. [Google Scholar] [CrossRef]

- Sun, J.; Ning, F.; Li, S.; Zhang, K.; Liu, T.; Zhang, L.; Jiang, G.; Wu, N. Numerical simulation of gas production from hydrate-bearing sediments in the Shenhu area by depressurising: The effect of burden permeability. J. Unconv. Oil Gas Res. 2015, 12, 23–33. [Google Scholar] [CrossRef]

- Moridis, G.J.; Reagan, M.T.; Kim, S.-J.; Seol, Y.; Zhang, K. Evaluation of the gas production potential of marine hydrate deposits in the Ulleung Basin of the Korean East Sea. SPE J. 2009, 14, 759–781. [Google Scholar] [CrossRef]

- Li, B.; Li, X.-S.; Li, G.; Chen, Z.-Y. Evaluation of gas production from Qilian Mountain permafrost hydrate deposits in two-spot horizontal well system. Cold Reg. Sci. Technol. 2015, 109, 87–98. [Google Scholar] [CrossRef]

- Hui, C.; Zhang, Y.; An, Y.; Hu, Z.; Zhuang, X.; Wang, J.; Qin, Y.; Li, G. Experimental research on fracture initiation and propagation behavior in argillaceous silt hydrate reservoirs. Geoenergy Sci. Eng. 2025, 249, 213774. [Google Scholar] [CrossRef]

- Yoneda, J.; Masui, A.; Konno, Y.; Jin, Y.; Kida, M.; Katagiri, J.; Nagao, J.; Tenma, N. Pressure-core-based reservoir characterization for geomechanics: Insights from gas hydrate drilling during 2012–2013 at the eastern Nankai Trough. Mar. Pet. Geol. 2017, 86, 1–16. [Google Scholar] [CrossRef]

- Carman, P.C. Fluid flow through granular beds. Chem. Eng. Res. Des. 1997, 75, S32–S48. [Google Scholar] [CrossRef]

- Dai, S.; Seol, Y. Water permeability in hydrate-bearing sediments: A pore-scale study. Geophys. Res. Lett. 2014, 41, 4176–4184. [Google Scholar] [CrossRef]

- Su, Z.; Moridis, G.J.; Zhang, K.; Wu, N. A huff-and-puff production of gas hydrate deposits in Shenhu area of South China Sea through a vertical well. J. Pet. Sci. Eng. 2012, 86, 54–61. [Google Scholar] [CrossRef]

- Sun, J.; Ning, F.; Liu, T.; Liu, C.; Chen, Q.; Li, Y.; Cao, X.; Mao, P.; Zhang, L.; Jiang, G. Gas production from a silty hydrate reservoir in the South China Sea using hydraulic fracturing: A numerical simulation. Energy Sci. Eng. 2019, 7, 1106–1122. [Google Scholar] [CrossRef]

- Zhang, D.; Ranjith, P.; Perera, M. The brittleness indices used in rock mechanics and their application in shale hydraulic fracturing: A review. J. Pet. Sci. Eng. 2016, 143, 158–170. [Google Scholar] [CrossRef]

- Hou, Z.-K.; Cheng, H.-L.; Sun, S.-W.; Chen, J.; Qi, D.-Q.; Liu, Z.-B. Crack propagation and hydraulic fracturing in different lithologies. Appl. Geophys. 2019, 16, 243–251. [Google Scholar] [CrossRef]

- Wu, P.; Li, Y.; Liu, W.; Sun, X.; Kong, X.; Song, Y. Cementation failure behavior of consolidated gas hydrate-bearing sand. J. Geophys. Res. Solid Earth 2020, 125, e2019JB018623. [Google Scholar] [CrossRef]

- Lei, L.; Seol, Y.; Choi, J.-H.; Kneafsey, T.J. Pore habit of methane hydrate and its evolution in sediment matrix–Laboratory visualization with phase-contrast micro-CT. Mar. Pet. Geol. 2019, 104, 451–467. [Google Scholar] [CrossRef]

- Mills, C.; Marshall, C.; Kay, A.; MacDonald, M. Flow measurement of high viscosity fluids. In Proceedings of the North Sea Flow Measurement Workshop, Tonsberg, Norway, 22–25 October 2013. [Google Scholar]

- Yu, Y.; Liu, J.; Ma, X.; Yang, G.; Sun, Y.; Sun, W.; Shi, W. Mechanism analysis of multi-cluster fracture interference in horizontal wells of hydrate reservoirs in the South China Sea. Energy Fuels 2022, 36, 3580–3595. [Google Scholar] [CrossRef]

- Lu, Q.; Zhang, L.; Guo, J.; Zou, L.; He, L.; Chen, L. Numerical investigation of fracture interference effects on multi-fractures propagation in fractured shale. Eng. Fract. Mech. 2023, 286, 109322. [Google Scholar]

- Huang, T.; Zhu, H.; Liu, Q.; Dai, X.; Tang, X.; Yi, X.; He, X.; She, C.; Zheng, M. Study on multi-cluster fracture interlaced competition propagation model of hydraulic fracturing in heterogeneous reservoir. Geoenergy Sci. Eng. 2025, 244, 213415. [Google Scholar] [CrossRef]

| Hydrate Saturation (%) | Elastic Modulus (MPa) | Tensile Strength (MPa) | Permeability Coefficient (m/s) | Void Ratio | Filtration Coefficient (m/(s·Pa)) | Poisson’s Ratio | |

|---|---|---|---|---|---|---|---|

| Case 1 | 30 | 266.85 | 0.490 | 7.13×10−9 | 0.7957 | 1.786 × 10−13 | 0.3 |

| Case 2 | 40 | 339.59 | 0.592 | 3.55 × 10−9 | 0.6124 | 1.786 × 10−13 | 0.3 |

| Case 3 | 50 | 439.50 | 0.417 | 1.66 × 10−9 | 0.4631 | 1.786 × 10−13 | 0.3 |

| Case 4 | 60 | 578.99 | 0.865 | 7.04 × 10−10 | 0.3390 | 1.786 × 10−13 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, L.; An, Y.; Wang, J.; Zhang, Y.; Liu, L.; Chen, M.; Gao, Y.; Han, J. Numerical Simulation of Multi-Cluster Fracture Propagation in Marine Natural Gas Hydrate Reservoirs. J. Mar. Sci. Eng. 2025, 13, 1224. https://doi.org/10.3390/jmse13071224

Liao L, An Y, Wang J, Zhang Y, Liu L, Chen M, Gao Y, Han J. Numerical Simulation of Multi-Cluster Fracture Propagation in Marine Natural Gas Hydrate Reservoirs. Journal of Marine Science and Engineering. 2025; 13(7):1224. https://doi.org/10.3390/jmse13071224

Chicago/Turabian StyleLiao, Lisha, Youkeren An, Jinshan Wang, Yiqun Zhang, Lerui Liu, Meihua Chen, Yiming Gao, and Jiayi Han. 2025. "Numerical Simulation of Multi-Cluster Fracture Propagation in Marine Natural Gas Hydrate Reservoirs" Journal of Marine Science and Engineering 13, no. 7: 1224. https://doi.org/10.3390/jmse13071224

APA StyleLiao, L., An, Y., Wang, J., Zhang, Y., Liu, L., Chen, M., Gao, Y., & Han, J. (2025). Numerical Simulation of Multi-Cluster Fracture Propagation in Marine Natural Gas Hydrate Reservoirs. Journal of Marine Science and Engineering, 13(7), 1224. https://doi.org/10.3390/jmse13071224