Modeling and Improvement Strategies for Safety Resilience in Maritime Hazardous Chemical Transportation System Based on Dissipative Structure Theory and System Dynamics

Abstract

1. Introduction

2. Analysis of Safety Resilience Evolution of MHCTS and Establishment of Entropy Model

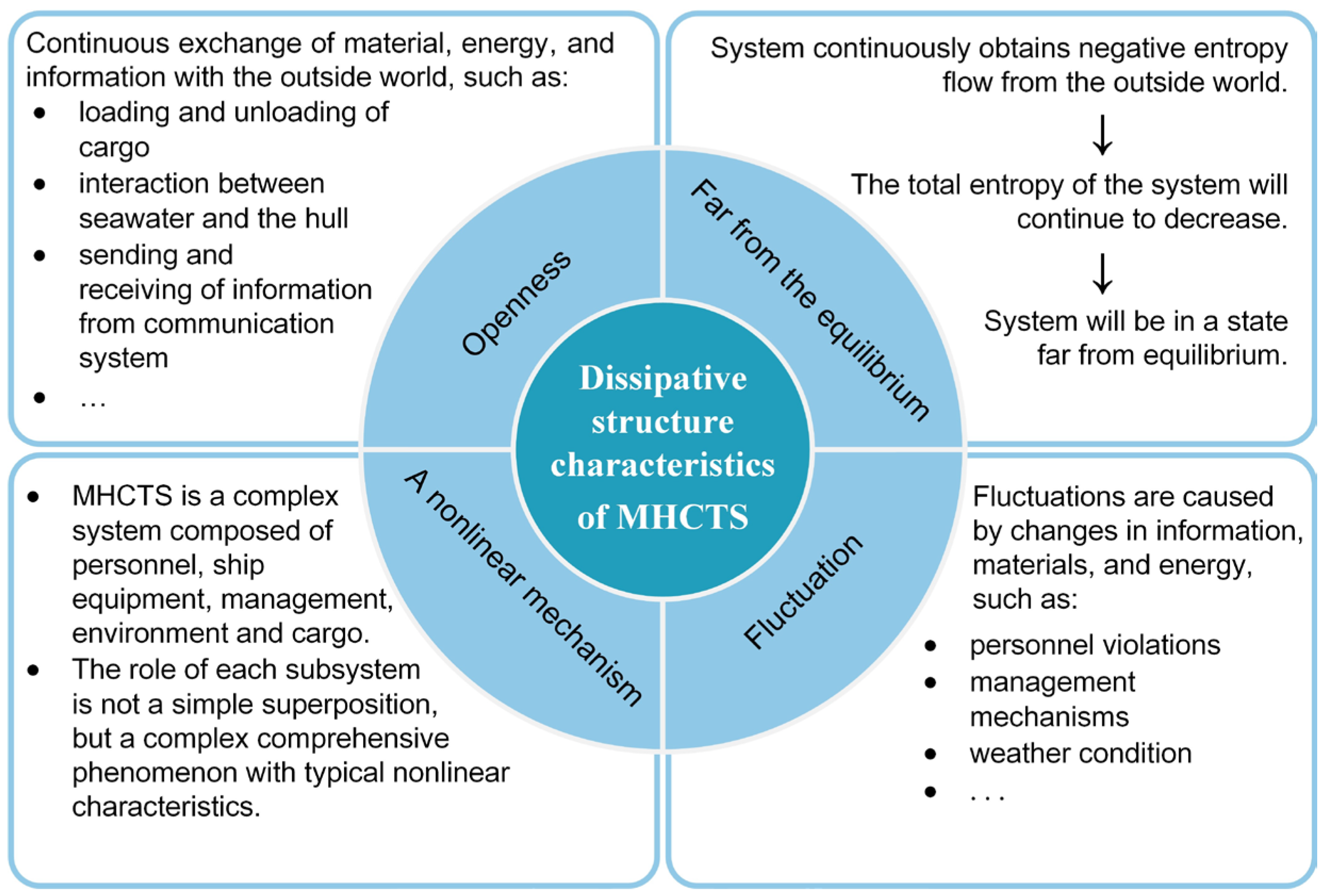

2.1. Analysis of Dissipative Structure Characteristics of MHCTS

2.2. Entropy Flow Mechanism of Resilience Evolution for MHCTS

2.3. Entropy Model of Safety Resilience Evolution of MHCTS

2.3.1. Entropy and Weight Calculation of Influencing Factors of Safety Resilience

2.3.2. Establishment of Entropy Model of Safety Resilience Evolution for MHCTS

3. Simulation and Modeling of Resilience Evolution Process Based on SD

3.1. Basic Principles of SD

3.2. SD Model of Safety Resilience Evolution of MHCTS

3.3. SD Model Function of Safety Resilience Evolution of MHCTS

4. Simulation Implementation and Result Analysis

4.1. Simulation Scenario Hypothesis

4.2. Simulation Results and Analysis

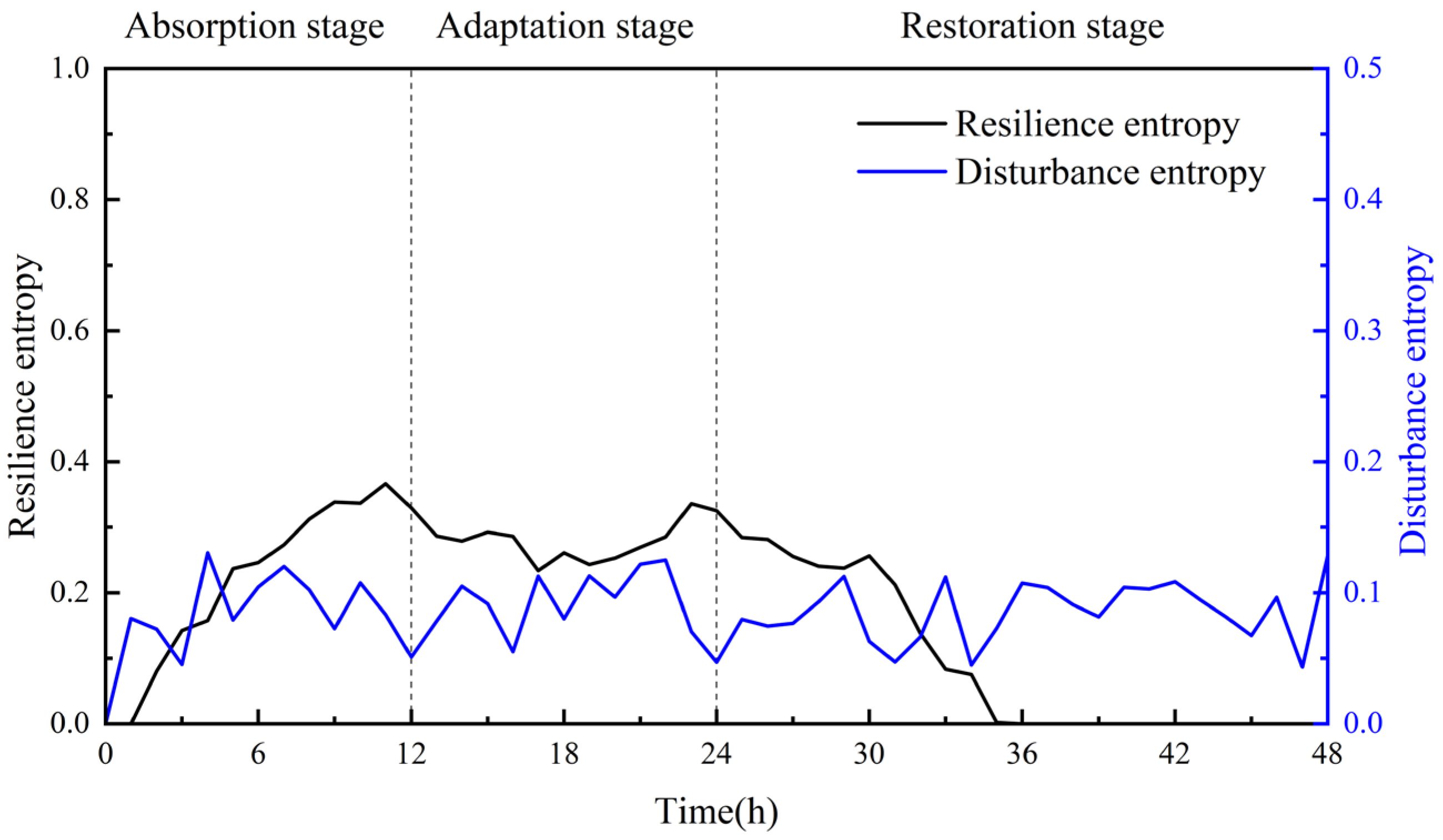

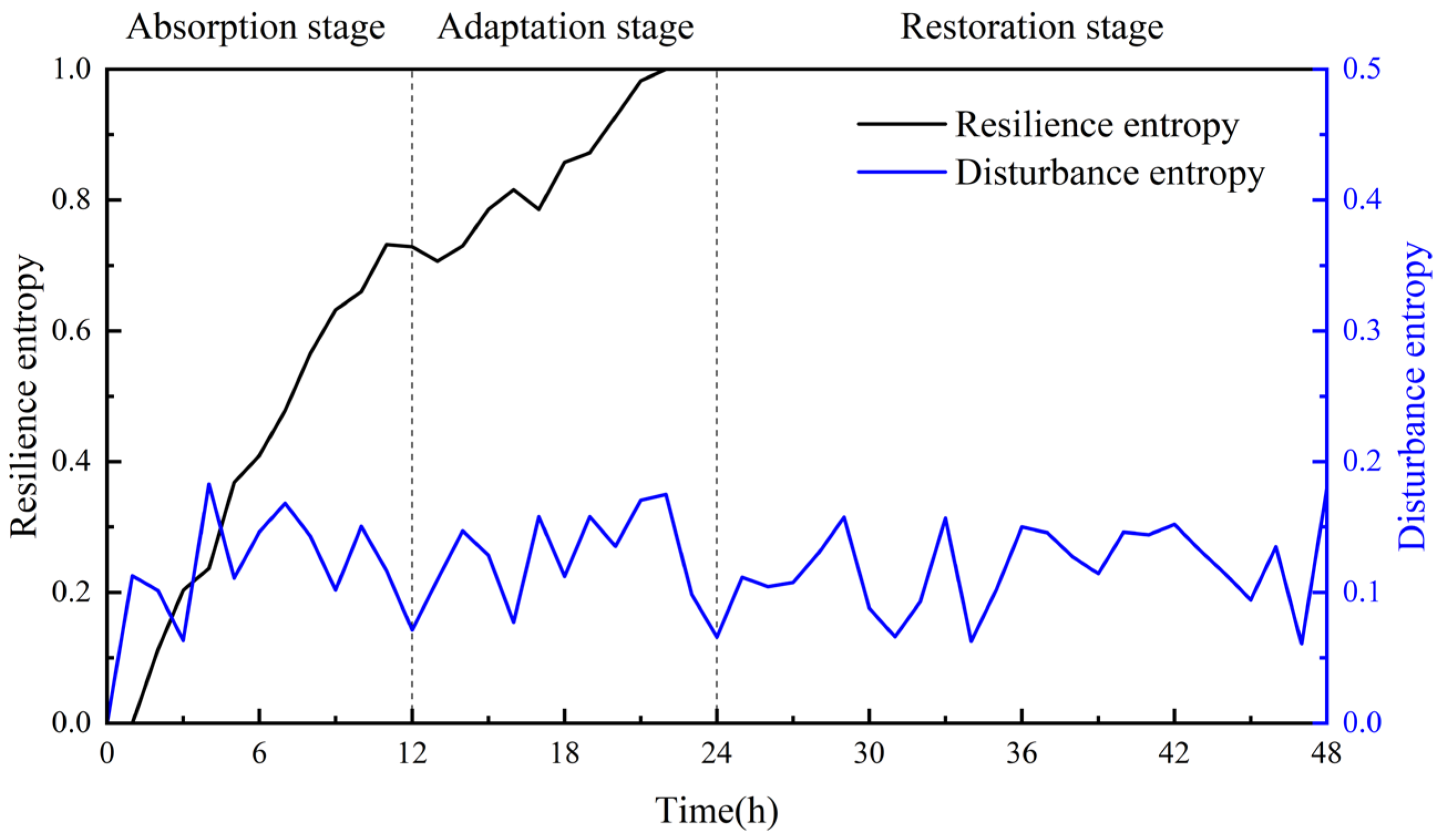

4.2.1. Simulation Results under Scenario 1

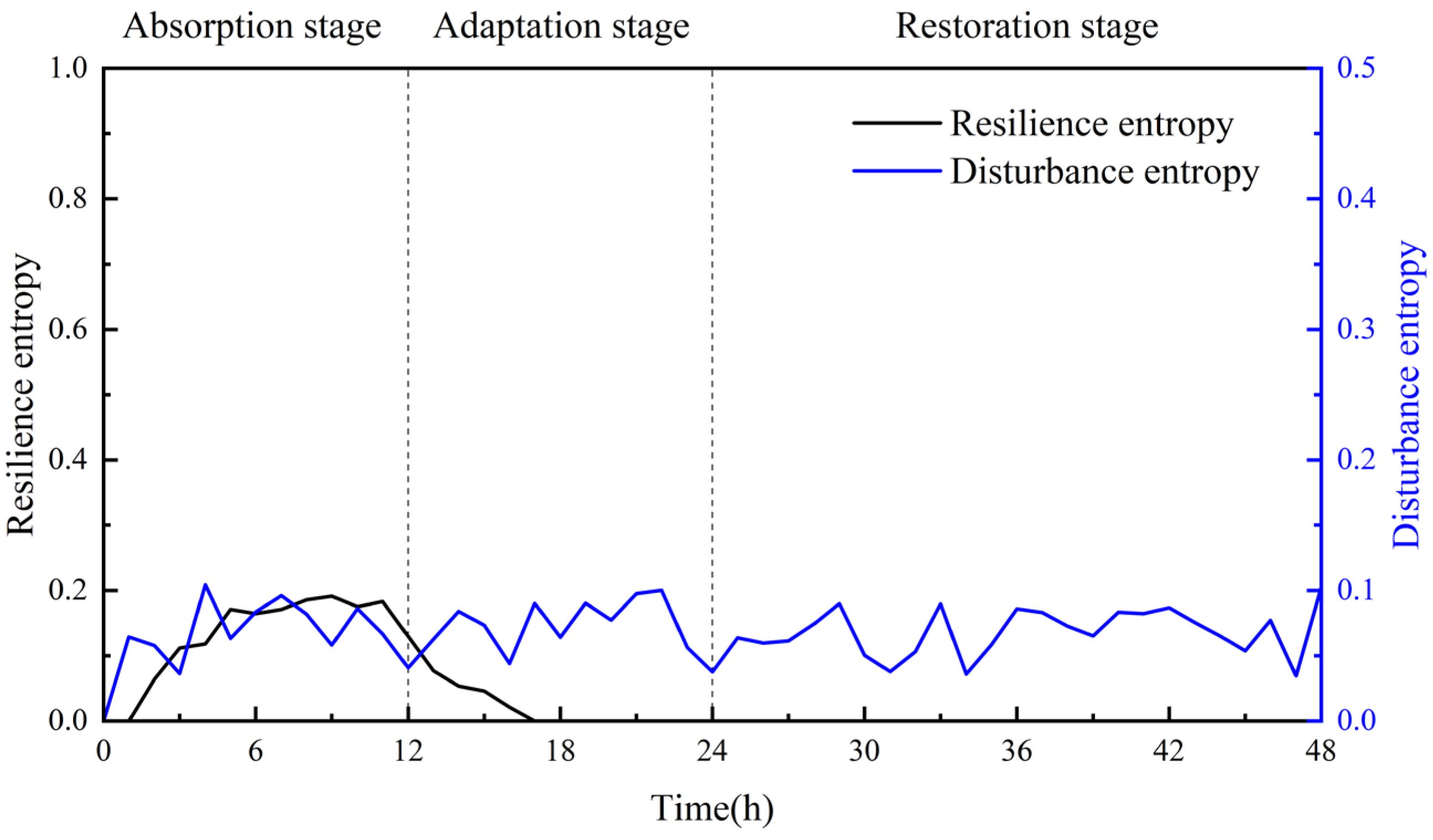

4.2.2. Simulation Results under Scenario 2

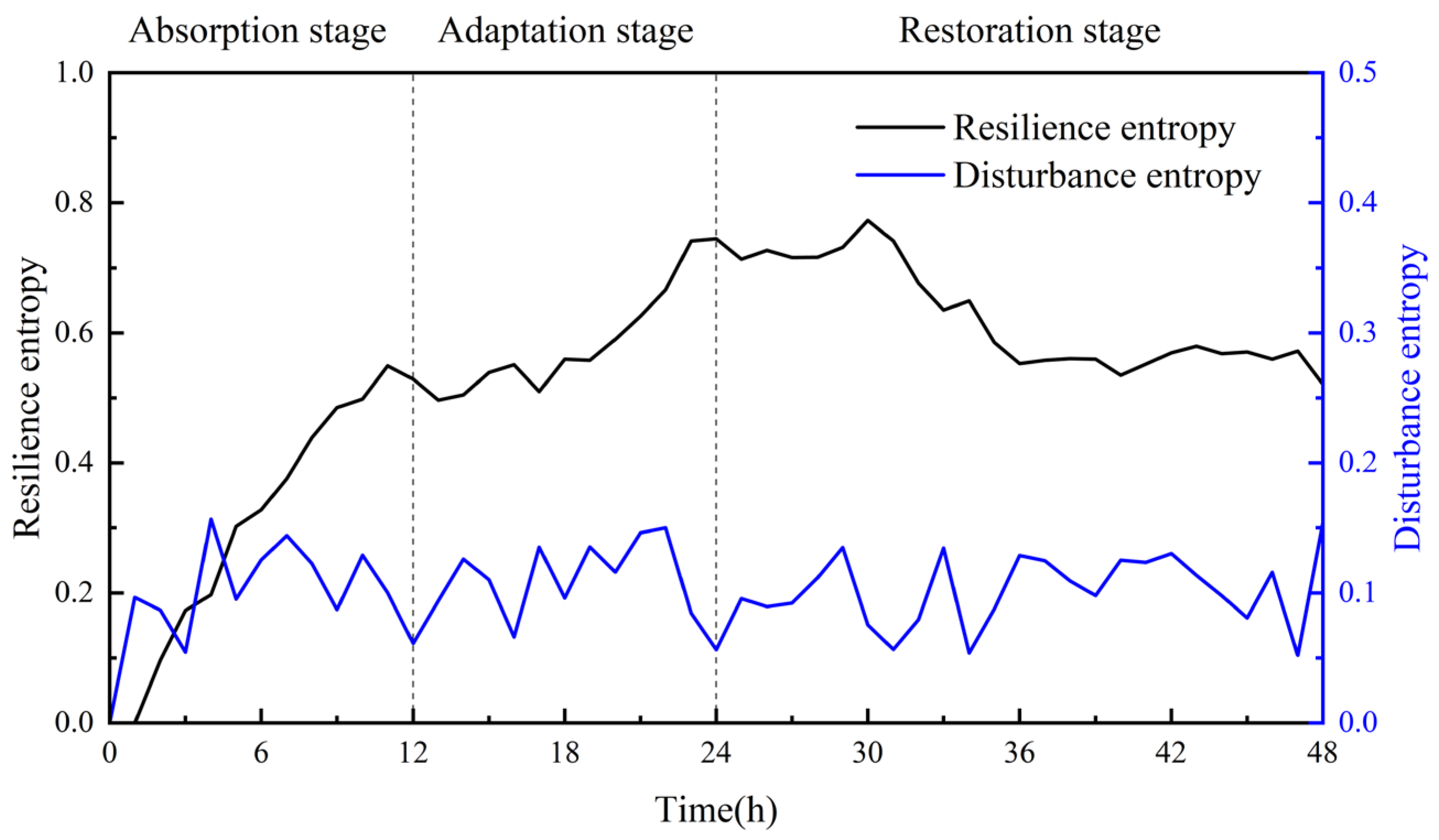

4.2.3. Simulation Results under Scenario 3

4.2.4. Simulation Results under Scenario 4

4.3. Analysis of Contribution Degree and Strategies for Improving Safety Resilience of MHCTS

4.3.1. Analysis of Contribution Degree and Strategy of Resilience Capacity for System Safety Resilience Improvement

4.3.2. Analysis of Contribution Degree and Strategy of Influencing Factors for Resilience Capacity Improvement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cimellaro, G.P.; Reinhorn, A.M.; Bruneau, M. Framework for analytical quantification of disaster resilience. Eng. Struct. 2010, 32, 3639–3649. [Google Scholar] [CrossRef]

- Xu, Y.T.; Fang, Y.M. Quantitative Analysis of seismic resilience of residential functions in urban areas. Urban Archit. 2021, 18, 157–162. [Google Scholar]

- Zhang, J.X.; Wang, H.M.; Huang, J.; Wang, Y.X.; Liu, G.F. A study on dynamic simulation and improvement strategies of flood resilience for urban road system. J. Environ. Manag. 2023, 344, 118770. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Li, Y.; Deng, N.H.; Du, L. Resilience modelling of complex urban public space system. Syst. Eng. Theory Pract. 2022, 42, 1964–1978. [Google Scholar]

- Fang, Y.M. Research on Quantitative Analysis and Promotion Strategy of Seismic Resilience of Urban Regional Disaster Response System. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2021. [Google Scholar]

- Yang, Q.; Zhang, Y.N.; Zhou, Y.Q.; Bai, L.B. A review of complex network theory and its application in the resilience of public transportation systems. China J. Highw. Transp. 2022, 35, 215–229. [Google Scholar]

- Henry, D.; Ramirez-Marquez, J.E. Generic metrics and quantitative approaches for system resilience as a function of time. Reliab. Eng. Syst. Saf. 2012, 99, 114–122. [Google Scholar] [CrossRef]

- Zhu, W.; Zhao, P.X.; Wang, Y.F. Modeling on the quantitative resilience assessment of urban emerging community based on systematics. In Proceedings of the 4th ACM SIGSPATIAL International Workshop on Safety and Resilience, Seattle, WA, USA, 6–9 November 2018; pp. 1–8. [Google Scholar]

- Li, J.M.; Qi, J.; Zheng, Z.Y.; Li, H.X. Transportation system of dangerous chemicals at sea based on entropy and dissipative structure theory. J. Dalian Marit. Univ. 2013, 39, 85–88. [Google Scholar]

- Chen, C.; Yang, M.; Reniers, G. A dynamic stochastic methodology for quantifying HAZMAT storage resilience. Reliab. Eng. Syst. Saf. 2021, 215, 107909. [Google Scholar] [CrossRef]

- Ma, J.J.; Chen, G.H.; Zeng, T.; Zhou, L.X.; Zhao, J.; Zhao, Y.F. Methodology for resilience assessment of oil pipeline network system exposed to earthquake. Sustainability 2023, 15, 972. [Google Scholar] [CrossRef]

- Kammouh, O.; Gardoni, P.; Cimellaro, G.P. Probabilistic framework to evaluate the resilience of engineering systems using Bayesian and dynamic Bayesian networks. Reliab. Eng. Syst. Saf. 2020, 198, 106813. [Google Scholar] [CrossRef]

- Jiang, S.Q.; Yang, L.; Cheng, G.; Gao, X.M.; Feng, T.; Zhou, Y.Y. A quantitative framework for network resilience evaluation using Dynamic Bayesian Network. Comput. Commun. 2022, 194, 387–398. [Google Scholar] [CrossRef]

- Vairo, T.; Pettinato, M.; Reverberi, A.P.; Milazzo, M.F.; Fabiano, B. An approach towards the implementation of a reliable resilience model based on machine learning. Process Saf. Environ. Protect. 2023, 172, 632–641. [Google Scholar] [CrossRef]

- Ding, Y.T.; Chen, S.; Zheng, Y.L.; Chai, S.L.; Nie, R. Resilience assessment of China’s natural gas system under supply shortages: A system dynamics approach. Energy 2022, 247, 123518. [Google Scholar] [CrossRef]

- Badr, A.; Li, Z.; El-Dakhakhni, W. Dynamic resilience quantification of hydropower infrastructure in multihazard environments. J. Infrastruct. Syst. 2023, 29, 04023012. [Google Scholar] [CrossRef]

- Li, Z.S.; Li, N.; Cimellaro, G.P.; Fang, D.P. System dynamics modeling-based approach for assessing seismic resilience of hospitals: Methodology and a case in China. J. Manag. Eng. 2020, 36, 04020050. [Google Scholar] [CrossRef]

- Wang, H.Y. Research on Safety Evaluation of Hazardous Chemicals Terminal Operation System Based on Dissipation and Entropy Theory. Master’s Thesis, Shandong Jiaotong University, Jinan, China, 2018. [Google Scholar]

- Li, J.M.; Song, S.Z.; Diao, Y.L.; Guan, W.; Yan, H.R. Study on safety of dangerous chemical marine transportation system based on entropy theory. J. Shanghai Marit. Univ. 2015, 36, 8–14. [Google Scholar]

- Li, J.M. Study on the Safety of Maritime Dangerous Chemical Transportation Based on Dissipative Theory. Ph.D. Thesis, Dalian Maritime University, Dalian, China, 2014. [Google Scholar]

- Vugrin, E.D.; Warren, D.E.; Ehlen, M.A. A resilience assessment framework for infrastructure and economic systems: Quantitative and qualitative resilience analysis of petrochemical supply chains to a hurricane. Process. Saf. Prog. 2011, 30, 280–290. [Google Scholar] [CrossRef]

- Maritime Safety Administration of the People’s Republic of China. Accident Investigation Reports. Available online: https://www.msa.gov.cn/page/outter/shiguyufang.jsp (accessed on 13 March 2023).

- German Federal Bureau of Investigation for Maritime Accidents. Investigation Reports. Available online: https://www.bsu-bund.de/EN/Publications/Unfallberichte/Unfallberichte_node.html (accessed on 29 March 2023).

- UK Marine Accident Investigation Branch. Marine Accident Investigation Branch Reports. Available online: https://www.gov.uk/maib-reports (accessed on 10 April 2023).

- USA National Transportation Safety Board. Investigation Reports. Available online: https://www.ntsb.gov/investigations/AccidentReports/Pages/Reports.aspx (accessed on 20 April 2023).

- Japan Transportation Safety Board. Marine Accident/Incident Investigation Reports. Available online: https://www.mlit.go.jp/jtsb/marrep.html (accessed on 3 May 2023).

- French Marine Casualties Investigation Board. Reports Published. Available online: https://www.bea-mer.developpement-durable.gouv.fr/reports-published-a586.html?lang=fr (accessed on 6 May 2023).

- Hu, S.P.; Liu, W.H.; Han, B.; Wu, Z.D. Dynamics simulation on safety resilience for Ro-Pas ship navigating in strait considering factor mutations. J. Saf. Environ. 2023, 23, 3408–3418. [Google Scholar]

- Ma, D.H. Study on Resilience of Maritime Dangerous Chemicals Transportation System. Master’s Thesis, Dalian Maritime University, Dalian, China, 2022. [Google Scholar]

- Wang, Q.F. New progress in theory and methodology of system dynamics. J. Syst. Manag. 1995, 2, 6–12. [Google Scholar]

- Brtis, J.S.; McEvilley, M.A.; Pennock, M.J. Resilience requirements patterns. In Proceedings of the INCOSE 31st Annual International Symposium, Honolulu, HI, USA, 17–22 July 2021; Volume 31, pp. 570–584. [Google Scholar]

| Target Layer | Classification | Influencing Factors | Description |

|---|---|---|---|

| MHCTS’s safety resilience (R) | Absorptive capacity (A) | Routine maintenance of ship hardware facilities and equipment (A1) | To ensure that the ship is in a good technical and seaworthy state, the crew should execute routine maintenance of the ship’s hardware facilities and equipment and eliminate various faults. |

| Crew safety awareness (A2) | Crew should have the awareness of paying attention to safety guarantees, protecting themselves, others, and ship safety. | ||

| Hazardous chemical cargo management ability (A3) | Crew of hazardous chemical transportation ships need to receive strict training and education, understand the characteristics and operation points of hazardous chemicals, and be familiar with various emergency treatment measures. | ||

| Safety supervision and management (A4) | Relevant departments should execute safety supervision and management on ships to ensure the normal operation of the ship safety management system. | ||

| Adaptive capacity (B) | Crew knowledge and skills (B1) | Strong knowledge and skills can help crew deal with emergencies and make correct judgments and implement emergency measures in a timely manner. | |

| Monitoring and alarm system (B2) | The monitoring and alarm system can transmit the cargo hold situation to the on-duty personnel in time and promptly discover and report the accident. | ||

| Crew physiological and psychological state (B3) | The crew’s physiological and psychological state has a great influence on the handling of maritime accidents, and a poor physiological and psychological state easily causes fatigue and slow response. | ||

| Restorative capacity (C) | Hardware facilities and equipment failure repair capability (C1) | The repair and upgrading of damaged ship hardware facilities and equipment is an important measure for system recovery. | |

| Spare facilities and equipment (C2) | The disturbance events may cause damage to facilities and equipment and affect system functions; hence, spare facilities and equipment can replace damaged facilities in time and quickly restore system functions. | ||

| Emergency rescue measures (C3) | Take proper emergency rescue measures to reduce system losses and restore system functions. | ||

| External environmental disturbance events (D) | Poor visibility (D1) | Visibility is limited owing to rain, fog, haze, sandstorms, and other reasons, which makes it difficult for the ship to look out, locate, navigate, and judge. | |

| Big storm (D2) | When the ship is navigating in heavy wind and waves, the ship will shake, slow down, and have an unstable course and resultant handling difficulties. | ||

| High temperature (D3) | High temperature will accelerate the evaporation, decomposition, oxidation, and spontaneous combustion of hazardous chemicals, which are prone to combustion and explosion accidents. | ||

| High navigable density of the channel (D4) | During the navigation of a ship with hazardous chemicals, several other ships will be around; the distance between ships is close, and the maneuvers are frequent. | ||

| Complex reef condition (D5) | The presence of the reefs on the route of the ship is complex, resulting in narrow and curved waterways, limited water depth, rapid tidal currents, and frequent accidents of stranding and reef collision. | ||

| Internal system disturbance events (E) | Unsafe behavior of the crew (E1) | The crew’s improper behavior violates laws and regulations or safety operation rules and regulations, thereby endangering the safety of the ship. | |

| Ship hardware facilities and equipment damaged (E2) | Damage of ship hardware facilities and equipment owing to technical failure, equipment aging, bad weather, etc. | ||

| Improper management of hazardous chemical cargo (E3) | Improper storage of hazardous chemical cargo, illegal operations, and non-compliance with requirements during transportation. | ||

| Insufficient ship supervision and management (E4) | Insufficient ship supervision and management by relevant departments caused insufficient staffing, unlicensed navigation, etc. |

| Influencing Factor | Entropy Code | p(x1) | p(x2) | Entropy Value | Influencing Factor | Entropy Code | p(x1) | p(x2) | Entropy Value |

|---|---|---|---|---|---|---|---|---|---|

| A1 | SA1 | 0.795 | 0.205 | 0.5069 | D1 | SD1 | 0.110 | 0.890 | 0.3455 |

| A2 | SA2 | 0.381 | 0.619 | 0.6645 | D2 | SD2 | 0.152 | 0.848 | 0.4268 |

| A3 | SA3 | 0.910 | 0.090 | 0.3036 | D3 | SD3 | 0.010 | 0.990 | 0.0538 |

| A4 | SA4 | 0.829 | 0.171 | 0.4581 | D4 | SD4 | 0.171 | 0.829 | 0.4581 |

| B1 | SB1 | 0.529 | 0.471 | 0.6915 | D5 | SD5 | 0.086 | 0.914 | 0.2925 |

| B2 | SB2 | 0.924 | 0.076 | 0.2694 | E1 | SE1 | 0.738 | 0.262 | 0.5750 |

| B3 | SB3 | 0.871 | 0.129 | 0.3837 | E2 | SE2 | 0.233 | 0.767 | 0.5433 |

| C1 | SC1 | 0.510 | 0.490 | 0.6930 | E3 | SE3 | 0.090 | 0.910 | 0.3036 |

| C2 | SC2 | 0.876 | 0.124 | 0.3744 | E4 | SE4 | 0.176 | 0.824 | 0.4656 |

| C3 | SC3 | 0.890 | 0.110 | 0.3455 |

| Classification | Weight Code | Weight | Influencing Factor | Weight Code | Weight |

|---|---|---|---|---|---|

| A | WA | 0.0749 | A1 | WA1 | 0.2386 |

| A2 | WA2 | 0.1623 | |||

| A3 | WA3 | 0.3369 | |||

| A4 | WA4 | 0.2622 | |||

| B | WB | 0.2659 | B1 | WB1 | 0.1863 |

| B2 | WB2 | 0.4413 | |||

| B3 | WB3 | 0.3723 | |||

| C | WC | 0.2252 | C1 | WC1 | 0.1935 |

| C2 | WC2 | 0.3942 | |||

| C3 | WC3 | 0.4124 | |||

| D | WD | 0.3357 | D1 | WD1 | 0.1912 |

| D2 | WD2 | 0.1674 | |||

| D3 | WD3 | 0.2764 | |||

| D4 | WD4 | 0.1583 | |||

| D5 | WD5 | 0.2067 | |||

| E | WE | 0.0983 | E1 | WE1 | 0.2012 |

| E2 | WE2 | 0.2162 | |||

| E3 | WE3 | 0.3296 | |||

| E4 | WE4 | 0.2530 |

| Variable Name | Variable Equation |

|---|---|

| Absorption entropy | |

| Absorption entropy increment | |

| Absorption entropy decrement | |

| Adaptation entropy | |

| Adaptation entropy increment | |

| Adaptation entropy decrement | |

| Restoration entropy | |

| Restoration entropy increment | |

| Restoration entropy decrement | |

| Disturbance entropy | |

| External environmental disturbance events | |

| Internal system disturbance events | |

| Disturbance entropy increment | |

| Disturbance entropy decrement | |

| Resilience entropy | |

| Resilience entropy increment | |

| Resilience entropy decrement |

| Scenario Key | Scenario Name | Scenario Value | Scenario Description |

|---|---|---|---|

| Scenario 1 | Basic Disturbances | The disturbance entropy is the function calculation result of the entropy of the influencing factors of the disturbance event calculated from the accident statistics in Table 2. | Basic disturbance events will cause the functional level of ships with hazardous chemicals to decrease, but most ships can recover to the normal state by virtue of their own resilience, such as a grounding accident for which the ship floating can be helped by throwing cargo and wind disasters that can be resisted by mooring. |

| Scenario 2 | Weak Disturbances | Based on this basic disturbance, the disturbance entropy was reduced by 20%. | Corresponding to the disturbance events that cause little or even negligible damage to the function of hazardous chemical transportation ships in an actual scene, it does not constitute personal casualties and property losses, such as navigation in heavy fog weather and collisions with small fishing boats. |

| Scenario 3 | Strong Disturbances | Based on the basic disturbance, the disturbance entropy increased by 20%. | Disturbance events causing large casualties and property loss were simulated. In this situation, ships need to rely on external forces to cope with the disturbance, such as large-scale hazardous chemical cargo explosion accidents and power loss caused by engine failure. |

| Scenario 4 | Extremely Strong Disturbances | Based on the basic disturbance, the disturbance entropy increased by 20%. | Disturbance events cause heavy casualties and property losses, such as ships experiencing cabin water and loss of buoyancy owing to external or unknown reasons, resulting in ship sinking, capsizing, and total loss. |

| Influencing Factors of Improvement | Entropy Value of Corresponding Resilience Capacity before Improvement | Entropy Value of Corresponding Resilience Capacity after Improvement | Improvement Degree | Ranking |

|---|---|---|---|---|

| A1 | 0.4512 | 0.4754 | 5.36% | 1 |

| A2 | 0.4728 | 4.78% | 3 | |

| A3 | 0.4717 | 4.53% | 4 | |

| A4 | 0.4752 | 5.32% | 2 | |

| B1 | 0.3906 | 0.4164 | 6.60% | 2 |

| B2 | 0.4144 | 6.09% | 3 | |

| B3 | 0.4192 | 7.31% | 1 | |

| C1 | 0.4241 | 0.4610 | 6.32% | 3 |

| C2 | 0.4537 | 6.96% | 1 | |

| C3 | 0.4526 | 6.72% | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, C.; Sun, X.; Zhang, Q.; Niu, L.; Meng, S. Modeling and Improvement Strategies for Safety Resilience in Maritime Hazardous Chemical Transportation System Based on Dissipative Structure Theory and System Dynamics. J. Mar. Sci. Eng. 2024, 12, 340. https://doi.org/10.3390/jmse12020340

Yuan C, Sun X, Zhang Q, Niu L, Meng S. Modeling and Improvement Strategies for Safety Resilience in Maritime Hazardous Chemical Transportation System Based on Dissipative Structure Theory and System Dynamics. Journal of Marine Science and Engineering. 2024; 12(2):340. https://doi.org/10.3390/jmse12020340

Chicago/Turabian StyleYuan, Changfeng, Xing Sun, Qing Zhang, Lulu Niu, and Shasha Meng. 2024. "Modeling and Improvement Strategies for Safety Resilience in Maritime Hazardous Chemical Transportation System Based on Dissipative Structure Theory and System Dynamics" Journal of Marine Science and Engineering 12, no. 2: 340. https://doi.org/10.3390/jmse12020340

APA StyleYuan, C., Sun, X., Zhang, Q., Niu, L., & Meng, S. (2024). Modeling and Improvement Strategies for Safety Resilience in Maritime Hazardous Chemical Transportation System Based on Dissipative Structure Theory and System Dynamics. Journal of Marine Science and Engineering, 12(2), 340. https://doi.org/10.3390/jmse12020340