Parametric Sensitivity Analysis of Mooring Chains of a Floating Offshore Wind Turbine in Shallow Water

Abstract

:1. Introduction

2. Model and Methodology

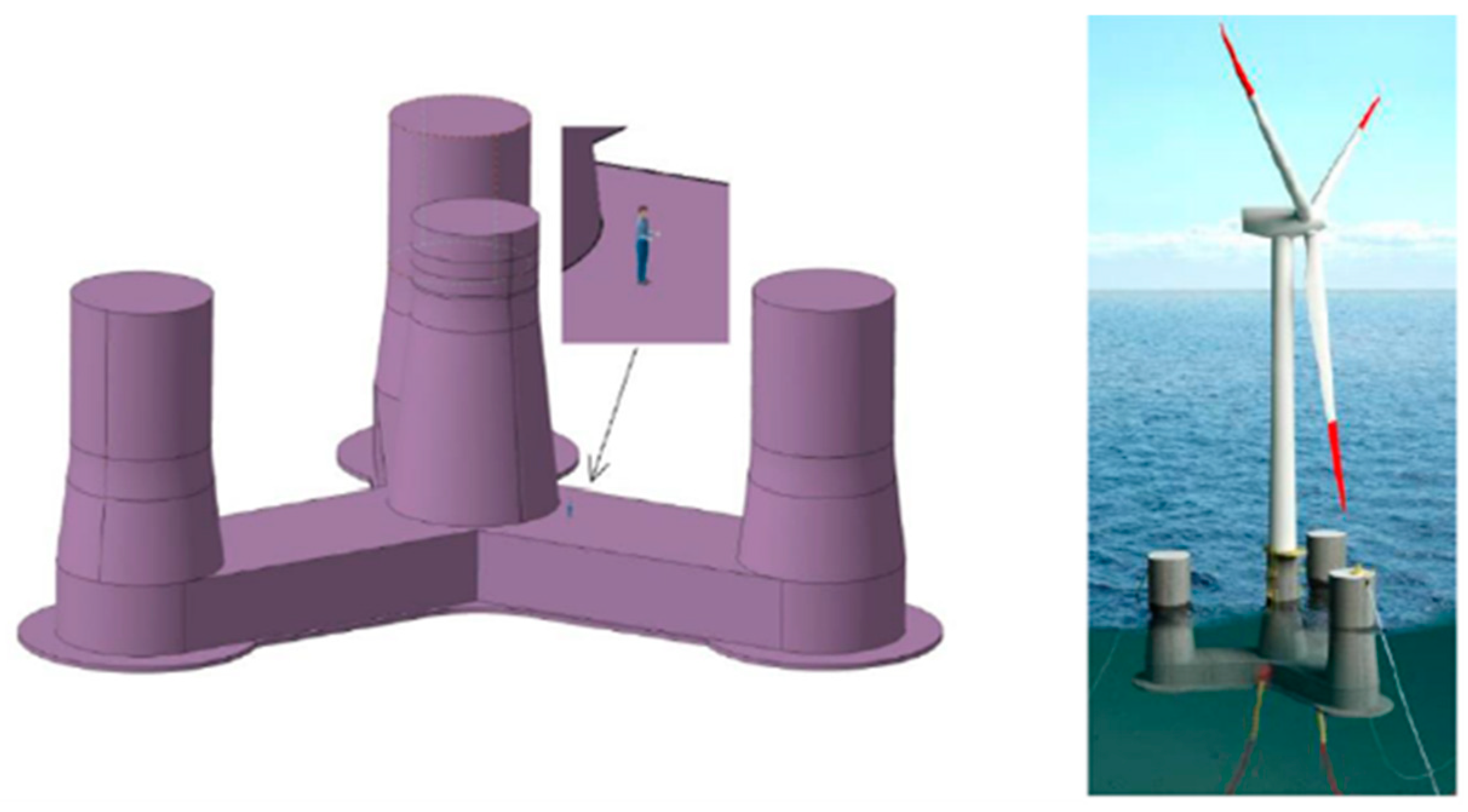

2.1. Parameters of the Floating Offshore Wind Turbine

2.2. Design of Mooring Chains in Shallow Water

2.3. Analysis Method

3. Testing Cases Setting

4. Results and Discussion

4.1. Length of Mooring Chains

4.1.1. Static Characteristics Analysis

4.1.2. Dynamic Characteristics Analysis

4.2. Nominal Diameter of Mooring Chains

4.2.1. Static Characteristics Analysis

4.2.2. Dynamic Characteristics Analysis

4.3. Clump Weights of Mooring Chains

4.3.1. Static Characteristics Analysis

4.3.2. Dynamic Characteristics Analysis

5. Conclusions

- (1)

- A shorter mooring chain has a larger pre-tension, but the tension of the mooring chain increases more significantly with the same offset of the FOWT with more obvious nonlinear characteristics, which is not conducive to mooring safety. In addition, it is found that the horizontal motion of a FOWT is strongly affected by the length of the mooring chain. A too long mooring chain causes a significant offset of the FOWT, while a too short mooring chain quickly increases the tension of the mooring chain. Therefore, it is crucial to design the appropriate length of the mooring chains to ensure the operation and safety of FOWTs.

- (2)

- The mooring chain with the larger nominal diameter has larger tension force under the same platform offset, but the spatial shape of the mooring chains with different nominal diameters is almost the same. The change in the nominal diameter of the mooring chain has a certain impact on the dynamic responses of the FOWT. As the nominal diameter of the mooring chain increases, the mean and maximum values of the horizontal movement of the FOWT will decrease, but it is not as significant as the impact from the change in the mooring chain length.

- (3)

- By analyzing the weight and position of the clump weights, it is evident that increasing the weight of clump weights improves the pre-tension of the mooring chain. Additionally, a heavier clump weight results in a shorter lying section under the same displacement of the FOWT. When the weight of the clump weight remains unchanged, positioning the clump weights as close to the touchdown point on the seabed as possible can improve the restoring force of the mooring system. Additionally, the horizontal restoring force provided by a design scheme with multiple counterweights is greater than that with only a single counterweight. Moreover, a reasonable layout of clump weights attached to mooring chains can effectively restrain the “slack-taut” effect of mooring chains in shallow water. This article only explores the influence of some key mooring chain parameters, such as mooring chain length, nominal diameter, and suspension clump weights, to reveal the nonlinear characteristics of mooring chains of a FOWT in shallow water. Within a limited range of design parameters, a suitable design scheme was selected, providing a certain reference for mooring chain design in shallow water. In addition, as a matter of fact, wave nonlinearity becomes more pronounced as the water depth decreases. According to DNV-RP-C205 [29], the Stokes waves may be more appropriate for describing the extreme wave conditions in the study rather than linear wave models.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Subbulakshmi, A.; Verma, M.; Keerthana, M.; Sasmal, S.; Harikrishna, P.; Kapuria, S. Recent advances in experimental and numerical methods for dynamic analysis of floating offshore wind turbines—An integrated review. Renew. Sustain. Energy Rev. 2022, 164, 112525. [Google Scholar] [CrossRef]

- Bashetty, S.; Ozcelik, S. Review on dynamics of offshore floating wind turbine platforms. Energies 2021, 14, 6026. [Google Scholar] [CrossRef]

- Stiesdal, H. Hywind: The world’s first floating MW-scale wind turbine. Wind. Dir. 2009, 31, 52–53. [Google Scholar]

- Skaare, B.; Nielsen, F.G.; Hanson, T.G.; Yttervik, R.; Havmøller, O.; Rekdal, A. Analysis of measurements and simulations from the Hywind Demo floating wind turbine. Wind. Energy 2015, 18, 1105–1122. [Google Scholar] [CrossRef]

- Patel, S. New floating wind array planned in Scotland. POWER Magazine, 1 July 2014. [Google Scholar]

- Anchustegui, I.H. Is Hywind Tampen’s State Aid Approval a Kick start for the Norwegian Offshore Wind Industry. Eur. St. Aid LQ 2020, 19, 225. [Google Scholar] [CrossRef]

- DNV. Floating Wind: The Power to Commercialize; DNV: Høvik, Norway, 2020. [Google Scholar]

- James, R.; Costa, M. Floating Offshore Wind: Market and Technology Review; Carbon Trust: London, UK, 2015. [Google Scholar]

- Yang, R.; Zheng, X.; Chen, J.; Wu, Y. Current status and future trends for mooring systems of floating offshore wind turbines. Sustain. Mar. Struct. 2022, 4, 40–54. [Google Scholar] [CrossRef]

- Ma, K.T.; Luo, Y.; Kwan, C.T.T.; Wu, Y. Mooring System Engineering for Offshore Structures; Gulf Professional Publishing: Woburn, MA, USA, 2019. [Google Scholar]

- Rui, S.; Zhou, Z.; Gao, Z.; Jostad, H.P.; Wang, L.; Xu, H.; Guo, Z. A review on mooring lines and anchors of floating marine structures. Renew. Sustain. Energy Rev. 2024, 199, 114547. [Google Scholar] [CrossRef]

- Stumpf, F.T.; de Ávila Barreto, M.; da Cruz, D.M.; Guilherme, C.E.M. Numerical simulation of multi-material hybrid lines for offshore mooring. Ocean. Eng. 2024, 305, 117979. [Google Scholar] [CrossRef]

- Hopstad, A.L.H.; Argyriadis, K.; Manjock, A.; Goldsmith, J.; Ronold, K.O. DNV GL standard for floating wind turbines. In International Conference on Offshore Mechanics and Arctic Engineering; American Society of Mechanical Engineers: New York, NY, USA, 2018; Volume 51975. [Google Scholar]

- Masciola, M.; Robertson, A.N.; Jonkman, J.M.; Coulling, A.; Goupee, A. Assessment of the importance of mooring dynamics on the global response of the DeepCWind floating semisubmersible offshore wind turbine. In Proceedings of the 23th International Conference on Offshore and Polar Engineering, Anchorage, Alaska, USA, June 30–July 4 2013; pp. 359–368. [Google Scholar]

- Li, Y.; Zhu, Q.; Liu, L.; Tang, Y. Transient response of a SPAR-type floating offshore wind turbine with fractured mooring lines. Renew. Energy 2018, 122, 576–588. [Google Scholar] [CrossRef]

- Bae, Y.H.; Kim, M.H.; Kim, H.C. Performance changes of a floating offshore wind turbine with broken mooring line. Renew. Energy 2017, 101, 364–375. [Google Scholar] [CrossRef]

- Sedghi, H.; Kimlaei, M. Effects of Mooring Line Design Parameters on the Line Dynamics and Fatigue Response of Subsea Mooring Lines. In International Conference on Offshore Mechanics and Arctic Engineering; American Society of Mechanical Engineers: New York, NY, USA, 2018; Volume 51203, p. V001T01A073. [Google Scholar]

- Zhao, Z.; Li, X.; Wang, W.; Shi, W. Analysis of dynamic characteristics of an ultra-large semi-submersible floating wind turbine. J. Mar. Sci. Eng. 2019, 7, 169. [Google Scholar] [CrossRef]

- Xu, K.; Larsen, K.; Shao, Y.; Zhang, M.; Gao, Z.; Moan, T. Design and comparative analysis of alternative mooring systems for floating wind turbines in shallow water with emphasis on ultimate limit state design. Ocean. Eng. 2021, 219, 108377. [Google Scholar] [CrossRef]

- Huang, W.H.; Yang, R.Y. Water depth variation influence on the mooring line design for FOWT within shallow water region. J. Mar. Sci. Eng. 2021, 9, 409. [Google Scholar] [CrossRef]

- Benassai, G.; Campanile, A.; Piscopo, V.; Scamardella, A. Ultimate and accidental limit state design for mooring systems of floating offshore wind turbines. Ocean. Eng. 2014, 92, 64–74. [Google Scholar] [CrossRef]

- Campanile, A.; Piscopo, V.; Scamardella, A. Mooring design and selection for floating offshore wind turbines on intermediate and deep water depths. Ocean. Eng. 2018, 148, 349–360. [Google Scholar] [CrossRef]

- Pegalajar-Jurado, A.; Bredmose, H.; Borg, M.; Straume, J.G.; Landbø, T.; Andersen, H.S.; Yu, W.; Müller, K.; Lemmer, F. State-of-the-art model for the LIFES50+ OO-Star Wind Floater Semi 10MW floating wind turbine. J. Phys. Conf. Ser. 2018, 1104, 012024. [Google Scholar] [CrossRef]

- Vågnes, D.; Monteiro, T.G.; Halse, K.H.; Hildre, H.P. Low-height lifting system for offshore wind turbine installation: Modelling and hydrodynamic response analysis using the commercial simulation tool SIMA. In International Conference on Offshore Mechanics and Arctic Engineering; American Society of Mechanical Engineers: New York, NY, USA, 2020; Volume 84317. [Google Scholar]

- Wendt, F.F.; Andersen, M.T.; Robertson, A.N.; Jonkman, J.M. Verification and validation of the new dynamic mooring modules available in FAST v8. In International Ocean and Polar Engineering Conference; ISOPE: Cupertino, CA, USA, 2016. [Google Scholar]

- Ramachandran, G.K.V.; Sahlberg-Nielsen, L.; Acampora, A.; Jia, H.; Brown, C. Coupling of aero-elastic and structural codes to carry out integrated load analysis of floating wind turbines. In Trends in Renewable Energies Offshore; CRC Press: Boca Raton, FL, USA, 2022; pp. 485–490. [Google Scholar]

- Hall, M. MoorDyn User’s Guide; Department of Mechanical Engineering, University of Maine: Orono, ME, USA, 2015; Volume 15. [Google Scholar]

- Myhr, A.; Bjerkseter, C.; Ågotnes, A.; Nygaard, T.A. Levelised cost of energy for offshore floating wind turbines in a life cycle perspective. Renew. Energy 2014, 6, 714–728. [Google Scholar] [CrossRef]

- Nestegård, A.; Ronæss, M.; Hagen, Ø.; Ronold, K.O.; Bitner-Gregersen, E. New DNV recommended practice DNV-RP-C205 on environmental conditions and environmental loads. In ISOPE International Ocean and Polar Engineering Conference; ISOPE: Cupertino, CA, USA, 2006. [Google Scholar]

| Unit | Value | |

|---|---|---|

| Mass of blades | kg | 230,717 |

| Mass of nacelle | kg | 446,006 |

| Mass of tower | kg | 1.257 × 106 |

| Height of tower | m | 104.63 |

| Mass of concrete platform (excl. tower and mooring systems) | kg | 2.1709 × 107 |

| Center of gravity | m | −15.225 |

| Draft | m | 22.0 |

| Displacement | m3 | 2.3509 × 104 |

| Iterm | Grade R3 | Grade R3S | Grade R4 | Grade R4S | Grade R5 |

|---|---|---|---|---|---|

| Proof load, stud link (kN) | 0.0156D2 (44-0.08D) | 0.0180D2 (44-0.08D) | 0.0216D2 (44-0.08D) | 0.0240D2 (44-0.08D) | 0.0251D2 (44-0.08D) |

| Proof load, studless (kN) | 0.0156D2 (44-0.08D) | 0.0174D2 (44-0.08D) | 0.0192D2 (44-0.08D) | 0.0213D2 (44-0.08D) | 0.0223D2 (44-0.08D) |

| Breaking load (kN) | 0.0223D2 (44-0.08D) | 0.0249D2 (44-0.08D) | 0.0274D2 (44-0.08D) | 0.0304D2 (44-0.08D) | 0.0320D2 (44-0.08D) |

| Weight, stud link (kg/m) | 0.0219D2 | ||||

| Five-link length (mm) | Minimum 22D and Maximum 22.55D | ||||

| Item | Unit | Chain I | Chain II | Chain III |

|---|---|---|---|---|

| Nominal diameter | m | 0.137 | 0.127 | 0.117 |

| Mass of chains per unit length (in air) | kg/m | 411.041 | 353.225 | 299.789 |

| Weight of chains per unit length (in water) | N/m | 3505.4 | 3012.4 | 2556.6 |

| Equivalent hydro-diameter | m | 0.257 | 0.239 | 0.220 |

| Axial stiffness (EA) | N | 1.6510 × 109 | 1.4188 × 109 | 1.2041 × 109 |

| Proof load | kN | 1.3395 × 104 | 1.1789 × 104 | 1.0242 × 104 |

| Breaking load | kN | 1.6992 × 104 | 1.4955 × 104 | 1.2993 × 104 |

| Item | Values |

|---|---|

| Quantity of mooring lines | 3 |

| Angle between adjacent mooring chains | 120° |

| Vertical distance from fairlead to water surface (m) | 9.5 |

| Radius of fairlead from centerline of floating body (m) | 44 |

| Vertical distance between anchor point and water surface z (m) | −44 |

| Horizontal distance between anchor point and fairlead x (m) | 634.184 |

| Radius from anchor point to center line of floating body (m) | 678.18 |

| Length of unextended mooring chain (m) | 637 |

| Seabed stiffness (Pa/m) | 3.0 × 106 |

| Seabed damping (PaS/m) | 3.0 × 105 |

| Load Cases | Still Water | Rated Operation | Extreme Shutdown |

|---|---|---|---|

| (DLC. 1) | (DLC. 2) | (DLC. 3) | |

| Direction (deg) | 0.0 | 0.0 | 90.0 |

| Wind speed (m/s) | 0.0 | 11.4 | 56.2 |

| Wind shear index | 0.0 | 0.067 | 0.096 |

| Significant wave height (m) | 0.0 | 1.75 | 11.53 |

| Wave period (s) | 0.0 | 7.5 | 14.93 |

| Peak elevation parameter | 0.0 | 3.3 | 3.3 |

| Current speed (m/s) | 0.0 | 0.46 | 1.19 |

| L(m) | 637 | 647 | 652 | 657 | |

|---|---|---|---|---|---|

| D (mm) | |||||

| 117 | EUR 377,310 | EUR 383,234 | EUR 386,195 | EUR 389,157 | |

| 127 | EUR 444,564 | EUR 451,543 | EUR 455,033 | EUR 458,522 | |

| 137 | EUR 517,331 | EUR 525,452 | EUR 529,513 | EUR 533,573 | |

| Design Factors | Static Characteristics | Dynamic Characteristics |

|---|---|---|

| Length |

|

|

| Nominal diameter |

|

|

| Clump weights |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Wang, C.; Wu, X.; Feng, F.; Li, Y. Parametric Sensitivity Analysis of Mooring Chains of a Floating Offshore Wind Turbine in Shallow Water. J. Mar. Sci. Eng. 2024, 12, 2202. https://doi.org/10.3390/jmse12122202

Chen J, Wang C, Wu X, Feng F, Li Y. Parametric Sensitivity Analysis of Mooring Chains of a Floating Offshore Wind Turbine in Shallow Water. Journal of Marine Science and Engineering. 2024; 12(12):2202. https://doi.org/10.3390/jmse12122202

Chicago/Turabian StyleChen, Jiahao, Chuanfu Wang, Xiaodi Wu, Fan Feng, and Yan Li. 2024. "Parametric Sensitivity Analysis of Mooring Chains of a Floating Offshore Wind Turbine in Shallow Water" Journal of Marine Science and Engineering 12, no. 12: 2202. https://doi.org/10.3390/jmse12122202

APA StyleChen, J., Wang, C., Wu, X., Feng, F., & Li, Y. (2024). Parametric Sensitivity Analysis of Mooring Chains of a Floating Offshore Wind Turbine in Shallow Water. Journal of Marine Science and Engineering, 12(12), 2202. https://doi.org/10.3390/jmse12122202