From Resource Assessment to AEP Correction: Methodological Framework for Comparing HAWT and VAWT Offshore Systems

Abstract

1. Introduction

- A top-tip height normalization procedure to ensure aerodynamic fairness between turbine types;

- A correction methodology for VAWT AEP estimation, accounting for air density, turbulence, and wake recovery effects;

- A validation path linking resource-level modeling (WAsP) with high-fidelity numerical simulations (CFD and coupled aero-hydro-servo-elastic analyses).

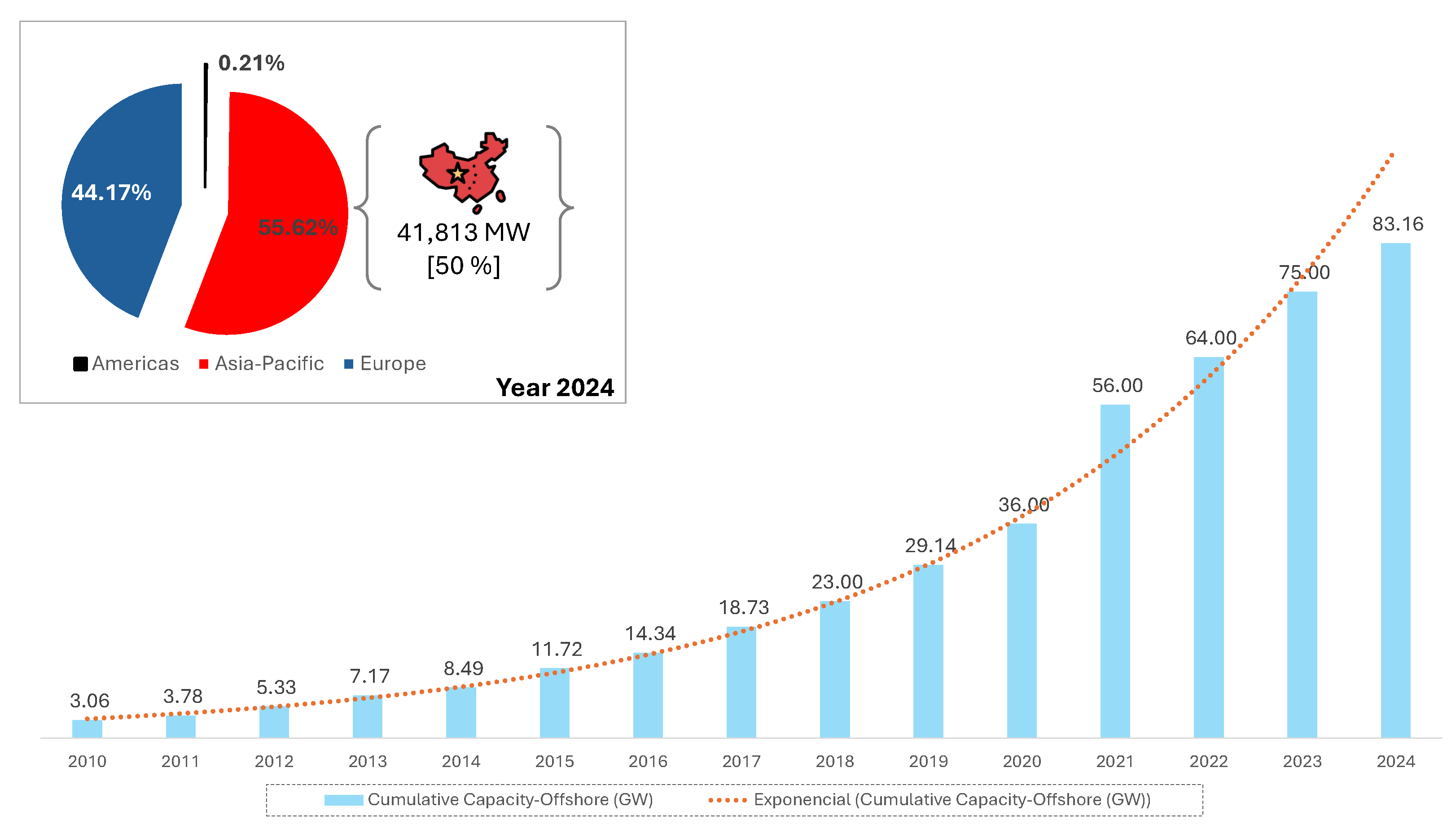

2. State of the Art

- GWind: Proposed a floating VAWT with fully coupled aero-hydro-elastic modeling to optimize dynamic responses under harsh offshore conditions [22].

- SeaTwirl: A commercial initiative from Sweden that offers operational and pre-commercial prototypes ranging from 30 kW to multi-MW configurations. SeaTwirl’s design locates the generator near the waterline and emphasizes modularity and ease of maintenance [23].

3. Materials and Methods

- Site selection (spatial and environmental constraints);

- Acquisition and quality control of meteorological data (minimum duration, quality, and corrections);

- Collection of turbine technical data (power and thrust curves and geometry);

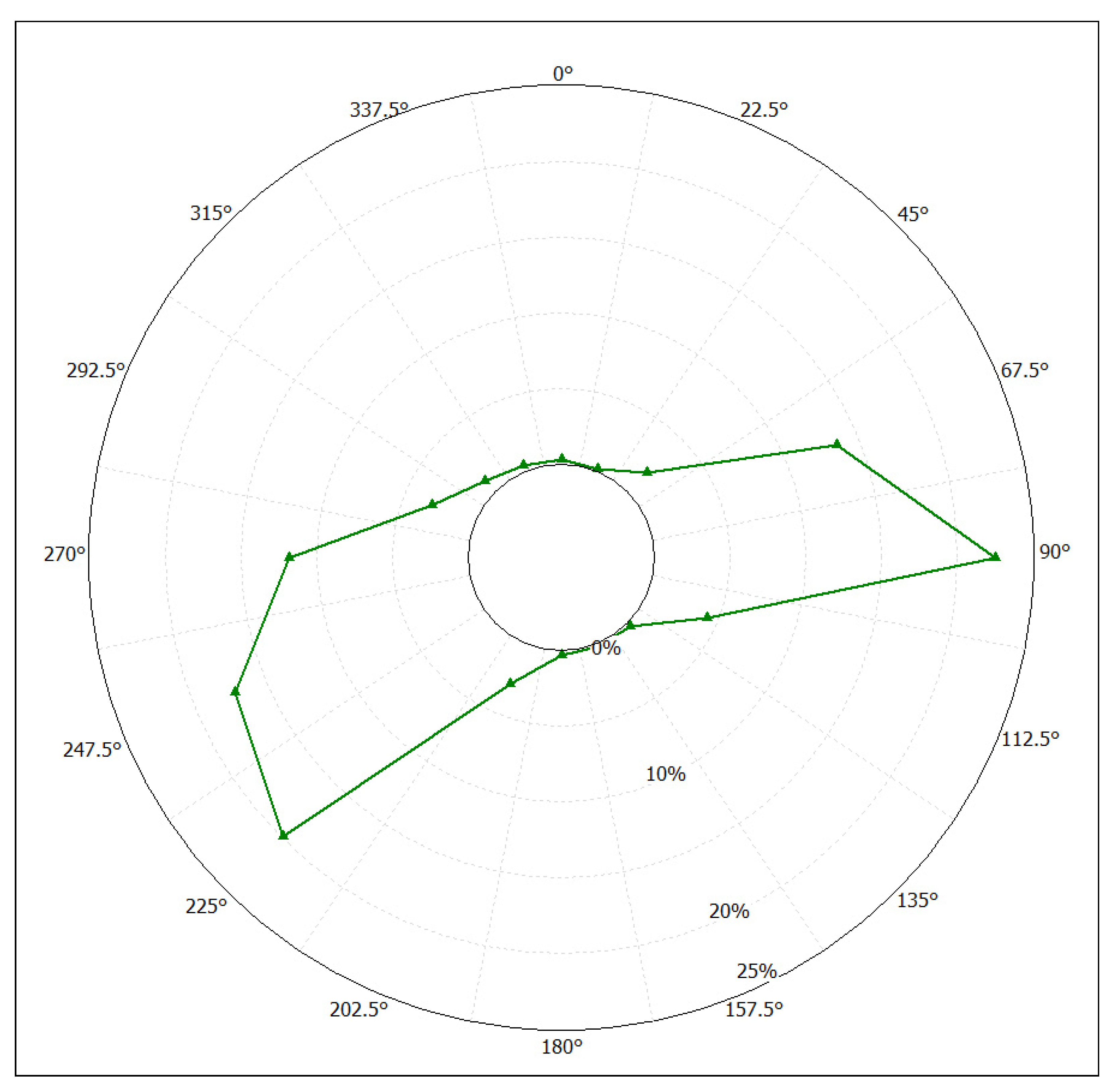

- Wind potential analysis (roses, Weibul fitting, and vertical profiles);

- AEP calculation (it can be determined as a HAWT using WAsP with corrections or with a specific software that directly models the AEP of VAWTs).

3.1. Site Selection

- Gather planning layers and exclude restricted areas:

- Protected areas (e.g., Natura 2000 and RAMSAR sites).

- Navigation routes, submarine cables, and military or fishing zones.

- Areas with unsuitable depth or seabed conditions (depending on floating/fixed technology).

- If no “Maritime Spatial Planning Plan” exists, document the exclusion policy used (e.g., 2 km buffer from routes and 500 m from cables).

- Generate an eligibility map (raster/vector) and shape-file with the final polygon of the selected area.

3.2. Acquisition and Quality Control of Wind Data

- Removing outliers and missing spikes.

- Marking periods with >10% data loss.

- Comparing with reanalysis datasets (ERA5 and MERRA-2) using measure–correlate–predict (MCP) for long-term correction.

3.3. Technical Data of Turbines (HAWT and VAWT)

- Power curve (preferably following 0.5 m/s bins).

- Thrust or power coefficient curve or .

- Geometry: Rotor diameter/radius, rotor height (for VAWT), hub height, mass, and generator position.

3.4. Wind Potential Analysis

- The Weibull distribution is fitted by sector:with A being the scale factor and k the shape factor.

- The turbulence intensity () must be computed by bin and sector, producing TI maps for VAWT corrections.

3.5. Annual Energy Production Calculation

3.5.1. HAWT

- Import wind atlas, orography, and roughness (offshore small).

- Create WTG file with and .

- Define farm layout (coordinates and spacing).

- Run a park calculation using a wake model (Jensen) and standard losses (electrical, availability, and blade soiling).

- Export: Gross AEP per turbine, loss breakdown, and wake deficit maps.

3.5.2. VAWT (If No Direct Tool Is Available)

- Option A: Proxy in WAsP + Corrections

- Build WTG file with VAWT curve (from experiments or DMST).

- Compute baseline .

- Apply correction factors , , and as detailed in Section 3.7.

- Option B: Dedicated Model

- Generate and using QBlade, DMST, or CFD (OpenFOAM).

- Apply wake models adjusted for VAWT (e.g., tuned Bastankhah parameters).

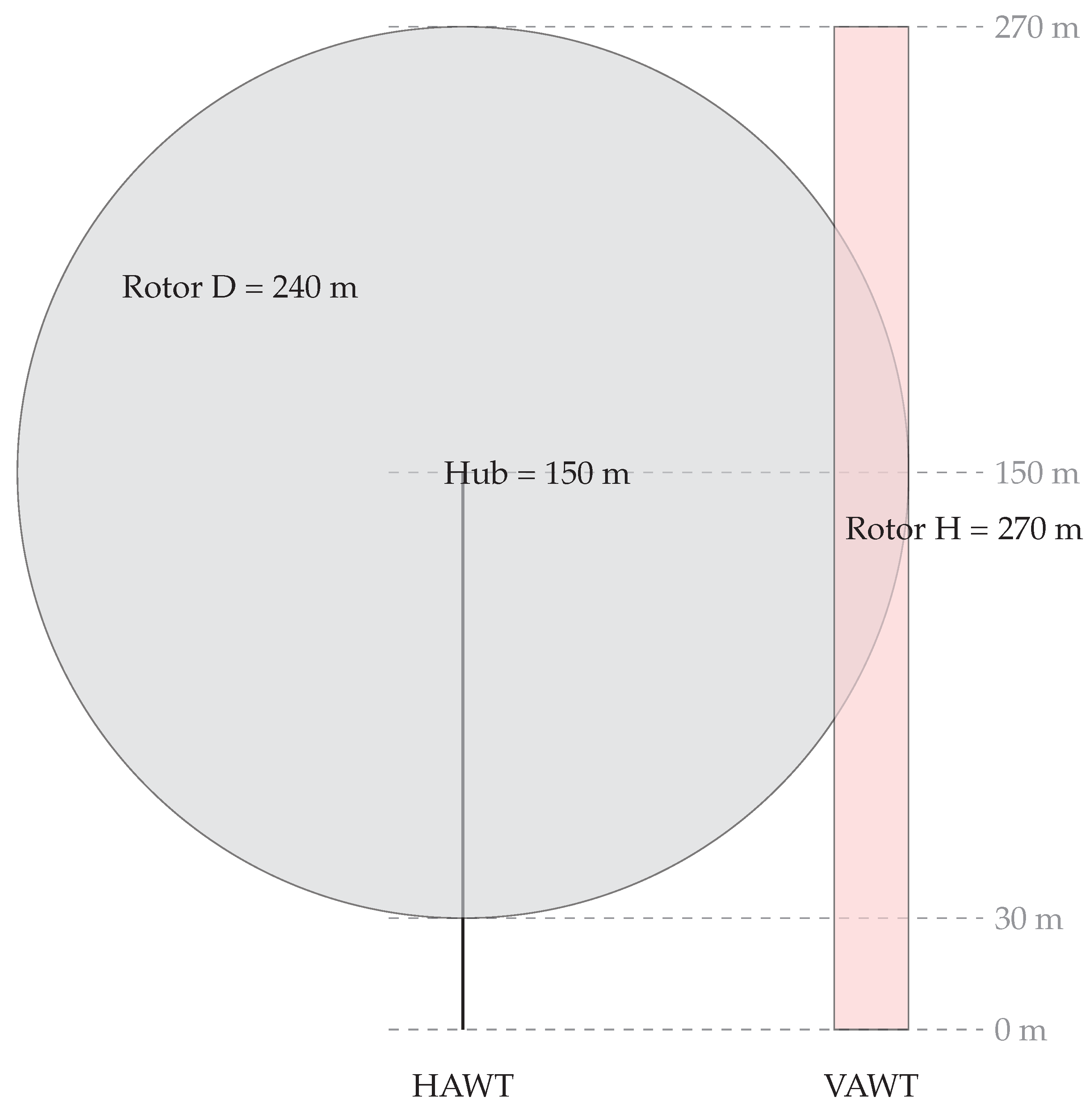

3.6. Geometric Normalization and Height Criterion for Fair Comparison

- Rotor-Averaged Wind Speed Equivalence

- Consistency with Load and Wake Analyses

- Implementation

- Set a target (e.g., 120 m a.s.l.) and derive .

- Choose a VAWT rotor height such that (with for floating configurations).

- Compute sector-wise for each concept using the same wind atlas and shear exponent ; feed (or the full bin distribution across z) into the energy model.

3.7. Adjustment Methodology for VAWT Energy Yield

- Air density correction (): Offshore air density may deviate from the reference value used in standard power curves due to variations in temperature and pressure. A correction proportional to was applied, typically affecting AEP within – [24].

- Turbulence intensity correction (): VAWTs respond differently to atmospheric turbulence compared to HAWTs. In high-turbulence regimes, dynamic stall phenomena may reduce performance, whereas at moderate TI levels some VAWT designs show robust or even improved efficiency [22]. A sensitivity coefficient was introduced to scale deviations from the reference turbulence intensity , leading to corrections in the range to depending on site conditions.

- Wake correction (): Conventional wake models implemented in WAsP assume Gaussian or Jensen-type deficits calibrated for HAWTs [25]. VAWT wakes, however, recover faster and produce lower downstream deficits, especially in farm configurations [6,11]. A correction factor between (conservative) and (optimistic) was therefore applied to account for the mismatch between HAWT-based wake models and VAWT behavior.

4. Results

4.1. Wind Resource Characterization

4.2. Geometric Normalization Applied

- The HAWT was modeled with a rotor radius of 120 m, resulting in a hub height of 150 m.

- The VAWT was modeled with a 270 m rotor height, starting near sea level.

4.3. Annual Energy Production

- IEA Wind 15 MW (horizontal axis): 10 wind turbines.

- SEA Twirl 10 MW (vertical axis): 15 wind turbines.

- Conservative scenario: ≈577 GWh (−0.2% relative to WAsP).

- Base scenario: ≈617 GWh (+6.8%).

- Optimistic scenario: ≈708 GWh (+22.6%).

5. Discussion and Conclusions

5.1. Comparative Performance of HAWTs and VAWTs

5.2. Structural Integration and Platform Considerations

5.3. Economic Implications

5.4. Conclusions

- HAWTs on semi-submersible platforms remain the reference solution for current commercial projects, with validated performance and lower technology risk.

- VAWTs mounted on spar-type structures, while less mature, present significant advantages in terms of wake recovery, structural integration, and farm density.

- Corrected AEP values suggest that VAWTs could reduce the performance gap with HAWTs, especially under high-density farm configurations in deep waters.

5.5. Limitations and Future Work

- Wake modeling: The corrections applied are based on simplified factors; dedicated VAWT wake models (e.g., dynamic stall-coupled CFD) are required to validate farm-level interactions.

- Platform–turbine dynamics: Coupled aero-hydro-servo-elastic simulations were not included, yet they are critical to assess fatigue loads and survivability.

- Economic assessment: Future work should integrate detailed cost modeling of manufacturing, installation, and O&M strategies.

- Experimental validation: Field-scale VAWT data remain scarce. Pilot projects and demonstration campaigns are essential to validate the numerical trends identified here.

- Applicability and limitations of pendulum tip height normalization: The top-tip height equalization adopted in this work ensures comparable aerodynamic exposure between HAWTs and VAWTs and provides a defensible baseline for AEP comparison. Nevertheless, adopting the same maximum tip elevation does not imply equivalence in structural loading nor in platform stability. In practical floating designs, hub height, mass distribution, and rotor dynamics determine overturning moments, pitch/roll responses, and mooring loads; thus, a VAWT tuned to match the HAWT top-tip elevation may still yield substantially different static and fatigue loads due to its lower center of gravity and different aerodynamic load paths. Several studies on floating VAWT/HWT dynamics and on platform design stress that aerodynamic load distribution and platform response must be evaluated with detailed coupled analyses before drawing conclusions for platform sizing or certification [24]. Therefore, the top-tip normalization should be seen as a resource normalization (fairness in wind sampling) rather than a structural design prescription; its use is appropriate for fair AEP comparison but requires subsequent platform-level verification (coupled aero-hydro-servo-elastic simulations) to determine design and safety loads.

- Need for fully coupled simulations: The present work does not include fully coupled aero-hydro-servo-elastic simulations. For floating systems, particularly under extreme sea states, the interaction between aerodynamic loads, platform motions, control system actions, and structural elasticity can produce nonlinear dynamic effects that significantly alter fatigue and extreme loads. Recent developments allow coupling aeroelastic solvers with CFD and hydro/motion modules (e.g., OpenFAST+OpenFOAM coupling and OWENS integrations), enabling high-fidelity assessment of floating VAWT performance and loads [32]. We therefore plan to extend this study with (i) single-turbine coupled case studies using OpenFAST + OpenFOAM (LES where feasible) to quantify the influence of platform motion on VAWT power and loads; (ii) sensitivity runs for extreme sea states (100-year storms) using nonlinear wave spectra and full mooring dynamics; and (iii) verification against scaled test data. These steps will allow us to move from resource-level comparisons to platform design recommendations.

- Extreme-event characterization: Future extensions of this framework will incorporate extreme weather scenarios such as hurricanes, typhoons, and combined wind–wave–current interactions. These conditions are increasingly relevant for large-scale floating systems and can strongly influence turbine loads, energy availability, and long-term reliability. Probabilistic modeling and time-domain simulations under such events will be integrated to evaluate the coupled aerodynamic and hydrodynamic response, ensuring a more comprehensive assessment of energy yield and survivability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gil-García, I.C.; Ramos-Escudero, A.; Ángel Molina-García; Fernández-Guillamón, A. GIS-based MCDM dual optimization approach for territorial-scale offshore wind power plants. J. Clean. Prod. 2023, 428, 139484. [Google Scholar] [CrossRef]

- Roga, S.; Bardhan, S.; Kumar, Y.; Dubey, S.K. Recent technology and challenges of wind energy generation: A review. Sustain. Energy Technol. Assessments 2022, 52, 102239. [Google Scholar] [CrossRef]

- Global Wind Report 2024. Technical Report, Global Wind Energy Council (GWEC). 2025. Available online: https://www.gwec.net/reports/globaloffshorewindreport (accessed on 20 May 2025).

- Su, X.; Wang, X.; Xu, W.; Yuan, L.; Xiong, C.; Chen, J. Offshore Wind Power: Progress of the Edge Tool, Which Can Promote Sustainable Energy Development. Sustainability 2024, 16, 7810. [Google Scholar] [CrossRef]

- Shields, M.; Beiter, P.; Nunemaker, J.; Cooperman, A.; Duffy, P. Impacts of turbine and plant upsizing on the levelized cost of energy for offshore wind. Appl. Energy 2021, 298, 117189. [Google Scholar] [CrossRef]

- Arredondo-Galeana, A.; Brennan, F. Floating Offshore Vertical Axis Wind Turbines: Opportunities, Challenges and Way Forward. Energies 2021, 14, 8000. [Google Scholar] [CrossRef]

- Cheng, Z.; Madsen, H.A.; Chai, W.; Gao, Z.; Moan, T. A comparison of extreme structural responses and fatigue damage of semi-submersible type floating horizontal and vertical axis wind turbines. Renew. Energy 2017, 108, 207–219. [Google Scholar] [CrossRef]

- Dagher, J.H.; Goupee, A.J.; Viselli, A.M. Optimized Floating Offshore Wind Turbine Substructure Design Trends for 10–30 MW Turbines in Low-, Medium-, and High-Severity Wave Environments. Designs 2024, 8, 72. [Google Scholar] [CrossRef]

- Ren, H.; Qiu, J.; Zhang, Y.; Liu, H.; Yang, J.; Ke, S. Nonlinear dynamic response analysis of 15 MW monopile offshore wind turbine under annular typhoon. Phys. Fluids 2025, 37, 087116. [Google Scholar] [CrossRef]

- Guan, X.; Yu, H.; Yuan, Y.; Kong, D.; Liu, B.; Tang, H. Study on structural dynamic response of offshore wind turbine under floating ice load. Sci. Rep. 2025, 15, 17050. [Google Scholar] [CrossRef]

- Ghigo, A.; Petracca, E.; Mangia, G.; Giorgi, G.; Bracco, G. Development of a floating Vertical Axis Wind Turbine for the Mediterranean Sea. J. Phys. Conf. Ser. 2024, 2745, 012008. [Google Scholar] [CrossRef]

- Borg, M.; Shires, A.; Collu, M. Offshore floating vertical axis wind turbines, dynamics modelling state of the art. Part I: Aerodynamics. Renew. Sustain. Energy Rev. 2014, 39, 1214–1225. [Google Scholar] [CrossRef]

- Worsnop, R.P.; Lundquist, J.K.; Bryan, G.H.; Damiani, R.; Musial, W. Gusts and shear within hurricane eyewalls can exceed offshore wind turbine design standards. Geophys. Res. Lett. 2017, 44, 6413–6420. [Google Scholar] [CrossRef]

- Li, W.; Ke, S.; Qian, K.; Ren, H. Instability mechanism and criterion of wind-wave co-generation structural system under typhoon-wave-current coupled action. Renew. Energy 2026, 256, 123888. [Google Scholar] [CrossRef]

- Cheng, Z.; Wen, T.R.; Ong, M.C.; Wang, K. Power performance and dynamic responses of a combined floating vertical axis wind turbine and wave energy converter concept. Energy 2019, 171, 190–204. [Google Scholar] [CrossRef]

- Collu, M.; Brennan, F.P.; Patel, M.H. Conceptual design of a floating support structure for an offshore vertical axis wind turbine: The lessons learnt. Ships Offshore Struct. 2014, 9, 3–21. [Google Scholar] [CrossRef]

- Shires, A. Development and Evaluation of an Aerodynamic Model for a Novel Vertical Axis Wind Turbine Concept. Energies 2013, 6, 2501–2520. [Google Scholar] [CrossRef]

- Paulsen, U.S.; Madsen, H.A.; Kragh, K.A.; Nielsen, P.H.; Baran, I.; Hattel, J.; Ritchie, E.; Leban, K.; Svendsen, H.; Berthelsen, P.A. DeepWind-from Idea to 5 MW Concept. Energy Procedia 2014, 53, 23–33. [Google Scholar] [CrossRef]

- Battisti, L.; Benini, E.; Brighenti, A.; Raciti Castelli, M.; Dell’Anna, S.; Dossena, V.; Persico, G.; Schmidt Paulsen, U.; Pedersen, T.F. Wind tunnel testing of the DeepWind demonstrator in design and tilted operating conditions. Energy 2016, 111, 484–497. [Google Scholar] [CrossRef]

- X-ROTOR: X-Shaped Radical Offshore Wind Turbine for Overall Cost of Energy Reduction, European Commission: Luxembourg, 2021. [CrossRef]

- McMorland, J.; Flannigan, C.; Carroll, J.; Collu, M.; McMillan, D.; Leithead, W.; Coraddu, A. A review of operations and maintenance modelling with considerations for novel wind turbine concepts. Renew. Sustain. Energy Rev. 2022, 165, 112581. [Google Scholar] [CrossRef]

- Cheng, Z.; Madsen, H.A.; Gao, Z.; Moan, T. A fully coupled method for numerical modeling and dynamic analysis of floating vertical axis wind turbines. Renew. Energy 2017, 107, 604–619. [Google Scholar] [CrossRef]

- SeaTwirl. Products–SeaTwirl. Available online: https://seatwirl.com/products/ (accessed on 25 February 2025).

- Myhr, A.; Bjerkseter, C.; Ågotnes, A.; Nygaard, T. Levelised cost of energy for offshore floating wind turbines in a life cycle perspective. Renew. Energy 2014, 66, 714–728. [Google Scholar] [CrossRef]

- Barthelmie, R.J.; Hansen, K.; Pryor, S.C. Quantifying the impact of wind turbine wakes on power output at offshore wind farms. J. Atmos. Ocean. Technol. 2010, 27, 1302–1317. [Google Scholar] [CrossRef]

- Talamalek, A.; Runacres, M.C.; De Troyer, T. Experimental investigation of the wake replenishment mechanisms of paired counter-rotating vertical-axis wind turbines. J. Wind. Eng. Ind. Aerodyn. 2024, 252, 105830. [Google Scholar] [CrossRef]

- BOE-A-2023-5704 Real Decreto 150/2023, de 28 de Febrero, por el que se Aprueban los Planes de Ordenación del Espacio Marítimo de las Cinco Demarcaciones Marinas Españolas. 2023. Available online: https://www.boe.es/buscar/doc.php?id=BOE-A-2023-5704 (accessed on 20 May 2025).

- Visor INFOMAR–MITECO, CEDEX. 2023. Available online: https://infomar.miteco.es/visor.html (accessed on 1 May 2025).

- Vortex FDC. Wind Resource Data for Wind Farm Developments. 2025. Available online: https://vortexfdc.com/ (accessed on 15 May 2025).

- Evan, G.; Rinker, J.; Sethuraman, L.; Zahle, F.; Anderson, B. Definition of the IEA 15-Megawatt Offshore Reference Wind; Technical Report NREL/TP-5000-75698; National Renewable Energy Laboratory: Golden, CO, USA, 2020. [Google Scholar]

- Ouro, P. SeaTwirl’s Wind Farm Layouts Analysis; SeaTwirl AB: Gothenburg, Sweden, 2022. [CrossRef]

- Campaña Alonso, G.; Martín-San-Román, R.; Méndez-López, B.; Benito-Cia, P.; Azcona-Armendáriz, J. OF2: Coupling OpenFAST and OpenFOAM for high-fidelity aero-hydro-servo-elastic FOWT simulations. Wind Energy Sci. 2023, 8, 1597–1611. [Google Scholar] [CrossRef]

| HAWT | VAWT | Rationale | |

|---|---|---|---|

| [m] | 120 | 120 | Equalized aerodynamic exposure |

| [m] | 90 | ≈0 | VAWT drivetrain near waterline |

| Rotor extent [m] | Concept-specific swept geometry | ||

| Generator elevation | Nacelle at | Near waterline | O&M and center of gravity advantages (VAWT) |

| HAWT | VAWT | |

|---|---|---|

| Hub height [m] | 150 | ≈0 |

| Rotor diameter [m] | 240 | – |

| Rotor radius [m] | 120 | – |

| Rotor swept range [m] | 30–270 | 0–270 |

| Top-tip height [m] | 270 | 270 |

| Generator elevation | Nacelle at hub | Near waterline |

| Parameter | IEA Wind 15 MW |

|---|---|

| Technology | Horizontal axis |

| Hub height | 150 m |

| Rotor diameter | 240 m |

| Rated power (unit) | 15 MW |

| Number of turbines | 10 |

| Installed power (wind farm) | 150 MW |

| Gross production | 644.760 GWh |

| Net production | 636.20 GWh |

| Wake losses | 1.33% |

| Energy delivered to grid | 585.31 GWh |

| Equivalent full-load hours | 3902.05 h |

| Capacity factor | 45% |

| Scenario | [-] | [-] | [-] | Total Factor | AEP [GWh] | [%] |

|---|---|---|---|---|---|---|

| Conservative | 0.99 | 0.96 | 1.05 | 0.998 | 577 | −0.2 |

| Base | 0.99 | 0.98 | 1.10 | 1.067 | 617 | +6.8 |

| Optimistic | 1.01 | 1.01 | 1.20 | 1.224 | 708 | +22.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz-Leo, M.L.; Gil-García, I.C.; Fernández-Guillamón, A. From Resource Assessment to AEP Correction: Methodological Framework for Comparing HAWT and VAWT Offshore Systems. J. Mar. Sci. Eng. 2025, 13, 2183. https://doi.org/10.3390/jmse13112183

Ruiz-Leo ML, Gil-García IC, Fernández-Guillamón A. From Resource Assessment to AEP Correction: Methodological Framework for Comparing HAWT and VAWT Offshore Systems. Journal of Marine Science and Engineering. 2025; 13(11):2183. https://doi.org/10.3390/jmse13112183

Chicago/Turabian StyleRuiz-Leo, María Luisa, Isabel C. Gil-García, and Ana Fernández-Guillamón. 2025. "From Resource Assessment to AEP Correction: Methodological Framework for Comparing HAWT and VAWT Offshore Systems" Journal of Marine Science and Engineering 13, no. 11: 2183. https://doi.org/10.3390/jmse13112183

APA StyleRuiz-Leo, M. L., Gil-García, I. C., & Fernández-Guillamón, A. (2025). From Resource Assessment to AEP Correction: Methodological Framework for Comparing HAWT and VAWT Offshore Systems. Journal of Marine Science and Engineering, 13(11), 2183. https://doi.org/10.3390/jmse13112183