1. Introduction

The design of a large cruise ship constitutes a highly complex engineering system, typically progressing through an iterative sequence of three stages: basic design, detailed design, and production design. The detailed design phase, serving as the critical link between conceptual innovation and physical construction, produces outcomes that not only refine and expand upon the basic design but also form the direct basis for subsequent production design and actual shipbuilding. During this phase, numerous specialized teams—including hull structure, machinery, electrical, piping, and outfitting—must collaborate to accomplish the detailed design tasks ranging from system layout to component selection.

While this collaborative design mode enhances specialized expertise, it simultaneously introduces a multitude of intertwined design constraints, forming a complex and dynamically evolving constraint network. This network encompasses mandatory design standards, owner and classification society requirements, as well as inherent dependencies among various design variables. As illustrated in

Figure 1, these constraints can be categorized according to object hierarchy (e.g., main segment, sub-segment, unit). Design variables can be further classified into independent variables and coupled variables: changes in the former (shown as red lines in

Figure 1) primarily affect a single design object; whereas the latter (shown as yellow lines in

Figure 1) are associated with multiple objects, and their modification can easily trigger chain reactions, representing a primary source of design conflicts. As the design process advances and constraints are continuously refined, insufficient or delayed information exchange between disciplines can make it difficult for designers to comprehensively manage constraint evolution, inevitably leading to the occurrence of conflicts.

Given the pivotal role of the detailed design phase (accounting for approximately 30–40% of the total design effort), conflicts arising during this stage, if not detected and resolved promptly, can significantly increase modification costs in subsequent phases and potentially delay the project schedule. Therefore, establishing an efficient conflict detection method to assist designers in early identification and resolution of conflicts is of paramount theoretical and practical importance for ensuring cruise ship design quality, controlling project risk, and accumulating design knowledge.

Although conflict detection has been extensively studied in fields such as mechanical engineering and architecture, its application to the detailed design of large cruise ships faces significant challenges. Firstly, existing methods predominantly focus on known, explicit constraints, lacking effective means for modeling and detecting the numerous unstated, implicit constraints prevalent in the design process. Secondly, published research specifically addressing conflict detection in the detailed design of complex internal systems (e.g., water supply, ventilation) within large cruise ships remains scarce.

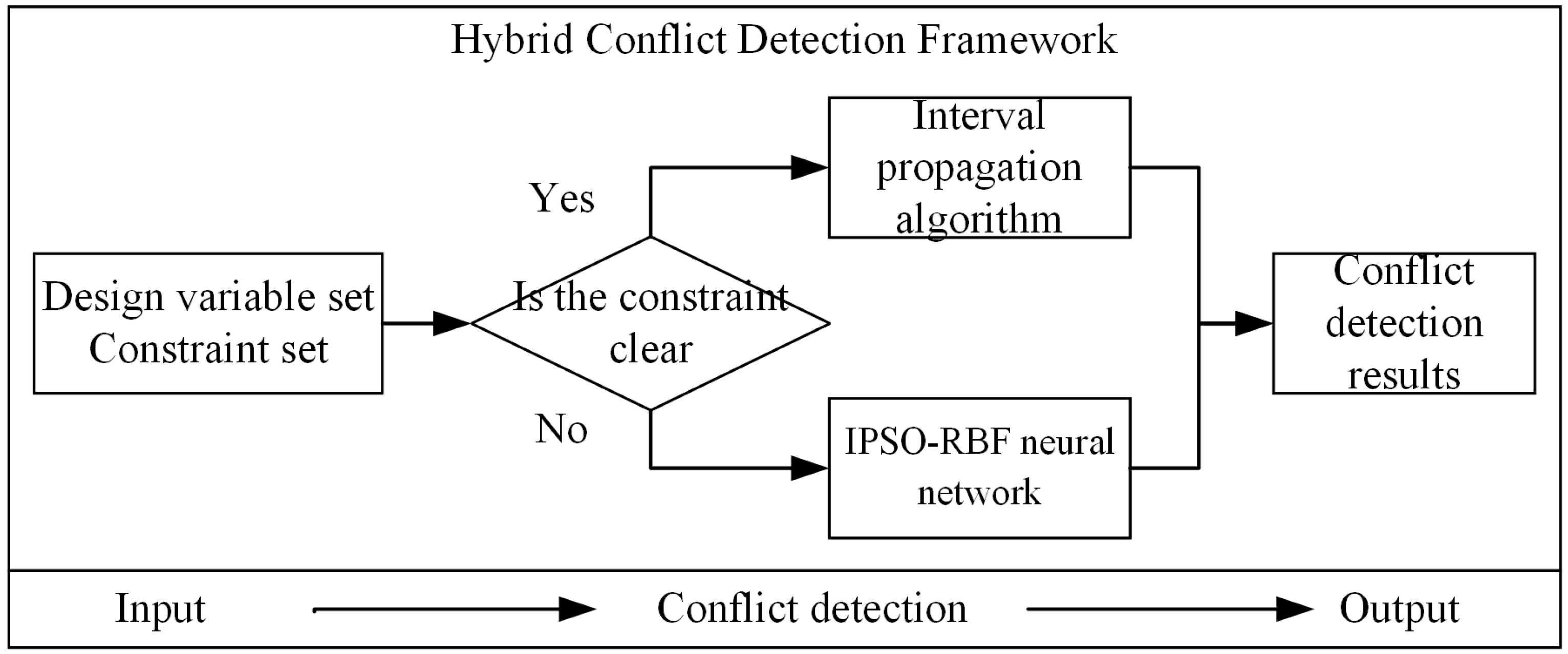

To address these challenges, this paper categorizes the core issues in conflict detection for large cruise ship detailed design into two classes: (1) Known Constraint Conflicts: How to achieve rapid, automated identification of conflicts involving explicitly modellable constraints. (2) Unknown Constraint Conflicts: How to achieve high-accuracy intelligent prediction of conflicts arising from implicit constraints that rely on historical experience and are difficult to define precisely. Accordingly, this paper proposes a hybrid conflict detection framework (the overall framework is shown in

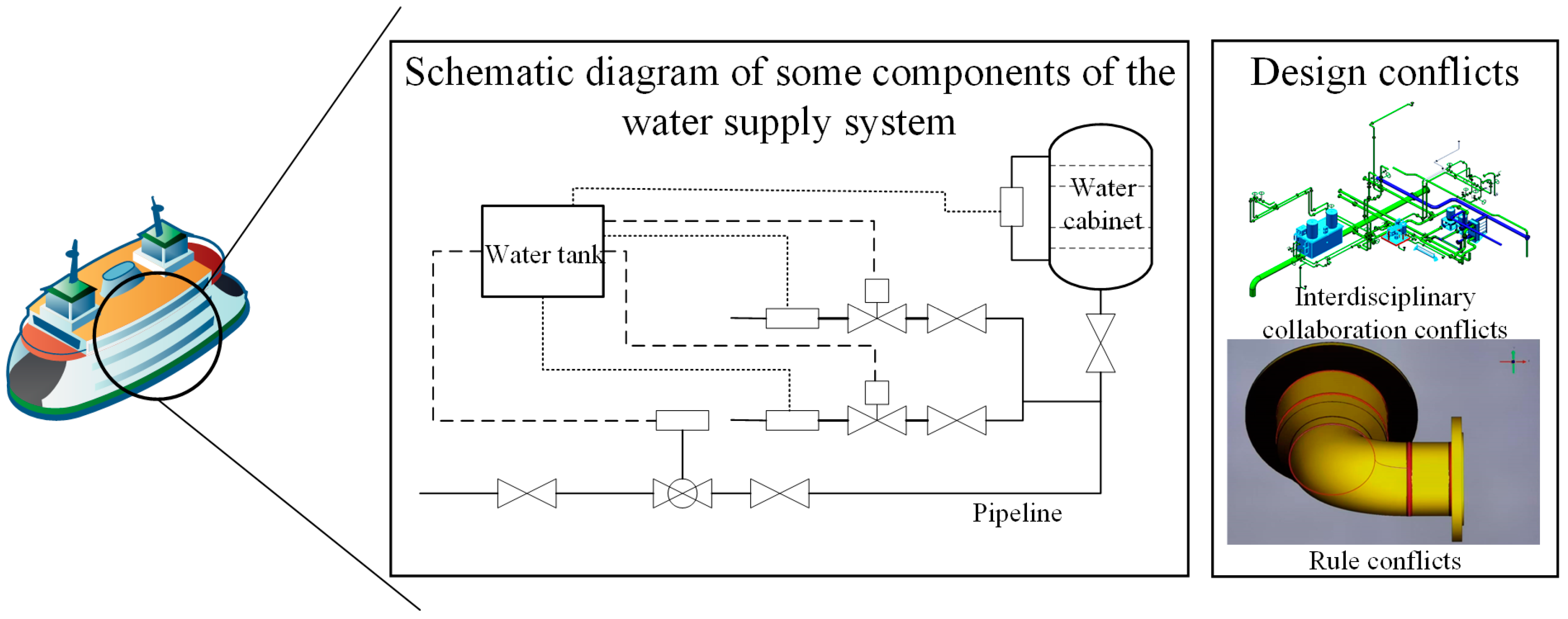

Figure 2) and uses the piping design of a large cruise ship’s water supply system as a continuous validation case study. The complexity and multi-disciplinary interaction characteristics of this system (whose schematic and typical conflicts are illustrated in

Figure 3) make it an ideal scenario for validating the conflict detection methodology. For instance, in pipeline penetration design, the structural discipline might restrict the opening diameter (e.g., d < 0.05 m) to ensure strength, while the piping discipline might require a larger diameter (e.g., d > 0.05 m) to meet flow rate requirements. Such conflicts, governed by explicitly definable rules, fall under known constraints. Conversely, certain layout schemes might comply with all codified regulations yet historically tend to cause water pressure imbalances or maintenance difficulties; these experience-based conflicts belong to the category of unknown constraints.

The main contributions of this paper are as follows:

(1) Framework Innovation: A divide-and-conquer hybrid detection framework is proposed, decomposing the Constraint Satisfaction Problem (CSP) into known and unknown constraint sets, addressed by an interval propagation algorithm and an intelligent prediction model, respectively. This provides a systematic solution for handling both certain and uncertain conflicts in complex design systems.

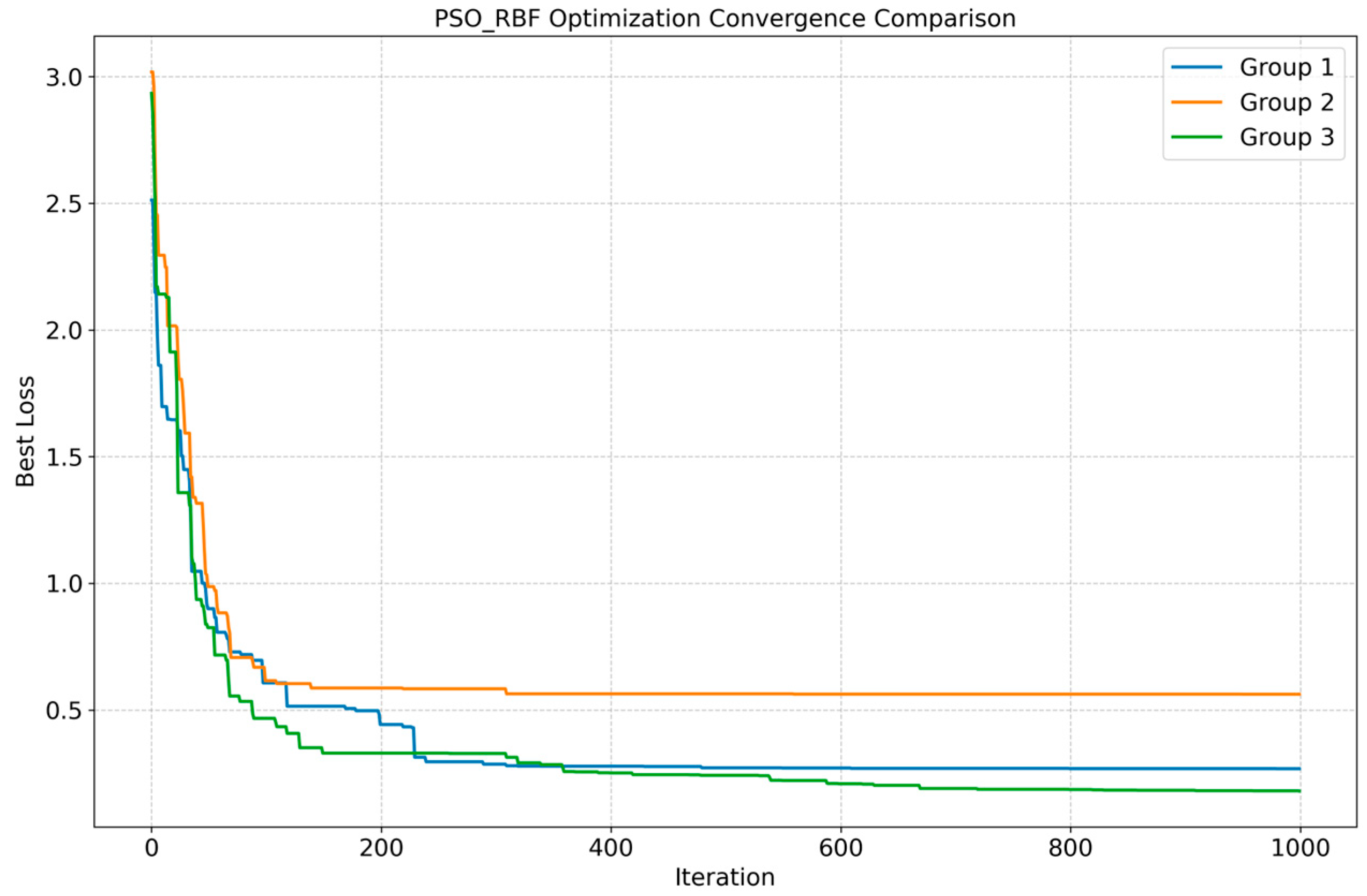

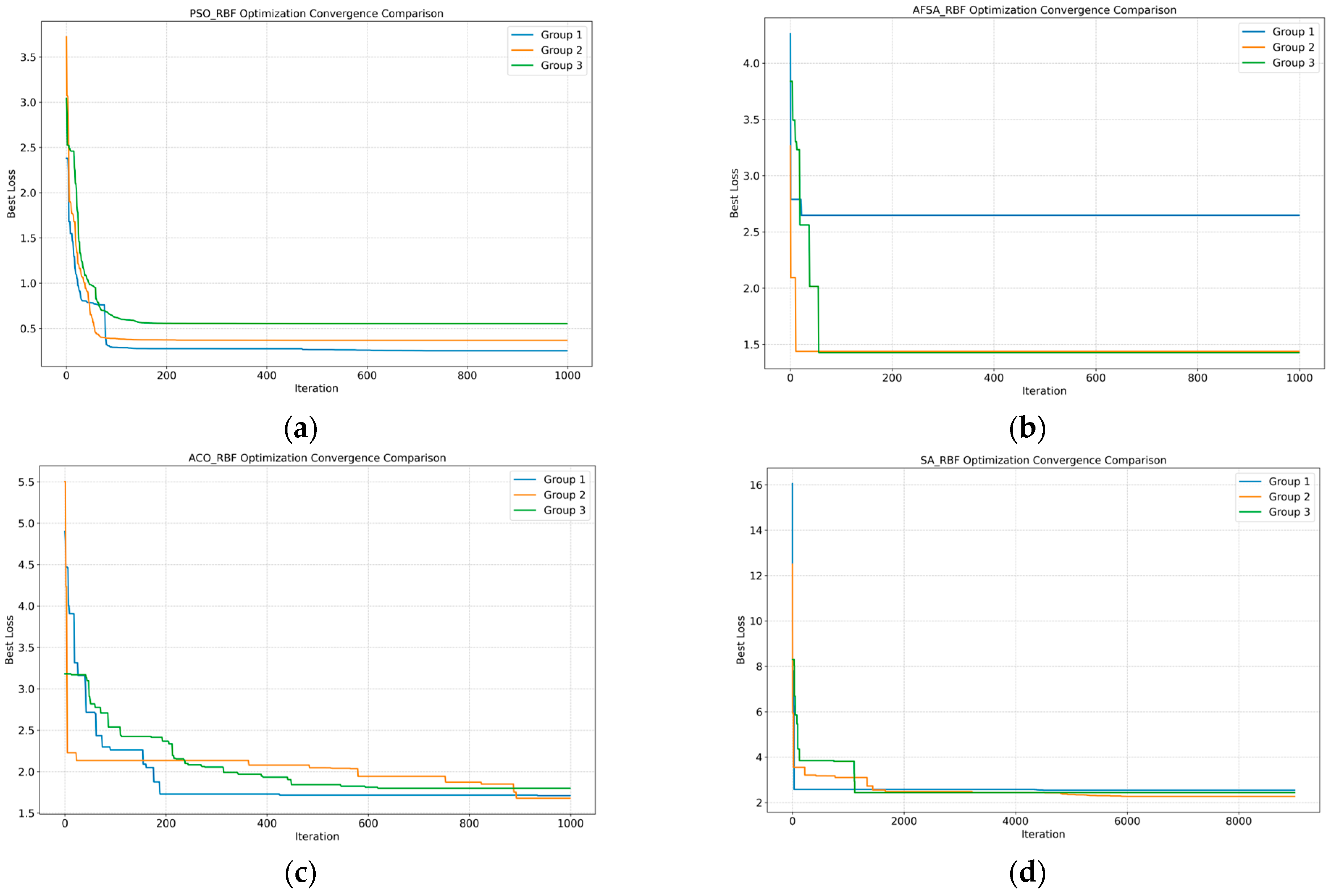

(2) Algorithm Innovation: An improved Particle Swarm Optimized Radial Basis Function (IPSO-RBF) neural network model is proposed. The novelty lies in the IPSO algorithm’s incorporation of dynamic inertia weights and a periodic particle reset mechanism, effectively overcoming the tendencies of standard PSO to premature convergence and RBF parameters to settle into local optima, thereby achieving superior predictive performance and robustness.

(3) Application Innovation: The aforementioned hybrid framework and algorithm are, for the first time, systematically applied to conflict detection in the detailed design of piping within a large cruise ship’s water supply system, filling a research gap in this specific domain. Experimental results demonstrate that the proposed method outperforms several mainstream models combining intelligent optimization algorithms in terms of detection accuracy and robustness.

The remainder of this paper is structured as follows:

Section 2 reviews the related literature.

Section 3 details the proposed conflict detection methodology.

Section 4 validates the effectiveness and superiority of the method through design instances from the water supply system. Finally,

Section 5 concludes the paper.

2. Literature Review

In contemporary shipbuilding and large-scale engineering design, the concepts of Building Information Modeling (BIM) and Product Lifecycle Management (PLM) are deeply integrated into specialized software ecosystems, such as AVEVA Marine, Ship Constructor, and NAPA. These platforms form the core working environment for modern cruise ship design. Their built-in conflict detection modules, which primarily rely on geometric rules and spatial interference analysis (e.g., clash detection), can efficiently identify physical collisions between pipes, cable trays, and structural members. Such methods are highly effective for resolving conflicts involving known, parametrizable geometric constraints and have become part of the standard industry workflow.

However, the conflict management processes within these industrial software suites possess inherent limitations. Firstly, their detection capabilities are highly dependent on comprehensive and precise 3D geometric information, meaning full-scale analysis can typically only be conducted during the middle or later stages of detailed design. Secondly, and more critically, these tools struggle to effectively handle non-geometric constraints and implicit knowledge. For instance, a design might pass all geometric clash checks flawlessly, yet its piping layout could lead to future maintenance difficulties, system pressure imbalances, or violate operational practices based on specific owner experience. These conflicts stem from complex coupling relationships between disciplines and historical experience, which cannot be fully captured by simple geometric rules or pre-defined parameter lists. The lack of robust modeling and detection capabilities for such “unknown” or “implicit” conflicts in existing tools represents a primary source of design iterations and late-stage modifications.

To compensate for the lack of practical tools, the academic community has conducted extensive explorations in the field of conflict detection. Design conflict detection is a critical step in ensuring the quality of complex product design and has long attracted attention from academia and industry. In the field of ship design, existing research mostly focuses on conflict detection methods based on rules, models, and intelligent algorithms, primarily applied to aspects like ship structural design and load checking. For example, Li et al. [

1] trained four machine learning models, including a Radial Basis Function (RBF) network, to predict the cyclic ultimate strength of stiffened plates in ship bottom structures under combined loads; Yurdakul et al. [

2] used Pareto frontiers to select better main dimension decision schemes among conflicting design criteria; Lee et al. [

3] proposed a hydrodynamic design method for an underwater hull cleaning robot by trading off conflicting design requirements. Regarding interdisciplinary collaboration, scholars often conduct conflict resolution research based on multi-agent systems, such as Lee et al. [

4,

5] who used case-based reasoning conflict resolution strategies to reduce conflicts occurring during interdisciplinary knowledge sharing.

In broader industrial fields, conflict detection methods have also diversified. Guermouche M et al. [

6] used fuzzy ARTAPP neural networks to classify fault-free diesel engine data, determining conflicts between samples based on hyper-rectangles; Khorshid E et al. [

7] detected infeasibility in mechanical design by analyzing inequality constraints and design variables, significantly reducing the number of constraint checks; Fradi M et al. [

8] proposed a method based on category theory to detect conflicts among numerous disciplinary and expert models in the context of mechatronics; Dang et al. [

9] used Convolutional Neural Networks (CNN) for aircraft conflict detection in restricted airspace; Zhou et al. [

10] also focused on conflict detection for aerial vehicles, designing a method based on mathematical calculations like the Hadamard product of matrices to detect conflicts among large numbers of UAVs in airspace.

At the methodological level, Han et al. [

11] proposed a Bayesian network resource conflict model for virtual manufacturing cells to detect the location and quantity of resource conflicts, addressing shortcomings in resource conflict detection; Zhao et al. [

12] proposed a three-layer Bayesian network based on Bayesian network theory, using graphs and qualitative methods to detail the relationships between first-layer causes, second-layer faults, and third-layer symptoms; Zhang et al. [

13] proposed an extended rule model SOECAP to detect design conflicts using fuzzy set theory, addressing the low efficiency of traditional ECA rule reasoning for conflict detection; Bliudze S et al. [

14] proposed an SMT-based conflict detection algorithm and discussed dynamically resolving conflicts based on resource usage priorities; Sun et al. [

15] proposed attribute and rule hierarchy evaluation criteria to detect design conflicts, addressing the lack of strategy quality assessment and constraint consideration in conventional detection methods; Leung [

16] used Radial Basis Functions in Deep Neural Networks (DNN) for feature selection, with experiments verifying an accuracy of up to 99.37% for network attack detection using this method.

Among various conflict detection methods, neural networks [

17] have become one of the mainstream prediction tools due to their powerful nonlinear fitting capability. The RBF neural network (Radial Basis Function Neural Network, RBFNN) is widely used in regression prediction [

18,

19], pattern recognition [

20,

21], and equation solving [

22,

23,

24,

25] due to its local approximation capability and fast learning characteristics. Traditional parameter optimization (e.g., centers, widths, weights) of RBF networks often uses gradient descent methods but is prone to falling into local optima. In recent years, with the development of artificial intelligence technology, various intelligent algorithms have been used to optimize the structure of RBF neural network models. Muneeswaran et al. [

26] used the Tree Seed Algorithm to optimize the clustering centers, widths, and weight values of RBF neural networks; Lin et al. designed a novel Modulated Window RBFNN (MW-RBFNN) with tunable activation functions, using Raised Cosine Radial Basis Functions (RC-RBF) as basic functions and adjusting their shape using exponential functions, then using the combined tunable shape basis functions as the NN’s activation function. Zhao et al. [

27] used the q-Gaussian function as the radial basis function for RBF neural networks and used the Particle Swarm Optimization algorithm to select network parameters; Zheng et al. [

28] designed a nearest-neighbor-based clustering algorithm for training RBF neural networks to reduce the number of parameters optimized during model structure training.

Besides these, metaheuristic algorithms such as Genetic Algorithm (GA) [

29], Simulated Annealing (SA) [

30], Ant Colony Optimization (ACO) [

31], Particle Swarm Optimization (PSO) [

32], and Differential Evolution (DE) [

33] have also been used to optimize various neural network model structures, including RBF and BP neural networks. These swarm intelligence optimization algorithms simulate optimization mechanisms in natural phenomena to optimize neural network model structures and promote model fitting quality. These studies fully demonstrate the effectiveness of combining intelligent optimization algorithms with neural networks, providing a feasible technical path for handling unknown and uncertain design constraints.

Although the aforementioned research has made significant progress, obvious limitations remain when applying it to the ultra-complex system of large cruise ships: the detailed design phase of cruise ships is a multi-disciplinary collaborative design process, where the factors considered far exceed those of ordinary products. Existing research mostly focuses on detecting conflicts involving known, explicit constraints, lacking effective modeling and detection means for the large number of implicit, unspecified, or uncertain constraint sets present during the design process. Secondly, at the algorithmic level, traditional optimization algorithms like PSO are prone to premature convergence and getting stuck in local optima, SA algorithms have slow convergence speeds, and ACO algorithms have complex parameter settings and low search efficiency. These limitations result in difficulty meeting the practical engineering requirements for detection accuracy and stability when handling high-dimensional, nonlinear cruise ship design constraint problems.

Simultaneously, most existing conflict detection research focuses on mechanical, architectural, or aerospace fields. Public literature on conflict detection specifically for large cruise ships, especially their internal complex systems (e.g., water supply, ventilation, electrical systems) during detailed design, is relatively scarce. Existing cruise ship design conflict detection methods rely on manual rules or preset models, exhibiting poor adaptability to unknown constraints. Addressing the above problems, this paper transforms conflict detection into a Constraint Satisfaction Problem (CSP) through a design constraint model, thereby proposing a hybrid framework for conflict detection in the detailed design of large cruise ships: using interval propagation algorithms for rapid verification of known constraints; and for unknown constraints, utilizing the global search capability of IPSO to optimize RBF parameters, combined with the nonlinear mapping capability of radial basis functions, to achieve intelligent prediction of conflicts.

3. Conflict Detection Method for Large Cruise Ship Detailed Design

In the detailed design phase of a cruise ship, all design variables are interconnected through various design constraint relationships, forming the overall design constraint network for this phase. Therefore, the detailed design phase of a cruise ship is essentially the process of finding reasonable assignments for design variables. This process can be transformed into solving a Constraint Satisfaction Problem (CSP).

A CSP can be described by a set of design variables

X, a domain set

I, and a set of related design constraints

C. A CSP can consist of

n variables and

m constraints, as shown in Equation (1).

where

represents the set of design variables;

represents the domain set, which is the value range of the design variables,

is the domain of

;

represents the set of design constraint conditions. Design constraints can be divided into two parts: the set of variables constrained by the constraint and the set defining the constraint relation, i.e.,

.

represents the set of variables constrained by design constraint

, and

represents the constraint relation on the set of design variables

, where

is the Cartesian product.

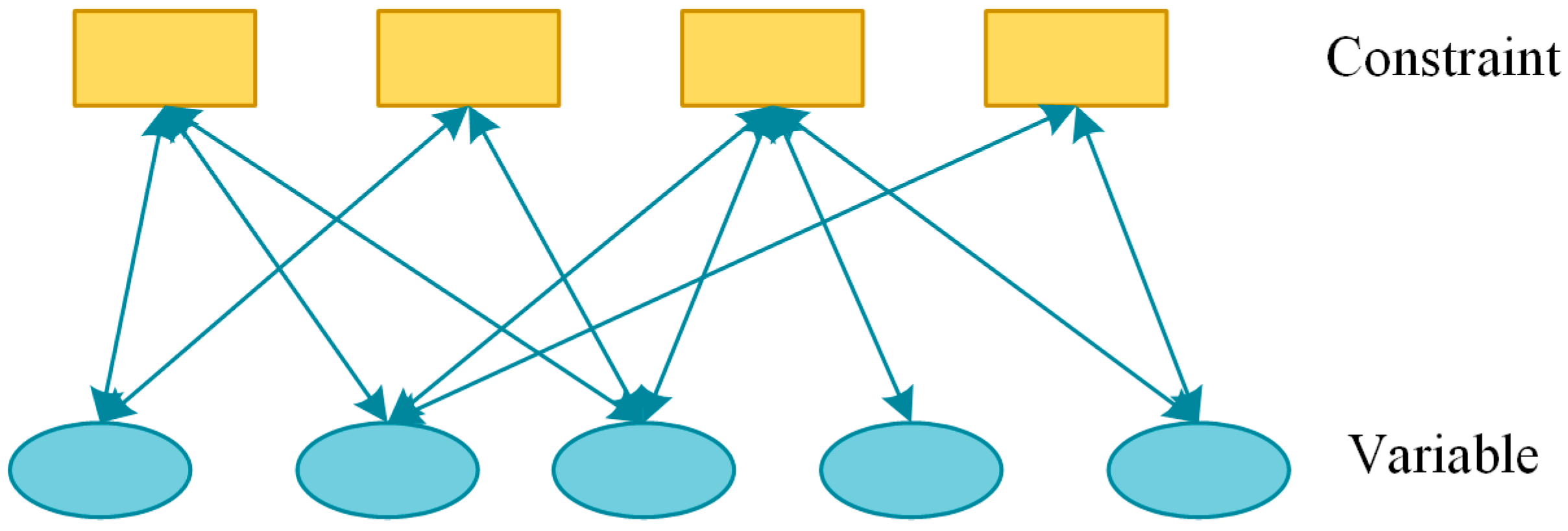

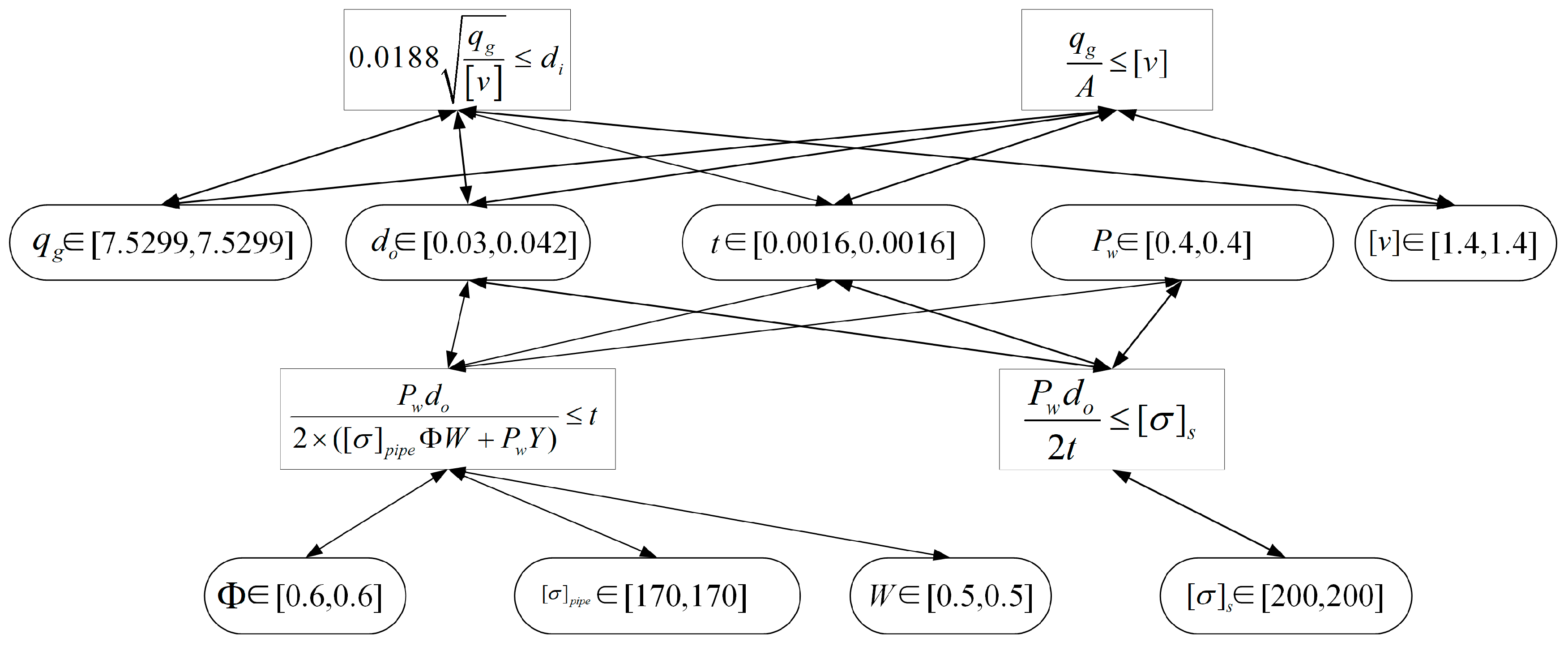

The design constraints form a constraint network, which can determine whether the design variables satisfy the constraint conditions. The constraint network for design conflict detection is shown in

Figure 4.

A solution to the CSP is expressed as

where

represents the projection of design variable

onto

;

represents all relations in the constraint network.

Solving a CSP involves searching within the value ranges of all design variables to find at least one assignment that satisfies all constraints. If has a solution, no design conflict exists; if no solution exists, a design conflict is present.

During the detailed design phase of a cruise ship, as the design deepens and iteratively optimizes, the set of design constraint relationships can be divided into a known constraint set and an unknown constraint set . The known constraint set refers to the explicitly defined constraints between different disciplines. The unknown constraint set refers to constraints that are not yet explicit or may emerge during the future design process. As information exchange between disciplines strengthens, the unknown constraint set will gradually become explicit and transform into the known constraint set.

Therefore, research on conflict detection methods for large cruise ship detailed design is conducted from two perspectives: conflict detection methods under known constraints and conflict detection methods under unknown constraints.

3.1. Known Constraint Conflict Detection Method Based on Interval Propagation Algorithm

In the cruise ship detailed design constraint network, selecting an appropriate conflict detection method for the known constraint set

is crucial. The primary method for conflict detection in the known constraint set

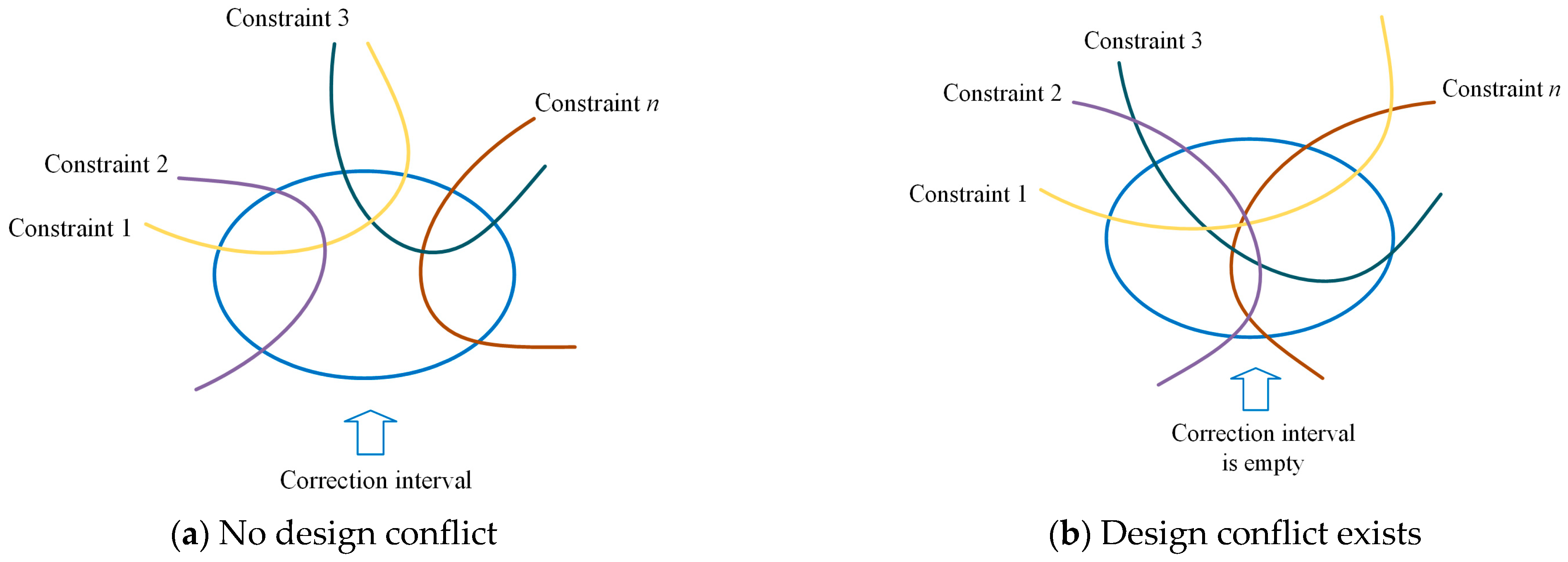

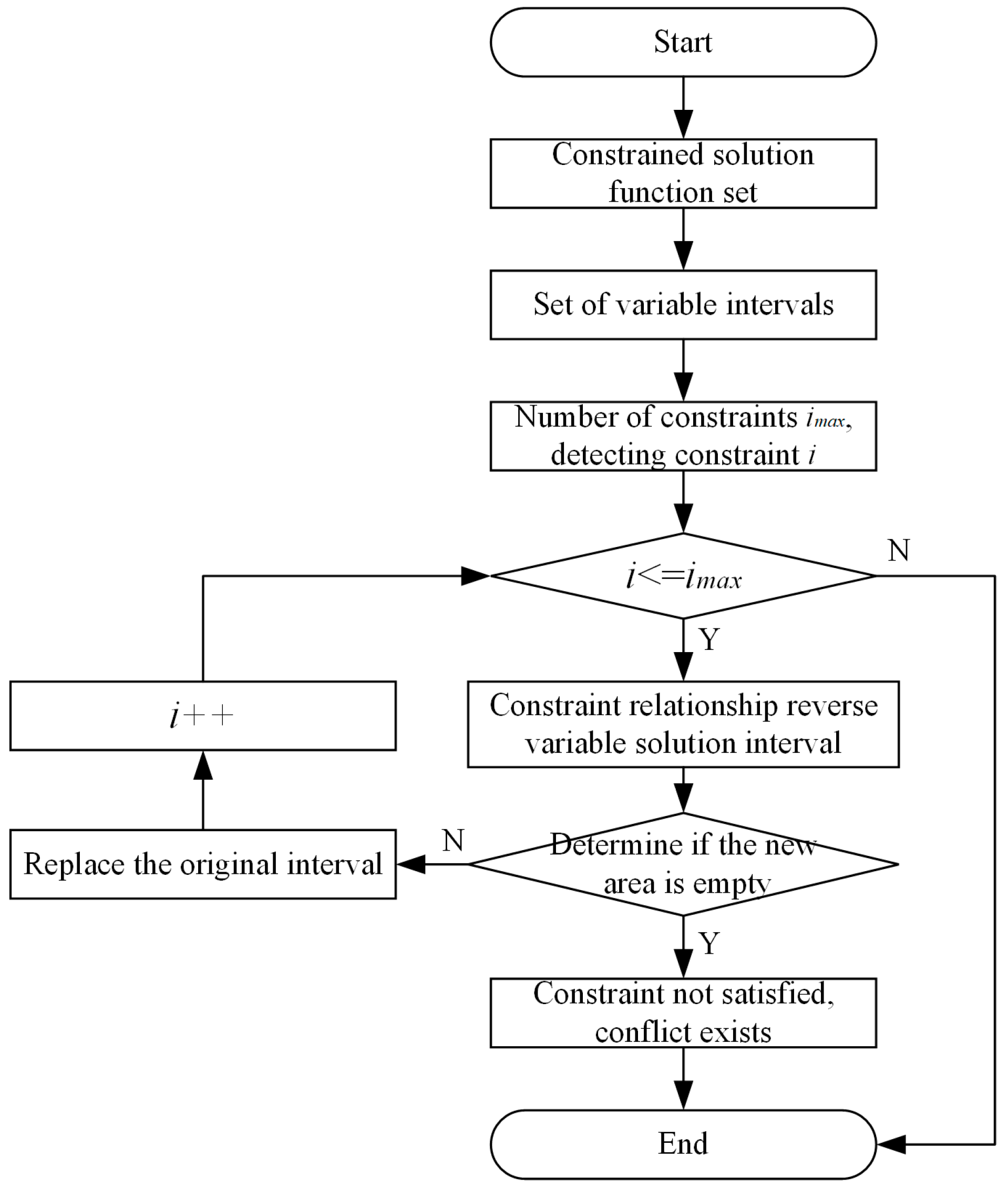

is the interval propagation algorithm. The interval propagation algorithm is a process of gradually refining the value intervals of design variables, as shown in

Figure 5.

When solving for cruise ship detailed design variables, the interval propagation algorithm can be regarded as an extension of real number arithmetic. In a CSP, ensuring all design constraints are satisfied, the interval propagation algorithm can adjust the value ranges of design variables.

For ease of computation, the upper and lower limits of the design variable value intervals are used to represent calculation results during the operation of the interval propagation algorithm. For any two design variables

,

, the basic arithmetic rules are shown in Equation (3).

The interval propagation algorithm analyzes the changes in the value ranges of design variables under the influence of design constraints to determine the feasible interval for a design variable under the action of the constraint set . Let the domain of design variable be . The new domain of under the action of constraint is .

represents inversely determining the feasible interval for

via constraint

. The final feasible solution intervals for each design variable are determined through the interval propagation algorithm. If the new feasible solution space for a design variable

, the domain of design variable

is continuously updated until a stable feasible solution interval is found or the function set becomes empty. If during the update process the feasible solution space of any design variable becomes empty, i.e.,

, it indicates that no design variable assignment satisfies all design constraints, meaning a design conflict exists during the design process.

Figure 6 shows the process of interval propagation algorithm. The steps of the interval propagation algorithm are as follows:

Step 1: Initialize the function set , and the design variable intervals .

Step 2: For each , use the interval propagation algorithm to solve the feasible interval for design variable .

Step 3: Judge . If , a design conflict exists; otherwise, set .

Step 4: Judge whether the function set is empty. If , execute Step 2; if , the interval propagation algorithm ends.

The interval propagation algorithm improves solving efficiency by continuously reducing the problem scale, does not rely on specific design experience, and gradually approaches the real design solution. Therefore, this paper uses the interval propagation algorithm to detect design conflicts in the known design constraint set during the cruise ship detailed design phase.

3.2. Unknown Constraint Conflict Detection Method Based on Improved PSO-RBF

At the beginning of the cruise ship detailed design phase, it is difficult to determine all design constraints, and the interval propagation algorithm cannot detect design conflicts under uncertain constraint conditions. Since the relationship between unknown constraints and conflicts exhibits highly complex nonlinearity, and the degree of influence between different design constraints varies, other methods are needed to detect design conflicts.

Owing to the highly complex nonlinear relationship between unknown constraints and conflicts, a powerful nonlinear mapping model is required. The Radial Basis Function (RBF) neural network was selected as the base model in this study due to its simple structure, fast convergence speed, and property of possessing a unique best approximation. However, the performance of traditional RBF neural networks is critically dependent on the selection of center values and widths, and they are prone to becoming trapped in local optima.

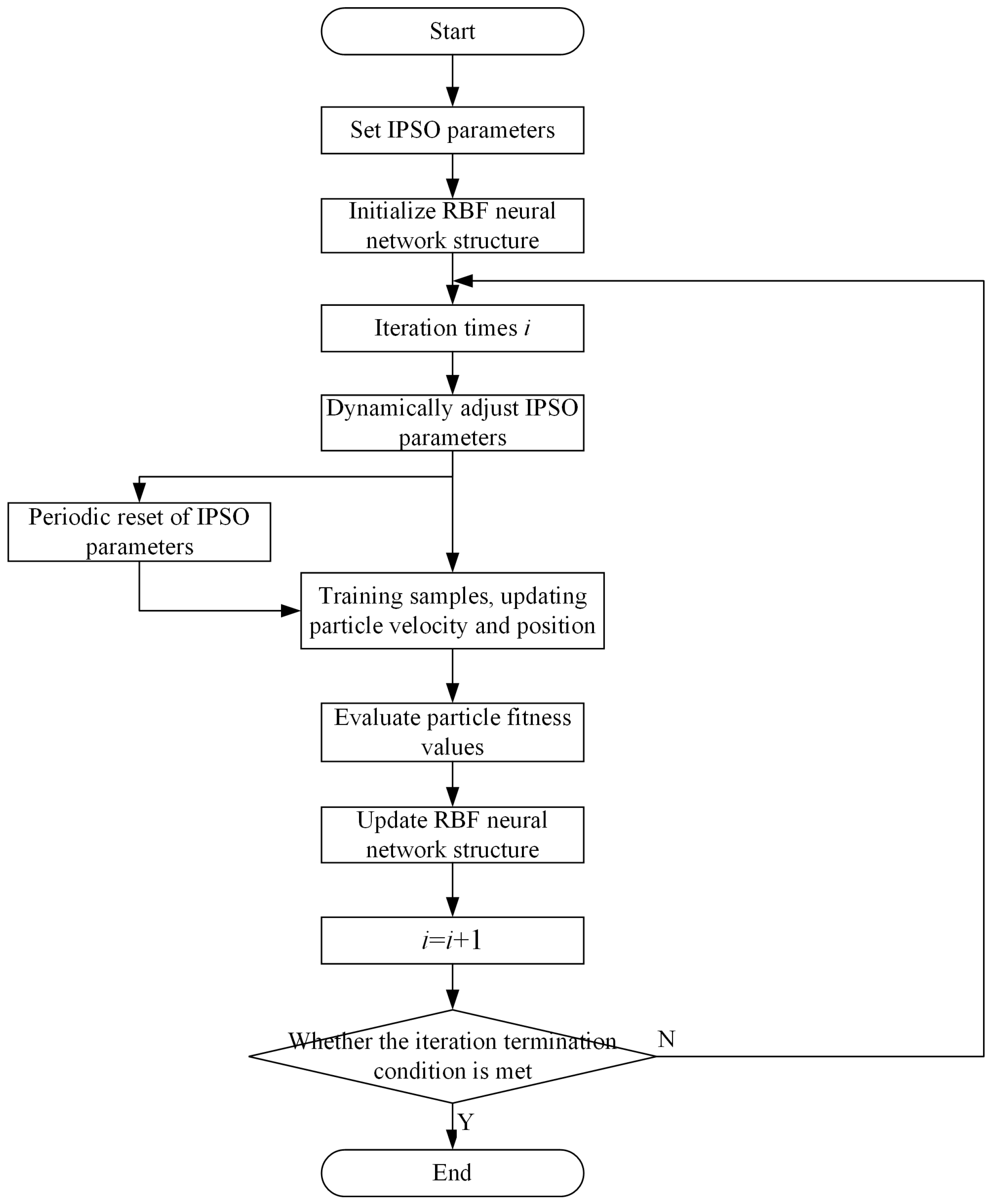

To address this, an Improved Particle Swarm Optimization (IPSO) algorithm is proposed for optimizing the parameters of the RBF neural network. The innovations and advantages of IPSO over standard PSO and other optimization algorithms are as follows: (1) Dynamic Inertia Weight: A strategy employing a decremental inertia weight, as defined in Equations (12)–(14), is adopted. This strategy maintains a higher value in the early iterations to facilitate global exploration and rapidly reduces it in the later stages to enhance local exploitation, thereby achieving a superior balance between exploration and exploitation. (2) Periodic Particle Reset Mechanism: Inspired by the mutation operator in Genetic Algorithms, this mechanism periodically resets the positions of a subset of particles. This injects new diversity into the swarm, effectively preventing premature convergence.

By jointly optimizing the centers, widths, and weights of the RBF network using IPSO, and employing the cross-entropy loss function as the optimization objective, this study aims to construct a conflict prediction model (IPSO-RBF) that exhibits both high accuracy and strong robustness, thereby addressing the challenges posed by unknown constraints in cruise ship design.

3.2.1. RBF Neural Network Model

The RBF neural network is a three-layer feedforward network, with its structure shown in

Figure 7.

The RBF neural network includes an input layer, a hidden layer, and an output layer.

(1) Input Layer: Transmits input data to the hidden layer. The number of nodes is consistent with the dimensionality of the design variables. The input layer receives normalized design parameters.

Different units of input data can degrade model performance and slow convergence; thus, data normalization is necessary for the neural network to better learn patterns within the data. Given the initial input sample data matrix

, this paper uses the Min-Max scaling method to scale the input cruise ship detailed design data to the range [0.1, 0.9], as shown in Equation (4).

where

represents the initial input design variable;

represents the minimum value of the input design variable;

represents the maximum value of the input design variable;

represents the result after normalizing the design variable data.

(2) Hidden Layer: Uses radial basis functions as activation functions. The number of hidden layer nodes is determined by the complexity of the problem.

This paper uses the Gaussian function as the radial basis function. The radial basis function for the i-th hidden layer node is shown in Equation (5).

where

is the normalized input vector,

is the center point of the i-th hidden layer node, and

is the width parameter of the i-th hidden layer node.

The conflict detection problem addressed in this paper is a binary classification problem. To improve the numerical stability of the output layer and enhance fitting quality, normalization is performed again after the hidden layer output:

where

and

are the mean and standard deviation of all sample output values for the i-th hidden layer node, respectively,

is the number of samples, and

is used for numerical stability.

(3) Output Layer: Produces the prediction result through a linear weighted combination of the hidden layer outputs.

where

represents the output result of the neural network;

represents the weight from the i-th hidden layer node to the output layer.

3.2.2. Improved Particle Swarm Optimization Algorithm

The PSO algorithm finds the optimal solution by simulating the information-sharing strategy in bird flock foraging behavior. During the optimization process, each particle represents a potential solution. In each iteration, particles update their velocity and position based on their individual best position and the global best position .

(1) Velocity and Position Update

Assume at the t-th iteration, the velocity of the k-th particle is

and its position is

. Then, the velocity and position update formulas for the next iteration are given by Equation (10):

where

is the inertia weight,

is the individual learning factor,

is the social learning factor, and

is a random factor.

To enhance the PSO algorithm’s ability to search for the optimal solution, this paper designs dynamic parameter adjustment strategies and a particle reset mechanism.

(2) Dynamic Parameter Adjustment

The inertia weight

: a larger

increases the ability to search globally for potential optimal solutions, while a smaller

enhances fine local search capability around known optimal solutions. This paper uses a linear decreasing strategy to adjust the inertia weight. Among them,

is the maximum inertia weight and

is the minimum inertia weight:

where

is the total number of iterations. Similarly, a linear decreasing strategy is used to update the individual learning factor, reducing the particle’s reliance on historical experience; a linear increasing strategy is used to update the social learning factor, enhancing the particle’s learning from the global optimum.

and

are the maximum and minimum individual learning factors, and

and

are the maximum and minimum social learning factors, respectively.

To avoid premature convergence of the PSO algorithm during multiple optimization iterations, this paper sets a rule to reset a portion of particles every iterations, reinitializing their velocity and position parameters. The particle initialization and reset strategies are detailed in the next section.

3.2.3. IPSO Algorithm for Optimizing RBF Neural Network Model Structure

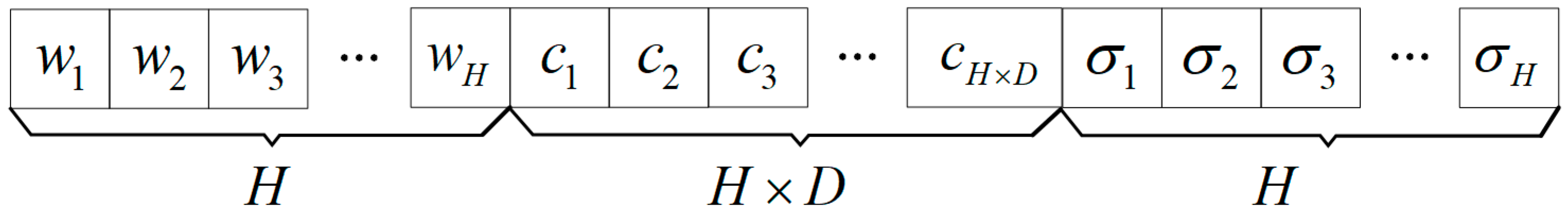

The neural network model primarily includes three parameters: center points , widths , and weights . Among them, defines the central position of the “perceptive range” for each radial basis function; controls the spread of the radial basis function, determining the influence radius of each node; adjusts the contribution degree of hidden layer nodes to the output. These three parameters determine the detection performance of the RBF neural network. Therefore, to ensure good fitting performance of the RBF neural network, an optimal parameter combination needs to be set for the model.

(1) Parameter Encoding

Let the design variable dimensionality be D, and the number of RBF hidden layer nodes be H. The dimensionality of the RBF neural network model parameter vector is set as follows: center matrix , width vector , weight vector . The total parameter dimensionality is .

This paper flattens the parameter vector into a 1-dimensional vector and uses this parameter vector of length as the particle position vector . The position vector of the k-th particle is set as. .

Parameter encoding is illustrated in

Figure 8.

(2) Initialization Strategy

(i) Center Points

The RBF neural network has H hidden layer nodes. Therefore,

H distinct samples are randomly selected from the training data as the initial center points for the RBF, avoiding random initialization that might lead parameters to deviate from valid regions. These are then flattened into a 1-dimensional vector.

(ii) Widths

Given the input sample data matrix

used for training, values are randomly and uniformly sampled based on the value range of the training sample matrix to adapt to input features of different scales. The number of values taken is equal to the number of hidden layer nodes

H:

where

and

represent the maximum and minimum values in the sample matrix, respectively.

(iii) Weights

Weights are randomly and uniformly sampled in the interval (−0.5, 0.5). The number of values taken is equal to the number of hidden layer nodes

H.

(iv) Particle Position

After initializing the above three parameters, they are concatenated and a random disturbance is added to avoid overfitting during algorithm optimization:

(v) Particle Velocity

Particle velocities are randomly and uniformly sampled in the interval (−0.1, 0.1). The number of values taken is equal to the parameter encoding size P.

(3) Periodic Particle Reset

To prevent overfitting when the PSO algorithm optimizes the RBF network structure, this paper refers to the mutation mechanism in Genetic Algorithms, introducing new individuals to avoid premature convergence. It is set to reset 10% of the particles every 10 iterations, reinitializing their positions and velocities. The method for generating new parameters is consistent with the initialization phase.

(4) Velocity Limiting

To prevent oscillations or overflow due to excessively large particle velocities leading to large steps, or narrow search ranges due to excessively small velocities, this paper sets velocity limits to stabilize the convergence process. For the velocity vector of the k-th particle, the value range for each velocity element

is given by Equation (22), and

is the maximum speed limit:

(5) Fitness Function

To prevent model overfitting, the cross-entropy loss function is used as the fitness function for the PSO algorithm:

where

is the true label of the input sample,

is the model’s predicted label, and n is the total number of samples.

After each iteration, the current fitness value is compared with the historical best fitness value, and the individual best and global best are updated.

The algorithm flow of IPSO improving RBF neural network is shown in

Figure 9:

(6) Conflict Detection

To achieve a binary classification result (whether a conflict exists in the large cruise ship detailed design), this paper uses the sigmoid function to transform the linearly weighted output of the RBF. A threshold judgment method is then applied to convert the processed predicted value into a binary (0, 1) label, which can be compared with the true target value in the input sample. A label of “1” indicates that the design scheme indeed triggered a conflict requiring modification in subsequent design stages, whereas a label of “0” signifies that the scheme successfully passed all reviews without any conflicts. This labeling criterion is objectively established based on whether the design scheme subsequently triggered a formally issued design change request during later project phases, such as production design or construction preparation, thereby ensuring the objectivity and accuracy of the conflict labels.

5. Conclusions

This paper addresses the frequent occurrence of design conflicts in multi-disciplinary collaboration during the detailed design phase of large cruise ships by proposing a hybrid conflict detection framework based on the Constraint Satisfaction Problem (CSP). The innovation of this framework lies in its “divide-and-conquer” strategy, which categorizes complex design constraints into known constraint sets and unknown constraint sets, providing targeted solutions for each.

The main conclusions and contributions of this research can be summarized as follows: (1) A hierarchical hybrid detection framework was proposed: For known, explicitly modellable constraints, an interval propagation algorithm was employed for rapid, automated reasoning and verification, enabling early screening of conflicts. For implicit constraints that are difficult to define explicitly, an IPSO-RBF intelligent prediction model was constructed. This model learns conflict patterns from historical data, achieving high-precision detection of conflicts arising from unknown constraints. (2) Algorithmic innovation and performance enhancement were achieved: The standard PSO algorithm was effectively improved by introducing a dynamic inertia weight and a periodic particle reset mechanism. The optimized IPSO algorithm significantly enhanced the ability to optimize RBF neural network parameters, overcoming the tendency to fall into local optima. Experimental results demonstrate that the IPSO-RBF model’s accuracy, precision, and recall on the test set (94.0%, 94.9%, and 98.94%, respectively) significantly outperform those of mainstream comparative models like PSO-RBF and AFSA-RBF. Particularly, its high recall rate of 98.94% adequately meets the core requirement for risk control in engineering practice. (3) Engineering integration and application value were clarified: This research does not aim to replace the basic conflict detection functions in existing CAD/PLM systems but rather serves as an enhancement and supplement. The proposed method can be integrated into the existing design workflow as an independent intelligent detection service. After completing a preliminary design in the PLM system, designers can invoke the algorithm developed herein for in-depth conflict analysis. The system then feeds the generated conflict report back to the PLM platform, guiding designers to conduct focused review and optimization, thereby forming a closed-loop workflow of “design—intelligent detection—feedback and optimization”. This front-load conflict resolution, improving overall design efficiency and quality.

Research proves that the solution framework designed in this paper for known and unknown constraint conflicts can serve as a reference tool for designers in conflict detection, effectively guiding design practice. With some component adjustments or encoding modifications, this method could also serve as a tool to support detailed design for other types of ships or to support detection involving non-numerical data, thereby providing a practical and efficient technical solution for conflict detection in the design of large cruise ships and other vessels.

However, this study has limitations that warrant future work: The IPSO process for the RBF network requires numerous iterations, resulting in computational costs higher than some simpler models. Future research will explore more efficient optimization algorithms or distributed computing to enhance efficiency. Furthermore, future work will investigate more representative feature engineering and attempt to introduce deep learning models, such as Graph Neural Networks (GNNs), into conflict detection to more naturally handle the topological and spatial relationships between design objects.