Multi-Objective Optimization for Ship Scheduling with Port Congestion and Environmental Considerations

Abstract

1. Introduction

2. Literature Review

3. Mathematical Formulation

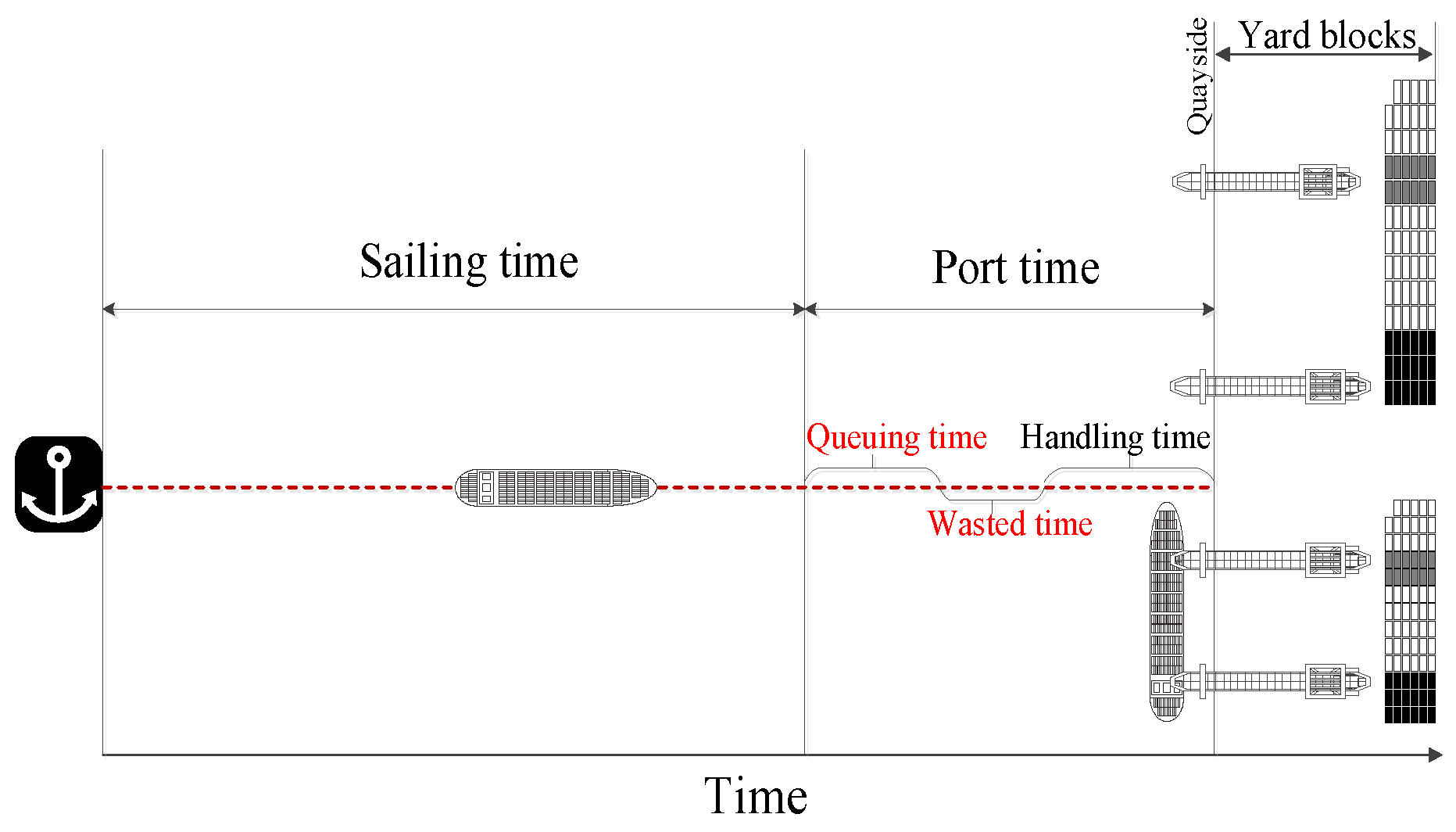

3.1. The System Dynamics

- The same type of vessel is deployed on the given liner route with a fixed sequence of ports of call, and all vessels are chartered;

- Even if any service schedule on these ship routes is adjusted, all vessels still arrive randomly following the Poisson distribution;

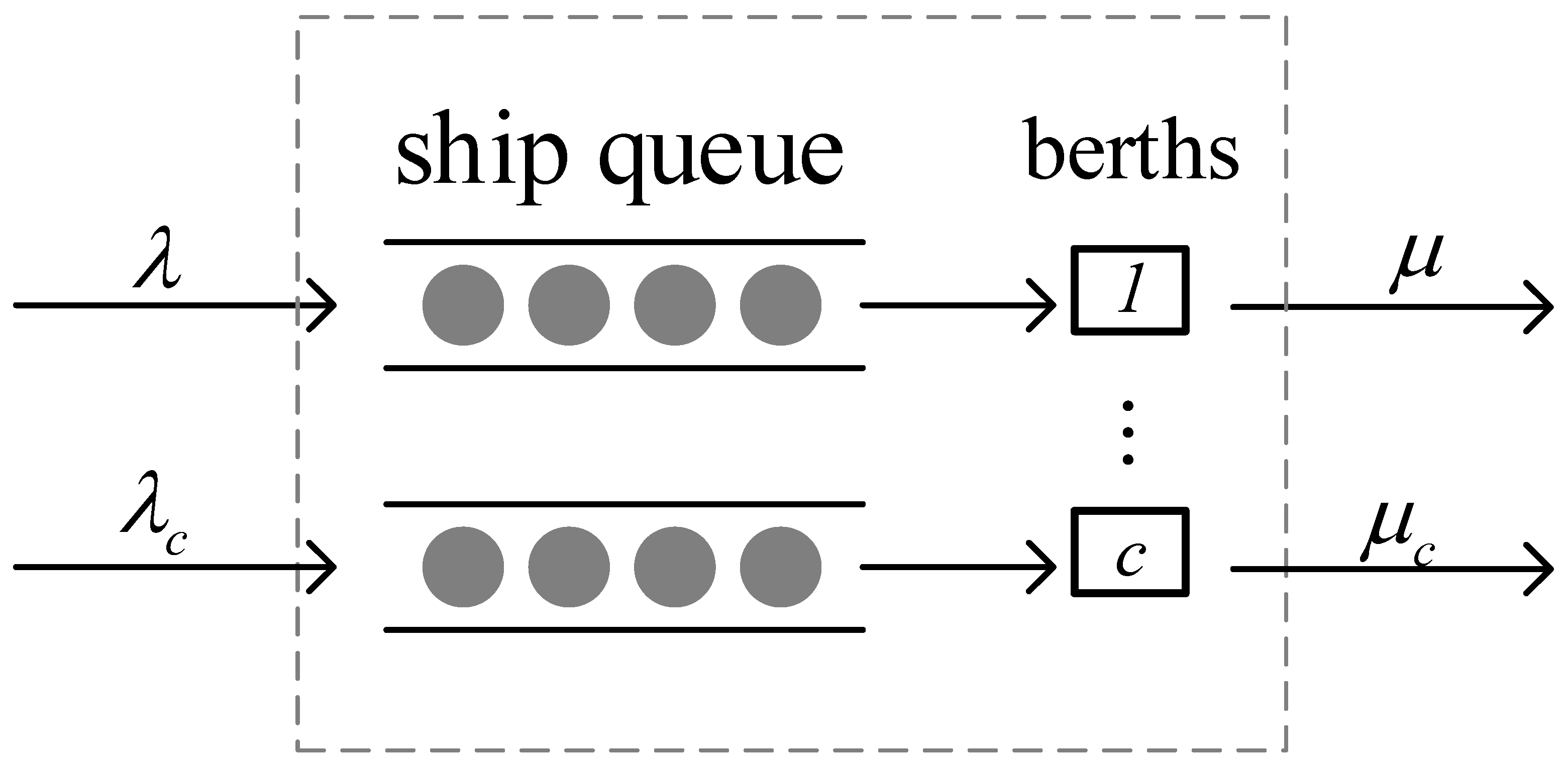

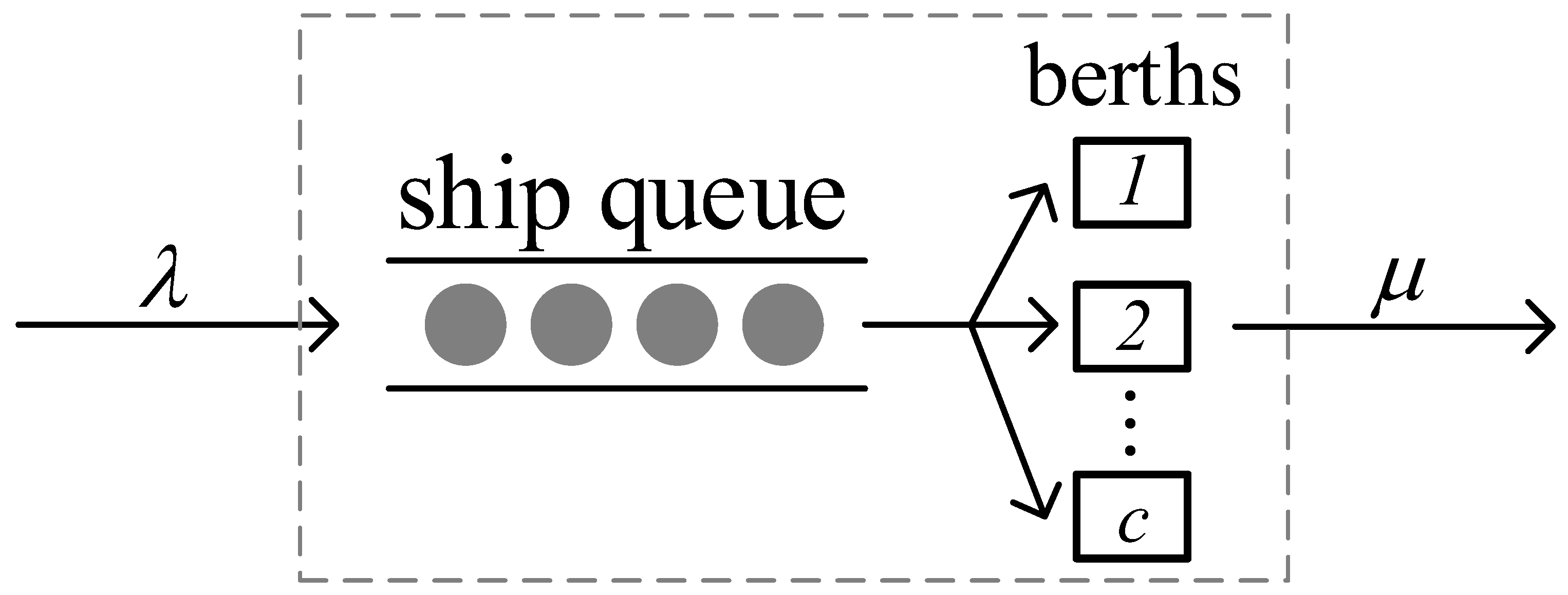

- If the berthing positions of vessels are known in advance, the single server queuing law () will be applied to calculate the waiting times. However, if the berthing positions are not yet known, the multi-server queuing law () will be applied;

- The loading and unloading volume at each port is assumed to be constant (i.e., the total amount of import containers unloaded from vessels and the total amount of export containers loaded on vessels are assumed to be fixed);

- The speed on each leg can be changed and optimized in the range between the minimum speed and the planned maximum speed. However, the use of higher vessel sailing speeds will cause higher fuel consumption.

3.2. Queuing Time at Single-Berth and Multi-Berth Facilities

- (a)

- The arrival process—ships arrive at random, subject to a Poisson probability distribution, and wait at the same anchorage point, even if vessel types can be different;

- (b)

- The queuing discipline—one waiting line and a ‘first-come-first-served’ rule. The arriving ships will wait when the berthing system is busy, and the queue length has an upper restriction;

- (c)

- The server discipline—each berth is mutually independent and has the same service ratio for the same type of ships. The service time is set as a random variable, subject to the negative exponential probability distribution.

- queuing system

- 2.

- queuing system

3.3. Multi-Objective Modeling

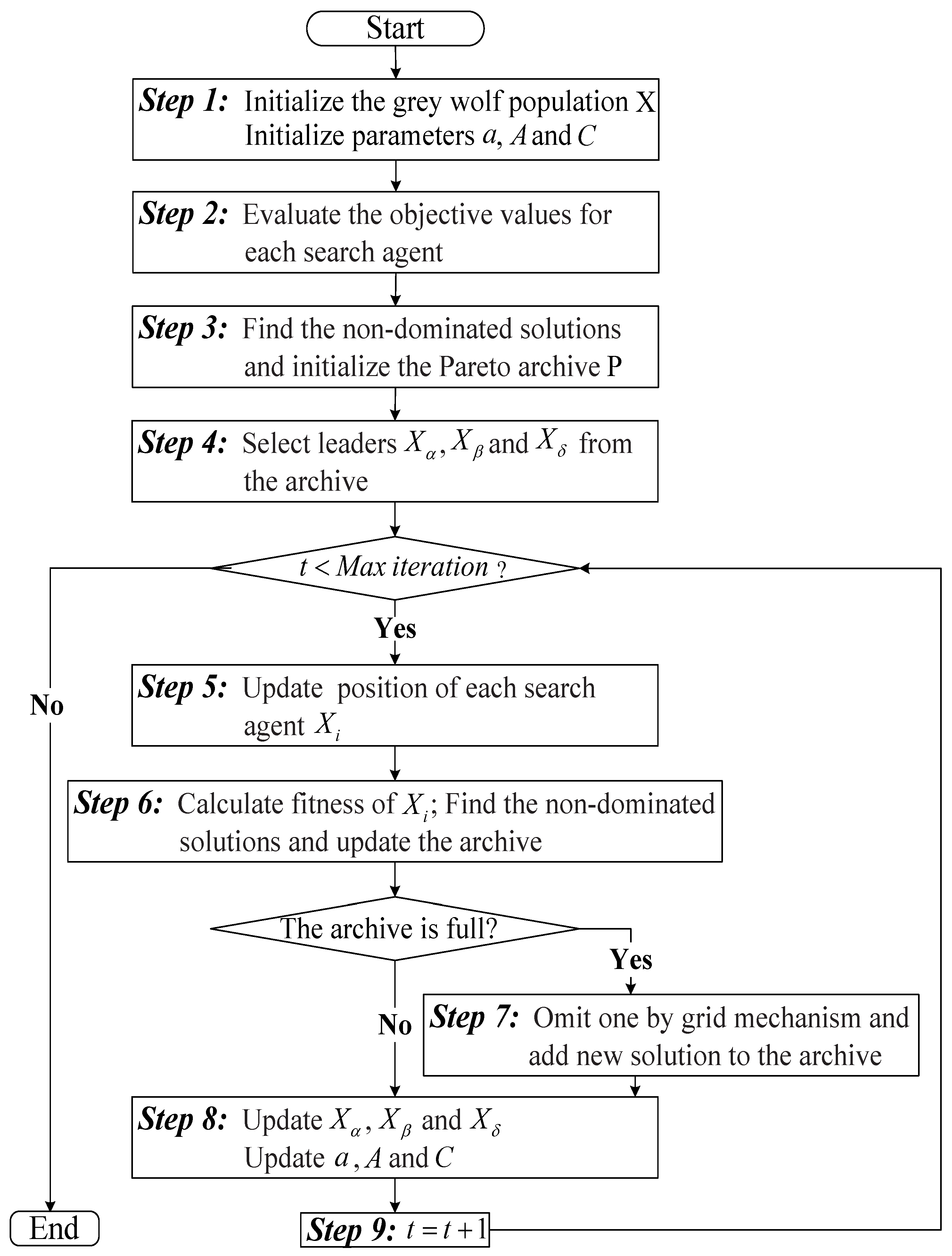

4. Algorithm Design

4.1. Multi-Objective Grey Wolf Optimizer (MOGWO)

4.2. Multi-Objective Genetic Algorithm (MOGA)

5. Numerical Experiments and Analysis

5.1. χ2 Fit Test

5.2. Scenario Settings

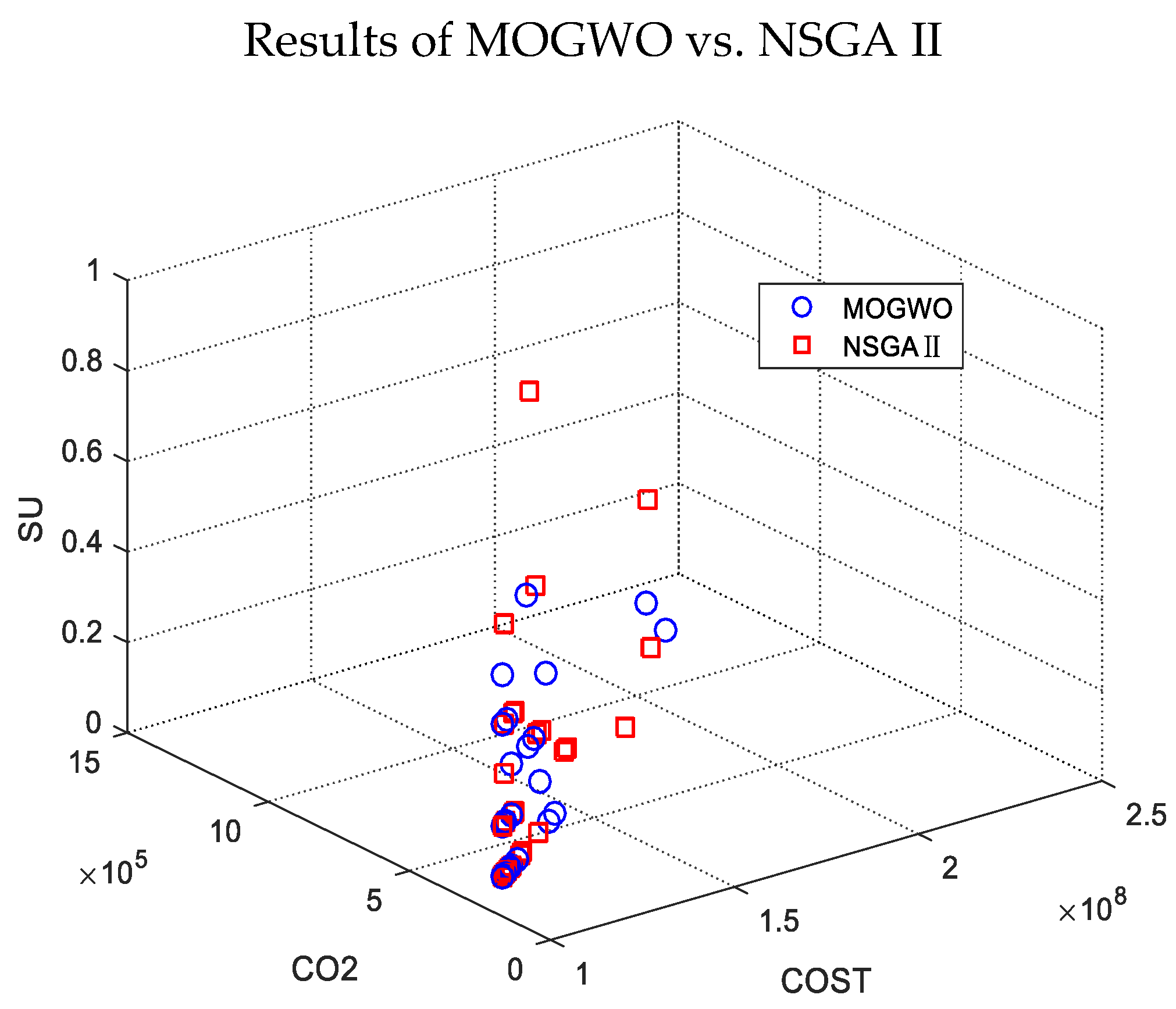

5.3. Computational Results

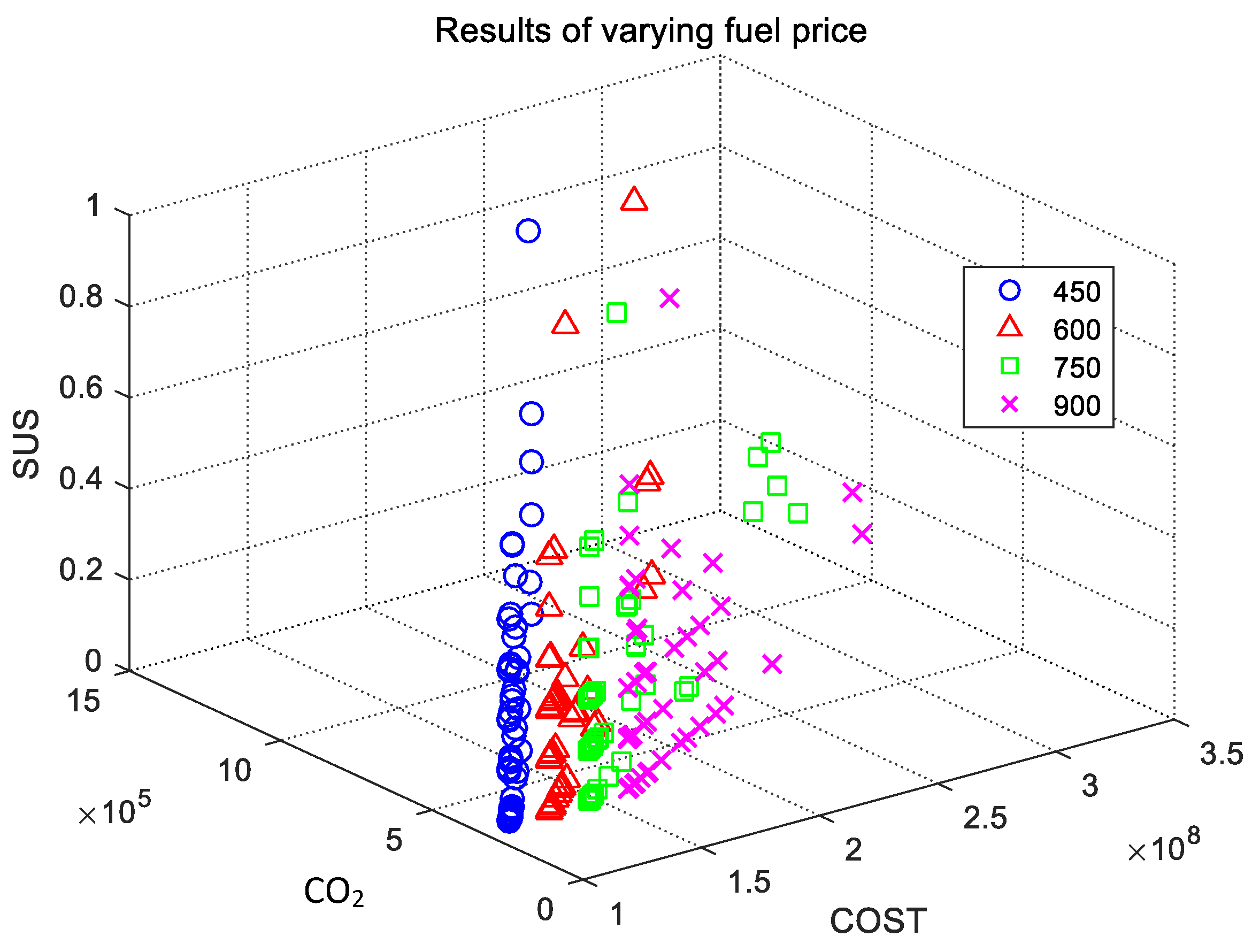

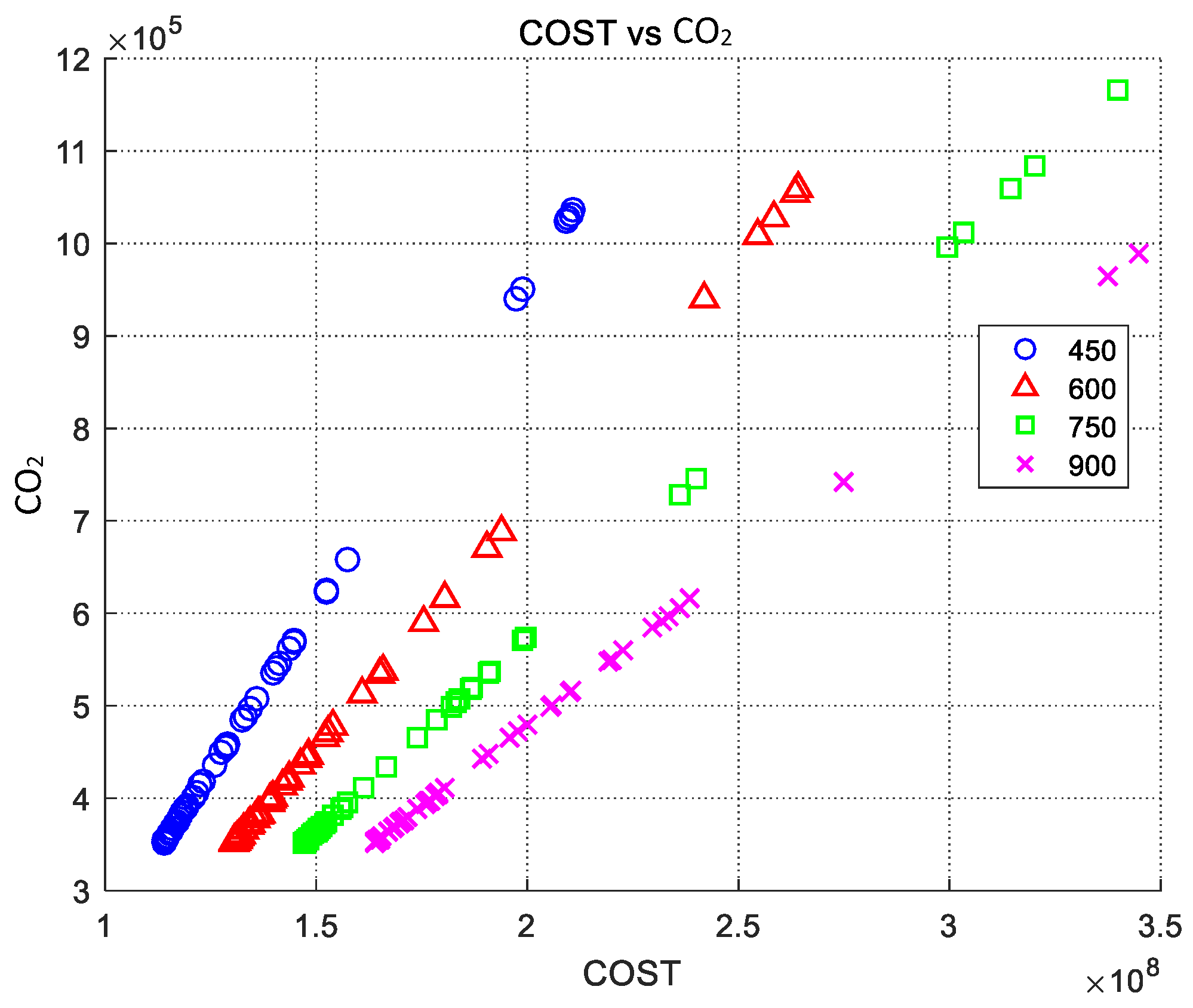

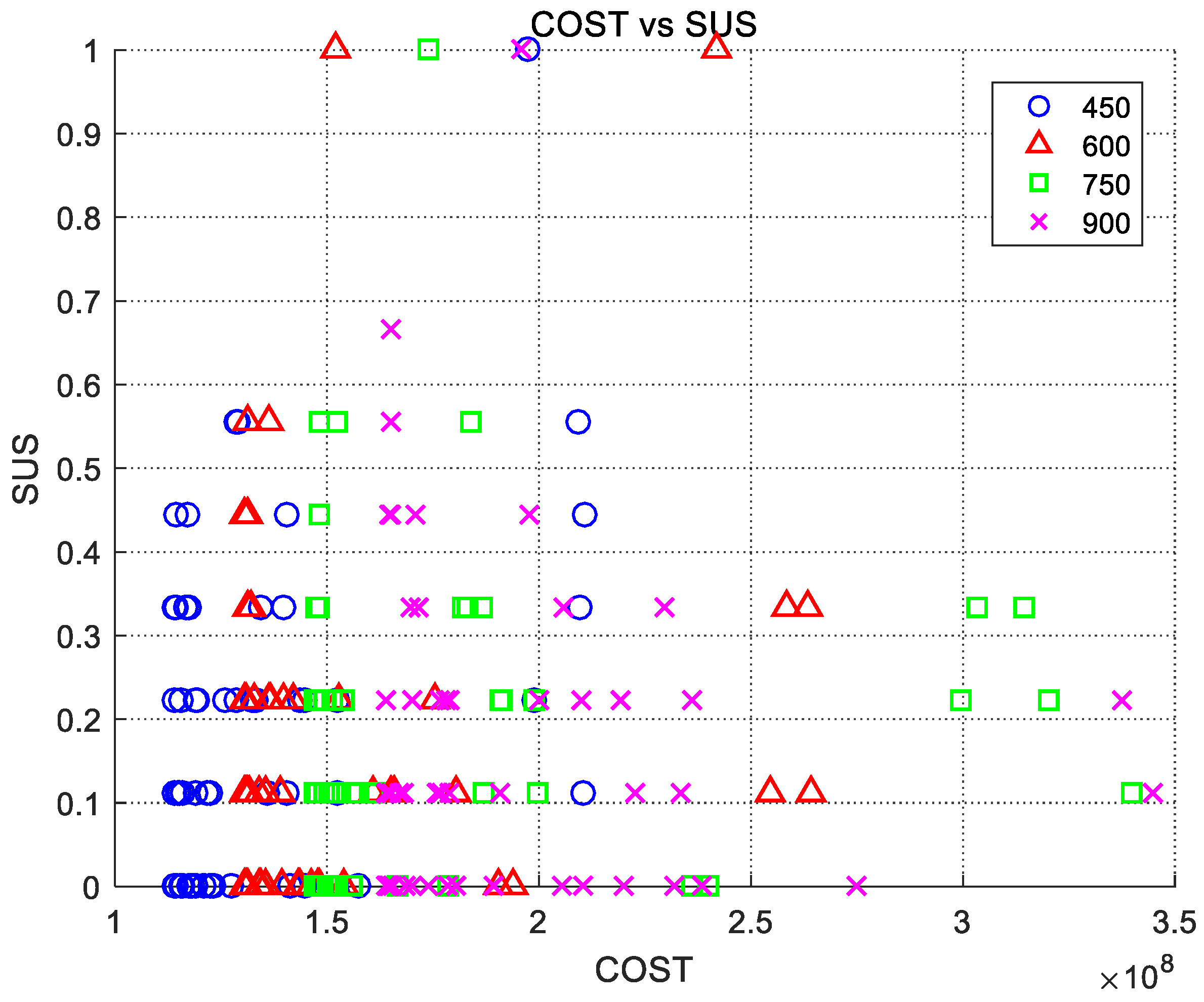

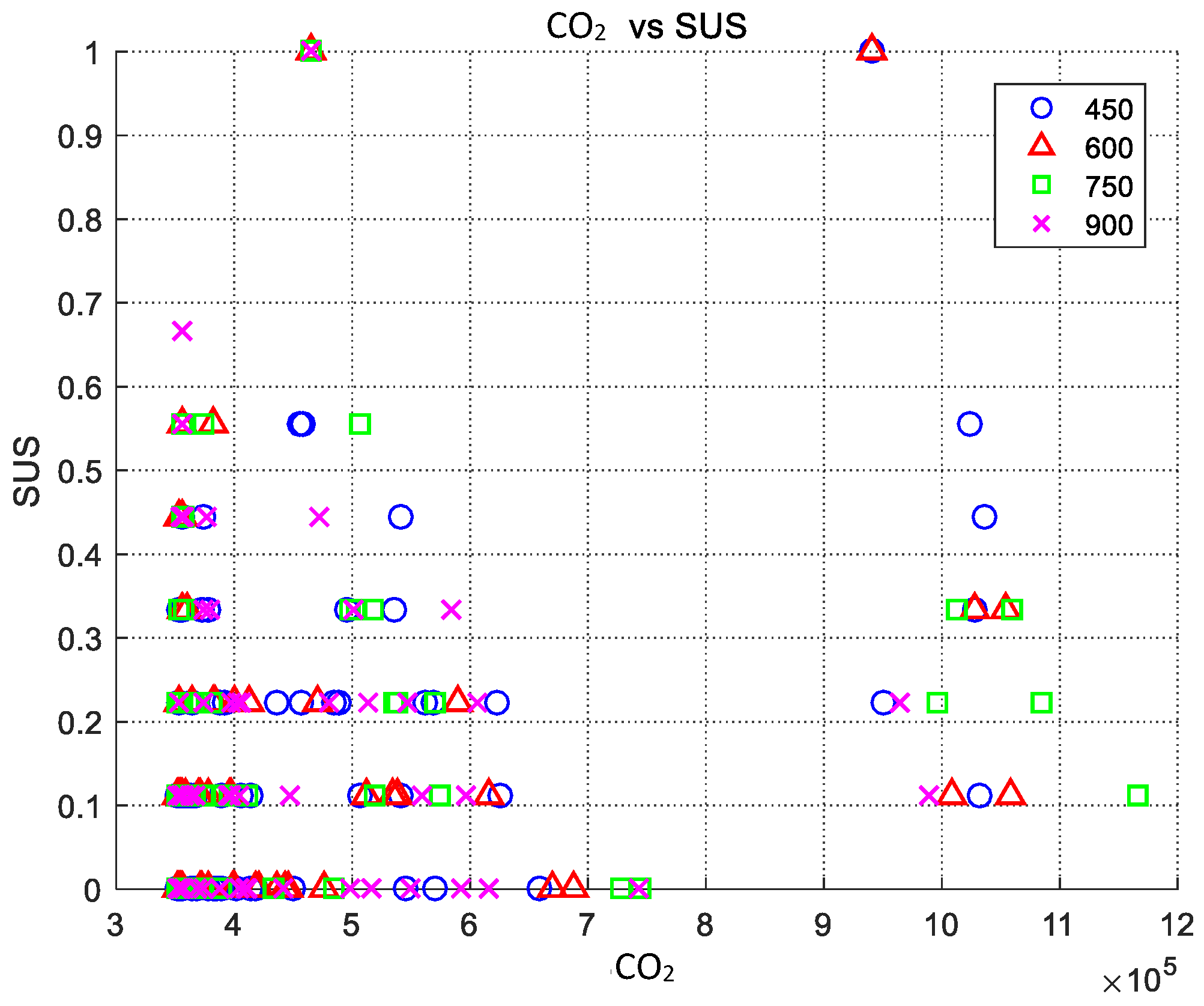

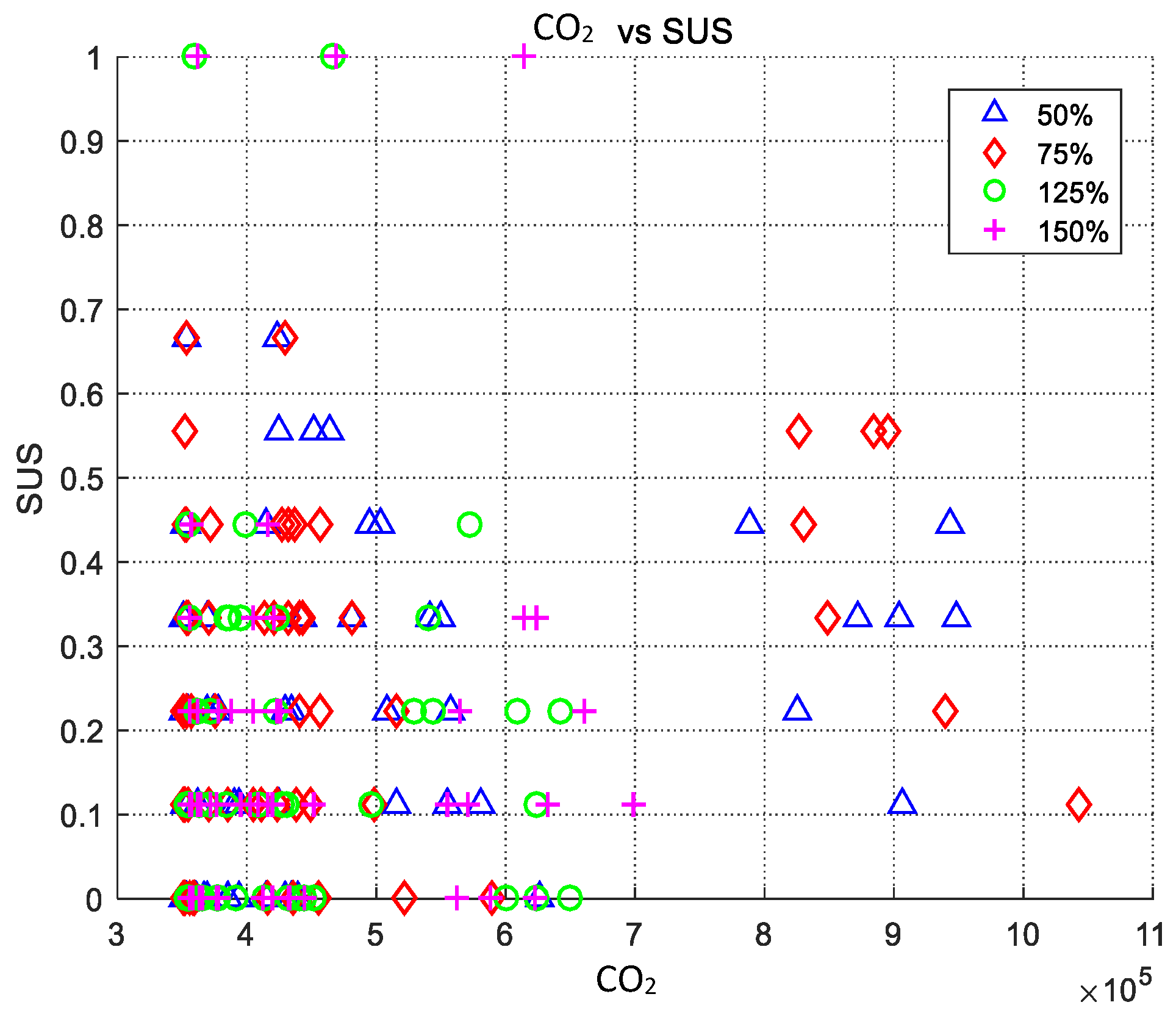

5.4. Sensitivity Analysis

6. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviation

| Parameters used for the queuing system modeling: | |

| the anticipated number of ship arrivals in one day, is the time interval between ships; | |

| the mean service rate in a queuing system; | |

| the mean service time per ship, ; | |

| the number of berths; | |

| the mean occupancy rate; | |

| the type of vessel; | |

| the expected service time of ship-type ; | |

| the expected number of ship-type arriving at the port; | |

| the largest number of vessels that are allowed in the queuing system. | |

| Other relevant parameters: | |

| the capacity of ship-type ; | |

| the loading and unloading ratios of each ship; | |

| container handling efficiency of port ; | |

| the total number of ports of calls in a voyage, i.e., a single round trip; | |

| the number of voyages by a vessel sailing along the shipping route continuously within the planning cycle; | |

| the distance between the th port of call and the th port of call ; | |

| the planned operating time at the th port of call ; | |

| the average wasted time during the arrival and departure process (between berthing and first move and between last move and departure) ; | |

| the minimum (maximum) sailing speed ; | |

| the fuel price for a different type of oil , which contains heavy oil and diesel oil ; | |

| the daily operating cost for ship-type ; | |

| the vessel’s arrival time window at the th port of call ; | |

| the main engine fuel economy of and , where denotes the vessel-type ; | |

| carbon emission factor . | |

| Decision variables: | |

| the number of deployed vessels on the shipping route; | |

| the designed maximum sailing speed subjects to ; | |

| the designed transit time between the th port of call and the th port of call . | |

| Auxiliary variables: | |

| the journey time of a voyage ; | |

| the planned arrival time of a vessel at the th port of call on the th voyage; | |

| the actual arrival time of a vessel at the th port of call on the th voyage; | |

| the actual departure time of a vessel at the th port of call on the th voyage; | |

| the actual sailing speed of a vessel on the leg from the th port of call to the next port of call on the th voyage ; | |

| the fuel consumption in the unit distance at sailing speed . | |

| Relevant variables used for queuing process modeling: | |

| the probability that a delay will occur; | |

| the probability that there are no ships at berths; | |

| the probability that there are ships at berths; | |

| the mean queuing length ; | |

| the mean queuing time per ship at th port on th voyage ; | |

| the annual total costs of all the vessels on the shipping route; | |

| the annual total CO2 emissions of all the vessels on the shipping route; | |

| the mean schedule unreliability of all ports of call on all voyages within the planning cycle. | |

References

- Fransoo, J.C.; Lee, C.Y. The Critical Role of Ocean Container Transport in Global Supply Chain Performance. Prod. Oper. Manag. 2013, 22, 253–268. [Google Scholar] [CrossRef]

- MEPC. Prevention of Air Pollution from Ships: Energy Efficiency Design Index; Session, T., Ed.; Agenda item 4; Marine Environment Protection Committee (MEPC) of IMO: London, UK, 2009. [Google Scholar]

- UNCTAD. Review of Maritime Transport 2017; United Nations Conference on Trade and Development: New York, NY, USA; Geneva, Switzerland, 2018. [Google Scholar]

- Lloyd’s Marine Intelligence Unit. Lloyd’s Maritime Directory 2009; Lloyd’s of London Press: London, UK, 2009. [Google Scholar]

- Drewry. Carrier Performance Insight; Drewry Shipping Consultants: London, UK, 2015. [Google Scholar]

- Pasha, J.; Dulebenets, M.A.; Fathollahi-Fard, A.M.; Tian, G.; Lau, Y.Y.; Singh, P.; Liang, B. An integrated optimization method for tactical-level planning in liner shipping with heterogeneous ship fleet and environmental considerations. Adv. Eng. Inform. 2021, 48, 101299. [Google Scholar] [CrossRef]

- Li, C.; Qi, X.T.; Song, D.P. Real-time schedule recovery in liner shipping service with regular uncertainties and disruption events. Transp. Res. Part B Methodol. 2016, 93, 762–788. [Google Scholar] [CrossRef]

- Notteboom, T.E. The time factor in liner shipping services. Marit. Econ. Logist. 2006, 8, 19–39. [Google Scholar] [CrossRef]

- Brouer, B.D.; Dirksen, J.; Pisinger, D.; Plum, C.E.M.; Vaaben, B. The vessel schedule recovery problem (VSRP)-A MIP model for handling disruptions in liner shipping. Eur. J. Oper. Res. 2013, 224, 362–374. [Google Scholar] [CrossRef]

- Gharehgozli, A.; Mileski, J.P.; Duru, O. Heuristic estimation of container stacking and reshuffling operations under the containership delay factor and mega-ship challenge. Marit. Policy Manag. 2017, 44, 373–391. [Google Scholar] [CrossRef]

- Wang, S.; Meng, Q. Robust schedule design for liner shipping services. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 1093–1106. [Google Scholar] [CrossRef]

- Qi, X.; Song, D.P. Minimizing fuel emissions by optimizing vessel schedules in liner shipping with uncertain port times. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 863–880. [Google Scholar] [CrossRef]

- Wang, S.; Meng, Q. Liner ship route schedule design with sea contingency time and port time uncertainty. Transp. Res. Part B Methodol. 2012, 46, 615–633. [Google Scholar] [CrossRef]

- Imai, A.; Nishimura, E.; Papadimitriou, S. The dynamic berth allocation problem for a container port. Transp. Res. Part B Methodol. 2001, 35, 401–417. [Google Scholar] [CrossRef]

- Imai, A.; Nishimura, E.; Papadimitriou, S. Berthing ships at a multi-user container terminal with a limited quay capacity. Transp. Res. Part E Logist. Transp. Rev. 2008, 44, 136–151. [Google Scholar] [CrossRef]

- Lai, K.K.; Shih, K. A study of container berth allocation. J. Adv. Transp. 1992, 26, 45–60. [Google Scholar] [CrossRef]

- Berg-Andreassen, J.A.; Prokopowicz, A.K. Conflict of Interest in Deep-Draft Anchorage Usage—Application of QT. J. Waterw. Port Coast. Ocean. Eng. 1992, 118, 75–86. [Google Scholar] [CrossRef]

- Easa, S.M. Approximate queueing models for analyzing harbor terminal operations. Transp. Res. Part B Methodol. 1987, 21, 269–286. [Google Scholar] [CrossRef]

- Kozan, E. Analysis of the economic effects of alternative investment decisions for seaport systems. Transp. Plan. Technol. 1994, 18, 239–248. [Google Scholar] [CrossRef]

- Sen, P. Optimal priority assignment in queues: Application to marine congestion problems. Marit. Policy Manag. 1980, 7, 175–184. [Google Scholar] [CrossRef]

- Canonaco, P.; Legato, P.; Mazza, R.M.; Roberto, M. A queuing network model for the management of berth crane operations. Comput. Oper. Res. 2008, 35, 2432–2446. [Google Scholar] [CrossRef]

- Dragović, B.; Park, N.K.; Radmilović, Z. Ship-berth link performance evaluation: Simulation and analytical approaches. Marit. Policy Manag. 2006, 33, 281–299. [Google Scholar] [CrossRef]

- Kiani, M.; Bonsall, S.; Wang, J.; Wall, A. A break-even model for evaluating the cost of container ships waiting times and berth unproductive times in automated quayside operations. WMU J. Marit. Aff. 2006, 5, 153–179. [Google Scholar] [CrossRef]

- Munisamy, S. Timber terminal capacity planning through queuing theory. Marit. Econ. Logist. 2010, 12, 147–161. [Google Scholar] [CrossRef]

- De Weille, J.; Ray, A. The Optimum Port Capacity. J. Transp. Econ. Policy 1974, 8, 244–259. [Google Scholar]

- Oyatoye, E.O.; Adebiyi, S.O.; Chinweze, O.J.; Bolanle, A.B. Application of Queueing theory to port congestion problem in Nigeria. Eur. J. Bus. Manag. 2011, 3, 23–36. [Google Scholar]

- Edmond, E.D.; Maggs, R.P. How Useful are Queue Models in Port Investment Decisions for Container Berths? J. Oper. Res. Soc. 1978, 29, 741–750. [Google Scholar] [CrossRef]

- El-Naggar, M.E. Application of Queuing Theory to the Container Terminal at Alexandria Seaport. J. Soil Sci. Environ. Manag. 2010, 1, 77–85. [Google Scholar]

- Saeed, N.; Larsen, O.I. Application of queuing methodology to analyze congestion: A case study of the Manila International Container Terminal, Philippines. Case Stud. Transp. Policy 2016, 4, 143–149. [Google Scholar] [CrossRef]

- Smith, T.W.; Jalkanen, J.P.; Anderson, B.A.; Corbett, J.J.; Faber, J.; Hanayama, S.; O’keeffe, E.; Parker, S.; Johansson, L.; Aldous, L.; et al. Third IMO Greenhouse Gas Study; IMO: London, UK, 2014. [Google Scholar]

- Dulebenets, M.A. Multi-objective collaborative agreements amongst shipping lines and marine terminal operators for sustainable and environmental-friendly ship schedule design. J. Clean. Prod. 2022, 342, 130897. [Google Scholar] [CrossRef]

- Tai, H.-H.; Lin, D.-Y. Comparing the unit emissions of daily frequency and slow steaming strategies on trunk route deployment in international container shipping. Transp. Res. Part D Transp. Environ. 2013, 21, 26–31. [Google Scholar] [CrossRef]

- Dulebenets, M.A. Green vessel scheduling in liner shipping: Modeling carbon dioxide emission costs in sea and at ports of call. Int. J. Transp. Sci. Technol. 2018, 7, 26–44. [Google Scholar] [CrossRef]

- Mansouri, S.A.; Lee, H.; Aluko, O. Multi-objective decision support to enhance environmental sustainability in maritime shipping: A review and future directions. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 3–18. [Google Scholar] [CrossRef]

- Cheng, T.C.E.; Zanjirani Farahani, R.; Lai, K.-h.; Sarkis, J. Sustainability in maritime supply chains: Challenges and opportunities for theory and practice. Transp. Res. Part E Logist. Transp. Rev. 2015, 78, 1–2. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, S.; Andersson, H.; Thun, K. Containership Routing and Scheduling in Liner Shipping: Overview and Future Research Directions. Transp. Sci. 2014, 48, 265–280. [Google Scholar] [CrossRef]

- Jansson, J.O.; Shneerson, D. Port Economics; MIT Press: Cambridge, MA, USA, 1982. [Google Scholar]

- Mooney, T. Lagging Berth Productivity Costs Shipping Billions. 2015. Available online: https://www.joc.com/port-news/port-productivity/lagging-berth-productivity-costs-shipping-billions_20151218.html (accessed on 15 October 2017).

- Song, D.P.; Li, D.; Drake, P. Multi-objective optimization for planning liner shipping service with uncertain port times. Transp. Res. Part E Logist. Transp. Rev. 2015, 84, 1–22. [Google Scholar] [CrossRef]

- Dulebenets, M.A. The green vessel scheduling problem with transit time requirements in a liner shipping route with Emission Control Areas. Alex. Eng. J. 2018, 57, 331–342. [Google Scholar] [CrossRef]

- Sundarapandian, V. Probability, Statistics and Queueing Theory; PHI Learning: Delhi, India, 1990. [Google Scholar]

- Qian, S. Operational Research, 4th ed.; Tsinghua University Press: Beijing, China, 2013. [Google Scholar]

- Du, Y.Q.; Chen, Q.S.; Quan, X.W.; Long, L.; Fung, R.Y.K. Berth allocation considering fuel consumption and vessel emissions. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 1021–1037. [Google Scholar] [CrossRef]

- Xi, X.; Changchun, L.; Lixin, M. A bi-objective robust model for berth allocation scheduling under uncertainty. Transp. Res. Part E Logist. Transp. Rev. 2017, 106, 294–319. [Google Scholar]

- Fagerholt, K.; Laporte, G.; Norstad, I. Reducing fuel emissions by optimizing speed on shipping routes. J. Oper. Res. Soc. 2010, 61, 523–529. [Google Scholar] [CrossRef]

- Wang, S. Fundamental properties and pseudo-polynomial-time algorithm for network containership sailing speed optimization. Eur. J. Oper. Res. 2016, 250, 46–55. [Google Scholar] [CrossRef]

- Wang, S.; Meng, Q. Liner shipping network design with deadlines. Comput. Oper. Res. 2014, 41, 140–149. [Google Scholar] [CrossRef]

- Mirjalili, S.; Saremi, S.; Mirjalili, S.M.; Coelho, L.d.S. Multi-objective grey wolf optimizer: A novel algorithm for multi-criterion optimization. Expert Syst. Appl. 2016, 47, 106–119. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- JOC. Berth Productivity: The Trends, Outlook and Market Forces Impacting Ship Turnaround Times. 2017. Available online: https://www.joc.com/ (accessed on 25 April 2017).

- BunkerIndex. 2018. Available online: http://www.bunkerindex.com/prices/europe.php (accessed on 8 October 2018).

- Clarkson 2017. Available online: https://sin.clarksons.net/Timeseries/Advanced (accessed on 10 October 2018).

- Lee, H.; Aydin, N.; Choi, Y.; Lekhavat, S.; Irani, Z. A decision support system for vessel speed decision in maritime logistics using weather archive big data. Comput. Oper. Res. 2017, 98, 330–342. [Google Scholar] [CrossRef]

- Buhaug, Ø.; Corbett, J.J.; Endresen, Ø.; Eyring, V.; Faber, J.; Hanayama, S.; Lee, D.S.; Lee, D.; Lindstad, H.; Markowska, A.Z.; et al. Second IMO Greenhouse Gas Study; International Maritime Organization: London, UK, 2009. [Google Scholar]

- Liao, C.-H.; Tseng, P.-H.; Lu, C.-S. Comparing carbon dioxide emissions of trucking and intermodal container transport in Taiwan. Transp. Res. Part D Transp. Environ. 2009, 14, 493–496. [Google Scholar] [CrossRef]

- Chang, C.C.; Wang, C.M. Assessment of the impact of a carbon tax on speed reductions and operating costs in shipping. Transp. Plan. J. 2010, 39, 441–460. [Google Scholar]

| No. of Ship Arrivals | Chi-Square | ||

|---|---|---|---|

| 0 | 1 | 0.0136 | 0.9299 |

| 1 | 0 | 0.0583 | 1.6907 |

| 2 | 5 | 0.1254 | 0.5112 |

| 3 | 6 | 0.1798 | 0.1184 |

| 4 | 6 | 0.1933 | 0.0277 |

| 5 | 4 | 0.1662 | 0.1394 |

| 6 | 2 | 0.1191 | 0.6120 |

| 7 | 3 | 0.0732 | 0.3625 |

| 8 | 1 | 0.0393 | 0.0171 |

| 9 | 0 | 0.0188 | 0.5452 |

| 10 | 0 | 0.0001 | 0.0029 |

| 11 | 1 | 0.00004 | — |

| Company | No. of Ship Arrivals | No. of Berths | |

|---|---|---|---|

| Zhendong | 124 | 5 | |

| Pudong | 112 | 3 | |

| Hudong | 182 | 4 | |

| Mingdong | 215 | 4 | |

| Shengdong | 146 | 9 | |

| Guandong | 134 | 7 |

| Parameter | Value | Source (s) |

|---|---|---|

| Gharehgozli et al. (2017) [10] | ||

| Gharehgozli et al. (2017) [10] | ||

| (TEUs) | Gharehgozli et al. (2017) [10] | |

| Gharehgozli et al. (2017) [10] | ||

| (TEU/h) | /[50;60;70;75] | Dulebenets (2018) [40] |

| (mins) | 50 | JOC (2017) [50] |

| (knots) | 14.1 (26) | Song et al. (2015) [39] |

| (USD/ton) | 450 (700) | BunkerIndex (2018) [51] |

| Daily chartering cost for a 10,000-TEU containership (USD/day) | 35,000 | Clarkson (2018) [52] |

| (h) | busy ports: 4/idle ports: 6 | Song et al. (2015) [39]; Lee et al. (2017) [53] |

| (tons/h) | 2.50 (0.06) | Tai and Lin (2013) [32] |

| (tons/ton) | 3.17 | Tai and Lin (2013) [32]; Buhaug et al. (2009) [54]; Liao et al. (2009) [55]; Chang and Wang (2010) [56] |

| Min COST | CPU Time (s) | Min CO2 | CPU Time (s) | Min SU | CPU Time (s) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| COST ($) | CO2 (tons) | SU (%) | COST ($) | CO2 (tons) | SU (%) | COST ($) | CO2 (tons) | SU (%) | ||||

| 5 | 198,845,792 | 953,743 | 22.5 | 276.8 | 198,845,792 | 953,743 | 22.6 | 295.8 | 210,299,255 | 1,032,856 | 11 | 312.1 |

| 6 | 139,875,293 | 538,721 | 33.7 | 297.5 | 139,875,293 | 538,721 | 33.7 | 262.9 | 144,793,425 | 570,023 | 0 | 293.2 |

| 7 | 119,176,237 | 396,742 | 0 | 258.2 | 119,176,237 | 396,742 | 0 | 273.1 | 119,176,237 | 397,529 | 0 | 289.5 |

| 8 | 116,043,260 | 369,379 | 11 | 303.9 | 116,043,260 | 369,379 | 11 | 301.9 | 118,437,429 | 384,592 | 0 | 291.2 |

| 9 | 113,871,396 | 354,738 | 0 | 297.5 | 113,871,396 | 354,738 | 0 | 278.3 | 113,875,303 | 353,190 | 0 | 286.1 |

| 6 | 132,581,521 | 485,432 | 22.5 | 305.7 | 132,581,521 | 485,432 | 22.7 | 274.5 | 141,317,289 | 546,742 | 0 | 293.4 |

| 7 | 117,536,973 | 379,209 | 0 | 295.6 | 117,536,973 | 379,209 | 0 | 285.7 | 117,526,781 | 379,568 | 0 | 297.1 |

| 8 | 115,289,727 | 363,576 | 11 | 296.2 | 115,289,727 | 363,576 | 11 | 289.8 | 115,532,980 | 365,341 | 0 | 274.3 |

| 9 | 114,042,975 | 353,709 | 0 | 283.9 | 114,042,975 | 353,709 | 0 | 292.2 | 114,041,289 | 35,709 | 0 | 286.9 |

| 6 | 128,794,567 | 458,209 | 22 | 312.6 | 128,794,567 | 458,209 | 22 | 281.9 | 135,881,809 | 508,029 | 11 | 281.3 |

| 7 | 119,551,283 | 393,129 | 22 | 309.1 | 119,551,283 | 393,129 | 22 | 273.8 | 122,652,891 | 415,901 | 0 | 271.8 |

| 8 | 114,152,709 | 355,190 | 11 | 268.3 | 114,152,709 | 355,190 | 11 | 276.9 | 118,052,132 | 382,318 | 0 | 287.9 |

| 9 | 113,832,781 | 352,771 | 0 | 256.3 | 113,832,781 | 352,771 | 0 | 291.2 | 113,837,819 | 353,110 | 0 | 245.1 |

| 6 | 128,931,249 | 459,231 | 56.9 | 281.3 | 128,931,249 | 459,231 | 57 | 271.4 | 128,929,170 | 459,243 | 57.1 | 291.8 |

| 7 | 116,829,817 | 373,742 | 33.9 | 235.7 | 116,829,817 | 373,742 | 33.4 | 275.3 | 119,189,451 | 389,798 | 11 | 259.8 |

| 8 | 114,398,028 | 359,450 | 0 | 280.3 | 114,398,028 | 359,450 | 0 | 273.8 | 114,397,688 | 35,610 | 0 | 278.5 |

| 9 | 113,837,891 | 353,142 | 0 | 292.5 | 113,837,891 | 353,142 | 0 | 273.5 | 113,834,123 | 352,579 | 0 | 269.8 |

| 7 | 114,319,725 | 356,328 | 45 | 273.5 | 114,319,725 | 356,328 | 44.9 | 286 | 114,319,725 | 356,328 | 33 | 239.7 |

| 8 | 113,838,694 | 353,172 | 0 | 287.2 | 113,838,694 | 353,172 | 0 | 272.1 | 113,838,694 | 353,172 | 0 | 297.3 |

| 9 | 113,838,694 | 353,172 | 0 | 280.1 | 113,838,694 | 353,172 | 0 | 276.5 | 113,838,694 | 353,172 | 0 | 282.1 |

| Min COST | CPU Time (s) | Min CO2 | CPU Time (s) | Min SU | CPU Time (s) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| COST ($) | CO2 (tons) | SU (%) | COST ($) | CO2 (tons) | SU (%) | COST ($) | CO2 (tons) | SU (%) | ||||

| 5 | 198,836,964 | 950,957 | 22 | 273.1 | 198,836,964 | 950,957 | 22 | 284.2 | 210,298,399 | 1,031,697 | 11 | 305.9 |

| 6 | 139,861,951 | 535,511 | 33 | 263.3 | 139,861,951 | 535,511 | 33 | 263.1 | 144,751,373 | 569,954 | 0 | 287.2 |

| 7 | 119,165,893 | 389,719 | 0 | 285.9 | 119,165,893 | 389,719 | 0 | 289.3 | 119,165,893 | 389,719 | 0 | 275.8 |

| 8 | 116,030,160 | 367,629 | 11 | 294.3 | 116,030,160 | 367,629 | 11 | 302.2 | 118,416,911 | 384,442 | 0 | 268.7 |

| 9 | 113,869,903 | 352,096 | 0 | 301.8 | 113,869,903 | 352,096 | 0 | 298.1 | 113,869,903 | 352,096 | 0 | 267.9 |

| 6 | 132,570,091 | 484,144 | 22 | 295.3 | 132,570,091 | 484,144 | 22 | 267.3 | 141,305,733 | 545,682 | 0 | 283.2 |

| 7 | 117,514,984 | 378,089 | 0 | 284.1 | 117,514,984 | 378,089 | 0 | 278.5 | 117,514,984 | 378,089 | 0 | 287.1 |

| 8 | 115,287,658 | 362,399 | 11 | 285.4 | 115,287,658 | 362,399 | 11 | 279.8 | 115,521,633 | 364,047 | 0 | 269.5 |

| 9 | 114,038,902 | 353,602 | 0 | 273.8 | 114,038,902 | 353,602 | 0 | 281.5 | 114,038,902 | 353,602 | 0 | 278.3 |

| 6 | 128,793,787 | 457,542 | 22 | 305.2 | 128,793,787 | 457,542 | 22 | 269.4 | 135,875,406 | 507,113 | 11 | 296.1 |

| 7 | 119,547,195 | 392,405 | 22 | 304.1 | 119,547,195 | 392,405 | 22 | 268.3 | 122,641,977 | 414,206 | 0 | 297.3 |

| 8 | 114,146,407 | 354,359 | 11 | 296.2 | 114,146,407 | 354,359 | 11 | 285.1 | 118,041,516 | 381,798 | 0 | 295.3 |

| 9 | 113,825,165 | 352,096 | 0 | 297.1 | 113,825,165 | 352,096 | 0 | 287.5 | 113,825,165 | 352,096 | 0 | 296.3 |

| 6 | 128,927,798 | 458,171 | 56 | 279.2 | 128,927,798 | 458,171 | 56 | 269.3 | 128,927,798 | 458,171 | 56 | 289.5 |

| 7 | 116,823,463 | 372,902 | 33 | 268.3 | 116,823,463 | 372,902 | 33 | 281.5 | 119,183,279 | 389,526 | 11 | 293.4 |

| 8 | 114,396,338 | 355,805 | 0 | 285.1 | 114,396,338 | 355,805 | 0 | 285.3 | 114,396,338 | 355,805 | 0 | 293.0 |

| 9 | 113,825,165 | 352,096 | 0 | 269.7 | 113,825,165 | 352,096 | 0 | 283.4 | 113,825,165 | 352,096 | 0 | 289.8 |

| 7 | 114,307,116 | 355,491 | 44 | 269.0 | 114,307,116 | 355,491 | 0.4444 | 299.3 | 114,377,076 | 355,984 | 33 | 296.8 |

| 8 | 113,825,165 | 352,096 | 0 | 283.2 | 113,825,165 | 352,096 | 0.0000 | 289.0 | 113,825,165 | 352,096 | 0 | 268.3 |

| 9 | 113,825,165 | 352,096 | 0 | 276.5 | 113,825,165 | 352,096 | 0.0000 | 297.3 | 113,825,165 | 352,096 | 0 | 291.0 |

| Min COST | CPU Time (s) | Min CO2 | CPU Time (s) | Min SU | CPU Time (s) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| COST ($) | CO2 (tons) | SU (%) | COST ($) | CO2 (tons) | SU (%) | COST ($) | CO2 (tons) | SU (%) | ||||

| 5 | 200,068,969 | 959,636 | 44 | 677.5 | 200,068,969 | 959,636 | 44 | 643.4 | 201,399,247 | 969,007 | 11 | 651.4 |

| 6 | 152,320,338 | 622,958 | 11 | 643.8 | 152,320,338 | 622,958 | 11 | 684.1 | 186,994,507 | 867,218 | 0 | 682.3 |

| 7 | 124,364,311 | 426,023 | 0 | 653.7 | 124,364,311 | 426,023 | 0 | 692.7 | 124,364,311 | 426,023 | 0 | 691.4 |

| 8 | 119,083,322 | 388,822 | 0 | 649.1 | 119,083,322 | 388,822 | 0 | 644.0 | 119,083,322 | 388,822 | 0 | 671.3 |

| 9 | 113,960,518 | 353,050 | 0 | 653.8 | 113,960,518 | 353,050 | 0 | 692.1 | 113,960,518 | 353,050 | 0 | 682.9 |

| 6 | 134,778,503 | 499,386 | 22 | 674.2 | 134,778,503 | 499,386 | 22 | 684.1 | 150,745,194 | 611,862 | 11 | 667.3 |

| 7 | 120,369,192 | 397,880 | 11 | 669.2 | 120,369,192 | 397,880 | 11 | 691.9 | 135,647,581 | 505,508 | 0 | 682.2 |

| 8 | 116,181,824 | 368,382 | 11 | 673.8 | 116,181,824 | 368,382 | 11 | 685.6 | 116,516,878 | 370,743 | 0 | 691.0 |

| 9 | 114,845,060 | 358,966 | 0 | 681.7 | 114,845,060 | 358,966 | 0 | 645.0 | 114,845,060 | 358,966 | 0 | 689.1 |

| 6 | 133,570,541 | 490,876 | 56 | 682.5 | 133,570,541 | 490,876 | 56 | 652.0 | 136,668,643 | 512,701 | 22 | 693.0 |

| 7 | 121,314,125 | 404,537 | 33 | 689.4 | 121,314,125 | 404,537 | 33 | 653.0 | 125,899,408 | 436,837 | 0 | 667.2 |

| 8 | 115,244,387 | 361,779 | 22 | 672.5 | 115,244,387 | 361,779 | 22 | 666.2 | 118,182,647 | 382,477 | 0 | 663.2 |

| 9 | 114,154,602 | 354,102 | 0 | 675.8 | 114,154,602 | 354,102 | 0 | 692.1 | 114,154,602 | 354,102 | 0 | 682.3 |

| 6 | 129,914,312 | 465,120 | 100 | 690.2 | 129,914,312 | 465,120 | 100 | 684.3 | 129,914,312 | 465,120 | 100 | 681.4 |

| 7 | 119,980,723 | 395,144 | 33 | 683.5 | 119,980,723 | 395,144 | 33 | 674.5 | 120,835,603 | 401,166 | 11 | 665.3 |

| 8 | 115,708,515 | 365,048 | 0 | 675.9 | 115,708,515 | 365,048 | 0 | 685.6 | 115,708,515 | 365,048 | 0 | 671.8 |

| 9 | 114,002,427 | 353,030 | 11 | 677.4 | 114,002,427 | 353,030 | 11 | 690.9 | 114,338,240 | 355,395 | 0 | 693.0 |

| 7 | 114,530,757 | 356,752 | 56 | 682.0 | 114,530,757 | 356,752 | 56 | 680.8 | 114,541,963 | 356,830 | 33 | 682.3 |

| 8 | 113,926,911 | 352,498 | 0 | 680.1 | 113,926,911 | 352,498 | 0 | 657.1 | 113,926,911 | 352,498 | 0 | 660.5 |

| 9 | 113,870,770 | 352,102 | 0 | 652.1 | 113,870,770 | 352,102 | 0 | 646.2 | 113,870,770 | 352,102 | 0 | 648.7 |

| COST ($) | CO2 (tons) | SU (%) | (knots) | (h) | (knots) | |

|---|---|---|---|---|---|---|

| 113,825,165 | 352,096 | 0 | 9 | 20 | {132,70,138,81,378,62,231,222,222} | {14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1} |

| 113,869,903 | 352,096 | 0 | 9 | 20 | {94,93,176,53,391,104,186,248,223} | {14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1} |

| 113,936,131 | 352,878 | 33 | 8 | 15 | {124,228,105,100,354,42,197,330,57} | {14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1} |

| 113,974,212 | 353,146 | 22 | 8 | 15 | {118,89,111,89,284,211,182,229,84} | {14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1} |

| 114,038,902 | 353,602 | 0 | 9 | 18 | {33,74,100,71,356,97,361,280,140} | {14.1,14.1,15.4,14.1,14.5,14.1,14.1,14.1,14.1} |

| 114,146,407 | 354,359 | 11 | 8 | 20 | {354,249,104,37,366,118,232,213,132} | {19.3,14.1,14.6,14.1,14.1,14.1,14.1,14.1,14.1} |

| 114,307,116 | 355,491 | 44 | 7 | 15 | {181,68,108,41,210,175,199,214,59} | {14.1,15,15,14.1,14.5,14.1,15,15,14.1} |

| 114,377,076 | 355,984 | 33 | 7 | 15 | {110,204,106,37,164,194,256,204,31} | {14.1,14.6,14.1,14.1,15,15,14.1,14.8,15} |

| 114,396,338 | 355,805 | 0 | 8 | 18 | {236,90,112,100,340,82,188,273,80} | {14.1,14.1,14.1,14.1,15.2,14.1,14.1,14.1,14.5} |

| 114,476,122 | 356,682 | 44 | 7 | 15 | {291,74,73,55,153,298,146,255,78} | {14.1,14.1,14.3,14.1,15,15,14.6,15,15} |

| 114,583,222 | 357,436 | 33 | 7 | 15 | {14,203,103,50,172,185,235,147,151} | {14.1,14.1,14.1,14.1,14.1,15, 15,15,15} |

| 115,287,658 | 362,399 | 11 | 8 | 23 | {292,180,95,96,352,82,164,242,191} | {22,14.1,16.6,14.1,14.7,14.1,14.8,14.1,14.1} |

| 115,521,633 | 364,047 | 0 | 8 | 23 | {208,89,149,69,325,113,160,292,97} | {14.1,14.1,14.1,14.1,16,14.1,15.2, 14.1,14.1} |

| 115,592,605 | 364,547 | 22 | 8 | 18 | {197,122,103,51,333,228,192,180,77} | {14.1,14.1,16.6,14.1,16,14.1,15.2,14.1,14.1} |

| 116,120,133 | 368,263 | 0 | 8 | 18 | {218,183,95,151,324,64,160,211,92} | {14.1,14.1,16.6,14.1,16,14.1,15.1,14.1,14.1} |

| 116,823,463 | 372,902 | 33 | 7 | 18 | {193,175,97,88,303,46,163,202,151} | {17.6,17.6,17.6,14.1,15.5,14.1,14.1,14.5,14.1} |

| 118,041,516 | 381,798 | 0 | 8 | 20 | {17,146,182,34,304,100,163,197,107} | {14.8,14.1,14.1,15.2,17.1,14.1,15,15.2,14.1} |

| 114,171,243 | 354,534 | 11 | 9 | 20 | {62,61,112,157,342,51,302,295,129} | {19.3,14.1,14.1,14.1,14.4,14.1,14.1,14.1,14.1} |

| 114,431,927 | 356,370 | 0 | 9 | 20 | {360,170,171,38,426,108,186,259,193} | {14.1,14.1,14.4,14.1,15.3,14.1,14.1,14.1,14.1} |

| 116,030,160 | 367,629 | 11 | 8 | 26 | {13,290,110,34,336,75,238,247,187} | {26,14.1,14.1,15.7,15.4,14.1,14.1,14.1,14.1} |

| COST ($) | CO2 (tons) | SU (%) | (knots) | (h) | (knots) | |

|---|---|---|---|---|---|---|

| 113,870,770 | 352,102 | 0 | 9 | 15 | {207,247,74,125,204,100,152,200,204} | {14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1} |

| 113,902,053 | 352,323 | 22 | 9 | 15 | {95,80,200,23,321,172,42,400,203} | {14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1} |

| 113,926,911 | 352,498 | 0 | 8 | 15 | {338,157,88,87,24,233,302,106,42} | {14.1,14.1,14.1,14.1,14.5,14.1,14.1,14.1,14.1} |

| 113,960,518 | 353,050 | 0 | 9 | 26 | {127,79,152,64,352,65,235,328,186} | {14.1,14.1,14.1,14.1,14.7,14.1,14.1,14.1,14.1} |

| 113,967,387 | 352,783 | 33 | 8 | 15 | {314,20,115,211,30,37,229,246,142} | {14.9,14.9,14.1,14.1,14.1,14.1,14.1, 14.1,15} |

| 114,002,427 | 353,030 | 11 | 9 | 18 | {200,230,272,53,100,212,11,242,192} | {19.6,14.1,14.1,14.1,14.1,14.1,14.1,14.1,14.1} |

| 114,154,602 | 354,102 | 0 | 9 | 20 | {144,142,163,196,139,247,225,64,192} | {14.1,14.1,14.1,14.1,14.9,14.1,14.1,14.1,14.1} |

| 114,173,055 | 354,232 | 11 | 9 | 20 | {90,264,77,351,143,110,84,281,112} | {20,14.1,14.1,14.1,14.1,14.1,14.1, 14.1,14.1} |

| 114,338,240 | 355,395 | 0 | 9 | 18 | {98,195,223,258,184,51,43,236,223} | {14.1,14.1,14.1,14.1,14.1,18,14.1,14.1,14.1} |

| 114,530,757 | 356,752 | 56 | 7 | 15 | {167,151,88,116,146,131,65,118,194} | {14.1,14.6,15,15,15,14.1,14.1,15,15} |

| 114,541,963 | 356,830 | 33 | 7 | 15 | {193,206,36,135,227,69,163,99,48} | {14.1,14.1,15,14.2,15,15,14.7,15,14.1} |

| 114,845,060 | 358,966 | 0 | 9 | 23 | {42,247,65,185,125,297,302,100,148} | {14.1,14.1,14.1,14.1,15.6,14.1,14.1,14.1,14.1} |

| 115,244,387 | 361,779 | 22 | 8 | 20 | {244,87,193,139,105,48,151,164,213} | {19.5,14.1,14.1,14.1,14.1,20,14.1,14.1,14.1} |

| 115,373,967 | 362,691 | 11 | 9 | 23 | {188,210,267,163,120,15,242,267,40} | {23,14.1,14.1,14.1,15.5,14.1,14.1,14.1,14.1} |

| 115,708,515 | 365,048 | 0 | 8 | 18 | {258,142,76,72,228,99,22,184,263} | {14.1,14.1,14.1,14.1,16.2,14.1,14.1,14.3,14.1} |

| 116,181,824 | 368,382 | 11 | 8 | 23 | {180,157,184,186,168,35,47,213,205} | {22.1,14.1,14.1,14.1,16.1,14.1,14.1,14.1,14.1} |

| 116,516,878 | 370,743 | 0 | 8 | 23 | {46,146,265,197,100,23,266,212,88} | {14.1,14.1,14.1,15.2,16.6,14.1,14.1,14.1,14.1} |

| 116,922,940 | 373,603 | 11 | 8 | 18 | {65,121,18,107,290,240,110,207,196} | {14.1,14.1,18,14.1,16.1,14.1,14.1,14.1,14.1} |

| 118,182,647 | 382,477 | 0 | 8 | 20 | {106,82,162,55,104,148,243,230,215} | {14.8,14.8,14.8,14.1,17.3,14.1,14.1,14.1,14.1} |

| 119,083,322 | 388,822 | 0 | 8 | 26 | {182,384,158,227,64,202,46,39,42} | {14.1,14.1,14.1,14.1,17.7,14.1,14.1,14.1,14.1} |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, X.; Chen, Q.; Yin, Y.-Q.; Lau, Y.-y.; Dulebenets, M.A. Multi-Objective Optimization for Ship Scheduling with Port Congestion and Environmental Considerations. J. Mar. Sci. Eng. 2024, 12, 114. https://doi.org/10.3390/jmse12010114

Wen X, Chen Q, Yin Y-Q, Lau Y-y, Dulebenets MA. Multi-Objective Optimization for Ship Scheduling with Port Congestion and Environmental Considerations. Journal of Marine Science and Engineering. 2024; 12(1):114. https://doi.org/10.3390/jmse12010114

Chicago/Turabian StyleWen, Xin, Qiong Chen, Yu-Qi Yin, Yui-yip Lau, and Maxim A. Dulebenets. 2024. "Multi-Objective Optimization for Ship Scheduling with Port Congestion and Environmental Considerations" Journal of Marine Science and Engineering 12, no. 1: 114. https://doi.org/10.3390/jmse12010114

APA StyleWen, X., Chen, Q., Yin, Y.-Q., Lau, Y.-y., & Dulebenets, M. A. (2024). Multi-Objective Optimization for Ship Scheduling with Port Congestion and Environmental Considerations. Journal of Marine Science and Engineering, 12(1), 114. https://doi.org/10.3390/jmse12010114