Design and Implementation of a LiDAR-Based Inspection Device for the Internal Surveying of Subsea Pipelines

Abstract

1. Introduction

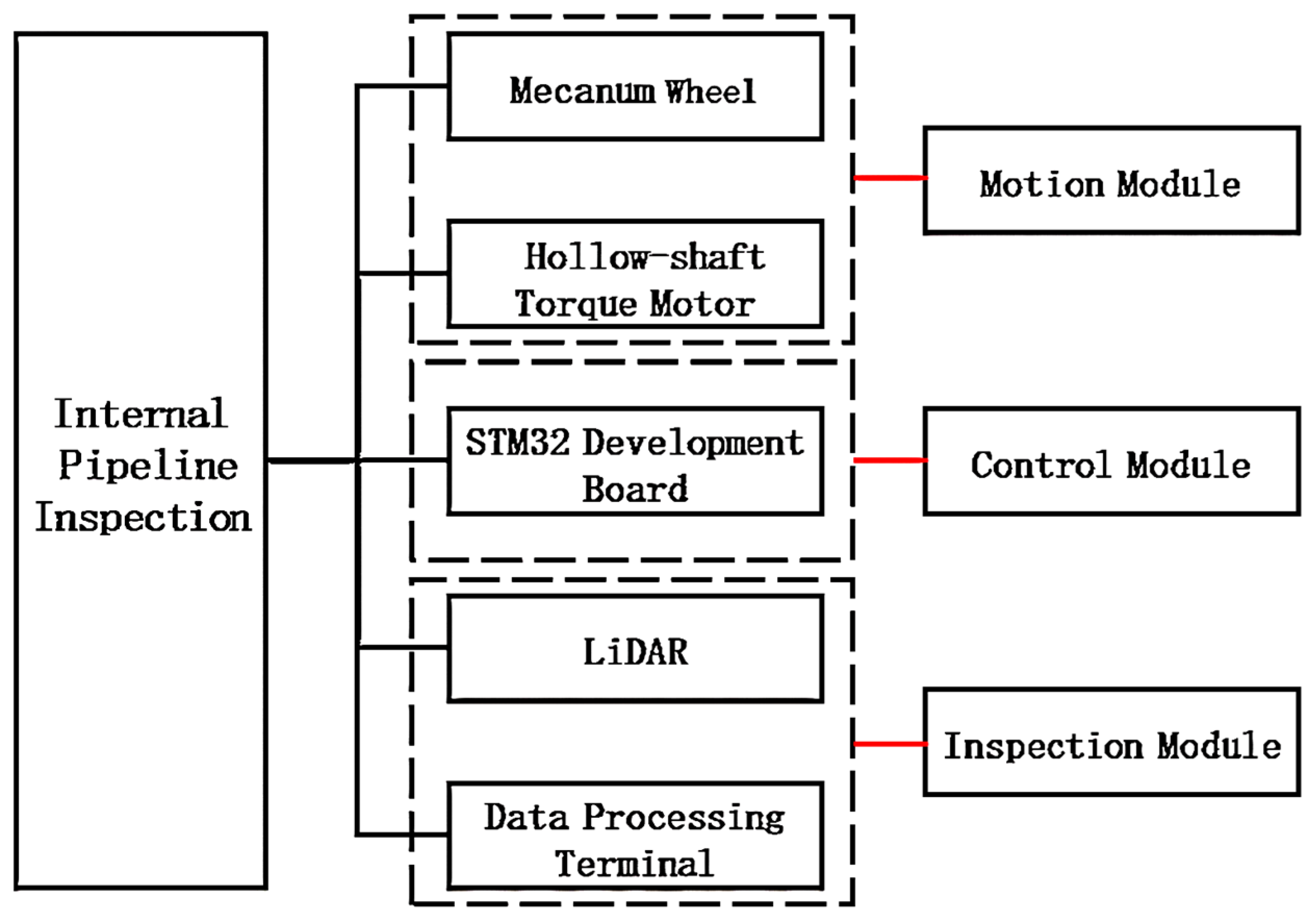

2. Overall Design of Subsea Pipeline Inspection Device

2.1. Overall Design Scheme

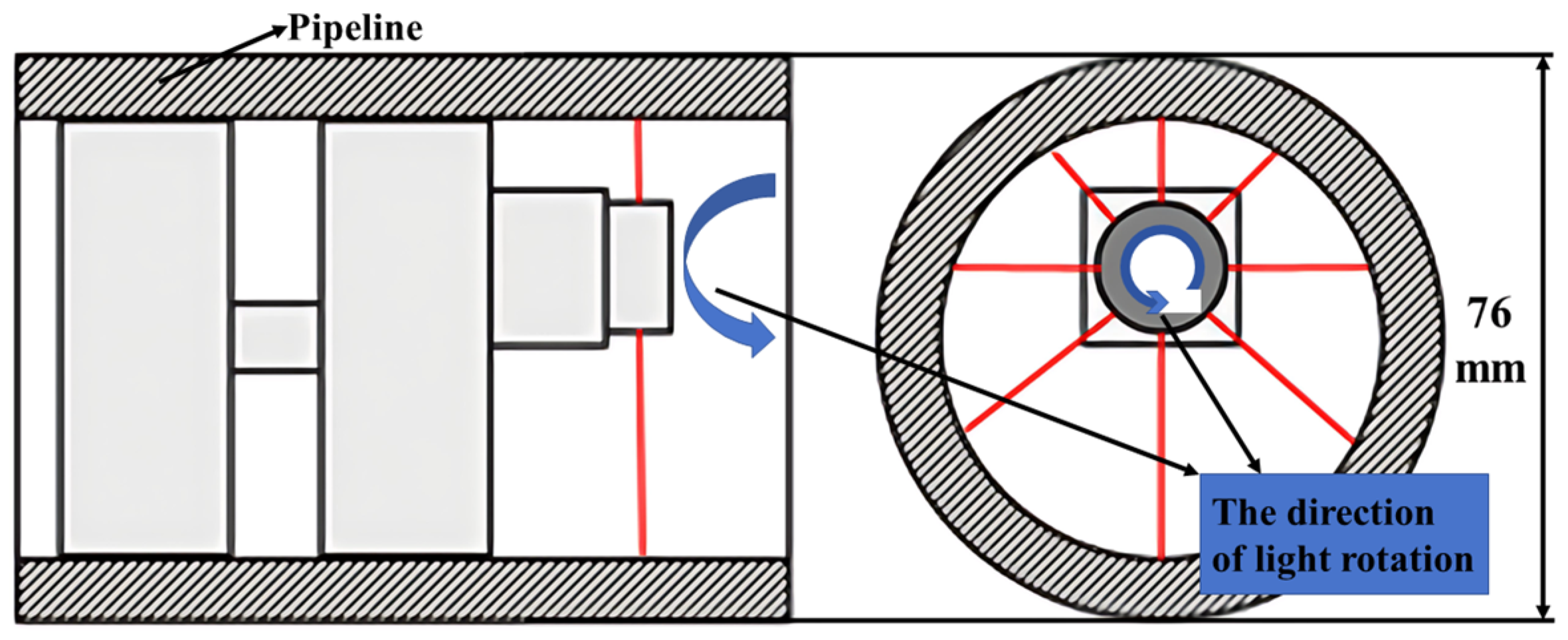

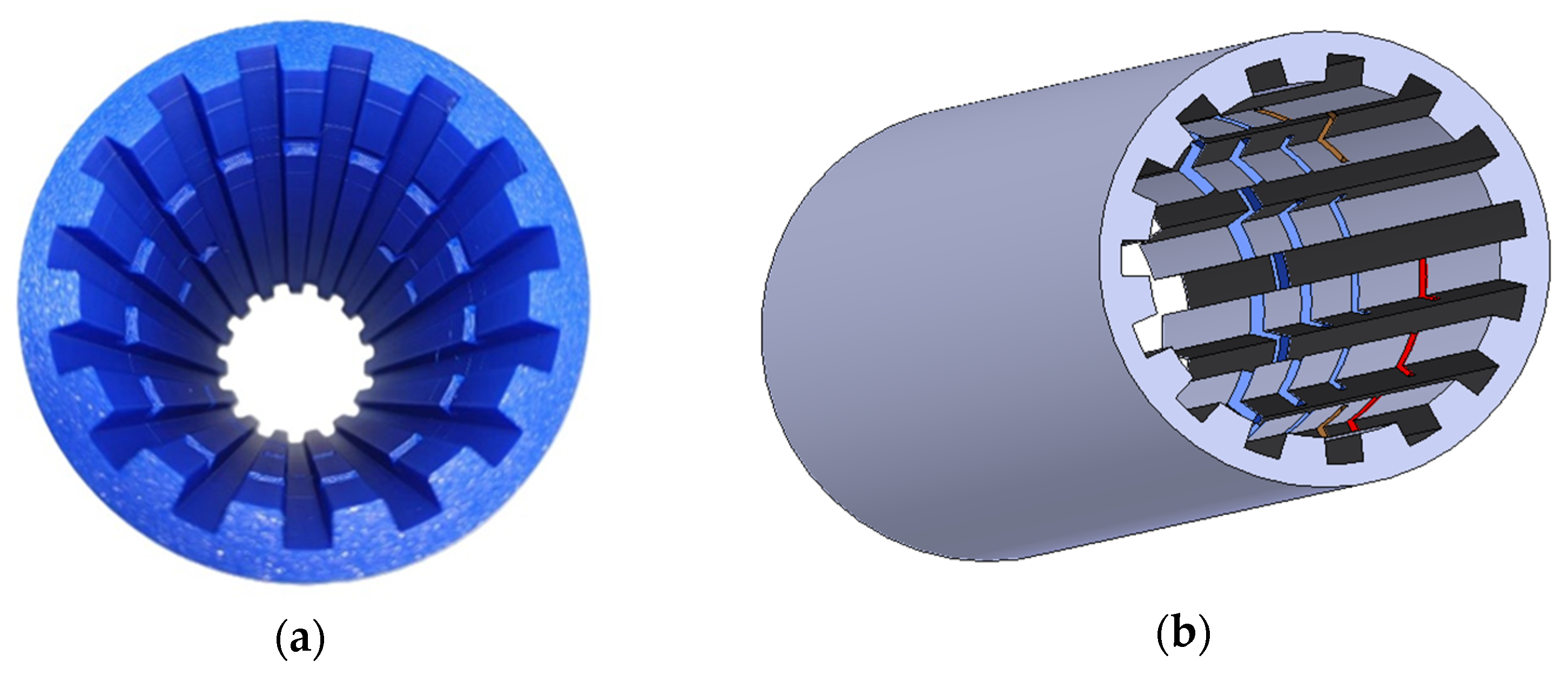

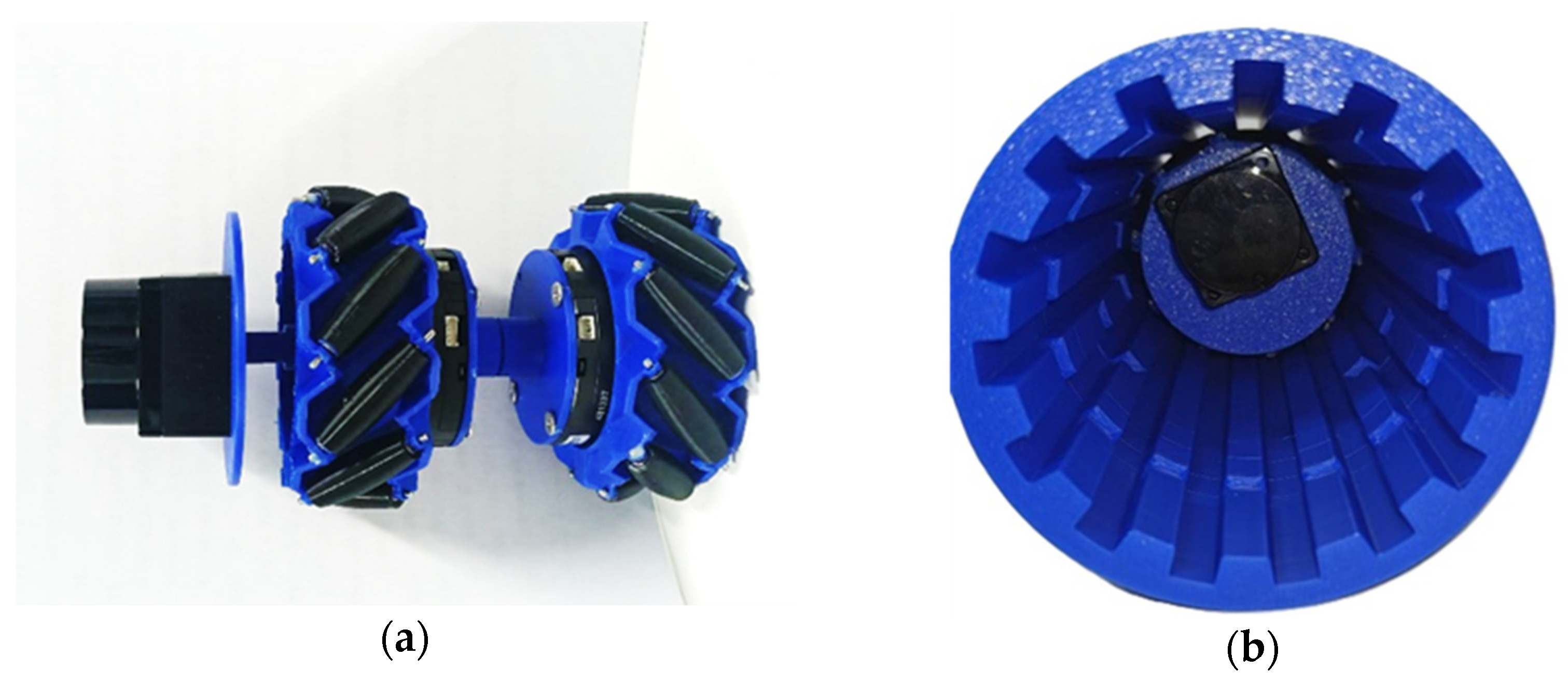

2.2. Locomotion Module Design

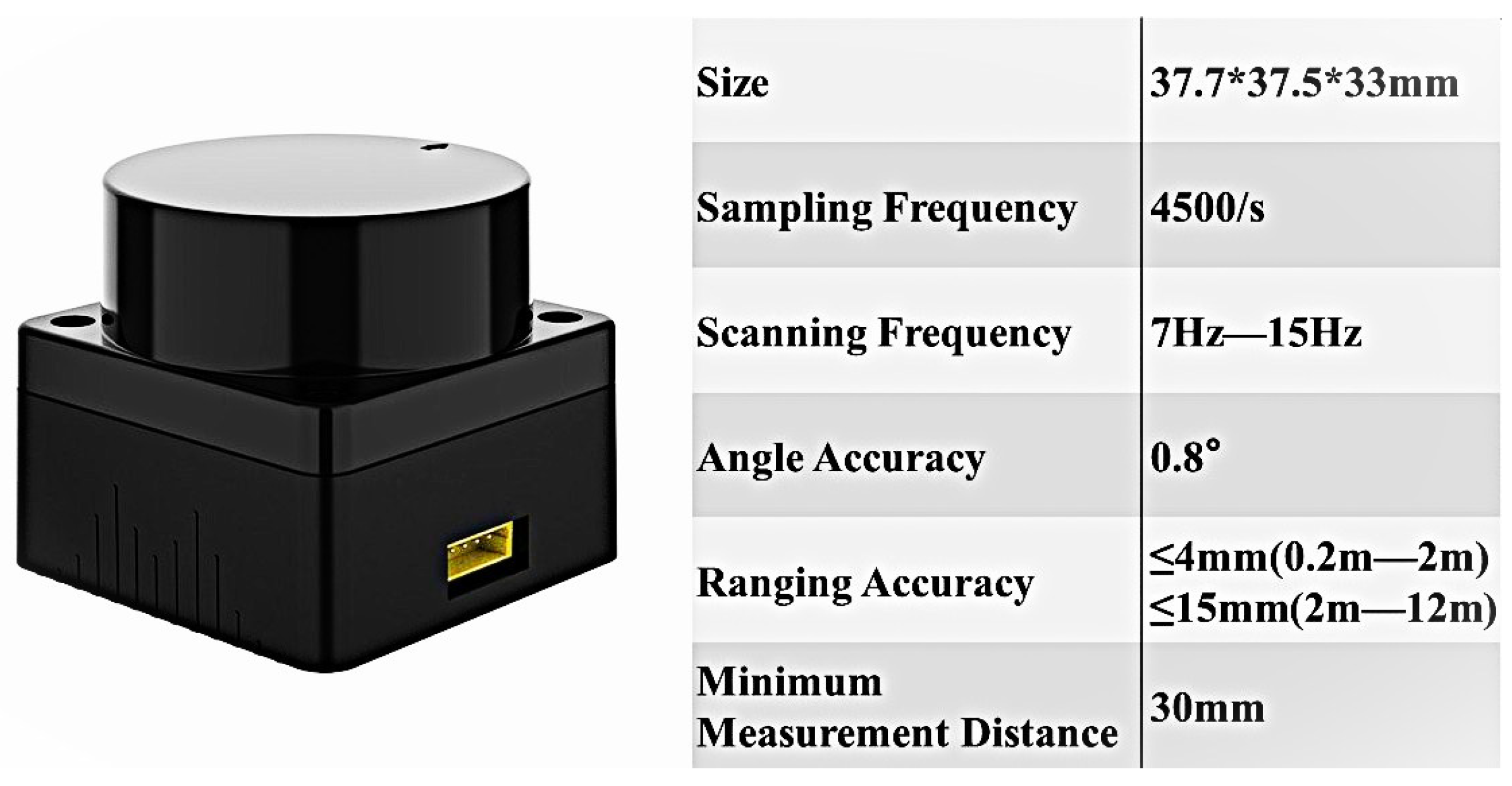

2.3. LiDAR and Control Board Selection

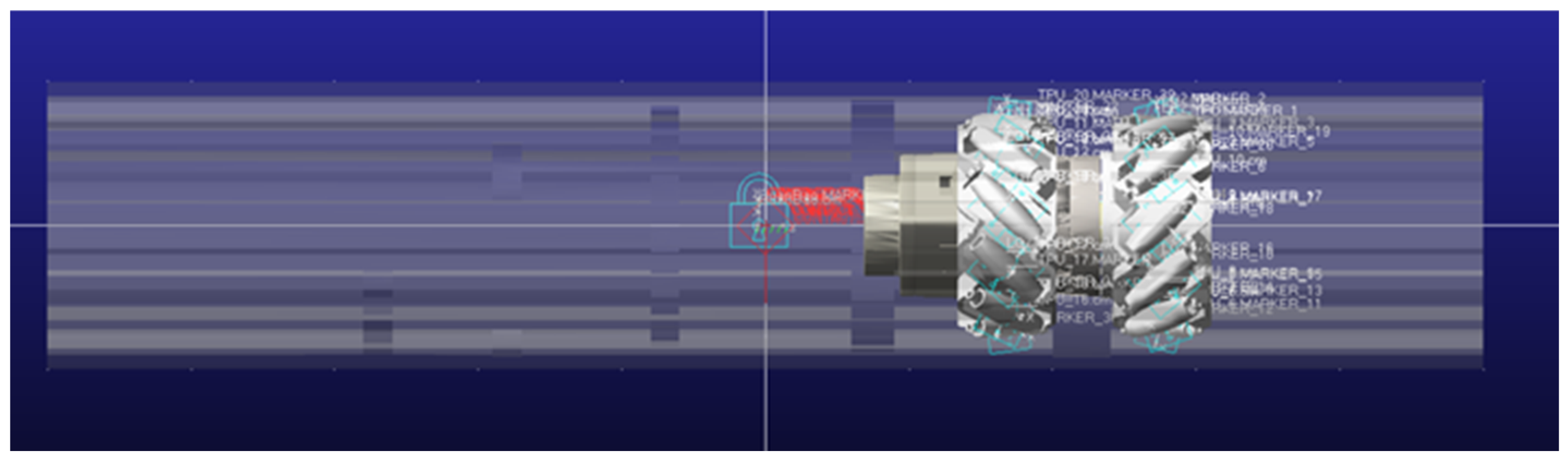

3. Simulation Verification

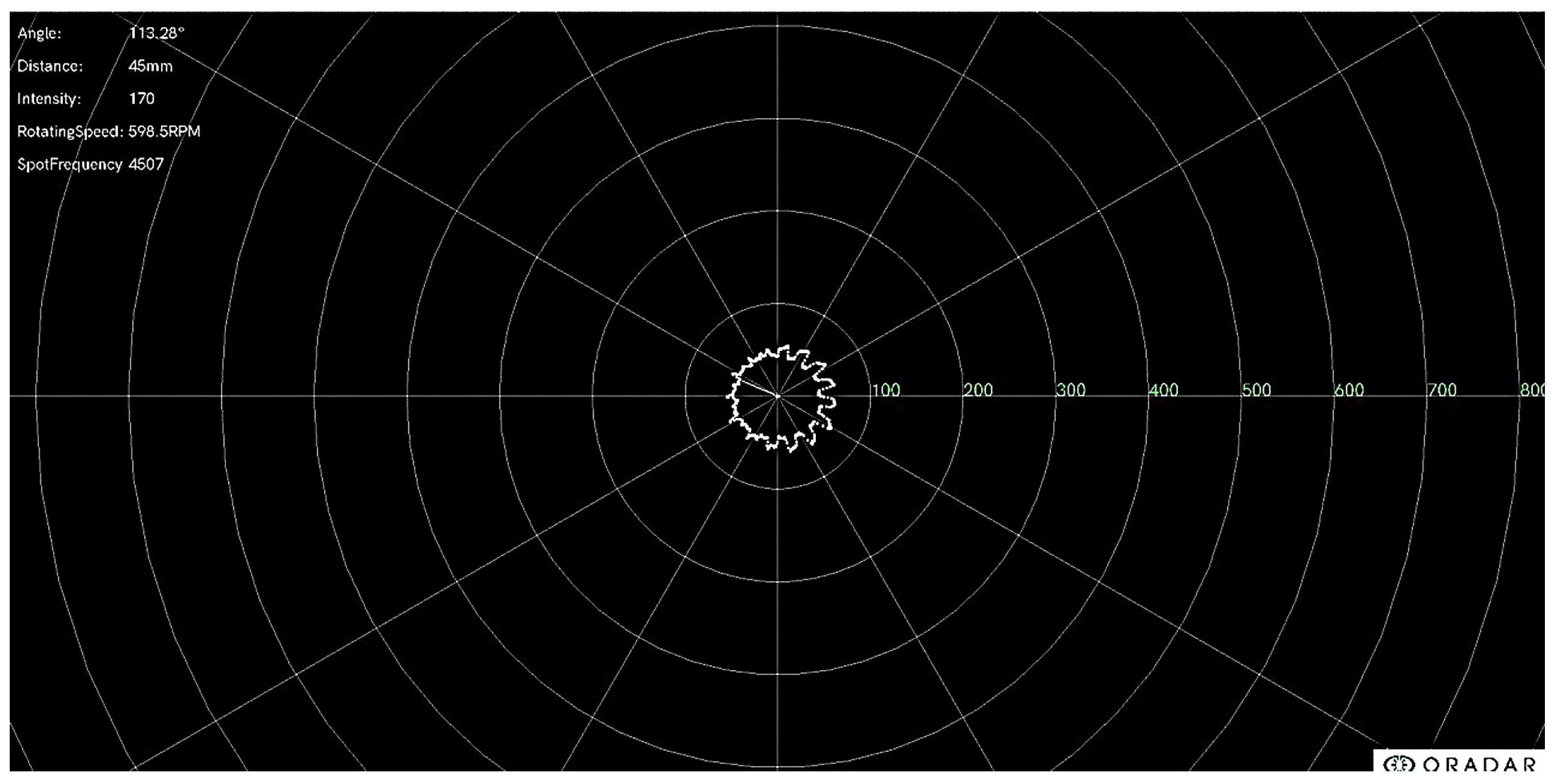

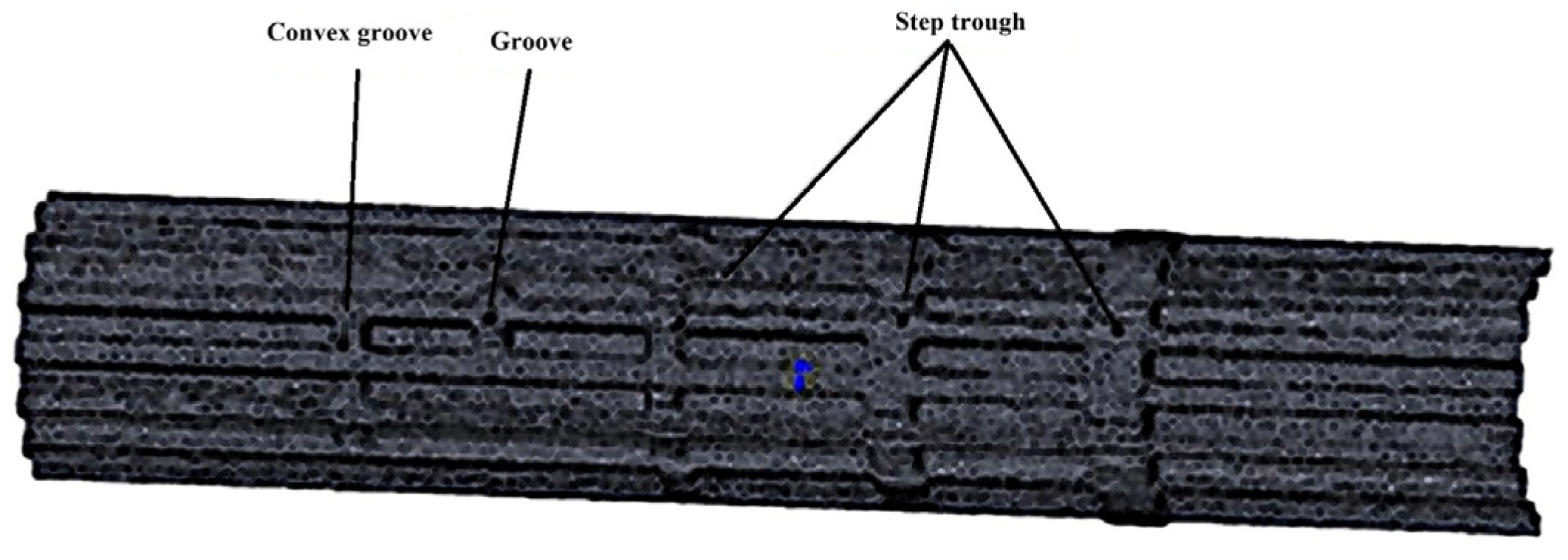

4. Experimental Validation

- (1)

- Device Advancement: The inspection device advances while the LiDAR remains in standby mode. The STM32 development board, utilizing a PID control algorithm, governs the device’s movement, controlling its progression in precise increments of 0.5 mm according to preset parameters.

- (2)

- Device Halt and Data Acquisition: The device halts, and the LiDAR acquires point cloud data. Following the cessation of the hollow-shaft torque motors, the host computer triggers the LiDAR to operate to capture the point cloud information.

- (3)

- Data Transmission and Resumption: Upon completion of the scan, the LiDAR transmits the acquired point cloud data back to the host computer. The host computer then commands the LiDAR to cease operation, and the inspection device resumes its advancement based on the programmed instructions.

- (4)

- Process Iteration: The cycle described above (steps 1–3) is repeated iteratively. This process accumulates point cloud data for a specific length of the pipeline’s internal bore.

- (5)

- Post-Processing and Reconstruction: After data acquisition is complete, the inspection device is retrieved from the pipeline. The collected data undergo preprocessing and subsequent 3D reconstruction through a dedicated data processing algorithm.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Du, F.; Li, C.; Wang, W. Development of Subsea Pipeline Buckling, Corrosion and Leakage Monitoring. J. Mar. Sci. Eng. 2023, 11, 188. [Google Scholar] [CrossRef]

- Ho, M.; El-Borgi, S.; Patil, D.; Song, G. Inspection and Monitoring Systems Subsea Pipelines: A Review Paper. Struct. Health Monit. 2020, 19, 606–645. [Google Scholar] [CrossRef]

- Davis, P.; Brockhurst, J. Subsea Pipeline Infrastructure Monitoring: A Framework for Technology Review and Selection. Ocean Eng. 2015, 104, 540–548. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, J.; Lin, R.; Wang, Y. Advanced Inspection Techniques for Submarine Pipeline Integrity. In Submarine Pipeline Integrity: Assessment of Failure Modes and Advanced Evaluation Techniques; Zhang, H., Zhang, J., Lin, R., Wang, Y., Eds.; Springer Nature: Cham, Switzerland, 2025; pp. 1–14. ISBN 978-3-031-92092-9. [Google Scholar]

- Ma, Q.; Liang, W.; Zhou, P. A Review on Pipeline In-Line Inspection Technologies. Sensors 2025, 25, 4873. [Google Scholar] [CrossRef]

- Wang, C.; Wu, S.; Xin, J.; He, R.; Chen, J.; Wang, D. Numerical Simulation of Oil and Gas Pipeline Crack Detection Based on Pulsed Eddy Current Testing Technology. In Proceedings of the 2021 4th International Conference on Electron Device and Mechanical Engineering (ICEDME), Guangzhou, China, 19–21 March 2021; pp. 46–50. [Google Scholar]

- Cao, W.Y. Research on Pipeline Acoustic Detection and Leak Localization Technology. Master’s Thesis, North China Electric Power University (Beijing), Beijing, China, 2024. [Google Scholar]

- Fahimipirehgalin, M.; Trunzer, E.; Odenweller, M.; Vogel-Heuser, B. Automatic Visual Leakage Detection and Localization from Pipelines in Chemical Process Plants Using Machine Vision Techniques. Engineering 2021, 7, 758–776. [Google Scholar] [CrossRef]

- Liang, Y. Discussion on Subsea Pipeline Internal Inspection and Anti-Corrosion Strategies. Petro. Chem. Equip. 2024, 27, 160, 164–167. [Google Scholar]

- Liu, Z. Series Design of Measuring Nodes for Subsea Pipeline Inspection Equipment. Orient. Enterp. Cult. 2013, 241–242. Available online: https://kns.cnki.net/kcms2/article/abstract?v=DJp2nd4LPS1cscr9z09rI124I3CYnNQJe1xTnqfyzdM49v_Gkxj5LsjL_Ohu98CnrTc8_EXRCCmOs-2qrGHgD24o0AjW4ijSoBqY1O4Vc273gnQ6qqJwCrszpPTaj50JWvBHFIo20kxe8FjgGFYHSjWZ2CKP3elU5p7uLXNG98pD_vcVOK3RmA==&uniplatform=NZKPT&language=CHS (accessed on 17 October 2025).

- Meniconi, S.; Brunone, B.; Tirello, L.; Rubin, A.; Cifrodelli, M.; Capponi, C. Transient Tests for Checking the Trieste Subsea Pipeline: Diving into Fault Detection. J. Mar. Sci. Eng. 2024, 12, 391. [Google Scholar] [CrossRef]

- Meniconi, S.; Brunone, B.; Tirello, L.; Rubin, A.; Cifrodelli, M.; Capponi, C. Transient Tests for Checking the Trieste Subsea Pipeline: Toward Field Tests. J. Mar. Sci. Eng. 2024, 12, 374. [Google Scholar] [CrossRef]

- Cawley, P. Practical Long Range Guided Wave Inspection–Applications to Pipes and Rail. Mater. Eval. 2003, 61, 66–74. [Google Scholar]

- Davidson, R.; Pipeline, H. An Introduction to Pipeline Pigging; Gulf Publishing: Houston, TX, USA, 2002. [Google Scholar]

- Bohorquez, J.; Lambert, M.F.; Alexander, B.; Simpson, A.R.; Abbott, D. Stochastic Resonance Enhancement for Leak Detection in Pipelines Using Fluid Transients and Convolutional Neural Networks. J. Water Resour. Plan. Manag. 2022, 148, 04022001. [Google Scholar] [CrossRef]

- Covas, D.; Ramos, H. Case Studies of Leak Detection and Location in Water Pipe Systems by Inverse Transient Analysis. J. Water Resour. Plan. Manag. 2010, 136, 248–257. [Google Scholar] [CrossRef]

- Mohapatra, P.K.; Chaudhry, M.H.; Kassem, A.A.; Moloo, J. Detection of Partial Blockage in Single Pipelines. J. Hydraul. Eng. 2006, 132, 200–206. [Google Scholar] [CrossRef]

- Brockhaus, S.; Ginten, M.; Klein, S.; Teckert, M.; Stawicki, O.; Oevermann, D.; Meyer, S.; Storey, D. 10–in-Line Inspection (ILI) Methods for Detecting Corrosion in Underground Pipelines. In Underground Pipeline Corrosion; Orazem, M.E., Ed.; Woodhead Publishing: Cambridge, UK, 2014; pp. 255–285. ISBN 978-0-85709-509-1. [Google Scholar]

- Mpesha, W.; Gassman, S.L.; Chaudhry, M.H. Leak Detection in Pipes by Frequency Response Method. J. Hydraul. Eng. 2001, 127, 134–147. [Google Scholar] [CrossRef]

- Kazeminasab, S.; Sadeghi, N.; Janfaza, V.; Razavi, M.; Ziyadidegan, S.; Banks, M.K. Localization, Mapping, Navigation, and Inspection Methods in in-Pipe Robots: A Review. IEEE Access 2021, 9, 162035–162058. [Google Scholar] [CrossRef]

- Liou, C.P. Pipeline Leak Detection by Impulse Response Extraction. J. Fluids Eng. 1998, 120, 833–838. [Google Scholar] [CrossRef]

- Gazis, D.C. Three-dimensional Investigation of the Propagation of Waves in Hollow Circular Cylinders. I. Analytical Foundation. J. Acoust. Soc. Am. 1959, 31, 568–573. [Google Scholar] [CrossRef]

- Jia, M.Y.; Shen, X.; Feng, X.X. Application of LiDAR Technology in Pipeline Inspection Robots. Metrol. Meas. Technol. 2025, 51, 64–67. [Google Scholar] [CrossRef]

- Liu, X.X. Research on Defect Detection Method for Pipeline Inner Wall Based on Point Laser Sensor. Master’s Thesis, Tianjin University of Science and Technology, Tianjin, China, 2025. [Google Scholar]

- Li, Y.; Dong, S.Q.; Shi, Y.; Chen, Q. Quantitative Detection Technology for Deformation Defects in Drainage Pipes Based on Laser Point Cloud Data. J. Eng. Geophys. 2024, 21, 54–61. [Google Scholar]

- Montoya, M.; Montelongo, Y.; Jiang, N.; Morris, S.M.; Parra-Michel, J. Free-Form Laser Profilometry for Pipeline Inspection and 3D Cylindrical Reconstructions. IEEE Sens. J. 2022, 22, 297–303. [Google Scholar] [CrossRef]

- Tian, T.; Wang, L.; Yan, X.; Ruan, F.; Aadityaa, G.J.; Choset, H.; Li, L. Visual-Inertial-Laser-Lidar (VILL) SLAM: Real-Time Dense RGB-D Mapping for Pipe Environments. In Proceedings of the 2023 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Detroit, MI, USA, 1–5 October 2023; pp. 1525–1531. [Google Scholar]

- Ambati, P.; Raj, K.M.S.; Joshuva, A. A Review on Pipeline Inspection Robot. AIP Conf. Proc. 2020, 2311, 060002. [Google Scholar] [CrossRef]

- Abdelrahim, M.; Hassan, A.; Ojo, D.; Hosny, M.; Ammar, H.H.; El-Samanty, M. A Novel Design of a T-Model Three Mecanum Wheeled Mobile Robot. In Proceedings of the 2022 International Conference on Advanced Robotics and Mechatronics (ICARM), Guilin, China, 9–11 July 2022; pp. 509–513. [Google Scholar]

- Zang, C.H.; Wang, H.J.; Gao, X.Y.; Ji, H.G.; Wang, K.; Zhao, L.X.; Qiu, N.C. Diameter and Roundness Measurement Method of Expanded Pipes Based on Laser Line Scanning 3D Reconstruction. Dev. Innov. Mach. Electr. Prod. 2021, 34, 79–81. [Google Scholar]

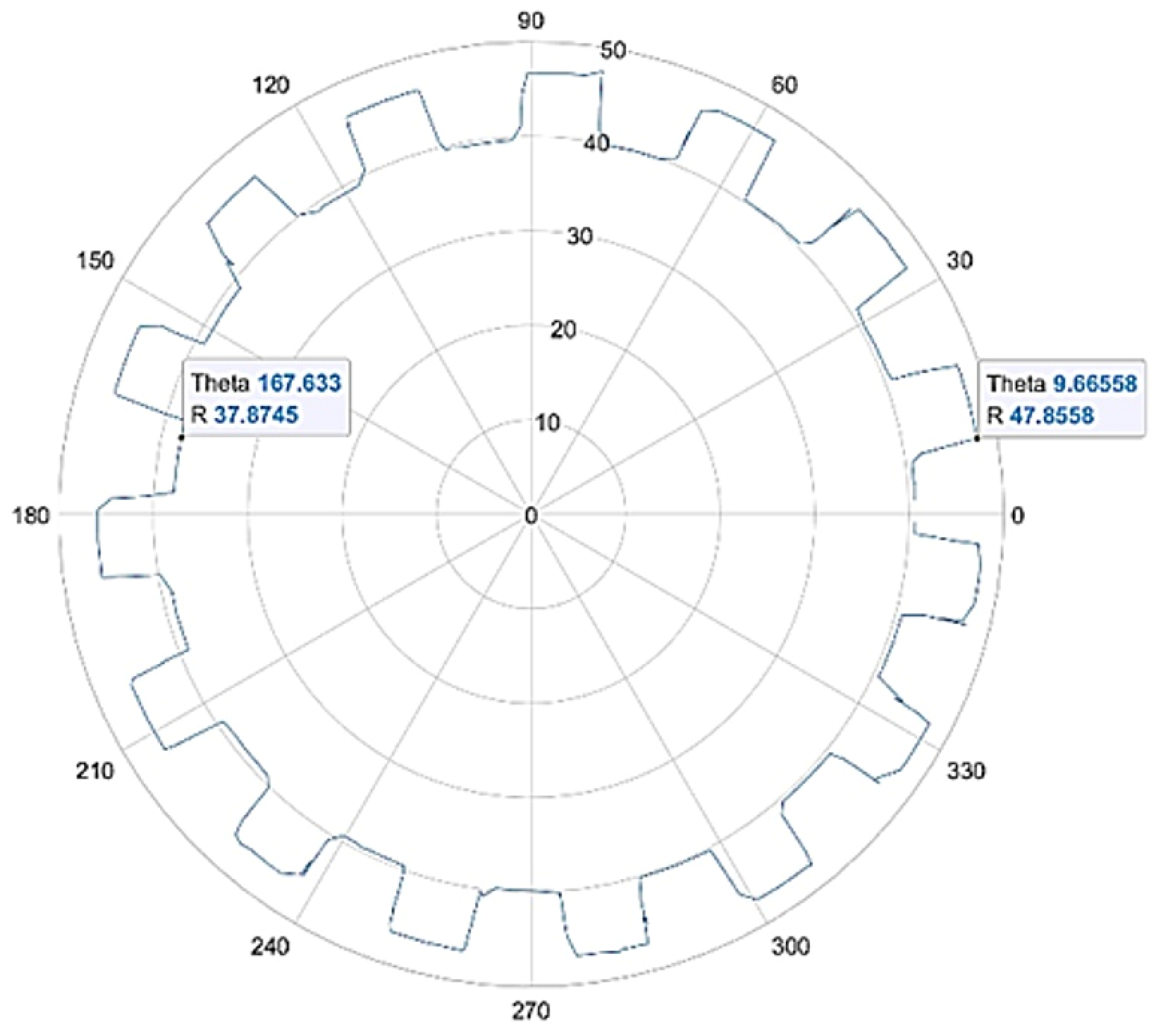

| Angle/° | Radius/mm | Angle/° | Radius/mm |

|---|---|---|---|

| 70.016 | 40 | 109.151 | 46 |

| 74.490 | 40 | 115.377 | 44 |

| 78.091 | 40 | 117.761 | 39 |

| 80.182 | 47 | 121.319 | 39 |

| 92.877 | 40 | 128.384 | 41 |

| 102.468 | 40 | 131.445 | 46 |

| 103.923 | 41 | 136.382 | 46 |

| 104.151 | 43 | 139.850 | 43 |

| Region | Defect Size/mm | Maximum Measured Dimension/mm |

|---|---|---|

| Groove | 45 | 48 |

| Convex groove | 38 | 38 |

| Step trough 1 | 46 | 48 |

| Step trough 2 | 44 | 46 |

| Step trough 3 | 42 | 44 |

| Depression 1 | 45.5 | 47 |

| Depression 2 | 41.8 | 43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Q.; Liang, W.; Chen, H.; Wang, Q.; Zhou, P.; Wang, Q. Design and Implementation of a LiDAR-Based Inspection Device for the Internal Surveying of Subsea Pipelines. J. Mar. Sci. Eng. 2025, 13, 2141. https://doi.org/10.3390/jmse13112141

Ma Q, Liang W, Chen H, Wang Q, Zhou P, Wang Q. Design and Implementation of a LiDAR-Based Inspection Device for the Internal Surveying of Subsea Pipelines. Journal of Marine Science and Engineering. 2025; 13(11):2141. https://doi.org/10.3390/jmse13112141

Chicago/Turabian StyleMa, Qingmiao, Weige Liang, Haoming Chen, Qianshi Wang, Peiyi Zhou, and Qingshan Wang. 2025. "Design and Implementation of a LiDAR-Based Inspection Device for the Internal Surveying of Subsea Pipelines" Journal of Marine Science and Engineering 13, no. 11: 2141. https://doi.org/10.3390/jmse13112141

APA StyleMa, Q., Liang, W., Chen, H., Wang, Q., Zhou, P., & Wang, Q. (2025). Design and Implementation of a LiDAR-Based Inspection Device for the Internal Surveying of Subsea Pipelines. Journal of Marine Science and Engineering, 13(11), 2141. https://doi.org/10.3390/jmse13112141