Application of ANN in Construction: Comprehensive Study on Identifying Optimal Modifier and Dosage for Stabilizing Marine Clay of Qingdao Coastal Region of China

Abstract

1. Introduction

2. Materials and Methods

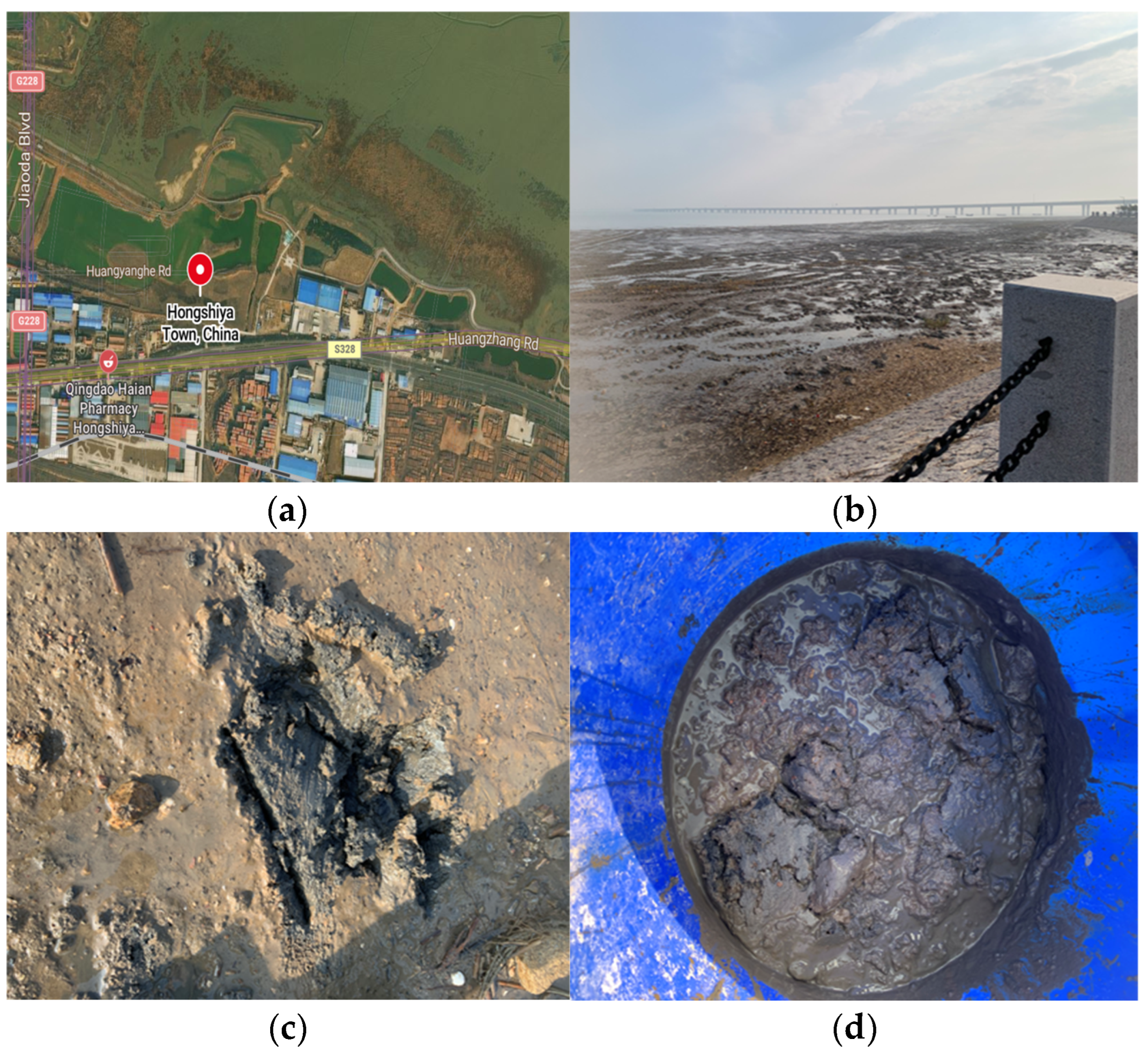

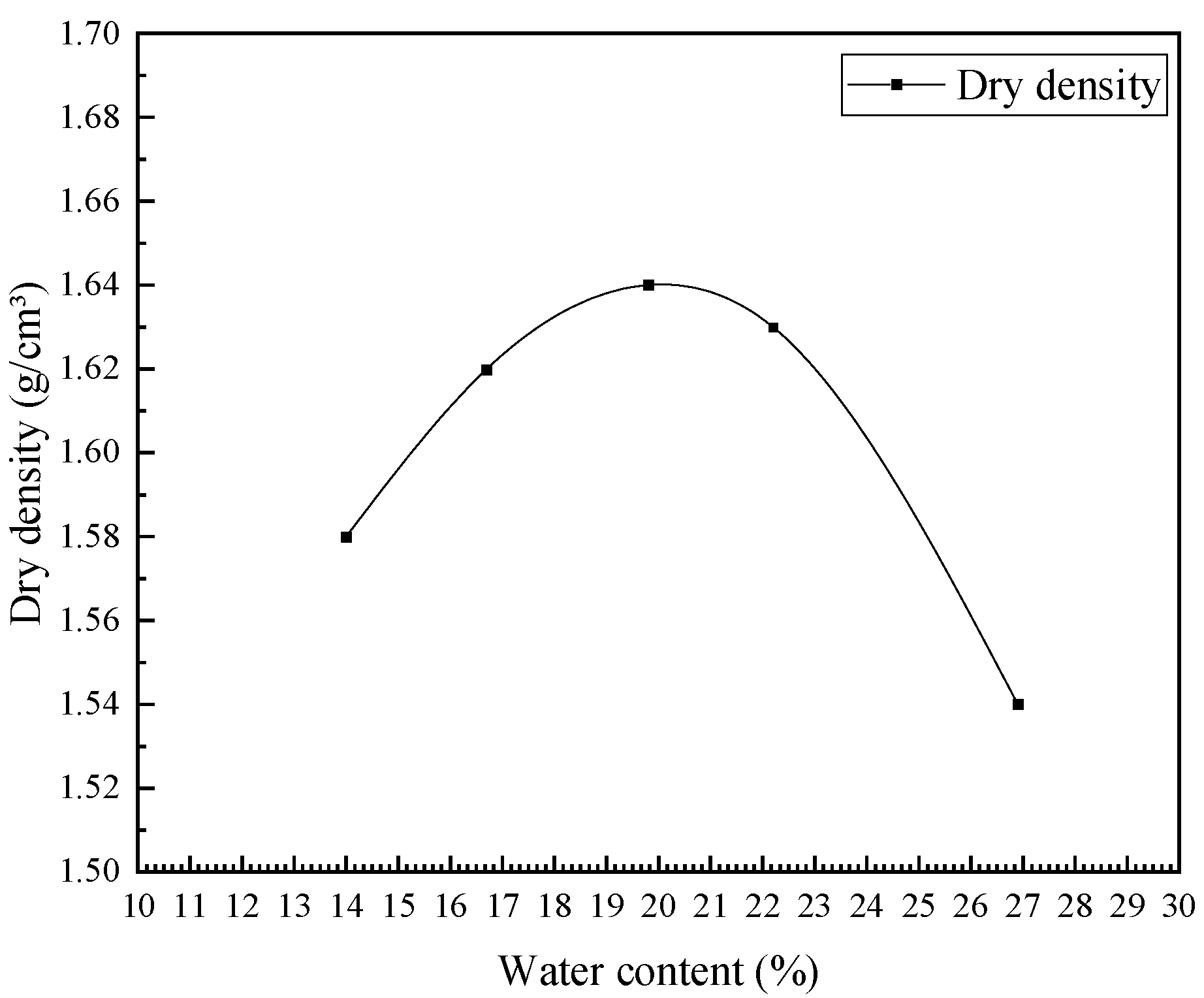

2.1. Sampling and Basic Properties of Marine Clay

2.2. Experimental Details

2.2.1. Main Stabilizer and Admixture

2.2.2. Unconfined Compressive Strength Tests

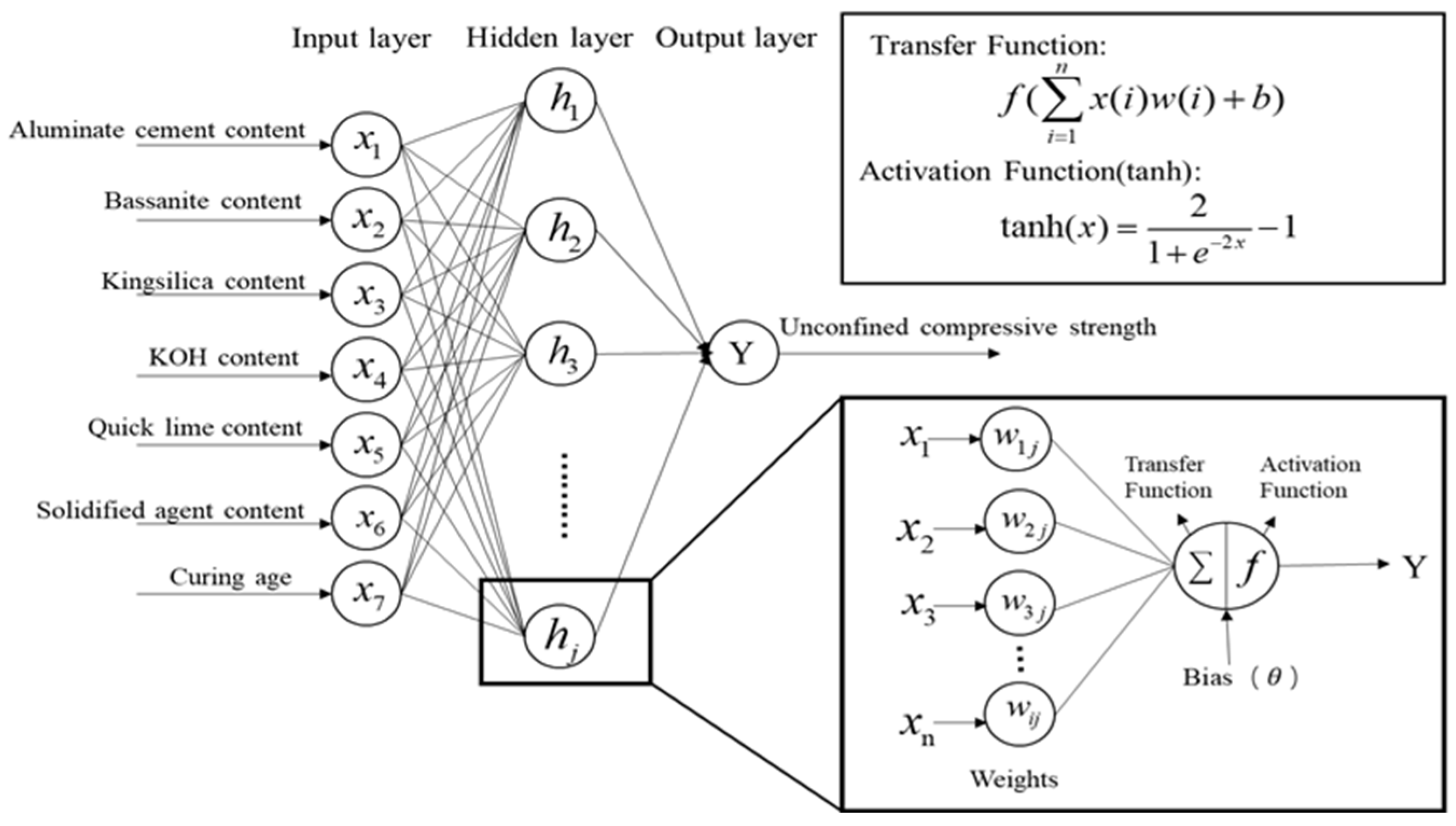

2.3. Development of Artificial Neural Network Model (ANN)

Parameter Setting for Optimization Analysis and Sensitivity Analysis

3. Results and Discussion

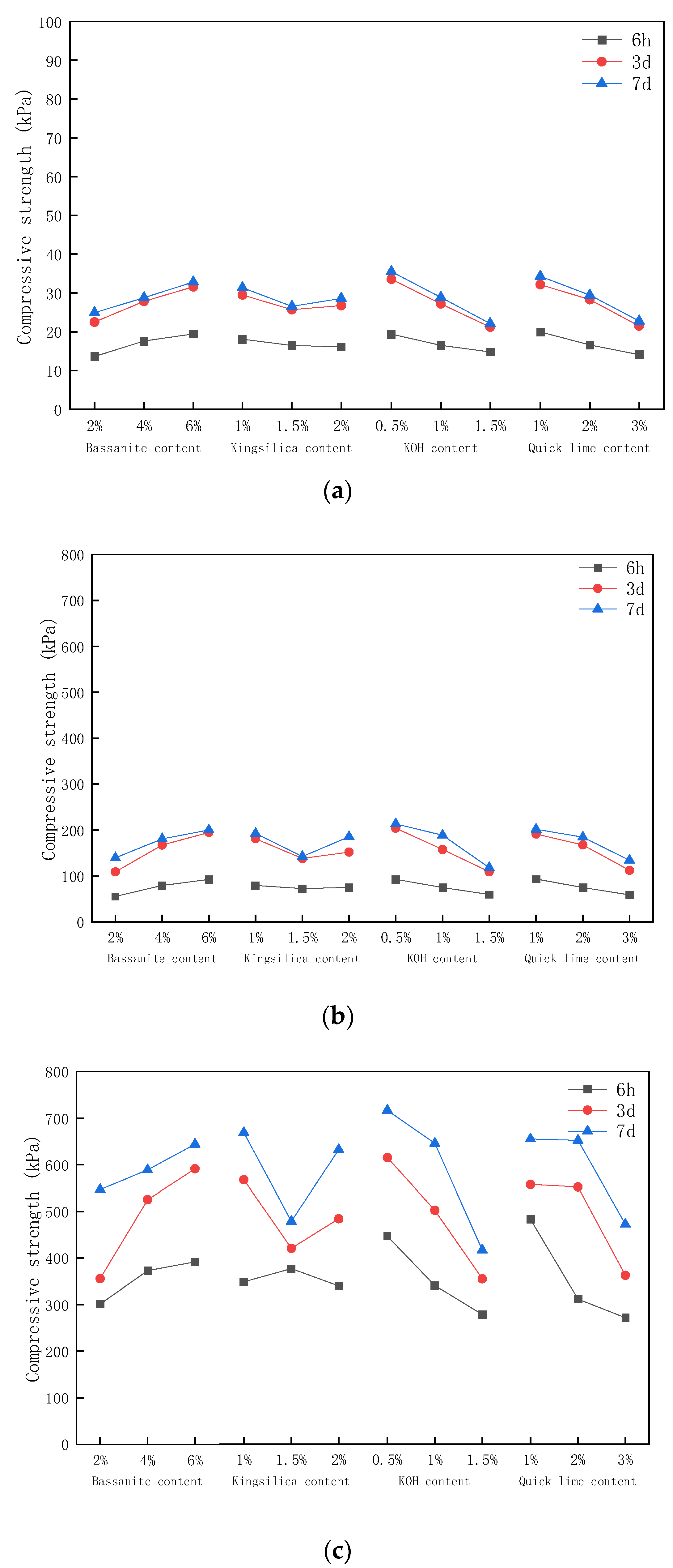

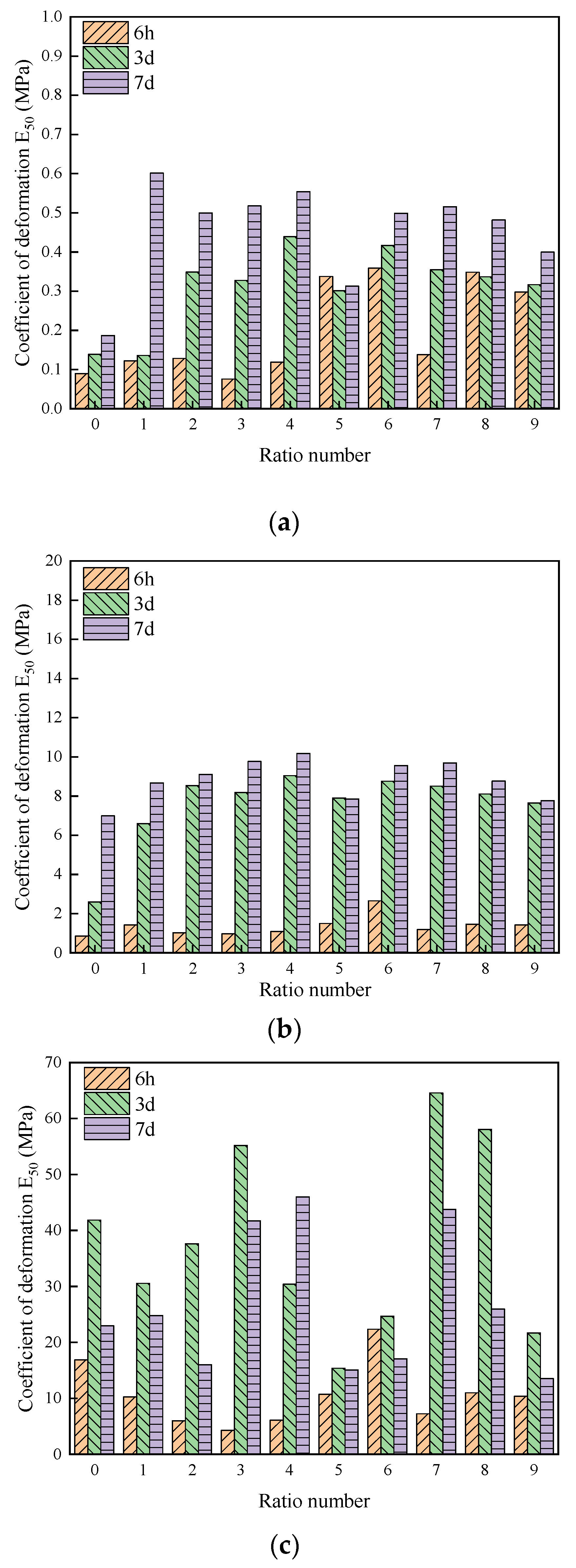

3.1. Effect of Chemical Treatment on Unconfined Compressive Strength (UCS) of Marine Clay

Stress–Strain Curve for Unconfined Compressive Strength Tests

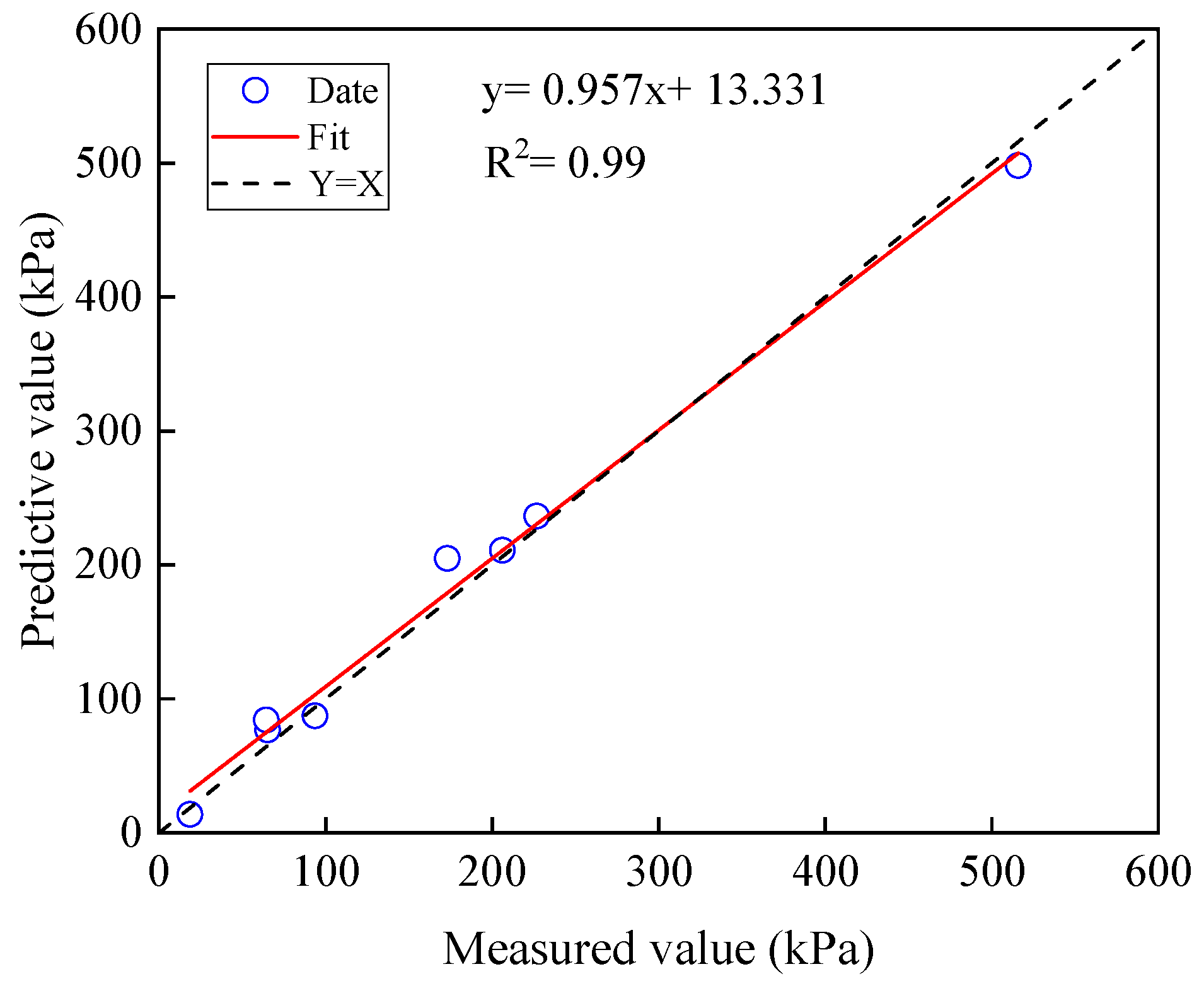

3.2. Prediction of Unconfined Compressive Strength Based on the ANN Model

3.2.1. Performance Analysis of Selected Neural Network Model

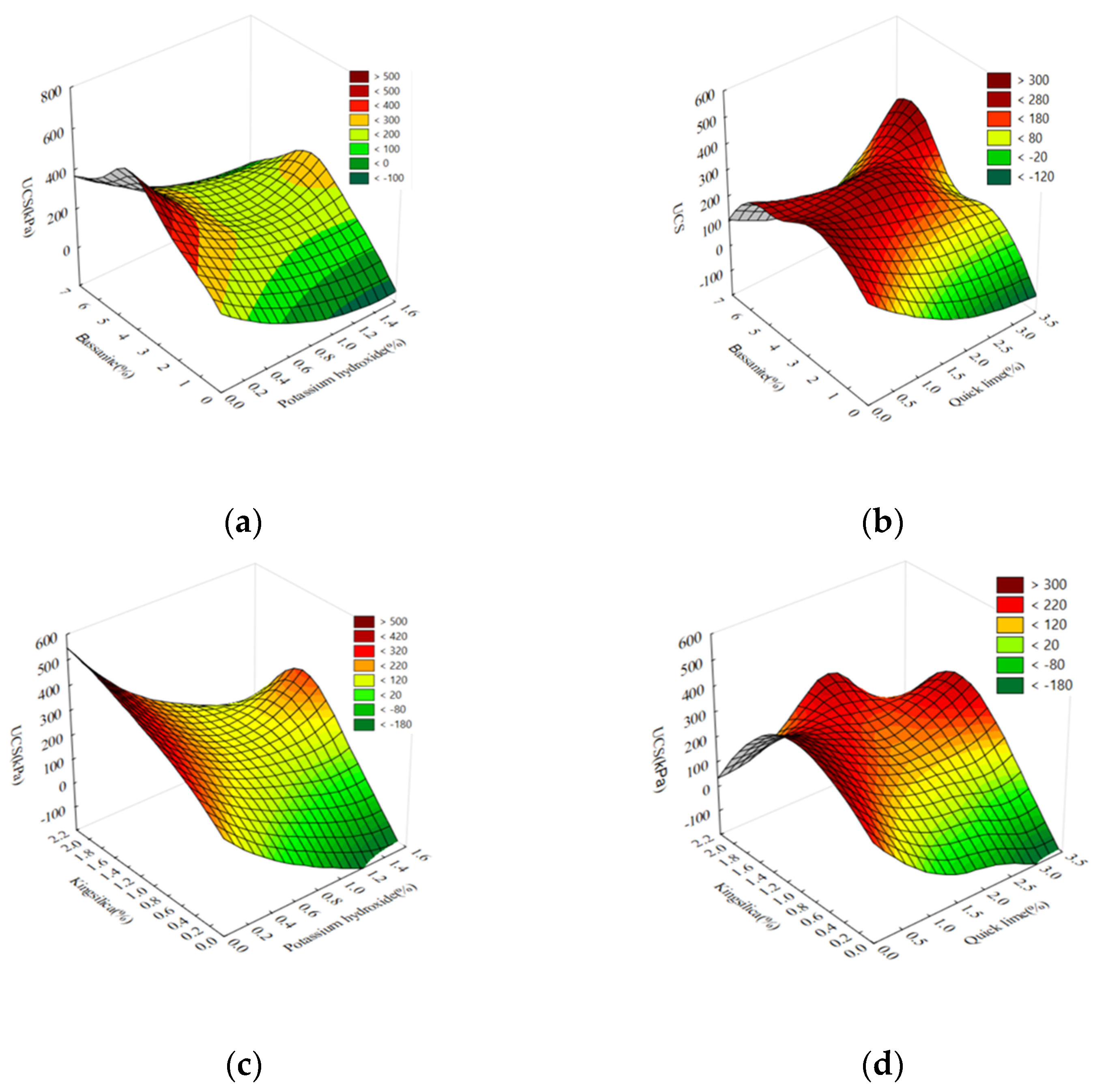

3.2.2. Influence of Different Parameters on Unconfined Compressive Strength

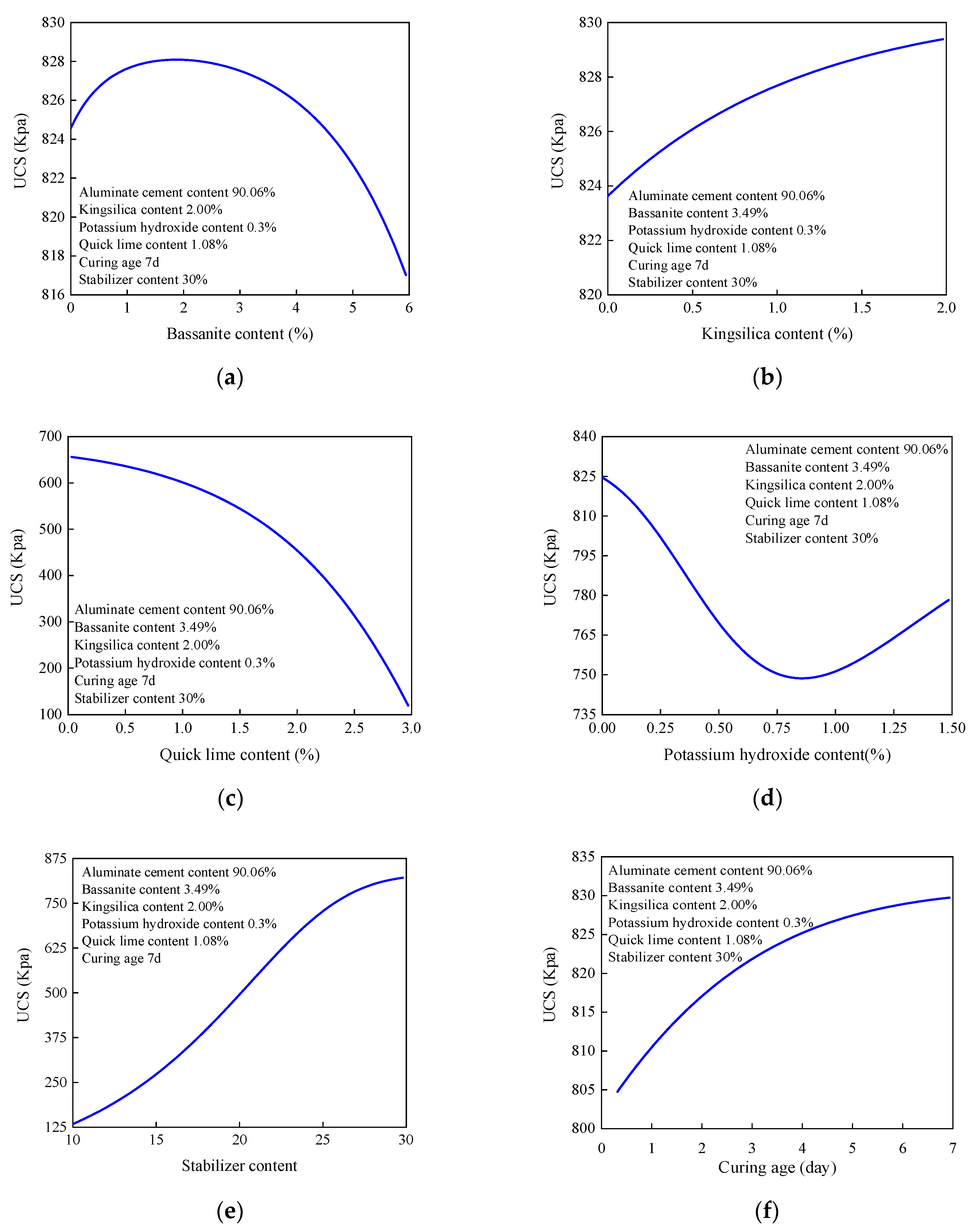

3.3. Optimization of Chemical Treatment Technology for Improving the Strength of Marine Clay

3.3.1. Sensitivity Analysis

3.3.2. Optimization Analysis

4. Conclusions

- Through the unconfined compressive strength test and range analysis, it can be found that there is a complex non-linear relationship between the influencing factors and the unconfined compressive strength under different stabilizer dosages and curing ages. The increment of stabilizer content from 10% to 30% shows a substantial increment in the unconfined compressive strength of the admixed soil after a 28 d curing period when the aluminate cement content is 89.5%, in which the primary and secondary order of influence on the unconfined compressive strength is potassium hydroxide > kingsilica > quick lime > bassanite.

- By analyzing the stress–strain behavior of soil samples, it is found that the strength increases continuously with an increase in stabilizer content and the extension of curing age, showing a trend of transition from plasticity to brittleness.

- The forecasting model is established using an artificial neural network (ANN), which verifies the validity and high performance of the model. It is proved that ANN-based modeling can be used as a tool to analyze complex non-linear relationship problems under multiple factors.

- Sensitivity analysis results based on the ANN model show that the unconfined compressive strength (UCS) is most sensitive to the change in quick lime content. The influence of quick lime should be given priority in the formulation design of stabilizers. The results are in agreement with the range analysis. It further proves that the artificial neural network has high performance and good forecasting ability.

- The results of optimization analysis based on the ANN model show that the maximum UCS can reach about 830 kPa. When the maximum UCS is reached, the model fits the values of various factors, similar to the results of the unconfined compressive strength tests, and the curing scheme can be optimized according to the results of the model.

- The influence of various influencing factors on the unconfined compressive strength of solidified soil can be optimized using the ANN model, and the influence trend of a single variable on UCS can be obtained. The results show that there is a critical value for the influence of the amount of bassanite and potassium hydroxide, which can be used for further optimize the design of stabilizer components.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, P.; Guo, Y.; Liu, Y.; Ding, H. Experimental study on installation of hybrid bucket foundations for offshore wind turbines in silty clay. Ocean Eng. 2016, 114, 87–100. [Google Scholar] [CrossRef]

- Ding, H.; Hu, R.; Zhang, P.; Le, C. Load bearing behaviors of composite bucket foundations for offshore wind turbines on layered soil under combined loading. Ocean Eng. 2020, 198, 106997. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H. Development of offshore wind power and foundation technology for offshore wind turbines in China. Ocean Eng. 2022, 266, 113256. [Google Scholar] [CrossRef]

- Sai, Z.; Wang, L.; Han, H.; Wu, W.; Sun, Z.; Wei, J.; Zhang, L.; Hu, G.; Wu, H. Mechanical and Self-Healing Performance of Yellow River Alluvial Silt Treated with Composite Flexible Curing Agent. Coatings 2022, 12, 870. [Google Scholar] [CrossRef]

- Ning, B. Permeability and Mechanical Behaviors of Stabilized Silt by Inorganic Soil Stabilizer. Ph.D. Thesis, Zhengzhou University, Zhengzhou, China, 2020. [Google Scholar]

- Chew, S.H.; Kamruzzaman, A.H.M.; Lee, F.H. Physicochemical and engineering behavior of cement treated clays. J. Geotech. Geoenviron. Eng. 2004, 130, 696–706. [Google Scholar] [CrossRef]

- Porbaha, A.; Shibuya, S.; Kishida, T. State of the art in deep mixing technology. Part III: Geomaterial characterization. Ground. Improv. 2000, 4, 91–110. [Google Scholar] [CrossRef]

- Lorenzo, G.A.; Bergado, D.T. Fundamental parameters of cement-admixed clay—New approach. J. Geotech. Geoenviron. Eng. 2004, 130, 1042–1050. [Google Scholar] [CrossRef]

- Horpibulsuk, S.K.; Rachan, R.L.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Wang, L.F. Analysis of microstructural characteristics and pores of nanometer silicon and cement-stabilized soils. Bull. Sci. Technol. 2012, 28, 31–35. [Google Scholar] [CrossRef]

- Ding, J.W.; Zhang, S.; Hong, Z.S.; Liu, S.Y. Experimental study of solidification of dredged clays with high water content by adding cement and phosphogypsum synchronously. Rock Soil Mech. 2010, 31, 2817–2822. [Google Scholar] [CrossRef]

- Sharma, L.; Sirdesai, N.; Sharma, K.; Singh, T. Experimental study to examine the independent roles of lime and cement on the stabilization of a mountain soil: A comparative study. Appl. Clay Sci. 2018, 152, 183–195. [Google Scholar] [CrossRef]

- Dahal, B.K.; Zheng, J.-J.; Zhang, R.-J.; Song, D.-B. Enhancing the mechanical properties of marine clay using cement solidification. Mar. Georesources Geotechnol. 2019, 37, 755–764. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, A.; Deng, Y.; Cui, Y.; Yu, Z.; Yu, C. Strength performance of cement/slag-based stabilized soft clays. Constr. Build. Mater. 2019, 211, 909–918. [Google Scholar] [CrossRef]

- Gong, X.; Niu, J.; Liang, S.; Feng, D.; Luo, Q. Solidification of Nansha soft clay using cement-based composite curing agents. Adv. Cem. Res. 2020, 32, 66–77. [Google Scholar] [CrossRef]

- Kurugodu, H.; Bordoloi, S.; Hong, Y.; Garg, A.; Garg, A.; Sreedeep, S.; Gandomi, A. Genetic programming for soil-fiber composite assessment. Adv. Eng. Softw. 2018, 122, 50–61. [Google Scholar] [CrossRef]

- Pacheco, V.L.; Bragagnolo, L.; Thomé, A. Artificial neural networks applied for solidified soils data prediction: A bibliometric and systematic review. Eng. Comput. 2021, 38, 3104–3131. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019. (In Chinese)

- NY/T 1121.16-2006; Soil Testing Part 16: Determination of Total Soil Water-Soluble Salts. Ministry of Agriculture and Rural Affairs: Beijing, China, 2006. (In Chinese)

- Nalbantoglu, Z.; Tuncer, E.R. Compressibility and hydraulic conductivity of a chemically treated expansive clay. Can. Geotech. J. 2001, 38, 154–160. [Google Scholar] [CrossRef]

- Rout, P.K. Study of Compressibility and Hydraulic Conductivity Characteristics of a Chemically Treated Expansive Clay. Int. J. Eng. Manag. Humanit. Soc. Sci. Paradig. 2018, 30, 284–295. [Google Scholar]

- Locat, J.; Trembaly, H.; Leroueil, S. Mechanical and hydraulic behaviour of a soft inorganic clay treated with lime. Can. Geotech. J. 1996, 33, 654–669. [Google Scholar] [CrossRef]

- Hartono, E.; Wardani SP, R.; Muntohar, A.S. The behavior of the clay shale stabilized by dry and wet cement mixing method. J. GeoEng. 2021, 16, 81–90. [Google Scholar]

- Garg, A.; Wani, I.; Kushvaha, V. Application of Artificial Intelligence for Predicting Erosion of Biochar Amended Soils. Sustainability 2022, 14, 684. [Google Scholar] [CrossRef]

- Cai, W.; Kumar, H.; Huang, S.; Bordoloi, S.; Garg, A.; Lin, P.; Gopal, P. ANN model development for air permeability in biochar amended unsaturated soil. Geotech. Geol. Eng. 2020, 38, 1295–1309. [Google Scholar] [CrossRef]

- Elangasinghe, M.A.; Singhal, N.; Dirks, K.N.; Salmond, J.A. Development of an ANN–based air pollution forecasting system with explicit knowledge through sensitivity analysis. Atmospheric Pollut. Res. 2014, 5, 696–708. [Google Scholar] [CrossRef]

- Nourani, V.; Fard, M.S. Sensitivity analysis of the artificial neural network outputs in simulation of the evaporation process at different climatologic regimes. Adv. Eng. Softw. 2012, 47, 127–146. [Google Scholar] [CrossRef]

- Golzar, F.; Nilsson, D.; Martin, V. Forecasting wastewater temperature based on artificial neural network (ANN) technique and monte carlo sensitivity analysis. Sustainability 2020, 12, 6386. [Google Scholar] [CrossRef]

- Chen, S.; Ren, Y.; Friedrich, D.; Yu, Z.; Yu, J. Sensitivity analysis to reduce duplicated features in ANN training for district heat demand prediction. Energy AI 2020, 2, 100028. [Google Scholar] [CrossRef]

- Jin, Y.; Zheng, X.; Cai, C.; Wang, G.; Sha, L. Study on the Strength and Curing Mechanism of Beach Silt Stabilized Soil Using Cement-fly Ash. Bull. Sci. Technol. 2015, 31, 132–136. (In Chinese) [Google Scholar] [CrossRef]

| Index | Value |

|---|---|

| Natural Density, | 1.68 |

| Moisture Content, | 120.1 |

| Specific gravity, | 2.73 |

| Void ratio, | 1.65 |

| Liquid limit, | 83 |

| Plastic limit, | 36 |

| pH | 8.25 |

| Soil soluble salts, | 29.6 |

| Stabilizer Component | Main Chemical Composition |

|---|---|

| Alumina cement | 3CaO·Al2O3 |

| Bassanite | CaSO4·0.5H2O |

| Kingsilica | SiO2 |

| Quick lime | CaO |

| Potassium hydroxide | KOH |

| Number | Aluminate Cement Content (%) | Bassanite Content (%) | Kingsilica Content (%) | KOH Content (%) | Quick Lime Content (%) | Solidified Agent Content (%) |

|---|---|---|---|---|---|---|

| 0 | 100 | 0 | 0 | 0 | 0 | |

| 1 | 95.5 | 2 | 1 | 0.5 | 1 | |

| 2 | 93.5 | 2 | 1.5 | 1 | 2 | |

| 3 | 91.5 | 2 | 2 | 1.5 | 3 | |

| 4 | 91 | 4 | 1 | 1 | 3 | 10% |

| 5 | 92 | 4 | 1.5 | 1.5 | 1 | 20%, 30% |

| 6 | 91.5 | 4 | 2 | 0.5 | 2 | |

| 7 | 89.5 | 6 | 1 | 1.5 | 2 | |

| 8 | 89 | 6 | 1.5 | 0.5 | 3 | |

| 9 | 90 | 6 | 2 | 1 | 1 |

| Index | Value |

|---|---|

| Net. name | MLP 7-8-1 |

| Training perf. | 0.984256 |

| Test perf. | 0.993253 |

| Validation perf. | 0.996300 |

| Training error | 0.000947 |

| Test error | 0.001037 |

| Validation error | 0.012440 |

| Algorithm | BFGS 54 |

| Error function | SOS |

| Hidden activation | Exponential |

| Output activation | Tanh |

| Variable | Sensitivity Analysis | Optimization Analysis |

|---|---|---|

| UCS | - | 830 kPa |

| Aluminate cement content | 4.032583 | 90.06% |

| Bassanite content | 5.186851 | 3.49% |

| Kingsilica content | 2.998604 | 2.00% |

| KOH content | 5.807388 | 0.3% |

| Quick lime content | 30.29768 | 1.08% |

| Curing age | 2.136436 | 7 days |

| Stabilizer content | 15.61476 | 30% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bo, Q.; Liu, J.; Shang, W.; Garg, A.; Jia, X.; Sun, K. Application of ANN in Construction: Comprehensive Study on Identifying Optimal Modifier and Dosage for Stabilizing Marine Clay of Qingdao Coastal Region of China. J. Mar. Sci. Eng. 2024, 12, 465. https://doi.org/10.3390/jmse12030465

Bo Q, Liu J, Shang W, Garg A, Jia X, Sun K. Application of ANN in Construction: Comprehensive Study on Identifying Optimal Modifier and Dosage for Stabilizing Marine Clay of Qingdao Coastal Region of China. Journal of Marine Science and Engineering. 2024; 12(3):465. https://doi.org/10.3390/jmse12030465

Chicago/Turabian StyleBo, Qirui, Junwei Liu, Wenchang Shang, Ankit Garg, Xiaoru Jia, and Kaiyue Sun. 2024. "Application of ANN in Construction: Comprehensive Study on Identifying Optimal Modifier and Dosage for Stabilizing Marine Clay of Qingdao Coastal Region of China" Journal of Marine Science and Engineering 12, no. 3: 465. https://doi.org/10.3390/jmse12030465

APA StyleBo, Q., Liu, J., Shang, W., Garg, A., Jia, X., & Sun, K. (2024). Application of ANN in Construction: Comprehensive Study on Identifying Optimal Modifier and Dosage for Stabilizing Marine Clay of Qingdao Coastal Region of China. Journal of Marine Science and Engineering, 12(3), 465. https://doi.org/10.3390/jmse12030465