1. Introduction

In recent decades, the energy demand of consumers has continuously increased; for instance, the total global primary energy consumption was 361 TWh in 1990, 572 TWh in 2000, 1174 TWh in 2010, and 2414 TWh in 2022 [

1]. Simultaneously, renewable energy technologies have been adopted quite rapidly in the energy sector in order to reduce environmental impacts caused by the traditional oil and gas industry (i.e., climate change and air pollution) and meet the demand for clean and sustainable energy [

2].

In this regard, the European Union (EU) has expressed its ambition of achieving 42.5% to 45.0% renewable energy in its new binding target by 2030; the United Kingdom has committed to 60% renewables by 2030 and China has established a target of 28% non-fossil energy by 2030 [

3]. Many other nations, such as the USA and India, have also set their green energy targets [

4,

5]. There are many forms of renewable energy, including solar, wind, geothermal, hydropower, bioenergy, and ocean energy. Offshore wind energy, in particular, plays an essential role in the production of renewable energy; for instance, global offshore wind energy devices produced 5.3 GW in 2012, 14.3 GW in 2016, 28.3 GW in 2019, and 63.2 GW in 2022 [

6].

Along with the rapid growth of offshore wind turbine (OWT) installations, there is a significant interest in the floating offshore wind turbine (FOWT) as a sustainable energy solution designed to harvest more stable and powerful wind energy at deeper waters and further from shore [

7]. The mooring systems of FOWTs ensure the stability and safety of FOWTs, especially in challenging marine environments; thus, the robust and reliable design of mooring systems is of the utmost importance [

8,

9]. However, one of the key issues is the lack of standardized criteria for mooring system design, particularly concerning line tension safety factors. This discrepancy poses significant challenges, as different international guidelines, including those from DNV (Det Norske Veritas), ABS (American Bureau of Shipping), and BV (Bureau Veritas), offer varying prescriptions for these safety factors. Such variations can lead to inconsistencies in design practices and the operational reliability of FOWTs.

Furthermore, the diverse environmental conditions and the unique dynamics of floating platforms further complicate the design of a one-size-fits-all mooring system. Therefore, a comprehensive comparative analysis involving various environmental conditions and mooring configurations is of timely relevance and relevant as it bridges the gaps in standardization. Moreover, the present study’s motivation goes beyond an academic pursuit, as there is a practical necessity to advance the field of offshore wind energy. Various regulatory bodies have simultaneously developed codes and standards to regulate the mooring system design.

In light of the motivation discussed above, the present work aims to contribute to the field of FOWT mooring systems by providing a comprehensive comparative analysis of line-tension safety factors across various international standards through an extensive literature review, methodical dynamic mooring analysis, and case studies, particularly for the VolturnUS platform. The study aims to highlight the variations and similarities in safety factor prescriptions of the international standards. By doing so, it not only bridges the gap in understanding different mooring guidelines but also offers valuable insights for optimizing mooring system design and enhancing safety in OWT deployments.

The present study is structured into distinct sections, beginning with an extensive literature review of floating platforms of OWT and corresponding mooring configurations. This is followed by a detailed methodology section that delineates the performance of mooring systems based on coupled dynamic response analysis. Afterwards, a comprehensive case study of the VolturnUS platform and a meticulous analysis incorporating both validation and additional case studies are presented. The following section offers a thorough discussion of the findings, drawing critical insights and implications. Finally, a summary of the key outcomes and their relevance to the field concludes the study.

2. Literature Review

There are three common types of floating platforms used to support offshore wind turbines: Spar, Semisubmersible, and Tensioned Leg Platform (TLP) [

10,

11]. Spar tends to have a very deep draft, with ballast water ensuring a lower center of gravity than the center of buoyancy, leading to great stability, whilst the downside is that the ultra-deep draft means they can only be deployed in sufficiently deep water. Semisubmersibles are widely used in both renewables and the oil and gas (O&G) industry; the towage and installation process has been well established and optimized [

12]. Semisubmersibles can be deployed across a wide range of water depths. They are particularly more suitable than spars or TLPs when the wind farm is close to shore and the water depth is shallow [

13].

TLP has multiple vertical tendons (tethers) connected to the anchors on the seabed, which means that the footprint of the installation is minimized compared to spars or semisubmersibles that need larger mooring ranges [

14]. TLPs can also offer excellent heave motion control due to their tendons. However, the installation, maintenance, repair, and decommission process can be more cumbersome than for the other two types of FOWT platforms [

15]. Among these floater types, semi-submersibles are often used in both the O&G and renewable energy sectors due to their flexibility during installation and cost-effectiveness.

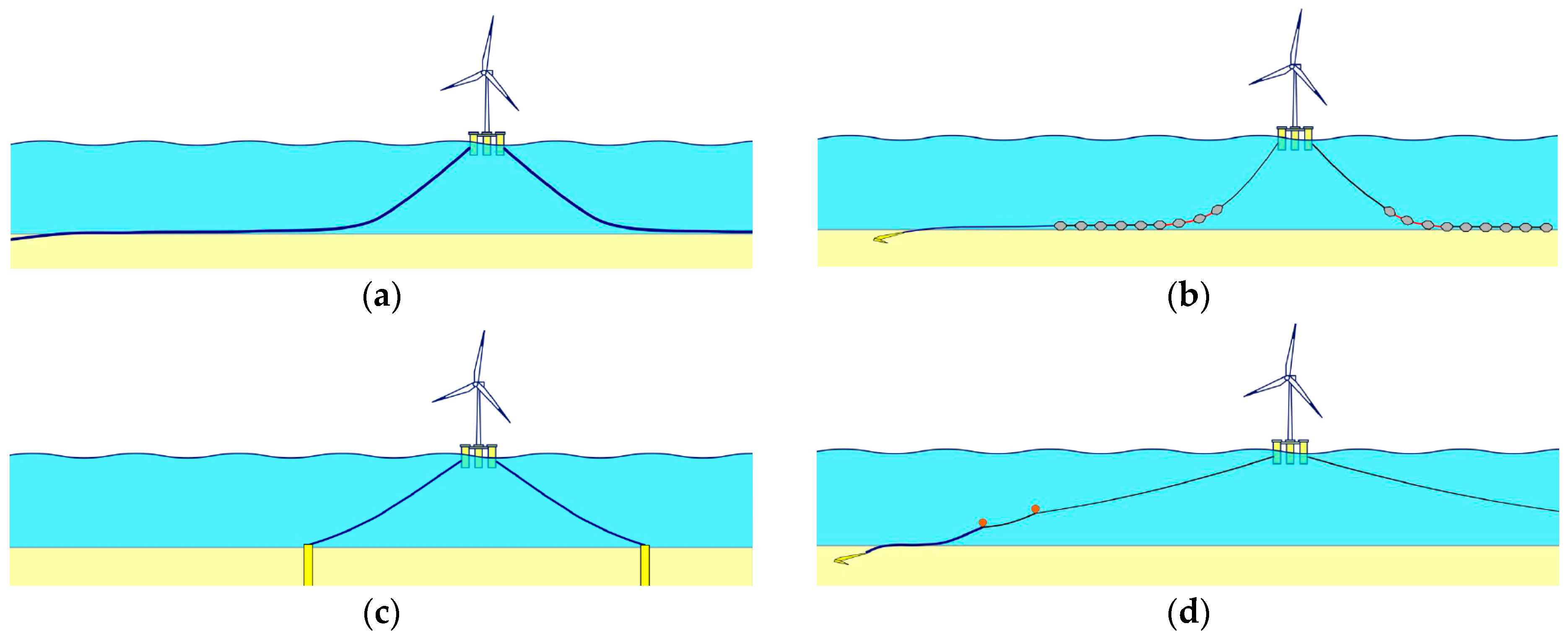

A series of the most typical mooring configurations for FOWT semi-submersibles is shown in

Figure 1, and they can be summarized as follows:

A conventional catenary mooring spread has all mooring lines made of a single component on each line; for instance, an all-chain system. It is easy and quick to install, with a relatively large footprint. It typically utilizes a drag embedment anchor at the end of the mooring line. The mooring restoring force (mooring stiffness) is ensured by the weight of the suspended chain [

16].

The multi-catenary spread is a modified solution to the conventional catenary, with clump weights attached at certain sections on the mooring line. Due to the increased line weight, the mooring system stiffness is improved, leading to an enhanced vessel offset/excursion [

17].

Taut leg mooring is unsuitable for use with drag embedment anchors due to the undesirable vertical loading characteristics. A pile anchor or a vertical loading anchor can be deployed [

18]. The anchor range is more compact than the conventional catenary mooring since it does not require a grounded chain length. It has minimal contact with the seabed, which is particularly beneficial when the subsea layout is congested.

Semi-taut mooring spread can be considered as a combination of a taut leg and a conventional catenary [

19]. A synthetic fiber rope may be used in the middle section of the mooring line, with optional buoyancy at both ends. Such a configuration provides good vertical clearance, energy absorption (leading to an improved factor of safety), and the ability to deploy drag-embedment anchors. The downside is that due to the relatively low axial stiffness of the fiber rope, a larger offset/excursion may be expected.

In addition to the above, a hybrid taut leg mooring system can be suggested, involving segments of clump weights at the anchor side and/or sub-surface buoys near the water surface, with the aim of reducing the vessel excursion, anchor range, and potential anchor uplifts [

20]. In this regard, the test presented in [

20] has shown improvement in vessel offset without significantly increasing tension if a sub-surface buoy is deployed.

Figure 1.

Mooring types (adapted from [

21]): (

a) conventional catenary, (

b) multi-catenary, (

c) taut leg, and (

d) semi-taut.

Figure 1.

Mooring types (adapted from [

21]): (

a) conventional catenary, (

b) multi-catenary, (

c) taut leg, and (

d) semi-taut.

There are usually two approaches to conducting a dynamic response analysis of moorings: time-domain analysis [

22] and frequency-domain analysis [

23]. The two approaches each have their own merits; frequency-domain analysis is often used when cost-efficient and quick computation is required, while time-domain analysis offers a more accurate method due to its ability to accurately solve non-linear problems, such as load coupling, the vessel’s low-frequency motions, and large deformation of the mooring lines [

24,

25].

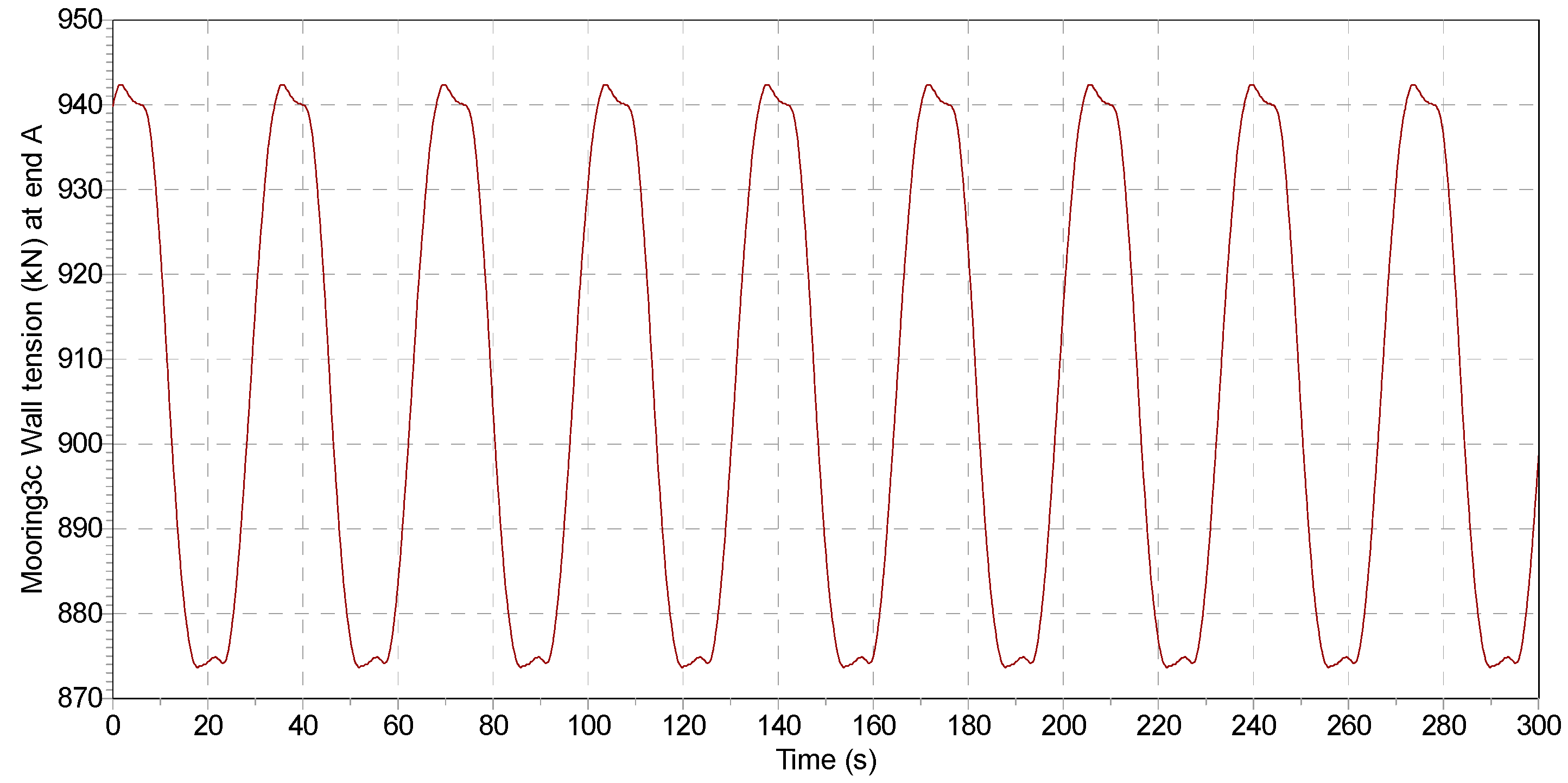

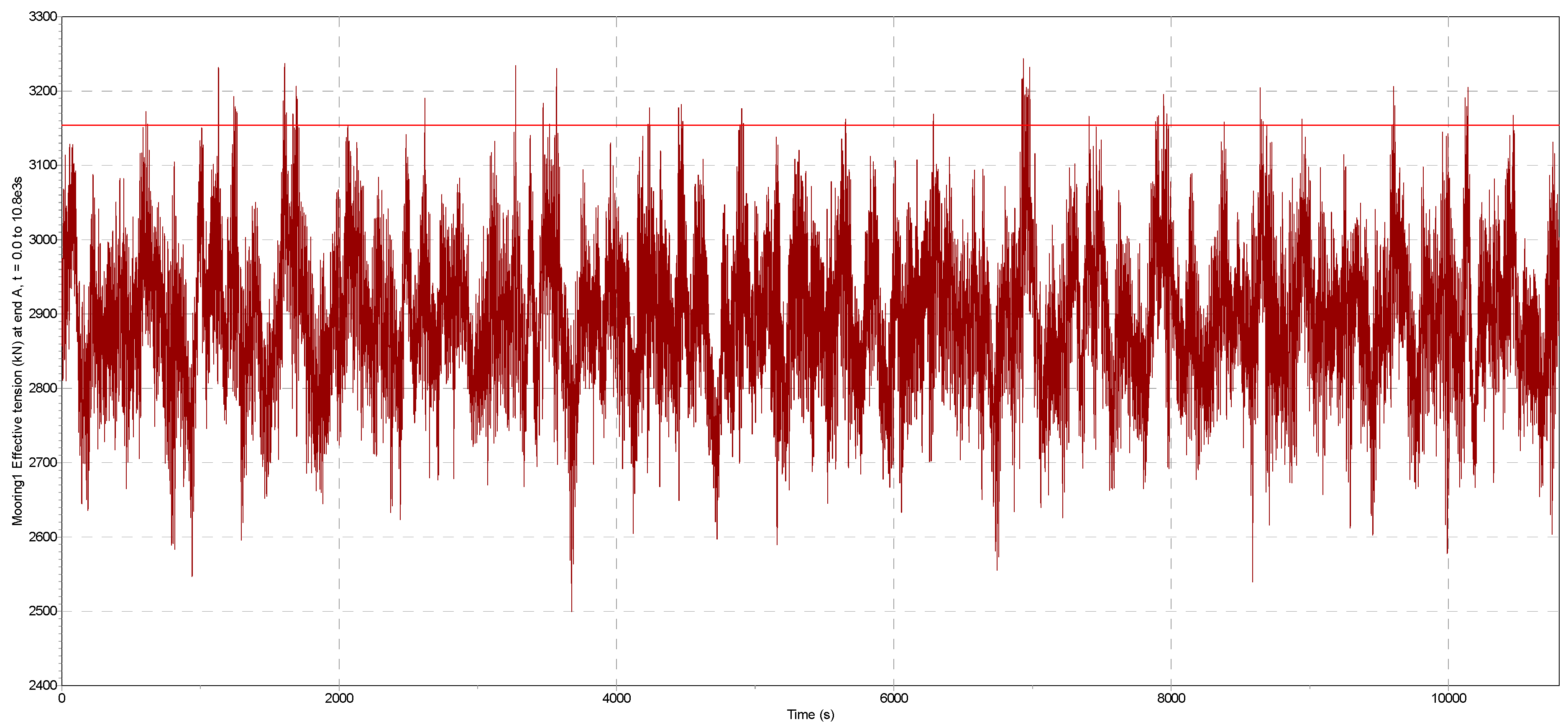

For a time-domain dynamic mooring analysis, it is critical to properly extract the most probable maximum (MPM) tensions or the extreme value (EV) tensions [

26,

27]. Some software packages have EV analysis features already built in, such as OrcaFlex [

28,

29,

30]. It has three built-in methods for obtaining MPM from a line-tension time-history output: the Rayleigh distribution method, the Weibull distribution method, and the generalized Pareto distribution (GPD) method. The Rayleigh distribution shall be carefully used when extracting the line tensions, since the peak responses must follow a Gaussian process [

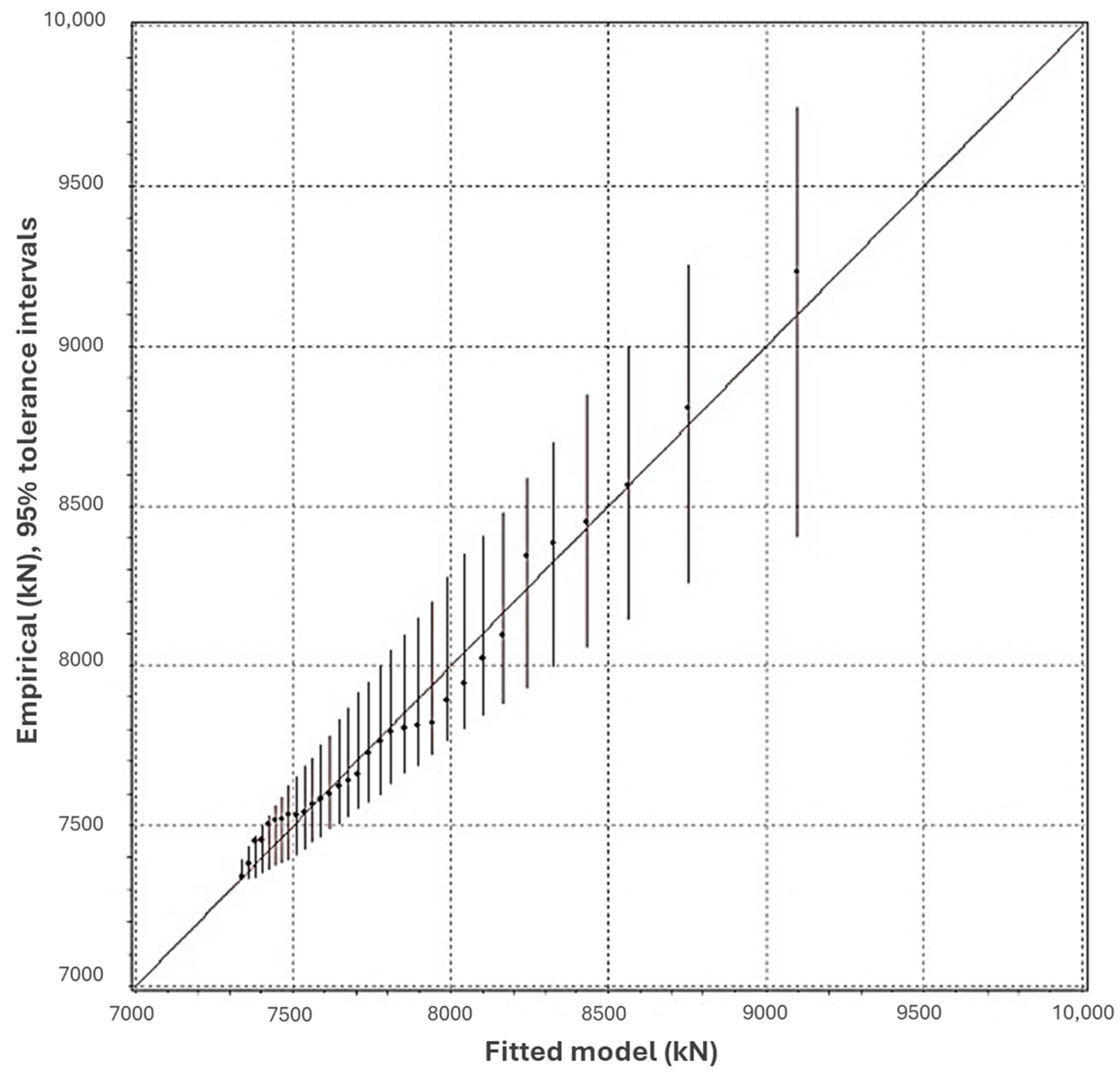

31]. The Weibull distribution method is a general-purpose statistical model, whereas the GPD is mainly used in EV extractions. In practice, the GPD-fitted model in OrcaFlex appears to be more robust than the Weibull-fitted model, which occasionally results in convergence issues.

In the offshore industry, from a practical point of view, the guideline of the American Petroleum Institute, as API RP 2SK—Design and Analysis of Station Keeping Systems for Floating Structures [

32]—summarizes three methods of determining the extreme response from a stochastic time history, as follows:

Probability density function (PDF) of a selected distribution model: API points out that this approach requires a considerable amount of simulation realizations, from which the extreme responses are to be extracted and fitted into a statistical distribution model, then the most probable maximum (MPM) is the maximum PDF of such a fitted model. To ensure the validity of the model, many realizations are required, which is time-consuming and not always practical [

33,

34].

Average of extreme responses: There are five to ten realizations often required for this approach. The extreme responses are then extracted from each realization, and the MPM is then taken from the average of such extreme responses. This approach is commonly used in the O&G industry, is easy to apply, and is considered acceptable by the class [

35].

Fitted probability distribution model: In this method, a probability distribution model with peak probabilities, such as Rayleigh, Normal, Gumbel, Weibull, and Exponential, is chosen. The model parameters are then determined using available response time histories. Subsequently, the anticipated extreme response is calculated based on the adjusted model. Although this method might require fewer iterations than Method 2, in practice, the fitted parametric model often fails to accurately capture the true upper-tail behavior, leading to biased predictions of extreme responses. To enhance accuracy, some analysts employ specialized techniques, such as fitting the upper tail or averaging predictions from multiple iterations [

36,

37]. Such a description might appear somewhat vague, yet acceptable if the time domain analysis is conducted with one realization only, from which the MPM is to be determined using a statistical model such as Rayleigh, Weibull, and Exponential distributions. However, a single realization may lead to biased results, and therefore, multiple realizations are preferable with MPMs that are then fitted into, for example, a Gumbel distribution to eliminate the bias. Alternatively, take the average of the MPMs to improve accuracy.

There have been ongoing discussions about obtaining MPM/EV within the research community, and numerous publications have addressed this topic from various perspectives. The uncertainty in extreme mooring loads due to various statistical models has been assessed by Zhao and Dong [

38], including average conditional exceedance rate, global maxima, peak-over-threshold methods with Gumbel distribution, generalized extreme value distribution, generalized Pareto distribution, and three-parameter Weibull distribution. The work concluded that the uncertainties/deviations introduced by different statistical models could be significant and recommended calibration for the line safety factors. A novel methodology was proposed in [

39], attempting to give a robust distribution of extremes using the peaks over threshold (POT) method.

A detailed discussion was given in [

40] to predict long-term mooring tensions with multiple statistical models, with the potential to reduce the number of realizations required in a time domain mooring analysis. The study demonstrated several common definitions of peaks in response time history and validated a two-parameter Weibull distribution for upper-tail behavior in mooring tension, which is appropriate for representing long-term structural response under extreme conditions [

41]. In addition, the study also covered some approaches to conduct the estimation of the parameters for the Weibull distribution.

Furthermore, research has been undertaken to demonstrate the equations to calculate the line catenary based on the water depth and top tension. The complexity of solving the equation is increased when there are multiple components involved in the line, i.e., the combination of chain, wire, fiber rope [

42,

43], buoyancy module, and clump weight. A numerical mooring model was developed for an offshore floating platform [

44] based on the vector form of the intrinsic finite elements method. Such a method of catenary calculation was validated against multiple validated codes and shows good accuracy.

A study on the mooring line dynamics response was conducted in [

45], where research catenary equations were given for single and multi-component mooring lines/cables, with seabed slope considered. A validation was performed against the model test and OrcaFlex results, which showed agreement.

The vessel position is determined mainly by the environmental forces and the mooring system stiffness matrix. Usually, iterative simulations were undertaken to find the equilibrium vessel position and mooring stiffness with environmental forces as variables. For the mooring of an offshore floating structure, the literature is available [

46,

47] to give solutions to the vessel position and environmental loads.

The basic principles of conducting a time-domain mooring analysis are briefly discussed here. However, many other factors are involved in the calculation process. For instance, low-frequency and wave frequency motions, added mass and damping matrices, seabed frictions and geometries, and the riser system are not covered in this study.

6. Discussion

The results indicate that tension calculations according to the DNV, BV, and ABS standards are broadly comparable, despite some differences. Notably, Load Case 17 (LC17) failed under DNV and BV standards but passed marginally under ABS. Overall, BV tends to yield more conservative (i.e., higher) tension safety factors, while DNV generally predicts lower tension safety factors, particularly in calm conditions. These variations arise from differing approaches to safety and risk assessment among the classification societies, and there is no absolute standard of correctness. This study focuses on benchmarking these standards under normal operational conditions and does not address damaged scenarios or Accidental Limit States, as defined by DNV. For simplicity, only one wave condition is considered, though a comprehensive mooring analysis would typically involve multiple sea states to statistically determine the most probable maximum line tensions.

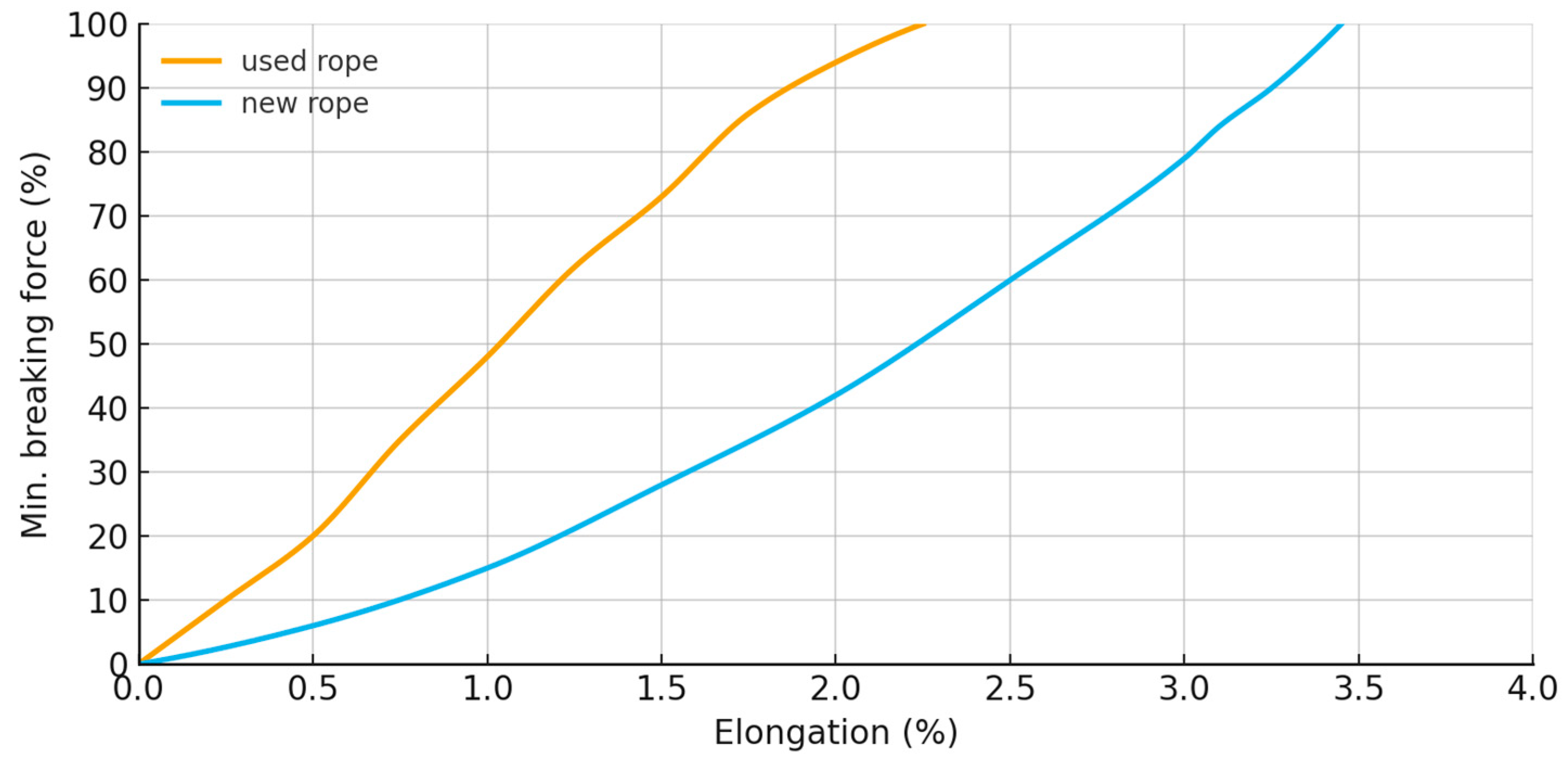

The analysis incorporates the non-linear behavior of Dyneema fiber ropes, although the long-term creep behavior is simplified by considering only “new” and “aged” rope conditions. Intermediate stages and time-dependent changes are not explicitly modeled. Similarly, while the peak-over-threshold method is used to identify characteristic maximum tensions, it involves subjective decisions that depend on the analyst’s experience. Extreme value analysis applied to the time-history data generally produced reliable fits, though some load cases showed wider confidence intervals that could be refined with threshold adjustments and additional data. The practical implications of these findings are significant for the offshore wind industry.

The variations in safety factors across different standards suggest that the choice of guidelines can have a considerable impact on the design and cost of mooring systems. For example, adhering to BV standards may result in higher initial costs due to the more conservative safety factors, particularly when synthetic ropes are used. However, this can be justified by the increased safety margin and potentially lower long-term maintenance costs, as these standards account more rigorously for material fatigue and creep.

Furthermore, the results indicate that hybrid mooring systems, such as those used in the VolturnUS platform, can offer superior performance under certain conditions but require careful design consideration to ensure long-term reliability. The higher tension variances observed in synthetic ropes under extreme conditions highlight the need for ongoing monitoring and maintenance to mitigate the risks associated with material degradation over time.

Several limitations of the current study should be acknowledged. The environmental conditions analyzed are specific to the North Sea and may not generalize to all offshore sites. Furthermore, the simplified modeling of rope stiffness and environmental interactions, along with the exclusion of transient phenomena such as wave slamming, may lead to the underestimation of actual mooring loads. These limitations suggest that caution is needed when interpreting the results.

Future research should focus on performing a more detailed evaluation of synthetic rope performance, including long-term fatigue and creep under real conditions. Expanding the scope to include damaged scenarios and more complex environmental interactions—potentially through stochastic and transient modeling—would improve design reliability. Additionally, integrating the strengths of DNV, BV, and ABS into a hybrid or harmonized standard may offer a more balanced and robust framework for mooring system design.

7. Conclusions

This study has made a critical advancement in the understanding of FOWT mooring systems by conducting a detailed comparative analysis of safety factors in line with tensions as prescribed by DNV, ABS, and BV guidelines. Utilizing the VolturnUS platform as a case study, the research employed dynamic mooring analysis through sophisticated simulation tools. This approach not only revealed the nuances and similarities between different standards but also provided a benchmark against which current and future mooring systems could be evaluated. The methodology, grounded in both theoretical and practical aspects, strengthens the study’s credibility and relevance to real-world applications.

This study assessed the effectiveness of international standards—DNV, ABS, and BV—in predicting mooring line safety for offshore wind turbines. The analysis, based on a single-wave condition, effectively demonstrated differences in mooring line behavior but did not capture the full complexity of material responses. Additionally, the subjectivity in identifying maximum line tensions highlights the need for more rigorous and standardized evaluation methodologies.

While broad alignment was observed, discrepancies emerged in specific cases, reflecting the distinct risk assessment frameworks embedded within each standard. The study does not intend to favor any classification society, as there is no absolute standard of correctness. Nonetheless, the study urges comprehensive structural reliability and risk analysis to define a partial safety or target reliability index for the next generation of floating structures.

The findings of this study have important implications for the design of reliable and cost-effective mooring systems not only for floating offshore wind turbines (FOWTs) but also for other floating offshore renewables systems, such as wave energy converters with similar risk profiles (likelihood × consequence). By revealing differences in safety factor requirements across standards, the research supports more informed design decisions that balance safety with economic considerations. In particular, the methodology presented to conduct a comparative analysis of different standards can be used by developers of innovative floating structures to make better-informed decisions in the long and arduous technology qualification process.

The study also emphasizes the need for the continuous refinement of mooring guidelines to meet the evolving demands of offshore wind applications. Future research should investigate damaged-state scenarios and the non-linear mechanical behavior of synthetic ropes to further improve mooring system resilience.