Abstract

This study investigates the water-stability performance and stabilization mechanism of a hybrid-modified dredged muck sampled from the protection channel of the southern seawall, Cangnan County, China, and explores the feasibility of reusing the modified soil as backfill or non-structural fill behind the dike body. The muck was amended with two industrial by-products: (i) coarse-grained spoil excavated from an adjacent power-plant project, serving as a particle-size modifier, and (ii) ordinary Portland cement, acting as the chemical stabilizer. Unconfined compressive strength (UCS) tests were conducted on specimens cured for 7 d and 28 d under both saturated and unsaturated conditions, complemented by scanning electron microscopy (SEM) to elucidate microstructural evolution. An optimal mix proportion that satisfies the prescribed water-stability criterion while maintaining cost-effectiveness was thereby identified. Experimental results demonstrate that cement content, coarse-spoil fraction and curing age govern the water-stability behavior, with cement dosage exerting the most pronounced influence. A 28 d cured blend containing only 5% cement yielded a low water-stability coefficient (31.8%) and negligible post-immersion strength. Conversely, a ternary mixture comprising 40% muck, 60% coarse spoil and 15% cement achieved the highest water stability, recording UCS values of 1582 kPa (saturated) and 2025 kPa (unsaturated), corresponding to 78.1%. These findings provide a theoretical basis and practical guidance for the valorization of waste soils in coastal engineering and for the design/construction of seawalls. These findings not only provide a theoretical basis and practical guidance for the valorization of waste soils in coastal engineering and for the design/construction of seawalls, but also substantially expand the available material source, drive down construction costs, and markedly mitigate the environmental impacts associated with the off-site disposal of excavated waste.

1. Introduction

As a special type of soil, coastal mucky soil is difficult to utilize in engineering due to its significant differences in physical and mechanical properties compared to conventional soil [1]. However, the mucky soil is widely distributed in coastal areas of China, and the treatment of mucky soil is often encountered in the construction, reinforcement, and restoration of seawalls [2,3,4,5]. With the development of social economy and the improvement of ecological protection concept, in densely populated and economically developed coastal areas, the transportation and stacking of engineering spoil have brought many problems, and the balance of earthwork and the disposal of engineering spoil in the engineering area are particularly prominent [6]. The improvement and resource utilization of mucky soil are particularly urgent [7]. By combining engineering practice with soil properties and usage locations, adopting appropriate soil improvement plans and techniques can not only improve the physical and mechanical properties of weak soil layers, but also make full use of them, and balance the use of soil in the region [8,9]. Improving engineering spoil in an economically practical way is expected to play an important role in the management and resource utilization of spoil, while also providing new solutions for environmental protection and green and low-carbon construction of engineering [10,11,12,13,14].

Currently, many scholars have conducted extensive research on the improvement of weak soil [15,16,17]. Wang et al. [18] used carbide slag and fly ash as solidifying agents to improve shield tunneling mucky soil. The compressive strength, immersion stability and durability of the solidified soil were evaluated through unconfined compression tests and wet–dry cycle tests. The test results showed that the strength of the solidified soil first increased and then decreased with the increase in carbide slag and fly ash content, and increased with the increase in solidification age. The modified soil can achieve good immersion stability and durability. Hu et al. [19] compared the effects of three curing processes on the water stability of the samples and found that the in situ curing method had the worst water stability. Therefore, this method should be avoided as much as possible during the construction process. Wang et al. [20] used polyurethane stabilizers to solidify the surface soil of river bank slopes, and analyzed the influence mechanism of the water-stability coefficient by electron microscopy scanning. The results showed that the water-stability coefficient was significantly affected by the polyurethane content and soil density. Yao et al. [21] studied the influence of different compaction degrees and moisture contents on cohesion and internal friction angle through triaxial shear and unconfined compression tests on high liquid limit fill soil of two sections of highway subgrade. The results showed that the internal friction angle greater than the optimal moisture content hardly changed under the same compaction degree. In order to improve the strength and water stability of soft clay, Yi et al. [22] added water glass on the basis of cement and fly ash as curing agents. The influence of water glass on the microstructure of soil was analyzed by X-ray diffraction and electron microscopy. The results showed that the highest strength and water stability were achieved when the mass ratios of cement, fly ash, fly ash and water glass were 3%, 7%, 7% and 2%, respectively. Zhu et al. [23] used strongly weathered rock particles as solidification materials for fluid filled soil and found that the compressive modulus of solidified soil gradually decreased with the addition of strongly weathered rock particles after immersion in water. Fan et al. [24] prepared FG curing agent using organic and inorganic materials, and studied the improvement effect of FG curing agent on the water stability of Yellow River mucky soil. Combined with SEM characterization technology, it was found that the curing agent can effectively bond particle interfaces and fill voids, thereby improving the water stability of the modified soil. Wang et al. [25] studied the feasibility of using environmentally friendly and sustainable magnesium potassium phosphate cement (MKPC) to solidify urban river sludge. The SEM images showed that with the increasing MKPC dosage and age, the crystals became significantly denser, and the microcracks appeared during the hydration and dehydration process due to the influence of surface tension. At the same time, replacing Polish cement with MKPC can improve the efficiency of mechanized construction and play a better role in improving the environment and reducing costs.

The above research results indicate that the improvement of abandoned soil and mucky soil in coastal engineering has practical engineering significance and promotion value. However, the existing research mostly focuses on the basic physical and mechanical properties of mucky soil after improvement [26]. In coastal areas with abundant water, the modified soil faces long-term immersion environments, and its water-stability performance is related to engineering durability and long-term service performance. However, research on this topic remains limited. The damage caused by solidification of mucky soil is mostly due to deformation of the soil when it encounters water. The water stability of the modified mucky soil becomes a key indicator equally important as its strength to measure its comprehensive performance [27]. In this study, the dredged mucky soil obtained from the protective pond river of the seawall project in Cangnan County, Wenzhou City, China, was utilized as the primary research material. This soil was stabilized by blending it with coarse-grained spoil sourced from a nearby power station, along with the incorporation of cement as a binding agent to enhance its engineering properties. Considering the influence of differences in site climate, hydrology and other conditions, the compressive strength and water-stability coefficient of the modified soil are obtained through unconfined compressive strength tests. The morphology and component distribution of the modified soil are also deeply analyzed from a microscopic perspective. This study can provide theoretical basis and technical guidance for the resource utilization of abandoned soil in coastal engineering and the design and construction of seawall engineering.

2. Overview of Study Area

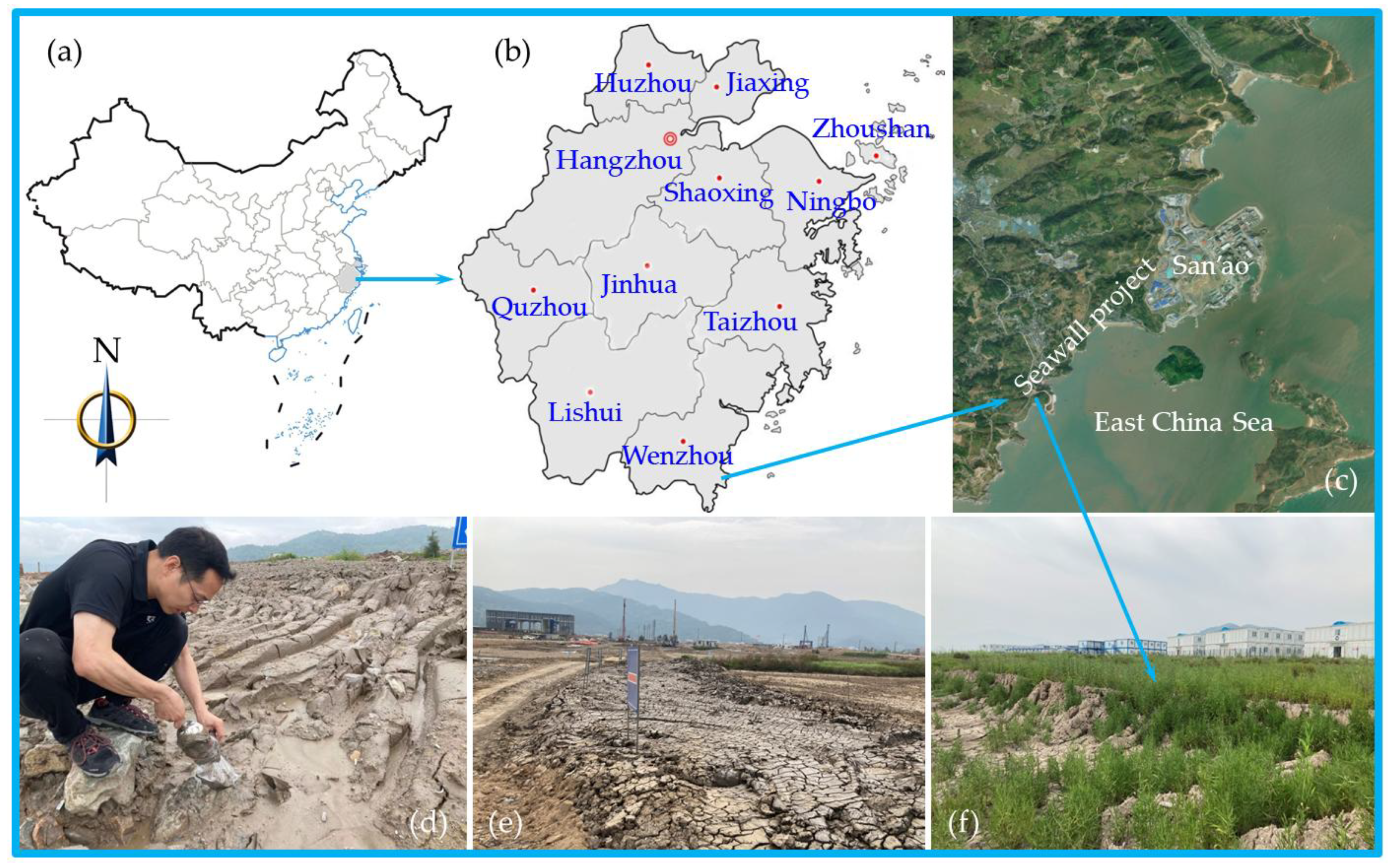

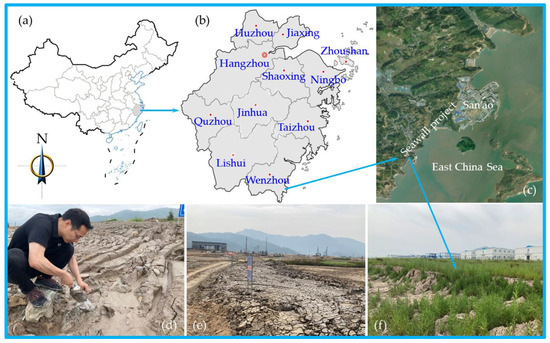

The project site is situated along the southeastern coast of Cangnan County, principally encompassing the coastal zones of Dayuwan and Yanpuwan. Exposed to the open ocean, the area is subject to frequent high winds and heavy seas and is correspondingly among the most typhoon- and flood-prone districts in Zhejiang Province, China. Green Energy Town is positioned in the southern portion of Cangnan County. It is bounded to the northeast by Provincial Highway S232, to the south by a seawall, and to the west by natural water bodies. Located 5 km from the San’ao Nuclear Power Plant, the town functions as a dedicated service and support base whose primary objective is to satisfy the logistical and operational requirements arising during the plant’s construction and subsequent operation. During the initial development phase, the construction of Green Energy Town produced a substantial volume of coarse-grained spoil, dominated by gravel, sandy soil, and silty clay. Concurrently, the seawall project in Cangnan County generated considerable quantities of dredged silt during the excavation of the Hutong River. The geographical setting and general layout of the works are illustrated in Figure 1. The two projects together generate large volumes of surplus soil whose off-site disposal would entail high hauling and tipping charges and, in addition, jeopardize the construction schedule. A synergistic solution is proposed: the coarse-grained spoil produced by Green Energy Town is blended with the soft dredged silt from the Hutang River at the Haitang Anlan site to obtain an improved grain-size distribution; a small dosage of chemical stabilizer is then added to meet geotechnical requirements. The resulting engineered fill can be placed as non-structural backfill behind the seawall. This strategy simultaneously reduces project cost, shortens the construction program and advances the circular use of waste soils.

Figure 1.

Location and overview of the project. (a) Schematic map of China. (b) Schematic map of Zhejiang Province. (c) Location of the project. (d) On-site sampling. (e) Dredged sludge being air-dried. (f) Dredged sludge stockpiled at the construction site.

3. Experimental Materials and Methods

3.1. Experimental Materials

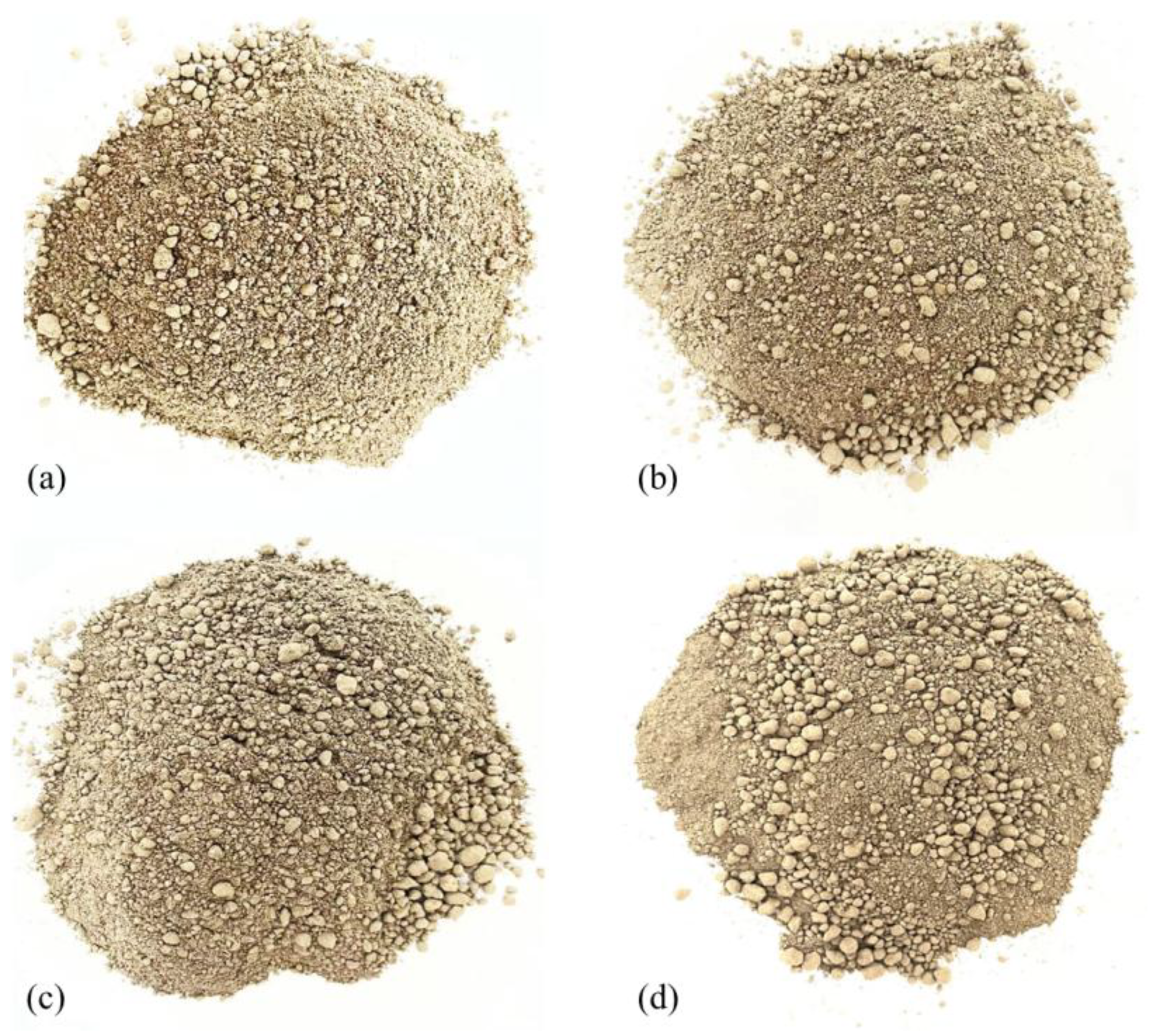

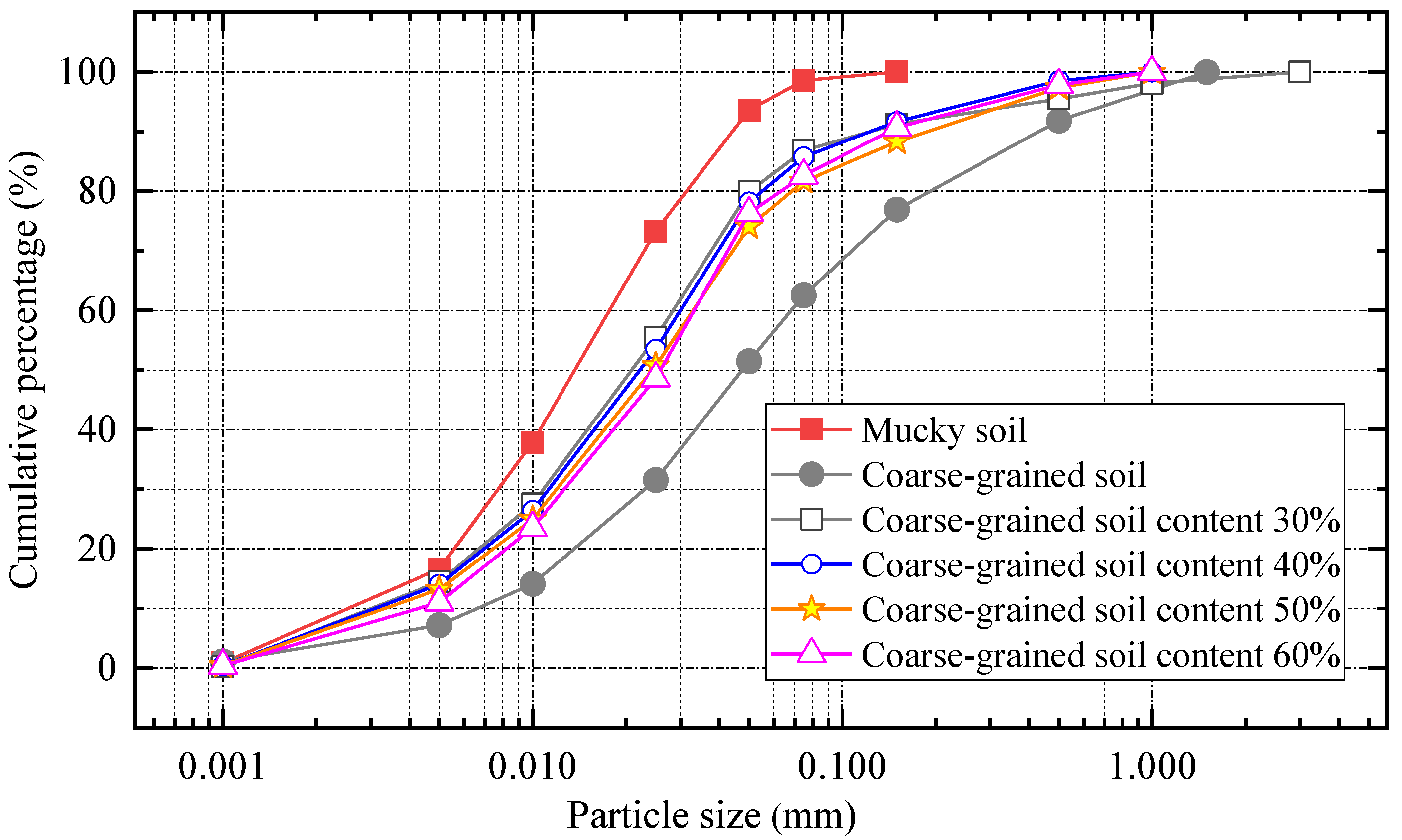

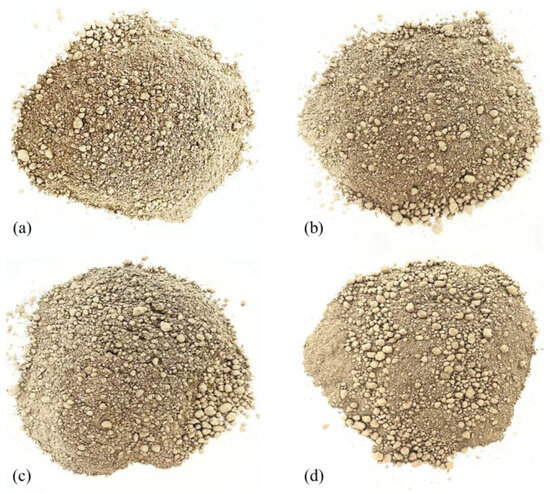

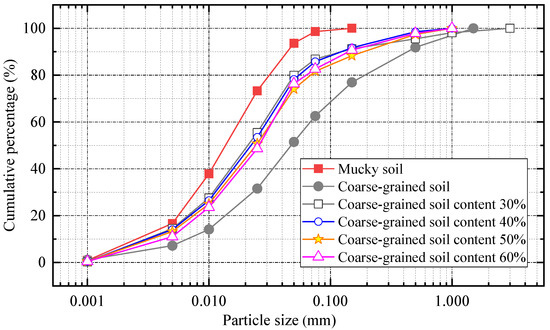

The mucky soil used in the experiment was taken from the Seawall Project in Cangnan County of Wenzhou City, China. The undisturbed mucky soil is grayish-black. After drying, it is noted that the water content of the mucky soil is generally high, among which the water content of the surface mucky soil exceeds 55%. Six groups of representative soil samples are taken on site, and their water contents have little difference. The main physical and mechanical property parameters are shown in Table 1. The coarse-grained soil is affected by rainfall, and the moisture content of two groups of abandoned soil at the construction site is measured to be over 22%. The particle size distribution of the modified soil with single coarse particles (as shown in Figure 2) was determined using a Malvern laser particle size analyzer (Malvern Instruments Ltd., Malvern, UK) [28]. In the particle curve analysis, the powder particles accounted for 84.74% and the clay particles accounted for 77.38%. The particle size distribution curves are shown in Figure 3. The curing agent used is P·O 42.5 Portland cement, and its basic parameters are shown in Table 2. The liquid limit, plastic limit and plasticity index of mucky soil are determined using the STGD-3 photoelectric cone liquid plastic limit combined measuring instrument according to the Chinese standard “Soil Test Method Standard” (GBT 50123-2019) [29]. The experimental plan for multiply modified coastal mucky soil with cement and coarse particle spoil is shown in Table 3.

Table 1.

Basic physical and mechanical parameters of the mucky soil.

Figure 2.

Soil mixed with coarse and fine particles. (a) Coarse-grained soil content 30%. (b) Coarse-grained soil content 40%. (c) Coarse-grained soil content 50%. (d) Coarse-grained soil content 60%.

Figure 3.

Particle size curves of undisturbed mucky soil, coarse-grained soil and their mixtures.

Table 2.

Basic physical compositional parameters of the P·O 42.5 Portland cement.

Table 3.

Test scheme of the modified soil.

3.2. Test Method

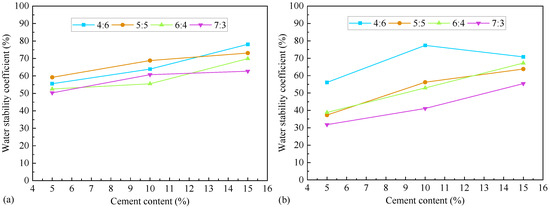

3.2.1. Unconfined Compression Strength Test

The uniaxial unconfined compressive strength refers to the maximum compressive stress that a soil can withstand without lateral constraints. After drying the mucky soil in the laboratory, it is crushed using a soil grinder and sieved through a 2 mm aperture sieve. The coarse grained soil is dried and sieved through a 5 mm aperture sieve. The sieved soil is stored in a sealed bag. According to Table 3, the soil sample is prepared as a cylindrical specimen with a dry density of 1.46 g/cm3, a moisture content of 30%, a diameter of 38 mm and a height of 76 mm. The prepared specimens are placed in an environmental chamber and kept at a safe distance. The curing temperature is set at 20 ± 2 °C and the relative humidity is above 95%. Unconfined compressive strength tests shall be conducted after the curing period reaches 7 d and 28 d. The sample mold and curing box are shown in Figure 4.

Figure 4.

Sample mold and curing box. (a) Sample mold. (b) Curing box.

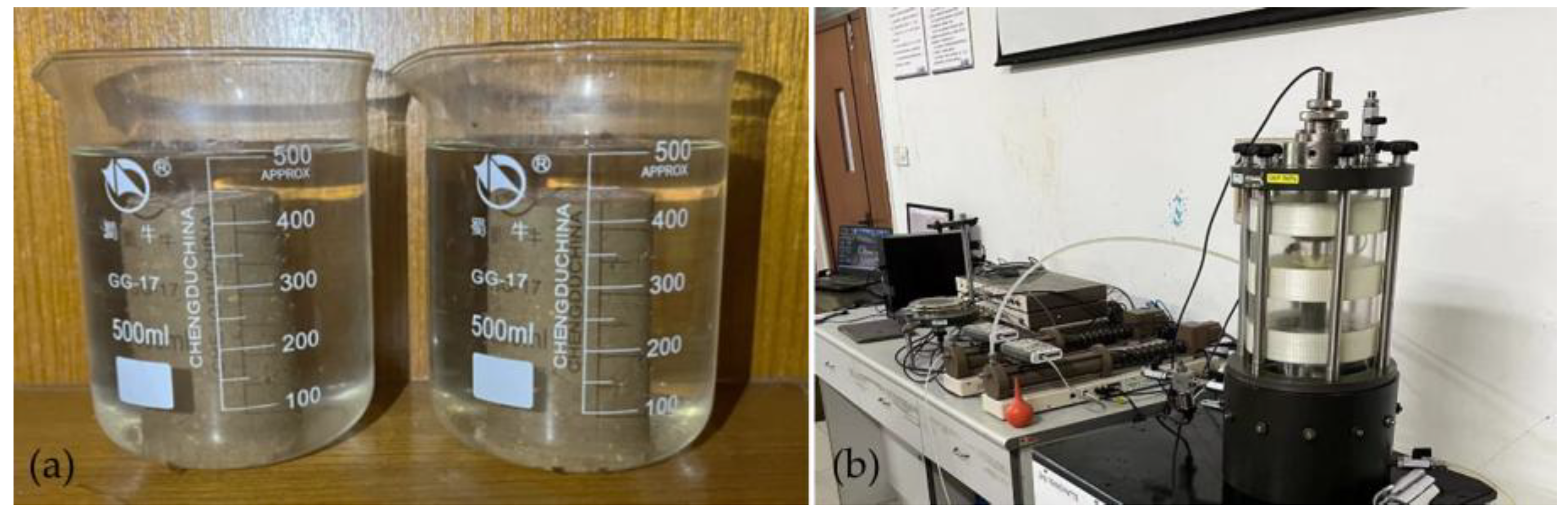

3.2.2. Water Stability Test

The determination of water stability usually includes two methods: immersion test and spray test. This experiment adopts the immersion test method. After curing the specimens for 6 d and 27 d, they are immersed in distilled water at a constant temperature of 22 °C for 24 h. To ensure that the water head height from the top surface of the specimen to the horizontal plane is consistent during immersion, the specimens are placed in a beaker, and 500 mL of water is added each time to maintain the same water level. The unconfined compressive strength test is conducted using a GDS triaxial apparatus. During the test, a cylindrical specimen with both ends flattened and kept perpendicular to the long axis is placed on the base of the triaxial apparatus. According to the Chinese Regulation “Geotechnical Test Regulations” (SL 237-1999) [30], the test loading rate is controlled by a strain-controlled method. The maximum target value of axial strain is set at 8%, and the compression speed is 1 mm/min. Figure 5 shows the immersion and unconfined compressive strength test of the specimen. The water-stability coefficient is generally denoted by [31], and its calculation formula is as follows:

where is the water-stability coefficient; is the unconfined compressive strength after immersion, kPa; is the unconfined compressive strength before immersion, kPa.

Figure 5.

Immersion and unconfined compressive strength test of specimens. (a) Soak the test piece. (b) Unconfined compressive strength test.

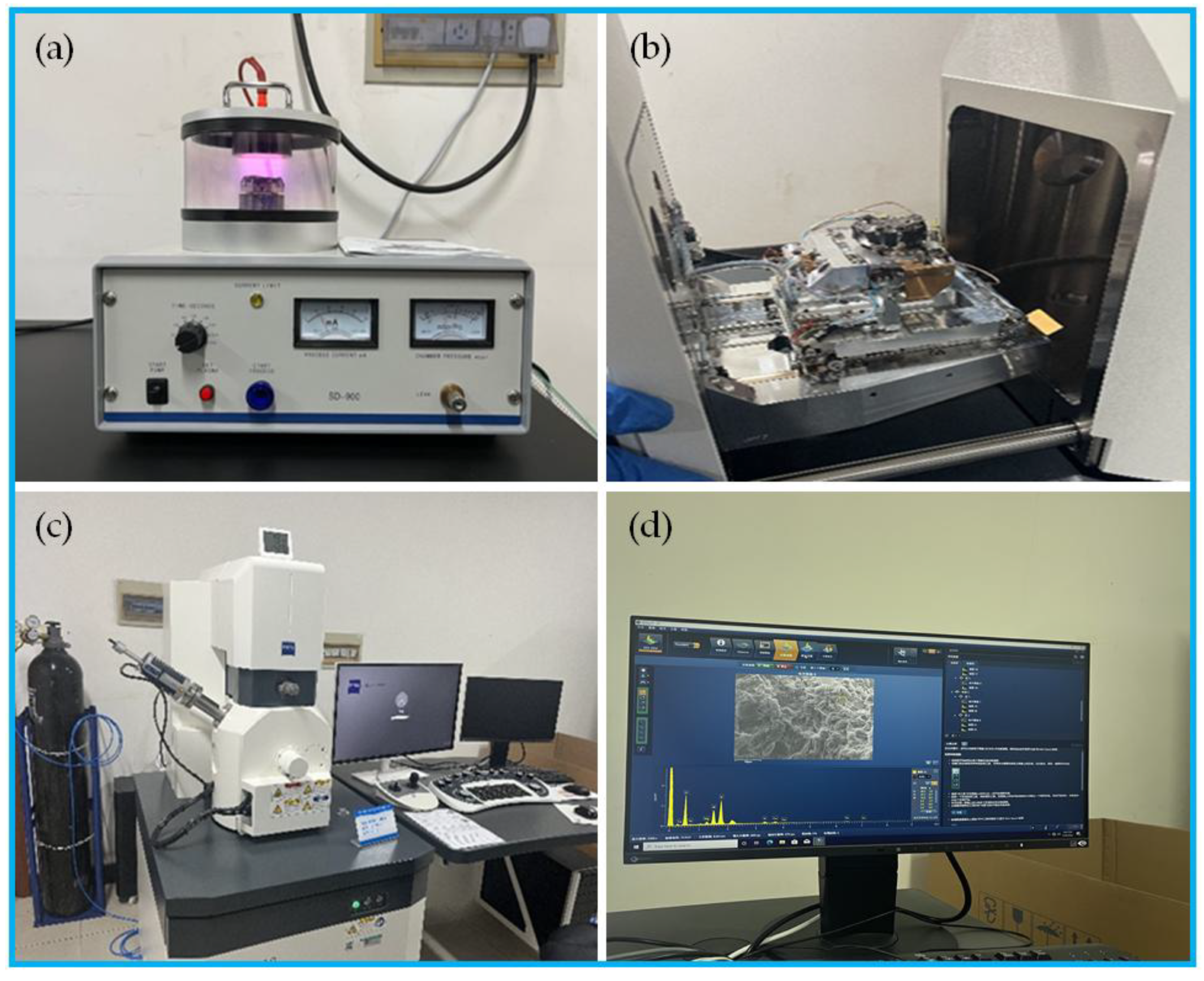

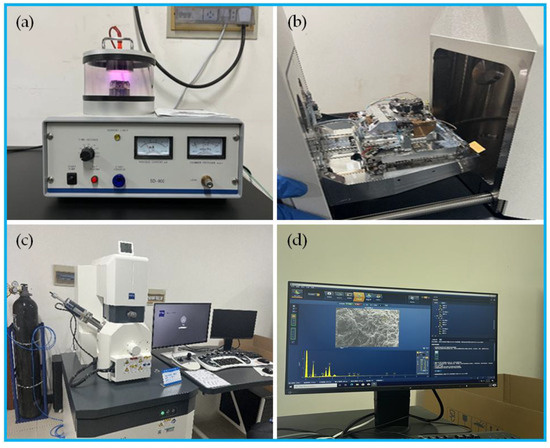

3.2.3. Microstructure Analysis

Electron microscopy (Zeiss EVO10, Carl Zeiss Microscopy GmbH, Oberkochen, Germany, as shown in Figure 6) was employed to characterize the surface morphology and energy-dispersive X-ray spectra of singly and multiply modified coarse soil particles. The micro experiment focuses on the maximum ratio specimen of multiply modified soil compressive strength, and the micro molecular structure and distribution of hydration products of modified soil at different curing ages were analyzed. The representative soil sample was taken from the specimen center, preferably with a flat surface and a size controlled at around 5 mm. The sample was dried for 8 h before testing. Due to the non-conductive nature of the modified soil, to ensure good conductivity and image clarity of the soil sample during the experiment, the soil was sprayed with gold before electron microscopy scanning. During the experiment, the sample was evacuated and sprayed with gold for 30 s, then rotated 180 degrees and sprayed again for another 30 s. The electron microscope scanning test voltage was set to 15 kV, and the appearance of the pattern was observed by magnifying it to 1000 and 2500 times, respectively. The sample was enlarged to 2500 times and select representative locations for EDS (Energy Dispersive Spectroscopy) spectral analysis. In energy spectrum analysis, the excited atoms emit X-rays of specific energy when a sample is exposed to an electron beam or X-ray beam. These X-rays are captured and analyzed by an energy spectrometer, and the results are then converted into an energy spectrum, which displays the intensity distribution of X-rays of different energies.

Figure 6.

Microscopic experimental testing process. (a) Gold sputter coating of the sample. (b) Soil sample loading. (c) SEM (Scanning Electron Microscopy) scanning test. (d) EDS spectral analysis.

4. Results and Discussions

4.1. Unconfined Compression Strength

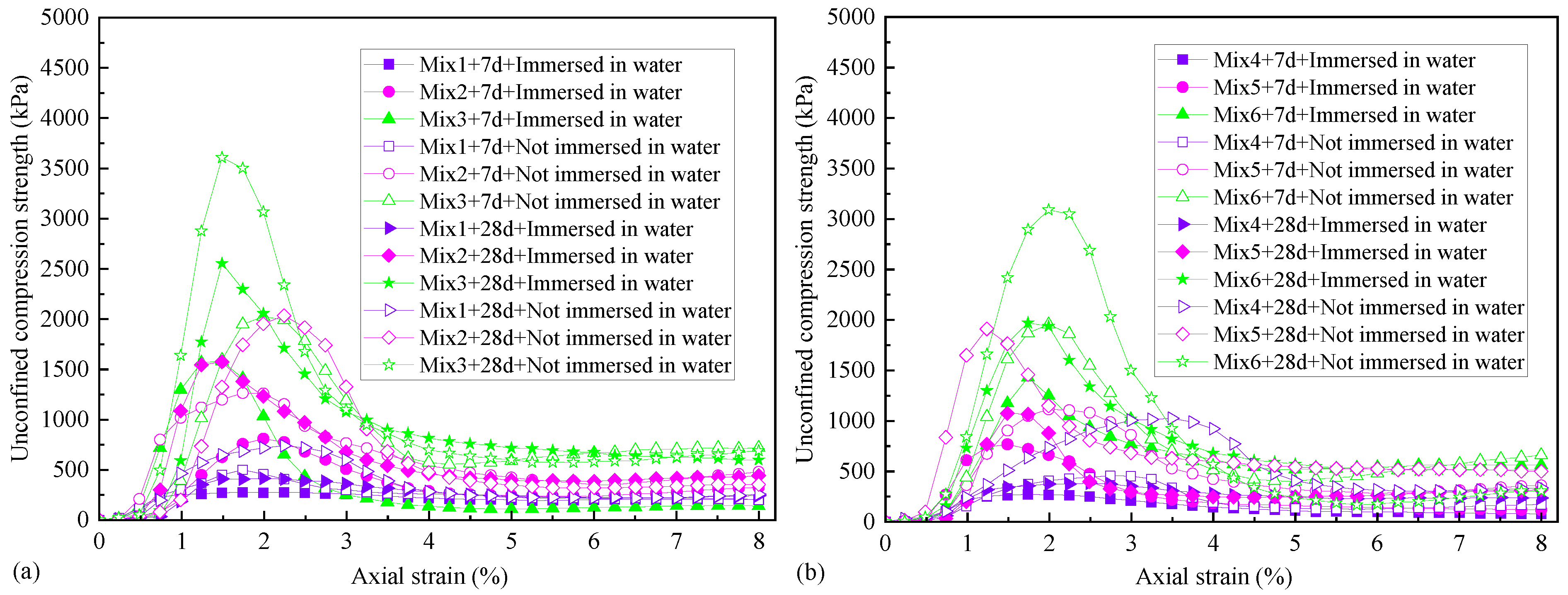

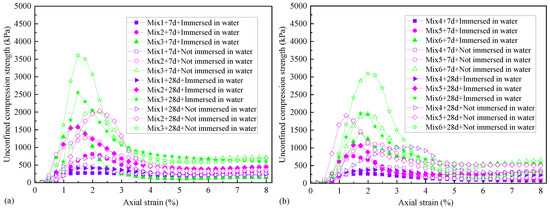

The stress–strain relationship curves obtained from UCS tests of multiply modified soil cured for 7 d and 28 d with and without immersion are shown in Figure 7. The data behind the first “+” sign represent the curing age, and the text behind the second “+” sign represents whether the soil sample is immersed in water.

Figure 7.

Unconfined compressive strength of samples with different proportions of coarse-grained soil and curing ages. (a) Coarse-grained soil content 30%. (b) Coarse-grained soil content 40%. (c) Coarse-grained soil content 50%. (d) Coarse-grained soil content 60%.

From Figure 7, it can be seen that the unconfined compressive strength and compression characteristics of the multiply modified soil at two curing ages are mainly affected by coarse particle soil and cement content. The cement content and curing age are positively correlated with the strength and stiffness of the modified soil. The strength of the soil sample decreases significantly after immersion compared to before immersion, which is consistent with the literature [31]. For the modified soil with a 7 d curing age, the unconfined compressive strength value of the soil with low cement content (5%) is small, and the stress–strain curve relationship shows a significant softening characteristic. The entire compressive failure process takes a long time, and the corresponding axial strain value span is large. The UCS values before and after immersion show an increasing trend with the decreasing coarse particle soil content. The UCS values of the modified soil with 60% and 50% coarse particle soil after immersion tend to approach 270 kPa, and the UCS values of the modified soil with 40% and 30% coarse particle soil after immersion tend to approach 300 kPa. The unconfined compressive strength of medium to high cement content (≥10%) is generally high, and the curing effect is significant. The stress–strain curve shows a hardening trend. The stress–strain curve with 15% cement content has steep peaks and valleys, a shorter compressive failure process, and a smaller span of axial strain values. However, the USC value before and after immersion decreases with the decrease in coarse particle soil content. For the modified soil with an age of 28 d, the increase in unconfined compressive strength with the increasing cement content is more obvious. The UCS value of low cement content (5%) increases with the decreasing coarse particle soil content, but the growth rate at this time is relatively slow and tends to 1000 kPa, which is consistent with the conclusion of the curing age at 7 d. The increase rate of UCS value is more significant when the cement content is larger than 10%. The unconfined compressive strength with a coarse particle soil content of 30–50% is less affected by coarse particle soil content. When the coarse particle soil content is 60% and 15% cement is added, the UCS value of the sample is the highest, reaching 3606 kPa. This is mainly because the hydrated calcium silicate gel (C-S-H gel), hydrated aluminate gel and a small amount of carbonate precipitates produced during the cement hydration process play a role, while the coarse particles themselves have low viscosity; thus, the influence of coarse particle soil content on unconfined compressive strength of modified soil is significantly reduced under the condition of moderate and high cement content during the 28 d curing period.

4.2. Water-Stability Coefficient

The water-stability coefficient is an important indicator of water resistance and erosion resistance in soil mechanics tests, referring to the degree to which the soil is affected by immersion. The quality of water stability depends on factors such as the particle size, shape and compaction degree of soil particles. The water-stability coefficients of the samples at 7 d and 28 d calculated according to Formula (1) are shown in Table 4 and Table 5. The closer the water-stability coefficient is to 1, the more stable the physical and mechanical properties of the specimen, and the better the soil sample’s resistance to immersion. On the contrary, the smaller the coefficient, the more likely the sample surface is to experience phenomena such as peeling and cracking, indicating that the water stability of the modified soil is worse [32].

Table 4.

Water-stability coefficients of the modified soils at 7 d curing age.

Table 5.

Water-stability coefficients of the modified soils at 28 d curing age.

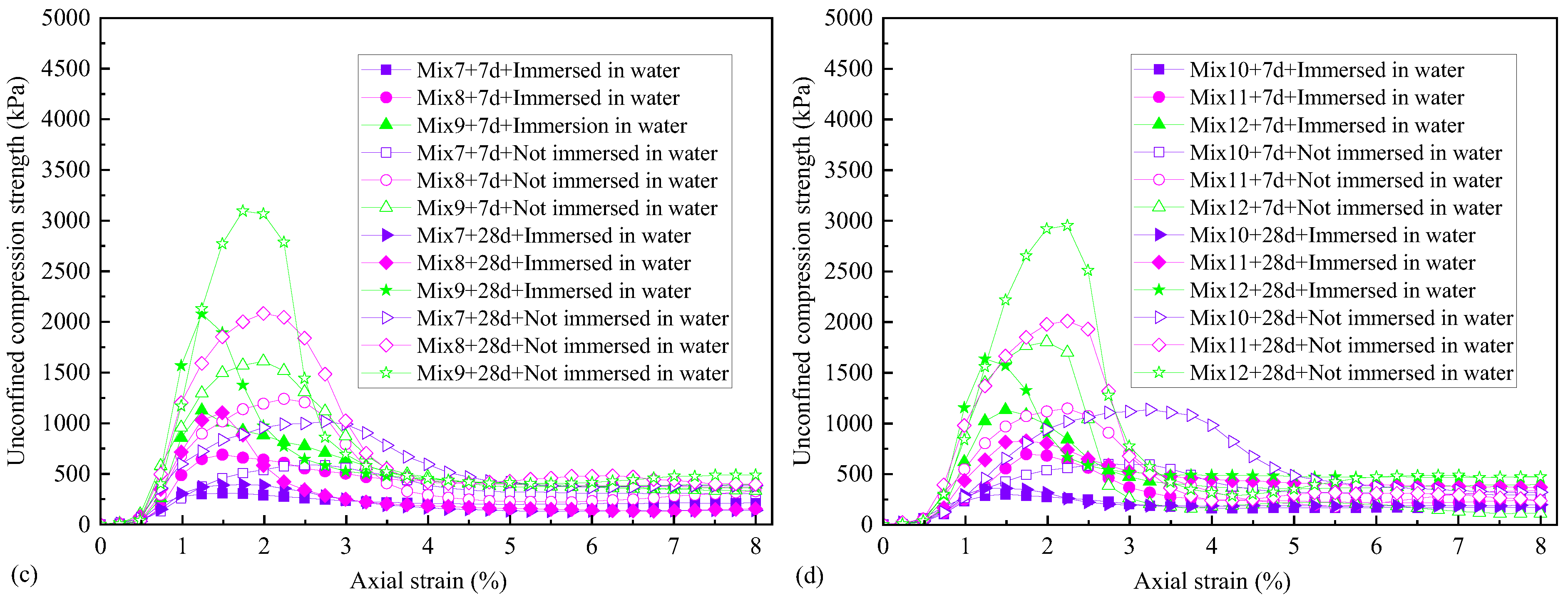

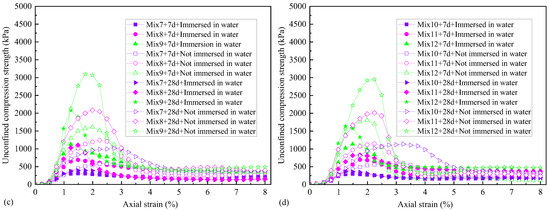

According to Table 4 and Table 5, the unconfined compressive strength of the modified soil with a curing age of 7 d and 28 d after immersion is lower than that before immersion. As the curing age increases, the UCS values before and after immersion increase exponentially. Among them, the UCS value of the non-immersed specimen increased significantly. Compared with the UCS value of 7 d, the UCS value of the specimen at 28 d doubled. After the cement content increased from 5% to 15%, the growth rate of the UCS value of the specimen was also higher. For samples with low cement content (5%) after immersion, the UCS value at 28 d showed little increase compared to the UCS value at 7 d. Additionally, the UCS of the modified soil without immersion with low cement content was lower, and the strength loss after immersion was also smaller, ranging from 59 kPa to 139 kPa. For the samples soaked with medium cement (10%) content, the UCS losses at 7 d and 28 d of curing ages were 31–44% and 22–58%, respectively. The loss after 7 d of curing age was relatively small, while the strength loss span at 28 d was large. For the samples with high cement content (15%) soaked in water, the UCS loss after 7 d and 28 d of curing age was 22–37% and 29–45%, respectively, which was reduced compared to the strength loss with medium cement content (10%). The above experimental results indicate that the modified soil with single coarse particles in the experiment will disintegrate after being immersed in water for a period of time, and the water-stability coefficient of the modified soil with single coarse particles is 0. The relationship between the water-stability coefficients of the sample and the cement contents is shown in Figure 8.

Figure 8.

The relationship between the water-stability coefficients of the sample and cement contents with different curing ages. (a) 7 d curing age; (b) 28 d curing age.

As shown in Figure 8, the water-stability coefficient of the two curing ages linearly increases significantly with the increasing cement content from 5% to 15%, and the regularity becomes more obvious with the increasing curing age. At a curing age of 7 d, the water-stability coefficient of the modified soil with 60% coarse particles has a small dispersion among the three cement proportions. At the 28 d curing age, the regularity of water-stability coefficients becomes more obvious, and its polarization development trend becomes more significant with the decreasing coarse particle content. The water-stability coefficient of the mixture with 60% coarse particles is the highest among the four coarse particle proportions, which is consistent with the conclusion obtained from the experiment at a curing age of 7 d. The sample mixed with 30% coarse particles obtained the lowest coefficient and the worst water stability. This is mainly due to the fact that when the content of mucky soil is much higher than that of coarse particles, the role of coarse particles as a skeleton is smaller, and the properties of the soil sample are more inclined towards the properties of unmodified mucky soil. The soil is easily dispersed when it encounters water, and the moisture in the mucky soil will cause soil particles to form a thin water film with water molecules, thereby reducing the friction between particles and increasing the fluidity between particles. There is not much difference in the water-stability coefficient of the modified soil at 28 d curing age when the coarse particle content reaches 40% and 50%.

4.3. Microstructure Analyses of Modified Soil

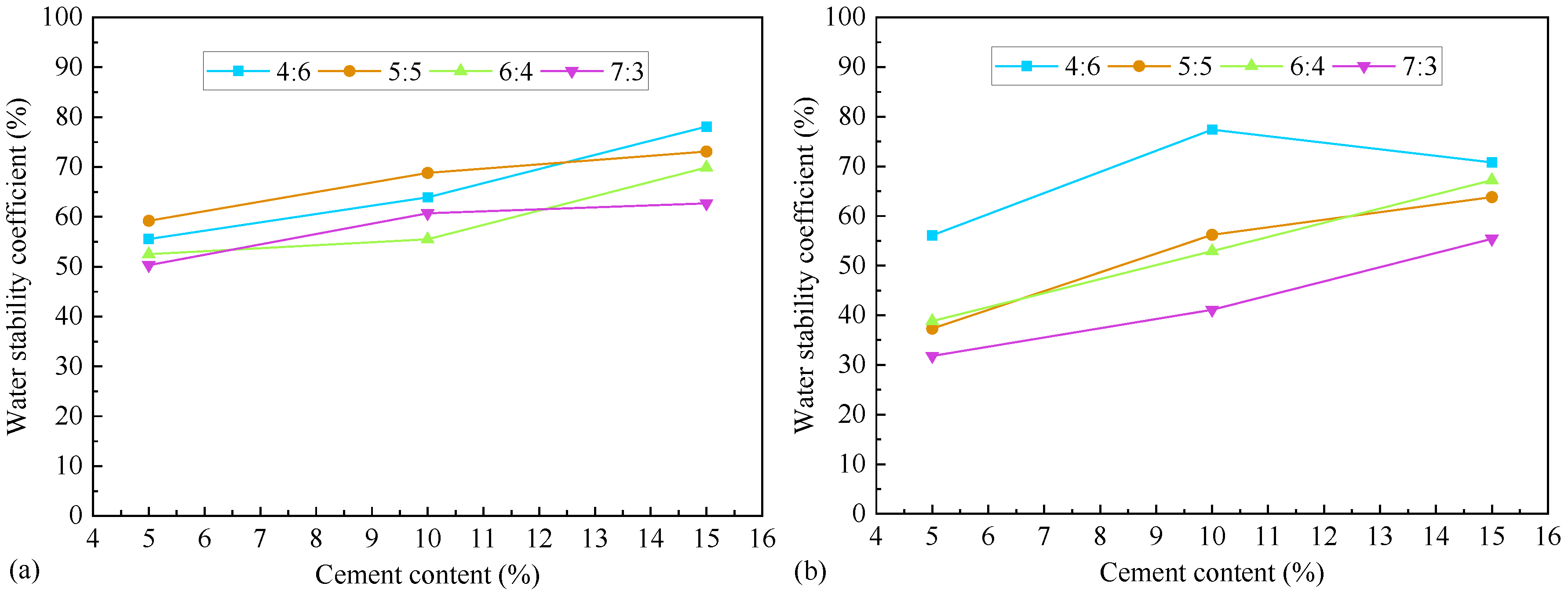

4.3.1. Microstructure and Morphology Analyses

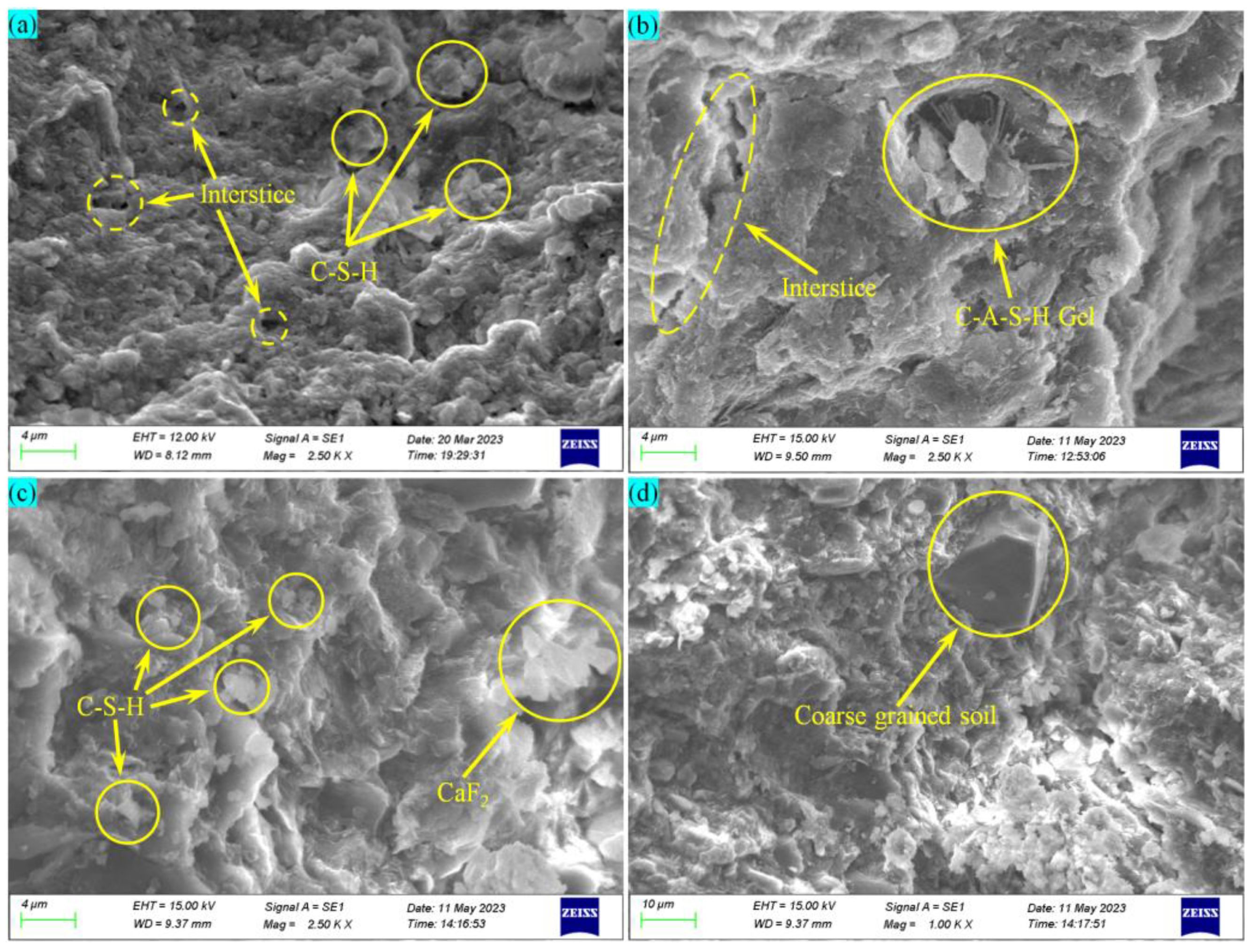

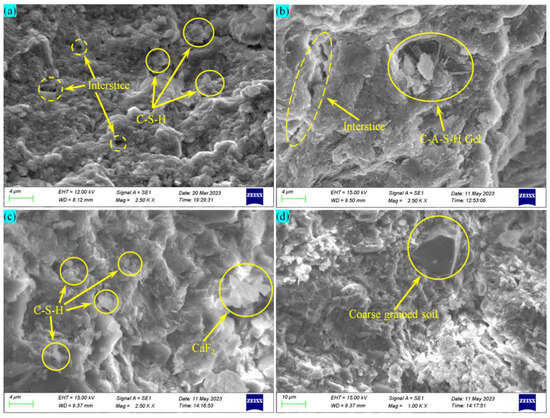

According to the unconfined compressive strength test mentioned above, the samples with a coarse particle content of 60% and a cement content of 15% showed good water-stability performance. With this group of samples as the research object, the SEM test technology was used to analyze the microscopic morphology, gel morphology and molecular distribution of hydration gel products of different curing ages. The test results are shown in Figure 9.

Figure 9.

SEM images of the samples at different curing ages. (a) The 7 d curing age sample with the SEM image magnified 2500 times. (b) The 28 d curing age sample with the SEM image magnified 2500 times. (c) The 56 d curing age sample with the SEM image magnified 2500 times. (d) The 56 d curing age sample with the SEM image magnified 1000 times.

As shown in Figure 9a, it can be seen that the microstructure of the modified soil with a 7 d curing age is not dense, with a relatively loose flocculent structure on the surface, accompanied by many pores with sizes of 1–3 μm (as shown by the red dashed line in the figure). There are not many sheet-like cementitious materials produced in the early stage, and the volume of the cementitious material is also small. The image shows more small particle like mucky soil, which is consistent with the conclusion that the unconfined compressive strength of the modified soil solidified in the early stage is low. As depicted in Figure 9b, the pore volume of the modified soil after a 28 d curing age is further reduced, the microstructure is denser, and the cross-section is smoother. The red dashed line in the picture shows long cracks, which are mainly caused by defects during the sample preparation process. With the increasing curing age, the cement hydration process generates more large-size hydrated calcium silicate gel (C-S-H gel) and hydrated calcium sulphoaluminate gel (C-A-S-H gel) [33,34]. The cementitious structure is shown as slender fibers and strips in the electron microscope image, presenting an interlaced and connected network, and filling the gap between mucky soil and coarse particles. The hardness and strength of modified soil are enhanced through crystallization and cementation. Similar findings are also found in the test of the literature [35]. It can be seen from Figure 9c that the internal microstructure of modified soil with a 56 d curing age becomes more compact as time goes on, which is mainly because the cement has enough time to carry out hydration reaction and the hydration reaction is more thorough, resulting in more C-S-H gel, C-A-S-H gel and hydrated tetracalcium ferroaluminate (C4AF). In Figure 9, there are many flat and flaky crystals with different sizes of clustered cementitious products, all of which are products of cement hydration. Among them, calcium hydroxide crystals have a smooth surface and clear grain boundaries, making them easier to identify. Due to the influence of hydration conditions and cement composition on the morphology of crystals, other small amounts of sulfate type compounds (such as calcium gypsum and calcium magnesium gypsum) may also exist in similar sheet-like crystal forms. The size of the sample observed at 2500 times is small and the range is limited, and no obvious coarse-grained soil morphology was observed in the test results. Therefore, by reducing the image to 1000 times, a larger range of microscopic morphology can be seen. As shown in Figure 9d, the coarse-grained soil has a prism-shaped cubic structure, with a size several times that of the mucky soil particles. The experimental results clearly show that the cementitious products are tightly filled in the gaps between coarse-grained soil and mucky soil particles, forming a strong network structure, making the multiply modified soil have higher strength and stability [36].

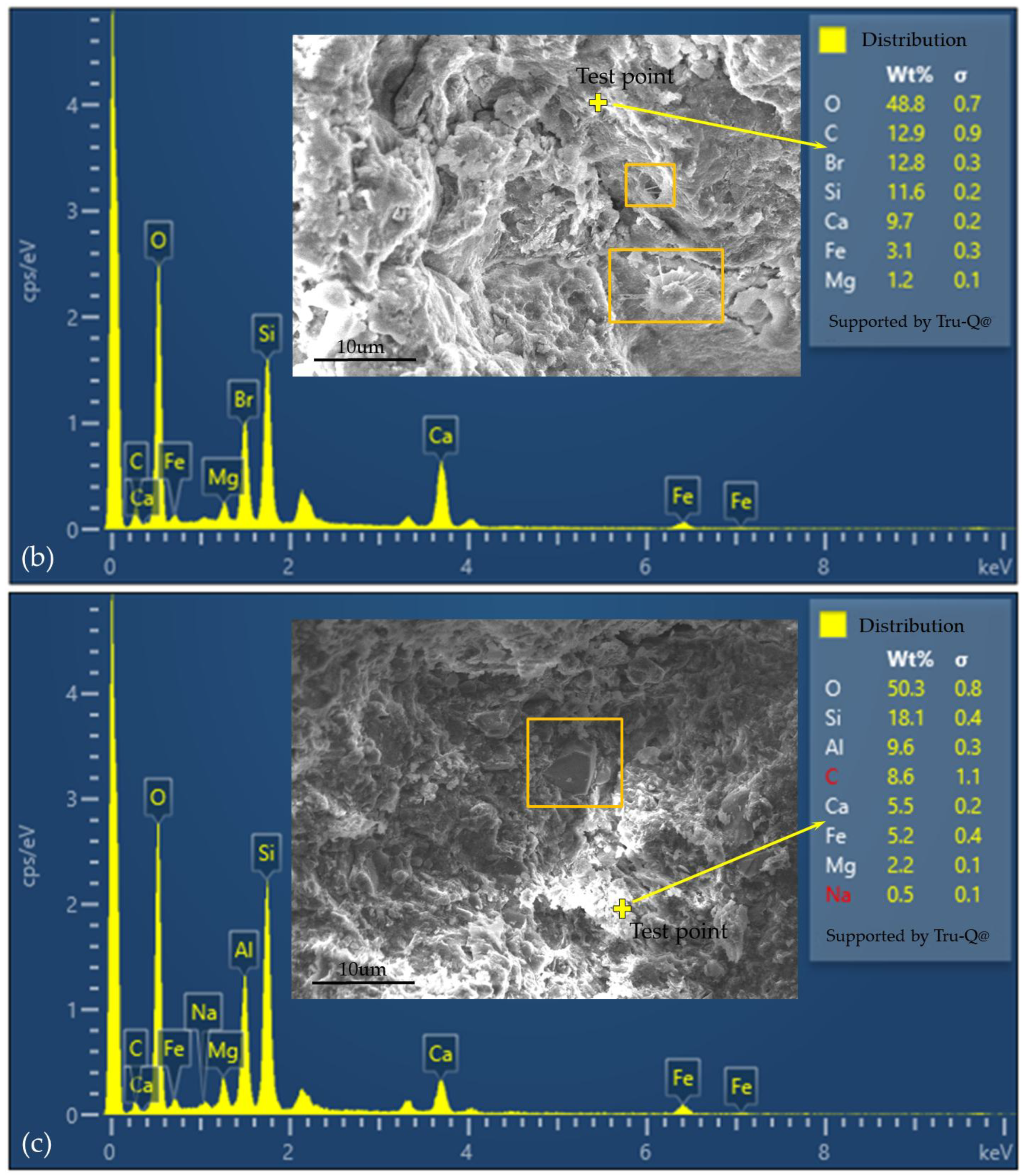

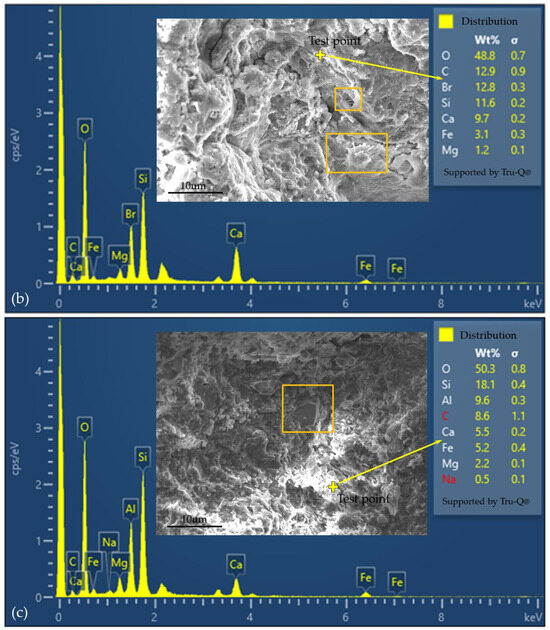

4.3.2. Microscopic Component Analyses

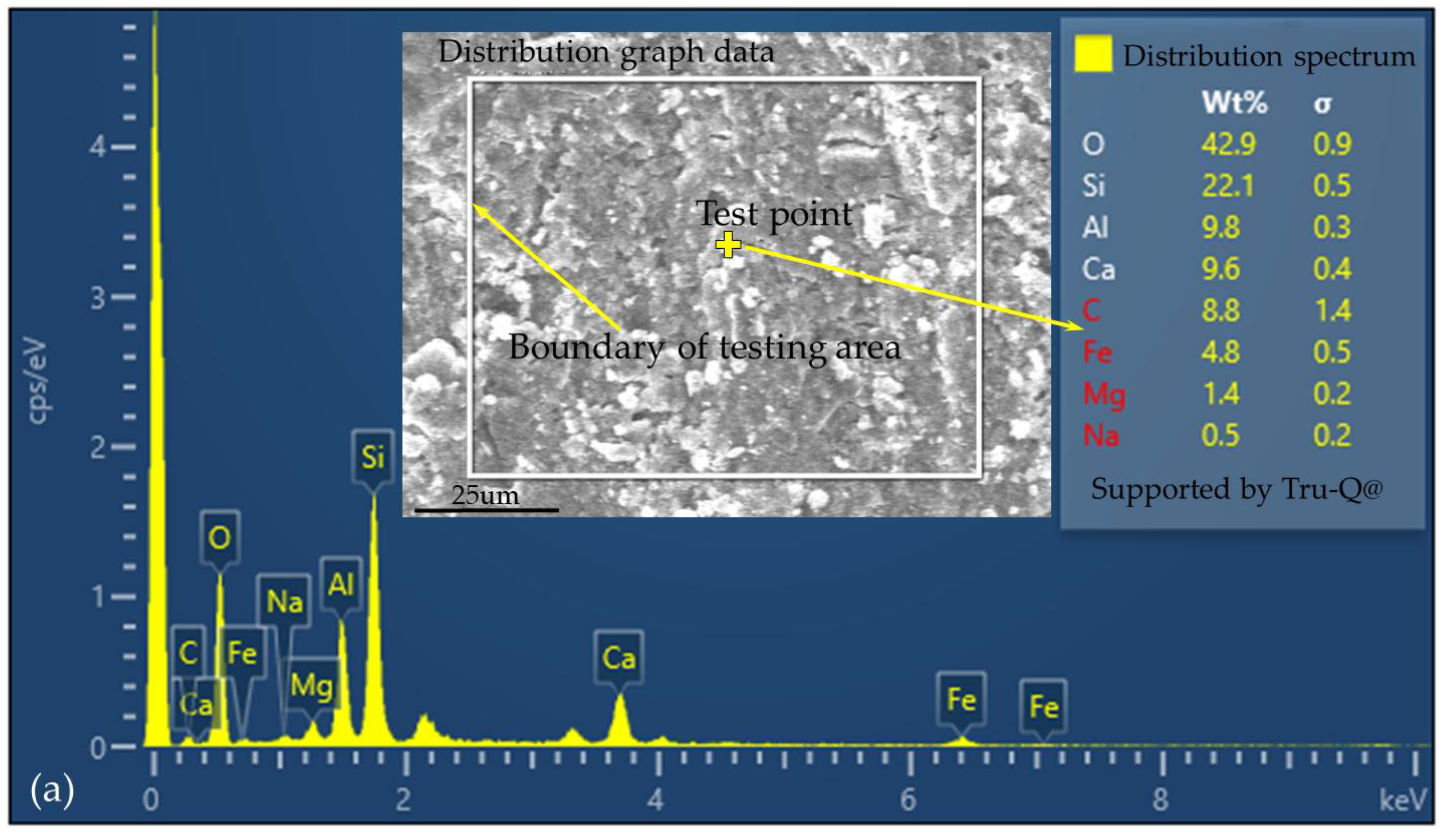

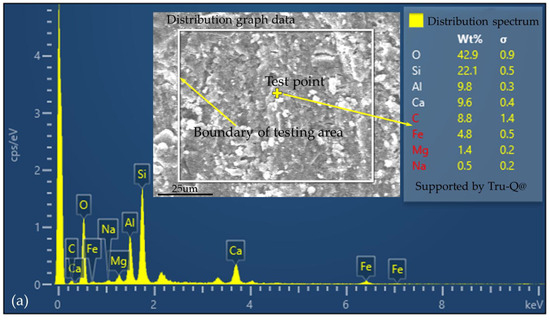

To investigate the spatial uniformity of hydration products within the stabilized soil, energy-dispersive X-ray spectroscopy (EDX) was employed to map elemental distributions across the analyzed area of a specimen cured for 28 d, as shown in Figure 10.

Figure 10.

EDX analysis results of samples with a 28 d curing age. (a) Total element distribution of the test points. (b) Elemental distribution map of the major constituents within the test area. (c) Oxygen (O) distribution. (d) Silicon (Si) distribution. (e) Aluminum (Al) distribution. (f) Calcium (Ca) distribution. (g) Magnesium (Mg) distribution.

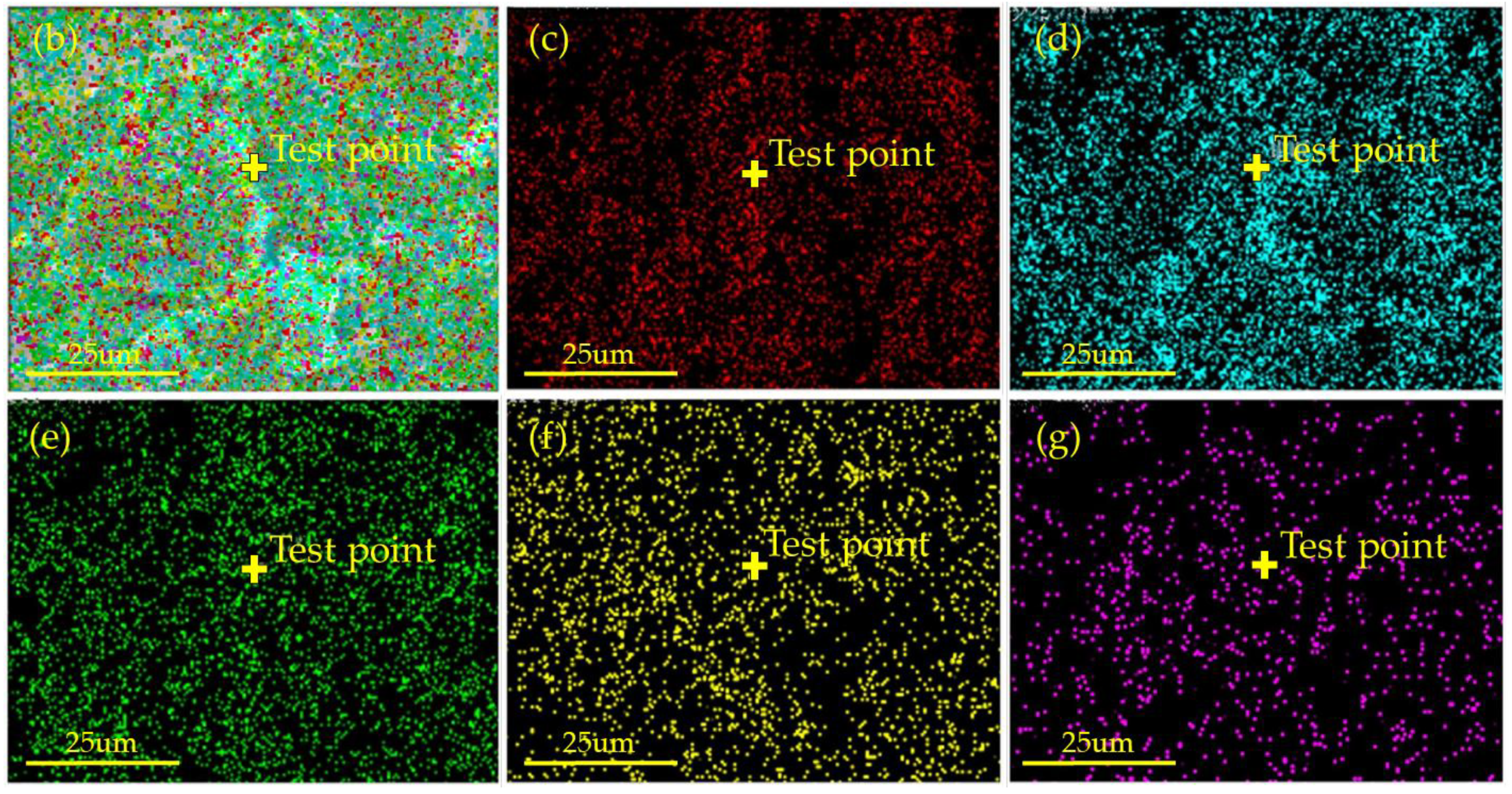

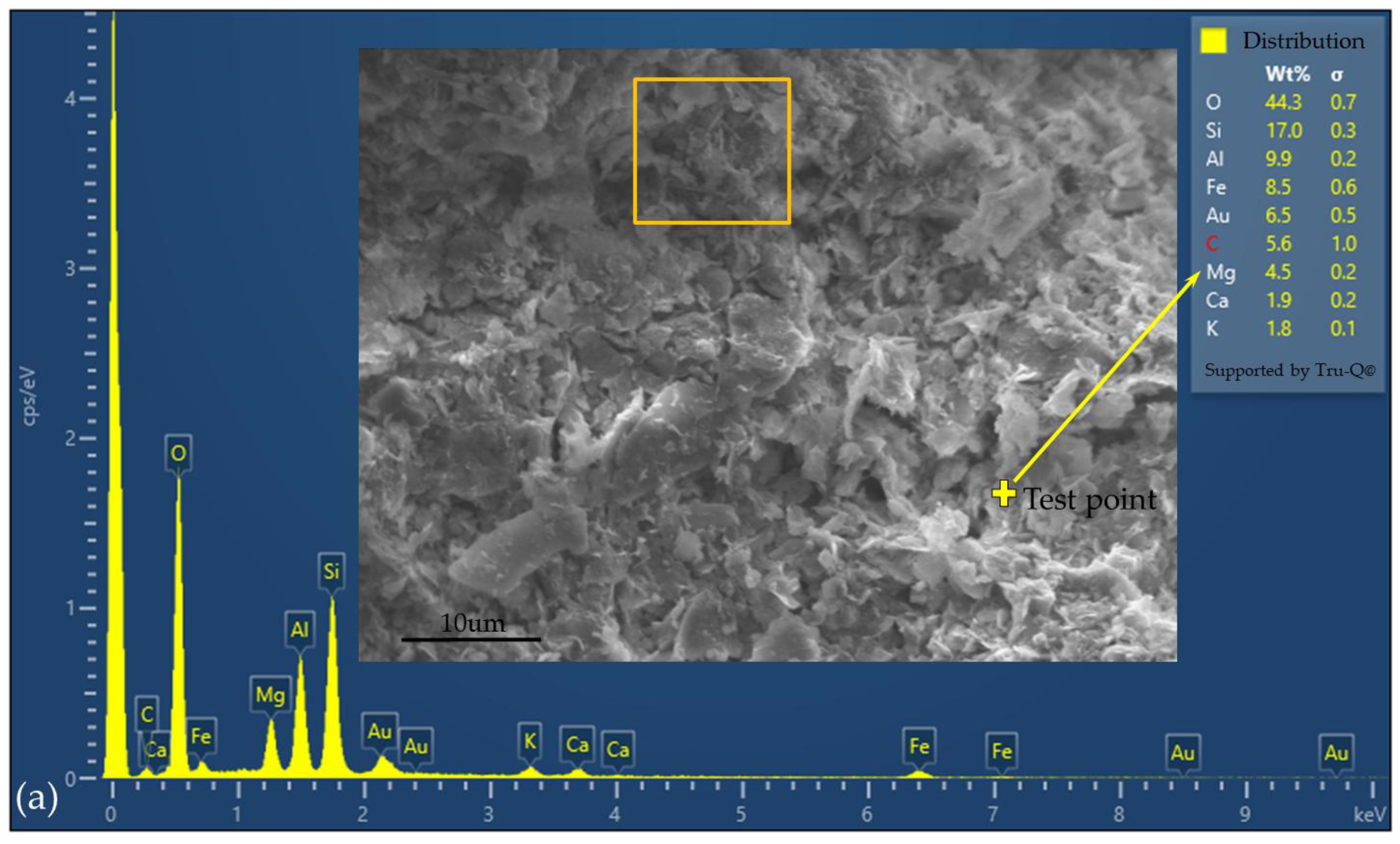

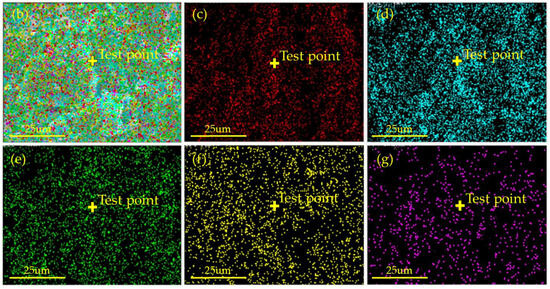

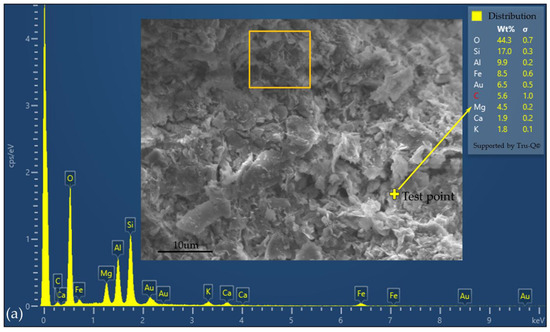

As shown in Figure 10, the dominant elements detected at the test point include oxygen (O), silicon (Si), aluminum (Al), and calcium (Ca). They are relatively evenly distributed in the testing area, indicating that the distribution of hydration products in the soil sample is also relatively uniform. This is beneficial for the hydration reaction of cement and the improvement of the physical and mechanical properties of the modified soil. Owing to the scarcity of hydration products in the 3 d curing age, microstructural characterization remains inconclusive. Consequently, a 56-day curing age was introduced, supplementing the existing 7- and 28-day series, to elucidate the long-term solidification mechanism of the stabilized soil. The EDX analysis was conducted to study the changes in the internal microscopic composition of the modified soil under different curing ages. The SEM results of the modified soil under different curing ages are shown in Figure 11.

Figure 11.

EDX analysis results of samples under 7 d, 28 d and 56 d curing ages. (a) Test results with a 7 d curing age. (b) Test results with a 28 d curing age. (c) Test results with a 56 d curing age.

From Figure 11, it can be seen that the content of oxides in the soil is relatively high, accounting for about 44.0–50.3% of the total composition, while the content of aluminum and iron is relatively low. The cementitious products contain a large number of oxide molecules mainly from the tricalcium chlorate and tetracalcium ferrocyanide produced after the cement hydration process. This component can effectively improve the strength of the soil [37], which is consistent with the conclusions of the relevant analysis above. There is a relatively low content of magnesium element in all three curing ages, mainly due to the magnesium gypsum in cement clinker. In addition, the silicon content exceeded 10% in all three test results, while the calcium content was relatively low in the early stages and increased significantly in the later stages. As silicon and calcium are important components of cement [38,39], an appropriate amount of silicon content can promote the reaction of cement minerals, form more hydration products, and thus improve the strength and water stability of the modified soil.

5. Conclusions

Taking the mucky soil excavated from the protective pond river of the seawall project in Cangnan County, China, as the research object, the multiply modified mucky soil with cement and coarse particles has significantly improved its water immersion stability, and its micro properties have also been significantly promoted. The main conclusions obtained are as follows:

- The unconfined compressive strength (UCS) of cement-stabilized soil is governed by the interactive effects of cement dosage, coarse-grained fraction and curing time. At a low cement content (5%), UCS decreases monotonically with increasing coarse-particle content for any given curing period. When the cement content is raised to an intermediate level (10%), the influence of the coarse fraction becomes negligible; instead, strength clusters narrowly around 1.2 MPa at 7 d and 2.0 MPa at 28 d regardless of the coarse-grained proportion. At a high cement content (15%), UCS exhibits a positive linear correlation with coarse-particle content. A maximum strength is attained when the coarse-grained fraction reaches 60% by mass, yielding peak UCS values of 2.02 MPa at 7 d and 3.61 MPa at 28 d.

- The UCS of the cement-modified soil after immersion is consistently lower than its pre-immersion value at both 7 d and 28 d. At 7 d, the blend containing 60% coarse-grained soil exhibits the highest water-stability coefficient under all three cement levels, peaking at 0.862 for the 4:6 aggregate/cement ratio with 5% cement. After 28 d of curing, the same 60% coarse-grained fraction again produces the greatest water-stability coefficient among the four granular contents, corroborating the 7 d trend and reaching a maximum of 0.774 at the 4:6 ratio with 10% cement. To enhance the stability of soil properties, a mix proportion of 60% coarse-grained soil combined with 15% cement is recommended; conversely, for scenarios in which cost-effectiveness is the primary concern, a blend comprising 60% or 50% coarse-grained soil and 10% cement may be adopted.

- Microstructural and compositional analyses demonstrate that inter-particle voids progressively diminish and crack apertures narrow as the curing period is extended. Coarse grains function as a rigid skeleton, while the ongoing cement-hydration reaction densifies the matrix. Hydration products, predominantly colloidal oxides, form extensive bonding networks, markedly enhancing both strength and water stability. Consequently, the synergistic modification of coastal mucky soil with cement and coarse-grained waste not only upgrades its physico-mechanical performance but also provides a high-volume outlet for engineering spoil. These findings furnish a robust theoretical framework for the stabilization of soft coastal deposits and the sustainable management of coarse-grained construction by-products.

Author Contributions

Conceptualization and methodology was contributed by Z.Q. and Y.T. Formal analysis, investigation and data collection were contributed by X.G., J.C., H.H. (Huang Huang), Z.Y., D.W., E.X., H.H. (Hanwei Huang) and X.C. Writing—original draft preparation, was contributed by Z.Q. and Y.T. Writing—review and editing, was contributed by all the authors. Funding acquisition was contributed by Z.Q. Resources were contributed by H.H. (Huang Huang), Z.Y., X.G., E.X., H.H. (Hanwei Huang) and X.C. Experimental testing was contributed by Z.Q., J.C. and X.G. Supervision was contributed by E.X. and H.H. (Huang Huang). All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported the Nanxun Scholars Program of ZJWEU (RC2024011063) and Zhejiang Provincial Natural Science Foundation of China under Grant (LTGG24E090002).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors thank the Cangnan County Water Resources Bureau of Wenzhou City for their support during on-site research, sampling, testing and manuscript writing.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhu, J.F.; Tao, Y.L.; Xu, R.Q.; Yang, H.; Pan, B.J. Investigation on the optimal formulation and mechanism of marine organic silt improved with magnesium-cement-based stabilizer. Constr. Build. Mater. 2022, 341, 127233. [Google Scholar] [CrossRef]

- Gong, S.M.; Feng, S.B.; Wang, S.Q.; Yu, L.M.; Chen, Y.Y.; Xu, Q. Strength and microstructural properties of silt soil cured by lime-activated fly ash-GGBS under different curing temperatures. Sci. Rep. 2024, 14, 6966. [Google Scholar] [CrossRef] [PubMed]

- Cao, P.K.; Ma, Q.W.; Zha, M.M.; Zhang, J.; Huo, Z.J. Study on the modification of silty soil sites using nanosilica and methylsilicate. Materials 2023, 16, 5646. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.Y.; Xiao, X.; Ji, W.W.; Ishimwe, A.; Wang, B.H.; Sun, K. Dynamic properties of the mucky clay improved with the steel slag and the rubber particles. Constr. Build. Mater. 2021, 294, 123489. [Google Scholar] [CrossRef]

- Tang, Y.Q.; Zhou, J.; Liu, S.; Yang, P.; Wang, J.X. Test on cyclic creep behavior of mucky clay in Shanghai under step cyclic loading. Environ. Earth Sci. 2011, 53, 321–327. [Google Scholar] [CrossRef]

- Li, S.; Wang, C.M.; Zhang, S.Y.; Li, T.; Khan, K.U.J. Bound water characteristics and microstructure evolution during uniaxial compression of mucky silty clay. J. Soils Sediments 2022, 22, 782–796. [Google Scholar] [CrossRef]

- Tang, Y.Q.; Sun, K.; Zheng, X.Z.; Yang, Q.; Zhou, J. The deformation characteristics of saturated mucky clay under subway vehicle loads in Guangzhou. Environ. Earth Sci. 2016, 75, 438. [Google Scholar] [CrossRef]

- Jiao, N.; Ding, J.W.; Wan, X.; Xue, C.R.; Zhang, K.X. Enhancing tunnel muck properties with ternary industrial solid wastes: Optimal mixing ratios and microscopic mechanisms. Eur. J. Environ. Civ. Eng. 2025, 29, 2388–2405. [Google Scholar] [CrossRef]

- Yu, L.C.; Liu, T.; Zheng, J.G.; Chen, J.; Li, M.Y.; Su, X.T.; Tian, Z.Q. Study on Freeze-Thaw Resistance of Basalt Fiber-Reinforced and Inorganic Curing Agent-Stabilized Shield Tunnel Muck. J. Mater. Civ. Eng. 2024, 36, 04024319. [Google Scholar] [CrossRef]

- Su, X.T.; Yu, L.C.; Chen, J.; Li, H.F.; Liu, Q.; Zhang, H.G.; Liu, T. Mechanical properties and microstructure of SWGA-BF improved rock muck discharged from slurry shield tunnels. Constr. Build. Mater. 2023, 409, 133969. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Kong, L.Y.; Tseng, M.L.; Song, Y.; Wang, H.Y. Solid waste material reuse analysis: Filling the road subgrade with riverway silt and sediment. Environ. Sci. Pollut. Res. 2022, 29, 35096–35109. [Google Scholar] [CrossRef]

- Shen, Q.J.; Jiang, P.; Zhang, X.N.; Sun, H.; Yang, Y.H.; Wang, S.; Li, L.; Shang, H.F. Evaluation and characterization of the use of industrial-solid-waste curing agent instead of cement on improved alluvial silt. Coatings 2022, 12, 1417. [Google Scholar] [CrossRef]

- Zhang, J.W.; Han, Y.; Wang, X.J.; Bian, H.L. Experimental investigation of the dynamic characteristics of treated silt using lignin: Case study of Yellow River flood basin. Int. J. Geomech. 2021, 21, 04021056. [Google Scholar] [CrossRef]

- Xu, J.; Xiao, C.; Wu, H.N.; Kang, X. Reuse of excavated clayey silt in cement-fly ash-bentonite hybrid back-fill grouting during shield tunneling. Sustainability 2020, 12, 1017. [Google Scholar] [CrossRef]

- Wu, X.T.; Qi, Y.; Liu, J.N.; Chen, B. Solidification effect and mechanism of marine muck treated with ionic soil stabilizer and cement. Minerals 2021, 11, 1268. [Google Scholar] [CrossRef]

- Jiao, N.; Ding, J.W.; Wan, X.; Gao, M.Y.; Xue, C.R. Mechanical properties and micro-mechanism of improved shield tunnel muck with phosphogypsum and lime. Constr. Build. Mater. 2023, 411, 134437. [Google Scholar] [CrossRef]

- Jiao, N.; Wan, X.; Ding, J.W.; Zhang, X.R.; Xue, C.R. Mechanical properties and microstructure of lime-treated shield tunnel muck improved with carbide slag and soda residue. Constr. Build. Mater. 2024, 428, 136419. [Google Scholar] [CrossRef]

- Wang, J.Z.; Fan, Y.; Xiong, X.X.; Zhao, F.C. Stabilization of shield muck treated with calcium carbide slag-fly ash. Buildings 2023, 13, 1707. [Google Scholar] [CrossRef]

- Hu, H.T.; Xu, J.; Jing, X.; Ruan, Y.H.; Zhang, L. Effect of Wetting-drying Cycle and Solidification Process on Water Stability and Strength Characteristic of Solidified Soil. Henan Sci. 2021, 39, 1453–1460. (In Chinese) [Google Scholar]

- Wang, Q.Y.; Liu, J.; Li, D.; Wu, S.Y.; Zhang, Y.T.; Wang, H.N. Experimental Study on Water Stability of Polymer Stabilized Sand on River Bank Slope Surface. J. Disaster Prev. Mitig. Eng. 2020, 40, 566–573. (In Chinese) [Google Scholar] [CrossRef]

- Yao, Z.; Zhu, Y.J.; Chen, Q.; Chen, Z.H. Experimental Study on the Compressibility and Strength of High Liquid Limit Roadbed. Adv. Eng. Sci. 2017, 49, 66–71. (In Chinese) [Google Scholar] [CrossRef]

- Yi, X.Z.; Luo, R.D.; Gao, Y.; Yu, H.H.; Tie, N.; Yao, M.H. Research on Strength Behavior and Water Stability of Solidified Waste Soft Clay. Bull. Chin. Ceram. Soc. 2022, 41, 976–984. (In Chinese) [Google Scholar] [CrossRef]

- Zhu, Y.P.; Wang, H.; Fang, G.W.; Liu, D.R.; Lv, Y.B. Orthogonal Experimental Study on Compression Characteristics of Fluid-solidified Soil Made from Strongly Weathered Rock. J. Yangtze River Sci. Res. Inst. 2023, 40, 103–109+117. (In Chinese) [Google Scholar]

- Fan, L.; Zhou, S.J.; Hou, J.L.; Wang, L. Composite Stabilization of Silty Soil near the Yellow River: Two Methods and Performance Comparison. J. Yangtze River Sci. Res. Inst. 2021, 38, 118–124. (In Chinese) [Google Scholar] [CrossRef]

- Wang, D.X.; Zhu, J.Y.; Wang, R.H. Assessment of magnesium potassium phosphate cement for waste sludge solidification: Macro- and micro-analysis. J. Clean. Prod. 2021, 294, 126365. [Google Scholar] [CrossRef]

- Li, F.; Sun, S.L.; Zhang, D.H. Experimental Study on Improving Physical Properties and Water Stability of Coastal Saline Soil. J. Hebei Univ. Eng. (Nat. Sci. Ed.) 2019, 36, 58–64. (In Chinese) [Google Scholar]

- Dong, J.M.; Zhu, H.; Bian, J.; Gao, H.M. Experimental Research on Mechanics Characteristics and Mechanism of Silty Soil Modified by Polymer Material. Chin. J. Rock Mech. Eng. 2014, 33, 4326–4333. (In Chinese) [Google Scholar] [CrossRef]

- Qin, Y.Y.; Qin, Z.P.; Huang, H.; Jiang, G.R.; Guo, X.D.; Huang, Y.X.; Zheng, Y.N.; Xu, E.J.; Gao, J.Q. Experimental Study on Composite Solidification and Improvement of Silt Soil by Cement and Coarse Particle Engineering Spoil. Sci. Technol. Eng. 2024, 24, 5076–5087. (In Chinese) [Google Scholar]

- GBT 50123-2019; Soil Test Method Standard. China Planning Press: Beijing, China, 2019.

- SL 237-1999; Geotechnical Test Regulations. China Water & Power Press: Beijing, China, 1999.

- Tan, P.; Xie, Z.W.; Deng, Q.C.; Zhao, X.W.; Wang, Y. Mechanics and water stability of composite solidified soil with high liquid limit. J. Railw. Sci. Eng. 2022, 19, 1298–1308. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.; Liu, J.; Song, Z.Z.; Bai, Y.X.; Wang, Q.Y.; Qi, C.Q.; Sun, S.R. Laboratory Study on Surface Sands and Soil of River Slope Reinforced with Ecotypic Soil Stabilizer. J. Nanjing Univ. (Nat. Sci.) 2018, 54, 1095–1104. (In Chinese) [Google Scholar] [CrossRef]

- Djenaoucine, L.; Picazo, A.; de la Rubia, M.A.; Moragues, A.; Gálvez, J.C. Influence of Graphene Oxide on Mechanical Properties and Durability of Cement Mortar. Materials 2024, 17, 1445. [Google Scholar] [CrossRef] [PubMed]

- Djenaoucine, L.; Picazo, A.; de la Rubia, M.A.; Gálvez, J.C.; Moragues, A. Effect of graphene oxide on the hydration process and macro-mechanical properties of cement. Bol. Soc. Esp. Ceram. Vidr. 2024, 63, 294–303. [Google Scholar] [CrossRef]

- Qing, R.X.; He, X.; Li, Q.F.; Li, Y.F.; Guo, L. Test on water stability of red soil layer solidified with mixture of new solidification agent and cement. New Build. Mater. 2017, 44, 5–9+13. (In Chinese) [Google Scholar]

- Yang, L.; Zhang, H.; Chen, Y.H.; Shi, J.W.; Chen, L. Solidification characteristics and strength deterioration mechanism of marine soft soil in Xuwei Port, Lianyungang. Port Waterw. Eng. 2023, 3, 157–164. (In Chinese) [Google Scholar] [CrossRef]

- Li, Z.Y.; Li, W.W.; Shi, H.P.; Zhao, Z.W.; Wang, B.T.; Wang, P.Q. Experimental Study on Water Stability of Plateau Clay Improved by Polyvinyl Alcohol. Sci. Technol. Eng. 2022, 22, 1205–1211. (In Chinese) [Google Scholar]

- Liang, S.H.; Feng, D.L. Experimental study on strength and water stability of concentrated solution sludge solidified with sulfoaluminate cement collaborating waste incineration by-products. Rock Soil Mech. 2022, 43, 1453–1468. (In Chinese) [Google Scholar] [CrossRef]

- Qiao, J.S.; Wang, X.Y.; Wang, G.H.; Zhao, J.Y. Dynamic Characteristics and Microscopic Mechanism of Muddy Clay Solidified by Ground Granulated Blast-Furnace Slag. Bull. Chin. Ceram. Soc. 2021, 40, 2306–2312. (In Chinese) [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).