Model for Wastage Allowance and Strength Properties of Pipe Piles Exposed to Marine Corrosion

Abstract

1. Introduction

2. Materials and Methods

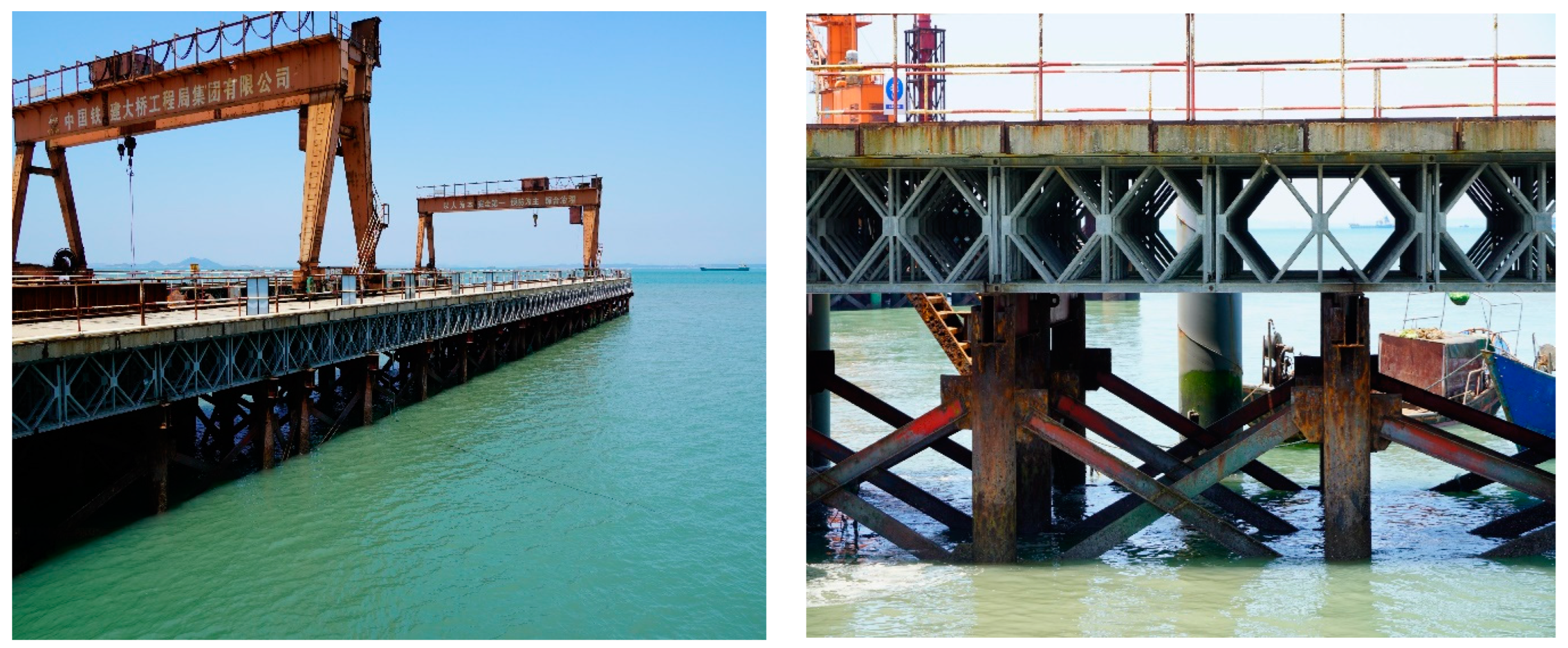

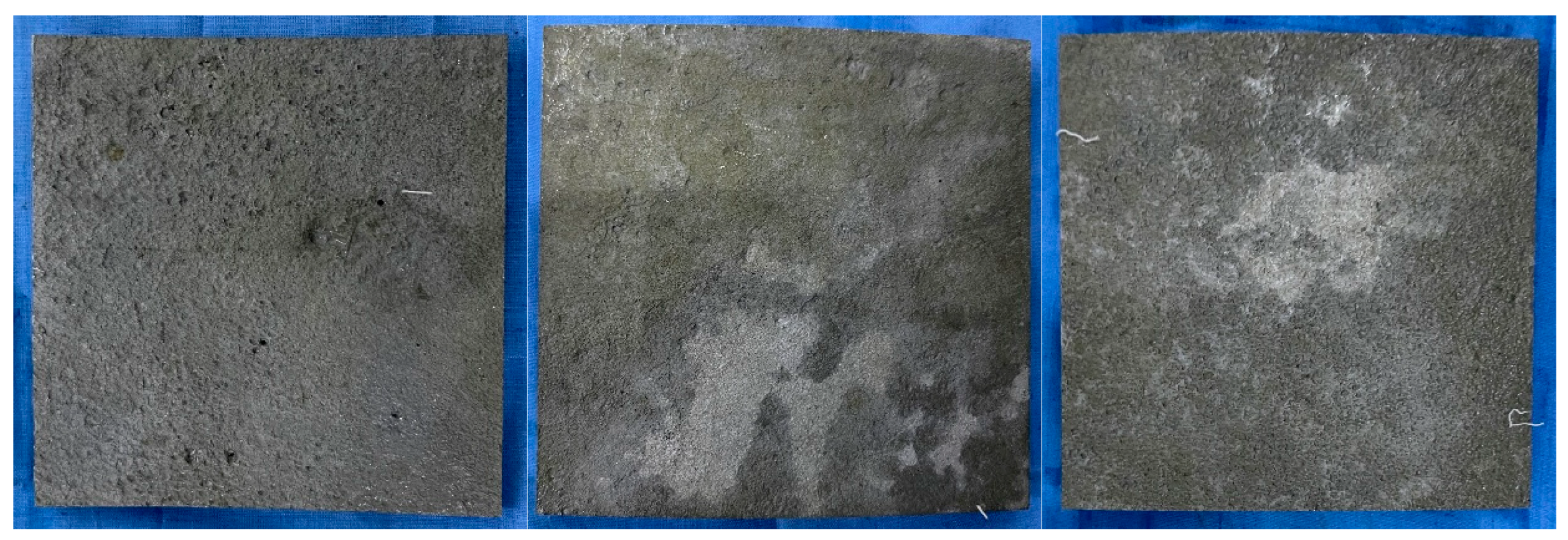

2.1. Specimen Acquisition

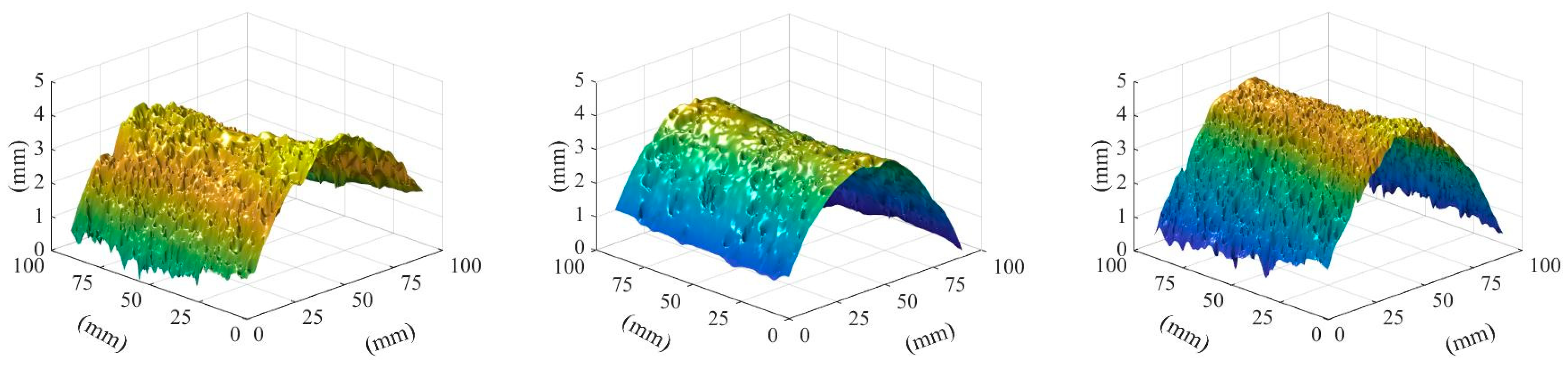

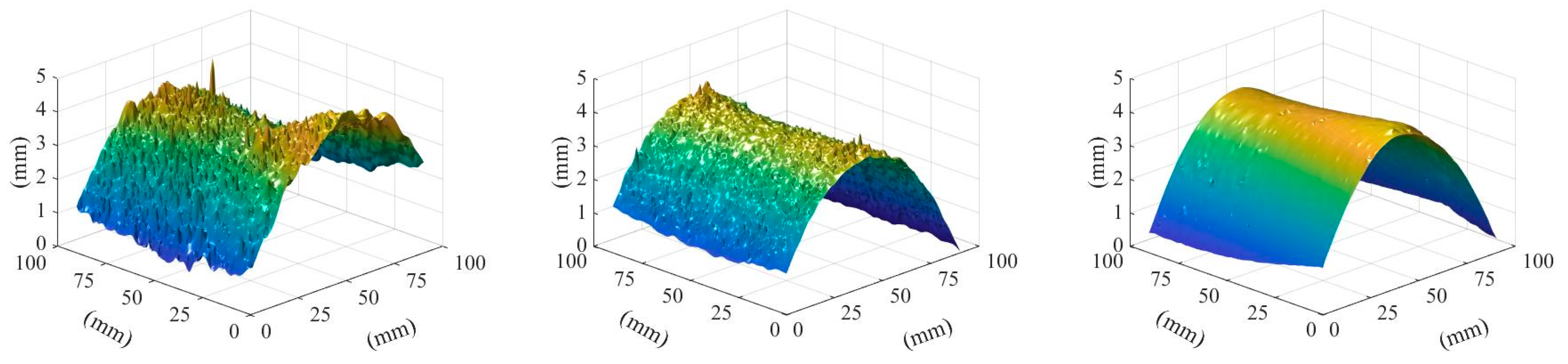

2.2. Reconstruction of Surface Topography

3. Tensile Test

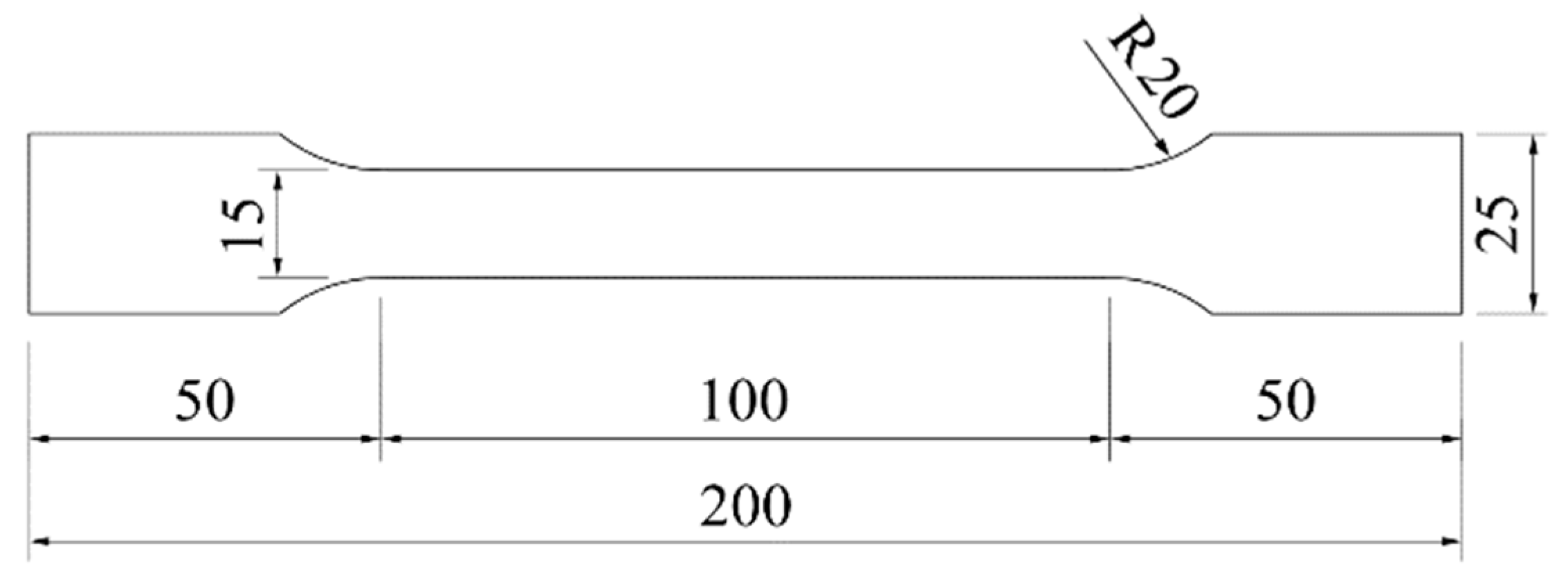

3.1. Tensile Specimen Production

3.2. Test Procedure

4. Strength Assessment

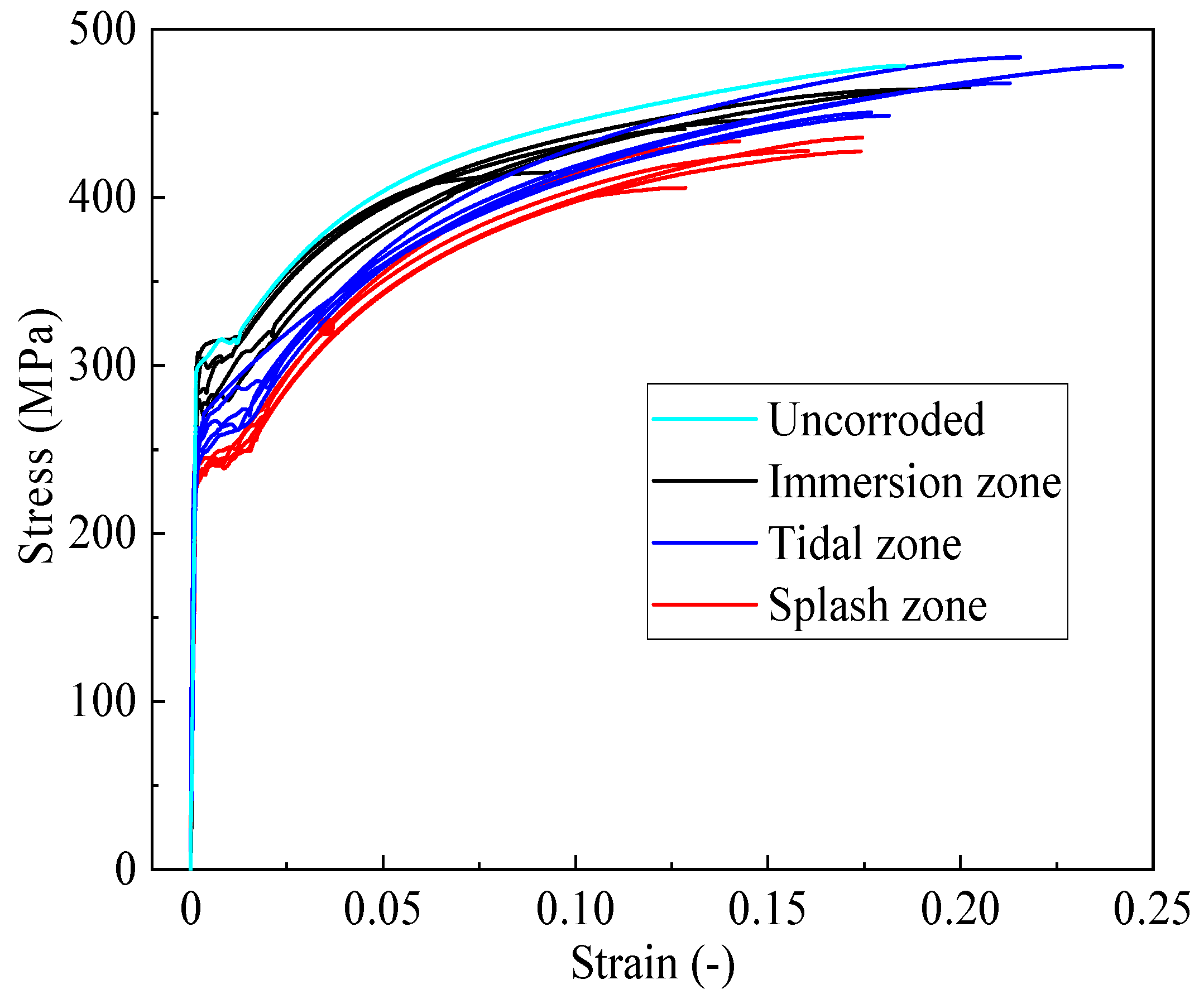

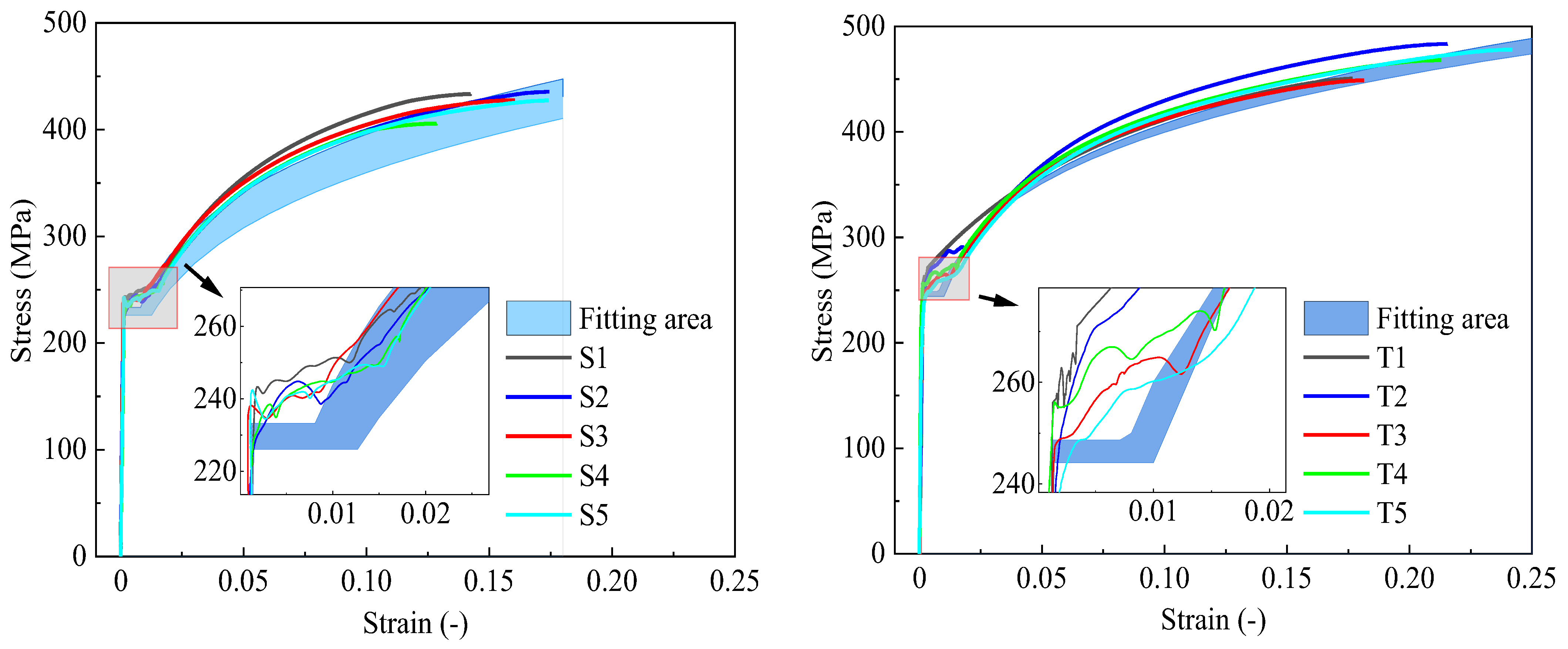

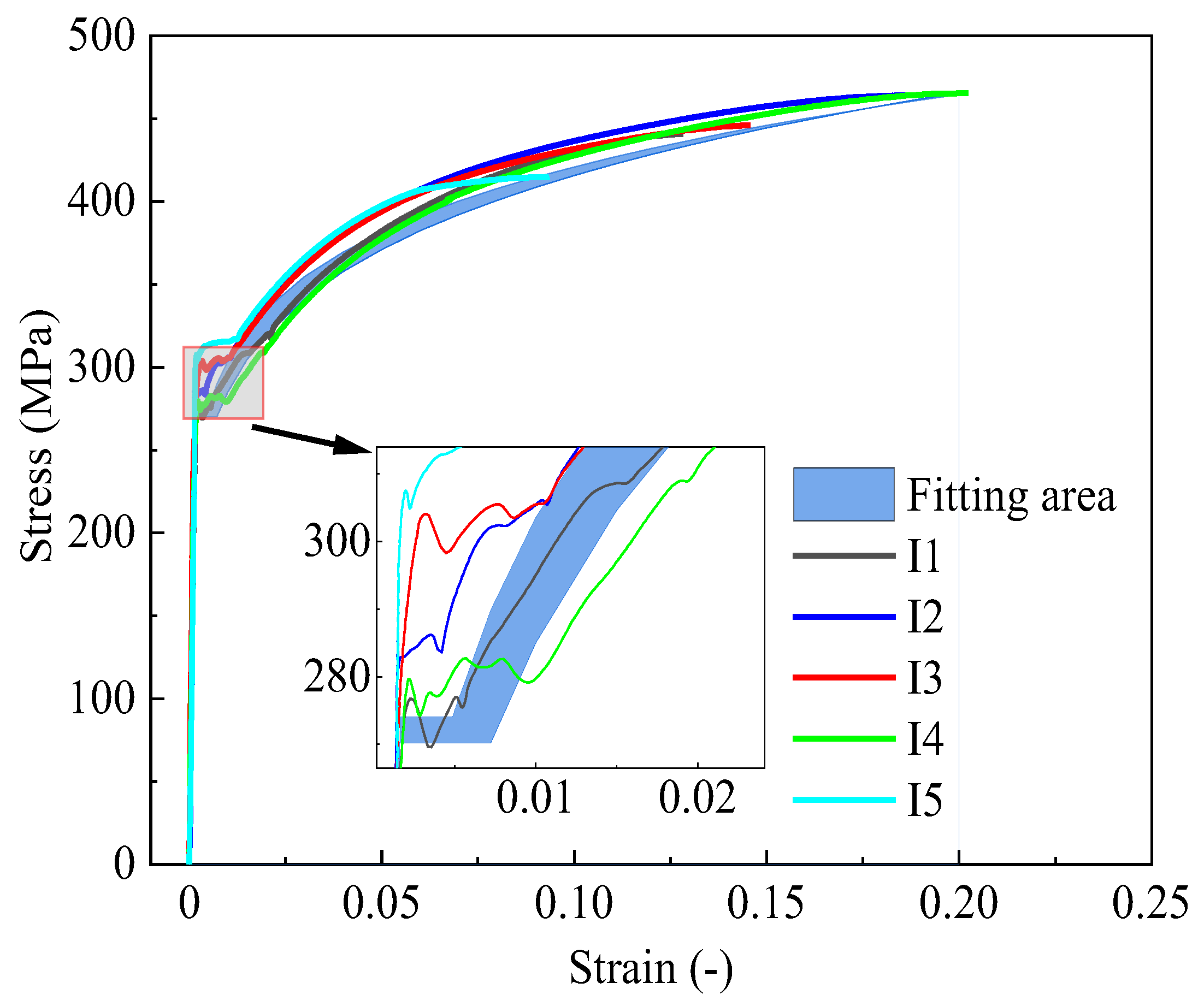

4.1. Stress–Strain Analysis

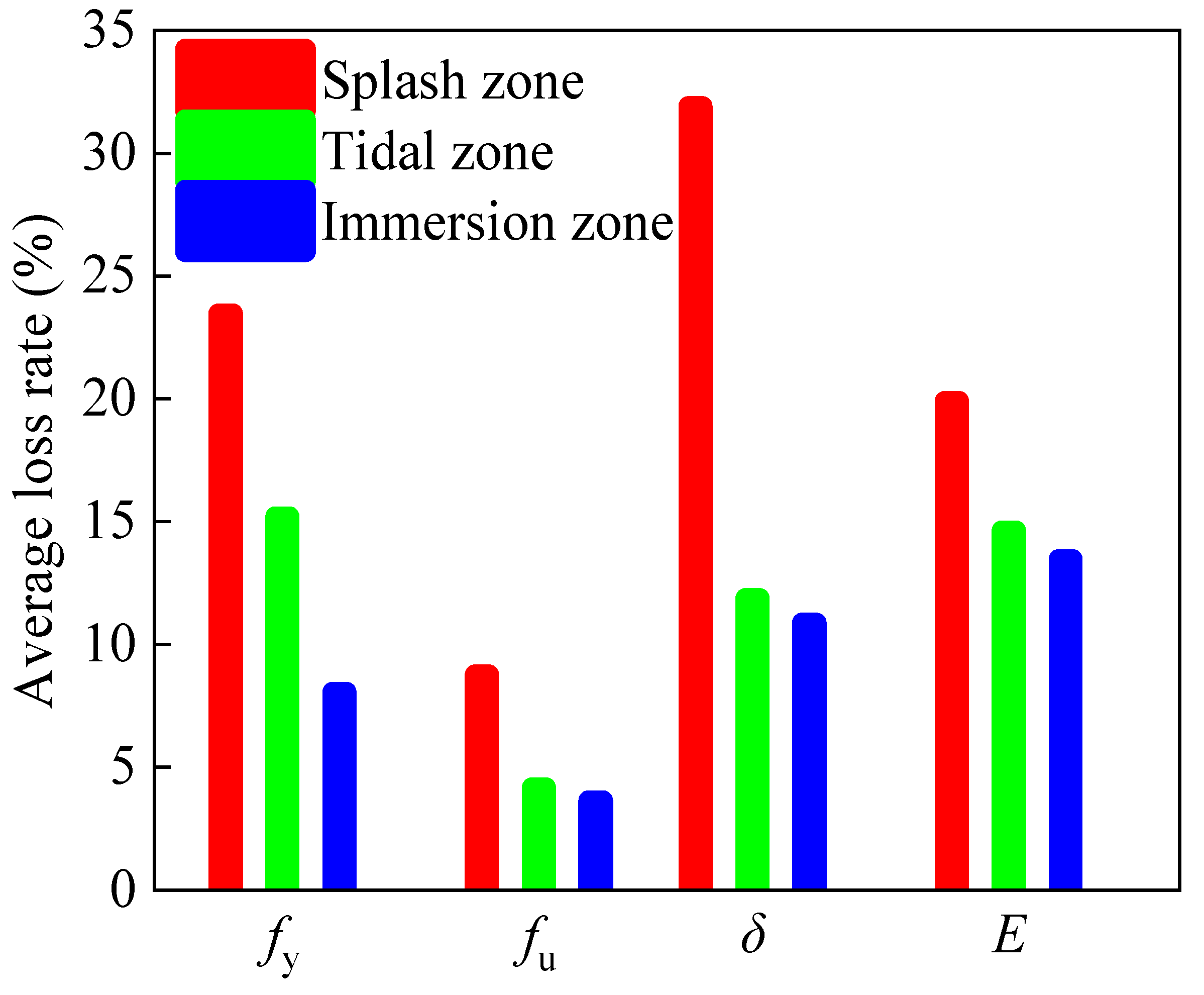

4.2. Mechanical Property Analysis

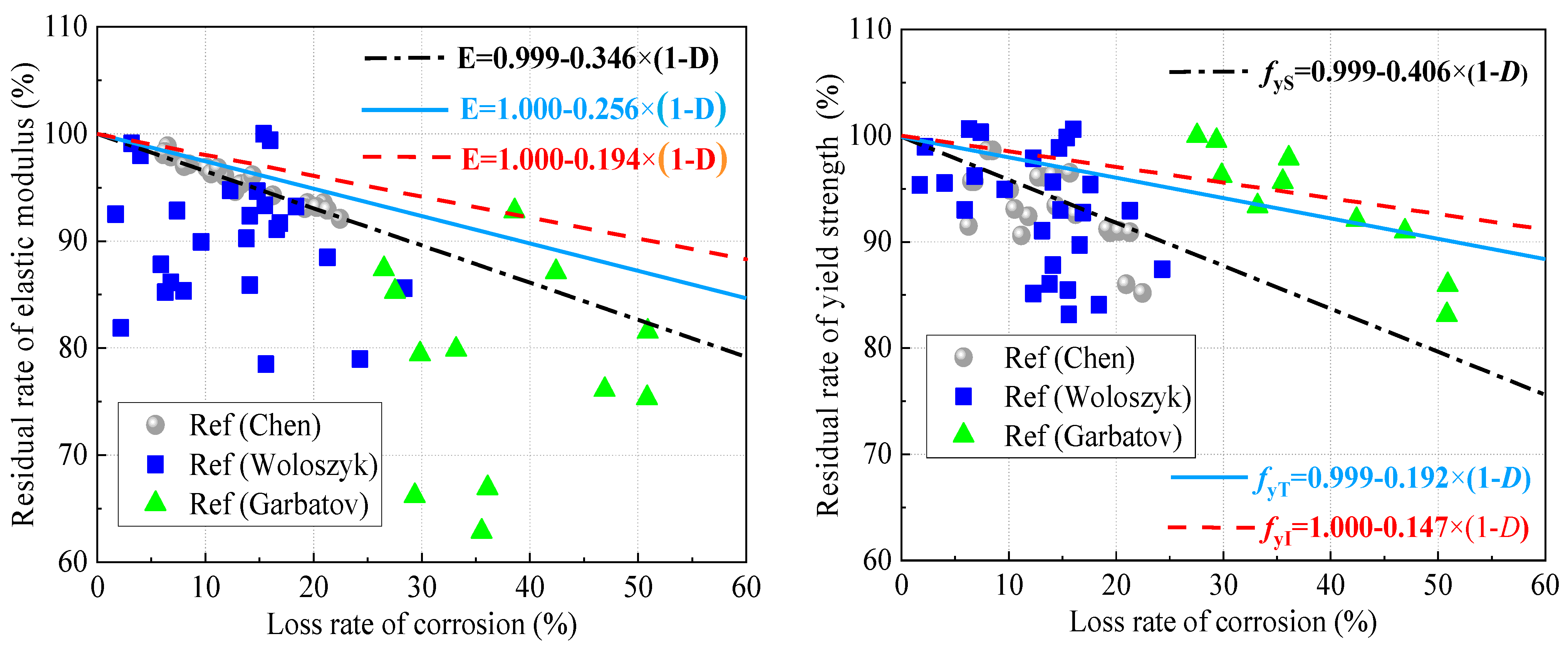

5. Stress–Strain Model

5.1. True Stress–Strain Model

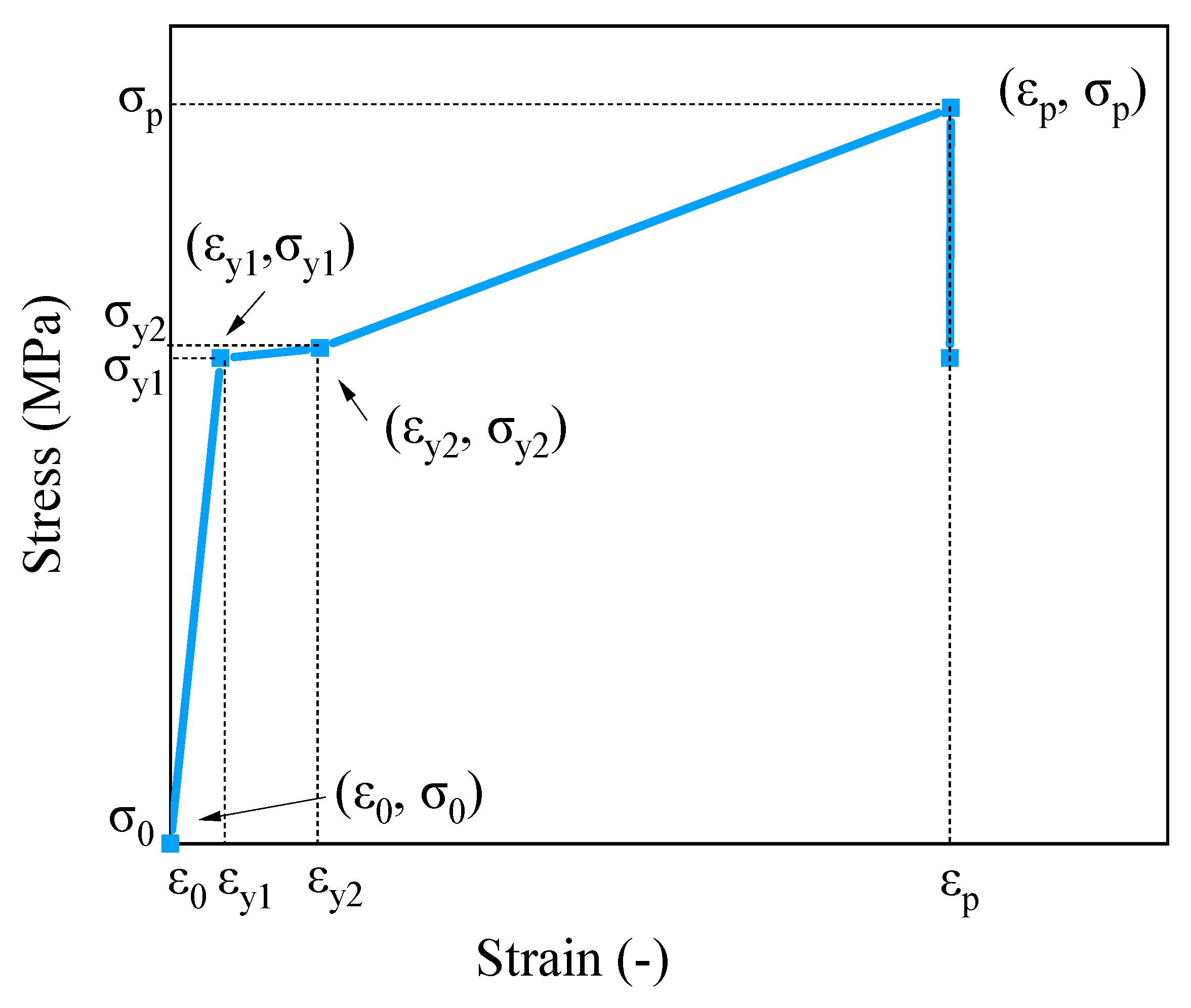

5.2. Tri-Linear Constitutive Model

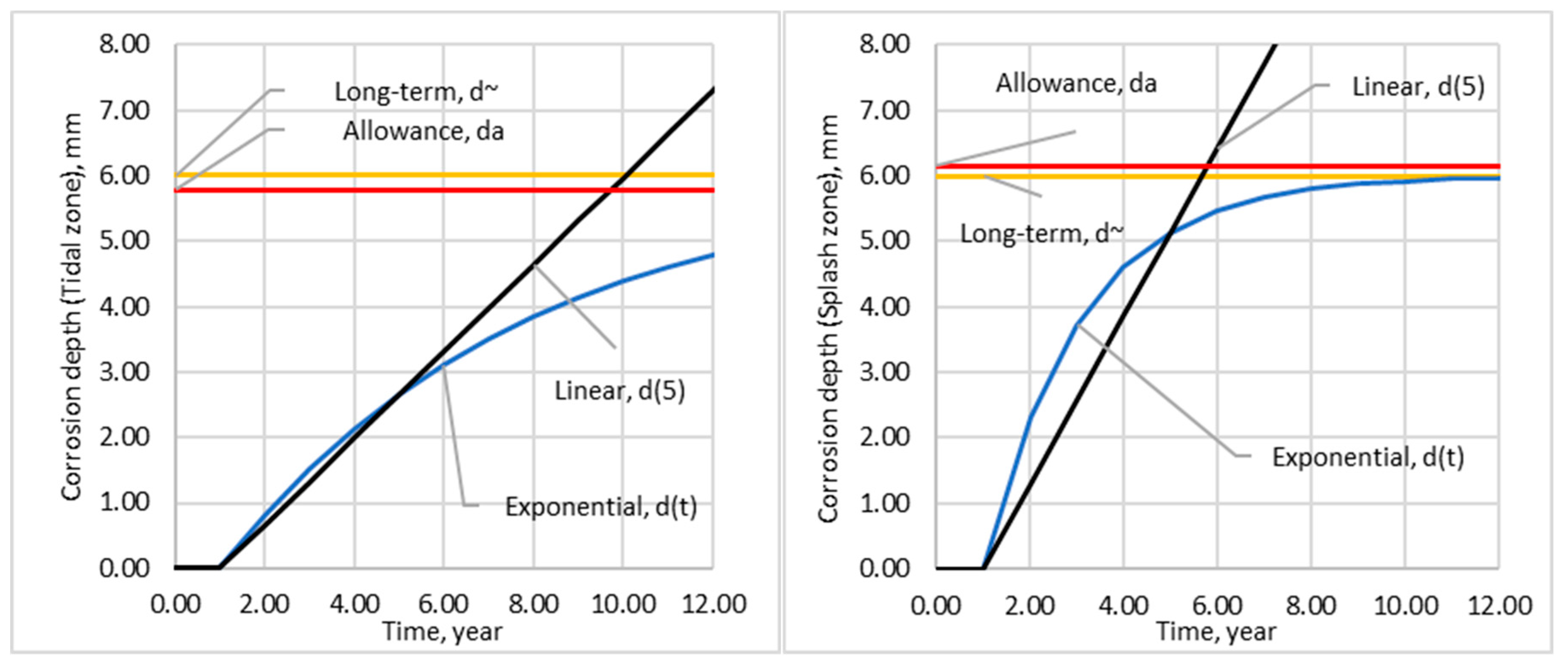

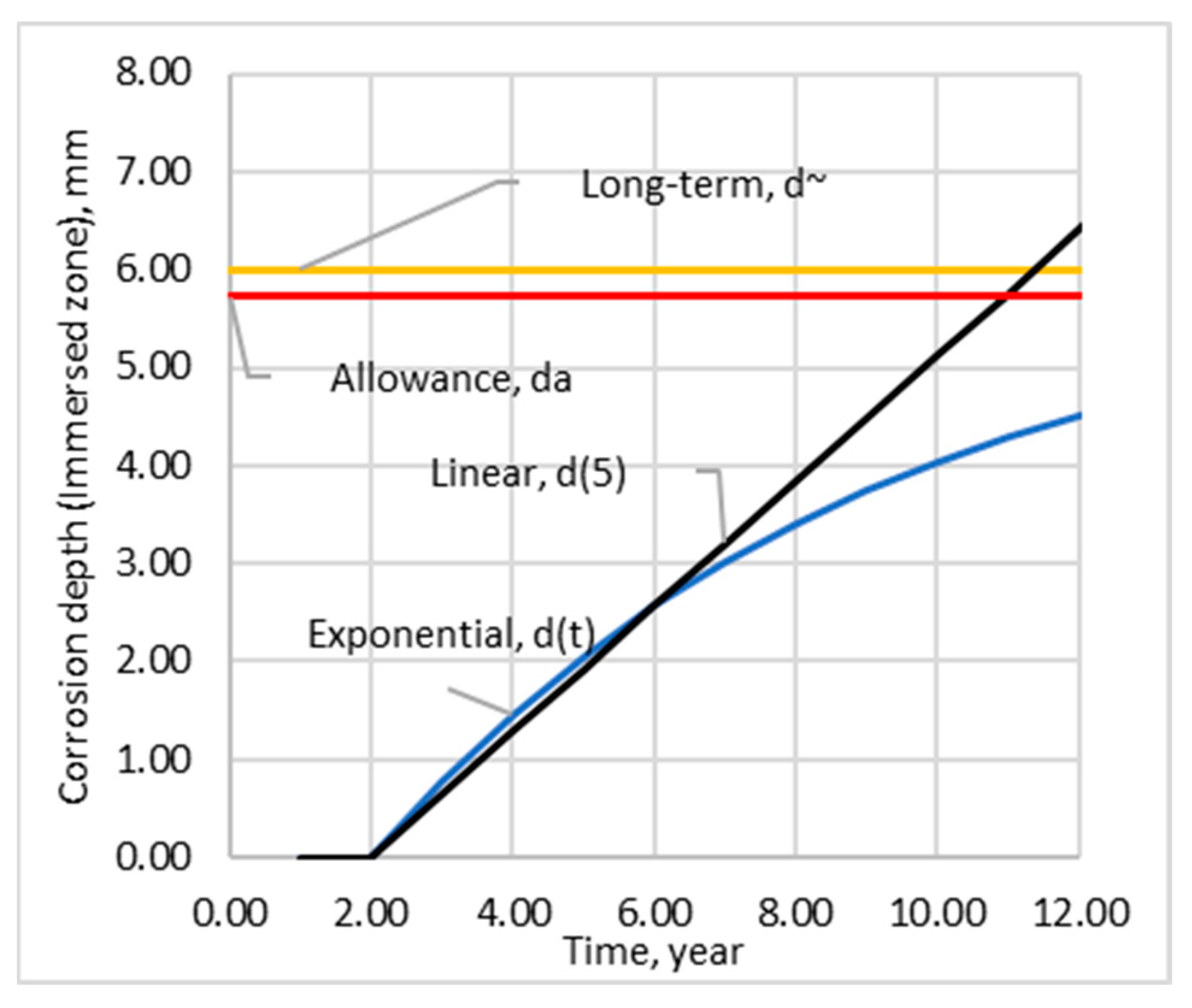

6. Corrosion Degradation Allowance

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, K.; Zhao, M. Mathematical model of homogeneous corrosion of steel pipe pile foundation for offshore wind turbines and corrosive action. Adv. Mater. Sci. Eng. 2016, 2016, 9014317. [Google Scholar] [CrossRef]

- Wei, K.; Yuan, W. Non-linear analysis of offshore jacket structures including ductility of welded tubular connections. In Proceedings of the International Conference on Smart City & Systems Engineering, Hunan, China, 25–26 November 2016; Volume 11, pp. 25–26. [Google Scholar]

- Otieno, M.B.; Beushausen, H.D.; Alexander, M.G. Modelling corrosion propagation in reinforced concrete structures–A critical review. Cem. Concr. Comp. 2011, 33, 240–245. [Google Scholar] [CrossRef]

- Alcántara, J.; Chico, B.; Simancas, J.; Díaz, I.; Morcillo, M. Marine atmospheric corrosion of carbon steel: A Review. Materials 2017, 10, 406. [Google Scholar] [CrossRef] [PubMed]

- Melchers, R.E.; Ahammed, M.; Jeffrey, R.; Simundic, G. Statistical characterization of surfaces of corroded steel plates. Mar. Struct. 2010, 23, 274–287. [Google Scholar] [CrossRef]

- Appuhamy, J.; Kaita, T.; Ohga, M.; Fujii, K. Prediction of residual strength of corroded tensile steel plates. Int. J. Steel. Struct. 2011, 11, 65–79. [Google Scholar] [CrossRef]

- Garbatov, Y.; Guedes Soares, C.; Parunov, J.; Kodvanj, J. Tensile strength assessment of corroded small–scale specimens. Corros. Sci. 2014, 85, 296–303. [Google Scholar] [CrossRef]

- Garbatov, Y.; Parunov, J.; Kodvanj, J.; Saad-Eldeen, S.; Guedes Soares, C. Experimental assessment of tensile strength of corroded steel specimens subjected to sandblast and sandpaper cleaning. Mar. Struct. 2016, 49, 18–30. [Google Scholar] [CrossRef]

- Sheng, J.; Xia, J. Effect of simulated pitting corrosion on the tensile properties of steel. Constr. Build. Mater. 2017, 131, 90–100. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, X.H.; Guedes Soares, C. Experimental analysis of residual ultimate strength of stiffened panels with pitting corrosion under compression. Eng. Struct. 2017, 152, 70–86. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, Q.; Tu, S.; Wang, Y.; Li, Y.; Huang, Y. A study on a time-variant corrosion model for immersed steel plate elements considering the effect of mechanical stress. Ocean. Eng. 2016, 125, 134–146. [Google Scholar] [CrossRef]

- Gathimaba, N.; Kitane, Y.; Yoshida, T.; Itoh, Y. Surface roughness characteristics of corroded steel pipe piles exposed to marine environment. Constr. Build. Mater. 2019, 203, 267–281. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, L.; Zhang, Z.; Wang, Y.; Qiu, L. Study on tensile properties of Q235nh after corrosion. Steel Constr. 2019, 37, 1–7. [Google Scholar] [CrossRef]

- Guo, Q.; Zhao, Y.; Xing, Y.; Jiao, J.; Fu, B.; Wang, Y. Experimental and numerical analysis of mechanical behaviours of long-term atmospheric corroded Q235 steel. Structures 2022, 39, 115–131. [Google Scholar] [CrossRef]

- Xia, R.; Jia, C.; Liu, C.; Liu, P.; Zhang, S. Non-uniform corrosion characteristics of the steel pipe pile exposed to marine environments. Ocean. Eng. 2023, 272, 113873. [Google Scholar] [CrossRef]

- Woloszyk, K.; Garbatov, Y.; Klosowski, P. Stress–strain model of lower corroded steel plates of normal strength for fitness-for-purpose analyses. Constr. Build. Mater. 2022, 323, 126560. [Google Scholar] [CrossRef]

- Paik, J.K.; Thayamballi, A.K.; Park, Y.I.; Hwang, J.S. A time-dependent corrosion wastage model for seawater ballast tank structures of ships. Corros. Sci. 2004, 46, 471–486. [Google Scholar] [CrossRef]

- Paik, J.K.; Kim, D.K. Advanced method for the development of an empirical model to predict time-dependent corrosion wastage. Corros. Sci. 2012, 63, 51–58. [Google Scholar] [CrossRef]

- Kiani, K.; Shodja, H.M. Prediction of the penetrated rust into the microcracks of concrete caused by reinforcement corrosion. Appl. Math Model. 2011, 35, 2529–2543. [Google Scholar] [CrossRef]

- Kiani, K.; Shodja, H.M. Response of reinforced concrete structures to macrocell corrosion of reinforcements. Part I: Before propagation of microcracks via an analytical approach. Nucl. Eng. Des. 2011, 241, 4871–4892. [Google Scholar] [CrossRef]

- Kiani, K.; Shodja, H.M. Response of reinforced concrete structures to macrocell corrosion of reinforcements. Part II: After propagation of microcracks via a numerical approach. Nucl. Eng. Des. 2012, 242, 7–18. [Google Scholar] [CrossRef]

- Shodja, H.M.; Kiani, K.; Hashemian, A. A model for the evolution of concrete deterioration due to reinforcement corrosionh. Math Comput. Model 2010, 52, 1403–1422. [Google Scholar] [CrossRef]

- Gong, M. Metal Corrosion Theory and Corrosion Control; Chemical Industry Press: Beijing, China, 2018. [Google Scholar]

- GB/T 16545-2015; Removal of Corrosion Products from Corrosion Specimens of Metals and Alloys. Standards Press of China: Beijing, China, 2015.

- GB/T 700-2006; Carbon Structural Steel. Standards Press of China: Beijing, China, 2006.

- GB/T 228.1-2010; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2010.

- Garbatov, Y.; Guedes Soares, C. Experimental evaluation of ageing marine structures. In Proceedings of the SNAME Maritime Convention and 5th World Maritime Technology Conference, Providence, RI, USA, 3–7 November 2015; p. D021S005R008. [Google Scholar] [CrossRef]

- Bai, P.; Ni, Y.; Lei, D. Measurement of true stress-strain relationship of stainless steel based on digital image correlation technique. Sci. Technol. Eng. 2020, 20, 5240–5246. [Google Scholar] [CrossRef]

- Chen, R. Research on the Degradation of Steel Structures for the Needs of Structural Life-Cycle Design and Time-Dependent Reliability in Corrosive Environment; Southeast University: Nanjing, China, 2022. [Google Scholar] [CrossRef]

- Woloszyk, K.; Garbatov, Y. Advances in Modelling and Analysis of Strength of Corroded Ship Structures. J. Mar. Sci. Eng. 2022, 10, 807. [Google Scholar] [CrossRef]

- de la Fuente, D.; Díaz, I.; Simancas, J.; Chico, B.; Morcillo, M. Long-term atmospheric corrosion of mild steel. Corros. Sci. 2011, 53, 604–617. [Google Scholar] [CrossRef]

- Melchers, R.E. Probabilistic Modelling of Marine Corrosion of Steel Specimens. In Proceedings of the 5th International Offshore and Polar Engineering Conference, The Hague, The Netherlands, 11–16 June 1995; pp. 204–210. [Google Scholar]

- Melchers, R.E. Modelling of Marine Corrosion of Steel Specimens. Corros. Test. Nat. Waters 1997, 2, 20–23. [Google Scholar]

- Yamamoto, N.; Ikagaki, K. A Study on the Degradation of Coating and Corrosion on Ship´s Hull Based on the Probabilistic Approach. J. Offshore Mech. Arct. 1998, 120, 121–128. [Google Scholar] [CrossRef]

- Melchers, R.E. Probabilistic Modelling of Immersion Marine Corrosion. In Structural Safety and Reliability; Shiraishi, N., Shinozuka, M., Wen, Y., Eds.; Balkema: Boca Raton, FL, USA, 1998; pp. 1143–1149. [Google Scholar]

- Yamamoto, N.; Yao, T. Hull girder strength of a tanker under longitudinal bending considering strength diminution due to corrosion. In Proceedings of the Structural Safety and Reliability, 8th International Conference (ICOSSAR2001), Newport Beach, CA, USA, 17–22 June 2001. [Google Scholar]

- Silva, J.E.; Garbatov, Y.; Guedes Soares, C. Reliability assessment of a steel plate subjected to distributed and localized corrosion wastage. Eng. Struct. 2014, 59, 13–20. [Google Scholar] [CrossRef]

- Rackwitz, R. First order reliability theories and stochastic models. In Proceedings of the International Conference ICOSSAR’77I, Munich, Germany, 19–21 September 1977. [Google Scholar]

- Gollwitzer, S.; Rackwitz, R. First-Order System Reliability of Structural Systems. In Proceedings of the 4th International Conference on Structural Safety and Reliability, Kobe, Japan, 27–29 May 1985; pp. 171–218. [Google Scholar]

- Garbatov, Y. Risk-based corrosion allowance of oil tankers. Ocean. Eng. 2020, 213, 107753. [Google Scholar] [CrossRef]

| Characteristic | Value |

|---|---|

| Mean tidal range, m | 4.3 |

| Water temperature, °C | 19.4 |

| Maximum water velocity, m/s | 2.23 |

| Average water velocity, m/s | 1.03 |

| Dissolved oxygen saturation, % | 95–100 |

| PH | 8.1–8.3 |

| Salinity, % | 3.0–3.2% |

| Average wind velocity, m/s | 6.9 |

| Tidal cycle, times/day | 2 |

| The most enormous wave height in history, m | 16 |

| Composition | C | Si | Mn | P | S |

|---|---|---|---|---|---|

| Content (%) | 0.176 | 0.198 | 0.5 | 0.023 | 0.019 |

| GB/T 700-2006 | ≤0.20 | ≤0.35 | ≤1.40 | ≤0.045 | ≤0.045 |

| Zone | Specimen | , (mm) | , (%) | Mean, (%)/ Var, (mm2) |

|---|---|---|---|---|

| Splash | S-1 | 6.972 | 58.1 | 57.24/ 0.0143 |

| S-2 | 6.979 | 58.2 | ||

| S-3 | 6.877 | 57.3 | ||

| S-4 | 6.691 | 55.8 | ||

| S-5 | 6.815 | 56.8 | ||

| Tidal | T-1 | 9.367 | 78.1 | 77.92/ 0.0233 |

| T-2 | 9.496 | 79.1 | ||

| T-3 | 9.094 | 75.8 | ||

| T-4 | 9.356 | 78.0 | ||

| T-5 | 9.428 | 78.6 | ||

| Immersion | I-1 | 9.422 | 78.5 | 78.64/ 0.0004 |

| I-2 | 9.451 | 78.8 | ||

| I-3 | 9.429 | 78.6 | ||

| I-4 | 9.464 | 78.9 | ||

| I-5 | 9.413 | 78.4 | ||

| Intact | P-1 | 4.003 | - | - |

| No. | , (MPa) | Mean, (MPa)/ Var, (MPa2) | , (MPa) | Mean, (MPa)/ Var, (MPa2) | , (%) | Mean, (%)/ Var, - | 105, (MPa) | Mean, 105 (MPa)/ Var, (MPa2) |

|---|---|---|---|---|---|---|---|---|

| S-1 | 248.81 | 237.40/ 42.005 | 382.01 | 371.51/ 52.161 | 20.38 | 22.68/ 9.853 | 1.67 | 1.67/0.001 |

| S-2 | 236.51 | 373.06 | 22.65 | 1.68 | ||||

| S-3 | 233.90 | 372.46 | 24.10 | 1.70 | ||||

| S-4 | 233.95 | 362.70 | 19.16 | 1.63 | ||||

| S-5 | 233.81 | 367.33 | 27.12 | 1.65 | ||||

| T-1 | 254.43 | 263.00/ 104.467 | 384.82 | 390.16/ 59.854 | 25.40 | 29.35/ 23.300 | 1.71 | 1.78/0.010 |

| T-2 | 279.48 | 402.60 | 35.00 | 1.93 | ||||

| T-3 | 258.37 | 382.68 | 24.58 | 1.71 | ||||

| T-4 | 266.15 | 390.60 | 33.90 | 1.83 | ||||

| T-5 | 256.56 | 390.12 | 27.86 | 1.70 | ||||

| I-1 | 268.62 | 285.12/ 229.482 | 392.41 | 392.33/ 27.420 | 28.5 | 29.68/ 3.367 | 1.73 | 1.80/0.009 |

| I-2 | 282.41 | 398.54 | 30.99 | 1.94 | ||||

| I-3 | 296.93 | 392.89 | 24.53 | 1.76 | ||||

| I-4 | 273.46 | 393.77 | 34.56 | 1.85 | ||||

| I-5 | 304.17 | 384.04 | 29.83 | 1.72 | ||||

| P-1 | 310.13 | 407.18 | 33.3 | 2.08 |

| No. | Loss Rate, (%) | Mean, (%)/ Var, - | Loss Rate, (%) | Mean, (%)/ Var, - | Loss Rate, (%) | Mean (%)/ Var, - | Loss Rate, (%) | Mean (%)/ Var, - |

|---|---|---|---|---|---|---|---|---|

| S-1 | 19.77 | 23.45/ 4.370 | 6.18 | 8.76/ 3.145 | 38.80 | 31.89/ 88.829 | 19.71 | 19.90/ 1.682 |

| S-2 | 23.74 | 8.38 | 31.98 | 19.23 | ||||

| S-3 | 24.58 | 8.53 | 27.63 | 18.27 | ||||

| S-4 | 24.56 | 10.92 | 42.46 | 21.63 | ||||

| S-5 | 24.61 | 9.79 | 18.56 | 20.67 | ||||

| T-1 | 17.96 | 15.20/ 10.866 | 5.49 | 4.18/ 3.619 | 23.72 | 11.87/ 210.164 | 17.79 | 14.64/ 23.933 |

| T-2 | 9.88 | 1.12 | −5.11 | 7.21 | ||||

| T-3 | 16.69 | 6.02 | 26.19 | 17.89 | ||||

| T-4 | 14.18 | 4.07 | −1.80 | 12.02 | ||||

| T-5 | 17.27 | 4.19 | 16.34 | 18.27 | ||||

| I-1 | 13.38 | 8.06/ 23.838 | 3.63 | 3.65/ 1.653 | 14.41 | 10.87/ 120.531 | 16.83 | 13.46/20.230 |

| I-2 | 8.94 | 2.12 | 6.94 | 6.73 | ||||

| I-3 | 4.26 | 3.51 | 26.34 | 15.38 | ||||

| I-4 | 11.82 | 3.29 | −3.78 | 11.06 | ||||

| I-5 | 1.92 | 5.68 | 10.42 | 17.31 |

| Zone | Average Loss Rate of | Average Loss Rate of | Average Loss Rate of | Average Loss Rate of |

|---|---|---|---|---|

| S-zone | 23.45% | 8.76% | 31.89% | 19.90% |

| T-zone | 15.20% | 4.18% | 11.87% | 14.63% |

| I-zone | 8.06% | 3.65% | 10.87% | 13.46% |

| S-zone | 0.514 | 0.722 | 0.851 |

| T-zone | 0.474 | 0.770 | 0.578 |

| I-zone | 0.592 | 0.515 | 0.794 |

| Equation | R2 | Equation | R2 | Equation | R2 | Equation | R2 | |

|---|---|---|---|---|---|---|---|---|

| S-zone | (4) | 0.539 | (7) | 0.350 | (12) | 0.164 | (15) | 0.181 |

| T-zone | (5) | 0.189 | (8) | 0.225 | (13) | 0.154 | (16) | 0.195 |

| I-zone | (6) | 0.724 | (9) | 0.197 | (14) | 0.286 | (17) | 0.391 |

| d(5), (mm) | , (Years) | |

|---|---|---|

| S-zone | 5.13 | 2.07 |

| T-zone | 2.65 | 6.86 |

| I-zone | 2.56 | 7.17 |

| S-zone | 6.1487 | 1.0165 | 1.0082 |

| T-zone | 5.7876 | 1.0141 | 1.0148 |

| I-zone | 5.7207 | 1.0157 | 1.0102 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, R.; Garbatov, Y.; Liu, C.; Sun, M. Model for Wastage Allowance and Strength Properties of Pipe Piles Exposed to Marine Corrosion. J. Mar. Sci. Eng. 2024, 12, 113. https://doi.org/10.3390/jmse12010113

Xia R, Garbatov Y, Liu C, Sun M. Model for Wastage Allowance and Strength Properties of Pipe Piles Exposed to Marine Corrosion. Journal of Marine Science and Engineering. 2024; 12(1):113. https://doi.org/10.3390/jmse12010113

Chicago/Turabian StyleXia, Ruilin, Yordan Garbatov, Changyong Liu, and Mingyang Sun. 2024. "Model for Wastage Allowance and Strength Properties of Pipe Piles Exposed to Marine Corrosion" Journal of Marine Science and Engineering 12, no. 1: 113. https://doi.org/10.3390/jmse12010113

APA StyleXia, R., Garbatov, Y., Liu, C., & Sun, M. (2024). Model for Wastage Allowance and Strength Properties of Pipe Piles Exposed to Marine Corrosion. Journal of Marine Science and Engineering, 12(1), 113. https://doi.org/10.3390/jmse12010113