Delay Propagation at U-Shaped Automated Terminals for Multilevel Handlings Based on Multivariate Transfer Entropy

Abstract

1. Introduction

- (1)

- This paper proposes an innovative method for constructing the interaction network of multilevel handlings in U-shaped automated container terminals utilizing multivariate transfer entropy. In contrast to previous studies that construct multilevel handling networks using handling tasks or entity associations as edges, this study employs causal analysis techniques within multilevel handling systems. This study utilizes data-driven computations of multivariate transfer entropy between pieces of equipment to delineate the interactive influence relationships among handling equipment.

- (2)

- Based on the SEIR model and considering the practical characteristics of multilevel handling delays, a multilevel handling delay propagation model that incorporates the equipment withdrawal rate is proposed. Additionally, a method for identifying node criticality is introduced, which comprehensively considers the network structure characteristics and the task volume of equipment, along with implementing immunity control for critical equipment.

2. Literature Review

2.1. Multilevel Handlings in Automated Terminals

2.2. Delays on Automation Terminal Handlings

3. Problem Description and Methodology

3.1. Multivariate Transfer Entropy

3.2. mRMR Feature Selection Algorithm

3.3. Data Processing and Network Construction

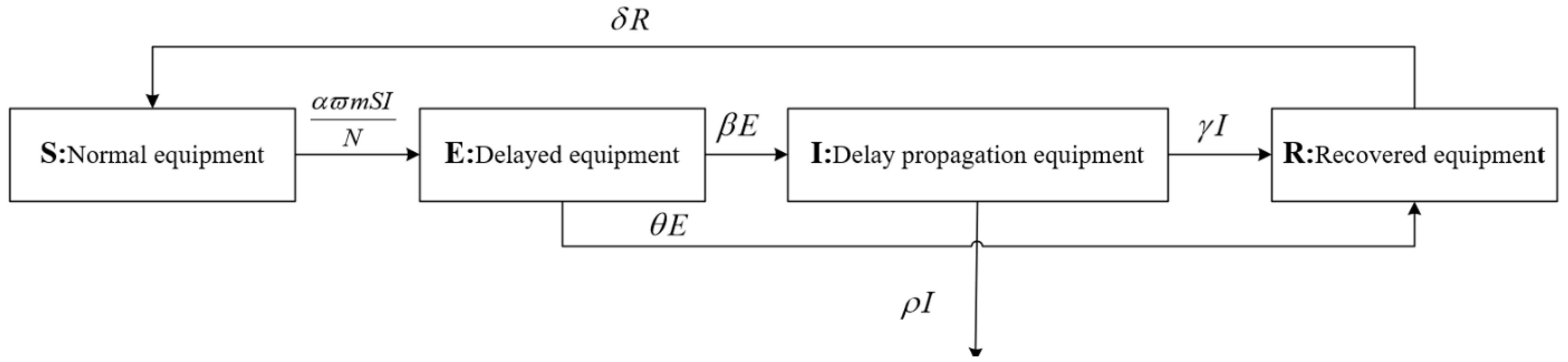

4. Delay Propagation Model

4.1. Adaptive Analysis of the SEIR Model

- (1)

- Delayed equipment can propagate their delay status to associated handling equipment through inter-stage connections, analogous to how infected individuals in the SEIR model propagate the virus to susceptible individuals.

- (2)

- For equipment nodes exhibiting a delay status, there exists a certain time window between handling stages, during which the delay status is not immediately propagated to other equipment. This is comparable to how susceptible individuals in the SEIR model become infected by virus carriers, initially propagating to non-infectious latent individuals before ultimately becoming infectious.

- (3)

- When delays occur, interventions by terminal management lead to the eventual dissipation of the delay status in affected equipment nodes, transforming them back into non-delayed equipment. This process is analogous to recovered individuals returning to normalcy and becoming immune after overcoming an infection.

4.2. Multilevel Handling Delay Propagation Model

- (1)

- When a node in a normal handling state comes into contact with a delay propagation node, it converts to a delay node with probability .

- (2)

- Due to the presence of time windows between handling phases, there are situations in which quay cranes, yard cranes, and AGVs may need to wait for one another. Consequently, equipment experiencing delays does not immediately propagate these delays to connected equipment. Delay nodes will convert to delay propagation nodes with probability , while delayed equipment will automatically propagate to a recovery state at a rate of .

- (3)

- Under the immediate control of the terminal management, delay propagation nodes will convert to recovery nodes with probability ; additionally, some delay propagation nodes that cannot be restored to normal status due to equipment failure will withdraw the handling process with probability .

- (4)

- Unlike nodes in infectious diseases that are immune and can no longer be infected, equipment in an immune state can still be affected by delays from other equipment during handling, leading to a renewed delay. Immune nodes will convert to susceptible nodes with probability .

5. Instance Analysis

5.1. Construction of a Multilevel Handling Interaction Impact Network

| Algorithm 1: Multivariate Transfer Entropy Flow | |

| 1: | Input: ; ; ; |

| 2: | Output: : The causal matrix; : MHII network |

| 3: | Phase1: Standardize Time Series Data |

| 4: | for each time series in do |

| 5: | Perform Z-Score standardization |

| 6: | Perform ADF stationarity test on the data |

| 7: | end for |

| 8: | Phase2: Multivariate Transfer Entropy Computation |

| 9: | Initialize the causal matrix of size , and |

| 10: | for each pair of time series in |

| 11: | if do |

| 12: | Initialize |

| 13: | Select conditional variables and maximum time lag |

| 14: | Calculate the |

| 15: | Update , |

| 16: | if then there is a causal relationship from to |

| 17: | end for |

| 18: | return the causal matrix |

| 19: | Phase3: The Construction of MHII Network |

| 20: | Initialize network |

| 21: | for in do |

| 22: | if then |

| 23: | Add edge from to in |

| 24: | return MHII network |

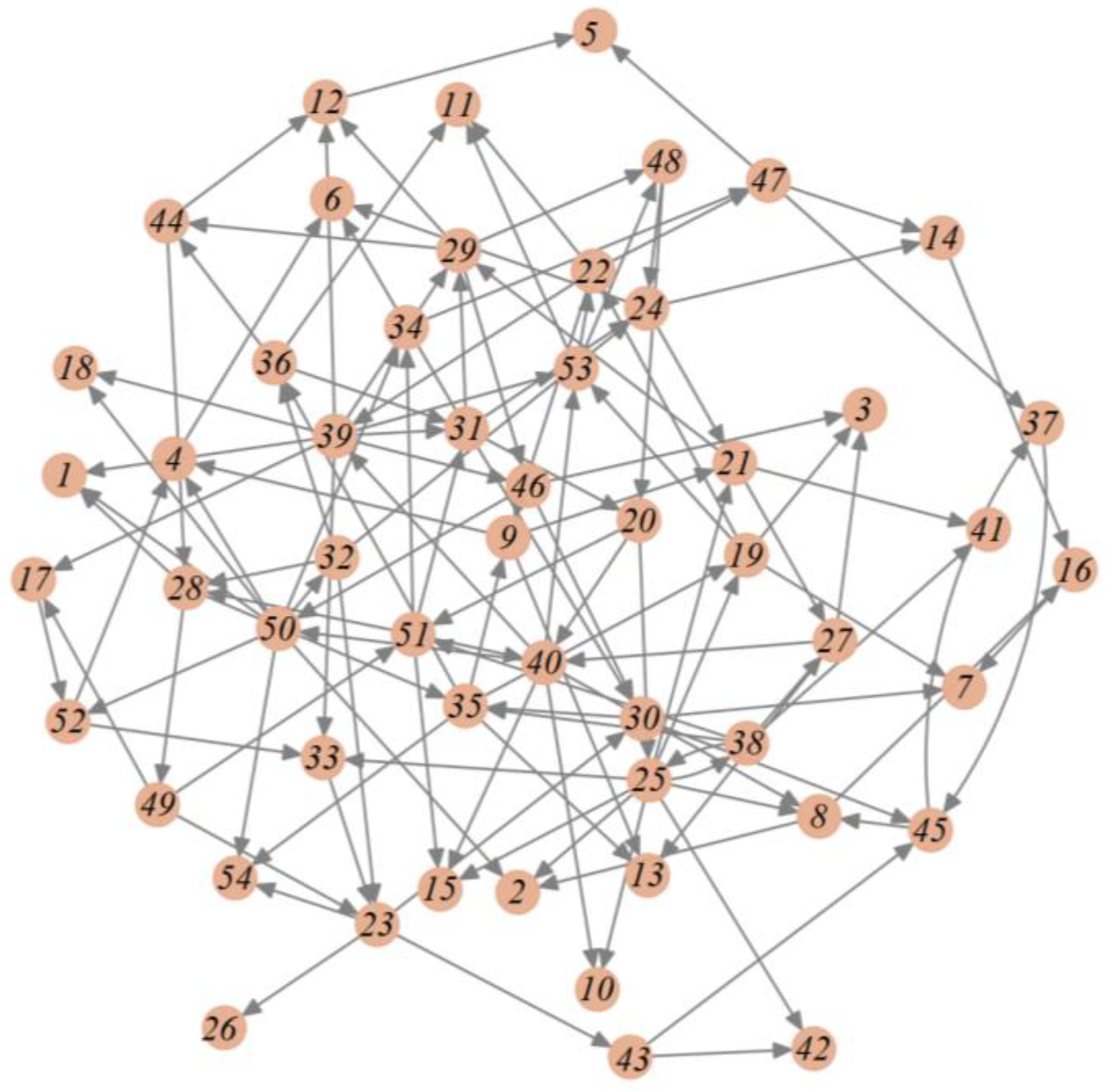

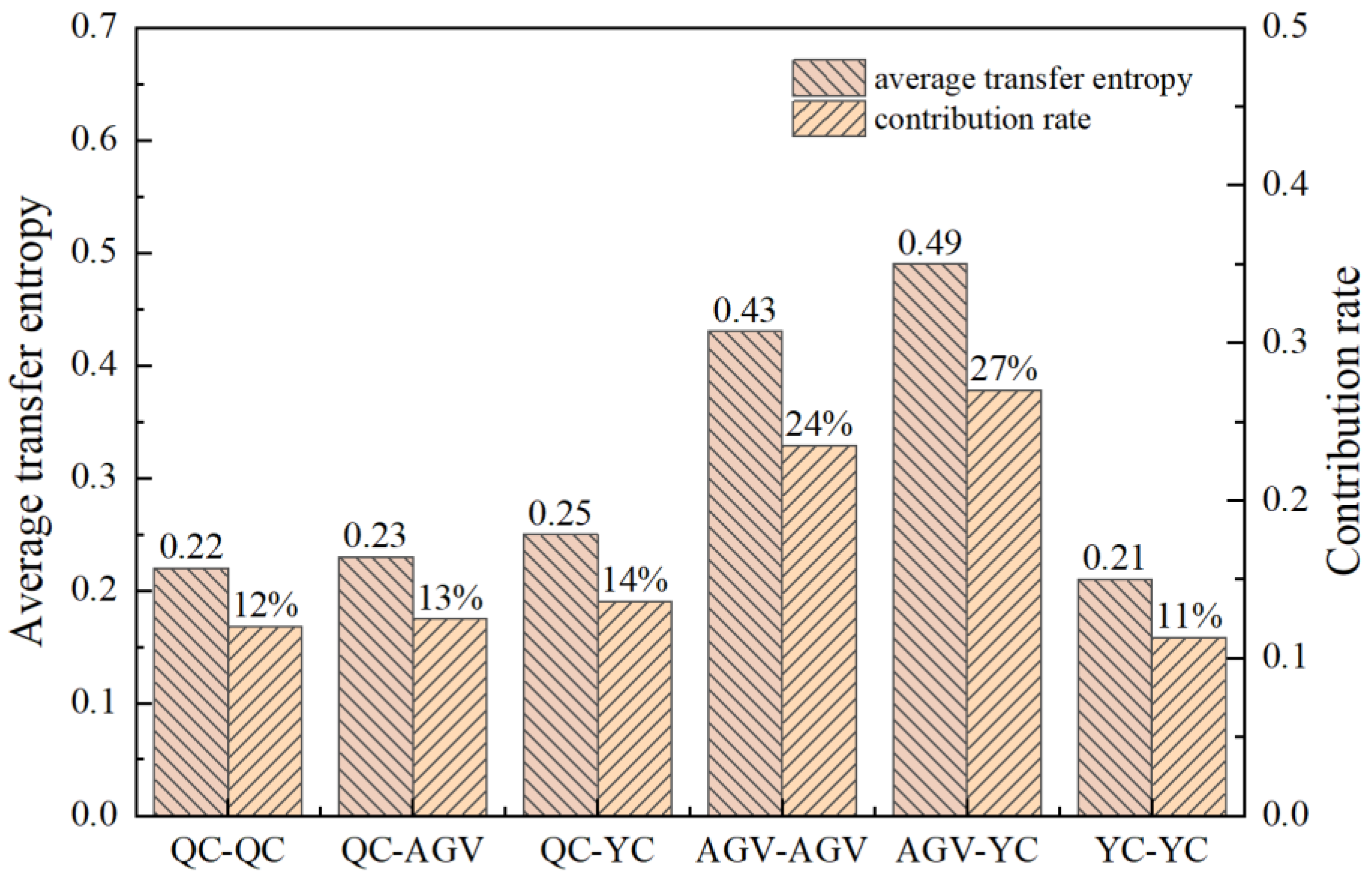

5.2. Network Characteristics Analysis

5.3. Delay Propagation Simulation

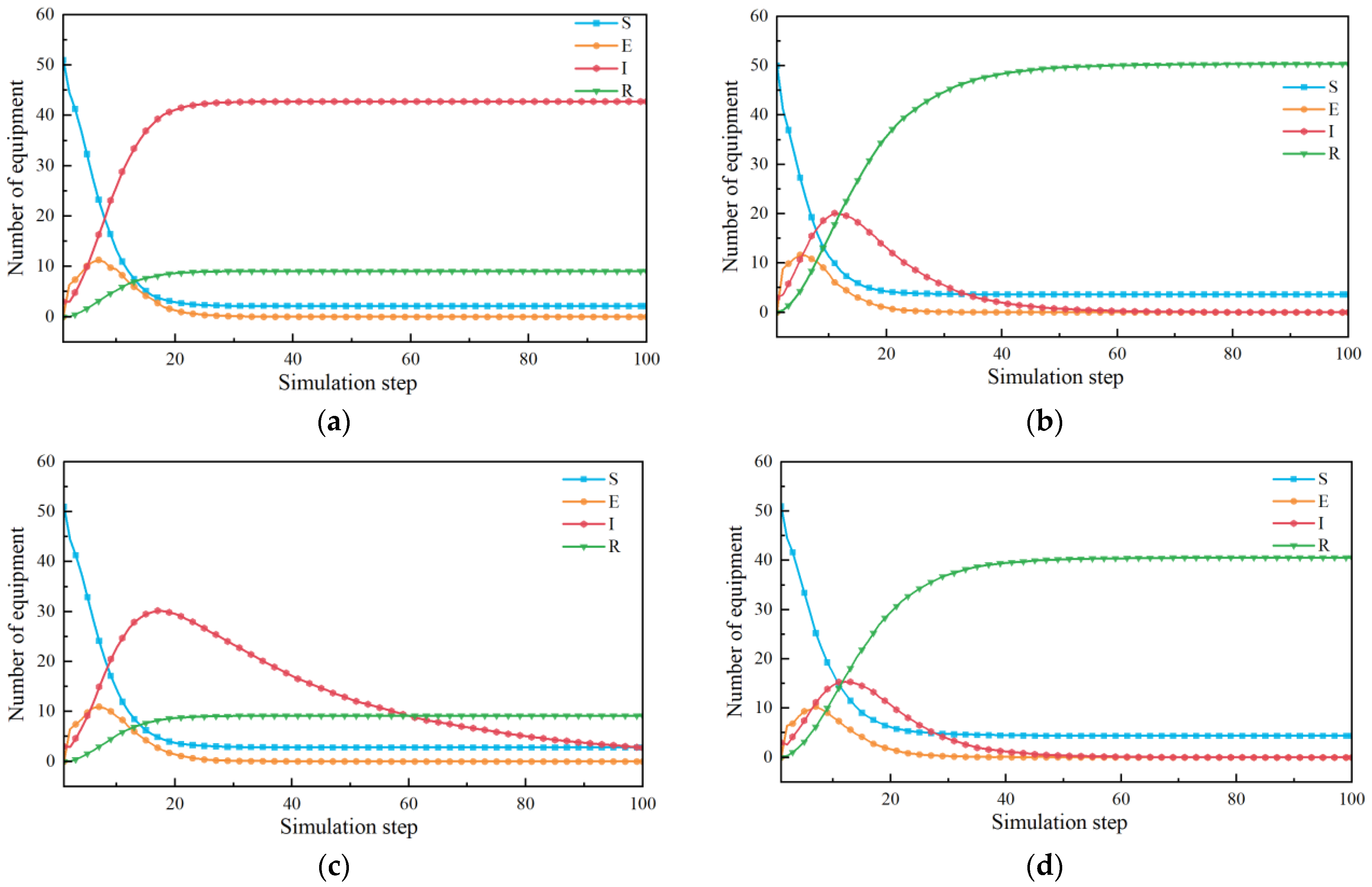

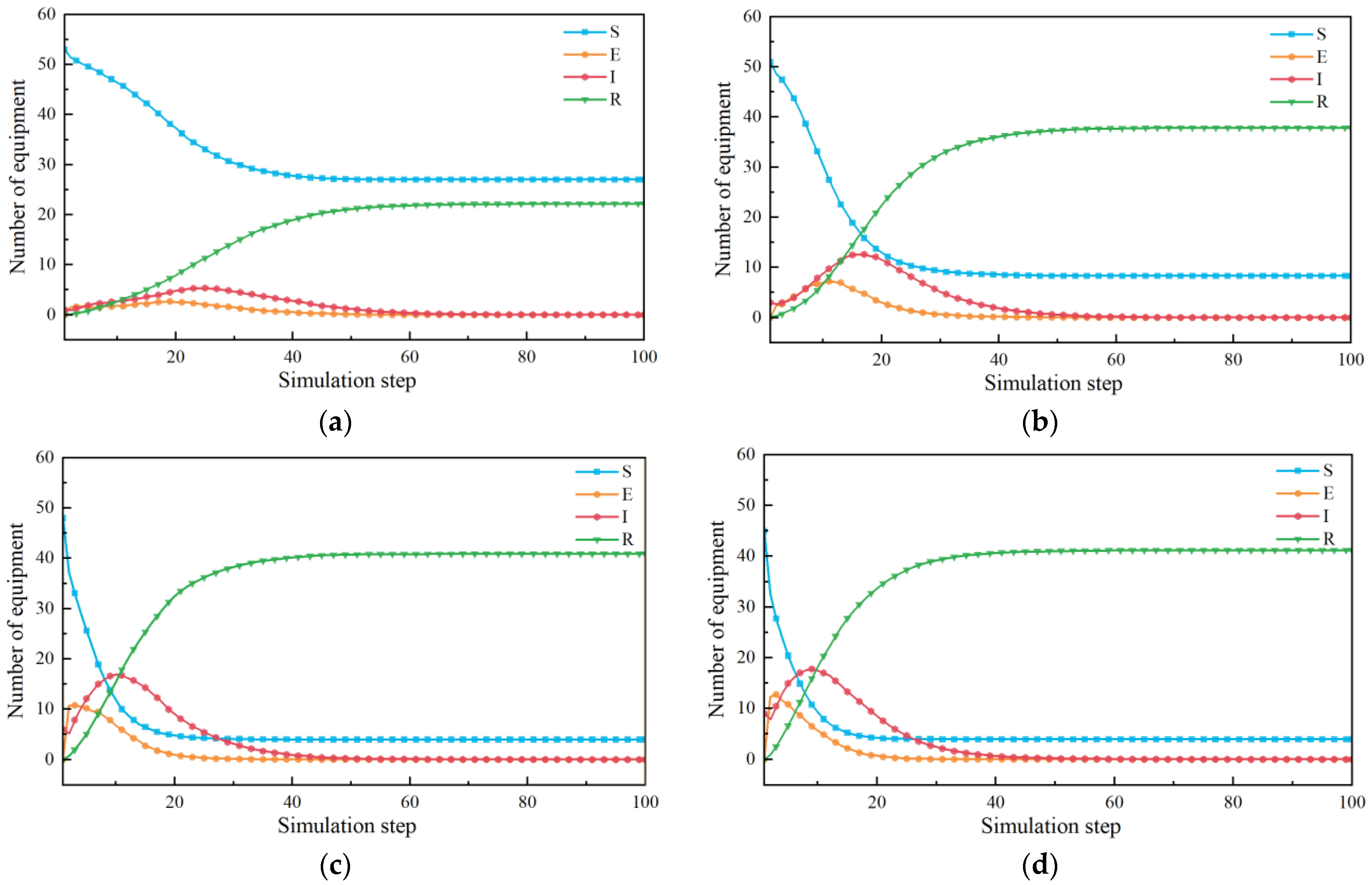

5.3.1. Analysis of Delay Propagation Under Different Control Strategies

5.3.2. Analysis of Delay Propagation Under Different Initial Delay Scales

5.3.3. Sensitivity Analysis of Parameters

5.4. Targeted Immunization Strategy Based on Critical Equipment

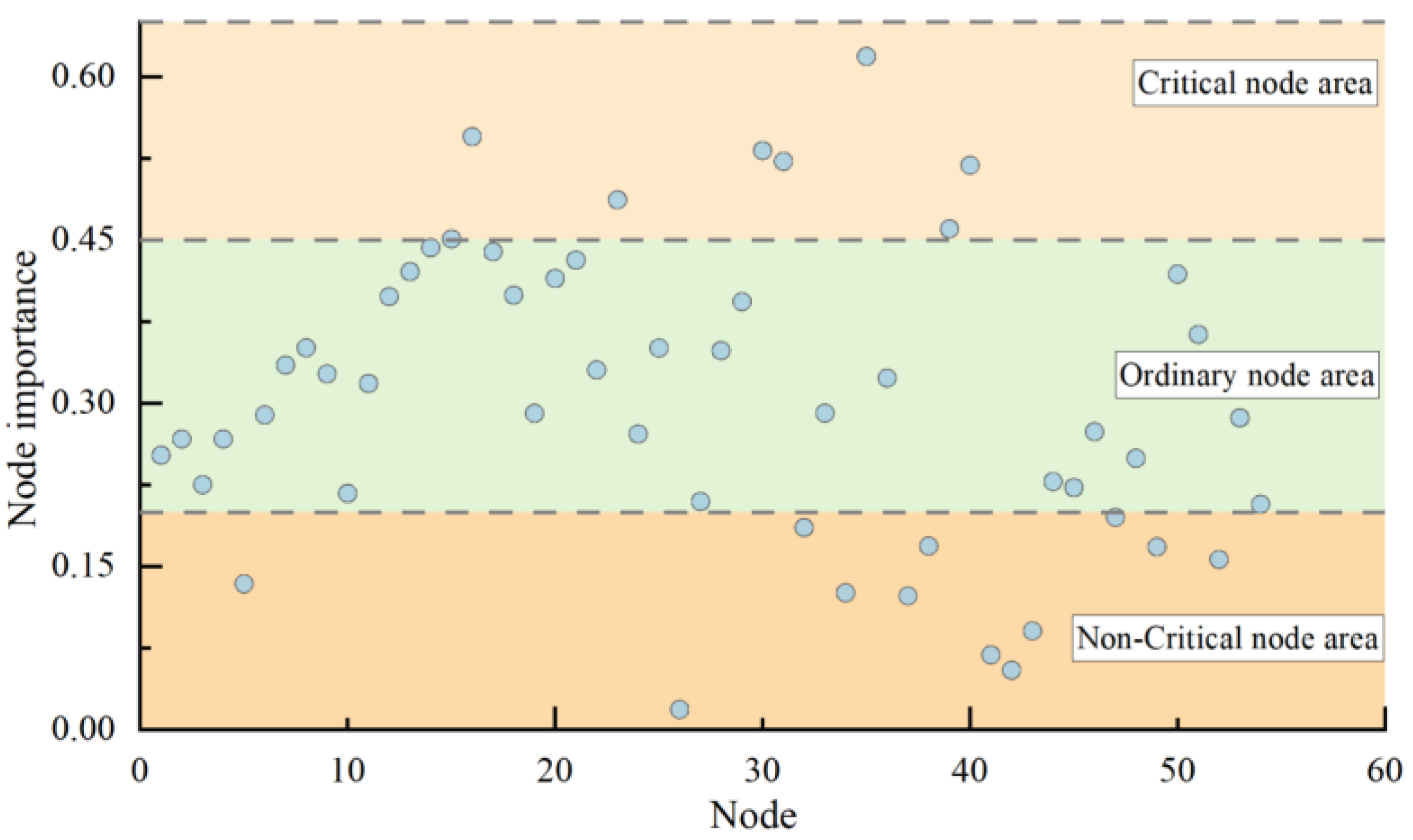

5.4.1. Identification of Critical Equipment

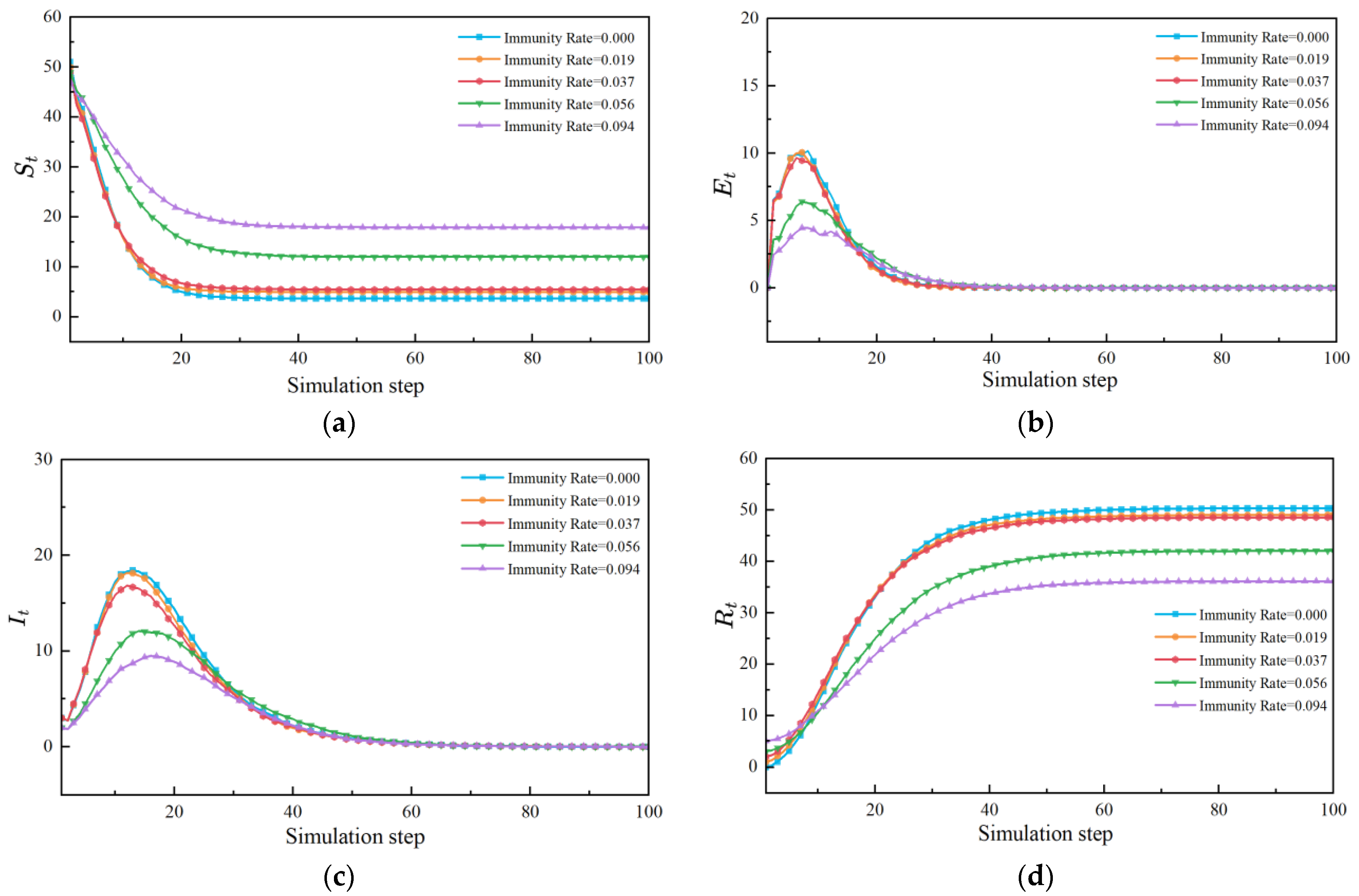

5.4.2. Simulation of Delay Propagation in Controlling Critical Equipment

6. Discussion

- (a)

- Considering that withdrawing delay-conducting equipment effectively reduces the impact scope of delays, equipment experiencing operational delays due to malfunctions should be promptly removed from the operational system. Simultaneously, equipment resource allocation can be optimized by designating specific quay cranes, AGVs, and other equipment as standby emergency resources to compensate for withdrawn units. Meanwhile, the configuration of backup equipment clusters should be adjusted according to real-time operational status monitoring to maintain system robustness.

- (b)

- Based on the constructed multilevel handling interaction network and critical equipment identification methodology, dynamic real-time monitoring should be implemented for critical equipment exhibiting critical influence, with timely optimization adjustments applied to abnormal units. For critical quay cranes and yard cranes, technical enhancements should include the installation of independent redundant power supplies, the deployment of dual Programmable Logic Controller (PLC) control modules, and dynamic maintenance cycle adjustments based on operational load rates. Regarding AGVs, comprehensive power monitoring systems should be established to automatically downgrade task priority for units with low battery levels while implementing adaptive scheduling strategies through intelligent task allocation mechanisms.

7. Conclusions

- (1)

- The multilevel handling interaction network demonstrates inherent randomness. AGVs serve a critical mediating function within the entire interaction network. The interaction relationships between the AGV transfer link and the AGVs with the yard cranes exhibit significant strength, thereby greatly influencing the overall interaction network. It is essential to enhance the coordination mechanism between AGVs and the yard cranes to facilitate the efficient operation of container transfer and storage processes.

- (2)

- Implementing comprehensive control measures for the withdrawal of propagation equipment can effectively mitigate the extent of delay propagation. In the absence of any control measures, the peak ratio of delay propagation equipment decreases by 51.3%. Additionally, compared to the implementation of a single strategy, delays dissipate more rapidly.

- (3)

- Under the same propagation probability and control strategy, an increased number of initially delayed equipment results in an accelerated delay propagation rate. The impact of large- and small-scale delays can dissipate promptly through the management controls implemented by terminal operators. When the proportion of initially delayed equipment exceeds 6 out of 54, further increases in initially delayed equipment do not significantly change the peak value of delay propagation.

- (4)

- The delay propagation process is directly proportional to both the delay propagation probability and the delay transfer rate, while it is inversely proportional to the equipment withdrawal and recovery rates. As these parameters increase, the delay propagation process exhibits reduced sensitivity. Implementing direct immunity control on core equipment nodes can effectively suppress the risk of delay propagation and prevent delays from causing large-scale impacts on container operations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ATMH | Multilevel handlings at automated terminals; |

| mRMR | Minimum Redundancy Maximum Relevance; |

| MHII | Multilevel handling interaction impact; |

| QC | Quay crane; |

| YC | Yard crane; |

| AGV | Automated Guided Vehicle |

References

- United Nations Conference on Trade and Development. Review of Maritime Transport 2024: Navigating Maritime Chokepoints; United Nations: Geneva, Switzerland, 2024. [Google Scholar]

- Notteboom, T.; Haralambides, H.; Cullinane, K. The Red Sea Crisis: Ramifications for Vessel Operations, Shipping Networks, and Maritime Supply Chains. Marit. Econ. Logist. 2024, 26, 1–20. [Google Scholar] [CrossRef]

- Singapore Port Container Logjam Worsens as Ships Avoid Red Sea. Available online: https://themalaysianreserve.com/2024/06/13/singapore-port-container-logjam-worsens-as-ships-avoid-red-sea/ (accessed on 17 October 2024).

- Carlo, H.J.; Vis, I.F.A.; Roodbergen, K.J. Transport Operations in Container Terminals: Literature Overview, Trends, Research Directions and Classification Scheme. Eur. J. Oper. Res. 2014, 236, 1–13. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, C. Minimizing the Risk of Seaport Operations Efficiency Reduction Affected by Vessel Arrival Delay. Ind. Manag. Data Syst. 2018, 118, 1498–1509. [Google Scholar] [CrossRef]

- He, J.; Tan, C.; Zhang, Y. Yard Crane Scheduling Problem in a Container Terminal Considering Risk Caused by Uncertainty. Adv. Eng. Inform. 2019, 39, 14–24. [Google Scholar] [CrossRef]

- Tan, C.; He, J. Integrated Proactive and Reactive Strategies for Sustainable Berth Allocation and Quay Crane As-signment under Uncertainty. Ann. Oper. Res. 2021, 1–32. [Google Scholar] [CrossRef]

- Jian, W.; Zhu, J.; Zeng, Q. An Optimization Model of Integrated AGVs Scheduling and Container Storage Problems for Automated Container Terminal Considering Uncertainty. Symmetry 2021, 13, 1904. [Google Scholar] [CrossRef]

- He, J.; Tan, C.; Yan, W.; Huang, W.; Liu, M.; Yu, H. Two-Stage Stochastic Programming Model for Generating Container Yard Template under Uncertainty and Traffic Congestion. Adv. Eng. Inform. 2020, 43, 101032. [Google Scholar] [CrossRef]

- Kenett, D.Y.; Perc, M.; Boccaletti, S. Networks of Networks—An Introduction. Chaos Solitons Fractals 2015, 80, 1–6. [Google Scholar] [CrossRef]

- Li, M.; Liu, R.-R.; Lü, L.; Hu, M.-B.; Xu, S.; Zhang, Y.-C. Percolation on Complex Networks: Theory and Application. Phys. Rep. 2021, 907, 1–68. [Google Scholar] [CrossRef]

- Xu, B.; Wang, L.; Li, J. Propagation of Uncertain Events in Multilevel Handlings at Container Terminals from the Perspective of Hypernetwork. Discret. Dyn. Nat. Soc. 2021, 2021, 6611181. [Google Scholar] [CrossRef]

- Li, J.; Yu, A.; Xu, B. Risk Propagation and Evolution Analysis of Multi-Level Handlings at Automated Terminals Based on Double-Layer Dynamic Network Model. Phys. A Stat. Mech. Its Appl. 2022, 605, 127963. [Google Scholar] [CrossRef]

- Naeem, D.; Gheith, M.; Eltawil, A. A Comprehensive Review and Directions for Future Research on the Integrated Scheduling of Quay Cranes and Automated Guided Vehicles and Yard Cranes in Automated Container Terminals. Comput. Ind. Eng. 2023, 179, 109149. [Google Scholar] [CrossRef]

- Han, Y.; Zheng, H.; Ma, W.; Yan, B.; Ma, D. Integrated Scheduling of Automated Rail-Mounted Gantries and Exter-nal Trucks in U-Shaped Container Terminals. IEEE Trans. Autom. Sci. Eng. 2024, 1–15. [Google Scholar] [CrossRef]

- Yue, L.; Fan, H.; Ma, M. Optimizing Configuration and Scheduling of Double 40 Ft Dual-Trolley Quay Cranes and AGVs for Improving Container Terminal Services. J. Clean. Prod. 2021, 292, 126019. [Google Scholar] [CrossRef]

- Xu, B.; Jie, D.; Li, J.; Yang, Y.; Wen, F.; Song, H. Integrated Scheduling Optimization of U-Shaped Automated Container Terminal under Loading and Unloading Mode. Comput. Ind. Eng. 2021, 162, 107695. [Google Scholar] [CrossRef]

- Tang, G.; Guo, Y.; Qi, Y.; Fang, Z.; Zhao, Z.; Li, M.; Zhen, Z. Real-Time Twin Automated Double Cantilever Rail Crane Scheduling Problem for the U-Shaped Automated Container Terminal Using Deep Reinforcement Learning. Adv. Eng. Inform. 2025, 65, 103193. [Google Scholar] [CrossRef]

- Li, H.; Peng, J.; Wang, X.; Wan, J. Integrated Resource Assignment and Scheduling Optimization with Limited Critical Equipment Constraints at an Automated Container Terminal. IEEE Trans. Intell. Transp. Syst. 2021, 22, 7607–7618. [Google Scholar] [CrossRef]

- Yang, A.; Liu, Y.; Xin, C.; Chen, Q.; Wang, L. Towards Intuitive Visualisation Goals for the Operation Optimisation of Automated Container Terminal Based on Digital Twin Technology. Marit. Policy Manag. 2024, 51, 631–652. [Google Scholar] [CrossRef]

- Li, Y.; Chang, D.; Gao, Y.; Zou, Y.; Bao, C. Automated Container Terminal Production Operation and Optimization via an AdaBoost-Based Digital Twin Framework. J. Adv. Transp. 2021, 2021, 1936764. [Google Scholar] [CrossRef]

- Ma, X.; Zhou, H.; Li, Z. On the Resilience of Modern Power Systems: A Complex Network Perspective. Renew. Sustain. Energy Rev. 2021, 152, 111646. [Google Scholar] [CrossRef]

- Saleh, M.; Esa, Y.; Mohamed, A. Applications of Complex Network Analysis in Electric Power Systems. Energies 2018, 11, 1381. [Google Scholar] [CrossRef]

- Zhang, M.; Huang, T.; Guo, Z.; He, Z. Complex-Network-Based Traffic Network Analysis and Dynamics: A Comprehensive Review. Phys. A Stat. Mech. Its Appl. 2022, 607, 128063. [Google Scholar] [CrossRef]

- Sano, H.H.; Berton, L. A Temporal Event Graph Approach and Robustness Analysis for Air Transport Network. IEEE Trans. Netw. Sci. Eng. 2021, 8, 3453–3464. [Google Scholar] [CrossRef]

- Liu, J.; Fu, Y.; Han, K.; Cui, Y. Resilience Analysis of the RCEP Shipping Network. Ocean Coast. Manag. 2024, 257, 107317. [Google Scholar] [CrossRef]

- Hearnshaw, E.J.S.; Wilson, M.M.J. A Complex Network Approach to Supply Chain Network Theory. Int. J. Oper. Prod. Manag. 2013, 33, 442–469. [Google Scholar] [CrossRef]

- Butts, C.T. The Complexity of Social Networks: Theoretical and Empirical Findings. Soc. Netw. 2001, 23, 31–72. [Google Scholar] [CrossRef]

- Gong, C.; Tang, P.; Wang, Y. Measuring the Network Connectedness of Global Stock Markets. Phys. A Stat. Mech. Its Appl. 2019, 535, 122351. [Google Scholar] [CrossRef]

- Tongal, H.; Sivakumar, B. Forecasting Rainfall Using Transfer Entropy Coupled Directed–Weighted Complex Networks. Atmos. Res. 2021, 255, 105531. [Google Scholar] [CrossRef]

- Pallis, P.L. Port Risk Management in Container Terminals. Transp. Res. Procedia 2017, 25, 4411–4421. [Google Scholar] [CrossRef]

- Khan, R.U.; Yin, J.; Mustafa, F.S.; Wang, S. Seaport Hazardous Cargo Loading and Unloading Risk Assessment Using Interval Type-2 Fuzzy Sets and Bayesian Networks. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2024, 10, 04023065. [Google Scholar] [CrossRef]

- Xing, M.; Luo, X.; Zan, Y.; Yang, L.; Jin, H.; Luo, J. Identification of Factors Affecting Hoisting Quality of Large Offshore Structures and Analysis of Their Coupling Relationship Based on Grey-DEMATEL-ISM-MICMAC. Ocean Eng. 2023, 280, 114805. [Google Scholar] [CrossRef]

- Kim, S.; Kim, H.; Park, Y. Early Detection of Vessel Delays Using Combined Historical and Real-Time Information. J. Oper. Res. Soc. 2017, 68, 182–191. [Google Scholar] [CrossRef]

- Li, C.; Qi, X.; Lee, C.-Y. Disruption Recovery for a Vessel in Liner Shipping. Transp. Sci. 2015, 49, 900–921. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, Q.; Quan, X. Robust Berth Scheduling with Uncertain Vessel Delay and Handling Time. Ann. Oper. Res. 2012, 192, 123–140. [Google Scholar] [CrossRef]

- Xiang, X.; Liu, C.; Miao, L. Reactive Strategy for Discrete Berth Allocation and Quay Crane Assignment Problems under Uncertainty. Comput. Ind. Eng. 2018, 126, 196–216. [Google Scholar] [CrossRef]

- Schreiber, T. Measuring Information Transfer. Phys. Rev. Lett. 2000, 85, 461–464. [Google Scholar] [CrossRef]

- Marschinski, R.; Kantz, H. Analysing the Information Flow between Financial Time Series. Eur. Phys. J. B 2002, 30, 275–281. [Google Scholar] [CrossRef]

- Fan, X.; Li, X. Minimizing Probing CostWith mRMR Feature Selection in Network Monitoring. IEEE Commun. Lett. 2017, 21, 2400–2403. [Google Scholar] [CrossRef]

- Li, K.; Chen, Z.; Cong, R.; Zhang, J.; Wei, Z. Simulated Dynamics of Virus Spreading on Social Networks with Various Topologies. Appl. Math. Comput. 2024, 470, 128580. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, H.; Jin, X. Risk Transmission in Complex Supply Chain Network with Multi-Drivers. Chaos Solitons Fractals 2021, 143, 110259. [Google Scholar] [CrossRef]

- Shahidinejad, A.; Ghobaei-Arani, M.; Masdari, M. Resource Provisioning Using Workload Clustering in Cloud Computing Environment: A Hybrid Approach. Clust. Comput. 2021, 24, 319–342. [Google Scholar] [CrossRef]

- Alsayed, A.; Higham, D.J. Betweenness in Time Dependent Networks. Chaos Solitons Fractals 2015, 72, 35–48. [Google Scholar] [CrossRef]

- Bonacich, P. Some Unique Properties of Eigenvector Centrality. Soc. Netw. 2007, 29, 555–564. [Google Scholar] [CrossRef]

- Wang, X.; Slamu, W.; Guo, W.; Wang, S.; Ren, Y. A Novel Semi Local Measure of Identifying Influential Nodes in Complex Networks. Chaos Solitons Fractals 2022, 158, 112037. [Google Scholar] [CrossRef]

- Zhong, S.; Zhang, H.; Deng, Y. Identification of Influential Nodes in Complex Networks: A Local Degree Dimension Approach. Inf. Sci. 2022, 610, 994–1009. [Google Scholar] [CrossRef]

- Xu, G.; Meng, L. A Novel Algorithm for Identifying Influential Nodes in Complex Networks Based on Local Propagation Probability Model. Chaos Solitons Fractals 2023, 168, 113155. [Google Scholar] [CrossRef]

- Yang, X.; Xiao, F. An Improved Gravity Model to Identify Influential Nodes in Complex Networks Based on K-Shell Method. Knowl.-Based Syst. 2021, 227, 107198. [Google Scholar] [CrossRef]

- Bian, T.; Hu, J.; Deng, Y. Identifying Influential Nodes in Complex Networks Based on AHP. Phys. A Stat. Mech. Its Appl. 2017, 479, 422–436. [Google Scholar] [CrossRef]

- Yuan, Y.; Au, F.T.K.; Yang, D.; Zhang, J. Large-Scale Baseline Model Exploration from Structural Monitoring Based on a Novel Information Entropy-Probability Learning Function. Comput. Struct. 2024, 292, 107239. [Google Scholar] [CrossRef]

- Nikougoftar, E. Strategic Node Identification in Complex Network Dynamics. Chaos Solitons Fractals 2024, 187, 115348. [Google Scholar] [CrossRef]

- de Farias Aires, R.F.; Ferreira, L. A New Approach to Avoid Rank Reversal Cases in the TOPSIS Method. Comput. Ind. Eng. 2019, 132, 84–97. [Google Scholar] [CrossRef]

| Parameter | Definition | Explanation |

|---|---|---|

| Total number of equipment | Total number of equipment involved in loading and unloading handlings | |

| Number of equipment in normal handling | Normal handling equipment easily affected by delays | |

| Number of equipment in delayed status | Equipment in delayed status affected by delay-conducting equipment | |

| Number of equipment causing delays | Equipment with delay propagation capability | |

| Number of equipment in recovery status | Equipment that has recovered to a rehabilitated state after being affected by delays | |

| Delay impact rate | Probability of normal equipment being impacted and transforming to a delayed state | |

| Delay propagate rate | Probability of propagation from delayed status to delay-propagating status | |

| Delay recovery rate | Probability of converting from delay propagation status to recovery status through regulation | |

| Automatic recovery rate | Probability of equipment automatically restored to its normal state after a delay | |

| Equipment withdrawal rate | Probability of delay-propagating equipment withdrawing the handling process | |

| Recurrence delay rate | Probability of equipment in recovery status transforming to a susceptible state |

| AGV ID | QC&YC ID | Start Time | End Time |

|---|---|---|---|

| AGV15 | QC091 | 12 May 2023 8:01 | 12 May 2023 8:09 |

| AGV47 | QC073 | 12 May 2023 8:01 | 12 May 2023 8:11 |

| AGV51 | QC082 | 12 May 2023 8:01 | 12 May 2023 8:10 |

| AGV03 | YC001 | 12 May 2023 8:01 | 12 May 2023 8:20 |

| AGV57 | QC072 | 12 May 2023 8:03 | 12 May 2023 8:09 |

| AGV18 | YC006 | 12 May 2023 8:03 | 12 May 2023 8:20 |

| AGV36 | QC082 | 12 May 2023 8:04 | 12 May 2023 8:17 |

| AGV06 | QC091 | 12 May 2023 8:05 | 12 May 2023 8:13 |

| Variable | Variable Explanation |

|---|---|

| A set of time series data, where represents the time series | |

| The maximum time lag considered when calculating multivariate transfer entropy | |

| The significance threshold for detecting causal relationships | |

| mRMR parameter for selecting conditional variables | |

| The set of conditional variables | |

| The causal matrix, with the elements is | |

| The MHII network | |

| The number of handling time series groups |

| Indicators | The Values of Indicators in the MHII Network | The Values of Indictors in Random Network |

|---|---|---|

| Number of nodes | 54 | 54 |

| Number of edges | 128 | 128 |

| Density | 0.045 | 0.089 |

| Average degree | 4.741 | 4.741 |

| Average path length | 2.656 | 2.719 |

| Clustering coefficient | 0.042 | 0.086 |

| Rank | ||||||

|---|---|---|---|---|---|---|

| Node ID | Equipment ID | Node ID | Equipment ID | Node ID | Equipment ID | |

| 1 | 35 | AGV44 | 16 | QC82 | 16 | QC82 |

| 2 | 16 | QC82 | 35 | AGV44 | 17 | QC91 |

| 3 | 30 | AGV36 | 17 | QC91 | 15 | QC81 |

| 4 | 31 | AGV38 | 15 | QC81 | 14 | QC73 |

| 5 | 40 | AGV52 | 14 | QC73 | 18 | QC92 |

| 6 | 23 | AGV25 | 18 | QC92 | 13 | QC72 |

| 7 | 39 | AGV51 | 13 | QC72 | 35 | AGV44 |

| 8 | 15 | QC81 | 30 | AGV36 | 12 | YC8 |

| Node ID | Equipment ID | Degree | Closeness Centrality | Betweenness Centrality | Eigenvector Centrality | Task Proportion | Rank |

|---|---|---|---|---|---|---|---|

| 35 | AGV44 | 8 | 0.1681 | 0.1167 | 0.1555 | 2.8% | 1 |

| 16 | QC82 | 3 | 0.1935 | 0.0041 | 0.1311 | 9.0% | 2 |

| 30 | AGV36 | 6 | 0.1872 | 0.0941 | 0.1795 | 2.7% | 3 |

| 31 | AGV38 | 8 | 0.1662 | 0.0810 | 0.1450 | 2.9% | 4 |

| 40 | AGV52 | 9 | 0.1436 | 0.0837 | 0.1493 | 2.5% | 5 |

| 23 | AGV25 | 7 | 0.1591 | 0.0848 | 0.1126 | 2.8% | 6 |

| 39 | AGV51 | 11 | 0.1422 | 0.0639 | 0.1223 | 2.6% | 7 |

| 15 | QC81 | 3 | 0.1311 | 0.0000 | 0.1489 | 7.7% | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Li, J.; Xu, B. Delay Propagation at U-Shaped Automated Terminals for Multilevel Handlings Based on Multivariate Transfer Entropy. J. Mar. Sci. Eng. 2025, 13, 581. https://doi.org/10.3390/jmse13030581

Guo X, Li J, Xu B. Delay Propagation at U-Shaped Automated Terminals for Multilevel Handlings Based on Multivariate Transfer Entropy. Journal of Marine Science and Engineering. 2025; 13(3):581. https://doi.org/10.3390/jmse13030581

Chicago/Turabian StyleGuo, Xinyu, Junjun Li, and Bowei Xu. 2025. "Delay Propagation at U-Shaped Automated Terminals for Multilevel Handlings Based on Multivariate Transfer Entropy" Journal of Marine Science and Engineering 13, no. 3: 581. https://doi.org/10.3390/jmse13030581

APA StyleGuo, X., Li, J., & Xu, B. (2025). Delay Propagation at U-Shaped Automated Terminals for Multilevel Handlings Based on Multivariate Transfer Entropy. Journal of Marine Science and Engineering, 13(3), 581. https://doi.org/10.3390/jmse13030581