A Finite Element Analysis of Lateral Buckling of Tensile Armor Layers of Flexible Pipes Considering Machining Geometry Defects

Abstract

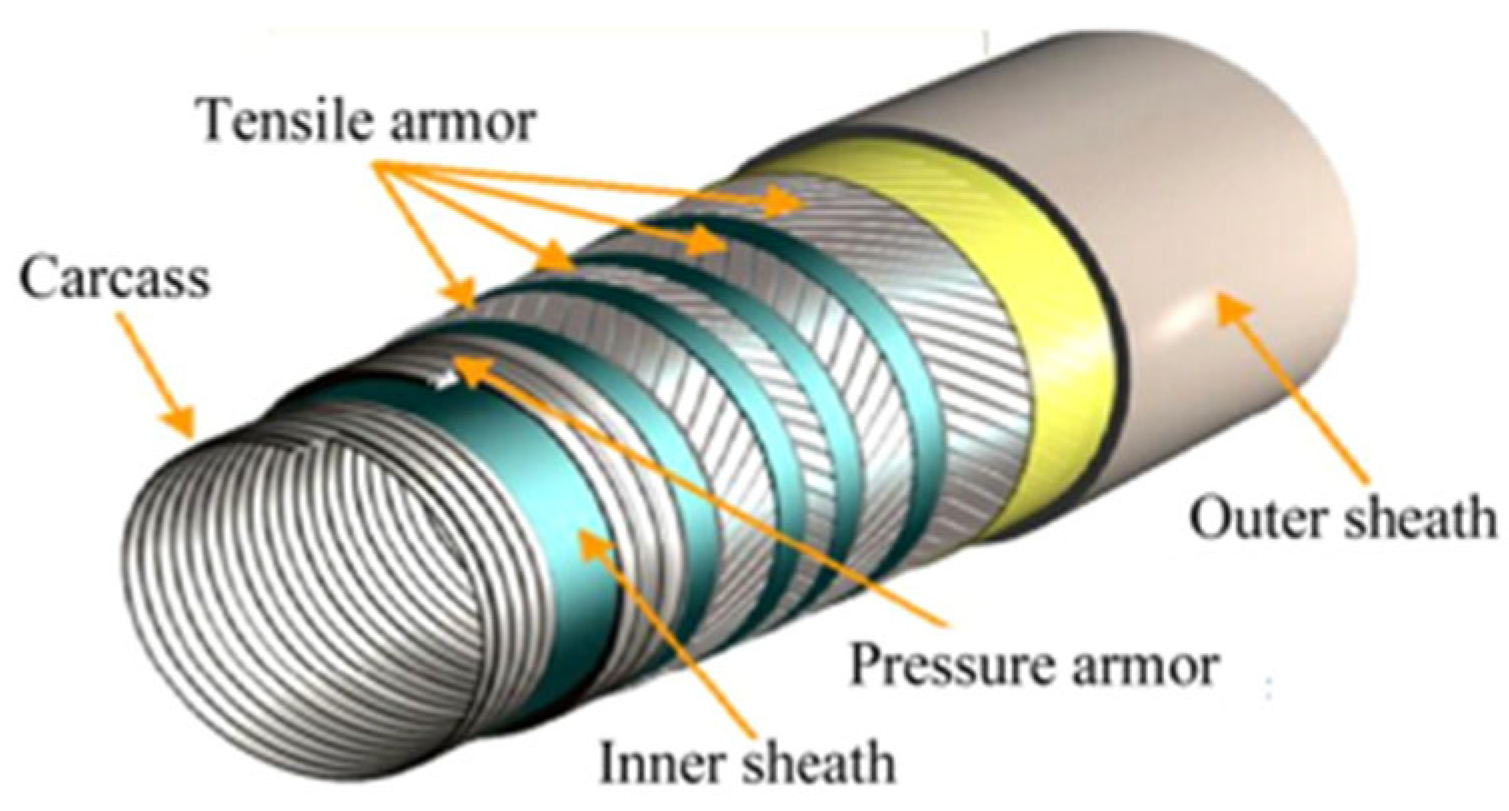

1. Introduction

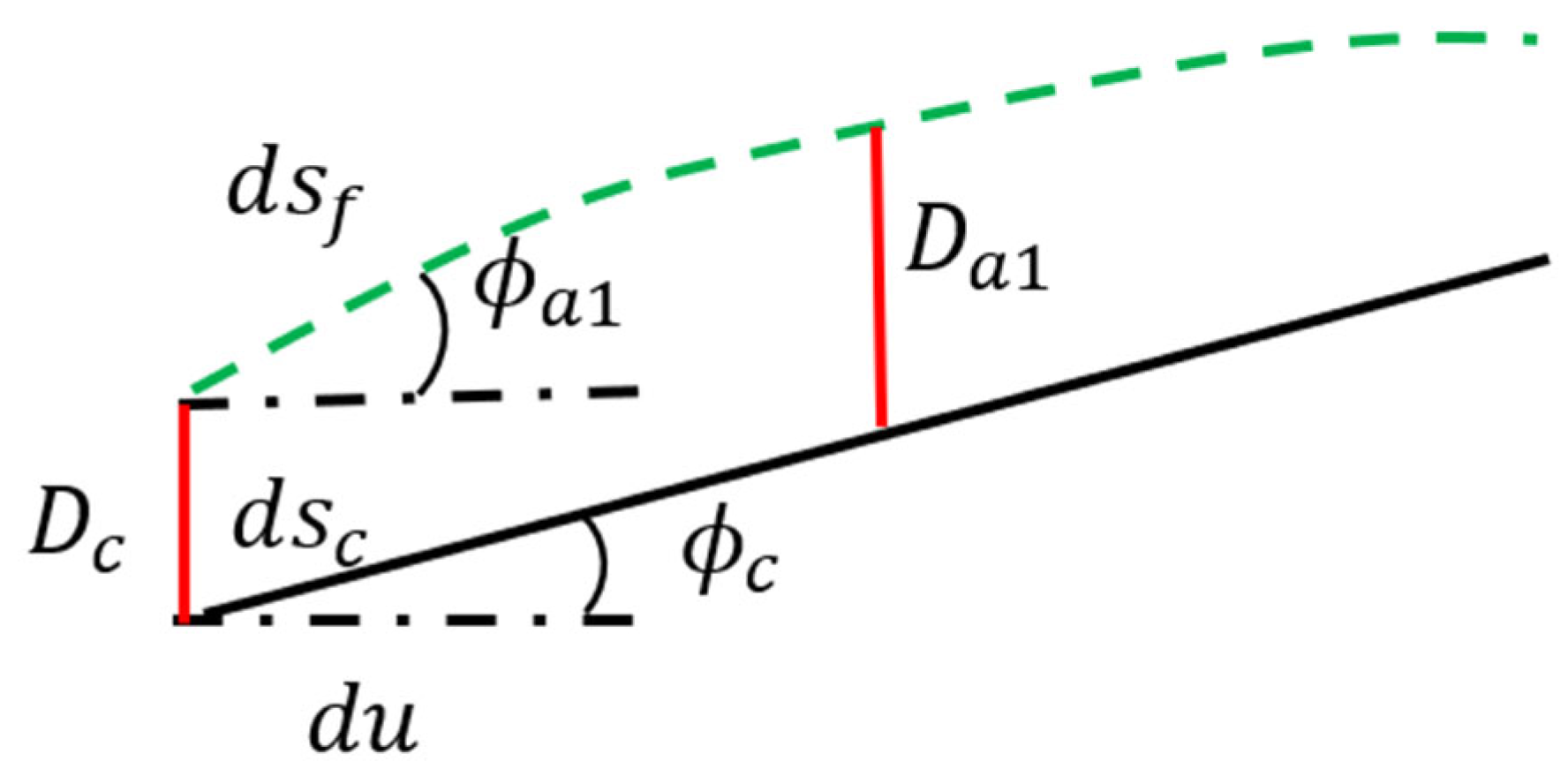

2. Geometric Equation of a Single Armor Wire

2.1. Curve Equation on a Torus

2.2. Curvature Components of Armor Wire

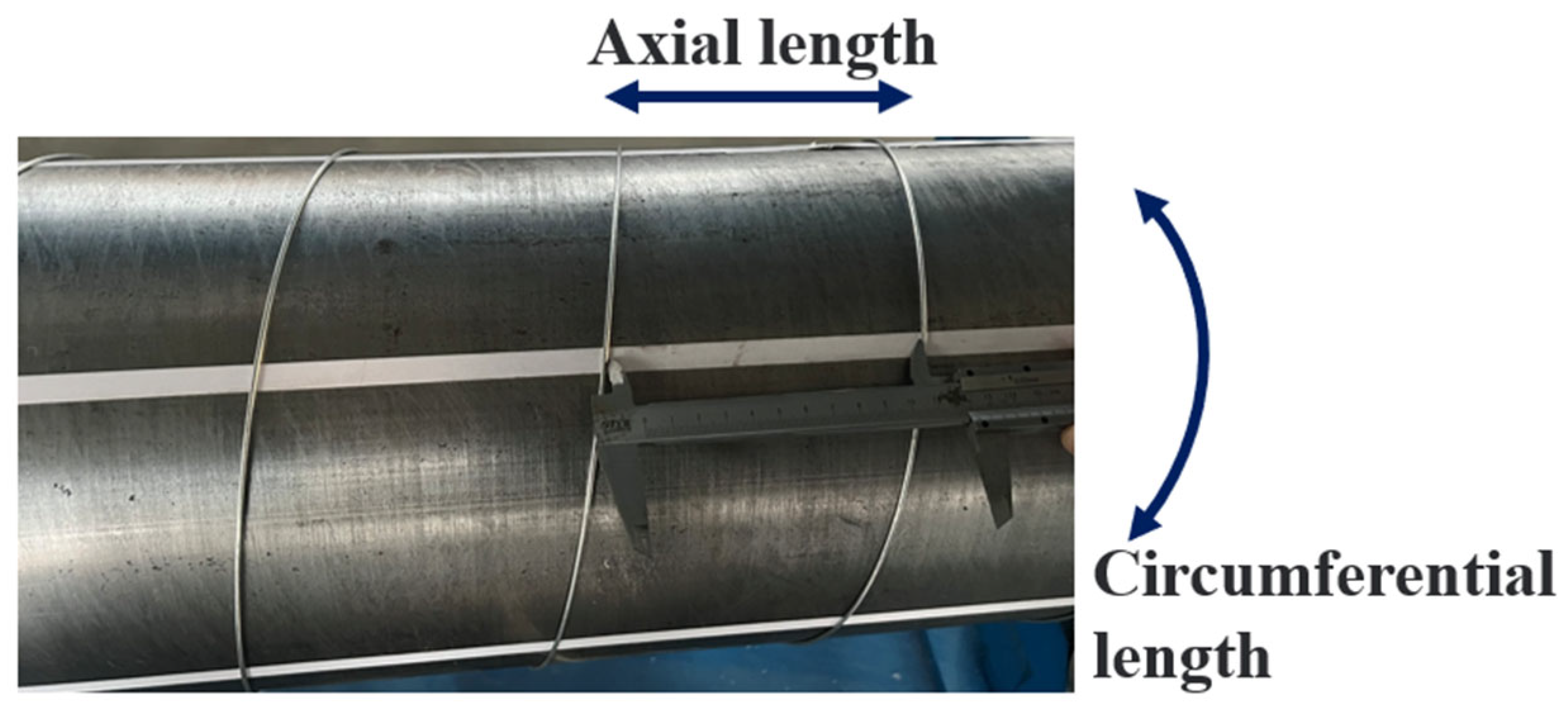

2.3. Quantification of Armor Wire Deviation

3. Finite Element Model

3.1. Geometric Model and Material Parameters

3.2. Boundary Conditions and Displacement Load

4. Results and Discussion

4.1. Load-Bearing Capacity Changes During Lateral Buckling of Steel Strip

- (1)

- In the initial stage, as the displacement load increases, the reaction force in the Z-axis direction starts from the origin O and grows almost linearly. Before reaching the critical load at point A, the steel strip remains in compression without any lateral buckling, and the structure stays stable.

- (2)

- Next, after the armor steel strip reaches the critical buckling load at point A, the structure enters a post-buckling state and becomes unstable. In the AB segment, the load and displacement values decrease as the simulation progresses, which is typical of an unstable static response. From the diagram, it can be observed that the distance between the OA and AB segments is short, with no significant hysteresis, primarily because the structure has not yet entered the plastic stage.

- (3)

- Finally, in the BC segment, the steel strip remains in the post-buckling stage, and the decrease in axial reaction force slows down. The free end of the armor wire enters the plastic stage, exhibiting noticeable lateral buckling deformation.

4.2. Mesh Convergence Analysis

4.3. Model Validation

4.4. Internal Force Changes in Armor Wire Cross-Section During Lateral Buckling

4.5. Circumferential Displacement Changes in Armor Wire During Lateral Buckling

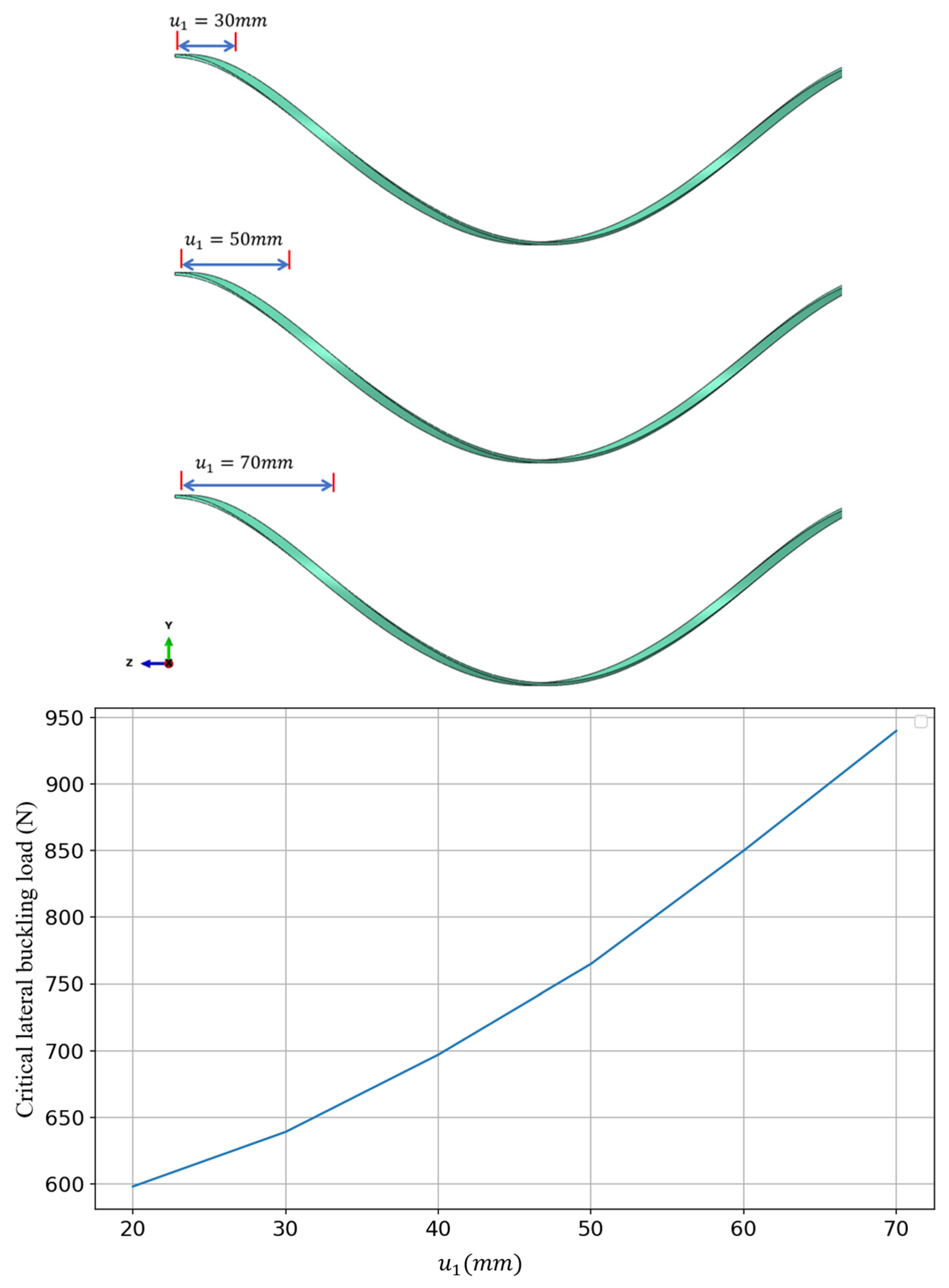

4.6. Influence of Defect Location on Critical Lateral Buckling Load

4.7. Influence of Deviation Severity on Critical Buckling Load

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Secher, P.; Bectarte, F.; Felix-Henry, A. Lateral Buckling of Armor Wires in Flexible Pipes: Reaching 3000m Water Depth. In Proceedings of the ASME 2011 30th International Conference on Ocean, Offshore and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011; Volume 4: Pipeline and Riser Technology. pp. 421–428. [Google Scholar] [CrossRef]

- Østergaard, N.H.; Lyckegaard, A.; Andreasen, J.H. On Lateral Buckling Failure of Armour Wires in Flexible Pipes. In Proceedings of the ASME 2011 30th International Conference on Ocean, Offshore and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011; Volume 4: Pipeline and Riser Technology. pp. 289–298. [Google Scholar] [CrossRef]

- Østergaard, N.; Lyckegaard, A.; Andreasen, J.H. Imperfection Analysis of Flexible Pipe Armor Wires in Compression and Bending. Appl. Ocean. Res. 2012, 38, 40–47. [Google Scholar] [CrossRef]

- Li, X.; Vaz, M.A.; Custódio, A.B. Analytical Model for Tensile Armors Lateral Deflections and Buckling in Flexible Pipes. Mar. Struct. 2019, 64, 211–228. [Google Scholar] [CrossRef]

- Sævik, S.; Thorsen, M.J. An Analytical Treatment of Buckling and Instability of Tensile Armors in Flexible Pipes. J. Offshore Mech. Arct. Eng. 2017, 139, 041701. [Google Scholar] [CrossRef]

- Tan, Z.; Loper, C.; Sheldrake, T.; Karabelas, G. Behavior of Tensile Wires in Unbonded Flexible Pipe Under Compression and Design Optimization for Prevention. In Proceedings of the 25th International Conference on Offshore Mechanics and Arctic Engineering, Hamburg, Germany, 4–9 June 2006; Volume 4: Terry Jones Pipeline Technology; Ocean Space Utilization; CFD and VIV Symposium. pp. 43–50. [Google Scholar] [CrossRef]

- Sævik, S.; Ji, G. Differential Equation for Evaluating Transverse Buckling Behavior of Tensile Armour Wires. In Proceedings of the ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014; Volume 6B: Pipeline and Riser Technology. p. V06BT04A021. [Google Scholar] [CrossRef]

- Sævik, S.; Thorsen, M.J. Techniques for Predicting Tensile Armour Buckling and Fatigue in Deep Water Flexible Pipes. In Proceedings of the ASME 2012 31st International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012; Volume 3: Pipeline and Riser Technology. pp. 469–482. [Google Scholar] [CrossRef]

- Caleyron, F.; Guiton, M.; Leroy, J.-M.; Perdrizet, T.; Charliac, D.; Estrier, P.; Paumier, L. A Multi-Purpose Finite Element Model for Flexible Risers Studies. In Proceedings of the ASME 2014 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014; Volume 6A: Pipeline and Riser Technology. p. V06AT04A015. [Google Scholar] [CrossRef]

- Ye, N.; Ji, G.; Sævik, S. Lateral Buckling of Tensile Armor Wires in Flexible Pipe Subject to Axial Compressive and Cyclic Bending Load. In Proceedings of the ASME 2023 42nd International Conference on Ocean, Offshore and Arctic Engineering, Melbourne, Australia, 11–16 June 2023; Volume 3: Materials Technology; Pipelines, Risers, and Subsea Systems. p. V003T04A013. [Google Scholar] [CrossRef]

- Lu, Q.; Yang, Z.; Yang, Y.; Yan, J.; Yue, Q. Study on the Mechanism of Bird-Cage Buckling of Armor Wires Based on Experiment. In Proceedings of the ASME 2017 36th International Conference on Ocean, Offshore and Arctic Engineering, Trondheim, Norway, 25–30 June 2017; Volume 5A: Pipelines, Risers, and Subsea Systems. p. V05AT04A018. [Google Scholar] [CrossRef]

- Favaro Borges, M.; Talgatti, O.L.; Mosquen, A. Radial Instability of Flexible Pipes with Defects in the High Resistance Bandage and External Sheath. In Proceedings of the ASME 2017 36th International Conference on Ocean, Offshore and Arctic Engineering, Trondheim, Norway, 25–30 June 2017; Volume 5A: Pipelines, Risers, and Subsea Systems. p. V05AT04A025. [Google Scholar] [CrossRef]

- Li, X.; Vaz, M.A.; Custódio, A.B. Analytical and Experimental Studies on Flexible Pipes Tensile Armors Lateral Instability in Cyclic Bending. Mar. Struct. 2019, 67, 102630. [Google Scholar] [CrossRef]

- Caleyron, F.; Leroy, J.-M.; Guiton, M.; Duchêne, P.; Estrier, P.; Vraniskoski, K.; Damiens, A. Stresses in Tensile Armour Layers of Unbounded Flexible Risers Loaded with External Pressure: Application to Lateral Buckling Mode. In Proceedings of the ASME 2017 36th International Conference on Ocean, Offshore and Arctic Engineering, Trondheim, Norway, 25–30 June 2017; Volume 5A: Pipelines, Risers, and Subsea Systems. p. V05AT04A006. [Google Scholar] [CrossRef]

- Yang, Z.; Yan, J.; Zhang, L.; Shi, D.; Lu, Q. Research on Lateral Buckling Mechanism of Tensile Armor Wires in Unbonded Flexible Pipe. In Proceedings of the ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering, Virtual, Online, 3–7 August 2020. Volume 4: Pipelines, Risers, and Subsea Systems. [Google Scholar] [CrossRef]

- Vaz, M.A.; Rizzo, N.A.S. A Finite Element Model for Flexible Pipe Armor Wire Instability. Mar. Struct. 2011, 24, 275–291. [Google Scholar] [CrossRef]

- De Paiva, L.F.; Vaz, M.A. An Empirical Model for Flexible Pipe Armor Wire Lateral Buckling Failure Load. Appl. Ocean Res. 2017, 66, 46–54. [Google Scholar] [CrossRef]

- Østergaard, N.H.; Lyckegaard, A.; Andreasen, J.H. A Method for Prediction of the Equilibrium State of a Long and Slender Wire on a Frictionless Toroid Applied for Analysis of Flexible Pipe Structures. Eng. Struct. 2012, 34, 391–399. [Google Scholar] [CrossRef]

- Zhou, C.; Sævik, S.; Ye, N.; Ji, G. Effect of Lay Angle of Anti-Buckling Tape on Lateral Buckling Behavior of Tensile Armors. In Proceedings of the ASME 2015 34th International Conference on Ocean, Offshore and Arctic Engineering, St. John’s, NF, Canada, 31 May–5 June 2015; Volume 5A: Pipeline and Riser Technology. p. V05AT04A040. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.; Liu, C.; Lu, Q.; Chen, J.; Yan, J.; Yue, Q. Modelling and Control of Tension in a Flexible Pipe Tensile Armour Manufacturing Process. Int. J. Adv. Manuf. Technol. 2024, 133, 3927–3936. [Google Scholar] [CrossRef]

- Dassault Systèmes, Abaqus/CAE User’s Guide, Dassault Systèmes. 2024. Available online: https://help.3ds.com (accessed on 7 January 2024).

| Parameter | D (MM) | u1 (mm) | u2 (mm) | u3 (mm) | u4 (mm) |

|---|---|---|---|---|---|

| A | 2 | 20 | 200 | 200 | Extended to quadruple pitch |

| B | 4 | 20 | 200 | 200 | Extended to quadruple pitch |

| Parameter | Value | ||||||

|---|---|---|---|---|---|---|---|

| E-mod (GPa) | 210 | ||||||

| Poisson’s ratio | 0.3 | ||||||

| Yield stress (MPa) | 650 | 676 | 685 | 691 | 717 | 730 | 744 |

| Plastic strain | 0 | 0.01 | 0.02 | 0.1 | 0.15 | 0.4 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Lu, Q.; Yue, X.; Lu, H.; Yue, Q.; Lu, Y. A Finite Element Analysis of Lateral Buckling of Tensile Armor Layers of Flexible Pipes Considering Machining Geometry Defects. J. Mar. Sci. Eng. 2025, 13, 580. https://doi.org/10.3390/jmse13030580

Li Y, Lu Q, Yue X, Lu H, Yue Q, Lu Y. A Finite Element Analysis of Lateral Buckling of Tensile Armor Layers of Flexible Pipes Considering Machining Geometry Defects. Journal of Marine Science and Engineering. 2025; 13(3):580. https://doi.org/10.3390/jmse13030580

Chicago/Turabian StyleLi, Yongyu, Qingzhen Lu, Xiufeng Yue, Hailong Lu, Qianjin Yue, and Yangcheng Lu. 2025. "A Finite Element Analysis of Lateral Buckling of Tensile Armor Layers of Flexible Pipes Considering Machining Geometry Defects" Journal of Marine Science and Engineering 13, no. 3: 580. https://doi.org/10.3390/jmse13030580

APA StyleLi, Y., Lu, Q., Yue, X., Lu, H., Yue, Q., & Lu, Y. (2025). A Finite Element Analysis of Lateral Buckling of Tensile Armor Layers of Flexible Pipes Considering Machining Geometry Defects. Journal of Marine Science and Engineering, 13(3), 580. https://doi.org/10.3390/jmse13030580