Abstract

Fatigue failure caused by frequent tension and bending loads is a crucial safety concern for mooring chains used on floating structures in the oil and gas industry. The bending effect for a chain’s fatigue is usually not considered by existing fatigue analysis methods, and even if it is considered, existing commercial software can only calculate the constant interlink bending stiffness without consideration of the stiffness variations due to tension and friction. To address this issue, this study develops an in-plane bending (IPB)/out-of-plane bending (OPB) fatigue assessment approach for offshore mooring chains considering the time-varying nonlinear interlink bending stiffness. Initially, the mooring tension and IPB/OPB angles are calculated by an in-house code MeCAP (multi-element coupled analysis program), considering the time-varying interlink stiffness between the chain links. The fatigue life of mooring chains for pure tension–tension (TT) and OPB combined fatigue at different hotspot locations (A, B, and C) is calculated by MeCAP-fatigue, a newly-developed module in MeCAP. Based on the analysis model, a comparative study is implemented to investigate the effects of interlink stiffness on fatigue damage. The differences and advantages of the combined fatigue calculation method over the pure TT fatigue assessment method are discussed. The results illustrate that combined fatigue would be underestimated significantly if zero interlink stiffness (hinge joint assumption) is applied or even constant interlink stiffness (calculated by mooring pretension), while pure TT fatigue will be largely unaffected. Moreover, compared to pure TT fatigue, the OPB combined fatigue assessment method, considering the effects of OPB/IPB and the time-varying properties of the connection between chain links, could evaluate fatigue life more comprehensively.

1. Introduction

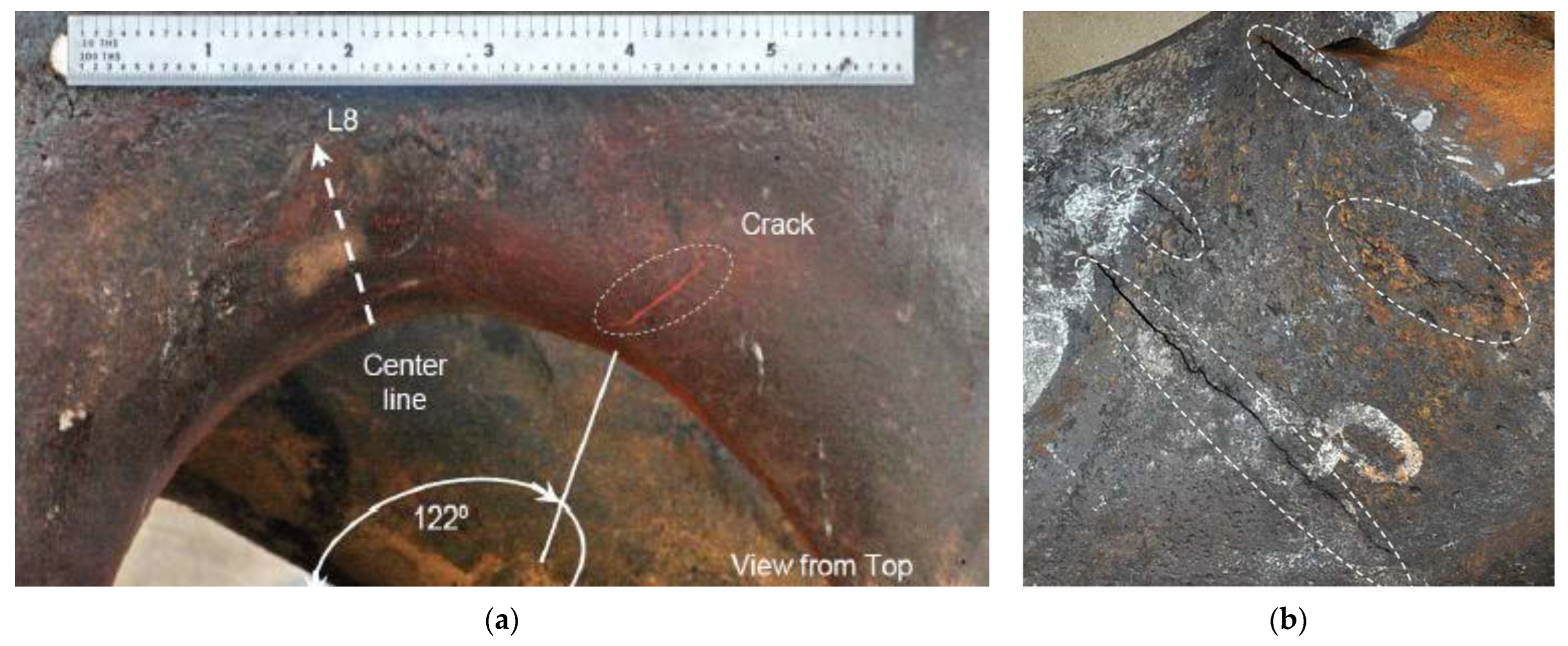

The mooring chain is a crucial component of offshore structures and, in many cases, is used as part of the mooring lines near fairleads and the seabed. Even with a significant safety factor assigned for the fatigue design of the mooring chain, several cases of mooring chain fatigue failure have occurred in the vicinity of fairleads over the last two decades [1], where two thirds of mooring chain failures were due to fatigue failure [2]. In 2002, several deepwater offshore mooring chains designed per the tension–tension (TT) fatigue method with T–N curves failed prematurely after only over 200 days of service, as shown in Figure 1 [3]. A new fatigue failure mechanism for mooring chains was discovered, with significant alternating in-plane bending (IPB) and out-of-plane bending (OPB) stresses due to the floater’s 6-DoF motion and the “Locking Mode” of two adjacent links. When the tension is small, the tangential force generated by friction is enough to balance that caused by the tension, and the adjacent links roll with each other. In this case, the OPB stresses are small, which meets the expectations of engineering design [4]. Moreover, in the case of high pretension, significant motion of mooring chains, and unsmooth contact surfaces of mooring chains or fairleads [5], the locking mode may occur due to the friction between adjacent links. Thus, the OPB loads produce significant stress concentrations on the surface and induce significant fatigue damage.

Figure 1.

Link failure due to OPB [3].

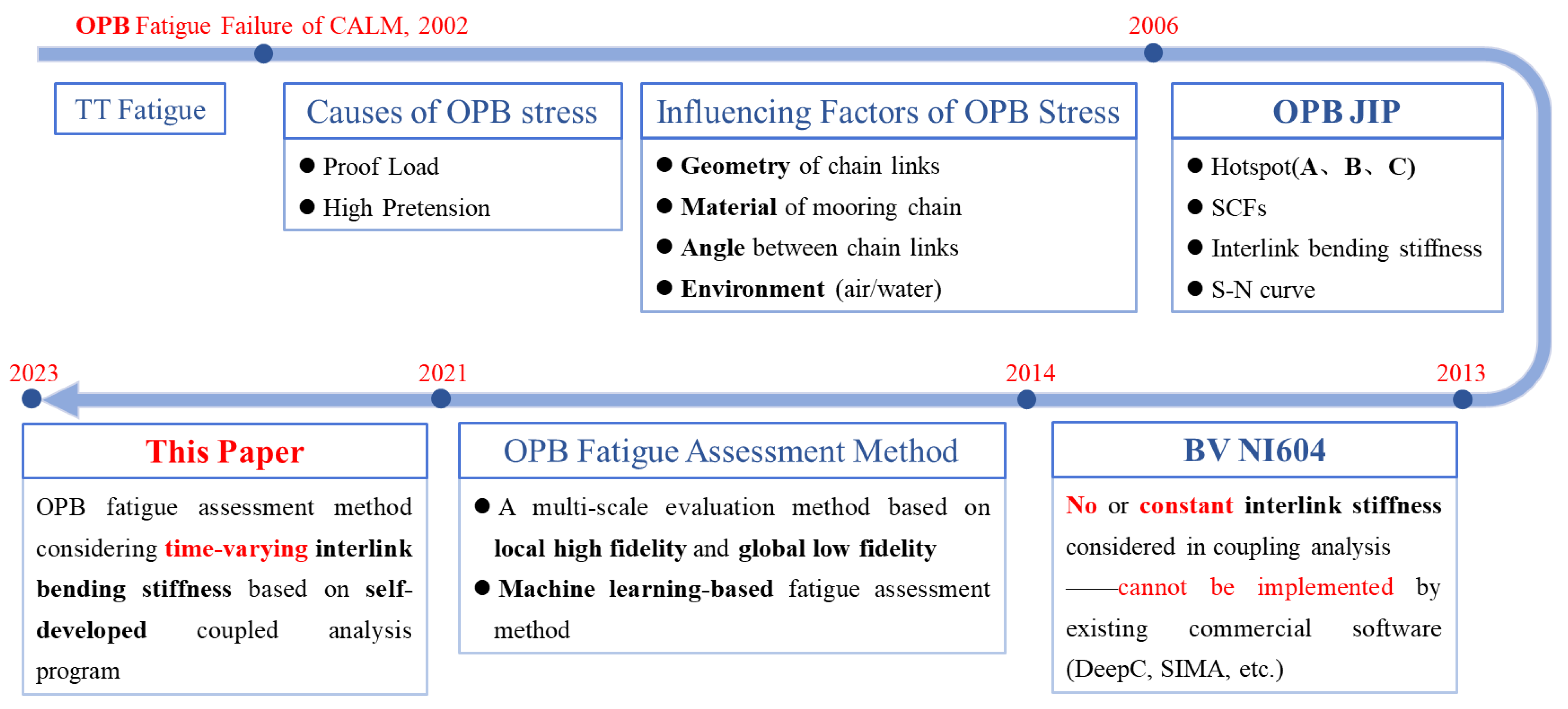

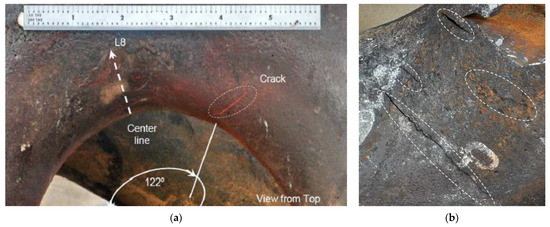

Since the accidental fatigue failure due to OPB of the mooring chain of deepwater floaters in 2002, extensive investigations of the failure mechanism of the fatigue due to OPB have been conducted. Vargas et al. provided procedures for calculating the stress concentration factors (SCF) of chain links subjected to OPB loads using finite-element analysis (FEA) [6]. Subsequently, many studies investigated the OPB fatigue phenomenon of mooring chains using either FEA or experimental methods [3,4,7,8,9,10,11], and the phenomenon and failure mechanism of OPB were studied and interpreted, as shown in Figure 2 [12]. The relationship between OPB stresses in mooring chains and pretension, interlink angles, and mooring chain materials has been established in related studies [3]; moreover, it was also found that high OPB stresses will be induced in the proof loading test [8].

Figure 2.

Chain link after fatigue test. (a) Small secondary crack found on unfailed link; (b) Secondary crack close to the border of the contact area from the secondary fracture failure [12].

Research on combined fatigue analysis criteria subjected to OPB for mooring chains is also in progress. A multi-axial criterion is more appropriate than the single-axis-based maximum principal stress criterion for chain fatigue analysis [13]. Furthermore, Rampi et al. investigated the interlink stiffness and SCFs of mooring chains subjected to OPB using the FEA approach and proposed multi-axial SCFs based on the Dang Van fatigue criterion [12,14,15].

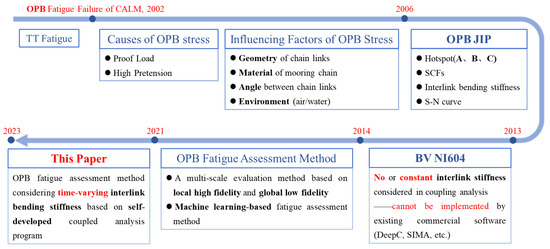

However, experiments and FEA methods only focus on the local OPB phenomenon of the mooring chains. Xue et al. evaluated the combined fatigue of the mooring chain using fracture mechanics (FM) and analyzed the effect of the chain stopper shape on the combined fatigue [16,17,18,19]. The FM method can provide accurate fatigue results and is suitable for accident or local chain fatigue analysis because of its low computational efficiency. Several companies initiated a joint industry project (JIP) to investigate the combined fatigue mechanism and propose recommended practices for mooring chain fatigue design [4,12,14,15,20,21]. A framework for mooring chain combined fatigue analysis based on the SN curve was proposed via numerical and experimental investigations [22]. Subsequently, Chung et al. proposed a multi-scale method for evaluating OPB-induced failure by time-varying interlink bending stiffness and investigated the effects of underwater chain stopper (UCS) bearing friction on combined fatigue [1,23]. With the development of artificial intelligence, Lee et al. proposed a local stress prediction method of mooring chains based on machine-learning technology and verified the reliability of its stress prediction results for three links’ OPB and IPB [24,25]. Fatigue analysis efficiency was effectively improved by the method, but many sample training as well as parameter sensitivity studies are still needed. As shown in Figure 3, although much work has been conducted and great progress has been made based on the previous studies, few of them can provide a systematical combined fatigue assessment process considering TT, OPB, and IPB. Additionally, for the existing commercial software, the role of time-varying interlink stiffness between chain links cannot be calculated in real time according to the tension and angle during the time-domain coupled analysis.

Figure 3.

Research background.

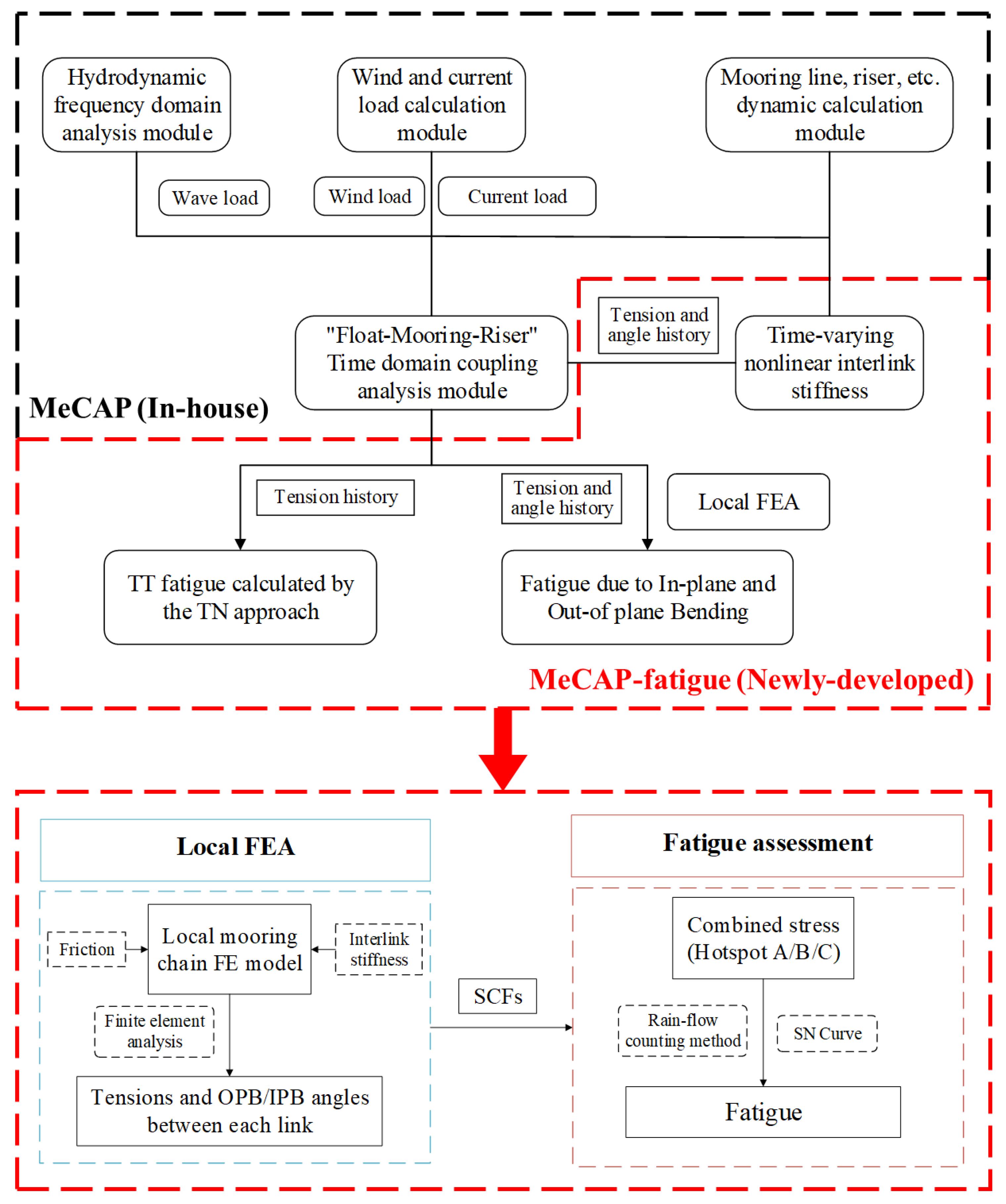

In this paper, a program named MeCAP-fatigue is developed within the framework of an in-house program MeCAP (multi-element coupled analysis program), in which the time-varying characteristic of interlink bending stiffness can be reasonably considered in the prediction of OPB combined fatigue. The interlink stiffness time-varying effect on the chain’s fatigue is investigated by comparisons of the zero interlink stiffness (hinge joint assumption), constant interlink stiffness (calculated by mooring pretension), and time-varying interlink stiffness. In addition, the accuracy and advantages of OPB combined fatigue over pure TT fatigue are illustrated. Finally, the influence of wind and current on OPB combined fatigue is discussed.

2. The Model for a Semi-Submersible Platform

2.1. The Floating Platform and Mooring System

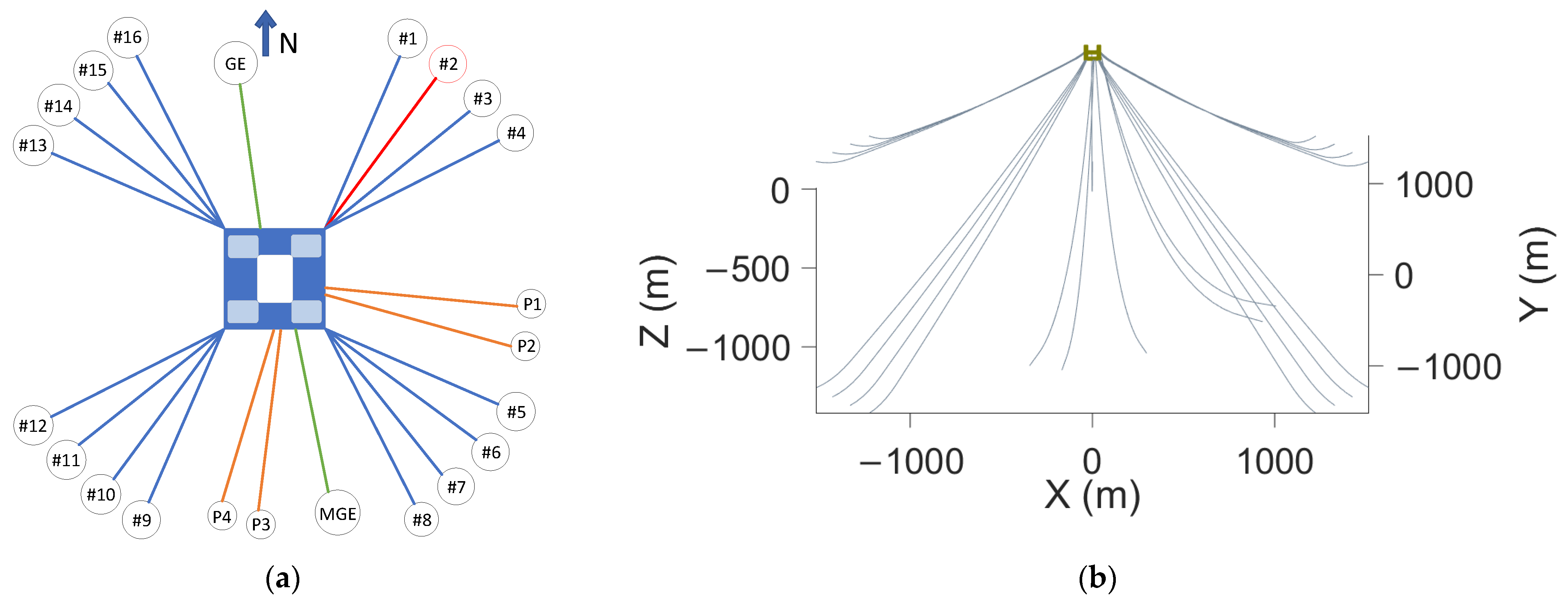

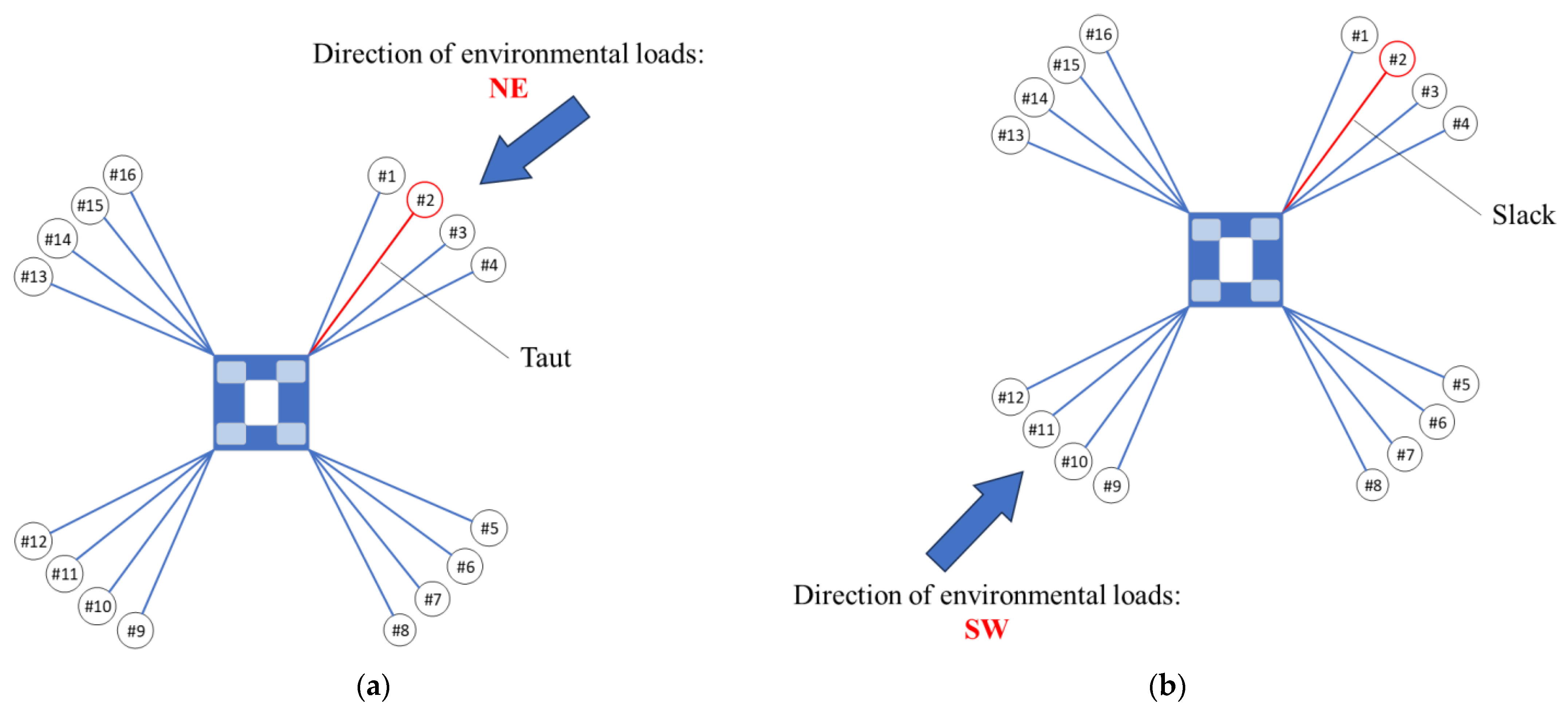

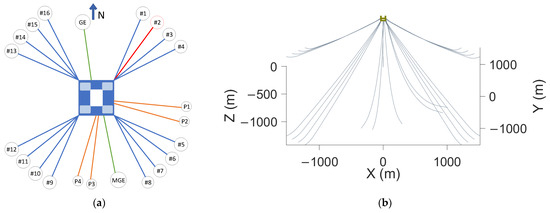

A four-column semi-submersible platform and its mooring system at a 1422 m water depth are used as a numerical example. The main particulars of the platform are shown in Table 1. A taut mooring system with 16 mooring lines is used, as shown in Figure 4a. Each mooring line consists of three segments: top chain, middle polyester, and bottom chain. Detailed material properties are shown in Table 2. In total, 6 steel category risers (SCRs) are supported by the platform.

Table 1.

Main particulars of the semi-submersible platform.

Figure 4.

(a) Mooring line layout; (b) coupled analysis model.

Table 2.

Sectional properties of mooring line.

The top 20 chains of the selected mooring line (mooring line #2 in Figure 4a) are refined to 20 elements to better simulate the interlink contact in the global coupled analysis (Figure 4b). The position, configuration, and tensions of the coupled system are calculated in static analysis. Then, they are used as the initial conditions for dynamic analysis.

2.2. Hydrodynamic Parameters

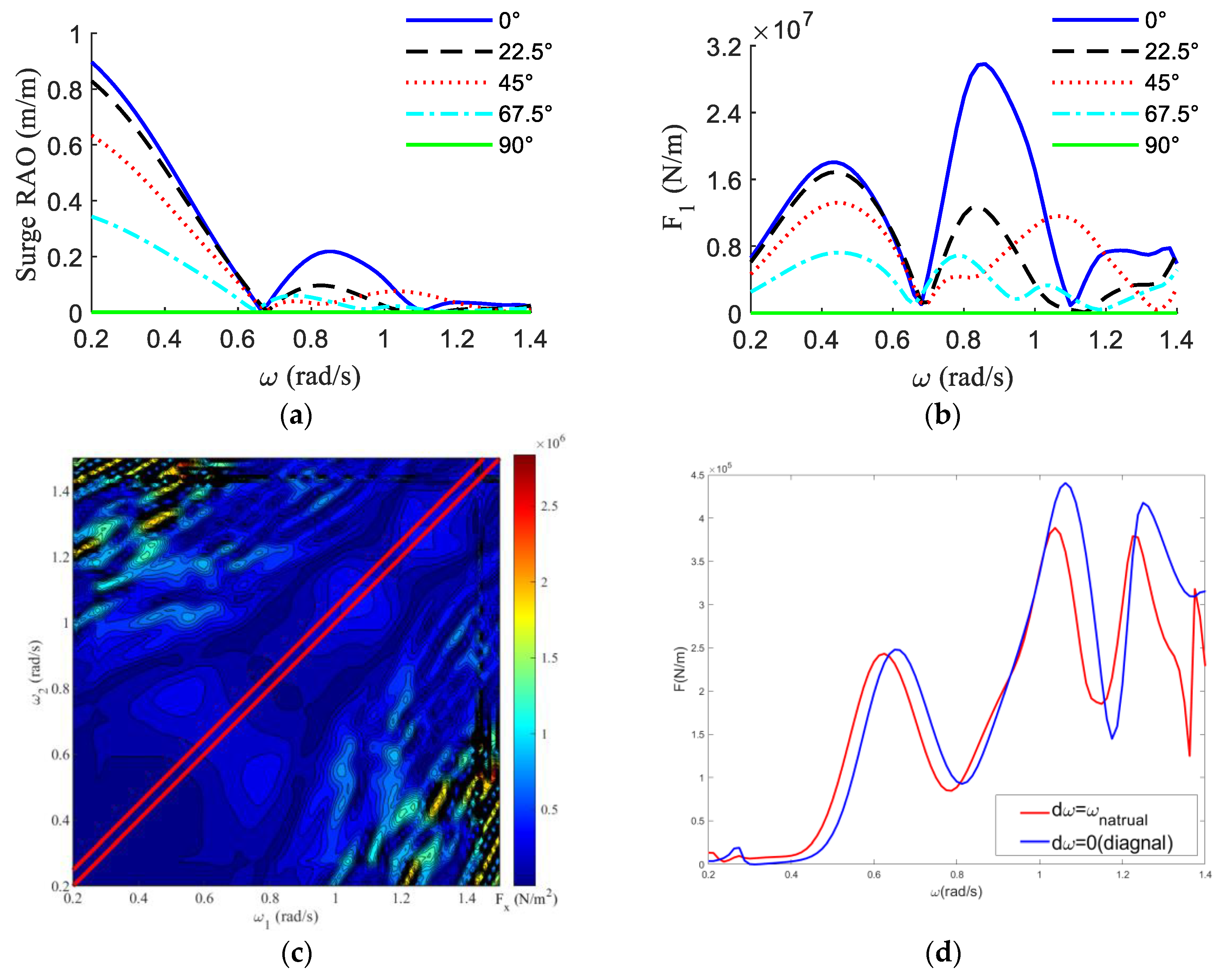

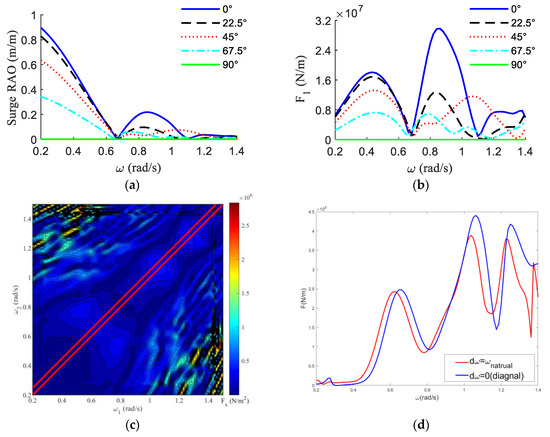

Hydrodynamic analysis is carried out in a range of 0.2–1.4 rad/s and five directions 0°, 22.5°, 45°, 67.5°, and 90° are considered. The motion response amplitude operator (RAO), linear transfer function (LTF), and quadratic transfer function (QTF) are obtained, as shown in Figure 5.

Figure 5.

(a) RAO of surge; (b) LTF of surge; (c) QTF cloud chart; (d) QTF curves at the diagonal and natural frequency.

2.3. Environment Conditions

There are 54 environment conditions in the sea area where the semi-submersible platform is located, detailed in Table A1. The directions of wind and waves are concentrated near the northeast (NE) direction, and large winds (with wind speeds of 20 m/s or more) are found in the NE direction, followed by the south (S) direction. The direction of the current is concentrated in the southwest (SW) direction, and the large current (current velocity of 1.2 m/s or more) is also concentrated in the SW direction. The environmental loads are mainly from the northeast, and the larger ones are also concentrated in the northeast. The mooring lines on the northeast side of the platform are subjected to large and frequent tension and fatigue loads. Therefore, the next fatigue analysis will focus on mooring line #2 on the northeast side of the platform.

2.4. Finite-Element Model

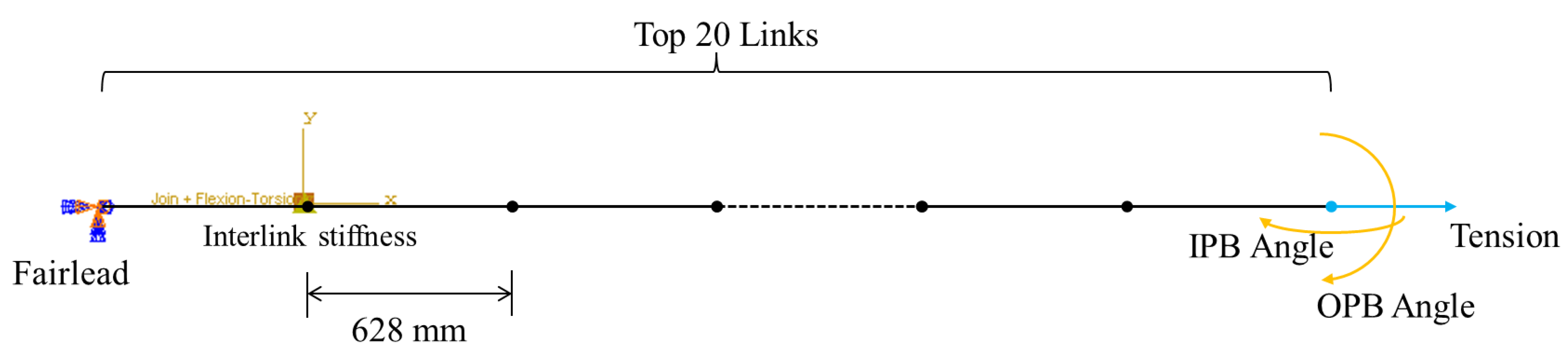

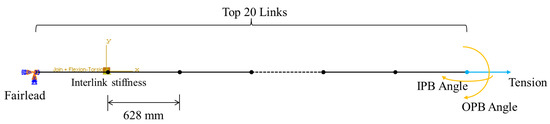

The nonlinear static finite-element analysis method is used to calculate the bending moments between each chain link of the top 20 links, in which the beam element is suggested to simulate the links [22]. The geometric and material properties of the chain link are listed in Table 3. As for the FE model, the element length is the equivalent length (4 times the nominal diameter) of the chain link and the cross-sectional diameter is its equivalent diameter ( times the nominal diameter), with the element type of a 2-node linear beam (B31). The mooring tension and in-plane and out-of-plane angles are applied as input loads to one end of the model, with a fixed constraint at the other end. And the interlink stiffness from the time-domain coupled analysis is applied to the interactions between chain links. A detailed exhibition of the FE model is illustrated in Figure 6.

Table 3.

The geometric and material properties of the chain link.

Figure 6.

Schematic of FE model.

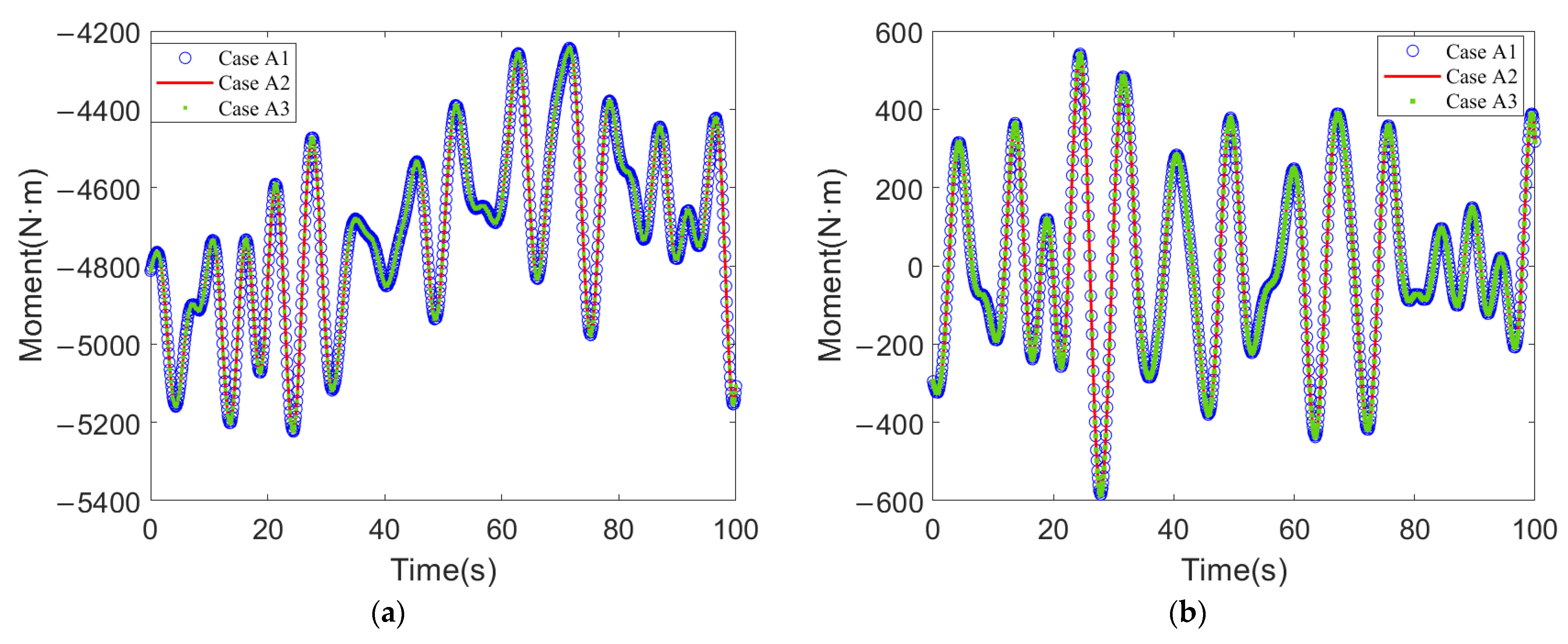

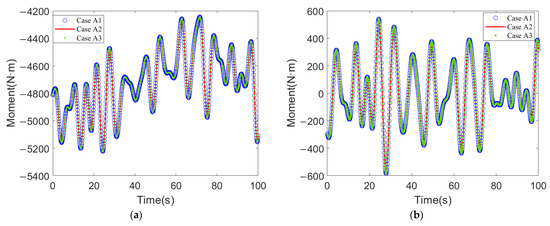

Its convergence is checked by different element lengths: (1) Case A1—31.4 mm, (2) Case A2—62.8 mm; (3) Case A3—125.6 mm. The results of finite-element analysis based on the above 3 element lengths are shown in Figure 7. The OPB and IPB moments obtained for these three cases are the same, and the element length of 62.8 mm (Case A2) is used in the next finite-element analysis.

Figure 7.

Results of FE convergence verification. (a) OPB moment between the top 2 links; (b) IPB moment between the top 2 links.

3. Implementation and Validation of MeCAP-Fatigue

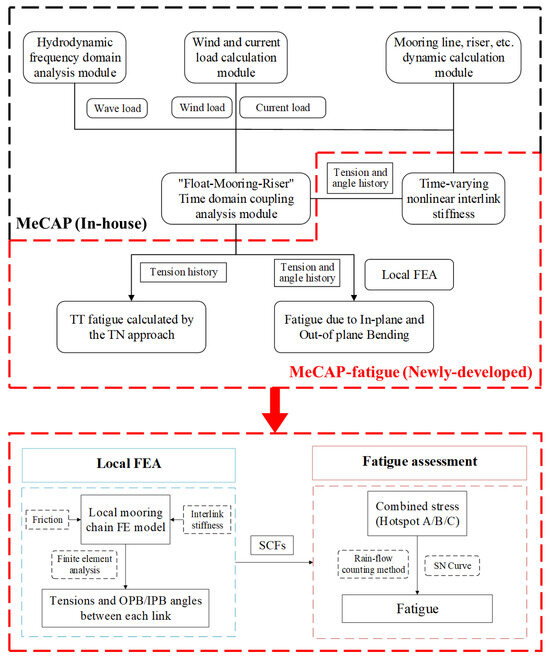

3.1. MeCAP-Fatigue for TT and OPB Combined Fatigue Assessment

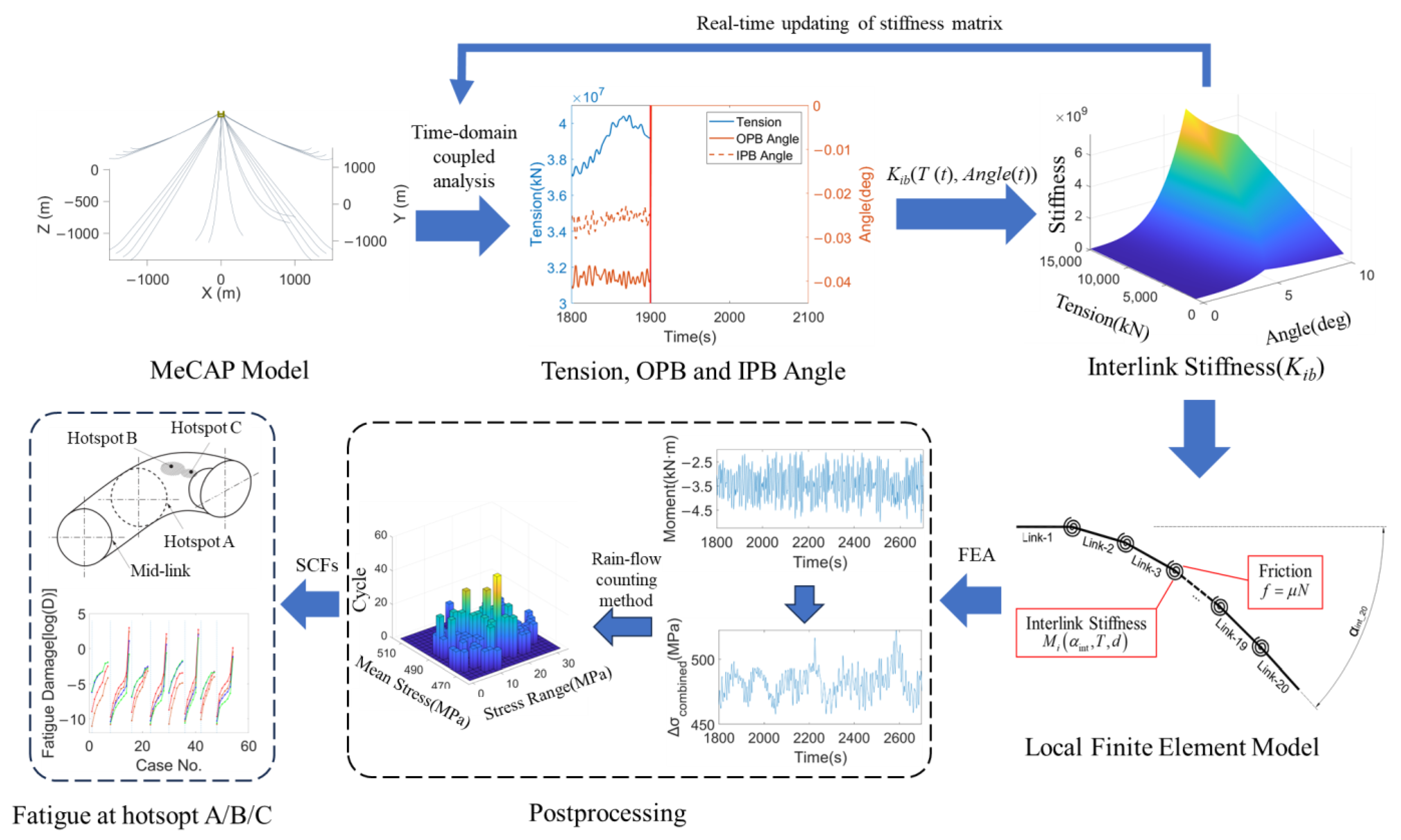

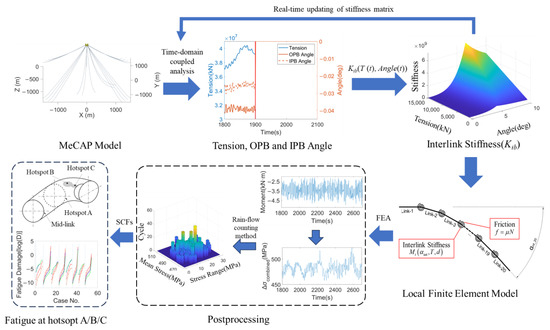

MeCAP is an in-house program to implement time-domain coupled analysis on floating platforms, moorings, risers, etc. Based on this, a program, named MeCAP-fatigue, for TT and OPB combined fatigue considering time-varying interlink stiffness is developed. A flowchart of the fatigue assessment method based on MeCAP is shown in Figure 8. First, hydrodynamic parameters such as the LTFs, QTFs, added mass coefficients, and potential damping of the platform are obtained. Then, the first- and second-order wave forces, retardation functions, etc., are calculated; the wind and current loads are calculated according to the wind and current load coefficient matrix; the rod theory is used for the dynamic simulation of slender structures, that is, moorings and risers; the coupling of the platform and slender structures is calculated by delivering motion and forces step by step; when the OPB combined fatigue is calculated, the bending stiffness between the chain links is calculated and updated in real time at each time step during the coupled analysis; the OPB combined fatigue is calculated by finite-element analysis and the rain-flow counting method.

Figure 8.

Flowchart of MeCAP-fatigue.

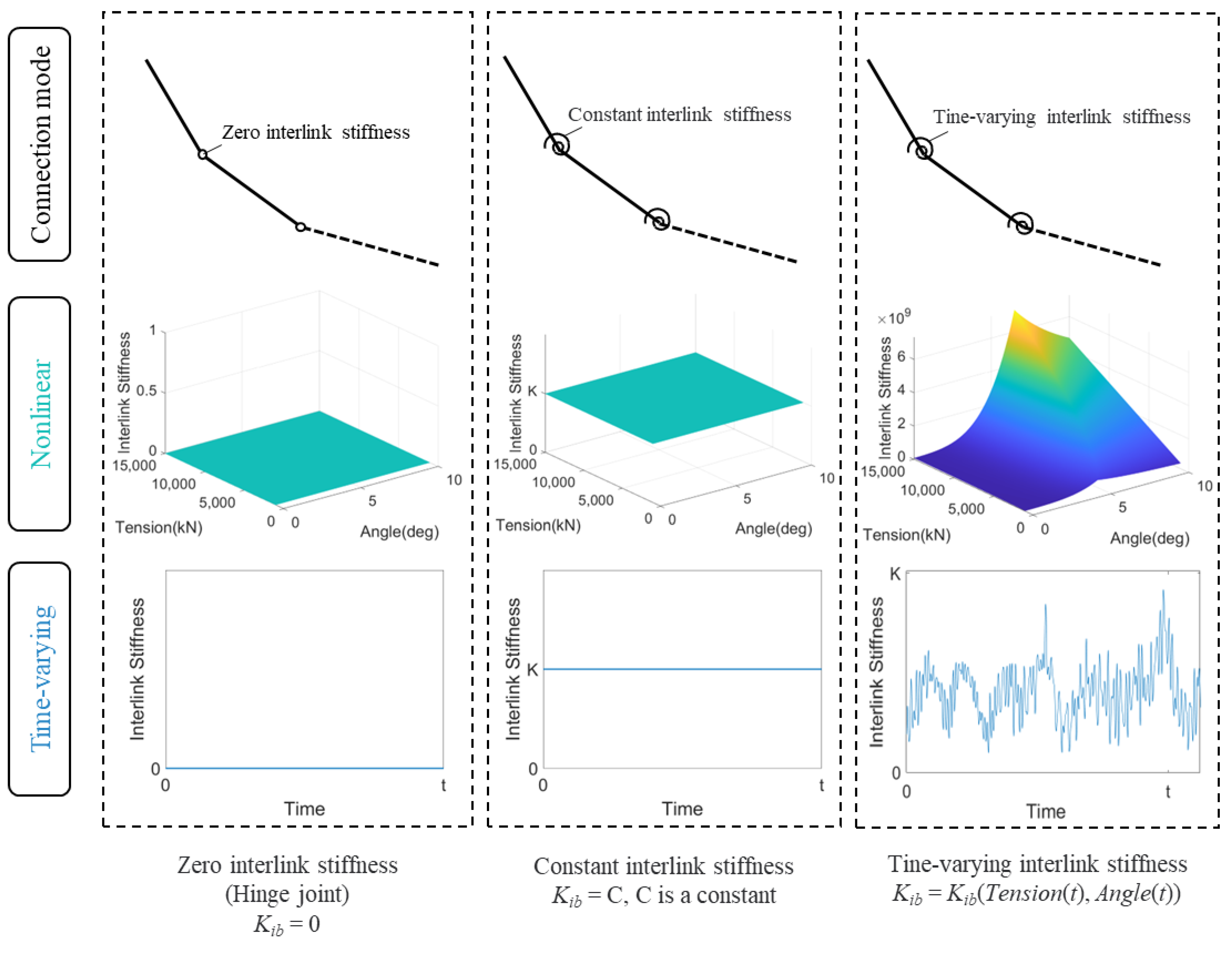

The three contact modes between chain links subjected to OPB and IPB stresses are as follows: (1) Rolling Mode: Chain links subjected to low pretension can freely rotate; (2) Locking Mode: The chain links cannot rotate or slide easily, which predominates the OPB stresses and fatigue; (3) Sliding Mode: While in rolling mode, the friction between the links increases as the mooring tension increases [7]. The bending stress generated by friction is minor, which slightly affects the chain fatigue. It results in a nonlinear characterization of the interlink stiffness.

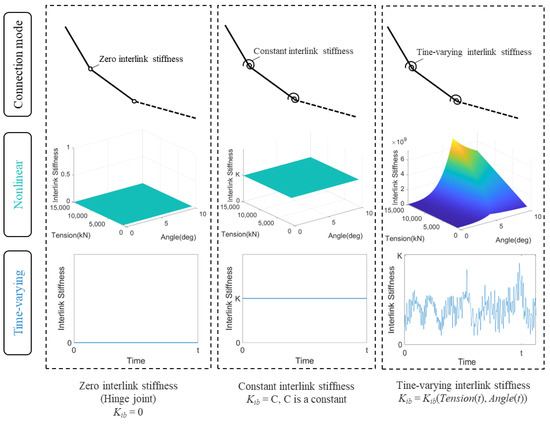

In numerical simulations of mooring lines, for existing commercial software (e.g., DeepC, Sima, etc.), the time-varying property of the bending stiffness between chain links cannot be considered (only zero or constant interlink stiffnesses can be considered). In this way, the bending stiffness between links is not only linear, but also a fixed value (0 or constant), as shown in Figure 9. Further, the change in interlink stiffness with tension and angle in the time domain cannot be reflected, whereas, for the MeCAP-fatigue program, the nonlinearity of the interlink stiffness is not only considered, but its time-varying property is also considered.

Figure 9.

Rod-to-rod connection mode.

3.2. Validation of the MeCAP Code

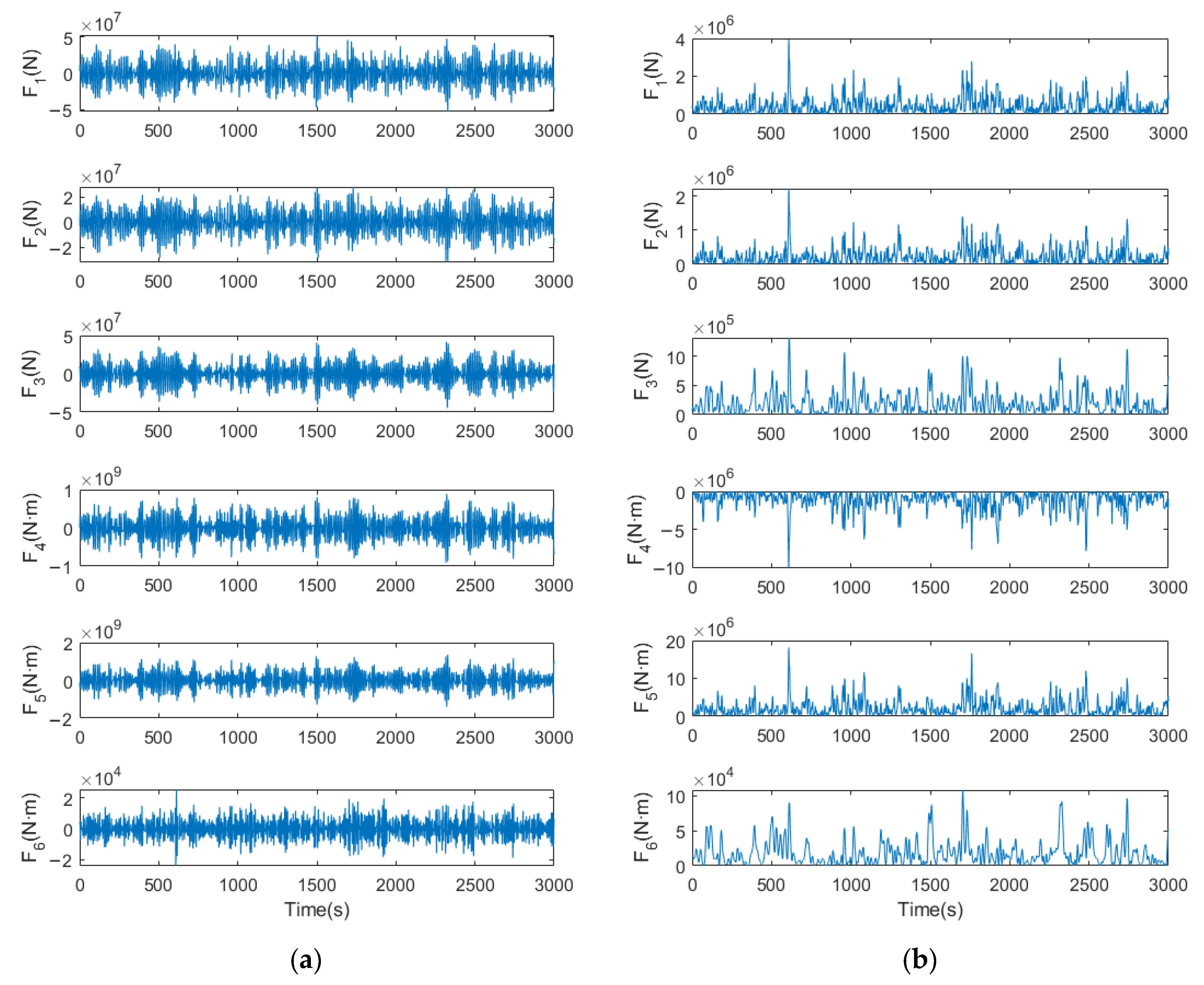

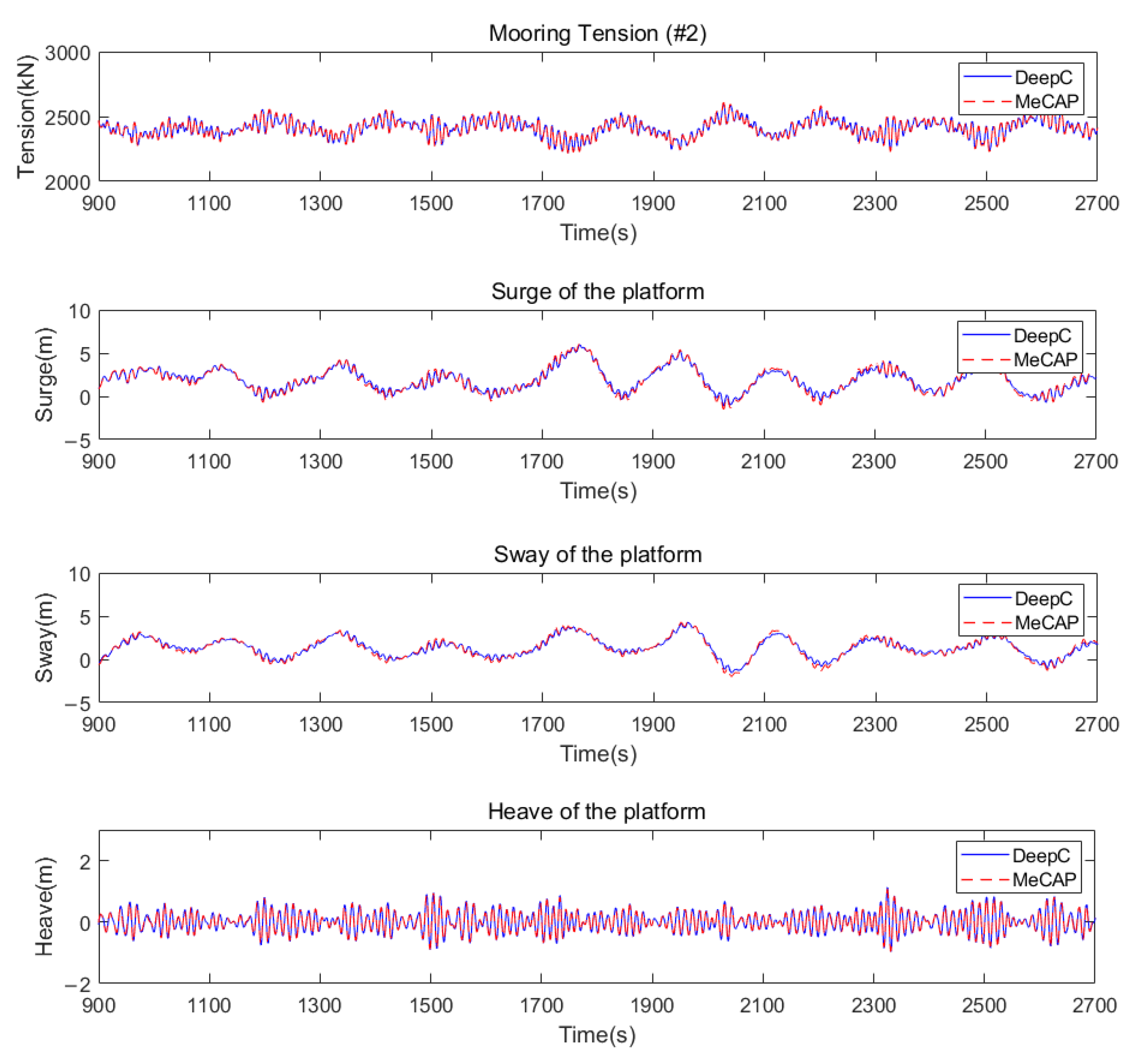

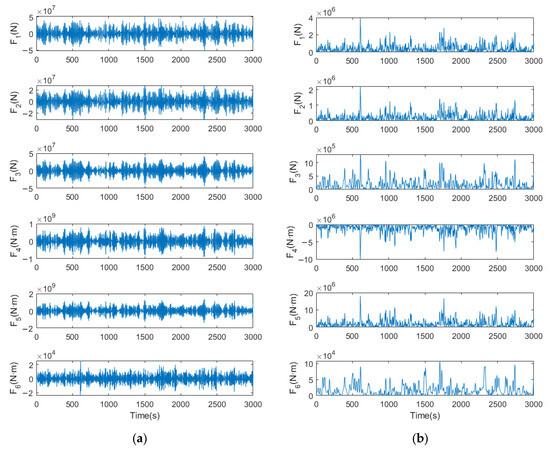

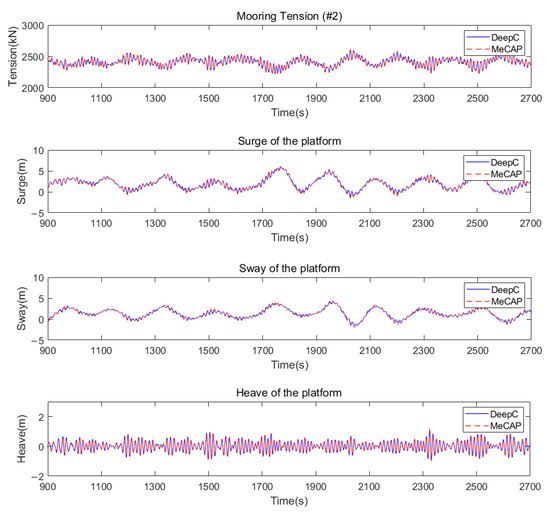

To verify the accuracy of the MeCAP to calculate the mooring tension and platform motion response under a random wave, the JONSWAP wave spectrum is chosen to simulate a random wave (Hs = 6.3 m, Tp = 12.1 s, γ = 2.0) with an incidence direction of 30°. The time history curves of the first- and second-order wave force under a certain random seed are shown in Figure 10. DeepC software and MeCAP are used to compute the mooring tension and the motion response of the platform, respectively, under the same randomly seeded wave action described above. The tension of mooring line #2 and the surge of the platform, sway, and heave are shown in Figure 11. Combined with Table 4, the mean and standard deviation of the results calculated by the MeCAP and DeepC software are within 5%, verifying the accuracy of the MeCAP.

Figure 10.

First-order (a) and second-order wave force (b) time course curve (F1~F6 are the wave forces in the direction of surge, sway, heave, roll, pitch, and yaw).

Figure 11.

Comparison of mooring tension and platform motion response.

Table 4.

Comparison of the statistical values for the mooring tension and platform motion response.

3.3. Real-Time Updating Approach for Interlink Bending Stiffness in MeCAP

In rod theory, the behavior of the slender rod is described in terms of the position of the rod’s centerline. The rod’s centerline in the deformed state is described by a space curve . The governing equations of the rod subjected to self-weight, hydrostatic, and hydrodynamic forces in water can be written as in [26]

and

where

where is the mass per element length, is the bending stiffness, is called the effective weight or the wet weight, is the hydrodynamic force on the rod per element length, is the axial stiffness, is the effective tension, is the buoyancy force.

To solve the equation conveniently, Equations (1) and (2) can be written as

where

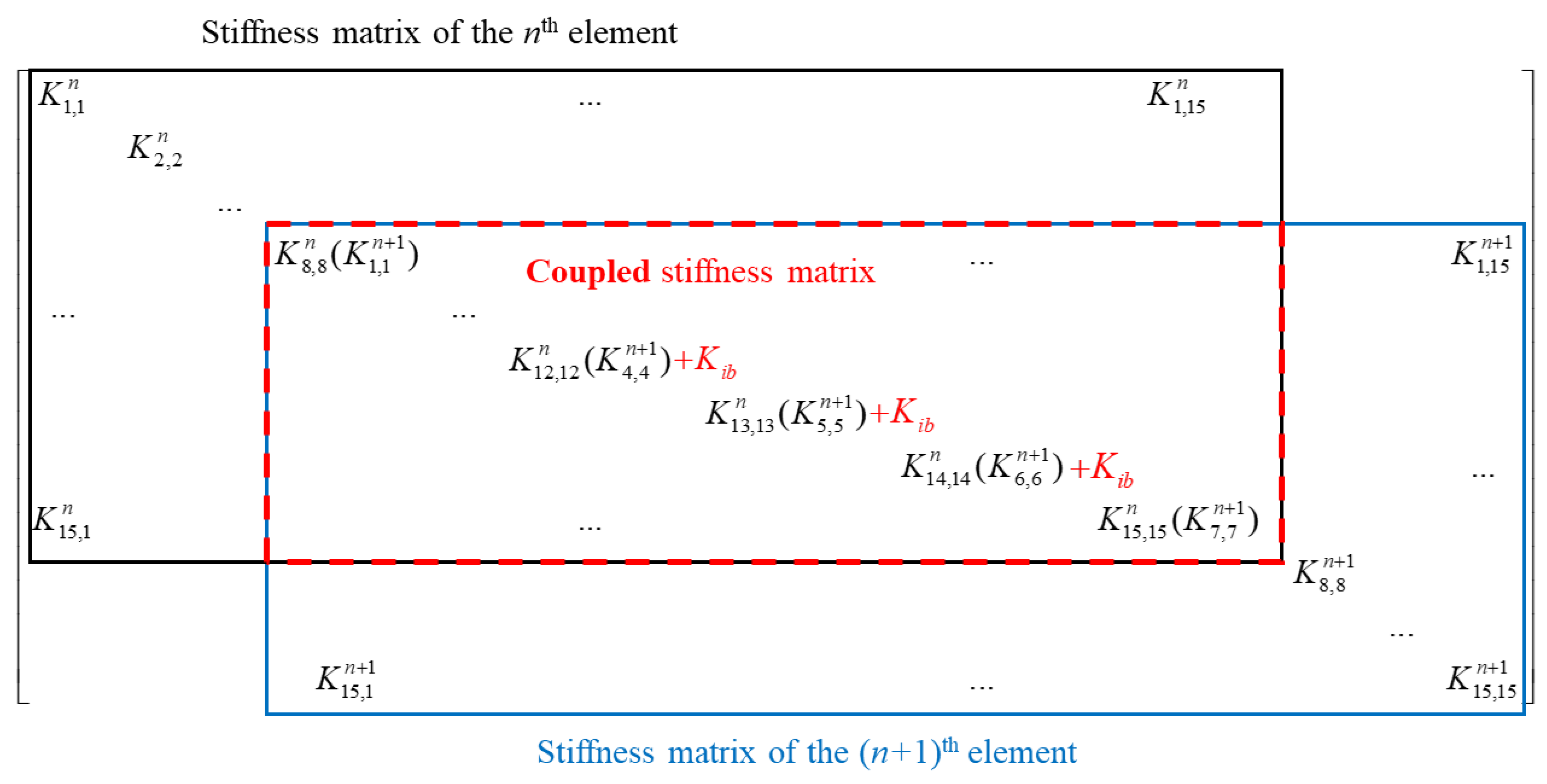

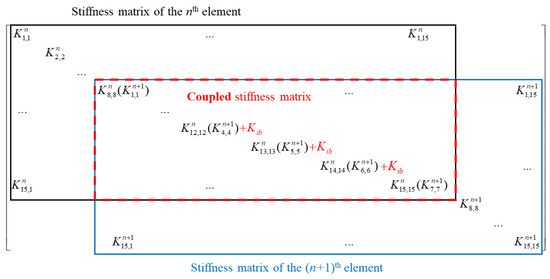

In Equation (5), K is the stiffness matrix. Expanding the stiffness matrices of the nth element and the (n + 1)th element can be expressed as shown in Figure 12, where ~ is the stiffness matrix of the nth element, and ~ is the stiffness matrix of the (n + 1)th element. The end-node stiffness of the nth element (~) and the top-node stiffness of the (n + 1)th cell (~) are the coupled stiffness of the two link elements. In the coupled stiffness matrix of the two link elements, , , are the bending stiffnesses [27]. Calculation of the interlink bending stiffness during the time-domain coupled analysis is implemented by adding the interlink stiffness () to , , of the coupled stiffness matrix between the two elements.

Figure 12.

Calculating the interlink bending stiffness in the theory of the rod.

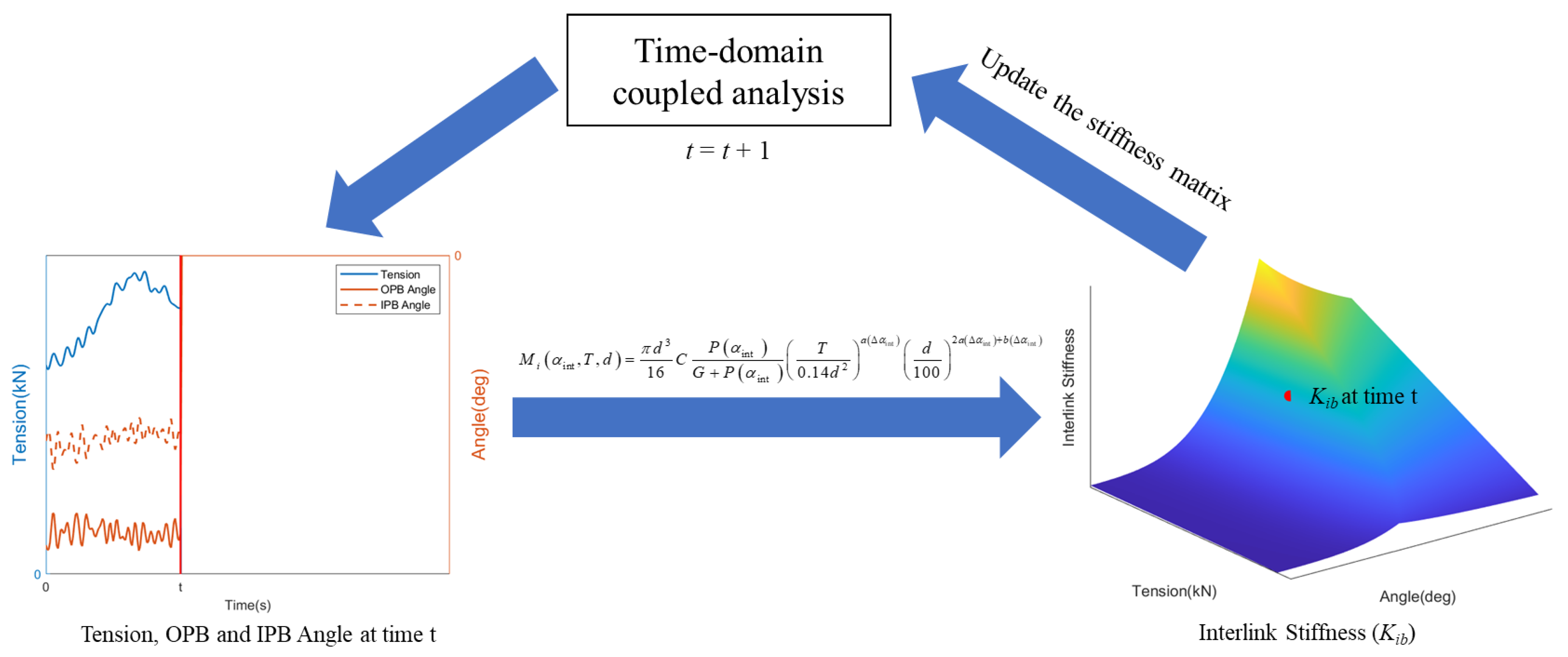

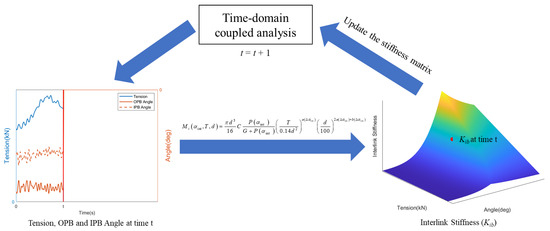

In addition, as the interlink stiffness is related to the mooring tension and the interlink angle, it is a variable that changes with time. In the time-domain coupled analysis, for each analysis step, the interlink stiffness is calculated based on the mooring tension and interlink angle at that moment and added to the global stiffness matrix in real time, shown as in Figure 13.

Figure 13.

Real-time updating of interlink bending stiffnesses.

4. Numerical Implementation

4.1. Main Procedure for OPB Combined Fatigue Assessment

The procedure of OPB combined fatigue assessment shown in Figure 14 is described as follows: (1) The global coupled analysis model is established, and the local mesh of mooring chain elements is refined to be size of the length of each chain; (2) The coupled analysis is performed with the real-time update of the interlink stiffnesses, and the time series of mooring tension and OPB/IPB angles are extracted; (3) The FEA model of the mooring chain is built, and the tension and interlink moment between each chain link of the top 20 chain links is calculated; (4) The combined stresses at Hotspots A, B, and C are calculated by the obtained tensions and interlink angles with SCFs assigned; (5) The rain-flow counting method is used to obtain the number of cycles for different combined stress amplitude ranges, then the short-term fatigue damage is calculated according to the S-N curves; (6) Miner’s rule is used to calculate the cumulative fatigue damage of a single sea state and the total fatigue damage per the probabilities of scatter bins is calculated. In the above process, the time-domain coupled analysis of the platform and mooring system under different sea states is performed by MeCAP, the bending moments between the chain links are calculated by the finite-element software ABAQUS, and finally the fatigue of the mooring chain is evaluated based on the MeCAP-fatigue module.

Figure 14.

Calculation procedure of OPB combined fatigue.

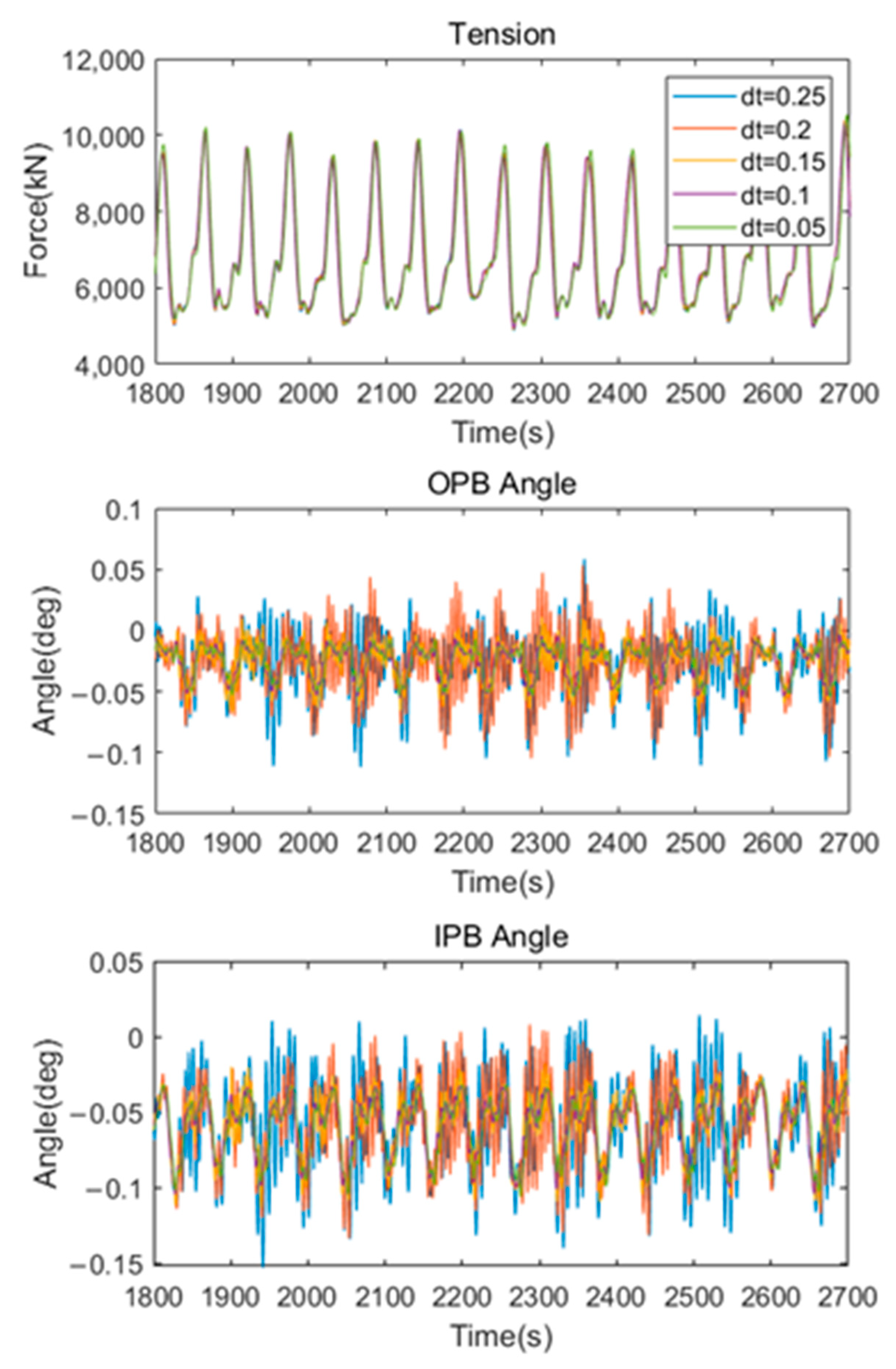

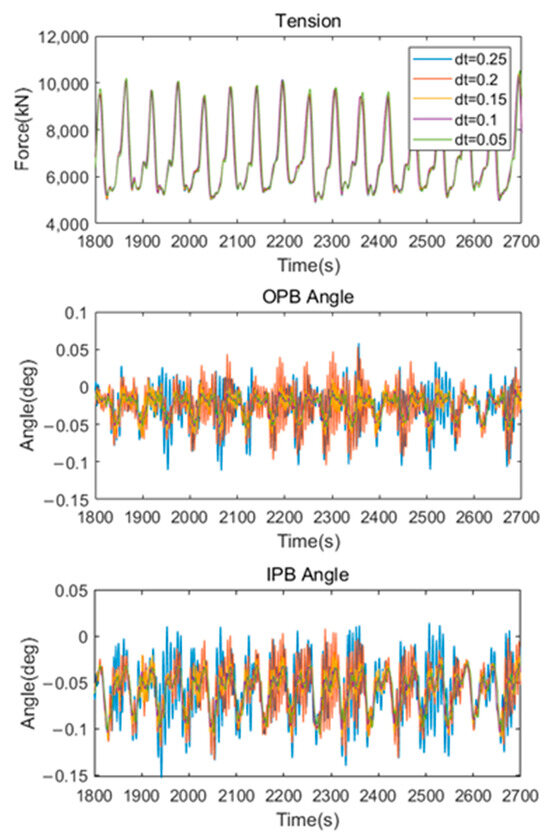

4.2. Time-Step Selection Principle

The mooring tensions and OPB/IPB angles by using various time steps (dt = 0.25 s, 0.2 s, 0.15 s, 0.1 s, and 0.05 s) are compared, as shown in Figure 15. The mean value and standard deviation of tensions are listed in Table 5. The results indicate that a time step of 0.2 s yields accurate mooring tensions. However, the OPB and IPB angles fluctuate when the time step is greater than 0.1 s, as shown in Figure 15, while the results at dt = 0.1 s and dt = 0.05 s agree well, and the difference between the mean and standard deviation is within 2% as shown in Table 5. Therefore, to consider both the computational accuracy and efficiency, a time step of 0.1 s is appropriate for calculating the OPB and IPB angles. Interlink angles are more sensitive to the time step than mooring tensions.

Figure 15.

Comparisons of mooring tensions and OPB/IPB angles.

Table 5.

Error comparisons by using various time steps (compared to dt = 0.05 s).

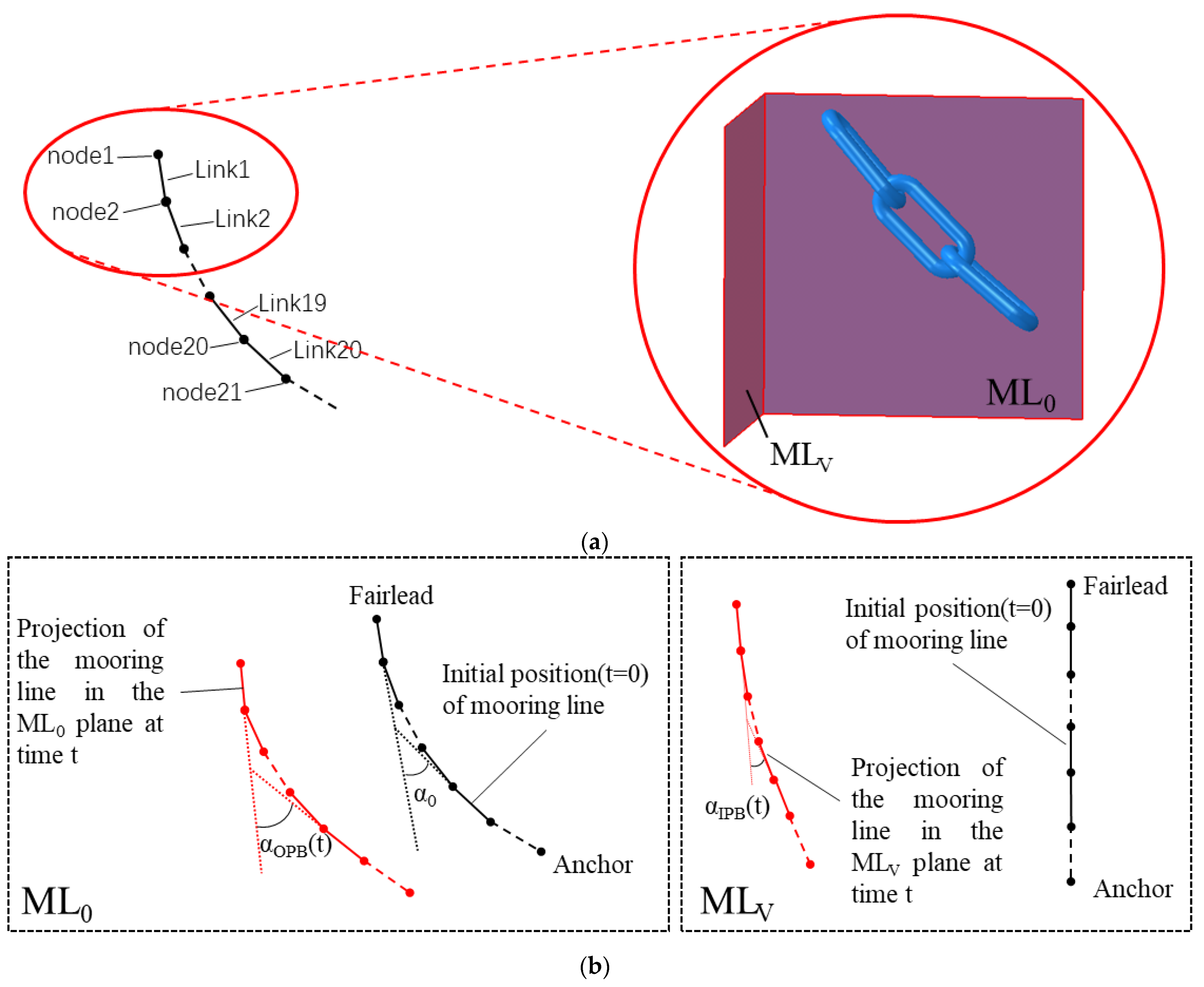

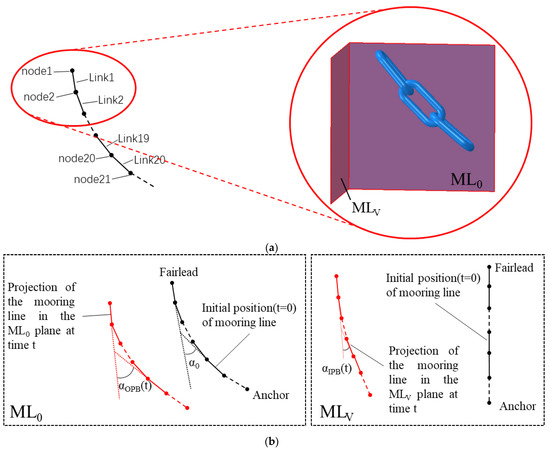

4.3. Extraction and Computation of Interlink Angles

The angle relationship of the local (top 20) links in the mooring chain are shown in Figure 16. The node coordinates of Link-1 and Link-20 are extracted from the results of the time-domain coupled analysis, and the time series of the OPB/IPB angles of the top 20 links, and , are calculated. The plumb plane is established based on the fairlead and anchor when the mooring line is located at the initial position (t = 0), denoted as plane ML0, and the plumb plane perpendicular to ML0 is established, denoted as MLv. For a certain time step, the difference between the angle of the top 20 links projected in the ML0 plane and the angle of the first 20 links at the initial position of the mooring line is denoted as the OPB angle (). And the angle of the top 20 links projected in the MLv plane is denoted as the IPB angle ().

Figure 16.

Schematic diagram for the definition of in-plane and out-of-plane angles: (a) Definition of the ML0 and MLv planes; (b) Definition of in-plane and out-of-plane angles.

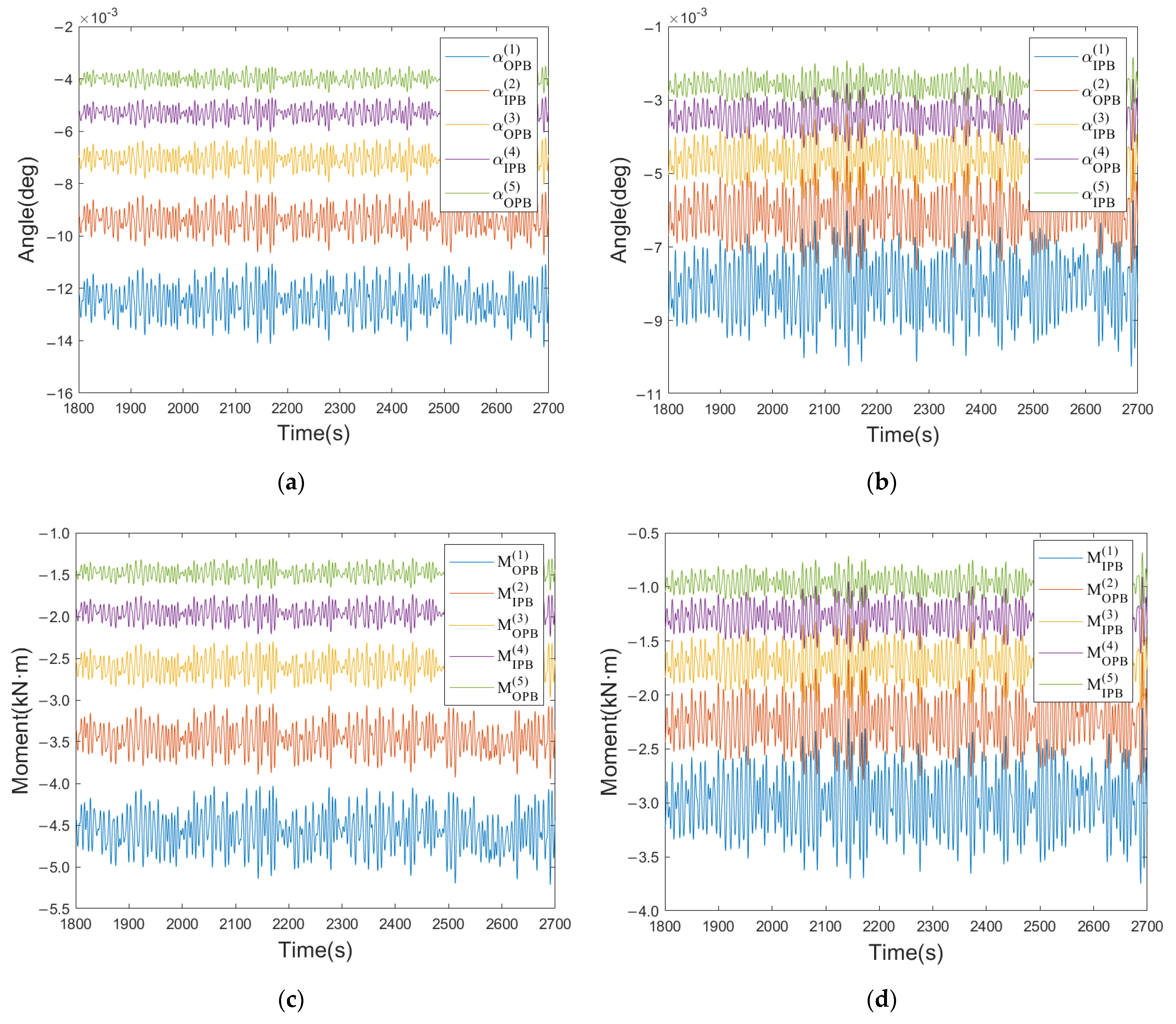

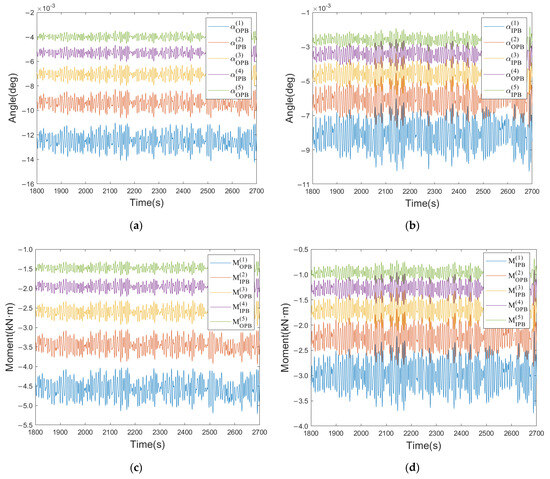

Subsequently, a local FEA model of the top 20 chain links is established, and the friction coefficients and time-varying nonlinear interlink stiffness properties are added. The time series of the tension, OPB, and IPB angle obtained by the global coupled analysis are applied to the FE model. Finally, the time series of the OPB and IPB moments between different chain links are extracted and calculated according to the results of finite-element analysis. The time series of the OPB/IPB angles and moments between the top 5 chain links of mooring line #2 in Sea State 12 are shown in Figure 17. The results indicate that the interlink angle and moment decrease gradually from Link-1 to Link-5, and the interlink angle and moment between the top two chain links are the largest. Therefore, this study focused on the OPB combined fatigue at the top two chain links.

Figure 17.

OPB/IPB angles and moments of Sea State 12: (a) Angles between links in the ML0 plane; (b) Angles between links in the MLv plane; (c) Moments between links in the ML0 plane; (d) Moments between links in the MLv plane.

4.4. Combined Stress and Fatigue Damage

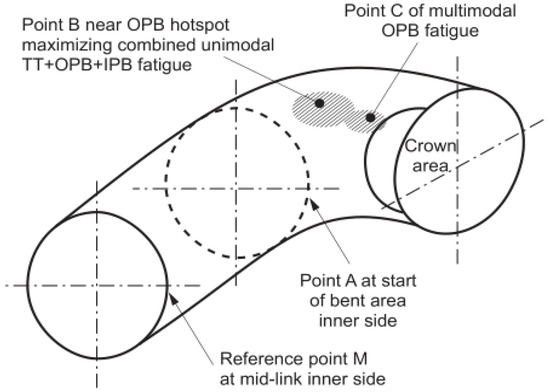

4.4.1. Stress Concentration Factors (SCFs)

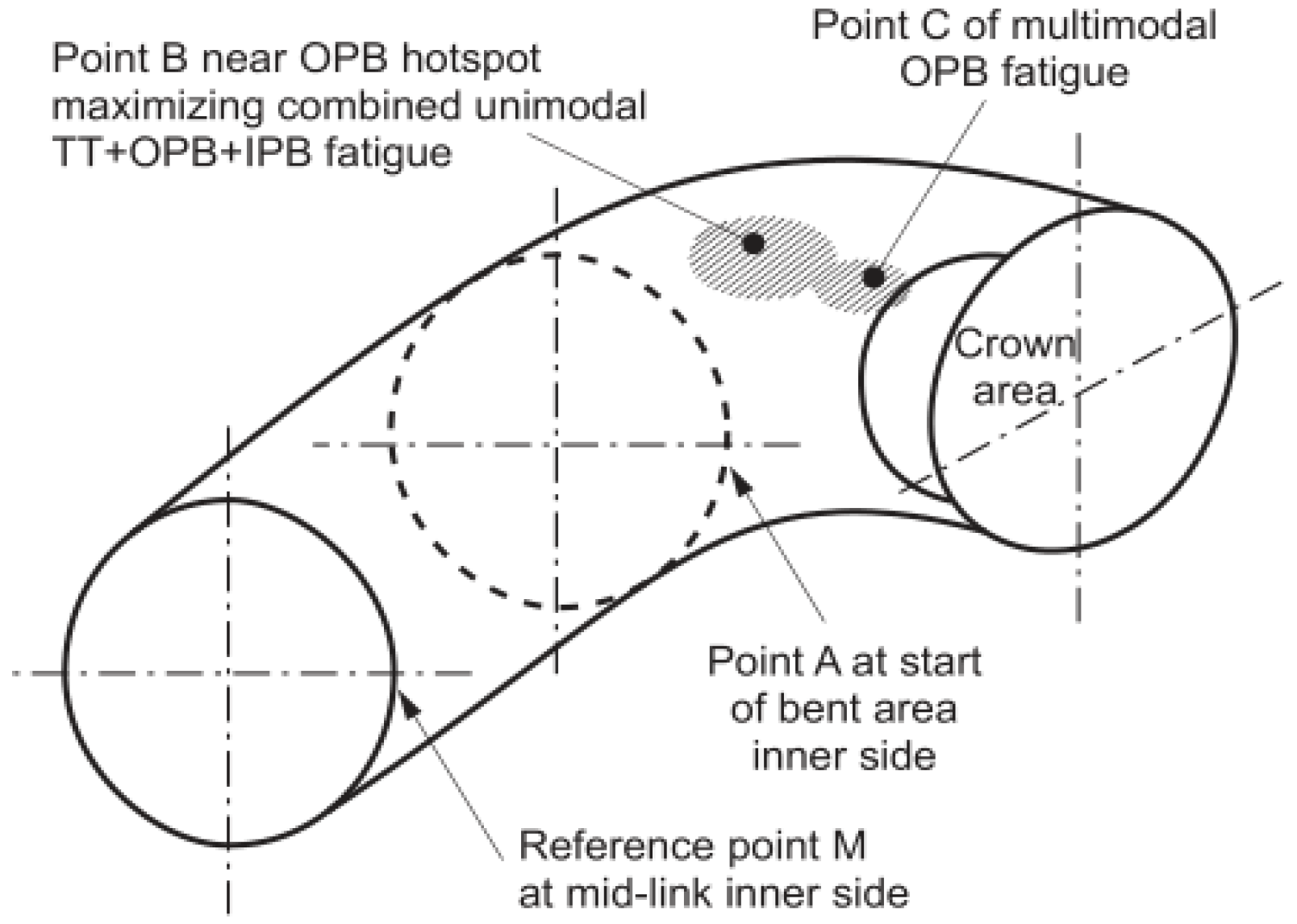

The following hotspot stresses are generally identified as the most critical in combined loading: (a) Pure tension-tension (TT), denoted as Hotspot A; (b) Uniaxial OPB hotspot maximizing TT, OPB, and IPB effects, denoted as Hotspot B; (c) Multi-axial OPB hotspot with multiaxiality effects, called Hotspot C [22], as shown in Figure 18. And the SCFs at Hotspots A, B, and C for the studless chain are listed in Table 6. And a mean SCF is introduced on the multi-axial OPB SCF as follows:

where P and MBL are the pretension and minimum breaking load of the mooring chain, respectively.

Figure 18.

Critical hotspot on chain link for OPB combined fatigue [22].

Table 6.

SCFs at three hotspots.

4.4.2. Combined Stress

Based on the FEA results, , , , and the combined stresses () are calculated by the following equations [22],

and

where d is the un-corroded nominal diameter of the chain, is a factor with a value of 2.33 (for studless chain) or 2.06 (for studlink chain), is the corrosion coefficient, taken as 1.08, and is the factor of the variability in chain stiffness, taken as 1.06, for free corrosion in seawater.

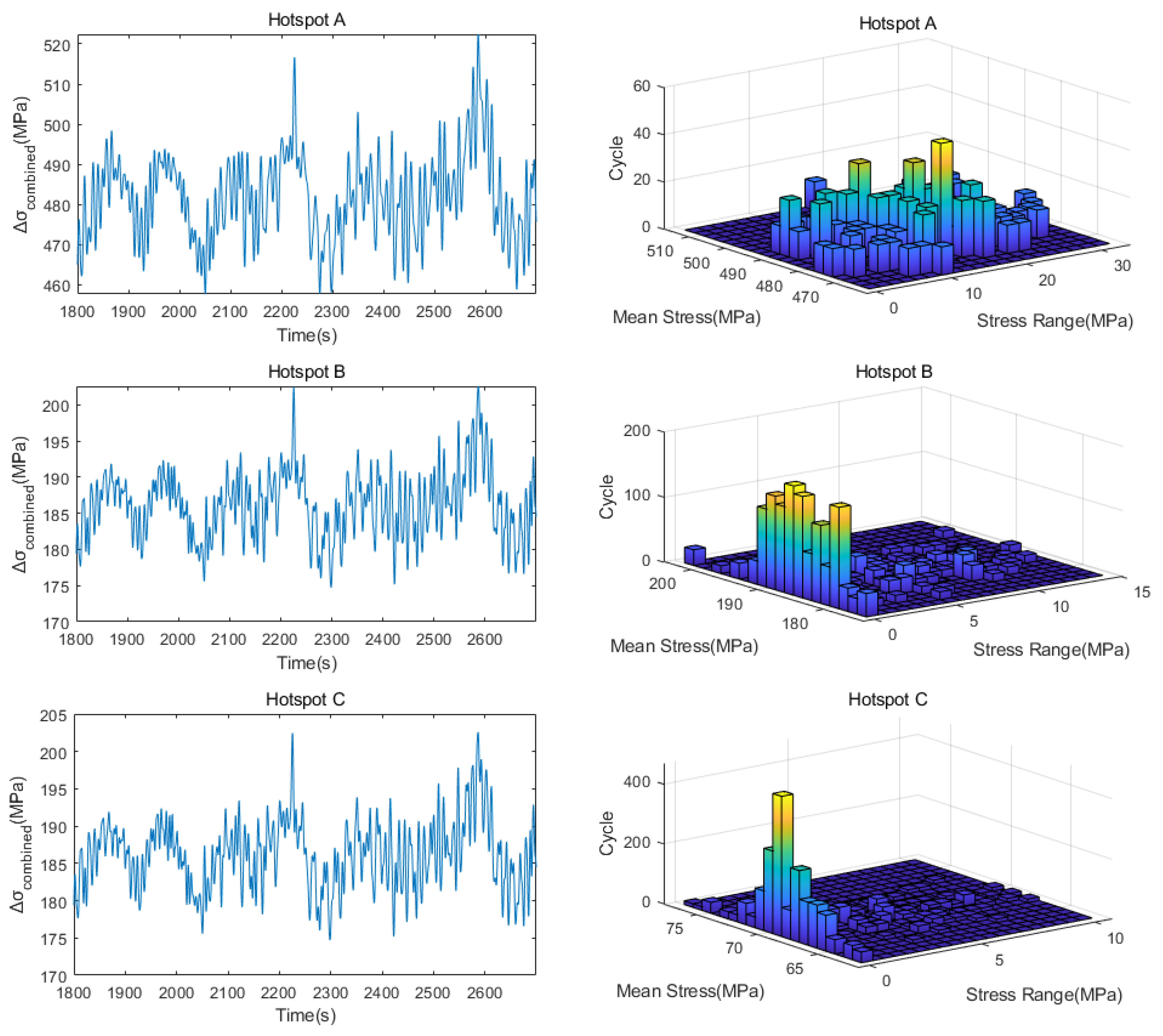

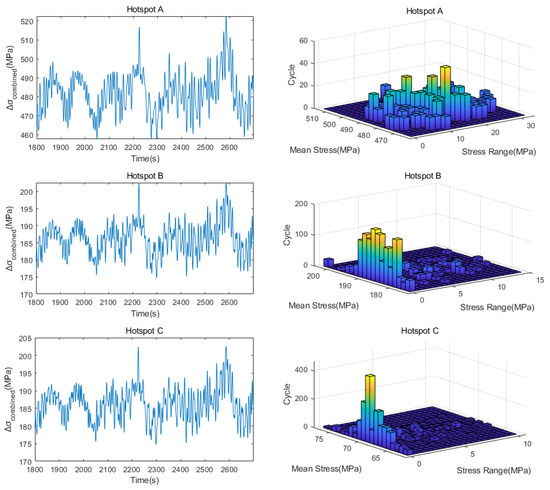

The range and cycle of the combined stress are extracted by the rain-flow counting method. The time history and cycle distribution with the stress amplitude range of the combined stress in Case 12 (Hs = 5.5 m, NE) are shown in Figure 19. The combined stress at Hotspot A is more than twice that at Hotspots B and C. Moreover, the combined stress at Hotspot A varies in the range of 5–20 MPa, while those of Hotspots B and C are mainly distributed in the range of 0–1 MPa. The fatigue of mooring chain #2 is dominated by Hotspot A in Case 12.

Figure 19.

Combined stress and stress range distribution in Case 12.

4.4.3. S-N Curve for Combined Fatigue

The short-term fatigue of a single sea state is calculated by the S-N curve [22], expressed as Equation (12). The parameters K and m are listed in Table 7. The total fatigue is calculated per Miner’s rule and probabilities in scatter bins.

Table 7.

Parameters of the SN curve.

5. Results and Discussion

5.1. Effect of Interlink Stiffness on the Fatigue

5.1.1. Comparison of Zero and Time-Varying Interlink Stiffness

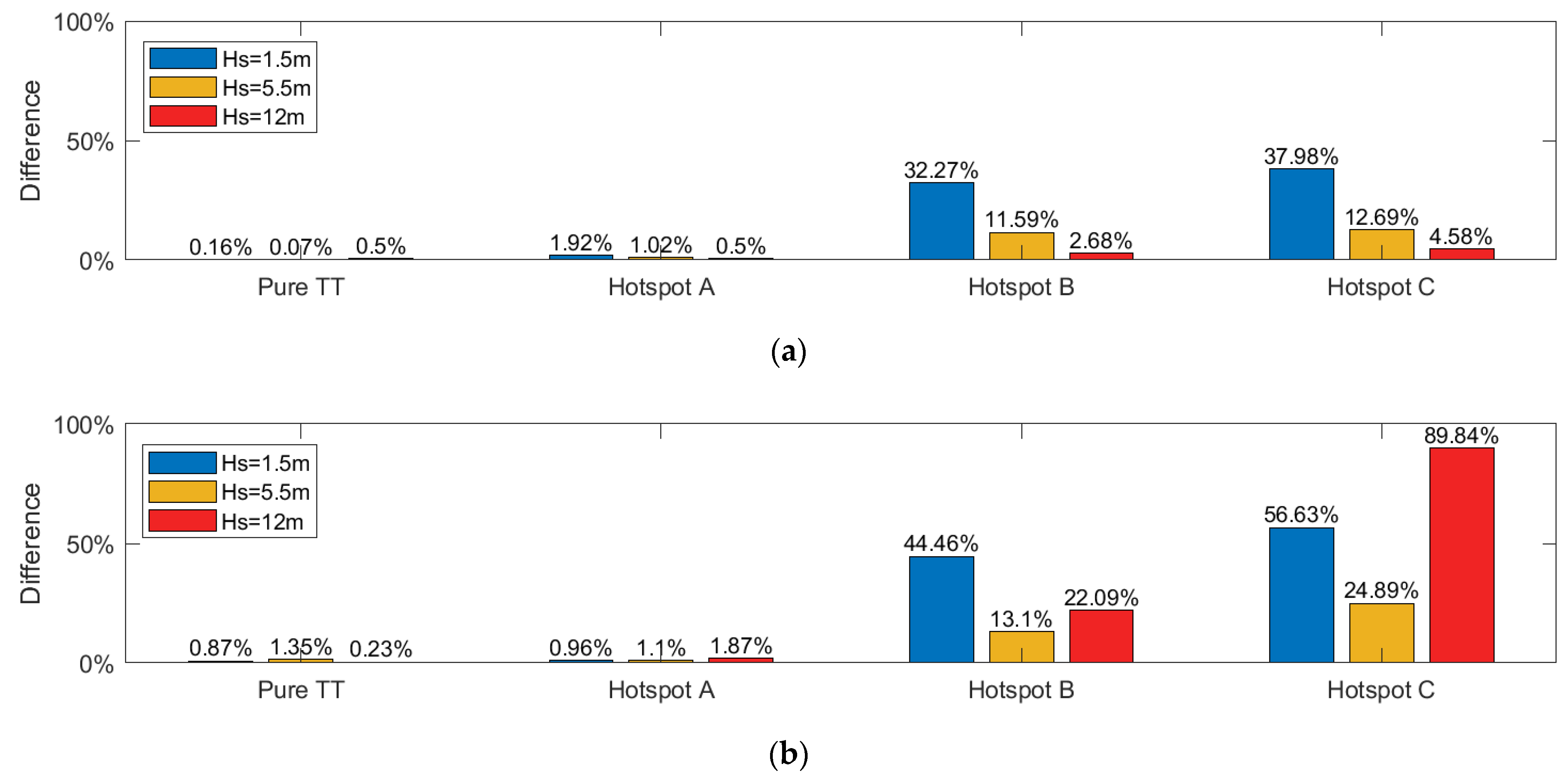

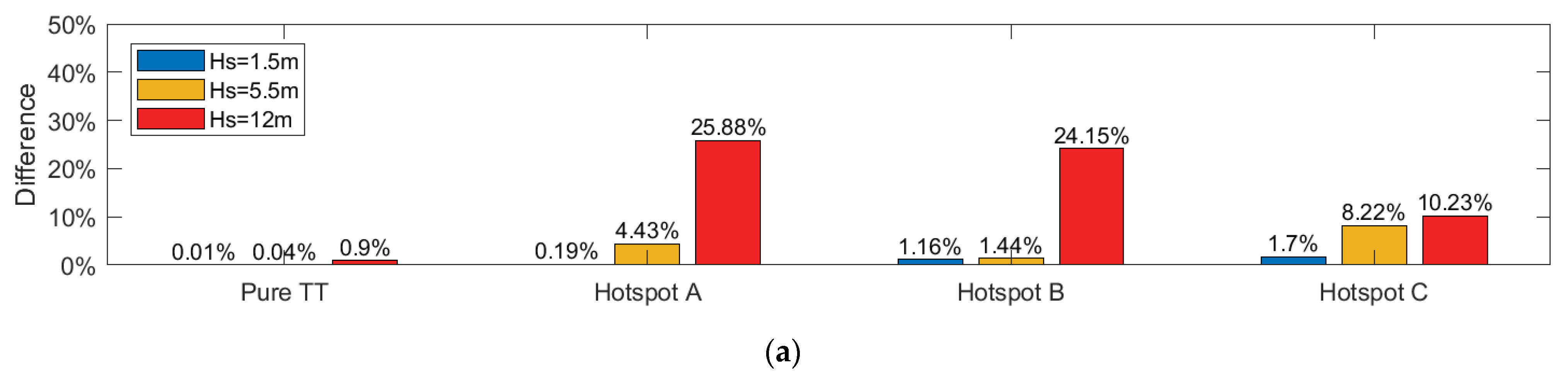

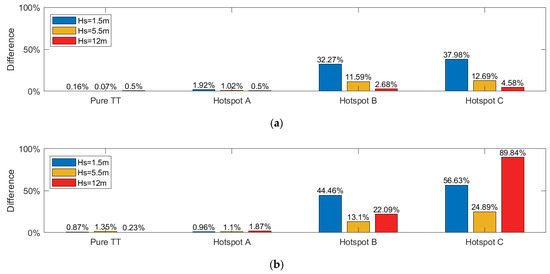

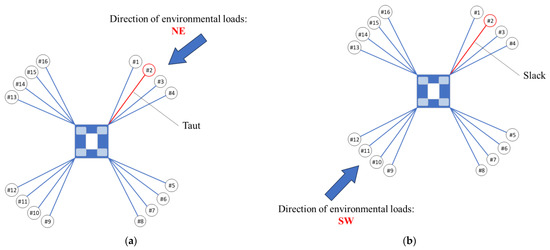

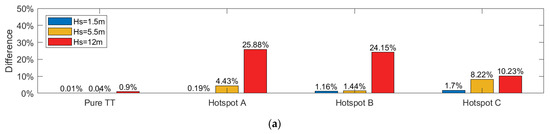

The effect of time-varying nonlinear interlink stiffness is investigated by comparison with the conditions: (1) zero interlink stiffness––the connection between links is hinged, and the links can rotate freely between each other; (2) time-varying interlink stiffness––the bending stiffness between the links is time dependent, as it is affected by the tension and angle between the links. The difference in fatigue damage is compared in Figure 20, with the “taut” and “slack” cases (Figure 21), the detailed data of which are listed in Table A2. Compared with the time-varying nonlinear interlink stiffness, the difference between TT and OPB combined fatigue at Hotspot A is insignificant (within 2%) when the interlink stiffness between chain links is zero. However, the fatigue at Hotspots B and C is sensitive to the interlink bending stiffness. As the time-varying interlink stiffness is considered, fatigue at Hotspot C has a more significant deviation than that at Hotspot B, indicating that Hotspot C is more sensitive to interlink stiffness. As listed in Table 6, the SCF of the OPB at Hotspot C is the largest, Hotspot B is the second largest, and Hotspot A is the smallest, consistent with the above conclusion. Therefore, if only the fatigue due to pure tension is considered, that is, the T-T fatigue or Hotspot A of combined fatigue, the interlink stiffness has little effect. In contrast, it has a greater impact on the multi-axis OPB combined fatigue (Hotspot C).

Figure 20.

Difference in the zero and time-varying interlink stiffness with the “taut” (a) and “slack” (b) cases.

Figure 21.

“Taut” (a) and “slack” (b) cases of mooring lines.

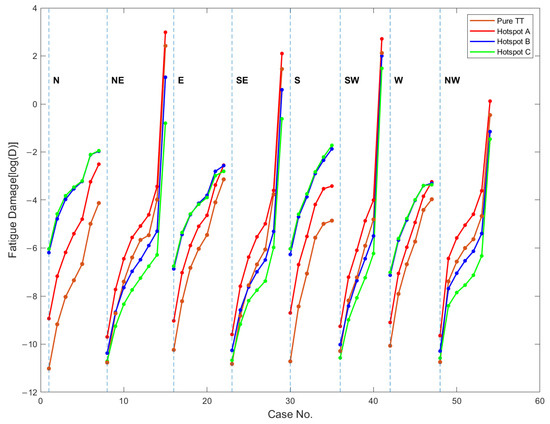

5.1.2. Constant Interlink Stiffness and Time-Varying Interlink Stiffness

The constant interlink stiffness is calculated based on the mean tension (or pretension) and mean OPB/IPB angles. The difference in the mooring chain considering a constant and time-varying interlink stiffness is shown in Figure 22, and the detailed data are listed in Table A3. TT fatigue is almost insensitive to interlink stiffness. The differences in the combined fatigue under constant and time-varying interlink stiffnesses are generally sensitive to wave conditions, as the interlink angle changes more with increasing wave height. By comparing Cases 8, 12, and 15 and Cases 36, 39, and 41, which represent “taut” and “slack” conditions with the significant wave height of 1.5, 5.5, and 12 m, respectively, the “taut” cases are more sensitive to constant or time-varying interlink stiffness than the “slack” cases, as the tension and IPB/OPB angles involved in the interlink stiffness differ more. For the sea states with a wide range of tension and angle amplitudes (e.g., Hs = 12 m), the interlink stiffness, which is taken as the mean value only, the variation in interlink stiffness over the entire period cannot be wholly reflected, leading to a significant error in fatigue. Therefore, the time-varying interlink stiffness must be considered instead of the constant interlink stiffness in the OPB combined fatigue calculation.

Figure 22.

Difference in constant and time-varying interlink stiffness with the “taut” (a) and “slack” (b) cases.

5.2. Discussion on Pure TT Fatigue and Combined Fatigue Damage

The fatigue life of mooring line #2 for pure TT fatigue and OPB combined fatigue with different hotspots are listed in Table 8, where a safety factor of 10 [22,28] is applied. The full fatigue damage data for detailed conditions are listed in Table A4. The results show that the fatigue life of Hotspot A is more than twice as long as that of Hotspots B and C, and Hotspot C has the smallest fatigue life. And the fatigue life of pure TT is even close to three times that of Hotspot A. It indicates that, for mooring line #2, since the fatigue life under OPB and IPB is smaller than that due to pure tension, the multiaxial OPB fatigue damage is critical to the fatigue life.

Table 8.

The fatigue damage and life of mooring line #2.

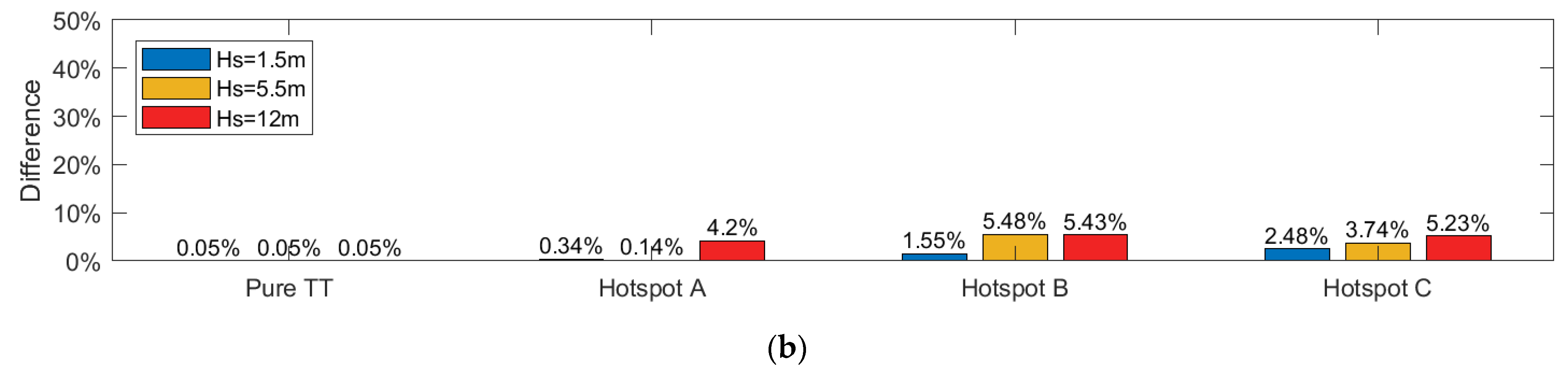

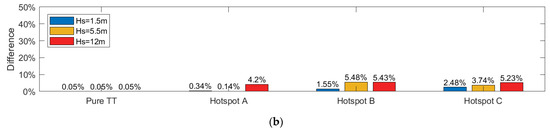

The pure TT fatigue damage and the combined fatigue damage considering the TT, OPB, and IPB at different hotspot locations are shown in Figure 23. In the figure, to better find the changes in fatigue, the ordinate in the figure is the natural logarithm of the fatigue damage. The combined fatigue damage of the mooring chain at Hotspot A is larger than the pure TT fatigue damage, which is because the combined fatigue damage of Hotspot A not only includes the axial stresses caused by the mooring tension, but also considers that caused by the IPB between chain links. On the other hand, the fatigue damage shows different patterns for different directions of environmental loads.

Figure 23.

Fatigue damage of pure TT and different hotspot for mooring #2.

The fatigue damage for different sea states show a consistent pattern when the chain is parallel (NE, SW) or perpendicular (SE, NW) to the wave direction. The fatigue damage in Hotspot A is the largest, followed by pure TT fatigue damage, then fatigue damage in Hotspot B, and the smallest damage in Hotspot C. As a result, chains in parallel and perpendicular wave directions are more susceptible to tension-induced fatigue damage. When the significant wave height is less than 8.5 m, the fatigue damage of pure TT and Hotspot A is “up-convex”, the fatigue damage at Hotspot B is almost a “straight line”, and the fatigue damage at Hotspot C is “down-convex”. This indicates that when the significant wave height is less than a certain value, the fatigue damage of Hotspot A and pure TT is more sensitive to the wave height. In contrast, the fatigue damage of Hotspot C is more sensitive when the wave height is large, and the fatigue damage of Hotspot B rises exponentially with the increase in the wave height. When the significant wave height is more than 8.5 m, the pure TT fatigue and OPB combined fatigue damage increase quickly, and the fatigue performance of the mooring chains decreases dramatically under the severe sea state.

When the angle between the mooring chain and the wave direction is 45°, the fatigue damage at Hotspot C, dominated by OPB, is the largest. Moreover, the damages at Hotspot B and Hotspot C are almost identical. In contrast, the fatigue damages at Hotspot A and pure TT, which are tension-dominated, are relatively small. The fatigue damage in the oblique wave direction is more sensitive to OPB stresses. It shows a “straight line” shape when the wave height is small and an “up-convex” shape when the wave height is large. Compared to the fatigue damage in parallel and perpendicular to the wave direction, the fatigue damage in the oblique wave directions increases without a sudden change in severe sea conditions.

The fatigue assessment method based on the T-N curve is a conservative approach to assessing the pure TT fatigue damage of the mooring chain based on the mooring tension. The combined fatigue damage assessment method developed in this paper is based on the mooring chain stress for calculating fatigue and considers the effect of in-plane and out-of-plane bending, with a more comprehensive consideration of factors. At the same time, the fatigue damage at different hotspots of the mooring chain is evaluated, which can predict, to a certain extent, the most likely location of the fatigue failure of the chain links. In this way, critical fatigue locations are focused on, and losses due to mooring chain fatigue failure are avoided in advance.

5.3. Influence of Wind and Current on the Fatigue

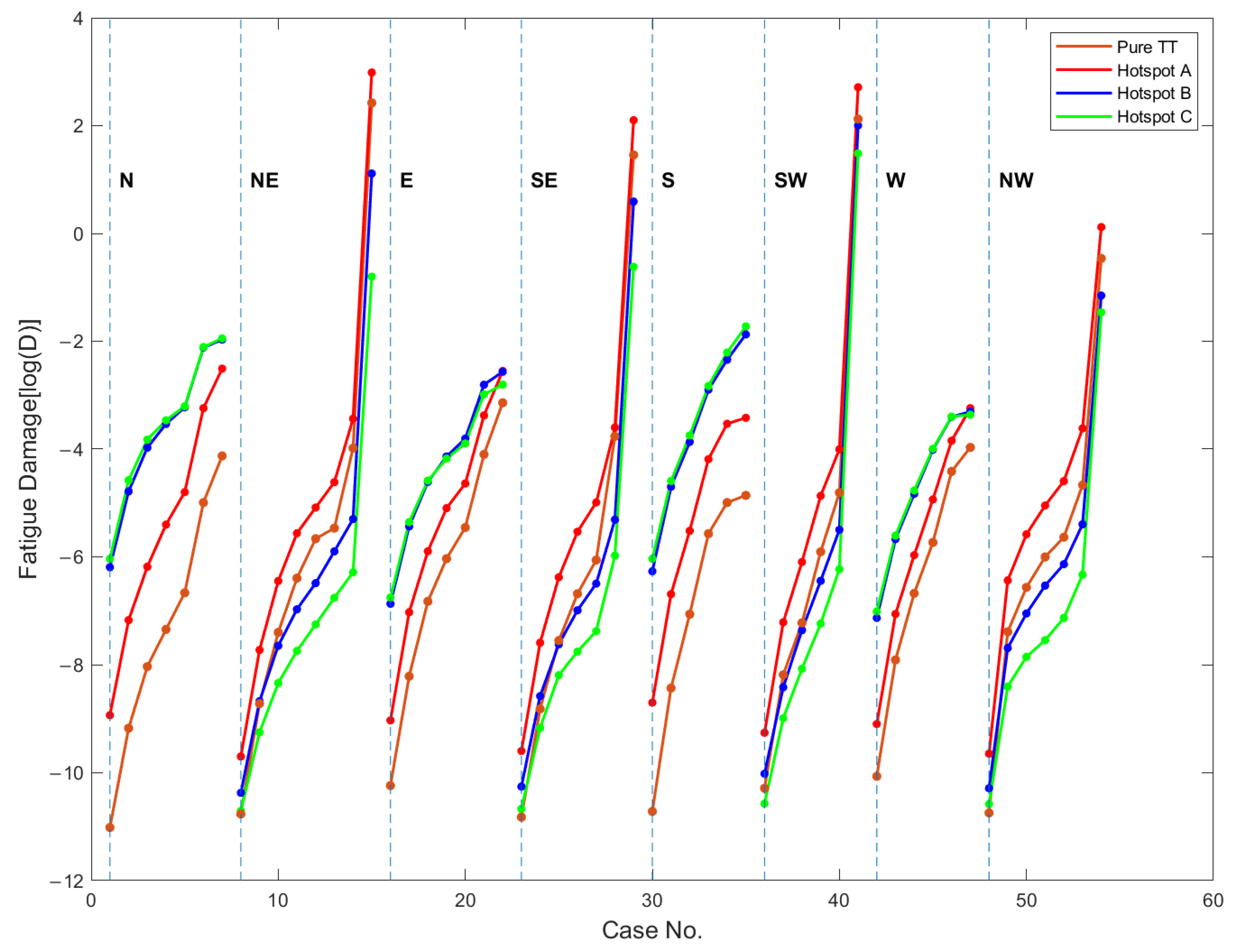

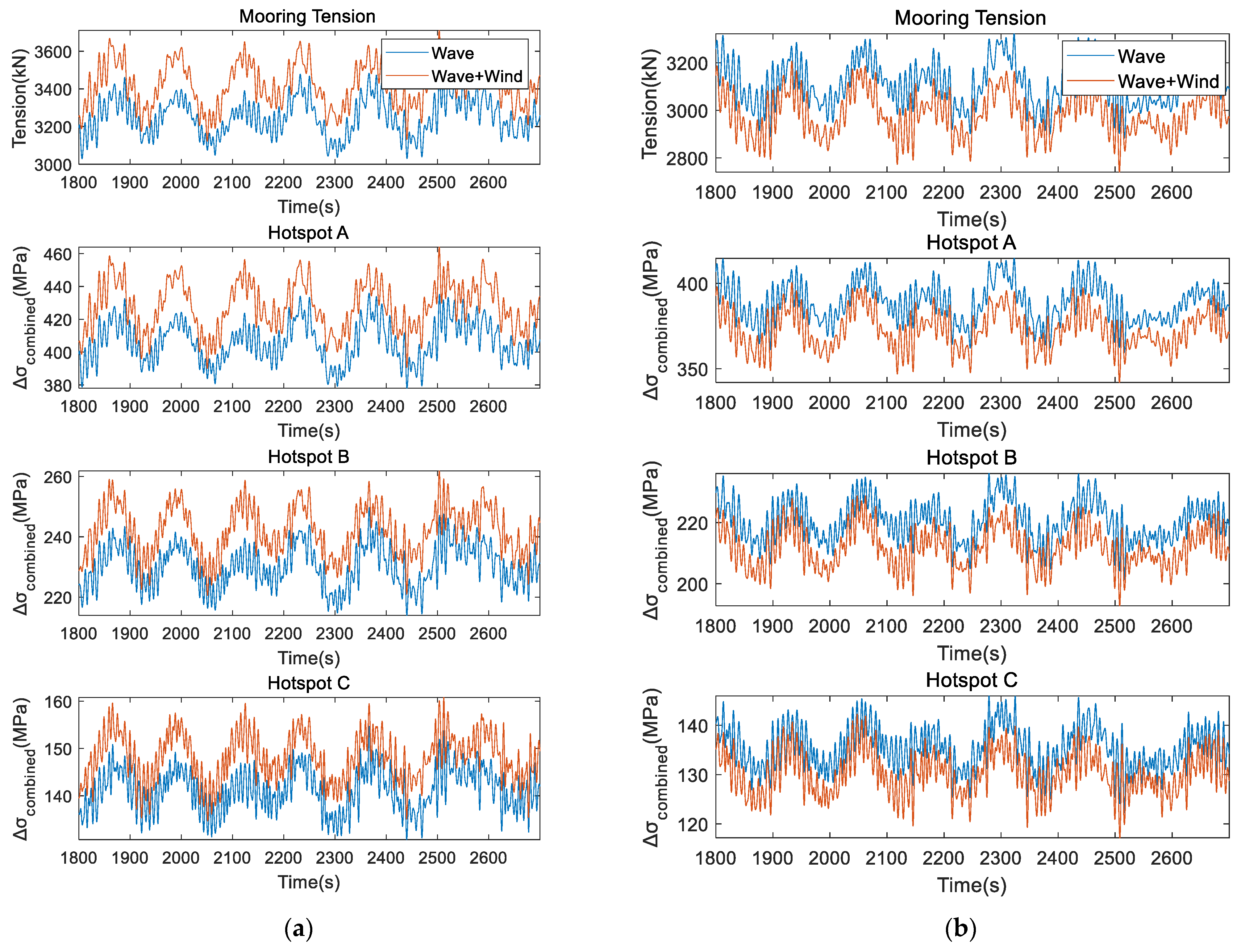

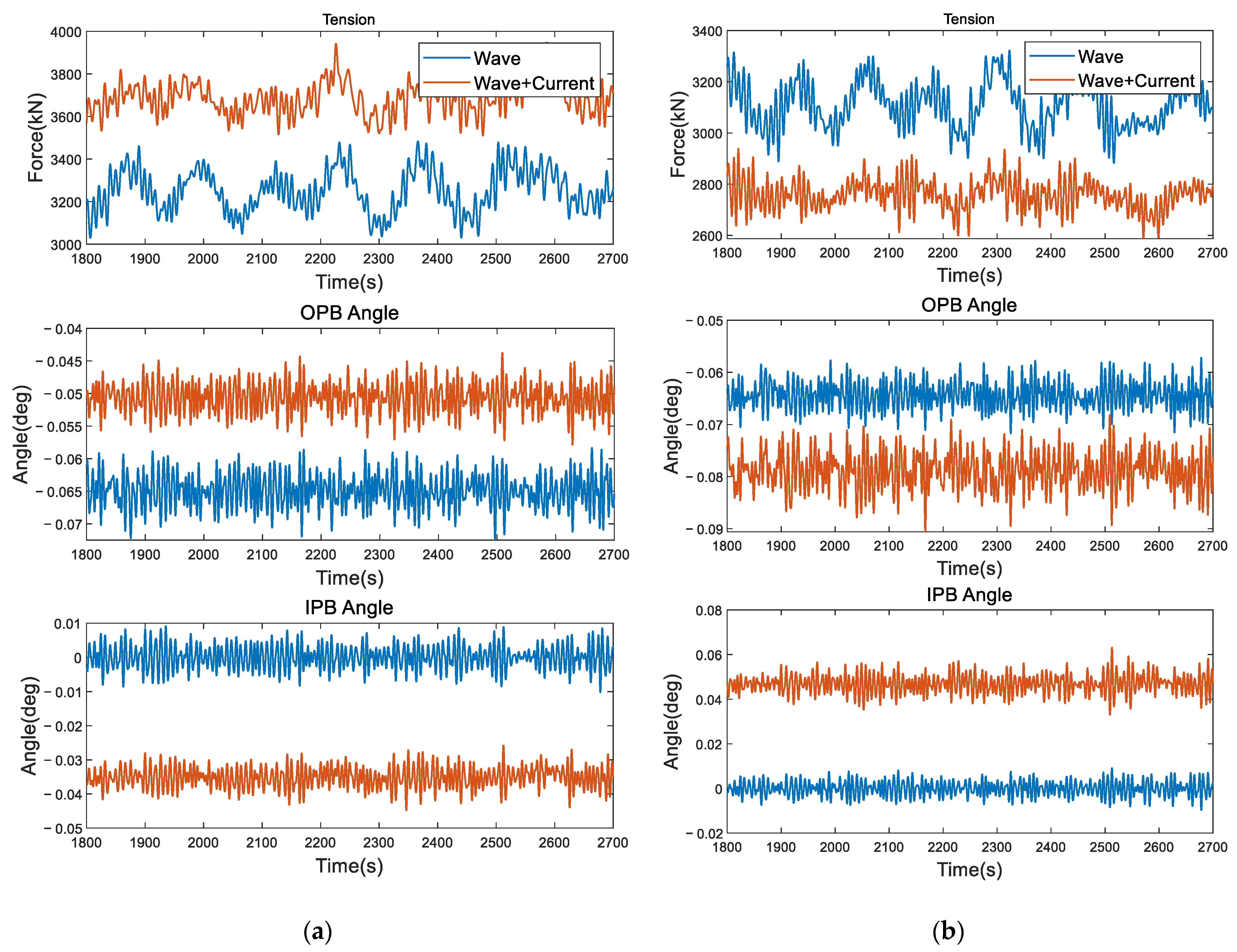

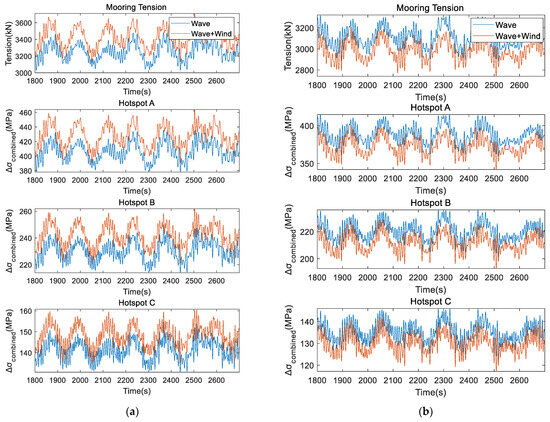

The fatigue damages of pure TT fatigue and combined fatigue at Hotspots A, B, and C are listed in Table 9. And the time histories of tension and combined stresses in mooring line #2 are compared, as shown in Figure 24. For TT fatigue in Case 12 (the “taut” condition), the wind load further caused a significant amplitude drift of the platform, thus increasing the mooring tension. If only waves are considered, the fatigue will be underestimated by 29.17% compared with the result under the action of waves and wind. The fatigue damage difference of pure TT, Hotspot A, Hotspot B, and Hotspot C decreases sequentially, which is consistent with the changes in their standard deviations and amplitudes, as listed in Table 10. In Case 39 (the “slack” case), if the wind is ignored, the fatigue will be underestimated by 9.61% compared to that considering wave and wind. For the combined fatigue at Hotspots A, B, and C, it will also be underestimated if the effect of wind is ignored. Among these, the fatigue at Hotspot A is the most significantly underestimated, and that at Hotspot C is less affected. Since the difference in standard deviation (listed in Table 11) is small (within 2%), the gap in amplitude has a significant impact on fatigue damage. Therefore, TT fatigue is more sensitive to wind, particularly in the “taut” case. For the three hotspots, the fatigue at Hotspot A is more sensitive to the wind. In general, under the pulsation action of wind, the fatigue life of the mooring chain will be reduced.

Table 9.

Fatigue damage under the wave alone and under the joint action of wave.

Figure 24.

Tension and combined stresses of mooring line #2 for Case 12 (a) and Case 39 (b).

Table 10.

Statistics of tension and combined stresses for Case 12.

Table 11.

Statistics of tension and combined stresses for Case 39.

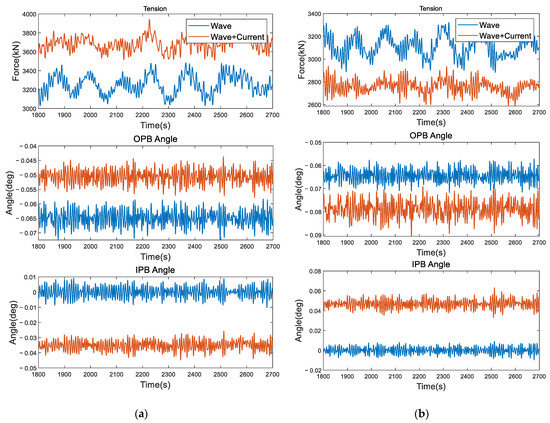

On the other hand, the comparison of pure TT and combined fatigue regarding the influence of the current is also carried out, as listed in Table 12. For TT fatigue, the fatigue damage is reduced by the influence of current, both in the “taut” case (Case 12) and in the “slack” case (Case 39). Combining the time history of tension (Figure 25) and the statistical values of the tension and IPB/OPB angles (Table 13), the mooring tension increases in the “taut” case and decreases in the “slack” case when the current is considered. However, the standard deviation of tension decreases in both the “taut” and “slack” cases, which is the main reason for the decrease in fatigue. If the current is neglected in the time-domain coupled analysis, the fatigue life will be more conservative, a common industrial practice.

Table 12.

Fatigue of the mooring chain subjected to wave only and wave and current.

Figure 25.

Tension and OPB/IPB angles of mooring line #2 for Case 12 (a) and 39 (b).

Table 13.

Statistical values of tension and angles.

Regarding the combined fatigue, the influence of the current on the fatigue at Hotspots A and B for the “taut” case is small, and the deviation is within 5%. As for the “slack” case, the fatigue is overestimated by 7.8% at Hotspot B and nearly 20% at Hotspot A, in the effect of current. This indicates that the fatigue is more sensitive to current in the “slack” case. As for the Hotspot C dominated by multi-axis OPB stress, combined with Table 13, the mean value and standard deviation of OPB/IPB angles increase in the “taut” case and decrease in the “slack” case if current is considered, leading to the fatigue at Hotspot C increasing (by 13.46%) in Case 12 and decreasing (by −12.06%) in Case 39, respectively. In summary, a more conservative fatigue life for TT fatigue will be obtained without the effect of current. In contrast, the combined fatigue due to OPB and IPB is more sensitive to current.

6. Conclusions

An OPB fatigue assessment approach for offshore mooring chains is developed, which considers real-time updating of the interlink bending stiffness. The advantages of this approach are that the nonlinear time-varying interlink bending stiffness and frictions are considered, and the top segment of the mooring chain is locally refined for a better description of the interlink function mechanism in the global coupled and local FE models. On the basis of the developed approach and models, the effects of interlink stiffness on mooring chain fatigue due to IPB/OPB are investigated, and this S-N-curves-based method is proven to be more reliable and accurate than the pure TT method based on T-N curves. The following key conclusions are listed below.

(1) The interlink stiffness time-varying effect on the chain’s fatigue is investigated by comparisons of the zero interlink stiffness (hinge joint assumption), constant interlink stiffness (calculated by mooring pretension), and time-varying interlink stiffness. It is found that the OPB combined fatigue will be underestimated significantly by assuming zero (with a maximum overvaluation of 89.84% at Hotspot C) or constant (with a maximum overvaluation of 25.88% at Hotspot A) interlink stiffness.

(2) Compared with the pure TT fatigue assessment method, the combined fatigue assessment method developed in this paper integrally considers the mooring tension, OPB, and IPB. The chain’s fatigue life of pure TT is close to 3 times that of Hotspot A and about 5–6 times that of Hotspots B and C. It takes more comprehensive consideration in calculating fatigue to obtain more reliable results.

(3) For the parallel and perpendicular wave directions (relative to the assigned mooring line), the chain fatigue is governed by the TT fatigue and combined fatigue Hotspot A, indicating being dominated by the variation in mooring tensions, while the chain fatigue in the oblique directions is dominated by multi-axis out-of-plane bending.

(4) The influence of wind and current on anchor chain fatigue damage is related to their behavior on the mooring chain (tensing or relaxing the chain). For the wind, tension-dominated fatigue is more affected by the wind and is particularly significant on the “taut” side (with a difference of 29.17%). In comparison, the OPB fatigue damage of the mooring chains increases on the “slack” side (by +13.46%) and decreases on the “taut” side (by −12.06%) under the influence of the current.

Although the proposed OPB combined fatigue assessment method for mooring chains has been proved to be universal and effective in the prediction of fatigue life considering TT, OPB, and IPB, there are still deficiencies in the assessment process due to the simplification of some influencing factors, such as torsion between the chain links not being considered. In addition, there is still room for further enhancement of this evaluation procedure, such as OPB combined fatigue being predicted directly through the MeCAP-fatigue without relying on FEA, which would greatly improve its computational efficiency.

Author Contributions

Conceptualization, J.W.; methodology, J.W., C.H. and J.D.; software, C.H. and K.H.; validation, J.W. and C.H.; formal analysis, J.W., C.H. and J.D.; investigation, K.H.; writing—original draft preparation, C.H.; writing—review and editing, J.W. and D.F.; supervision, J.W. and D.F.; project administration, J.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant Nos. 52088102, 51879287 and 52271298).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

There are 54 environment conditions in the sea area where the semi-submersible platform is located, detailed in Table A1.

Table A1.

Condensed scatter diagram.

Table A1.

Condensed scatter diagram.

| Case No. | Direction | Hs (m) | Tp (s) | WS 1 h (m/s) | Vc Surf (m/s) | Probability |

|---|---|---|---|---|---|---|

| 1 | NN | 1.5 | 7.7 | 6.5 | 0.38 | 0.77320% |

| 2 | NN | 2.5 | 8.8 | 8.9 | 0.49 | 0.28073% |

| 3 | NN | 3.5 | 9.5 | 11.4 | 0.6 | 0.15456% |

| 4 | NN | 4.5 | 10.1 | 13.8 | 0.71 | 0.07473% |

| 5 | NN | 5.5 | 10.6 | 16.2 | 0.82 | 0.02146% |

| 6 | NN | 8.5 | 11.5 | 28 | 1.1 | 0.00056% |

| 7 | NN | 12 | 13.5 | 35.2 | 1.43 | 0.00008% |

| 8 | NE | 1.5 | 7.7 | 6.5 | 0.38 | 19.20280% |

| 9 | NE | 2.5 | 8.8 | 8.9 | 0.49 | 7.04573% |

| 10 | NE | 3.5 | 9.5 | 11.4 | 0.6 | 3.90135% |

| 11 | NE | 4.5 | 10.1 | 13.8 | 0.71 | 1.86217% |

| 12 | NE | 5.5 | 10.6 | 16.2 | 0.82 | 0.48021% |

| 13 | NE | 6.5 | 11.1 | 18.6 | 0.93 | 0.05442% |

| 14 | NE | 8.5 | 11.5 | 28 | 1.1 | 0.01412% |

| 15 | NE | 12 | 13.5 | 35.2 | 1.43 | 0.00209% |

| 16 | EE | 1.5 | 7.7 | 6.5 | 0.38 | 12.83061% |

| 17 | EE | 2.5 | 8.8 | 8.9 | 0.49 | 4.65853% |

| 18 | EE | 3.5 | 9.5 | 11.4 | 0.6 | 2.56466% |

| 19 | EE | 4.5 | 10.1 | 13.8 | 0.71 | 1.24004% |

| 20 | EE | 5.5 | 10.6 | 16.2 | 0.82 | 0.31977% |

| 21 | EE | 8.5 | 11.5 | 28 | 1.1 | 0.04491% |

| 22 | EE | 12 | 13.5 | 37.9 | 1.57 | 0.00213% |

| 23 | SE | 1.5 | 7.7 | 6.5 | 0.38 | 8.13501% |

| 24 | SE | 2.5 | 8.8 | 8.9 | 0.49 | 2.95365% |

| 25 | SE | 3.5 | 9.5 | 11.4 | 0.6 | 1.62608% |

| 26 | SE | 4.5 | 10.1 | 13.8 | 0.71 | 0.78622% |

| 27 | SE | 5.5 | 10.6 | 16.2 | 0.82 | 0.20274% |

| 28 | SE | 8.5 | 11.5 | 28 | 1.1 | 0.02846% |

| 29 | SE | 12 | 13.5 | 37.9 | 1.57 | 0.00135% |

| 30 | SS | 1.5 | 7.7 | 6.5 | 0.38 | 14.68679% |

| 31 | SS | 2.5 | 8.8 | 8.9 | 0.49 | 5.33247% |

| 32 | SS | 3.5 | 9.5 | 11.4 | 0.6 | 2.93569% |

| 33 | SS | 5.5 | 10.6 | 16.2 | 0.82 | 1.78547% |

| 34 | SS | 8.5 | 11.5 | 28 | 1.1 | 0.05140% |

| 35 | SS | 12 | 13.5 | 37.9 | 1.57 | 0.00243% |

| 36 | SW | 1.5 | 7.7 | 6.5 | 0.38 | 2.04144% |

| 37 | SW | 2.5 | 8.8 | 8.9 | 0.49 | 0.74120% |

| 38 | SW | 3.5 | 9.5 | 11.4 | 0.6 | 0.40805% |

| 39 | SW | 5.5 | 10.6 | 16.2 | 0.82 | 0.24817% |

| 40 | SW | 8.5 | 11.5 | 28 | 1.1 | 0.00713% |

| 41 | SW | 12 | 13.5 | 35.2 | 1.43 | 0.00034% |

| 42 | WW | 1.5 | 7.7 | 6.5 | 0.38 | 1.27450% |

| 43 | WW | 2.5 | 8.8 | 8.9 | 0.49 | 0.46275% |

| 44 | WW | 3.5 | 9.5 | 11.4 | 0.6 | 0.25476% |

| 45 | WW | 5.5 | 10.6 | 16.2 | 0.82 | 0.15494% |

| 46 | WW | 8.5 | 11.5 | 28 | 1.1 | 0.00447% |

| 47 | WW | 12 | 13.5 | 35.2 | 1.43 | 0.00021% |

| 48 | NW | 1.5 | 7.7 | 6.5 | 0.38 | 0.20461% |

| 49 | NW | 3.5 | 9.5 | 11.4 | 0.6 | 0.11518% |

| 50 | NW | 4.5 | 10.1 | 13.8 | 0.71 | 0.01978% |

| 51 | NW | 5.5 | 10.6 | 16.2 | 0.82 | 0.00509% |

| 52 | NW | 6.5 | 11.1 | 18.6 | 0.93 | 0.00059% |

| 53 | NW | 8.5 | 11.5 | 28 | 1.1 | 0.00014% |

| 54 | NW | 12 | 13.5 | 35.2 | 1.43 | 0.00003% |

Appendix B

The fatigue damage for different sea states (the significant wave height is 1.5, 5.5, and 12 m; the wave direction is NE and SW) and connection relations (zero, constant and time-varying interlink stiffness) is calculated, and the detailed results are listed in Table A2 and Table A3.

Table A2.

Fatigue damage of zero and time-varying interlink stiffness.

Table A2.

Fatigue damage of zero and time-varying interlink stiffness.

| Case 8 | Case 12 | Case 15 | Case 36 | Case 39 | Case 41 | ||

|---|---|---|---|---|---|---|---|

| Environment | Hs (m) | 1.5 | 5.5 | 12 | 1.5 | 5.5 | 12 |

| Dir | NE | NE | NE | SW | SW | SW | |

| TT | Zero stiffness | 1.95 × 10−5 | 3.13 × 10−3 | 8.32 × 100 | 3.30 × 10−5 | 2.73 × 10−3 | 9.60 × 100 |

| Time-varying stiffness | 1.95 × 10−5 | 3.13 × 10−3 | 8.37 × 100 | 3.27 × 10−5 | 2.69 × 10−3 | 9.58 × 100 | |

| Difference | 0.16% | 0.07% | −0.50% | 0.87% | 1.35% | 0.23% | |

| Hotspot A | Zero stiffness | 6.22 × 10−5 | 6.25 × 10−3 | 1.97 × 101 | 9.58 × 10−5 | 7.78 × 10−3 | 1.48 × 101 |

| Time-varying stiffness | 6.10 × 10−5 | 6.19 × 10−3 | 1.98 × 101 | 9.49 × 10−5 | 7.69 × 10−3 | 1.51 × 101 | |

| Difference | 1.92% | 1.02% | −0.50% | 0.96% | 1.10% | −1.87% | |

| Hotspot B | Zero stiffness | 4.15 × 10−5 | 1.35 × 10−3 | 3.12 × 100 | 6.45 × 10−5 | 1.80 × 10−3 | 9.04 × 100 |

| Time-varying stiffness | 3.13 × 10−5 | 1.52 × 10−3 | 3.04 × 100 | 4.47 × 10−5 | 1.59 × 10−3 | 7.41 × 100 | |

| Difference | 32.27% | −11.59% | 2.68% | 44.46% | 13.10% | 22.09% | |

| Hotspot C | Zero stiffness | 3.08 × 10−5 | 6.18 × 10−4 | 4.69 × 10−1 | 4.02 × 10−5 | 8.97 × 10−4 | 8.38 × 100 |

| Time-varying stiffness | 2.23 × 10−5 | 7.08 × 10−4 | 4.48 × 10−1 | 2.57 × 10−5 | 7.18 × 10−4 | 4.42 × 100 | |

| Difference | 37.98% | −12.69% | 4.58% | 56.63% | 24.89% | 89.84% |

Table A3.

Fatigue damage of constant and time-varying interlink stiffness.

Table A3.

Fatigue damage of constant and time-varying interlink stiffness.

| Case 8 | Case 12 | Case 15 | Case 36 | Case 39 | Case 41 | ||

|---|---|---|---|---|---|---|---|

| Environment | Hs (m) | 1.5 | 5.5 | 12 | 1.5 | 5.5 | 12 |

| Dir | NE | NE | NE | SW | SW | SW | |

| TT | Constant stiffness | 1.95 × 10−5 | 3.13 × 10−3 | 8.44 × 100 | 3.27 × 10−5 | 2.69 × 10−3 | 9.57 × 100 |

| Time-varying stiffness | 1.95 × 10−5 | 3.13 × 10−3 | 8.37 × 100 | 3.27 × 10−5 | 2.69 × 10−3 | 9.58 × 100 | |

| Difference | −0.01% | 0.04% | 0.90% | −0.05% | −0.05% | −0.05% | |

| Hotspot A | Constant stiffness | 6.12 × 10−5 | 6.46 × 10−3 | 1.47 × 101 | 9.46 × 10−5 | 7.70 × 10−3 | 1.44 × 101 |

| Time-varying stiffness | 6.10 × 10−5 | 6.19 × 10−3 | 1.98 × 101 | 9.49 × 10−5 | 7.69 × 10−3 | 1.51 × 101 | |

| Difference | 0.19% | 4.43% | −25.88% | −0.34% | 0.14% | −4.20% | |

| Hotspot B | Constant stiffness | 3.10 × 10−5 | 1.54 × 10−3 | 2.31 × 100 | 4.54 × 10−5 | 1.50 × 10−3 | 7.81 × 100 |

| Time-varying stiffness | 3.13 × 10−5 | 1.52 × 10−3 | 3.04 × 100 | 4.47 × 10−5 | 1.59 × 10−3 | 7.41 × 100 | |

| Difference | −1.16% | 1.44% | −24.15% | 1.55% | −5.48% | 5.43% | |

| Hotspot C | Constant stiffness | 2.27 × 10−5 | 7.66 × 10−4 | 4.02 × 10−1 | 2.63 × 10−5 | 6.91 × 10−4 | 4.65 × 100 |

| Time-varying stiffness | 2.23 × 10−5 | 7.08 × 10−4 | 4.48 × 10−1 | 2.57 × 10−5 | 7.18 × 10−4 | 4.42 × 100 | |

| Difference | 1.70% | 8.22% | −10.23% | 2.48% | −3.74% | 5.23% |

Appendix C

The fatigue damage data for mooring line #2 based on the sea states in Table A1 are fully computed, as shown in Table A4.

Table A4.

The fatigue damage of mooring line #2.

Table A4.

The fatigue damage of mooring line #2.

| Case | TT | Hotspot A | Hotspot B | Hotspot C |

|---|---|---|---|---|

| 1 | 1.27 × 10−7 | 1.02 × 10−6 | 1.58 × 10−5 | 1.85 × 10−5 |

| 2 | 2.90 × 10−7 | 2.15 × 10−6 | 2.35 × 10−5 | 2.88 × 10−5 |

| 3 | 5.00 × 10−7 | 3.19 × 10−6 | 2.91 × 10−5 | 3.37 × 10−5 |

| 4 | 4.82 × 10−7 | 3.37 × 10−6 | 2.18 × 10−5 | 2.33 × 10−5 |

| 5 | 2.73 × 10−7 | 1.77 × 10−6 | 8.53 × 10−6 | 8.69 × 10−6 |

| 6 | 3.80 × 10−8 | 2.19 × 10−7 | 6.73 × 10−7 | 6.81 × 10−7 |

| 7 | 1.29 × 10−8 | 6.51 × 10−8 | 1.12 × 10−7 | 1.14 × 10−7 |

| 8 | 4.06 × 10−6 | 1.17 × 10−5 | 6.02 × 10−6 | 4.29 × 10−6 |

| 9 | 1.15 × 10−5 | 3.10 × 10−5 | 1.20 × 10−5 | 6.72 × 10−6 |

| 10 | 2.38 × 10−5 | 6.18 × 10−5 | 1.86 × 10−5 | 9.31 × 10−6 |

| 11 | 3.11 × 10−5 | 7.15 × 10−5 | 1.74 × 10−5 | 8.05 × 10−6 |

| 12 | 1.67 × 10−5 | 2.97 × 10−5 | 7.31 × 10−6 | 3.40 × 10−6 |

| 13 | 2.30 × 10−6 | 5.39 × 10−6 | 1.49 × 10−6 | 6.32 × 10−7 |

| 14 | 2.63 × 10−6 | 4.54 × 10−6 | 7.06 × 10−7 | 2.63 × 10−7 |

| 15 | 2.35 × 10−4 | 4.14 × 10−4 | 6.35 × 10−5 | 9.37 × 10−6 |

| 16 | 4.60 × 10−6 | 1.53 × 10−5 | 1.33 × 10−4 | 1.49 × 10−4 |

| 17 | 1.26 × 10−5 | 4.13 × 10−5 | 2.03 × 10−4 | 2.20 × 10−4 |

| 18 | 2.78 × 10−5 | 7.05 × 10−5 | 2.55 × 10−4 | 2.62 × 10−4 |

| 19 | 2.98 × 10−5 | 7.59 × 10−5 | 1.98 × 10−4 | 1.90 × 10−4 |

| 20 | 1.37 × 10−5 | 3.09 × 10−5 | 7.12 × 10−5 | 6.50 × 10−5 |

| 21 | 7.45 × 10−6 | 1.53 × 10−5 | 2.71 × 10−5 | 2.27 × 10−5 |

| 22 | 9.21 × 10−7 | 1.66 × 10−6 | 1.64 × 10−6 | 1.29 × 10−6 |

| 23 | 1.62 × 10−6 | 5.51 × 10−6 | 2.86 × 10−6 | 1.89 × 10−6 |

| 24 | 4.36 × 10−6 | 1.49 × 10−5 | 5.53 × 10−6 | 3.06 × 10−6 |

| 25 | 8.53 × 10−6 | 2.76 × 10−5 | 7.96 × 10−6 | 4.49 × 10−6 |

| 26 | 9.83 × 10−6 | 3.10 × 10−5 | 7.23 × 10−6 | 3.36 × 10−6 |

| 27 | 4.74 × 10−6 | 1.38 × 10−5 | 3.06 × 10−6 | 1.27 × 10−6 |

| 28 | 6.59 × 10−6 | 7.77 × 10−6 | 1.41 × 10−6 | 7.22 × 10−7 |

| 29 | 5.78 × 10−5 | 1.10 × 10−4 | 2.44 × 10−5 | 7.27 × 10−6 |

| 30 | 3.26 × 10−6 | 2.44 × 10−5 | 2.79 × 10−4 | 3.52 × 10−4 |

| 31 | 1.16 × 10−5 | 6.62 × 10−5 | 4.85 × 10−4 | 5.39 × 10−4 |

| 32 | 2.51 × 10−5 | 1.18 × 10−4 | 6.13 × 10−4 | 6.93 × 10−4 |

| 33 | 6.80 × 10−5 | 2.71 × 10−4 | 9.85 × 10−4 | 1.05 × 10−3 |

| 34 | 3.49 × 10−6 | 1.51 × 10−5 | 4.94 × 10−5 | 5.64 × 10−5 |

| 35 | 1.88 × 10−7 | 7.95 × 10−7 | 3.73 × 10−6 | 4.33 × 10−6 |

| 36 | 6.96 × 10−7 | 1.94 × 10−6 | 9.12 × 10−7 | 5.24 × 10−7 |

| 37 | 2.06 × 10−6 | 5.46 × 10−6 | 1.63 × 10−6 | 9.21 × 10−7 |

| 38 | 2.97 × 10−6 | 9.20 × 10−6 | 2.59 × 10−6 | 1.27 × 10−6 |

| 39 | 6.76 × 10−6 | 1.91 × 10−5 | 3.94 × 10−6 | 1.78 × 10−6 |

| 40 | 5.81 × 10−7 | 1.30 × 10−6 | 2.92 × 10−7 | 1.41 × 10−7 |

| 41 | 2.84 × 10−5 | 5.12 × 10−5 | 2.52 × 10−5 | 1.50 × 10−5 |

| 42 | 5.42 × 10−7 | 1.42 × 10−6 | 1.02 × 10−5 | 1.15 × 10−5 |

| 43 | 1.70 × 10−6 | 3.97 × 10−6 | 1.59 × 10−5 | 1.70 × 10−5 |

| 44 | 3.21 × 10−6 | 6.52 × 10−6 | 2.03 × 10−5 | 2.16 × 10−5 |

| 45 | 5.02 × 10−6 | 1.11 × 10−5 | 2.80 × 10−5 | 2.86 × 10−5 |

| 46 | 5.41 × 10−7 | 9.56 × 10−7 | 1.49 × 10−6 | 1.50 × 10−6 |

| 47 | 3.97 × 10−8 | 8.21 × 10−8 | 7.69 × 10−8 | 7.28 × 10−8 |

| 48 | 4.42 × 10−8 | 1.32 × 10−7 | 6.98 × 10−8 | 5.20 × 10−8 |

| 49 | 7.11 × 10−7 | 1.84 × 10−6 | 5.27 × 10−7 | 2.57 × 10−7 |

| 50 | 2.78 × 10−7 | 7.45 × 10−7 | 1.72 × 10−7 | 7.67 × 10−8 |

| 51 | 1.26 × 10−7 | 3.27 × 10−7 | 7.41 × 10−8 | 2.69 × 10−8 |

| 52 | 2.11 × 10−8 | 5.96 × 10−8 | 1.28 × 10−8 | 4.71 × 10−9 |

| 53 | 1.32 × 10−8 | 3.76 × 10−8 | 6.34 × 10−9 | 2.50 × 10−9 |

| 54 | 1.89 × 10−7 | 3.37 × 10−7 | 9.47 × 10−8 | 6.94 × 10−8 |

References

- Chung, W.C.; Kang, H.Y.; Kim, M.H. Multi-Scale Approach for Chain-Mooring Opb-Induced Failure Considering Time-Varying Interlink Bending Stiffness and Fairlead Condition. Appl. Ocean Res. 2020, 98, 102128. [Google Scholar] [CrossRef]

- Fontaine, E.; Kilner, A.; Carra, C.; Washington, D.; Ma, K.T.; Phadke, A.; Laskowski, D.; Kusinski, G. Industry Survey of Past Failures, Pre-Emptive Replacements and Reported Degradations for Mooring Systems of Floating Production Units. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014. [Google Scholar]

- Melis, C.; Jean, P.; Vargas, P. Out-of-Plane Bending Testing of Chain Links. In Proceedings of the ASME 2005 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 12–17 June 2005. [Google Scholar]

- Rampi, L.; Vargas, P. Fatigue Testing of Out-of-Plane Bending Mechanism of Chain Links. In Proceedings of the 25th International Conference on Offshore Mechanics and Arctic Engineering, Hamburg, Germany, 4–9 June 2006. [Google Scholar]

- Hwang, O. Fatigue Assessment for Mooring Chain Link of Spread-Moored FPSO in Deepwater Considering Bending Phenomenon. Ph.D. Dissertation, Korea Maritime University, Busan, Republic of Korea, 2012. [Google Scholar]

- Vargas, P.M.; Hsu, T.-M.; Lee, W.K. Stress Concentration Factors for Stud-Less Mooring Chain Links in Fairleads. In Proceedings of the ASME 2004 23rd International Conference on Offshore Mechanics and Arctic Engineering, Vancouver, British Columbia, 20–25 June 2004. [Google Scholar]

- Jean, P.; Goessens, K.; L’Hostis, D. Failure of Chains by Bending on Deepwater Mooring Systems. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2005.

- Vargas, P.; Jean, P. FEA of Out-of-Plane Fatigue Mechanism of Chain Links. In Proceedings of the ASME 2005 24th International Conference on Offshore Mechanics and Arctic Engineering, Halkidiki, Greece, 12–17 June 2005. [Google Scholar]

- ter Brake, E.; van der Cammen, J.; Uittenbogaard, R. Calculation Methodology of Out of Plane Bending of Mooring Chains. In Proceedings of the ASME 2007 26th International Conference on Offshore Mechanics and Arctic Engineering, San Diego, CA, USA, 10–15 June 2007. [Google Scholar]

- Mamiya, E.N.; Castro, F.C.; Ferreira, G.V.; Nunes Filho, E.L.S.A.; Canut, F.A.; Neves, R.S.; Malcher, L. Fatigue of mooring chain links subjected to out-of-plane bending: Experiments and modeling. Eng. Fail. Anal. 2019, 100, 206–213. [Google Scholar] [CrossRef]

- Kowalski, M.; Böhm, M.; Rozumek, D.; Kurek, A.; Correia, J. Fatigue Strength of New Explosively Welded Steel-Aluminum Transition Joint Used in Ships. Ocean Eng. 2023, 288, 115990. [Google Scholar] [CrossRef]

- Rampi, L.; Gerthoffert, A.; Francois, M.; Bignonnet, A.; Vargas, P. Chain out of Plane Bending (Opb) Fatigue Joint Industry Project (Jip) Fatigue Test Program Results and Methodology. In Proceedings of the ASME 2016 35th International Conference on Ocean, Offshore and Arctic Engineering, Busan, Republic of Korea, 19–24 June 2016. [Google Scholar]

- Calf, I. Multiaxial Fatigue Criteria for Offshore Mooring Chains Subjected to Out-of-Plane Bending. Master’s Thesis, TU Delft, Delft University of Technology, Delft, The Netherlands, 2015. [Google Scholar]

- Rampi, L.; Bignonnet, A.; Le Cunff, C.; Bourgin, F.; Vargas, P. Chain out of Plane Bending (Opb) Fatigue Joint Industry Project (Jip) Fea Results and Multiaxiality Study Results. In Proceedings of the ASME 2016 35th International Conference on Ocean, Offshore and Arctic Engineering, Busan, Republic of Korea, 19–24 June 2016. [Google Scholar]

- Rampi, L.; Dewi, F.; Francois, M.; Gerthoffert, A.; Vargas, P. Chain out of Plane Bending (Opb) Fatigue Joint Industry Project (Jip) Static Test Program and Opb Interlink Stiffness. In Proceedings of the ASME 2016 35th International Conference on Ocean, Offshore and Arctic Engineering, Busan, Republic of Korea, 19–24 June 2016. [Google Scholar]

- Xue, X.; Chen, N.-Z.; Pu, Y.; Gao, X. Fracture Mechanics Analysis for Mooring Chain Links Subjected to out-of-Plane Bending (Opb). Mar. Struct. 2020, 71, 102740. [Google Scholar] [CrossRef]

- Xue, X. Fracture Mechanics Based Offshore Mooring Fatigue Assessment. Ph.D. Thesis, Newcastle University, Newcastle upon Tyne, UK, 2020. [Google Scholar]

- Xue, X.; Chen, N.-Z.; Pu, Y. Mooring Fatigue Assessment Evaluating Chain Twist and out-of-Plane Bending for a Semi-Submersible. J. Offshore Mech. Arct. Eng. 2020, 142, 061703. [Google Scholar] [CrossRef]

- Xue, X.; Chen, N.-Z.; Pu, Y.; Chen, L.; Wang, L. Fracture Mechanics Assessment for Mooring Chain Links Tensioned over a Curved Surface. Appl. Ocean Res. 2021, 117, 102900. [Google Scholar] [CrossRef]

- Rampi, L.; Vargas, P. Methodology to Account for Corrosive Environment on Accelerated Fatigue Test on Mooring Chains Within the Chain Out of Plane Bending (Opb) Fatigue Joint Industry Project (Jip). In Proceedings of the Fatigue Design 2011, Cetim, Senlis, France, 23–24 November 2011. [Google Scholar]

- Rampi, L.; Dewi, F.; Vargas, P. Chain out of Plane Bending (Opb) Joint Industry Project (Jip) Summary and Main Results. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 2015. [Google Scholar]

- Veritas, B. Fatigue of Top Chain of Mooring Lines Due to in-Plane and out-of-Plane Bendings; Guidance Note NI 604; Bureau Veritas: Neuilly-sur-Seine, France, 2014. [Google Scholar]

- Chung, W.C.; Kim, M. Effects of Various Fairlead-Connection Parameters on Chain-Mooring Opb-Induced Failure. Mar. Struct. 2021, 76, 102926. [Google Scholar] [CrossRef]

- Lee, J.-B.; Koo, W.; Choung, J. Out-of-Plane Bending Moment-Induced Hotspot Stress Evaluation Using Advanced Numerical Technique. In Proceedings of the ASME 2018 37th International Conference on Ocean, Offshore and Arctic Engineering, Madrid, Spain, 17–22 June 2018. [Google Scholar]

- Lee, J.-B.; Tayyar, G.T.; Choung, J. In-Plane and out-of-Plane Bending Moments and Local Stresses in Mooring Chain Links Using Machine Learning Technique. Int. J. Nav. Archit. Ocean Eng. 2021, 13, 848–857. [Google Scholar] [CrossRef]

- Garrett, D.L. Dynamic Analysis of Slender Rods. J. Energy Resour. Technol. 1982, 104, 302–306. [Google Scholar] [CrossRef]

- Ran, Z. Coupled Dynamic Analysis of Floating Structures in Waves and Currents; Texas A&M University: College Station, TX, USA, 2000. [Google Scholar]

- API (American Petroleum Institute). Design and Analysis of Stationkeeping Systems for Floating Structures; API: New York, NY, USA, 2005. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).