Hydrodynamic Effects and Scour Protection of a Geotextile Mattress with a Floating Plate

Abstract

1. Introduction

- Dynamic GMFP-flow interaction. Previous studies have primarily treated the sloping angle of the plate as a static, independent parameter [23,25]. In fact, the angle is governed by the incoming flow velocity [22]. The lack of research on this coupled interaction has become a significant bottleneck in predicting GMFP performance in real-world, unsteady marine environments. While the rigid sloping curtain in [22] was analyzed, the distinct configuration of a rigid curtain and a GMFP leads to fundamentally different hydrodynamics response of the two structures [20,25], making their findings not directly transferable.

- Effects on the water surface variation. The water surface profile is a main attribution to the pressure difference across the structure and a critical factor for assessing seepage failure risk [23]. Despite its critical role in the stability of the GMFP, the water surface profile and its influence factors have not been comprehensively examined before.

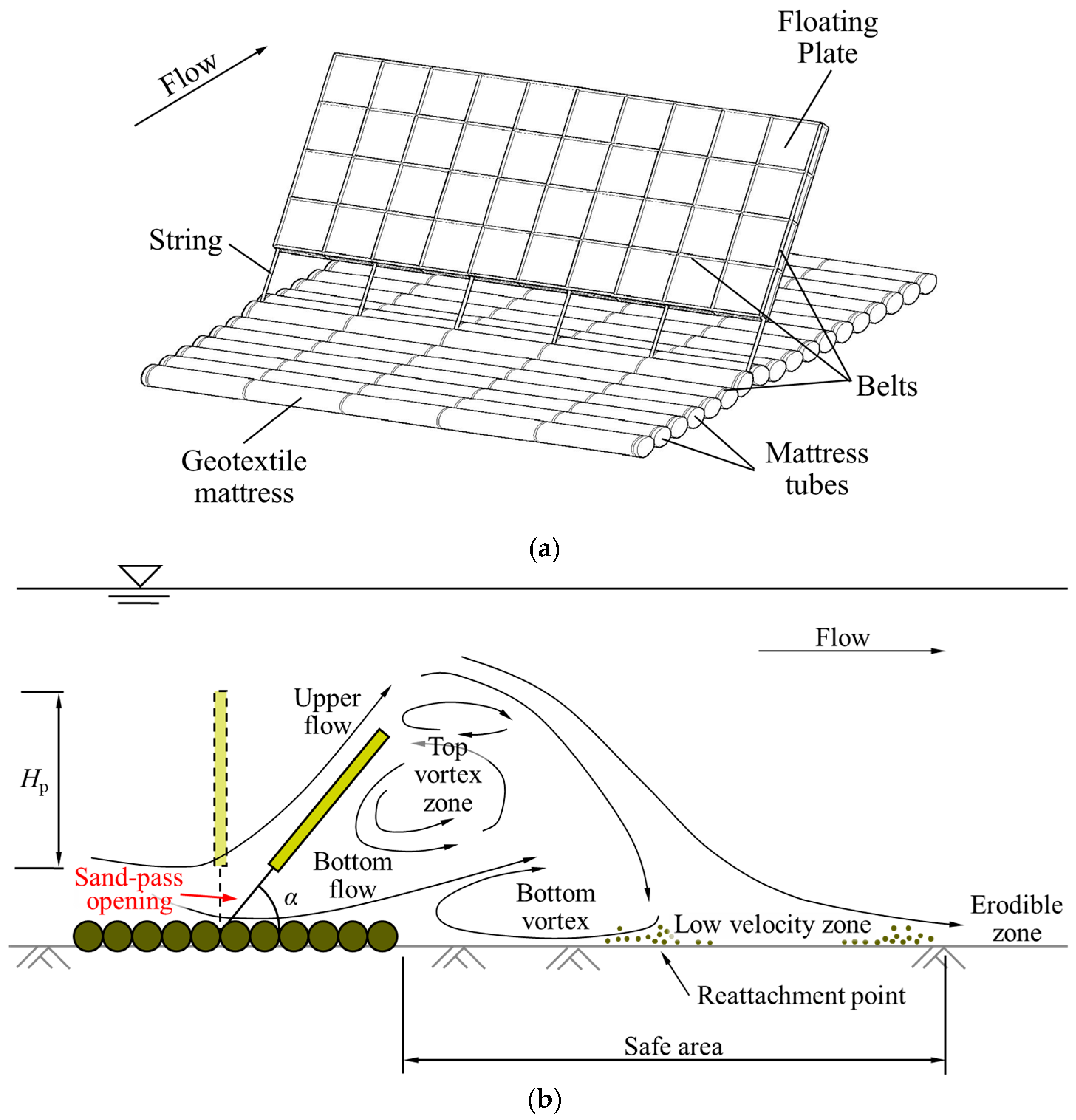

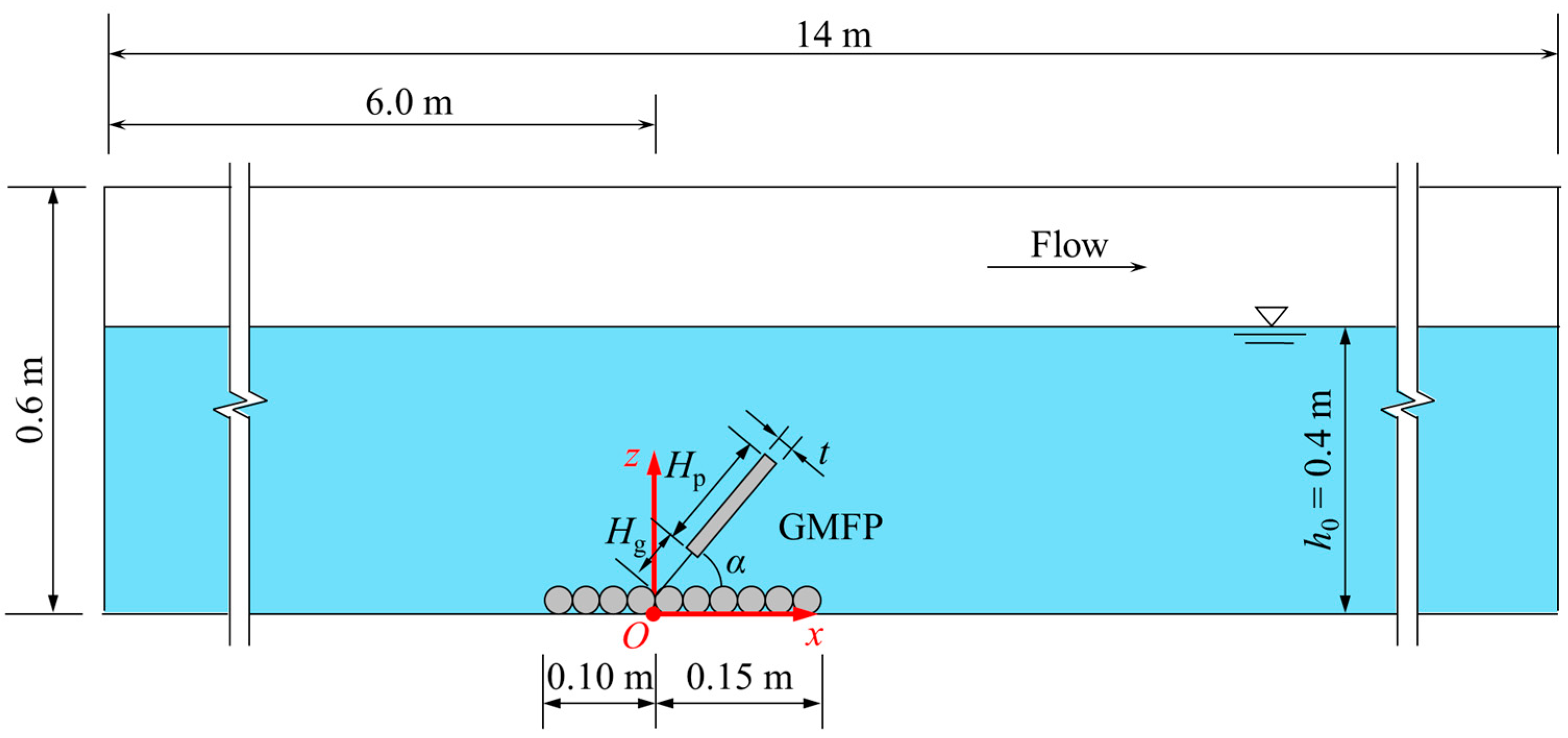

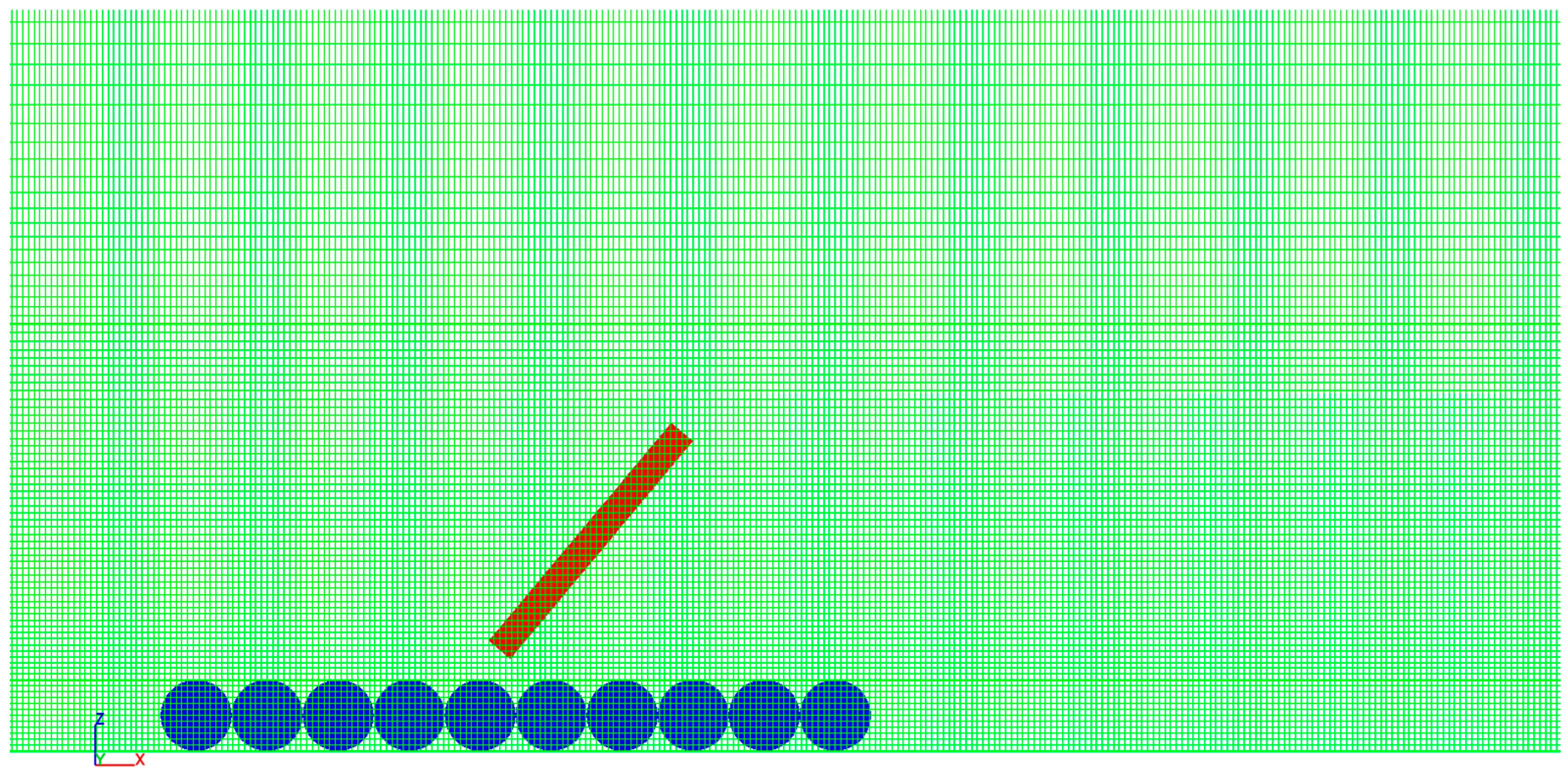

2. Numerical Model

2.1. Governing Equations

2.2. Model Setup

- Flume entrance (X Min): Specified velocity, with velocity values set per case and a fixed fluid elevation of 0.4 m.

- Flume exit (X Max): Specified pressure, with a fixed fluid elevation of 0.4 m.

- Flume bottom (Z Min): Wall, no-slip boundary.

- Flume top (Z Max): Specified pressure, with a fluid fraction of 0.

- Side walls (Y Min and Y Max): Symmetry.

2.3. Simulation Cases

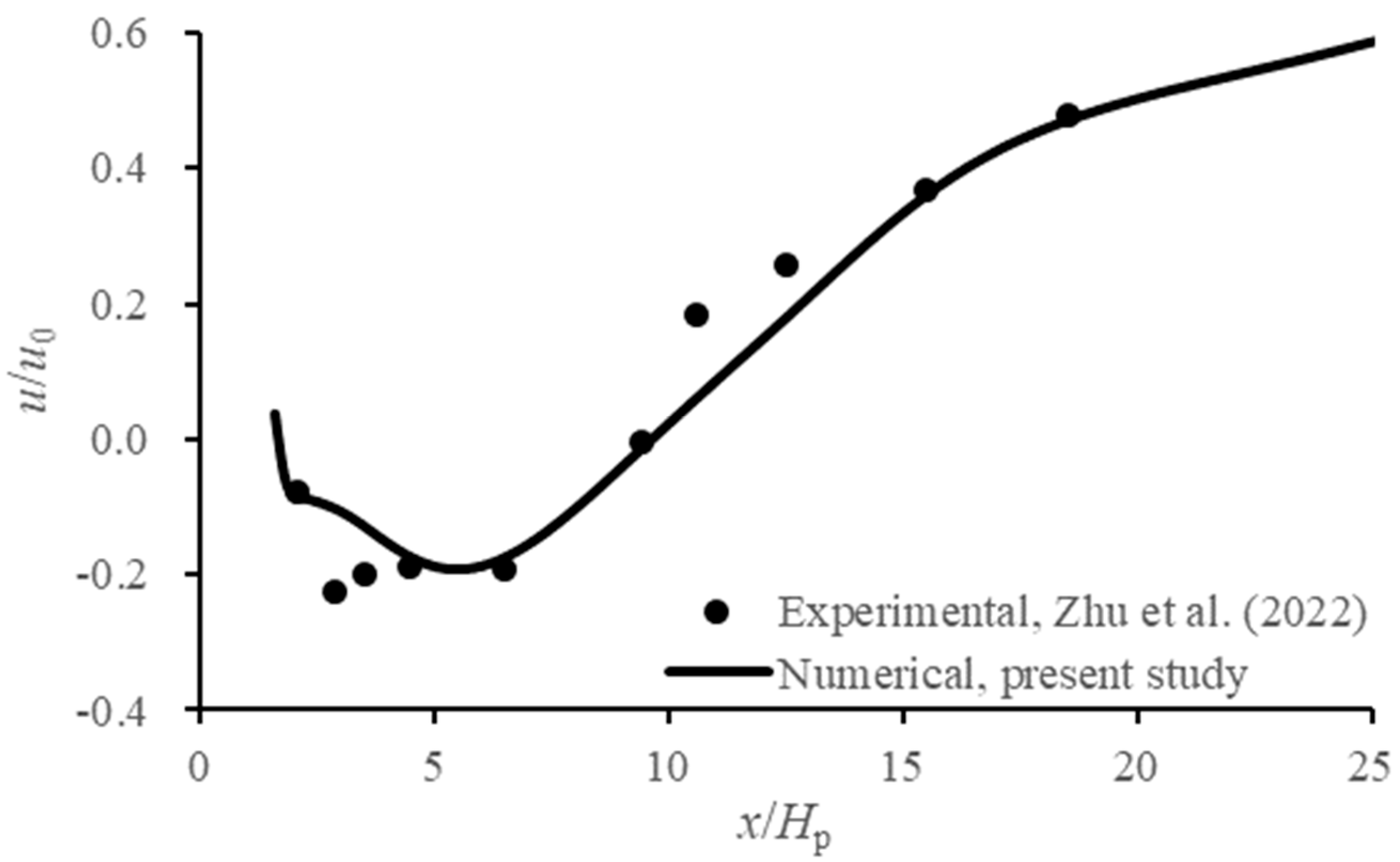

2.4. Model Validation

2.4.1. Validation of the Local Flow Pattern

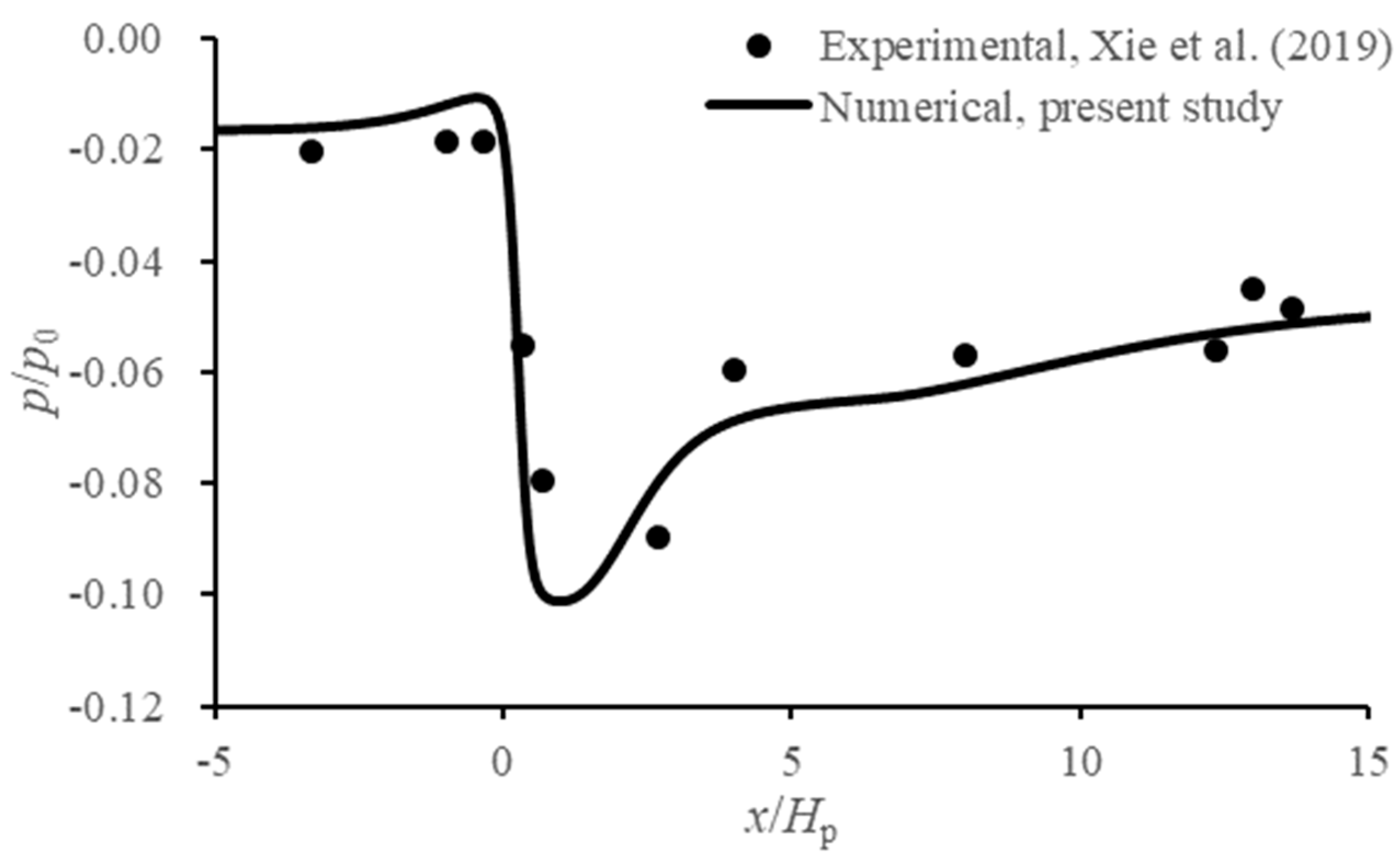

2.4.2. Validation of Local Bed Pressure

2.4.3. Mesh and Time Step Dependence Check

3. Results: Effects of the Approaching Flow Velocity

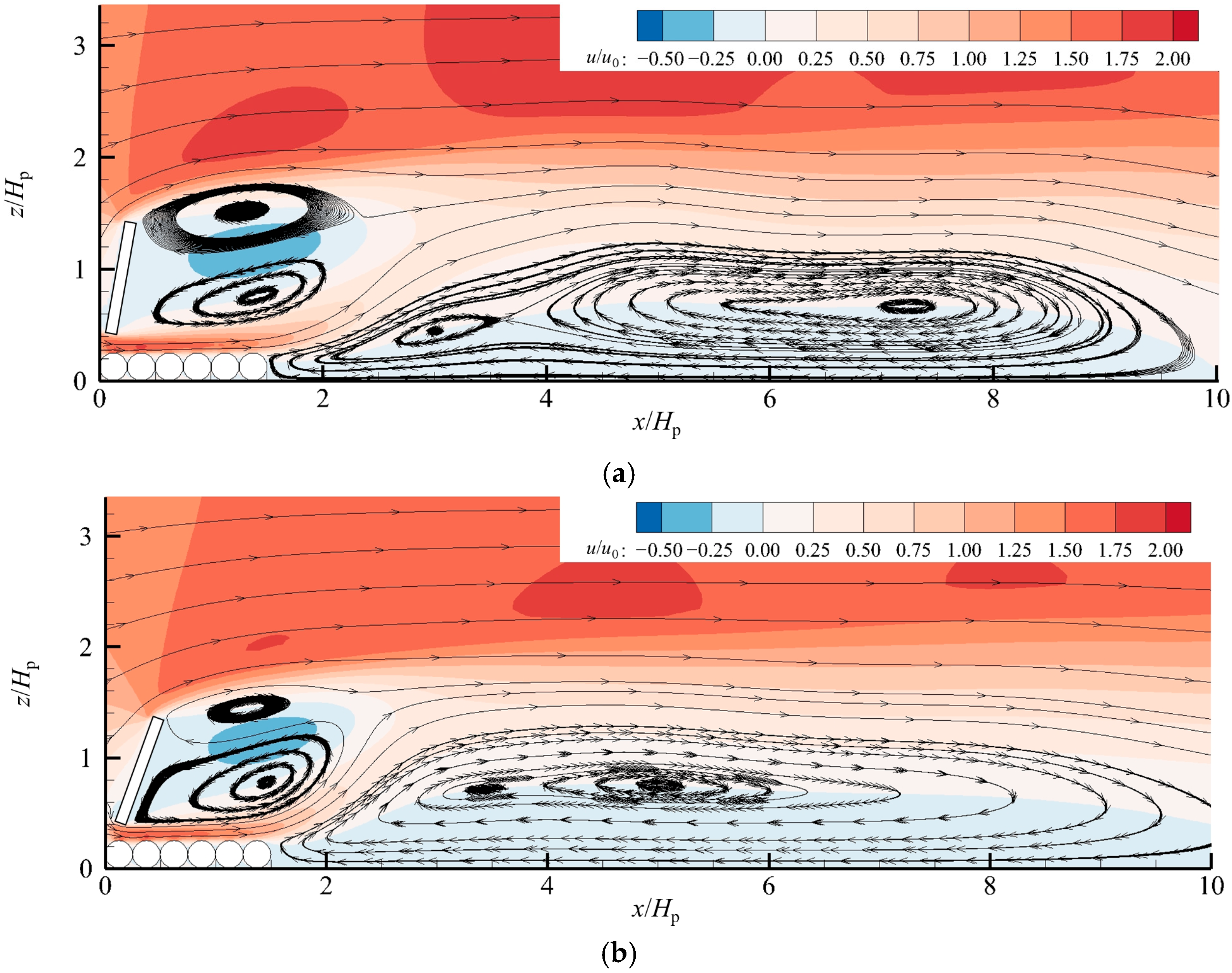

3.1. Effect on the Flow Field

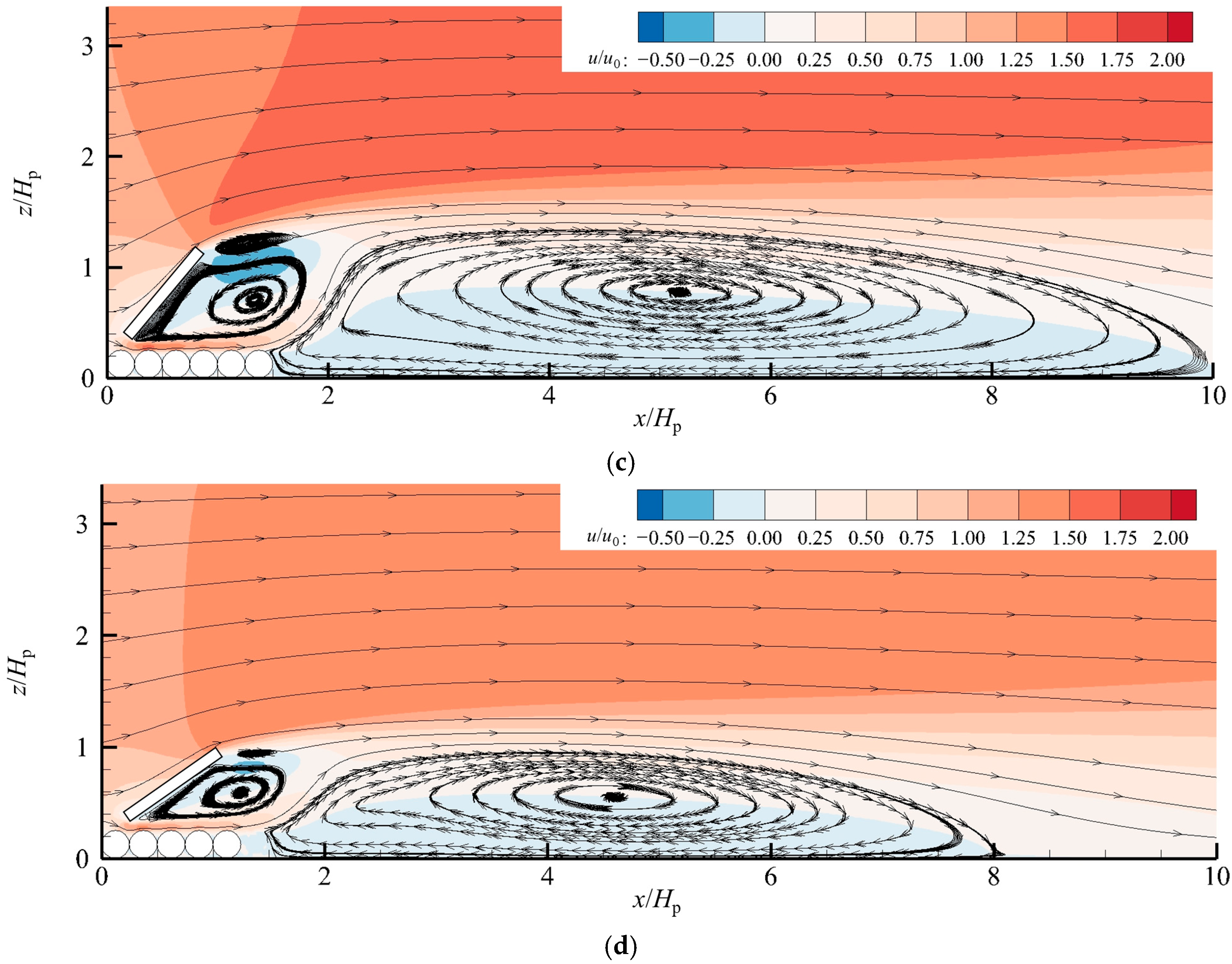

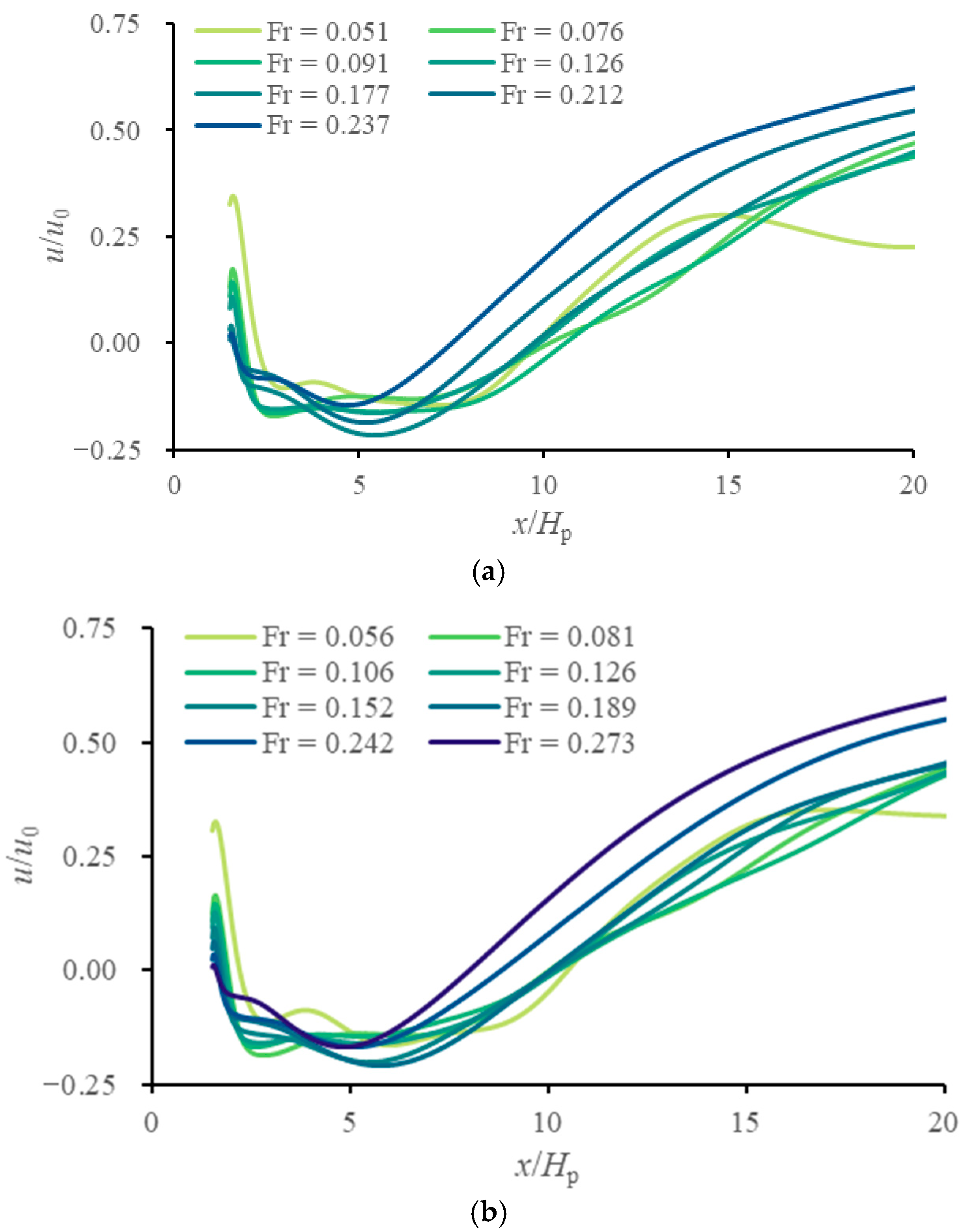

3.2. Effect on the Near-Bottom Velocity

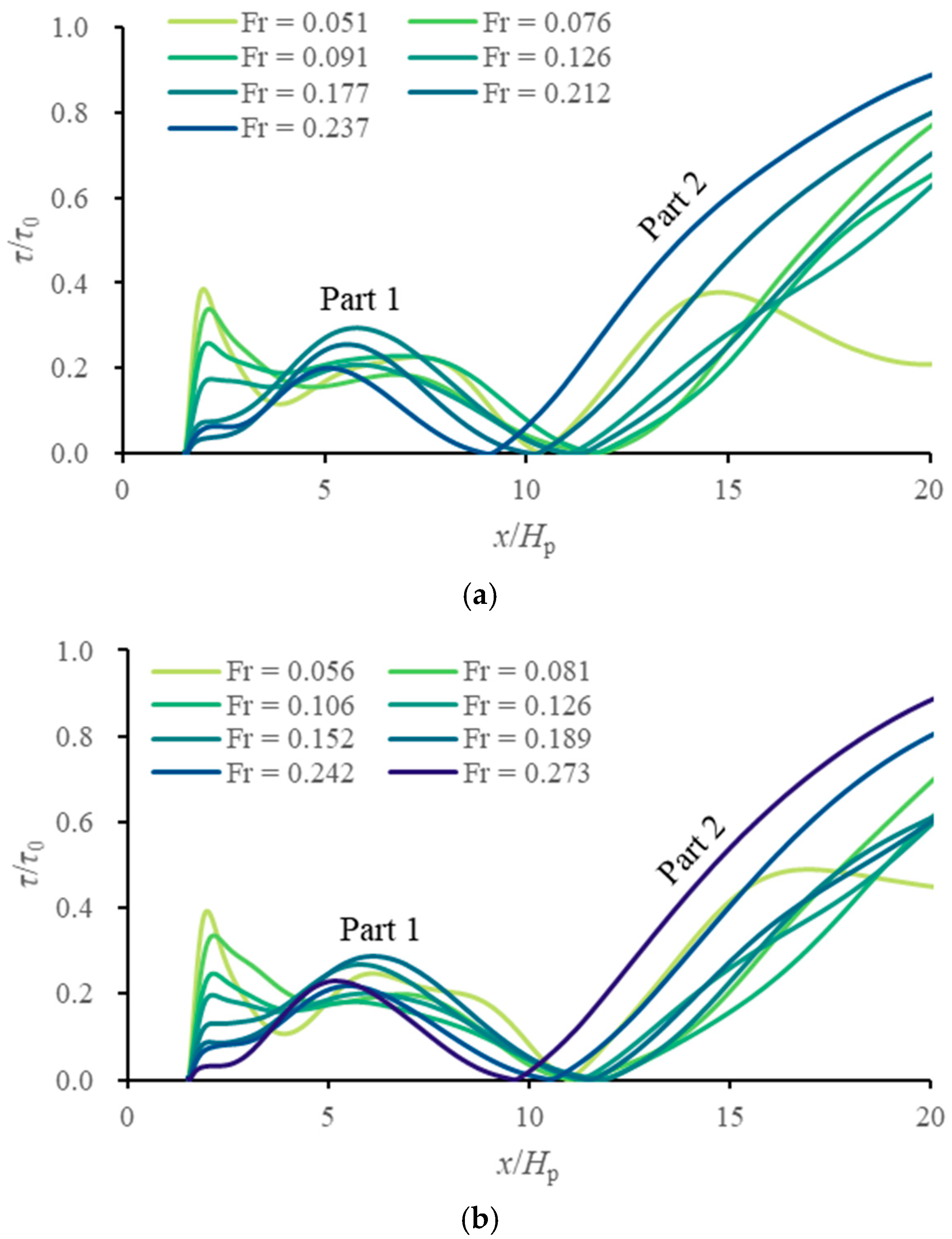

3.3. Effects on the Shear Stress

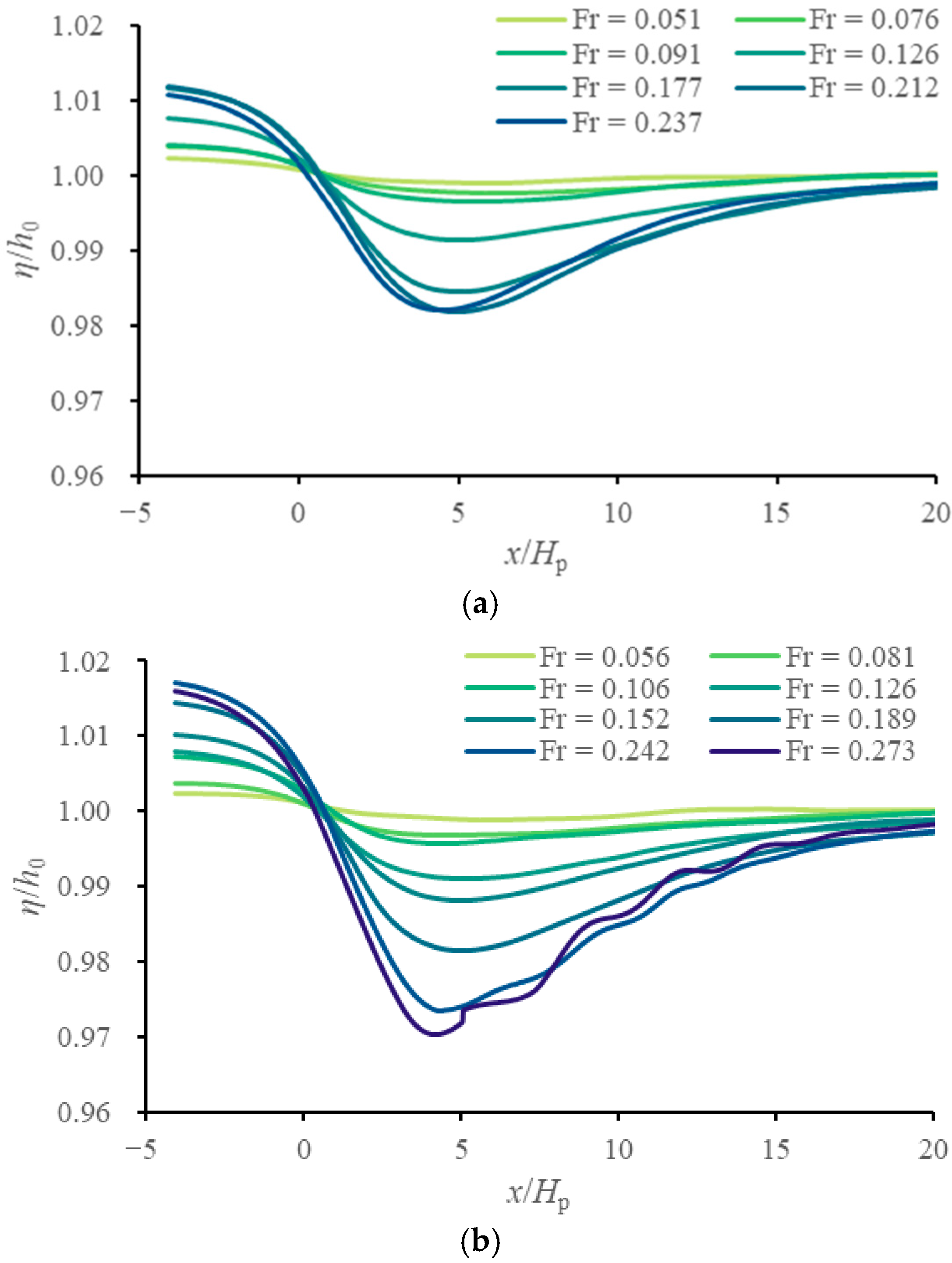

3.4. Effects on the Water Surface Profile

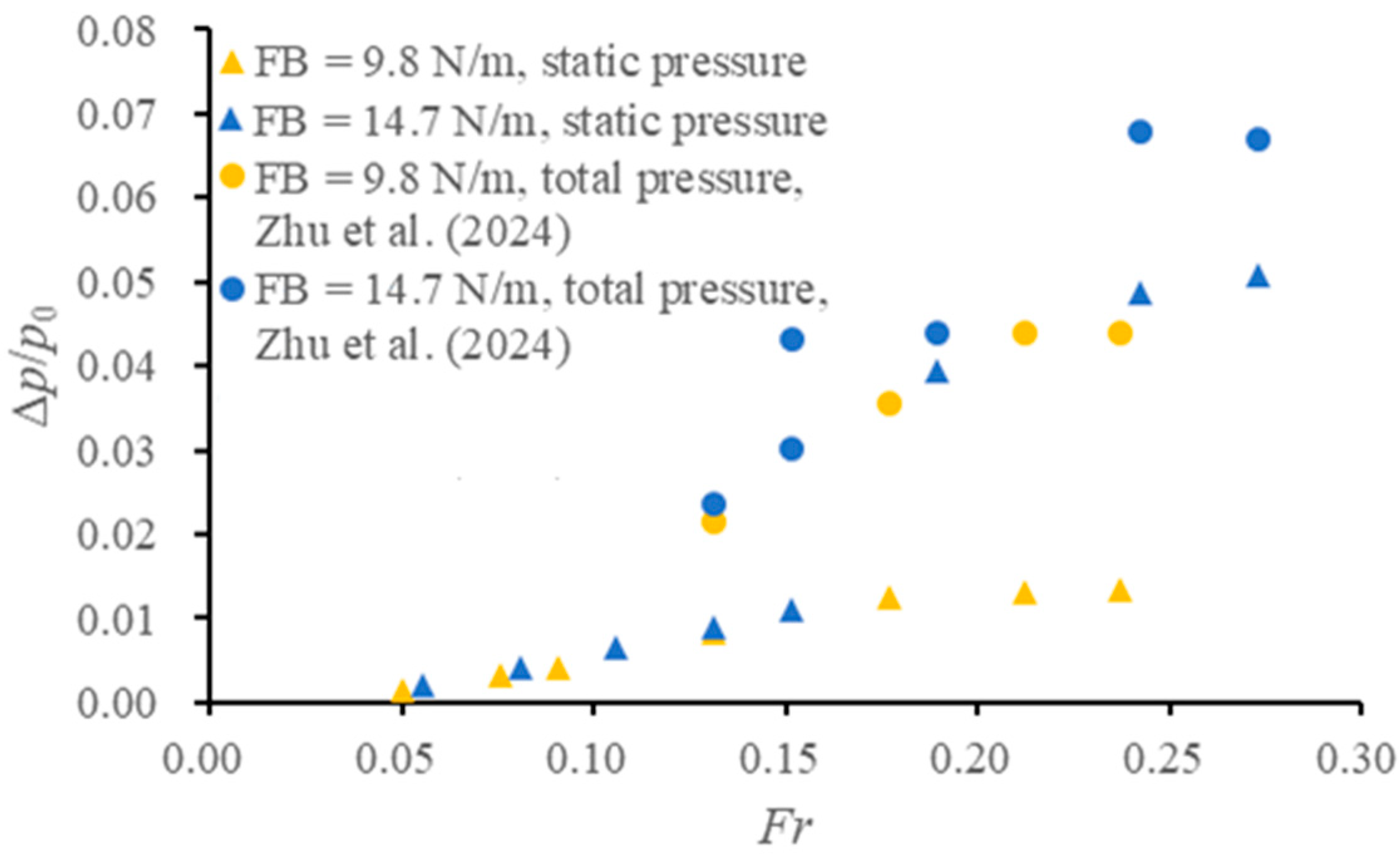

4. Discussion on the Protection Effect of the GMFP

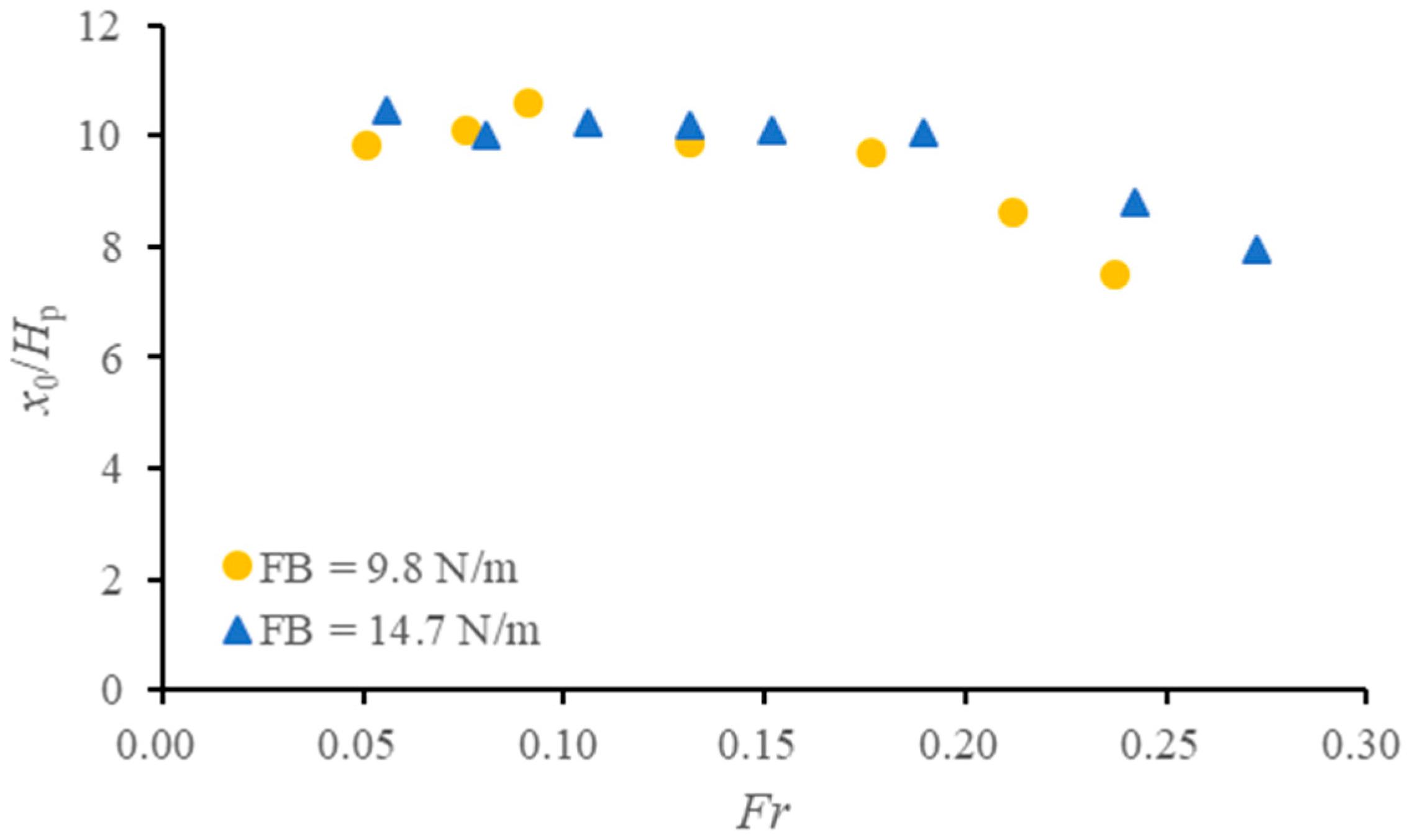

4.1. Variation in the Reattachment Point with the Froude Number

4.2. Application to Practical Engineering Design

5. Conclusions

- The bottom vortex shows a two-stage response to increasing Froude numbers. The reattachment point remains stable at lower flow intensities but moves upstream when the Froude number exceeds a critical value, which can be attributed to competing influences of bottom vortex development and the reduction in the effective obstruction height of the plate.

- The critical condition of the bottom vortex response, which is dependent on the plate’s buoyancy, demarcates a regime of stable, optimal protection from one where the bottom vortex contracts and protection effect is substantial but diminished. This condition provides a central design criterion for ensuring structural resilience under varying flow conditions.

- The GMFP is capable of reducing bed shear stress, providing effective scour protection over a significant downstream distance. The extent of bed shear stress within the bottom vortex is less than 40% of that in the unprotected conditions.

- Asymmetric water backup and drawdown are observed over the GMFP due to the blockage effect, constituting the dominant component of the bed pressure difference across the GMFP. The magnitude of upstream backup is much smaller than that of the drawdown on the leeside.

- As the Froude number increases, the flow regime evolves from a complex, unsteady state with a complex dual-core structure at lower Froude numbers to a consolidated and stable vortex system at higher Fr values, accompanied by a remarkable shrinkage of the vortices in the top vortex zone.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- A Study of U.S. Bridge Failures (1980–2012). Available online: https://www.buffalo.edu/mceer/catalog.host.html/content/shared/www/mceer/publications/MCEER-13-0008.detail.html (accessed on 12 August 2025).

- Rashidi, H.; Najarchi, M.; Hezaveh, S.M.M. Investigating and modeling of the scour downstream of a tree trunk deflector in a straight channel. Water 2023, 15, 3483. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Zhao, F.; Sheng, H. Effect of flow deflectors on local scour around artificial reefs under steady current: Experimental and numerical investigations. Appl. Ocean Res. 2025, 157, 104509. [Google Scholar] [CrossRef]

- Bahrami-Yarahmadi, M.; Erick, R.; Shafai-Bejestan, M.; Mosselman, E. A laboratory-scale numerical study of the effects of bank-attached vane submergence on flow pattern and bed shear stress distribution. J. Hydraul Res. 2025, 63, 15–31. [Google Scholar] [CrossRef]

- Esmaeli, P.; Boudaghpour, S.; Rostami, M.; Mirzaee, M. Experimental investigation of permeability and length of a series of spur dikes effects on the control of bank erosion in the meandering channel. Ain Shams Eng. J. 2022, 13, 101701. [Google Scholar] [CrossRef]

- Aung, H.; Zhang, M.; Oliveto, G.; Onorati, B.; Yu, G. Reattachment length of flow at the lee side of a vertical spur dike in an open channel. J. Waterw. Port Coast. Ocean Eng. 2024, 150, 04024012. [Google Scholar] [CrossRef]

- Guguloth, S.; Chaudhuri, A.R.; Shafighi, N.; Kumar, S. Influence of submergence ratio on scour morphology around spur dike: Experimental and numerical analysis. Acta Geophys. 2025, 73, 6051–6066. [Google Scholar] [CrossRef]

- Fan, J.; Kuang, C.; Li, H.; Mao, X.; Gong, L.; Zhang, J. Influence mechanisms of the submerged sand engine on coastal protection as the extension of beach nourishment. Ocean Eng. 2025, 316, 119970. [Google Scholar] [CrossRef]

- Muroi, S.; Bertone, E.; Cartwright, N.; Alvarez, F. Hybrid one-line/2DH model of submerged breakwater for coastal protection. Environ. Model. Softw. 2024, 172, 105897. [Google Scholar] [CrossRef]

- Muroi, S.; Bertone, E.; Cartwright, N.; Alvarez, F. Machine learning methods for predicting shoreline change from submerged breakwater simulations. Eng. Appl. Artif. Intell. 2025, 152, 110726. [Google Scholar] [CrossRef]

- Peng, M.; Zhang, J.; Zhu, Y.; Gao, L.; Li, S.; Pan, X. Experimental study on wave attenuation and stability of ecological dike system composed of submerged breakwater, mangrove, and dike under storm surge. Appl. Ocean Res. 2024, 151, 104144. [Google Scholar] [CrossRef]

- Broekema, Y.; van Steijn, P.; Wu, M.; Robijns, T. Predicting loose rock scour protection deformation around monopiles using the relative mobility number and the Keulegan-Carpenter number. Ocean Eng. 2024, 300, 117475. [Google Scholar] [CrossRef]

- Menéndez-Vicente, C.; López-Querol, S.; Harris, J.; Tavouktsoglou, N. Numerical study on the stiffening properties of scour protection around monopiles for offshore wind turbines. Eng. Geol. 2025, 345, 107835. [Google Scholar] [CrossRef]

- Hu, R.; Lu, Y.; Leng, H.; Liu, H.; Shi, W. A novel countermeasure for preventing scour around monopile foundations using ionic soil stabilizer solidified slurry. Appl. Ocean Res. 2022, 121, 103121. [Google Scholar] [CrossRef]

- Hu, R.; Wang, X.; Liu, H.; Leng, H. Scour protection of submarine pipelines using ionic soil stabilizer solidified soil. J. Mar. Sci. Eng. 2022, 10, 76. [Google Scholar] [CrossRef]

- Wang, C.; Jin, L.; Qian, Y.; Wu, Y.; Liang, F. Investigation of the protection mechanism and failure modes of solidified soil utilized for scour mitigation. Constr. Build. Mater. 2025, 472, 140858. [Google Scholar] [CrossRef]

- Yang, H.; Lu, Y.; Zuo, L.; Yuan, C.; Lu, Y.; Zhu, H. Numerical analysis of interaction between flow characteristics and dynamic response of interlocked concrete block mattress during sinking process. Ocean Eng. 2023, 286, 115574. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, W.; Zhou, P.; Du, F.; Wang, L. Experimental investigation on scour development and scour protection for offshore converter platform. Mar. Struct. 2023, 90, 103440. [Google Scholar] [CrossRef]

- Wang, G.; Xu, S.; Zhang, Q.; Zhang, J. An Experimental study of the local scour protection methods around the monopile foundation of offshore wind turbines. Ocean Eng. 2023, 273, 113957. [Google Scholar] [CrossRef]

- Zhu, Y.; Xie, L.; Su, T.-C. Scour Protection effects of a geotextile mattress with floating plate on a pipeline. Sustainability 2020, 12, 3482. [Google Scholar] [CrossRef]

- Xie, L.; Huang, W.; Yu, Y. Experimental study of sediment trapping by geotextile mattress installed with sloping curtain. Geosynth. Int. 2013, 20, 389–395. [Google Scholar] [CrossRef]

- Wang, H.; Si, F.; Lou, G.; Yang, W.; Yu, G. Hydrodynamic characteristics of a suspended curtain for sediment trapping. J. Waterw. Port Coast. Ocean. Eng. 2015, 141, 04014030. [Google Scholar] [CrossRef]

- Xie, L.; Zhu, Y.; Li, Y.; Su, T.-C. Experimental study on bed pressure around geotextile mattress with sloping plate. PLoS ONE 2019, 14, e0211312. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, Q.; Wu, G.; Li, Y.; Xie, L. Effects on the potential for seepage failure under a geotextile mattress with floating plate. J. Mar. Sci. Eng. 2024, 12, 1975. [Google Scholar] [CrossRef]

- Zhu, Y.; Xie, L.; Su, T.-C. Flow characteristics on the leeside of a geotextile mattress with floating plate. Ocean Eng. 2022, 265, 112624. [Google Scholar] [CrossRef]

- Flow Science Inc. FLOW-3D Documentation; Release 10.1.0; Flow Science, Inc.: Santa Fe, NM, USA, 2012; pp. 76–206. [Google Scholar]

- Xia, Y.; Liu, J.; Yang, S.; Wang, S.; Li, L. Scour depth around cylinders under combined effects of river flow and tidal currents. J. Mar. Sci. Eng. 2025, 13, 1114. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Z.; Zhao, Z.; Zhao, D.; Zhang, Y. Hydraulic Characteristics of a new vertical slot fishway with staggered baffles configuration. Water 2025, 17, 809. [Google Scholar] [CrossRef]

- Valizadeh, R.; Arman, A.; Ghobadian, R. Controlling the local scouring of the bottom of the protective inclined apron in a 90-degree mild bend using a numerical model. Ocean Eng. 2024, 307, 118177. [Google Scholar] [CrossRef]

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Bina, K.; Rikhtehgarmashhad, S.; Hosseini, K.; Karami, H. Numerical estimation of discharge coefficient for non-circular bottom intake racks. Appl. Water Sci. 2024, 14, 103. [Google Scholar] [CrossRef]

- Al-Jubouri, M.; Ray, R.P.; Abbas, E.H. Advanced Numerical Simulation of Scour around Bridge Piers: Effects of Pier Geometry and Debris on Scour Depth. J. Mar. Sci. Eng. 2024, 12, 1637. [Google Scholar] [CrossRef]

| Case | u0 (m/s) | Fr | sin α | FB (N/m) |

|---|---|---|---|---|

| 01 | 0.100 | 0.051 | 0.985 | 9.8 |

| 02 | 0.150 | 0.076 | 0.966 | 9.8 |

| 03 | 0.180 | 0.091 | 0.940 | 9.8 |

| 04 | 0.260 | 0.126 | 0.866 | 9.8 |

| 05 | 0.350 | 0.177 | 0.766 | 9.8 |

| 06 | 0.420 | 0.212 | 0.643 | 9.8 |

| 07 | 0.470 | 0.237 | 0.574 | 9.8 |

| 11 | 0.110 | 0.056 | 0.985 | 14.7 |

| 12 | 0.160 | 0.081 | 0.966 | 14.7 |

| 13 | 0.210 | 0.106 | 0.940 | 14.7 |

| 14 | 0.260 | 0.126 | 0.906 | 14.7 |

| 15 | 0.300 | 0.152 | 0.866 | 14.7 |

| 16 | 0.375 | 0.189 | 0.819 | 14.7 |

| 17 | 0.480 | 0.242 | 0.643 | 14.7 |

| 18 | 0.540 | 0.273 | 0.574 | 14.7 |

| Model Number | Minimum Grid Size (m) | Total Grid Number | Initial Time Step (s) | x0/Hp |

|---|---|---|---|---|

| Coarse mesh | 4.5 × 10−3 | 4.7 × 104 | 0.001 | 8.59 |

| Medium mesh | 3.0 × 10−3 | 8.4 × 104 | 9.05 | |

| Fine mesh 1 | 1.5 × 10−3 | 1.4 × 105 | 9.70 | |

| Fine mesh 2 | 1.0 × 10−3 | 2.1 × 105 | 9.42 | |

| Initial time step 1 | 1.5 × 10−3 | 1.4 × 105 | 0.002 | 9.65 |

| Initial time step 2 | 0.001 | 9.70 | ||

| Initial time step 3 | 0.00075 | 9.71 | ||

| Initial time step 4 | 0.0005 | 9.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Li, Y.; Xie, L. Hydrodynamic Effects and Scour Protection of a Geotextile Mattress with a Floating Plate. J. Mar. Sci. Eng. 2025, 13, 2215. https://doi.org/10.3390/jmse13122215

Zhu Y, Li Y, Xie L. Hydrodynamic Effects and Scour Protection of a Geotextile Mattress with a Floating Plate. Journal of Marine Science and Engineering. 2025; 13(12):2215. https://doi.org/10.3390/jmse13122215

Chicago/Turabian StyleZhu, Yehui, Yanhong Li, and Liquan Xie. 2025. "Hydrodynamic Effects and Scour Protection of a Geotextile Mattress with a Floating Plate" Journal of Marine Science and Engineering 13, no. 12: 2215. https://doi.org/10.3390/jmse13122215

APA StyleZhu, Y., Li, Y., & Xie, L. (2025). Hydrodynamic Effects and Scour Protection of a Geotextile Mattress with a Floating Plate. Journal of Marine Science and Engineering, 13(12), 2215. https://doi.org/10.3390/jmse13122215