The Reliability of Offshore Jacket Platforms Based on Bayesian Calibration

Abstract

1. Introduction

2. Introduction to Bayes’ Theory

2.1. Classification of Uncertainty

2.2. Bayesian Model Calibration

3. Design Model Bias Factor Calibration

3.1. Jacket Platform Database

3.2. Calibration Model

3.3. Calibration Results

4. Reliability of Generic Offshore Jacket Platforms in GoM

4.1. Simplified Reliability Model

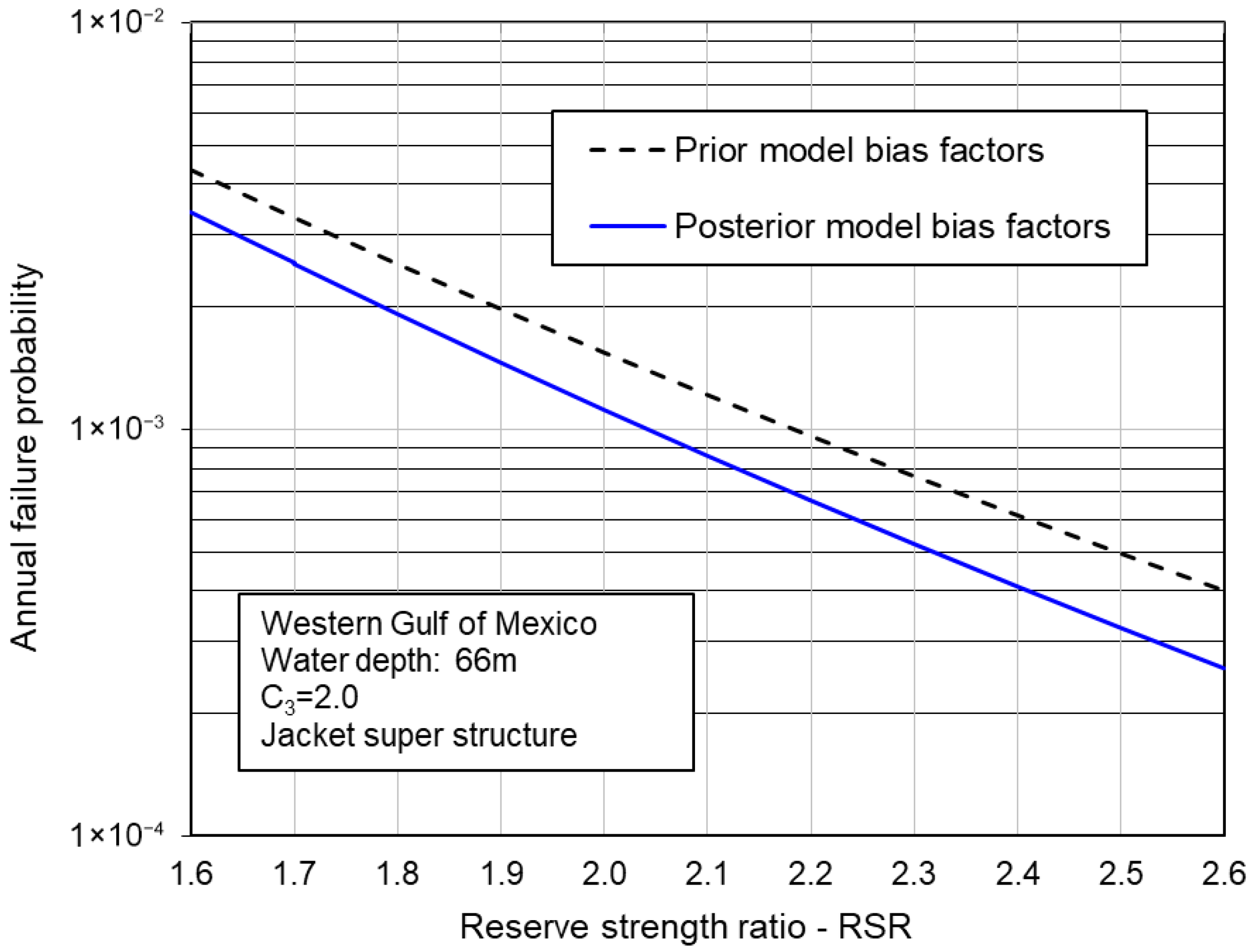

4.2. Reliability of a Jacket Superstructure System

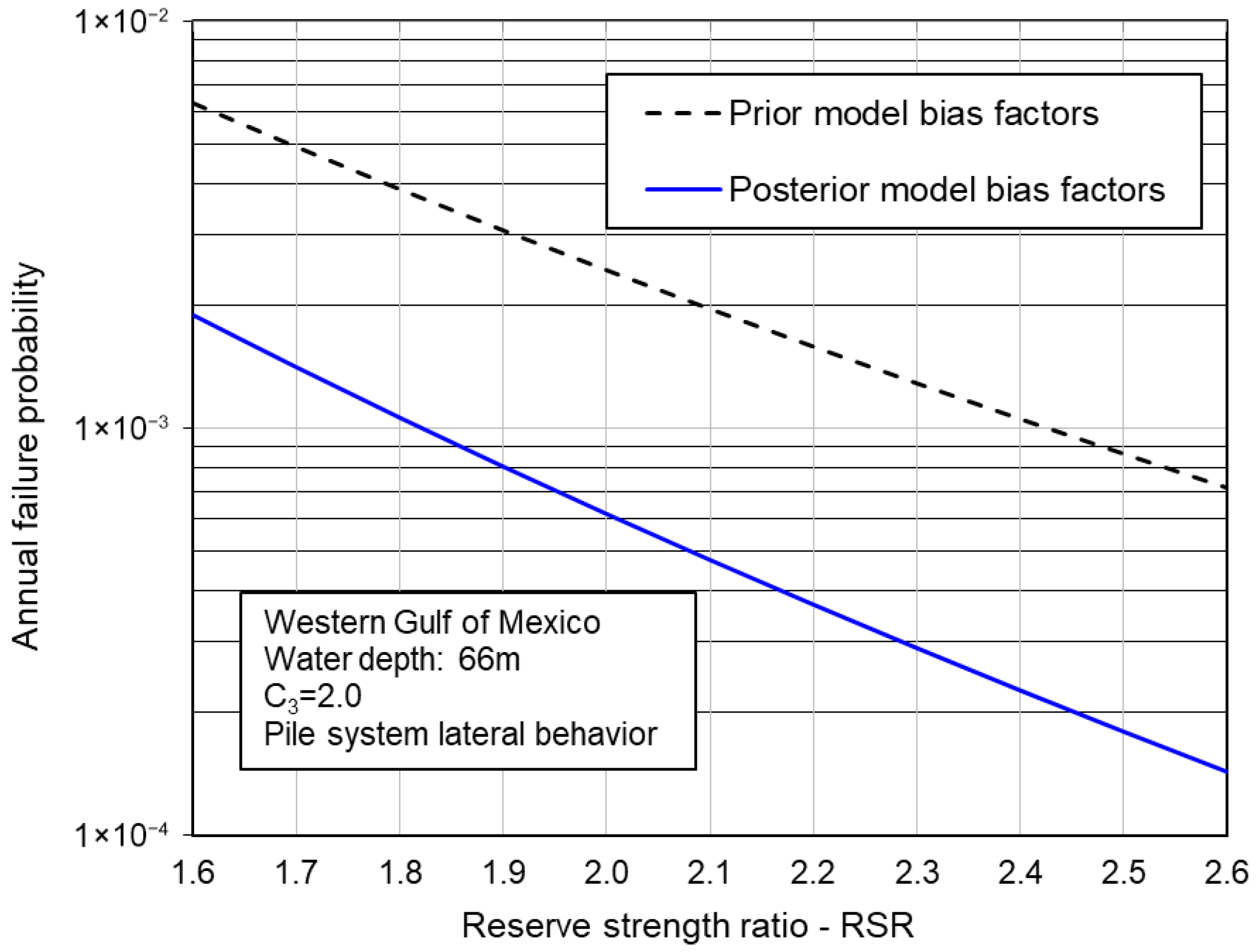

4.3. Reliability of a Pile System Against Lateral Failure

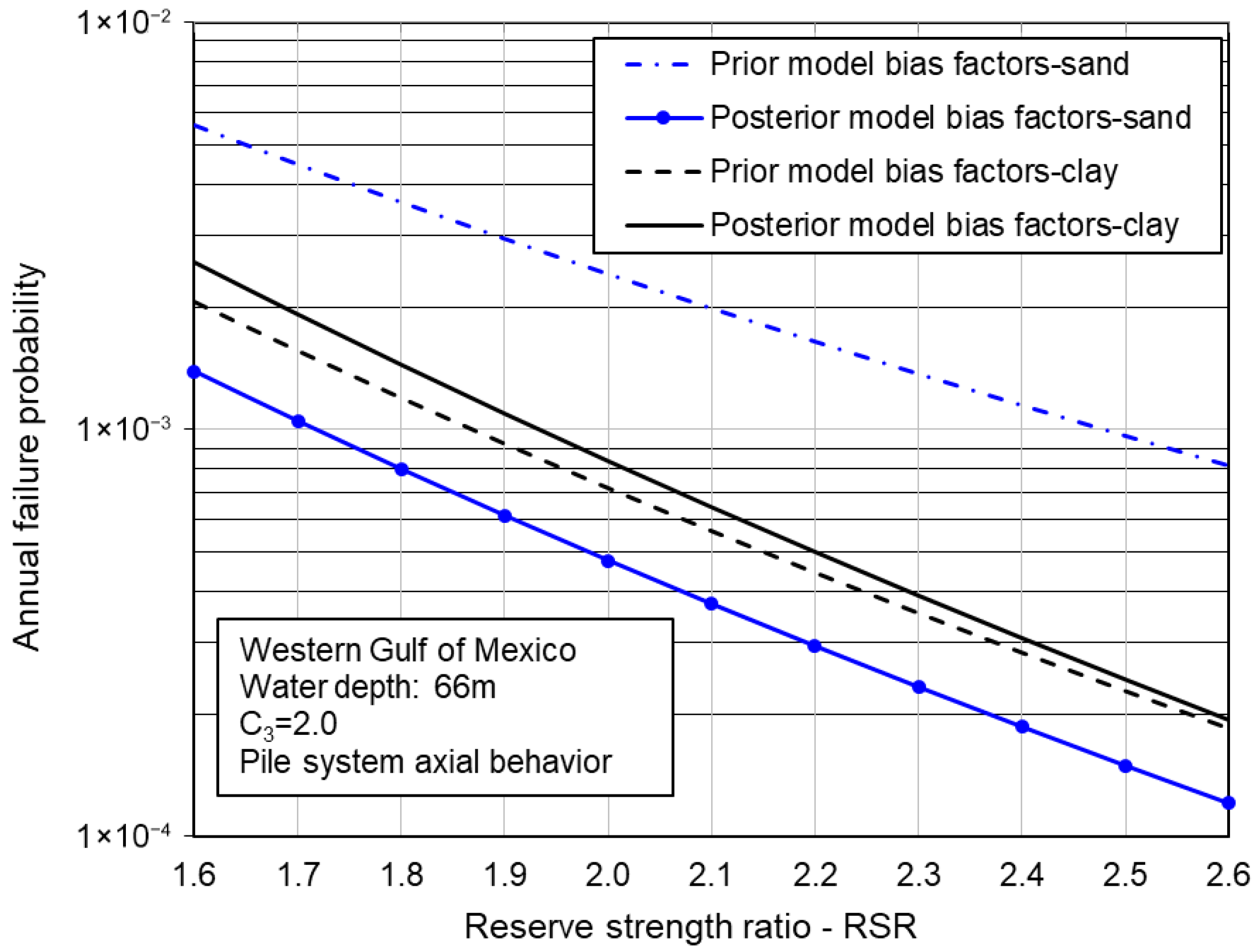

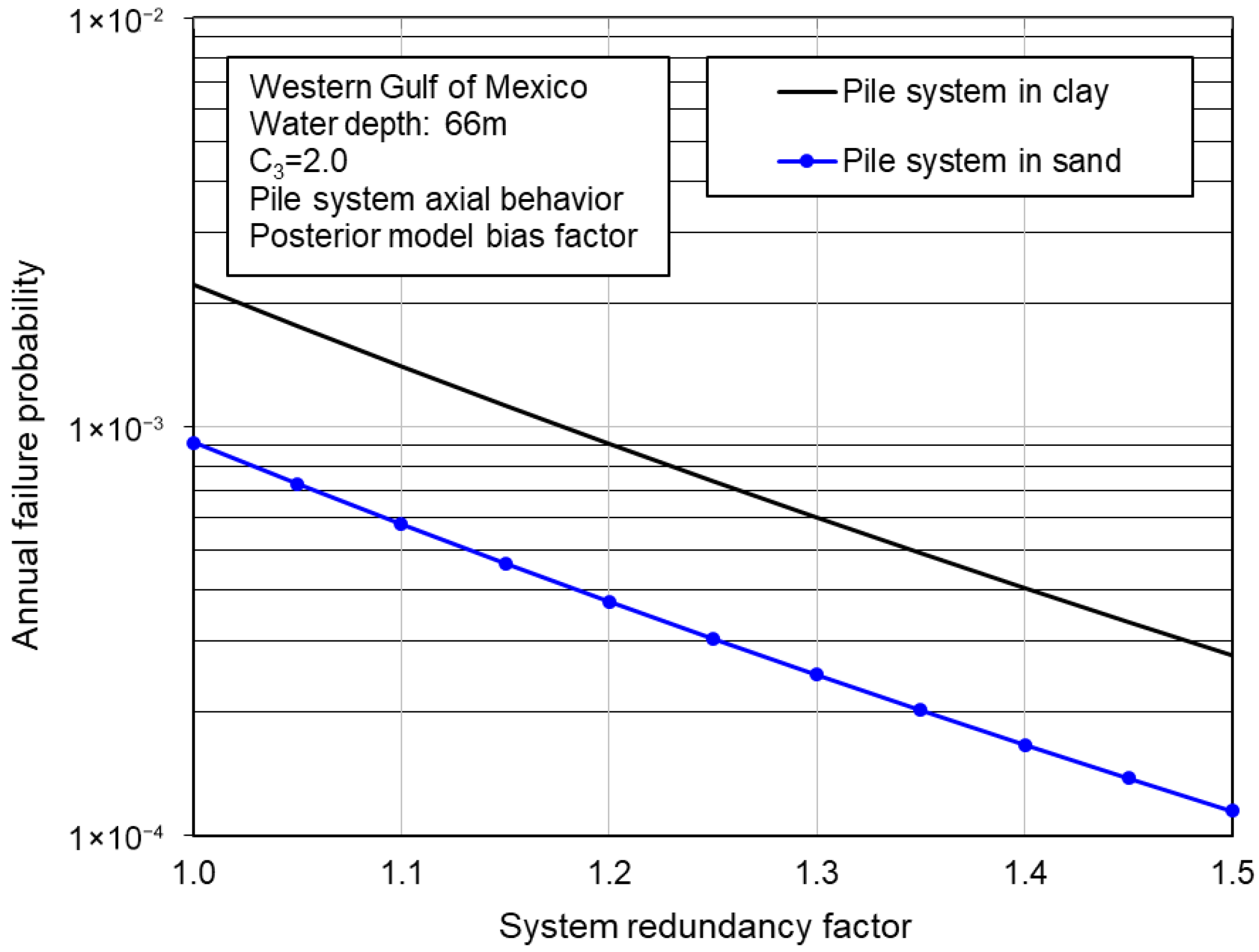

4.4. Reliability of a Pile System Against Overturning Failure

5. Reliability of the Case Study of Offshore Jacket Platforms in Northern China

5.1. In-Place Design Check

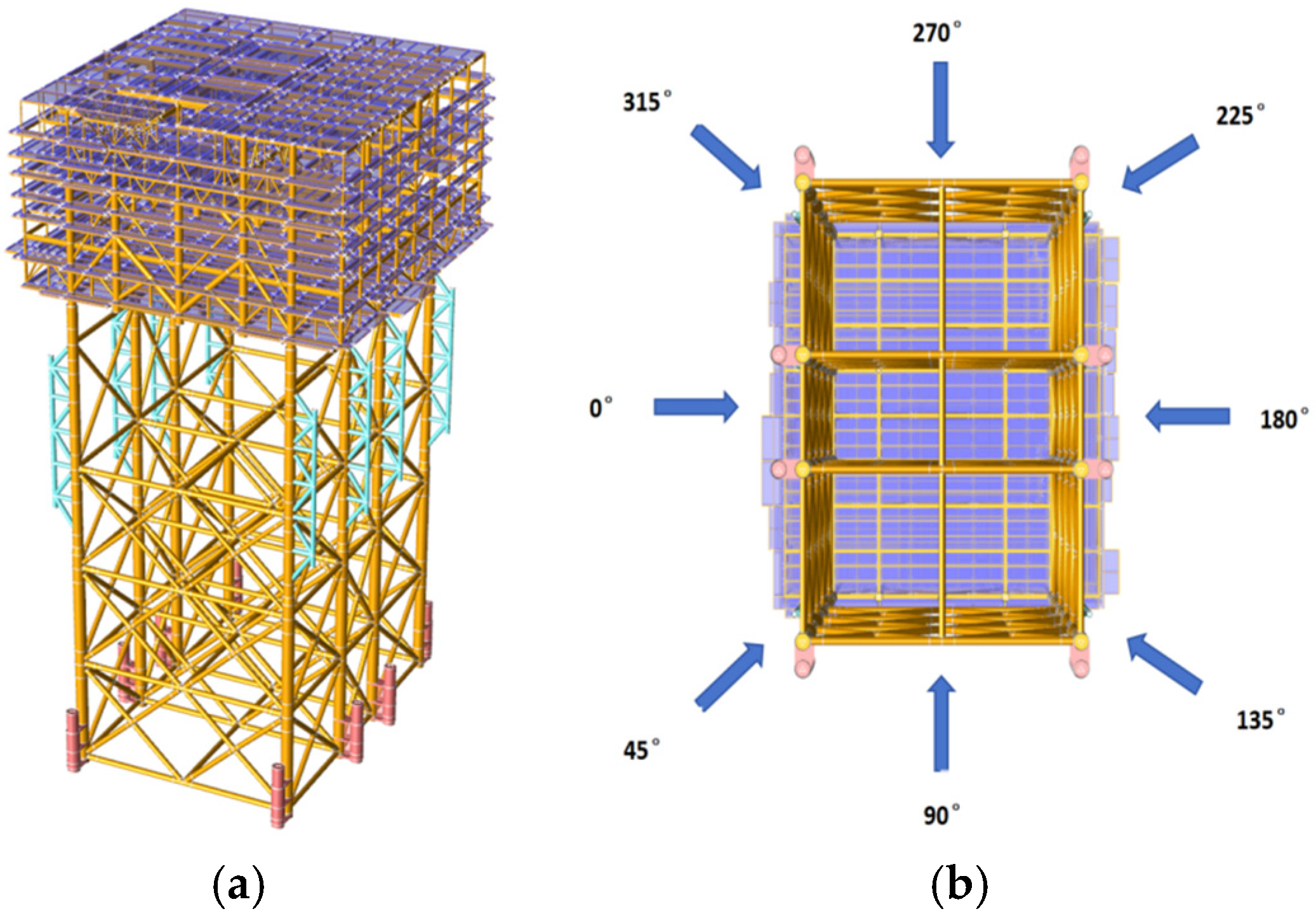

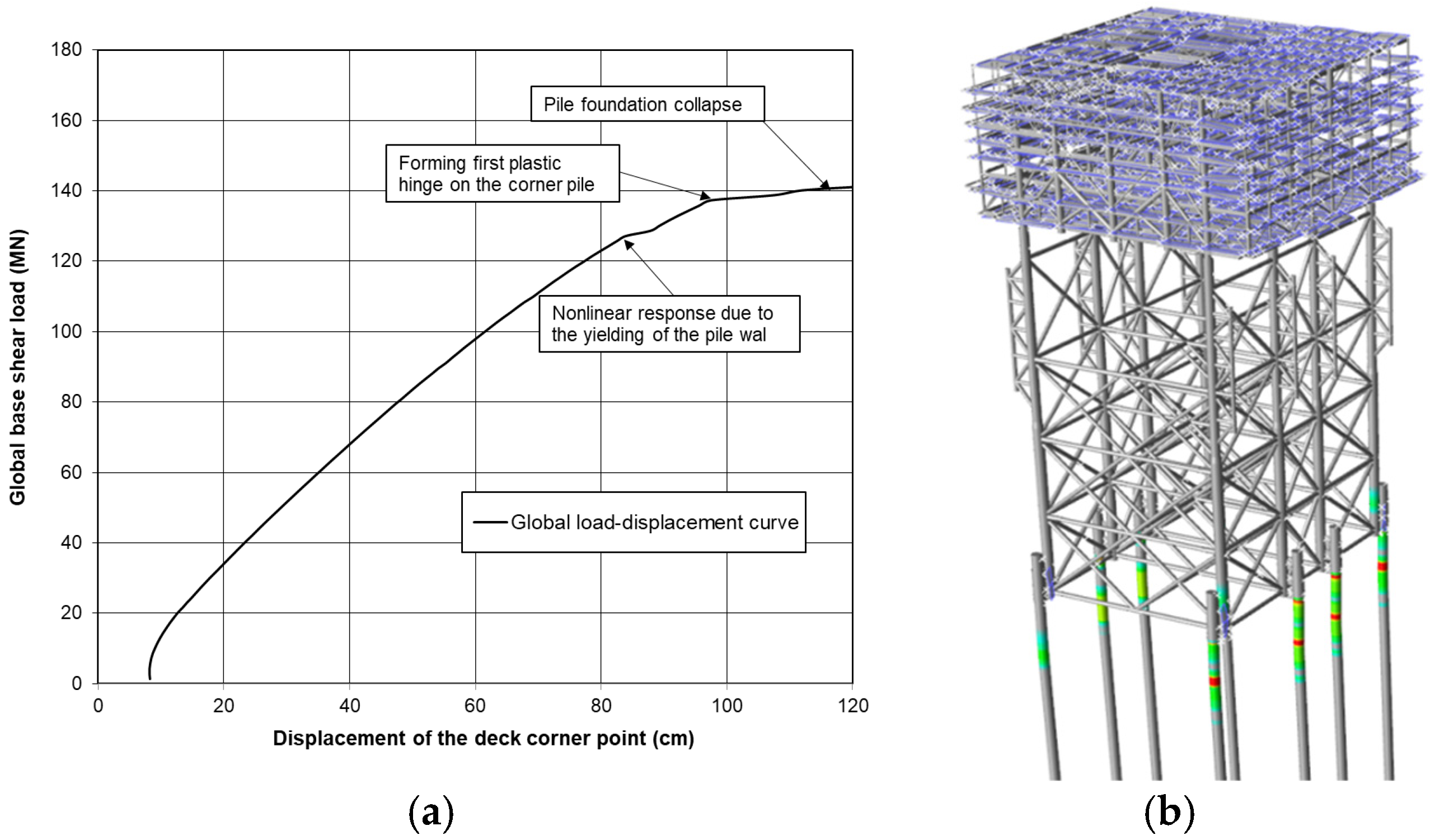

5.2. Static Pushover Analysis

5.3. Long-Term Failure Probability Analysis

5.3.1. Characterization of Environmental Loading Uncertainty

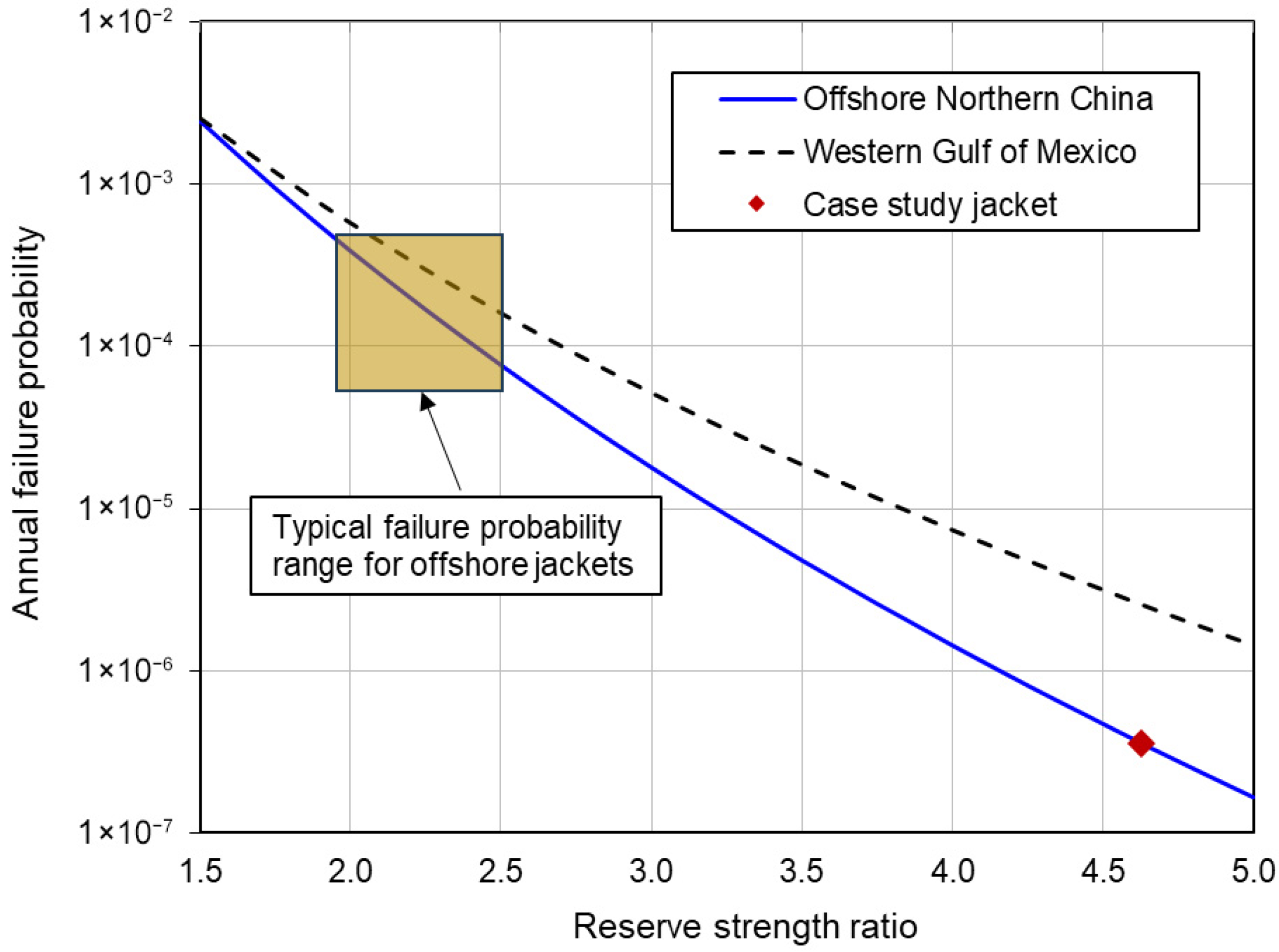

5.3.2. Substation Failure Probability Calculation

5.3.3. Discussions

6. Conclusions

- (1)

- Based on the failure performance of 18 jacket platforms during GoM hurricanes, Bayesian calibration indicates that the API design standards are marginally conservative for the structural design of jackets and pile foundations in clay and overly conservative for pile foundation designs in sand. However, the current findings are based on the platforms studied and may be revised with more data points or real-world offshore experiments. The readers need to be aware of this shortcoming of this paper.

- (2)

- The annual failure probability of a generic offshore platform in the GoM decreases with the increase in reserve strength ratio and typically is lower than , indicating that extreme weather overload is not the major concern. With the updated model bias factors, the failure probability of jacket superstructures reduces slightly, and the probability of a pile system overturning failure in clay remains largely the same. However, the updated failure probability of a pile system in the lateral direction and against overturning in sand reduces significantly.

- (3)

- The case study’s offshore substation has an , indicating that the design may be on the conservative side. Using the Bayesian-calibrated bias factors, the long-term failure probability analysis yields an annual failure probability of approximately . Because this annual failure probability is significantly lower than that of common offshore oil and gas jacket platforms, the design of this jacket is on the conservative side.

- (4)

- Conventional offshore oil and gas jacket platforms in the GoM are typically governed by extreme wave loading. However, for offshore substations with heavy topsides in offshore northern China, the structural self-weight largely controls the design of the jacket members. In addition, the metocean statistics between the Chinese waters and the GoM are largely different. This raises the question on the suitability of API RP2A-LRFD 2nd (2019) [4] load factors for gravity load and extreme wave loads for offshore substations with heavy topsides in Chinese waters, and more research will be needed to further investigate this topic.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GoM | Gulf of Mexico |

| API | American Petroleum Institute |

| COV | Coefficient of Variation |

| FoS | Factor of Safety |

| RSR | Reserve Strength Ratio |

| SRF | System Redundancy Factor |

| FE | Finite Element |

References

- Shelley, S.A.; Boo, S.Y.; Kim, D.; Luyties, W.H. Concept design of floating substation for a 200 MW wind farm for the northeast US. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2020. [Google Scholar] [CrossRef]

- Robak, S.; Raczkowski, R. Substations for offshore wind farms: A review from the perspective of the needs of the Polish wind energy sector. Bull. Pol. Acad. Sci. Tech. Sci. 2018, 66, 517–528. [Google Scholar] [CrossRef]

- API RP 2A-WSD; Recommended Practice for Planning, Designing and Constructing Fixed Offshore Platforms—Working Stress Design. American Petroleum Institute: Washington, DC, USA, 2014.

- API RP 2A-LRFD; Planning, Designing, and Constructing Fixed Offshore Platforms—Load and Resistance Factor Design. American Petroleum Institute: Washington, DC, USA, 2019.

- API RP 2GEO; Geotechnical and Foundation Design Considerations. American Petroleum Institute: Washington, DC, USA, 2011.

- API RP 2MET; Derivation of Metocean Design and Operating Conditions. American Petroleum Institute: Washington, DC, USA, 2014.

- Liu, J.; Yu, Y.; Wang, B.; Wang, J. Safety of Jacket Platform of Rod Pumping. China Offshore Platf. 2023, 38, 75–79. [Google Scholar]

- Wang, C. Safety evaluation analysis of deep sea conductor jacket platform. China Strateg. Emerg. Ind. 2018, 151. (In Chinese) [Google Scholar] [CrossRef]

- Chen, J. Deterministic and Probabilistic Analyses of Offshore Pile Systems. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2016. Available online: https://repositories.lib.utexas.edu/items/7f3aa035-8b6f-4385-9a65-31404322f55b (accessed on 5 June 2025).

- ABS Consulting. Hurricane Lili′s Impact on Fixed Platforms: Final Report Prepared for Minerals Management Service; MMS Order No.: 0103PO72325; U.S. Department of the Interior—Minerals Management Service: Herndon, VA, USA, 2004. [Google Scholar]

- Energo Engineering, Inc. Reliability vs. Consequence of Failure for API RP2A Platforms Using RP2MET; U.S. Department of the Interior—Minerals Management Service: Herndon, VA, USA, 2009. [Google Scholar]

- Chen, J.-Y.; Gilbert, R.B.; Puskar, F.J.; Verret, S. Case study of offshore pile system failure in hurricane Ike. J. Geotech. Geoenviron. Eng. 2013, 139, 1699–1708. [Google Scholar] [CrossRef]

- Jesper, T.; Allan, Z. AWARE Project: General project introduction, structural reliability analysis, and code wrapper development. In Proceedings of the Offshore Structure Reliability Conference, Delft, The Netherlands, 25–28 October 2022; Available online: https://www.iogp.org/event/2022-offshore-structures-reliability-conference-osrc/ (accessed on 25 September 2025).

- Gilbert, R.B.; Chen, J.Y.; Materek, B.; Puskar, F.; Verret, S.; Carpenter, J.; Young, A.; Murff, J.D. Comparison of observed and predicted performance for jacket pile foundations in hurricanes. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3–6 May 2010. [Google Scholar]

- Xu, L.; Chen, G. Updating probabilistic reliability model based on fuzzy bayesian theory. J. Pet. Univ. (Nat. Sci. Ed.) 2003, 53–56, 151–152. (In Chinese) [Google Scholar]

- Li, M.; Zhang, R.; Hong, M. Marine disaster risk assessment based on weighted bayesian network. Mar. Sci. Bull. 2018, 37, 121–128. [Google Scholar]

- Alfredo, H.S.A.; Wilson, H. Probability Concepts in Engineering Planning and Design; John Wily Sons: New York, NY, USA, 1975; Volume 268. [Google Scholar] [CrossRef]

- Forristall, G.Z. On the statistical distribution of wave heights in a storm. J. Geophys. Res. Ocean. 1978, 83, 2353–2358. [Google Scholar] [CrossRef]

- Lacasse, S.; Nadim, F.; Langford, T.; Knudsen, S.; Yetginer, G.L.; Guttormsen, T.R.; Eide, A. Model uncertainty in axial pile capacity design methods. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2013. [Google Scholar] [CrossRef]

- Chen, J.; Gilbert, R.B.; Ku, A.; Chen, J.-Y.; Marshall, P.W. Calibration of model uncertainties for fixed steel offshore platforms based on observed performance in Gulf of Mexico hurricanes. J. Geotech. Geoenviron. Eng. 2020, 146, 04020039. [Google Scholar] [CrossRef]

- Puskar, F.; Verret, S. Assessment of Fixed Offshore Platform Performance in Hurricanes Katrina and Rita; Energo Engineering Inc.: Houston, TX, USA, 2007. [Google Scholar]

- Chen, J.; Gilbert, R.B.; Manuel, L.; Ku, A. Comparative assessment of component and system reliability for offshore platform pile foundations. In Innovations in Geotechnical Engineering; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 371–388. [Google Scholar] [CrossRef]

- Amouzadrad, P.; Mohapatra, S.C.; Guedes Soares, C. Review on sensitivity and uncertainty analysis of hydrodynamic and hydroelastic responses of floating offshore structures. J. Mar. Sci. Eng. 2025, 13, 1015. [Google Scholar] [CrossRef]

- Cornell, C.A. Structural reliability-some contributions to offshore technology. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 1995. [Google Scholar] [CrossRef]

- Wang, Y. An enhanced second-order method in structural reliability analyses. Structures 2025, 80, 109766. [Google Scholar] [CrossRef]

- Varela, G.; Tolentino, D. Reliability assessment of offshore structures considering cumulative damage over time. Structures 2025, 76, 109025. [Google Scholar] [CrossRef]

- Hu, Z.; Mansour, R.; Olsson, M.; Du, X. Second-order reliability methods: A review and comparative study. Struct. Multidiscip. Optim. 2021, 64, 3233–3263. [Google Scholar] [CrossRef]

- Krieger, W.; Banon, H.; Lloyd, J.; De, R.; Digre, K.; Nair, D.; Irick, J.; Guynes, S. Process for assessment of existing platforms to determine their fitness for purpose. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 1994. [Google Scholar] [CrossRef]

- Guo, J.; Liu, M.; Fang, Z.; Chen, W.; Pan, X.; Yang, L. An experimental study on the influence of wind-wave-current coupling effect on the global performance of a 12 MW semi-submersible floating wind turbine. Ocean Eng. 2024, 304, 117795. [Google Scholar] [CrossRef]

- Mohapatra, S.C.; Amouzadrad, P.; Bispo, I.B.d.S.; Guedes Soares, C. Hydrodynamic response to current and wind on a large floating interconnected structure. J. Mar. Sci. Eng. 2025, 13, 63. [Google Scholar] [CrossRef]

- Lamei, A.; Hayatdavoodi, M.; Riggs, H.; Ertekin, R. Wave–current–wind interaction with elastic floating offshore wind turbines. Eng. Anal. Bound. Elem. 2025, 171, 106052. [Google Scholar] [CrossRef]

- Aggarwal, R.; Litton, R.; Cornell, C.; Tang, W.; Chen, J.; Murff, J. Development of pile foundation bias factors using observed behavior of platforms during Hurricane Andrew. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 1996. [Google Scholar] [CrossRef]

- Marshall, P.W. Design of Welded Tubular Connections: Basis and Use of AWS Code Provisions; Elsevier: Amsterdam, The Netherlands, 2013; Volume 37. [Google Scholar]

- Moses, F. Development of Preliminary Load and Resistance Design Document for Fixed Offshore Platforms: API-PRAC Project 85-22; American Petroleum Institute: Washington, DC, USA, 1986. [Google Scholar]

- Liu, Z.; Nadim, F.; Lacasse, S.; Lehane, B.; Choi, Y.J. Method uncertainty for five axial pile capacity design methods. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2019. [Google Scholar] [CrossRef]

- Moses, F. System reliability developments in structural engineering. Struct. Saf. 1982, 1, 3–13. [Google Scholar] [CrossRef]

- Chen, J.; Gilbert, R.B.; Manuel, L. Study of Environmental Load Factor in API RP2A LRFD; University of Texas at Austin: Austin, TX, USA, 2017. [Google Scholar]

| Current Platform No. | Predicted Base Shear Load (MN) | Predicted Ultimate Capacity (MN) | Predicted Platform Performance | Observed Platform Performance | Comments |

|---|---|---|---|---|---|

| B1 | 16.7 | 16.9 | Failure | Survival | Design is conservative |

| B2 | 4.6 | 6.3 | Survival | Survival | Design is fair |

| B3 | 15.8 | 14.5 | Failure | Failure | Design is fair |

| B4 | 10.3 | 8.0 | Failure | Failure | Design is fair |

| B5 | 20.0 | 16.5 | Failure | Damage | Design is conservative |

| B6 | 5.4 | 7.3 | Survival | Damage | Design is unconservative |

| B7 | 6.0 | 7.2 | Damage | Failure | Design is unconservative |

| B8 | 6.0 | 4.9 | Failure | Damage | Design is conservative |

| B9 | 24.5 | 37.4 | Survival | Survival | Design is fair |

| B10 | 14.5 | 15.3 | Damage | Damage | Design is fair |

| B11 | 18.8 | 16.2 | Failure | Damage | Design is conservative |

| B12 | 18.9 | 18.6 | Failure | Survival | Design is conservative |

| B13 | 17.6 | 25.1 | Survival | Damage | Design is unconservative |

| B14 | 16.5 | 18.6 | Damage | Damage | Design is fair |

| B15 | 4.4 | 11.4 | Survival | Damage | Design is unconservative |

| B16 | 11.3 | 14.3 | Damage | Damage | Design is fair |

| B17 | 15.4 | 15.0 | Failure | Survival | Design is conservative |

| B18 | 5.3 | 5.4 | Failure | Failure | Design is fair |

| Variable | Seabed Geotechnical Sampling Condition | ||||

|---|---|---|---|---|---|

| Mean value | — | 1.0 | 1.0 | 1.0 | 1.0 |

| Coefficient of variation (COV) | Project-specific static sampling | 0.15 | 0.1 | 0.1 | 0.2 |

| Project-specific driven sampling | 0.15 | 0.15 | 0.2 | 0.3 | |

| No project-specific seabed soil samples | 0.15 | 0.2 | 0.3 | 0.5 |

| Statistical Value | ||||||

|---|---|---|---|---|---|---|

| Prior distribution | Mean value | 0.93 | 1.00 | 1.00 | 1.30 | 1.30 |

| Coefficient of variation (COV) | 0.20 | 0.20 | 0.30 | 0.30 | 0.50 | |

| Posterior distribution | Mean value | 0.92 | 0.95 | 1.17 | 1.05 | 1.46 |

| Coefficient of variation (COV) | 0.13 | 0.13 | 0.24 | 0.19 | 0.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, F.; Meng, F.; Zhao, Y.; Chen, J.; Zhao, R.; Zhang, Y.; Han, Z.; Bao, Y. The Reliability of Offshore Jacket Platforms Based on Bayesian Calibration. J. Mar. Sci. Eng. 2025, 13, 1989. https://doi.org/10.3390/jmse13101989

Zhou F, Meng F, Zhao Y, Chen J, Zhao R, Zhang Y, Han Z, Bao Y. The Reliability of Offshore Jacket Platforms Based on Bayesian Calibration. Journal of Marine Science and Engineering. 2025; 13(10):1989. https://doi.org/10.3390/jmse13101989

Chicago/Turabian StyleZhou, Fang, Fansheng Meng, Yuhan Zhao, Jinbo Chen, Rui Zhao, Yongfei Zhang, Zhaolong Han, and Yan Bao. 2025. "The Reliability of Offshore Jacket Platforms Based on Bayesian Calibration" Journal of Marine Science and Engineering 13, no. 10: 1989. https://doi.org/10.3390/jmse13101989

APA StyleZhou, F., Meng, F., Zhao, Y., Chen, J., Zhao, R., Zhang, Y., Han, Z., & Bao, Y. (2025). The Reliability of Offshore Jacket Platforms Based on Bayesian Calibration. Journal of Marine Science and Engineering, 13(10), 1989. https://doi.org/10.3390/jmse13101989