A Numerical Study on the Seakeeping Performance and Ride Comfort of a Small MonoHull Vessel With and Without Hydrofoil in Regular Head Seas

Abstract

1. Introduction

1.1. Background and Motivation

1.2. Research Gap and Novelty

- Cross-compare heave and pitch RAOs from linear seakeeping (Maxsurf Motions) and nonlinear CFD to verify consistency.

- Quantify hydrofoil effects by comparing heave and pitch RAOs of the bare hull and the hydrofoil-fitted hull.

- Derive vertical-acceleration frequency responses at passenger locations under operating conditions and exposure durations for MSI assessment.

1.3. Research Objective

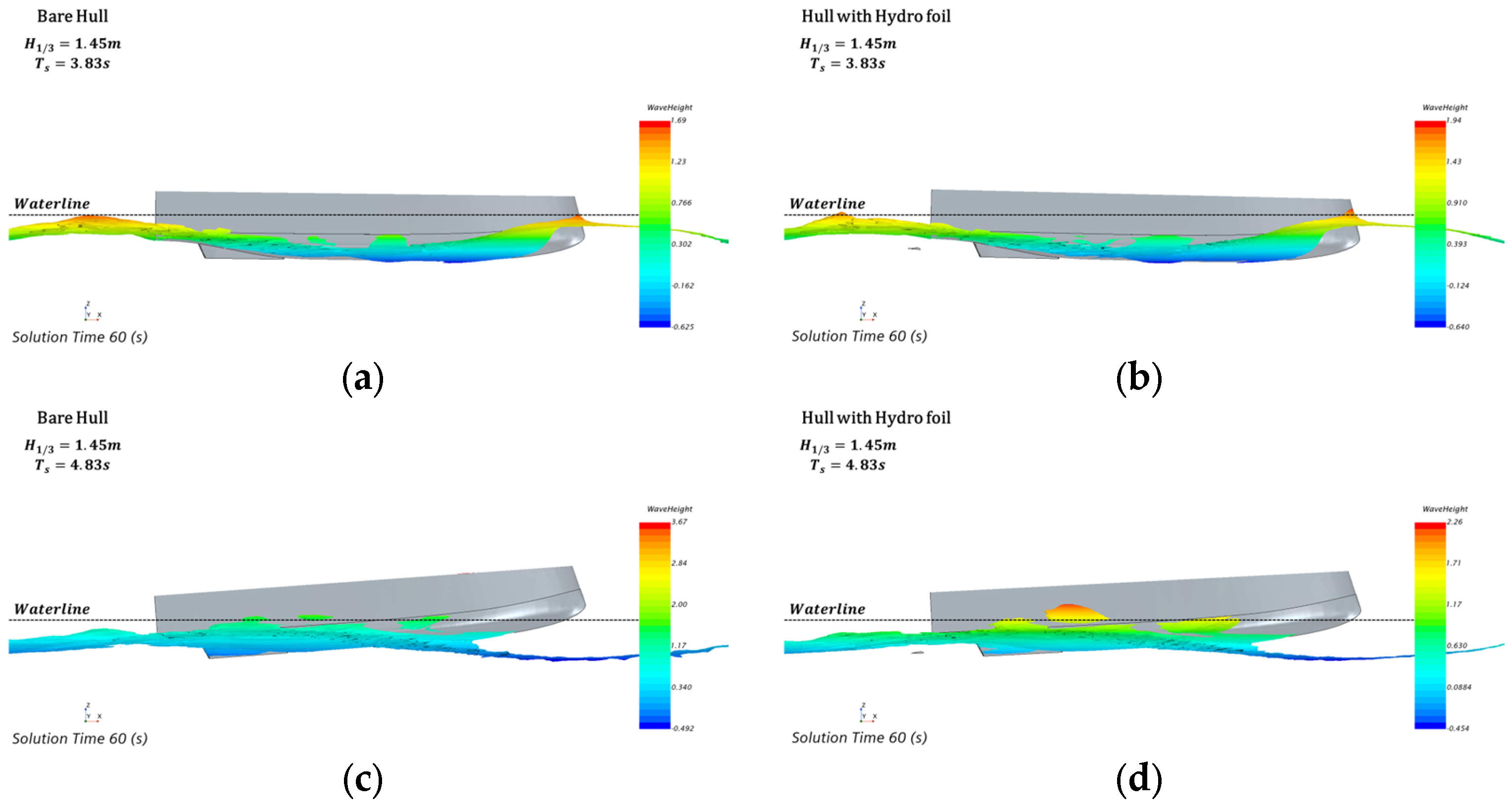

2. Numerical Methodology

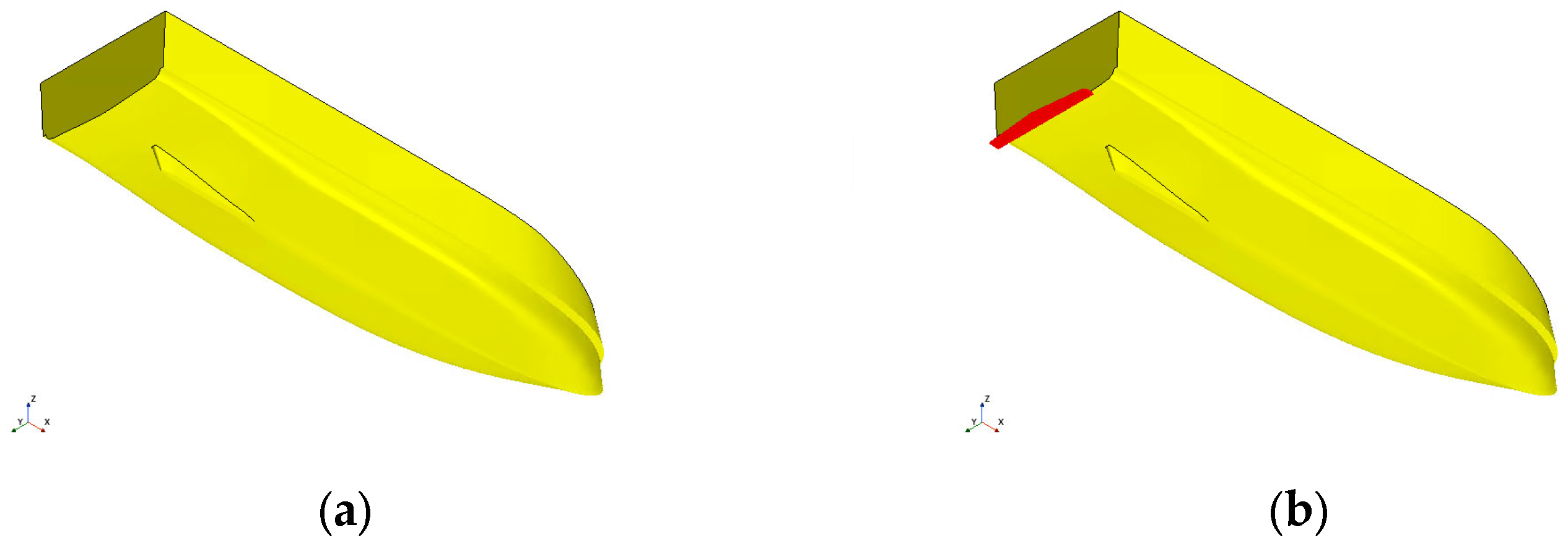

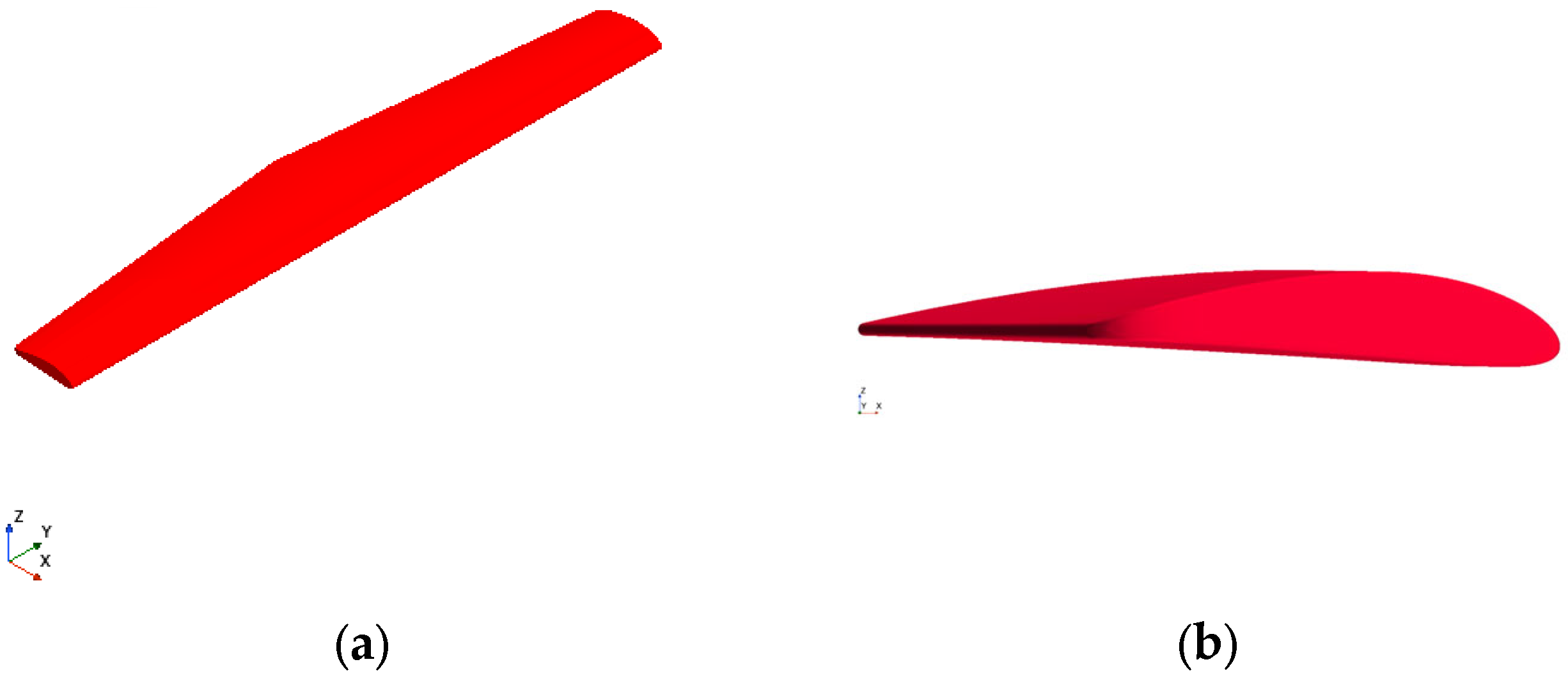

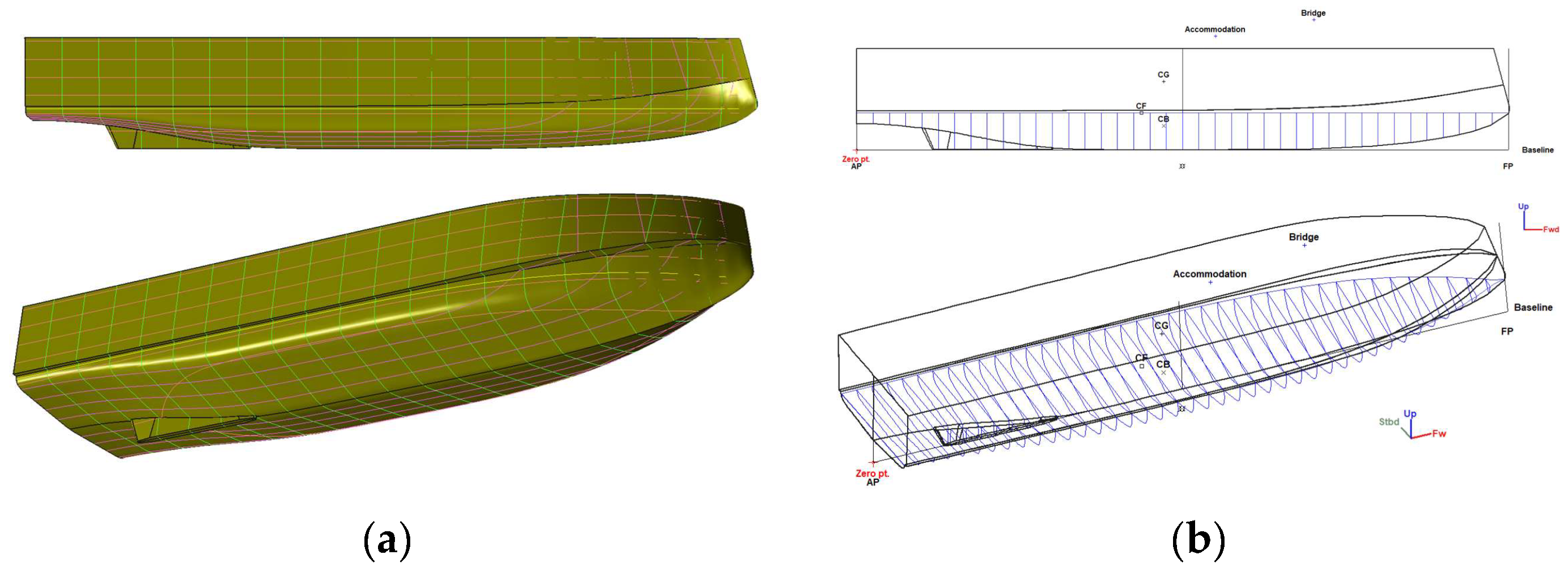

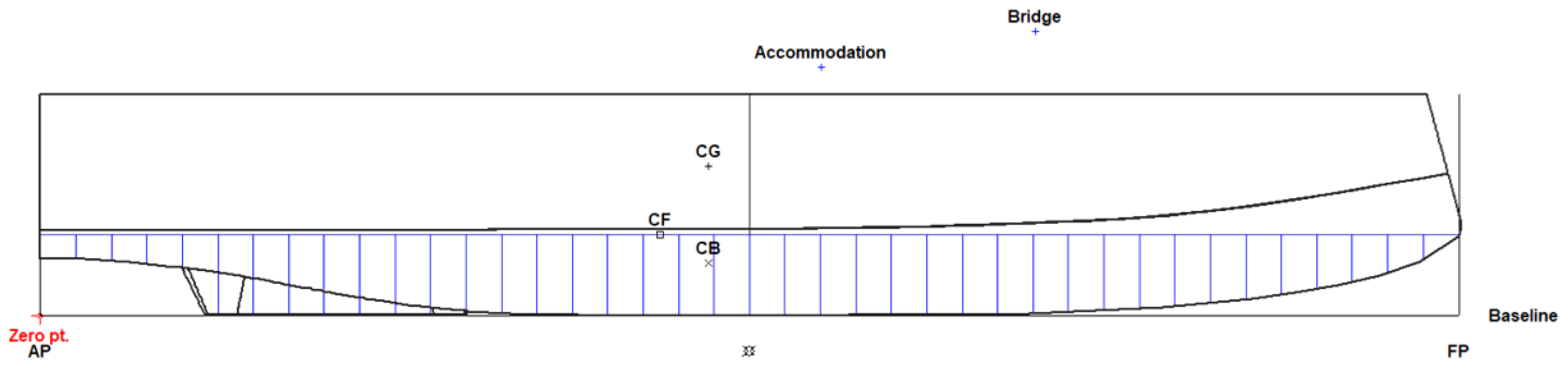

2.1. Vessel Description and Hydrofoil Configuration

2.2. Linear Seakeeping Analysis Using Maxsurf Motions

2.3. Nonlinear CFD-Based Seakeeping Analysis

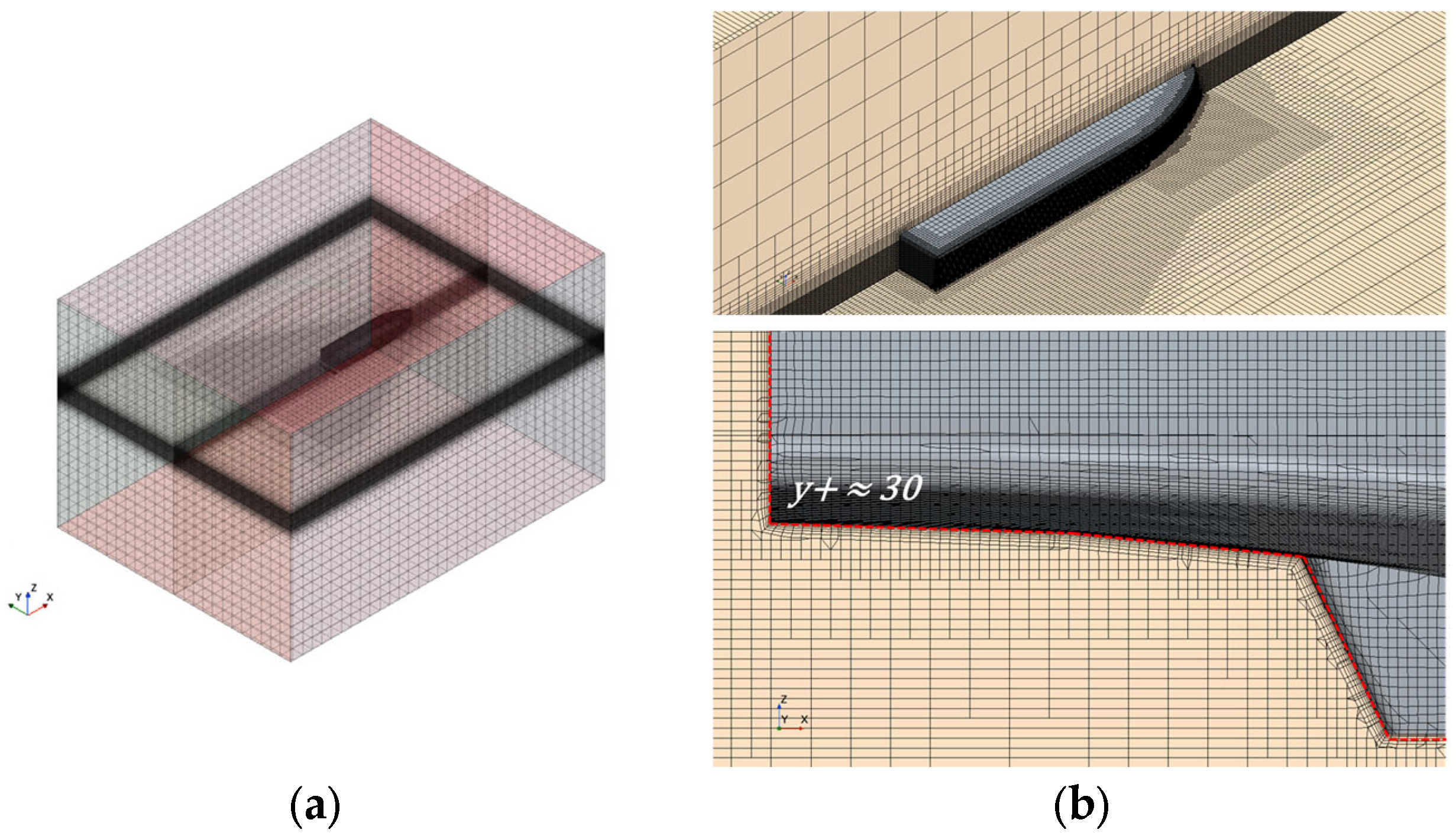

2.4. Estimation of Motion Sickness Incidence

3. Verification

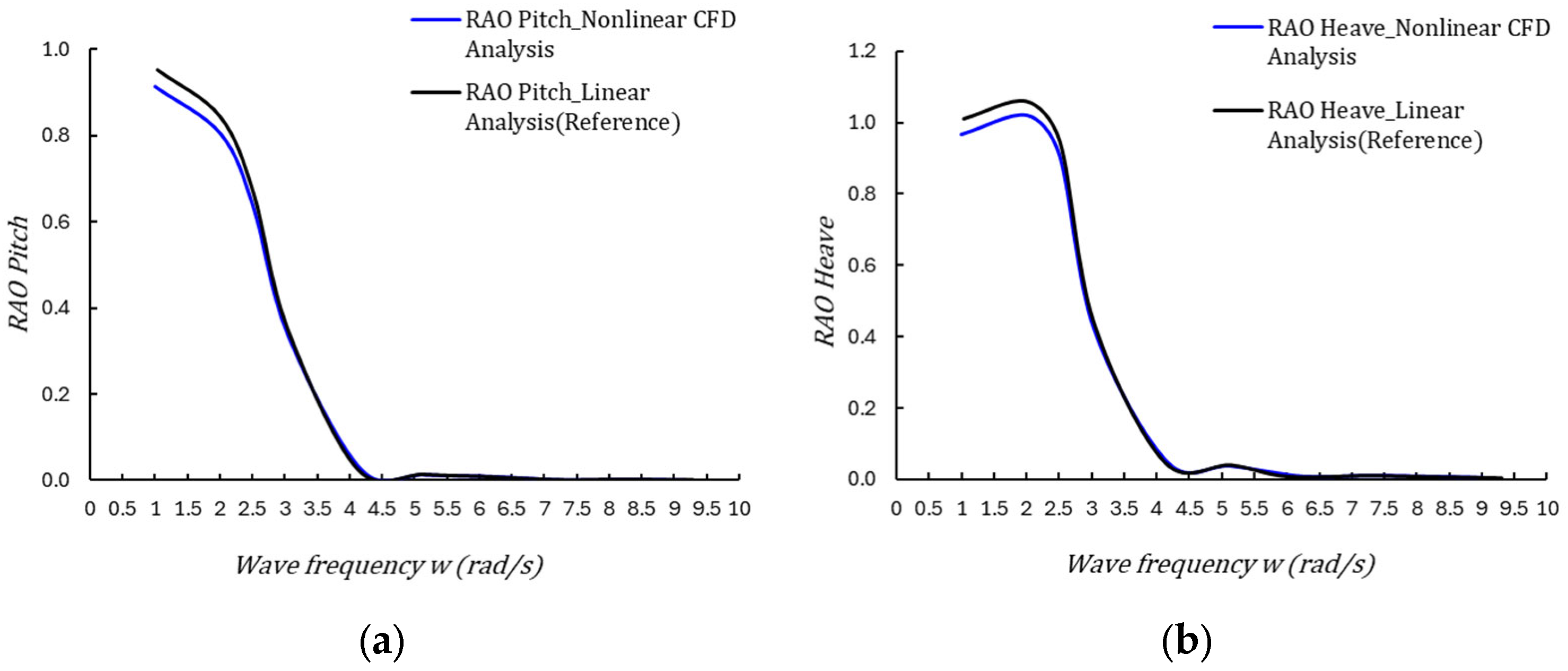

- Comparison of peak response locations across key frequency ranges

- Quantitative error analysis of RAO amplitudes

- Evaluation of average and maximum error rates across the entire frequency range

- Heave RAO

- Pitch RAO

4. Results and Discussion

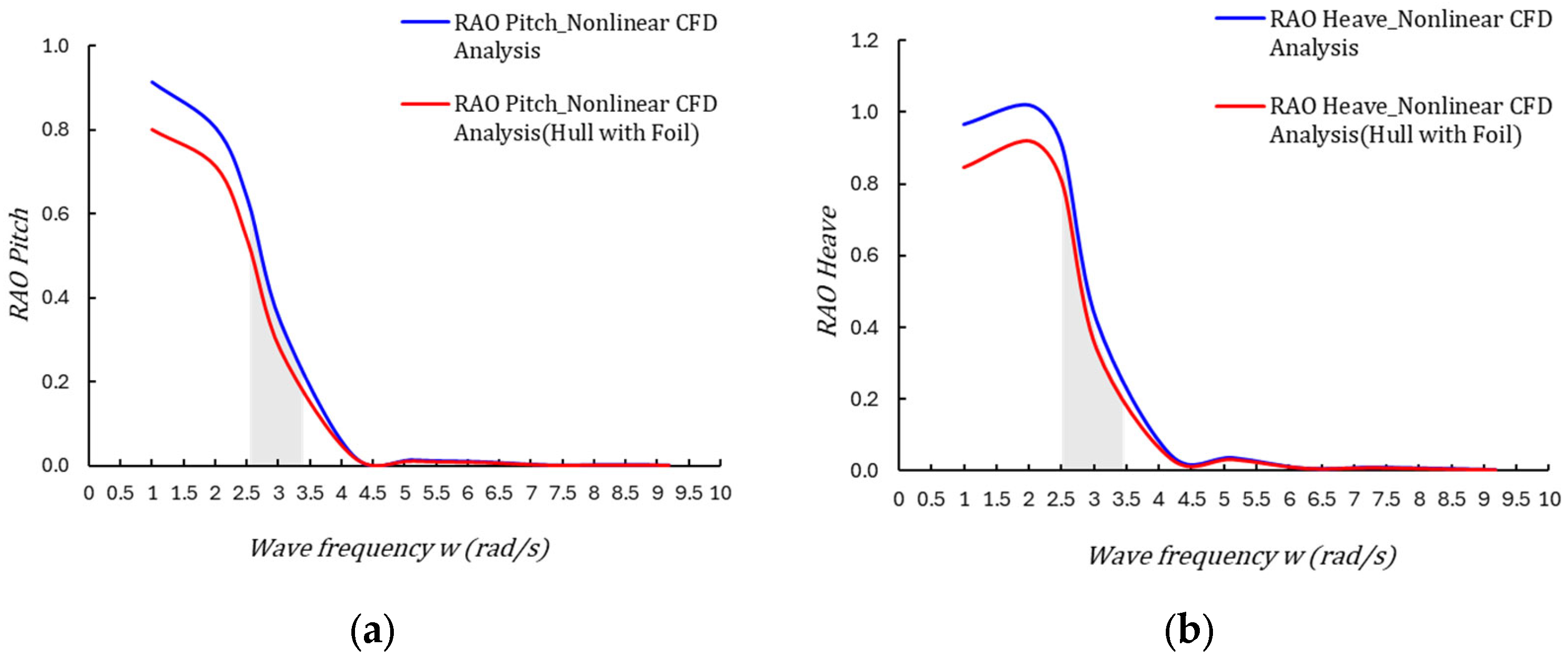

4.1. Seakeeping RAO Comparison: With vs. Without Hydrofoil

- The peak frequency of the maximum response amplitude appeared in the range of approximately 1.5–2.5 rad/s under both with-foil and without-foil conditions, indicating that the fundamental hull characteristics were preserved.

- With hydrofoils installed, the maximum RAO values decreased by an average of 16.7%, with the most significant attenuation observed in the mid–high-frequency range (1.0–1.5 rad/s).

- In the high-frequency region (>4 rad/s), the difference between the two conditions was relatively small, since shorter wave periods caused rapid decay of vessel motions, with radiation damping effects becoming dominant.

- With hydrofoil installation, the maximum pitch RAO amplitudes decreased by approximately 16.1% on average, with attenuation effects appearing more pronounced than in heave motions.

- In particular, near the peak response frequency (around 1.0 rad/s), the amplitude decreased from 0.9 deg/m (without foil) to 0.7 deg/m (with foil), representing a perceptibly significant reduction.

- In the high-frequency region (>4 rad/s), the difference between the two cases diminished sharply, which can be attributed to the vessel’s reduced wave-following capability at higher frequencies, thereby limiting the effect of the foil.

4.2. MSI Comparison Under Various Wave Frequencies

5. Conclusions

5.1. Summary of Findings

- With hydrofoil installation, the amplitudes of heave and pitch responses in the frequency domain (RAO analysis) were reduced by approximately 16%.

- For the bare-hull condition, MSI estimated using the linear analysis program showed that under Gentle Breeze conditions, seasickness incidence remained low even with long exposure times (up to 6 h), while under Moderate conditions, passengers at both the bridge and accommodation did not experience seasickness even after exposure of up to 30 min across the entire encounter frequency range.

- These results indicate that, except for certain frequency bands, seasickness incidence remains low in primary passenger and crew spaces such as accommodation and the bridge, even during long-term voyages. Thus, the vessel analyzed in this study can be generally evaluated as having excellent operational stability.

- Although direct MSI estimation was not feasible for the hydrofoil-fitted condition using the linear analysis program, the quantitative reduction in motion amplitudes reasonably suggests a significant decrease in MSI.

- This study numerically demonstrated that hydrofoils can serve as an effective structural means of improving motion stability and enhancing ride comfort not only for high-speed vessels but also for small coastal vessels operating at low speeds.

5.2. Engineering Implications

5.3. Limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maxsurf Motions V8i. Available online: https://www.bentley.com/software/maxsurf (accessed on 23 September 2025).

- STAR-CCM+, Version 19.06. Available online: https://plm.sw.siemens.com/en-US/simcenter/fluids-thermal-simulation/star-ccm/ (accessed on 23 September 2025).

- Lau, C.-Y.; Ali-Lavroff, J.; Holloway, D.S.; Shabani, B.; Mehr, J.A.; Thomas, G. Influence of an active T-foil on motions and passenger comfort of a large high-speed wave-piercing catamaran based on sea trials. J. Mar. Sci. Technol. 2022, 27, 856–872. [Google Scholar] [CrossRef]

- Lau, C.-Y.; Ali-Lavroff, J.; Dashtimanesh, A.; Holloway, D.S.; Mehr, J.A. High-speed catamaran response with ride control system in regular waves by Forcing Function Method in CFD. Ocean Eng. 2024, 297, 117111. [Google Scholar] [CrossRef]

- Javanmard, E.; Mehr, J.A.; Ali-Lavroff, J.; Holloway, D.S.; Davis, M.R. An experimental investigation of the effect of ride control systems on the motions response of high-speed catamarans in irregular waves. Ocean Eng. 2023, 281, 114899. [Google Scholar] [CrossRef]

- Bowker, J.A.; Townsend, N.C. Evaluation of bow foils on ship delivered power in waves using model tests. Appl. Ocean Res. 2022, 123, 103148. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, D.; Wang, Y.; Zong, Z.; Wu, Z. Model experimental study on a T-foil control method with anti-vertical motion optimization of the mono hull. J. Mar. Sci. Eng. 2023, 11, 1551. [Google Scholar] [CrossRef]

- Moreira, D.; Mathias, N.; Morais, T. Dual flapping foil system for propulsion and harnessing wave energy: A 2D parametric study for unaligned foil configurations. Ocean Eng. 2020, 217, 107875. [Google Scholar] [CrossRef]

- Li, F.; Yu, P.; Wang, Q.; Li, G.; Wu, X. Numerical analysis of the effect of flexibility on the propulsive performance of a heaving hydrofoil undergoing sinusoidal and non-sinusoidal motions. Pol. Marit. Res. 2021, 28, 4–19. [Google Scholar] [CrossRef]

- Wang, W.Q.; Li, W.; Yan, Y.; Zhang, J. Parametric study on the propulsion and energy harvesting performance of a pitching foil hanging under a wave glider. Renew. Energy 2022, 184, 830–844. [Google Scholar] [CrossRef]

- Yasukawa, H.; Ishikawa, T. Improvement of propulsive performance of a catamaran in waves by a biologically inspired hydrofoil. In Proceedings of the 11th Symposium on High-Performance Marine Vehicles, Zevenwacht, South Africa, 11–13 September 2017. [Google Scholar]

- Xu, G.D.; Duan, W.Y.; Zhou, B.Z. Propulsion of an active flapping foil in heading waves of deep water. Eng. Anal. Bound. Elem. 2017, 84, 63–76. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, L.; Zhou, Y. A wave foil with passive angle of attack adjustment for wave energy extraction for ships. Ocean Eng. 2022, 260, 110627. [Google Scholar] [CrossRef]

- Mei, L.; Yan, W.; Zhou, J.; Shi, W. Thrust Enhancement of DTMB 5415 with Elastic Flapping Foil in Regular Head Waves. J. Mar. Sci. Eng. 2023, 11, 632. [Google Scholar] [CrossRef]

- Kuang, W.; Wang, D.; Hu, Z. Seakeeping Performance Analysis of a Ship with Hydrofoils in Regular Waves. SSRN Preprint 2024. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=475324 (accessed on 20 September 2025).

- Niklas, K.; Pruszko, H. The retrofitting of ships by applying retractable bow hydrofoils: A case study. J. Ocean Eng. Mar. Energy 2023, 9, 767–788. [Google Scholar] [CrossRef]

- Fitriadhy, A.; Adam, N.A.; Zikry, M.S. Computational Analysis on Heave and Pitch Motions Performance of a Hydrofoil Ship. JMEST 2021, 1, 156. [Google Scholar] [CrossRef]

- ISO 2631-1:1997; Mechanical Vibration and Shock—Evaluation of Human Exposure to Whole-Body Vibration—Part 1: General Requirements. ISO: Geneva, Switzerland, 1997.

- International Maritime Organization (IMO). International Code of Safety for High-Speed Craft, 2000 (2000 HSC Code); International Maritime Organization: London, UK, 2008. [Google Scholar]

- Karimkhani, M.; Ghassemi, H.; He, G. Review on the active and passive control systems for the planing boats. Am. J. Civ. Eng. Archit. 2025, 13, 62–72. [Google Scholar] [CrossRef]

- Khalid, H.; Turan, O.; Bos, J.E.; Incecik, A. Application of the subjective vertical–horizontal conflict physiological motion sickness model to the field trials of contemporary vessels. Ocean Eng. 2011, 38, 22–33. [Google Scholar] [CrossRef]

- Rhino ver.8, Robert McNeel & Associates, Seattle, WA, USA. Available online: https://www.rhino3d.com (accessed on 24 September 2025).

- O’Hanlan, J.F.; McCawley, M.E. Motion sickness incidence as a function of the frequency and acceleration of vertical sinusoidal motion. Aerosp. Med. 1974, 45, 366–369. [Google Scholar]

| Name | Value | Unit |

|---|---|---|

| Profile | NACA 0012 | - |

| Chord | 0.15 | m |

| Span (tip to root) | 1.00 | m |

| Attack angle | 0.00 | ° |

| Submergence depth | 0.30 | m |

| Dimension | Value | Unit |

|---|---|---|

| Length overall, LOA | 20.00 | m |

| Breadth, B | 5.00 | m |

| Draft, D | 1.13 | m |

| Displacement, ▽ | 57.00 | ton |

| Design speed, V | 10.00 | knots |

| Longitudinal Center of Gravity, LCG | 8.83 | m |

| Vertical Center of Gravity, VCG | 2.10 | m |

| Radius of gyration in pitch, kyy/L | 25 | % |

| Item | Value | Unit |

|---|---|---|

| Design speed, V | 10.00 | knots |

| Encounter angle | 180.00 | ° |

| Encounter Frequency | 1.00~9.20 | rad/s |

| Wave Height | 0.14–0.62 | m |

| Wave type | Regular wave | - |

| Boundary | Condition Setting |

|---|---|

| Inlet, Top, Bottom | Velocity inlet |

| Outlet | Pressure outlet |

| Side | Symmetry |

| Item | Value | Unit |

|---|---|---|

| Dimensionality | Three-Dimensional | – |

| Governing equations | Reynolds-Averaged Navier–Stokes (RANS) | – |

| Flow type/Solver | Segregated flow (pressure-based) | – |

| Temporal scheme (order) | Implicit unsteady (second-order) | – |

| Time-step Δt | 0.02 | s |

| Inner iterations per time-step | 20 | – |

| Turbulence model | Reynolds Stress Tublence High y+ Wall Treatment (Wall Distance enabled) | – |

| Free-surface method | Volume of Fluid (VOF) with VOF Waves | – |

| Gravity | 9.81 | m·s−2 |

| Multiphase interaction | Enabled | – |

| Solution time (total) | 60 | s |

| Dimensionality | Three-Dimensional | – |

| Case | Base Size (m) | Mesh Cells (Million, M) | RAO |

|---|---|---|---|

| 1 | 0.150 | 1.0 | 0.728 |

| 2 | 0.212 | 2.0 | 0.568 |

| 3 | 0.300 | 3.0 | 0.501 |

| 4 | 0.424 | 4.5 | 0.471 |

| 5 | 0.600 | 6.0 | 0.452 |

| 6 | 0.849 | 9.0 | 0.443 |

| 7 | 1.200 | 15.0 | 0.441 |

| Parameter | Value | Unit |

|---|---|---|

| Wave Heading | 180 | ° |

| Wave Height | 0.27–1.45 | m |

| Encounter Frequency | 1.00~9.20 | rad/s |

| Ship speed | 10.00 | knots |

| Hydrofoil configuration | With hydrofoil/Without hydrofoil | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Oh, W.; Kwon, W. A Numerical Study on the Seakeeping Performance and Ride Comfort of a Small MonoHull Vessel With and Without Hydrofoil in Regular Head Seas. J. Mar. Sci. Eng. 2025, 13, 1895. https://doi.org/10.3390/jmse13101895

Kim J, Oh W, Kwon W. A Numerical Study on the Seakeeping Performance and Ride Comfort of a Small MonoHull Vessel With and Without Hydrofoil in Regular Head Seas. Journal of Marine Science and Engineering. 2025; 13(10):1895. https://doi.org/10.3390/jmse13101895

Chicago/Turabian StyleKim, Jungeun, Woojun Oh, and Wook Kwon. 2025. "A Numerical Study on the Seakeeping Performance and Ride Comfort of a Small MonoHull Vessel With and Without Hydrofoil in Regular Head Seas" Journal of Marine Science and Engineering 13, no. 10: 1895. https://doi.org/10.3390/jmse13101895

APA StyleKim, J., Oh, W., & Kwon, W. (2025). A Numerical Study on the Seakeeping Performance and Ride Comfort of a Small MonoHull Vessel With and Without Hydrofoil in Regular Head Seas. Journal of Marine Science and Engineering, 13(10), 1895. https://doi.org/10.3390/jmse13101895