2.1. Hydrodynamic Analysis: Theoretical Basis

Hydrodynamic loads acting on marine structures primarily originate from the kinematics of water particles within waves, vessel motions, and wave–structure interactions. These loads are typically classified into three categories: drag forces, wave excitation forces, and inertia forces. Among these, drag forces are generally negligible in this context, as their contribution becomes significant only under conditions of large wave amplitudes. They are induced by viscosity and are proportional to the square of relative velocity between fluid particle and structure surface. In small amplitude waves, the wave exciting load consists of the first order incident wave force (Froude Krylov force) and the diffraction force which is induced by the disturbance wave due to the existence of a body, the second order forces may be neglected. The wave inertia load is caused by the disturbed waves induced by the body motions. Therefore, considering the analyzed sea state condition, wave excitation and inertia loads are the dominant components considered in the current analysis.

Fluid potential theories are commonly used for solving the wave inertia load and wave exciting load. To analyze the hydrodynamic behavior of the vessel under wave action, three-dimensional panel methods are widely employed. These approaches rely on potential flow theory and involve discretizing the wetted surface of the structure into a mesh of diffraction panels to simulate wave-structure interactions. For smaller structural elements, the Morison equation is commonly used to calculate hydrodynamic forces, with these components also being divided into discrete segments. The computational model employed in this study integrates both the panel method and the Morison equation in a hybrid framework, allowing for a more thorough assessment of hydrodynamic load distribution. For the diffraction analysis, a numerical approach known as the Source Distribution Method is used to calculate first-order wave loads under the assumption of small-amplitude waves and ideal fluid conditions. This method assumes the existence of a spatially dependent velocity potential function. Using linear hydrodynamic theory, the interaction between fluid and structure is modeled by a system of potential flow equations that incorporate both wave diffraction and radiation effects, as detailed in prior studies [

15,

16]. In this study, the vessel is modeled as a rigid body. In this framework, hydrodynamic loads induced by waves are applied to the hull, while the structural deformations are not coupled back into the fluid model. This assumption is widely used in potential flow-based analyses and provides a computationally efficient first-order prediction of hydrodynamic loads. More advanced formulations including structural flexibility, nonlinear effects, and full two-way FSI are beyond the scope of this work but represent directions for future research. The fluid–structure interaction behavior is described by the following set of equations:

where “

” is the velocity potential of the fluid, a scalar function from which the velocity field can be derived through the gradient:

, “

” the Laplacian of the potential “

”, which represents the sum of the second derivatives with respect to the three spatial coordinates.

where “

” is fluid velocity potential, “

” is wave angular frequency, “

g” gravitational acceleration,

partial derivative of the potential with respect to the vertical coordinate “

Z”,

Z = 0 is still water level (mean free surface).

normal derivative of the potential on the body surface, representing the fluid velocity normal to the surface, “

” represents the velocity potential function describing the initial incoming sinusoidal wave system. “

” is imaginary unit (

) used in the harmonic formulation, “

” normal velocity of the body in the

j-th degree of freedom

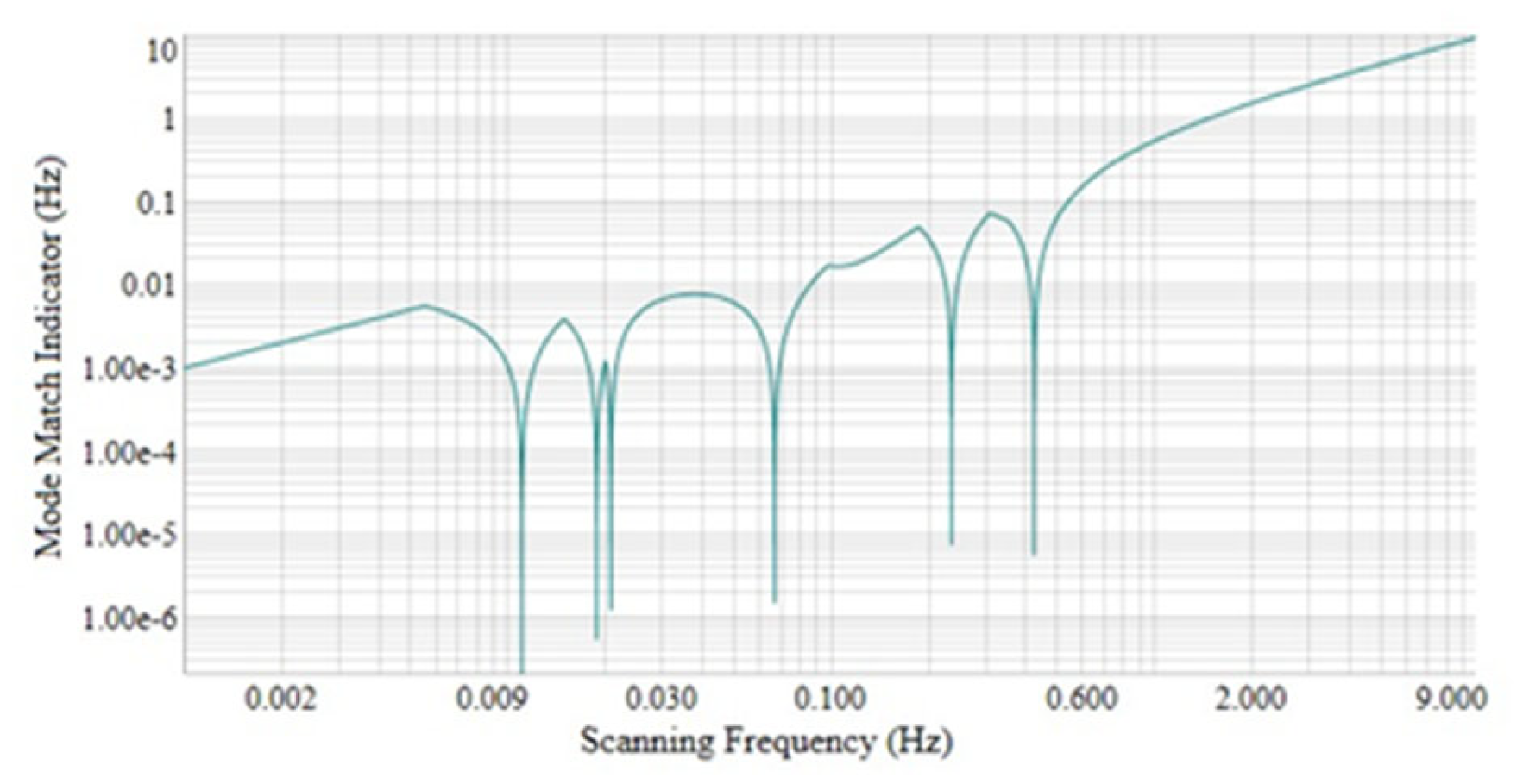

The hydrodynamic problem was solved using ANSYS AQWA (2024), a specialized software package that employs a boundary integration (boundary element), approach to compute the fluid velocity potential under the defined boundary conditions. This method enables an accurate representation of the interaction between waves and the floating structure, capturing the essential hydrodynamic effects required for subsequent structural analyses.

The numerical outputs generated by AQWA were subsequently exported and imported into MATLAB (2024) for post-processing, including RAOs, motions, vertical bending moment calculations, fatigue analyses, and comparison with classification rule-based criteria. In

Figure 1 the computational workflow used in this study is shown, which provides a visual summary of the methodology implemented.

A fundamental aspect of this approach is the use of the pulsating Green’s function in the frequency domain [

17,

18], which satisfies boundary conditions of a linear free surface, seabed, and far-field wave radiation as those given in previously. However, direct evaluation of the frequency domain using this Green’s function is computationally intensive. To overcome this challenge, the present study utilizes a precomputed database of Green’s functions, enabling efficient evaluation of both the function and its first-order derivatives. The low frequency behavior of the Green’s function in this database is defined by Equation (5), as described in [

17,

18]

where “

” is the water depth and

g are the gravity acceleration.

Under zero forward-speed conditions, the hydrodynamic loads induced by regular harmonic waves are considered, enabling the analysis of both wave excitation and radiation forces acting on a floating structure. First-order potential theory is employed to model wave diffraction and radiation effects, with the velocity potential in the fluid domain determined using the principle of linear superposition. Once the velocity potential is established, Bernoulli’s equation is applied to compute the hydrodynamic pressure distribution. By integrating this pressure over the wetted surface of the hull, the resulting hydrodynamic forces can be accurately determined. When forward speed is introduced, the governing equations become more complex, necessitating adjustments to the zero-speed formulations to accurately capture vessel–wave interactions. Furthermore, the Source Distribution Method, which utilizes the pulsating Green’s function in the frequency domain, does not inherently consider forward speed in its original formulation. To address this limitation, the translating-pulsating source method is introduced, which, unlike the standard pulsating source approach, incorporates moderate forward speeds into its theoretical framework. Under these conditions, the differences in the computed hydrodynamic responses between the two methods are typically minimal, making the translating-pulsating source method a reliable extension for scenarios involving low to moderate vessel speeds. An important factor introduced under forward-speed conditions is the encounter frequency, which adjusts the wave frequency to reflect the relative motion between the vessel and the incident wave, which can be defined as follows Equation (6):

where “

” is the wave frequency, “

” is the forward velocity, “

” is the acceleration of gravity, “

” is the angle between the incident wave and the ship.

Second-order wave forces can also be estimated through the use of the Quadratic Transfer Function (QTF) matrix, particularly under multi-directional wave conditions. However, such effects are often neglected to reduce computational complexity, especially in moderate sea states where wave amplitudes are relatively small. As the current analysis focuses on the interaction between the fluid and the vessel, a key element is the harmonic response of the structure to a regular wave, expressed by the Response Amplitude Operator (RAO). Derived from the linear equation of hydrodynamic motion [

19], RAO represents the dynamic motion response of a structure subjected to wave excitation over a range of frequencies. It serves as a transfer function that relates the wave input to the resulting structural motion, providing a critical tool for predicting the behavior of the vessel under wave loading, as described by the following Equation (7):

where

is the amplitude of motion and

is the amplitude of wave.

Ship motions result from external excitations such as wind, currents, and wave action. However, the degree of sensitivity to these excitations varies depending on the type and characteristics of the vessel. The complex hydrodynamic interaction between the ship and the fluid—an inherently infinite-degree-of-freedom system—is commonly simplified by modeling the vessel as a rigid body with six degrees of freedom: three translational (surge, sway, heave) and three rotational (roll, pitch, yaw), often referred to as primary and complementary motions [

20]. Generally, smaller motion amplitudes and slower oscillations are associated with better seakeeping performance. Conversely, large and rapid motions indicate poor seakeeping behavior. For this reason, seakeeping is considered a fundamental aspect of naval architecture and vessel design. For the subsequent estimation of total bending moments, the study adopts the empirical formulas provided by the Norwegian classification society (DNV), specifically for hogging (ship bending upward at midship) and sagging (ship bending downward at midship) conditions [

21]. These formulae account for the combined effects of still water and wave-induced bending moments as shown in Equations (8) and (9) and are specifically tailored for high-speed light craft, with application to monohull vessels.

where “

Msw” is still water bending moment (moment due to static loading conditions without wave effects), “

CW” is Wave coefficient (empirical coefficient related to wave loads), “

L” is Ship length between perpendiculars, “

B” is Ship breadth, “

CB” is Block coefficient (ratio of the underwater volume of the ship to the volume of a rectangular block with the same length, breadth, and draft) [

22].

Fatigue analysis was conducted considering the sea states commonly observed in the studied area. The evaluation focused on an operational design life of 20 years. After identifying the most critical sea states according to DNV limits, fatigue life assessment was carried out to determine the time to fatigue failure of the vessel structures. The investigation focused on different materials typically used in ship construction: AA5083, S355, and Ti6Al4V. Further details of the analysis, along with the use of Miner’s rule and Navier’s equation, are provided in

Section 3.2.

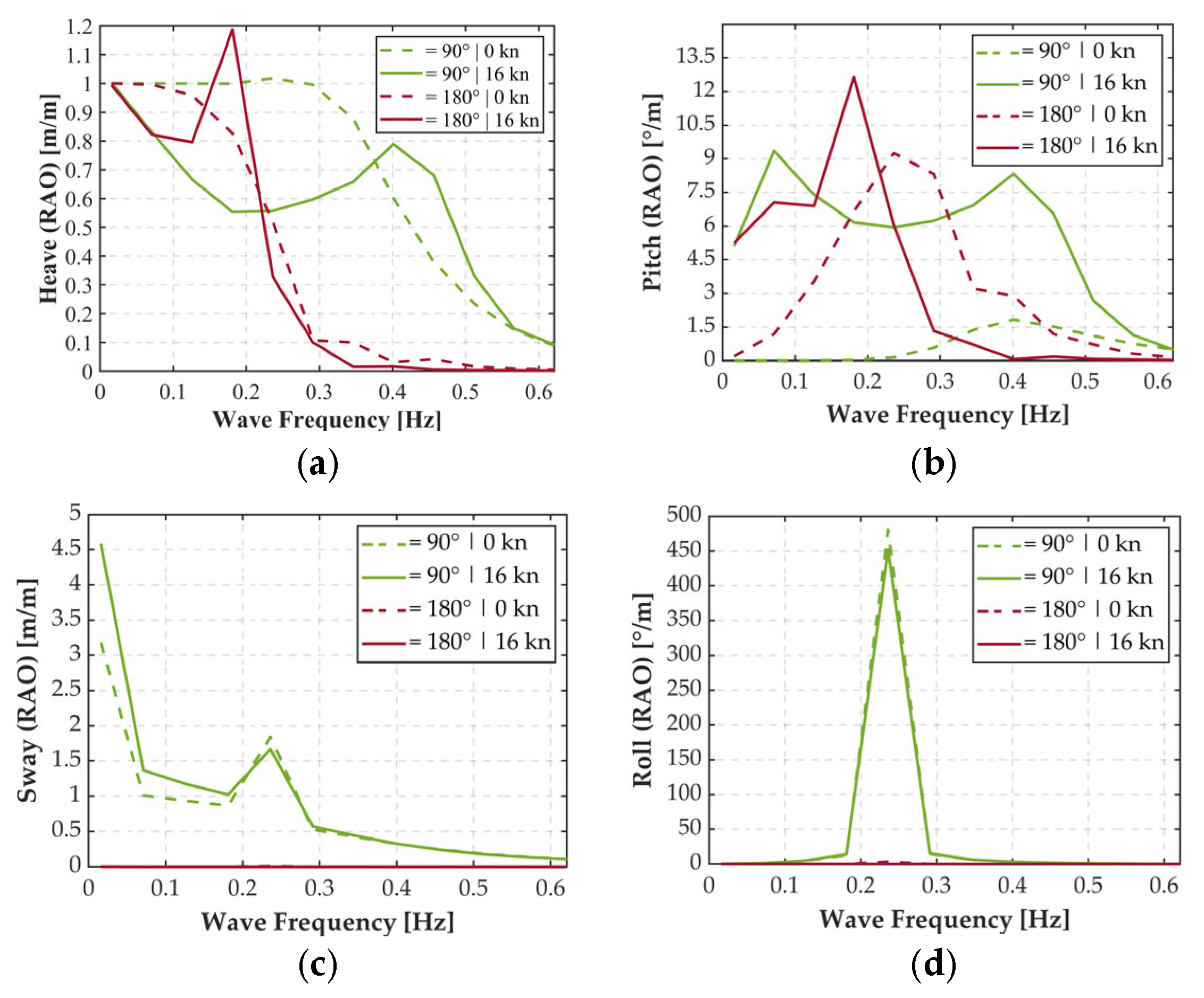

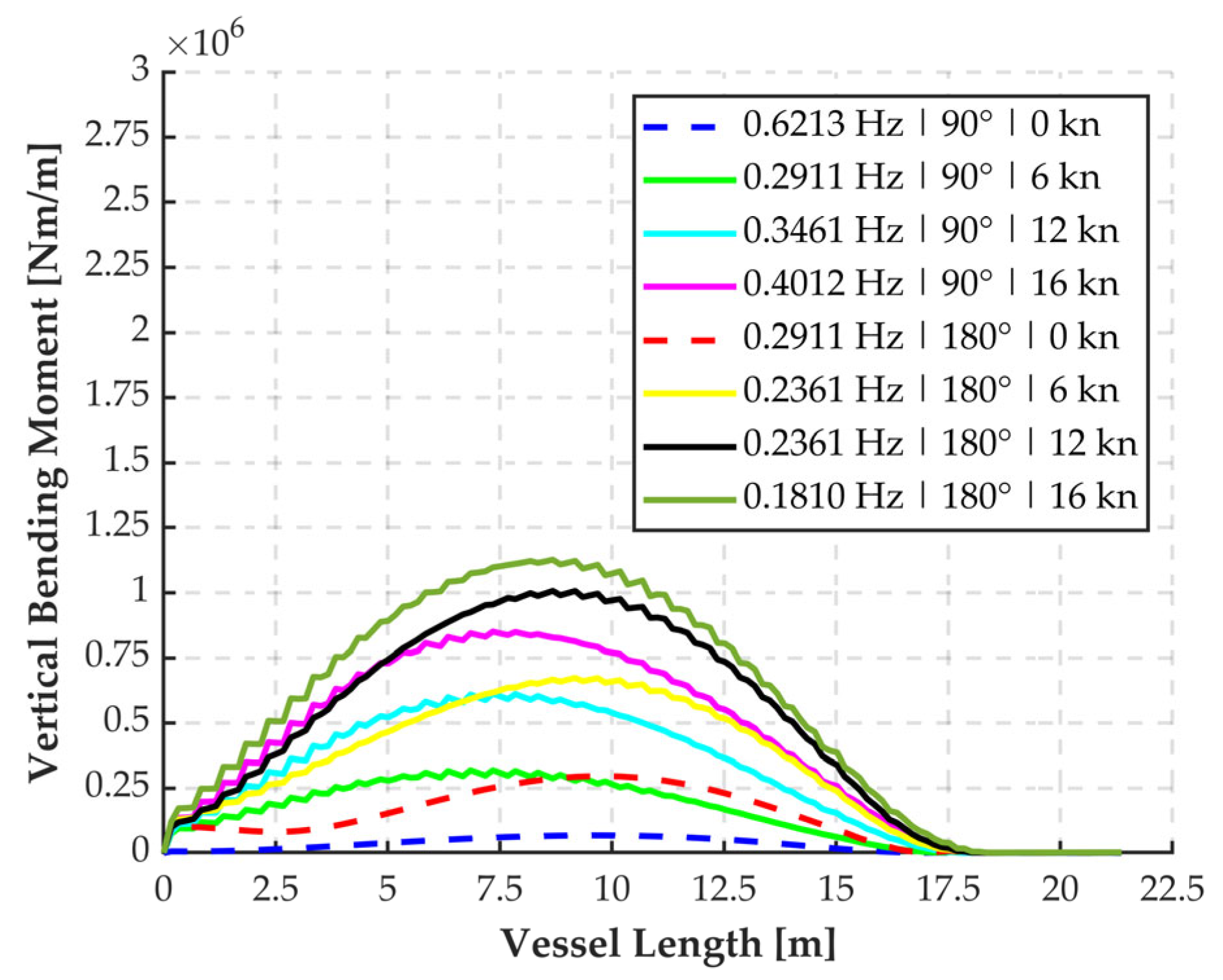

2.2. Case Study

Hydrodynamic simulations were carried out analyzing vessel motions and computing the corresponding Response Amplitude Operators (RAOs) under wave excitation. The analyses were conducted by varying wave train characteristics, both in calm water and under operational conditions. A numerical approach was employed to evaluate the vessel’s seakeeping performance across different scenarios. The simulation results were subsequently compared with bending moment estimates derived from empirical formulas provided by the Norwegian classification society (DNV), enabling a comparative assessment of the numerical and empirical approaches. The outcomes of the motion analysis provide a foundational dataset for further investigations into the vessel’s structural reliability under realistic sea conditions. The principal dimensions of the vessel analyzed are presented in

Table 1.

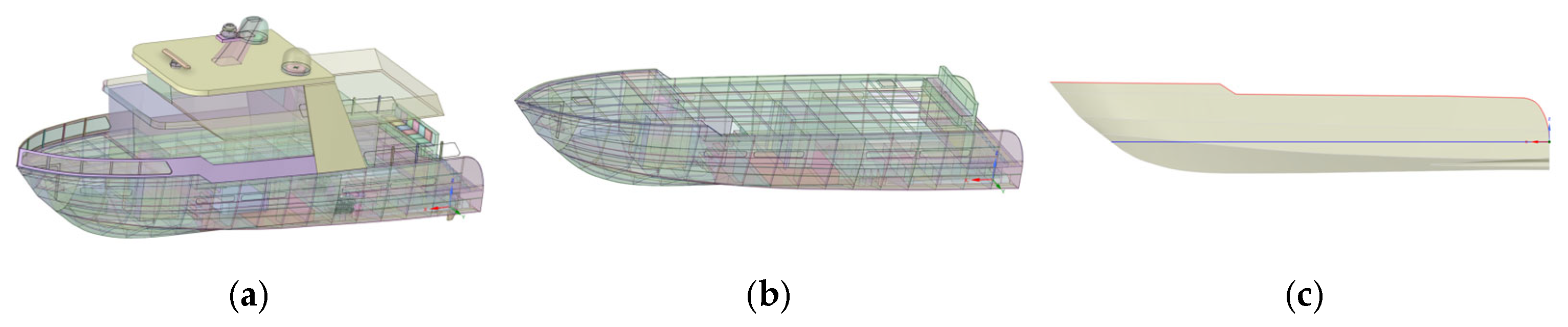

In the considered region, various types of pleasure craft operate or transit. For the analysis, the CAD model of a representative pleasure craft was used, as its main characteristics closely resemble those of the most common private and recreational vessels frequently found in the area. This vessel is shown in

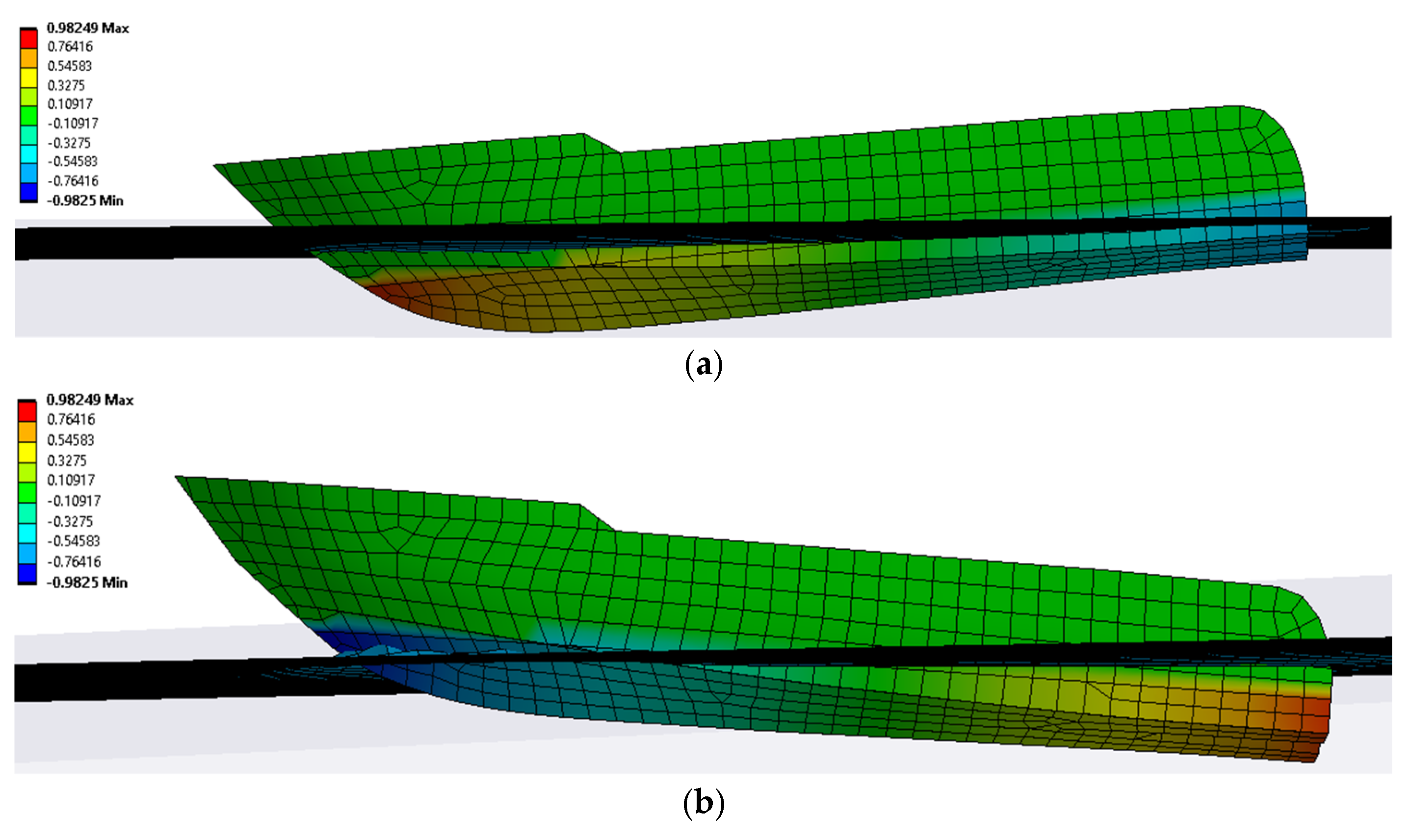

Figure 2a. Only the external hull surfaces were included in the hydrodynamic simulations, while all internal structural components, deemed non-essential for this analysis, were excluded. Additionally, all openings in the hull were sealed to ensure they did not influence the simulation results, as illustrated in

Figure 2b,c. Subsequently, the hull was divided into two sections using the waterline, located 1.2 m above the baseline (keel line), as the reference plane. This step was necessary to meet the modeling requirements of the hydrodynamic analysis software.

The wetted hull surface was discretized into diffraction panels, and a constant time step of 0.05 s was adopted to ensure numerical stability and accurate resolution of wave–structure interactions.

The vessel was modeled as a rigid-body hull surface, which allows efficient evaluation of global hydrodynamic loads such as vertical bending moments. While this approach does not capture structural flexibility, it provides reliable first-order results suitable for structural assessment at the global scale and a comparison with classification societies rules. Internal structural details were excluded, and hull openings were sealed to avoid spurious effects in the numerical simulations. This simplification preserves the main hydrodynamic characteristics while ensuring robustness of the model.

The vessel’s operational area is located in the Strait of Messina, as shown in

Figure 3a. The sea conditions in this region can be effectively represented using the JONSWAP (Joint North Sea Wave Project) spectrum. As highlighted in a recent global assessment of its suitability in coastal areas [

23], the JONSWAP spectrum has demonstrated good performance in modeling real sea states within the Mediterranean Sea. Although the spectrum describes irregular waves, regular wave components derived from it are employed in this study to analyze the hull’s response. According to data from APAT [

24], the average significant wave height in the vessel’s operating area is approximately 2 m. Regarding forward speed, reference is made to the guidelines issued by the Messina Vessel Traffic Service [

25], which establish a maximum allowable navigation speed of 16 knots within the Strait. Furthermore, local bathymetric conditions were defined using data from a study by ENEA (the Italian National Agency for New Technologies, Energy, and Sustainable Economic Development) [

26] which validated a marine circulation model for the Strait of Messina. This reference provided input parameters for the simulations, including an average sea depth of approximately 100 m, with localized areas reaching depths of up to 250 m, as illustrated in

Figure 3b.

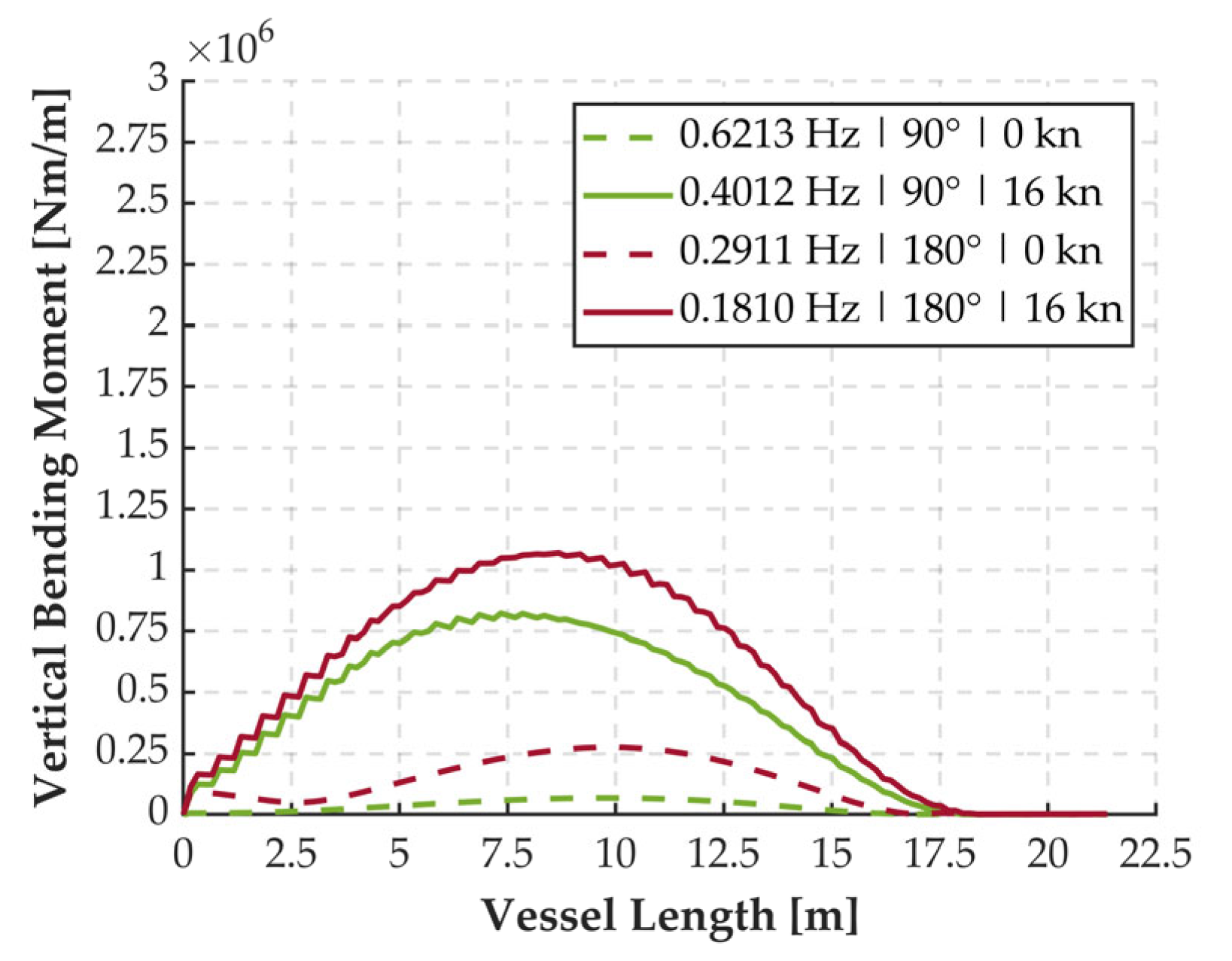

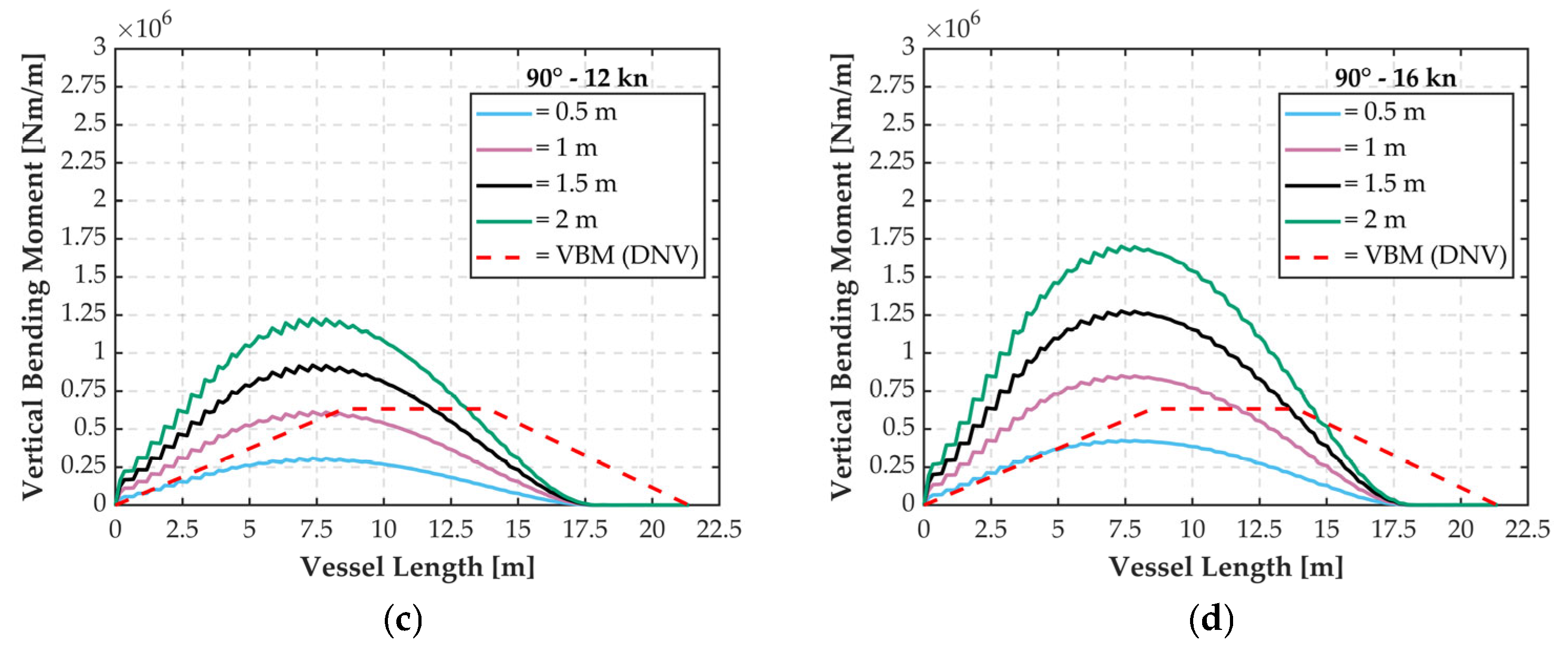

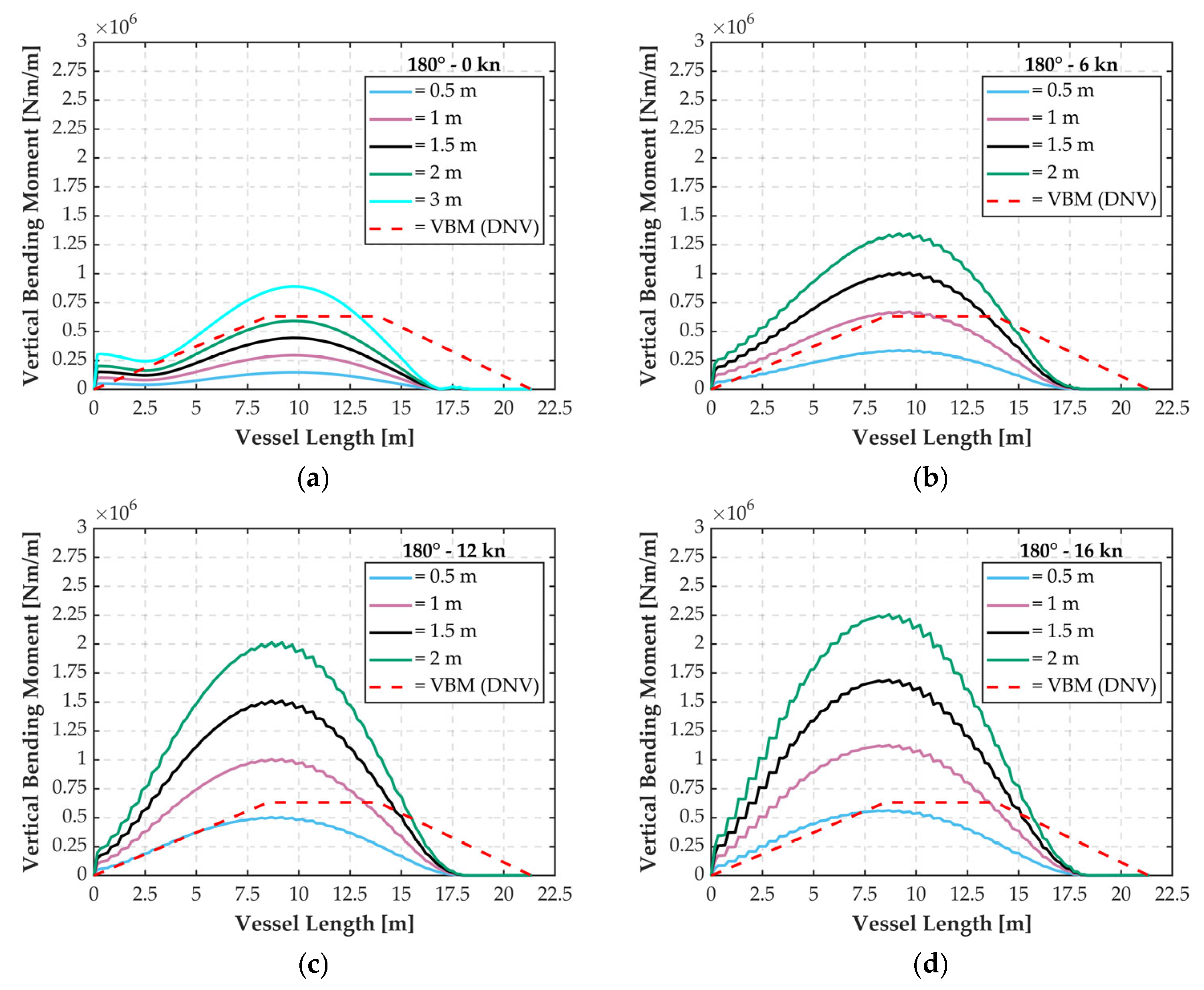

Regarding wave incidence, the most critical directions 180° (head seas) and 90° (beam seas) were considered for the analysis. The corresponding frequency range evaluated is presented in

Table 2.

The gyration radii used in this study are based on the recommendations provided by the International Towing Tank Conference (ITTC) [

27] as listed in

Table 3.

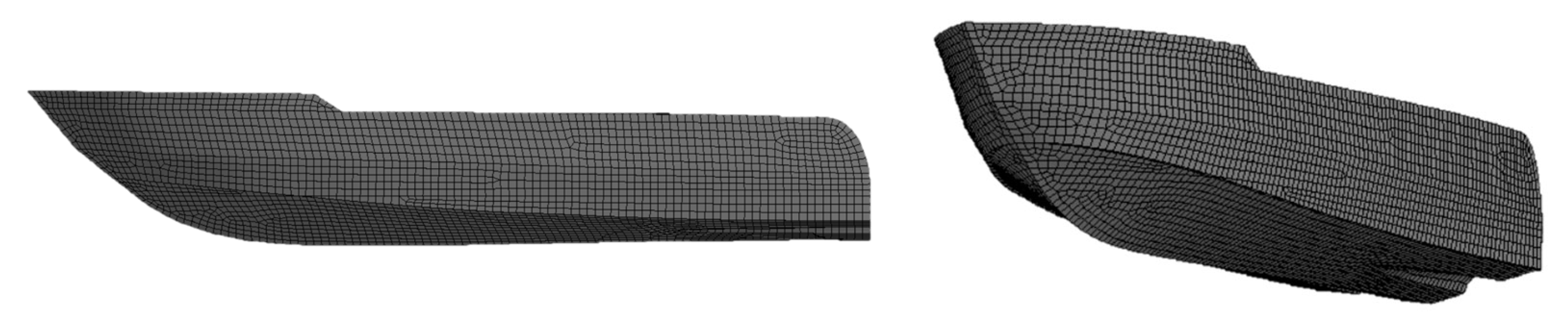

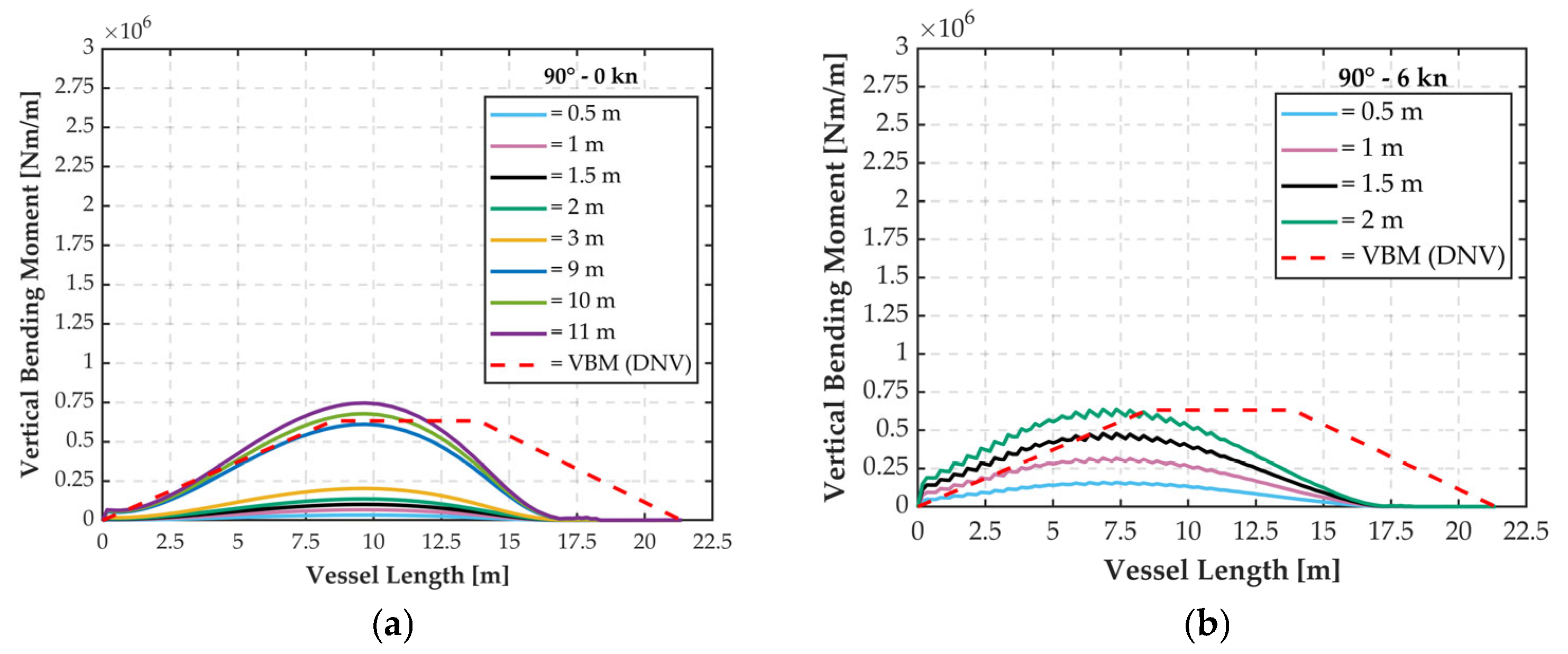

The mesh was chosen for analysis purposes, prioritizing computational efficiency, several analyses were performed by progressively refining the mesh from an element size of 0.5 m down to 0.2 m, observing that the results of the simulations did not differ significantly. Considering the hull dimensions and the required level of accuracy for the hydrodynamic analysis, the computational mesh was suitably refined to ensure both reliability and precision of the results. An illustration of the generated mesh is shown in

Figure 4.

Details of the mesh are shown in

Table 4.

The mesh was refined using an element size of 0.2 m, resulting in a higher total number of elements. An illustration of the generated mesh is shown in

Figure 5. Details of the mesh are shown in

Table 5.

However, the simulation results obtained using the 0.5 m mesh did not show significant deviations when compared to those derived from the finer 0.2 m mesh. For instance, considering the bending moment at 180° without velocity, the 0.5 m mesh produced a value of 2.97 × 10

5 N·m/m, while the refined 0.2 m mesh resulted in 2.87 × 10

5 N·m/m. The percentage difference is calculated with the following formula:

where

is the value with the coarse mesh and

is the reference value with the finer mesh.

This corresponds to a difference of approximately 3.3%, indicating that the coarser mesh still provides a sufficiently accurate representation for the purposes of this study. The relatively small deviation between the results obtained with the 0.5 m and 0.2 m mesh resolutions demonstrate that the coarser mesh is capable of capturing the structural behavior without significant loss of accuracy. Therefore, in order to reduce computational effort, optimize resource usage, and accelerate the simulation process, the 0.5 m mesh configuration was selected for all subsequent analyses. This choice ensures a good balance between computational efficiency and solution reliability, allowing for parametric studies while maintaining the accuracy of the results.