1. Introduction

It is argued that the carriage of dangerous goods

1 in packaged form shall comply with the relevant provisions of the International Maritime Dangerous Goods (IMDG) Code

2, and that shipping operators (including shipping companies, terminal operators, shippers, watchmen, etc.) should be thoroughly trained so as to have the correct awareness to conduct their duties (Chen et al. [

1]). The port authorities must, in addition, regulate the safe operation rules for specific cargoes (e.g., pressurized tanks) during different types of operating environments, such as storage and segregation, and loading and unloading [

2]. In addition, the necessary safe facilities (including fire-fighting equipment) should be well-established, and the required policies on marking, storage limitations (e.g., classes

3 and the maximum amount and height of dangerous goods), segregation, and emergency operation procedures when dangerous goods suffer from risk issues (e.g., explosion or spillage) should be implemented and monitored.

Nevertheless, although many strict regulations have been established and conducted, and despite the undertaking of much research into storing and preventing accidents involving dangerous goods (e.g., Chen et al. [

1], Jia and Fagerholt [

2], Birk [

3], and Hervas-Peralta et al. [

4]), accidents due to the mishandling of dangerous goods in the port area still occur, arguably due to the many complex and unpredictable factors surrounding their storage and behavior. For example, on 12 August 2015, dangerous cargo in the Ruihai International Logistics warehouses at Tianjin Port exploded and resulted in 165 people dying and 8 people going missing [

4,

5,

6,

7]. This explosion resulted in severe damage around the accident site up to distances of at least three kilometers [

7]. Moreover, on 4 August 2020, an explosion in Beirut Port (Lebanon) caused the deaths of 200 people and devastated 300,000 homes, also leaving countless Lebanese injured and traumatized. This was all due to the inadequate storage of 2750 tons of ammonium nitrate

4. Arguably, and analogously with the concept of a chain reaction or of a domino-type effect of one domino falling one after another, it is the first stage, or first domino, that is the key one in determining what subsequently happens. Similarly, in the case of accidents involving dangerous goods in port environments, the data from this paper show that it is the first, determining stage that is perceived by the experts consulted to be the key one. According to the statistics of the European Maritime Safety Agency report

5, regarding the causes of accident events for ships with hazardous material

6 from 2014 to 2021, ‘environment (44.3%)’ is the main factor, followed by ‘human behavior (27.5%)’, ‘rule, procedure, and training (16.1%)’, and ‘tools and equipment (12.1%)’. Thus, the port and ship authorities should regularly collect and analyze environmental information (e.g., typhoons approaching) and adopt effective response strategies. Improving response strategies and avoiding accidents of dangerous goods requires a complex decision analysis. Such a research problem with multi-criteria decision-making methods has seldom been investigated in the past, especially in Taiwan. In order to fill this research gap, this paper adopts Taiwan as a case study to illustrate key criteria (sub-criteria) via an expert questionnaire survey, the results of which are transferable to other contexts.

Port operations themselves are subject to many risks due to the complex environment and the existence of uncertain factors. In order to identify the potential risks of dangerous goods and quickly recover port operations when disaster happens, a critical safety assessment model with key criteria for resource allocation on dangerous goods operations in the port area is important. Such a model would both complement and build upon the findings and recommendations of existing research. For example, in previous research, Birk [

3] conducted the fire testing of pressure vessels in dangerous goods transportation in Canada, finding that small-scale testing often fails to replicate the reality of what happens to dangerous goods; as revealed by the large-scale testing of goods in their natural transportation contexts. Chen et al. [

1] conducted a factor diagnosis of dangerous goods accidents in China’s ports to identify three key areas to focus on when handling, storing, and transporting dangerous goods: warehousing management, facilities equipment, and goods registration. Jia and Fagerholt [

2] studied step-wise stowage planning in roll-on roll-off ships transporting dangerous goods with a view to identifying the optimum processes for the safe and economically efficient transport and storage of dangerous goods using roll-on roll-off shipping. Further, in terms of port issues, Hervás-Peralta et al. [

4] conducted the layout design of terminals with dangerous goods in Spain. In Norway, Eski and Tavacioglu [

7] evaluated port operators’ general awareness of dangerous goods transport in Turkey. In addition, Eski and Tavacioglu [

7] investigated key factors relating to chemical spills in the port area during maritime dangerous cargo transport.

Nevertheless, and despite referring to the official guidelines for the classification of dangerous goods, research to date has not yet developed models or guidelines for actually detecting, recovering, rescuing, and resisting dangerous goods in ports, particularly if an accident occurs. Drawing on a fuzzy analytic hierarchy process (FAHP) based on an initial literature review and a subsequent data collection stage through questionnaires administered to 25 experts, this paper does this. It thereby complements the existing research in the field, with the ultimate aim of increasing the safety capacity of ports for a range of stakeholders (cf. [

8]), including both policymakers and those individuals working in ports, and also for the environment and ecology of the immediate and surrounding port area. It does this in the specific context of the island of Taiwan, yet also with a view to providing findings that are theoretically transferable for comparison in other contexts (cf. Flyvbjerg [

9]), and, importantly, in the context of a key shipping hub and global transportation center. Notably, only relatively few studies have considered the issue of the handling of dangerous goods in ports, although much research has focused on how dangerous goods are transported. For example, from a qualitative perspective, Floden and Woxenius [

8] used interviews to collect stakeholders’ concerns regarding the land transport of dangerous goods and presented a three-level framework of the transport infrastructure, transport network, and freight flow. Guo et al. [

9] used an analytic hierarchy process and N-K model to identify key factors affecting road transportation accidents of hazardous materials in complicated maritime environments. These key factors included the driver, vehicle, hazmat, meteorological environment, road environment, and management.

In one study focused on the handling of dangerous goods in a shipping context, Ma [

10] identified 20 risk factors in maritime transport accidents of dangerous good. These were poor quality in packing dangerous goods, concealed and false declaration of dangerous goods, a lack of familiarity with the physical and chemical properties of dangerous goods, improper operations on board, crew fatigue, working with naked fire illegally, live-line work illegally, improper loading and unloading operations of dangerous goods, improper operations in tank cleaning and degassing, improper maintenance of ship equipment, failure of critical equipment on board, poor communication between ship and shore, inadequate safety checks on board and ashore, low visibility, rough sea, insufficient emergency resources in port, inadequate emergency drills between ship and shore, inadequate effectiveness of crew training, and defects in the safety management system on board and ashore. Ma’s [

10] results were based on a decision-making trial and evaluation laboratory (DEMATEL) analysis.

In an oil exploration context, Daneshfar and Ardjmand [

11] evaluated the optimal site selection of landfills for drilling cuttings from petroleum and gas fields and identified 15 criteria of distance from city centers, distance from roads, distance from rivers, distance from the airport, land covering, industrial building, distance from gas lines, oil storage, elevation, distance from industrial areas, fault line, slope, vegetation, distance from oil lines, and geology. Daneshfar and Ardjmand’s [

11] results were based on a fuzzy DEMATEL analysis. Elsewhere, based on five sets of expert data, Vojinovic et al. [

12] identified nine criteria of dangerous goods classified and permitted under the agreement concerning the International Carriage of Dangerous Goods by Road, all the necessary information available being made available by the consignor, documents in the transport unit, visual inspection of the transport unit, the testing time of tanks being controlled, vehicle load being controlled, making and labeling the transport unit, equipment in the transport unit, and documentation retention for the evaluation of companies for the transport of dangerous goods in Serbia. Vojinovic et al.’s [

12] results were based on fuzzy-rough multi-criteria decision-making (MCDM).

Taiwan is an island that is highly reliant on shipping trade. Ports are a fundamental infrastructure for Taiwan’s economic development. Dangerous goods accidents in ports, therefore, constitute both a risk and a threat to the logistics and supply chain operations, and can create a bottleneck in international trade and transportation routes. In addition to their immediate impact, they could also arguably have a medium- to longer-term impact on Taiwan’s reputation and safety image, and potentially lead to major logistics suppliers choosing alternative routes.

Three major container shipping companies (Evergreen, Yang Ming, and Wang Hai) in Taiwan were ranked sixth, ninth, and eleventh in 2023, respectively, in the world based on Alphaliner statistics

7. In order to complement the existing research, this study adopted Taiwan as a case study to conduct an empirical survey based on fuzzy analytic hierarchy process (FAHP). The research findings can help port stakeholders (e.g., terminal operators and stowage co-ordinators) who take charge of dangerous goods in the port or ship enhance the safety evaluation mechanism and reduce potential property losses and human casualties. In addition, based on the FAHP findings shown below, the correct priority of resource allocation can be established when dangerous goods accidents happen. The structure of the remainder of this paper is as follows: In the subsequent literature review section, the study and findings in relation to dangerous goods in port operation and past related studies are considered. Next, the methodology illustrates the FAHP, outlining its value and noting its limitations.

Section 4 then analyzes and summarizes the results of the FAHP from the data obtained through questionnaires based on the literature review and administered to 25 experts. A sensitivity analysis is also conducted to verify the reliability and validity of the findings. Finally,

Section 5 discusses the research findings and concludes this paper. Ultimately, based on the data from the experts consulted, the paper illustrates the paramount importance of the initial stage of determining dangerous goods in order to help prevent accidents from happening. In the discussion and conclusion, suggestions are made for how to most effectively succeed in ensuring this determining process functions effectively.

3. Methodology

This paper adopted a fuzzy analytic hierarchy process (FAHP) to prioritize the key dimensions and indicators of the safety management of dangerous goods in the port. FAHP is an extended form of AHP in a fuzzy environment, with the extension having the aim to reflect the subjective judgments of ambiguity [

26,

27]. In the AHP, a 1~9 ratio scale is used to compare two criteria for identifying the strength of their relative preference. Since the criteria and sub-criteria might be vaguely defined, the measurement criteria and sub-criteria are conducted in an intrinsically imprecise manner. The extension of the AHP into the FAHP holds a number of benefits over the standard AHP process by its ability to also account for ambiguities and subtleties, or ‘fuzziness’, that the standard AHP lacks. In this context, Zadeh [

26] argued that a fuzzy set is a class of objects with a continuum of grades of membership ranging between zero and one. Thus, a fuzzy number with a ratio value provided by the experts can be used to reflect the fuzziness of the survey assessment. This paper adopted a column geometric mean method to calculate the weights [

27,

28]. For example, when the ratio value given is 5 (which is “strongly more important”), the fuzzy assessment represents a triangular fuzzy number (3, 5, and 7)

11. Therefore, the fuzzy weights can be used so that they are normalized and aggregated to obtain an overall priority value for the criteria and sub-criteria. Such a multi-criteria decision-making method can help decision-makers develop effective resource priorities in dealing with high-risk dangerous goods issues. The expert elicitation with a questionnaire survey is used to synthesize the weight analysis and handle uncertain problems. Here, in this paper, expert elicitation is defined to collect senior experts’ opinions, and they must have qualified abilities to provide professional replies for our questionnaire. The potential questionnaire participants must have 10 years (at least) of relevant work experience and possess dangerous goods transportation knowledge. We do not score for each questionnaire from the experts although their experiences (e.g., education degree, job title, etc.) might be different. The importance of each expert questionnaire is the same. Whilst it could be argued that each expert’s experience and knowledge could be weighted according to, for example, their educational qualifications (with higher points for one with a Ph.D. than with a Master’s), we considered the key criteria to be for them to have the 10 years of minimum experience and, if they had this, we considered them experts for our purposes.

As shown in

Figure 2, a triangular fuzzy number with a membership function is defined by the triplet (l, m, and u) as in Equation (1) [

28,

29].

where

m is the most possible value of the fuzzy number U(x), and

l and

u are the lower and upper bounds, respectively.

The analysis process of the FAHP included the construction of the assessment model, questionnaire design, construction of the pairwise comparison matrix, fuzzy number calculation, the fuzzy positive reciprocal matrix construction, fuzzy weights calculation, defuzzification, normalization, and synthetic analysis. An FAHP with a nine-point rating scale was designed to measure the respondents’ perceptions of what was relatively important. Since dangerous goods accidents might quickly result in serious casualties, there is a need to immediately provide emergency rescue works in order to construct port resilience. Thus, how to reduce accident probabilities and the consequences of accidents, and the time needed to recover from accidents is an important decision work for maintaining the safe operation of a port. Based on Bruneau et al. [

10], a hierarchical assessment model with four dimensions (including detection capability, resistance capability, rescue capability, and recovery capability) and fifteen criteria were summarized. The pairwise comparison processes with fuzzy ratios are used to evaluate the weights. To validate the measurement scale, six experts (including two port operators, two port officials, and two academics) who are familiar with this topic were invited to pre-test the content of the questionnaire. The consistency index (CI) and consistency ratio (CR) were checked for each questionnaire’s suitability.

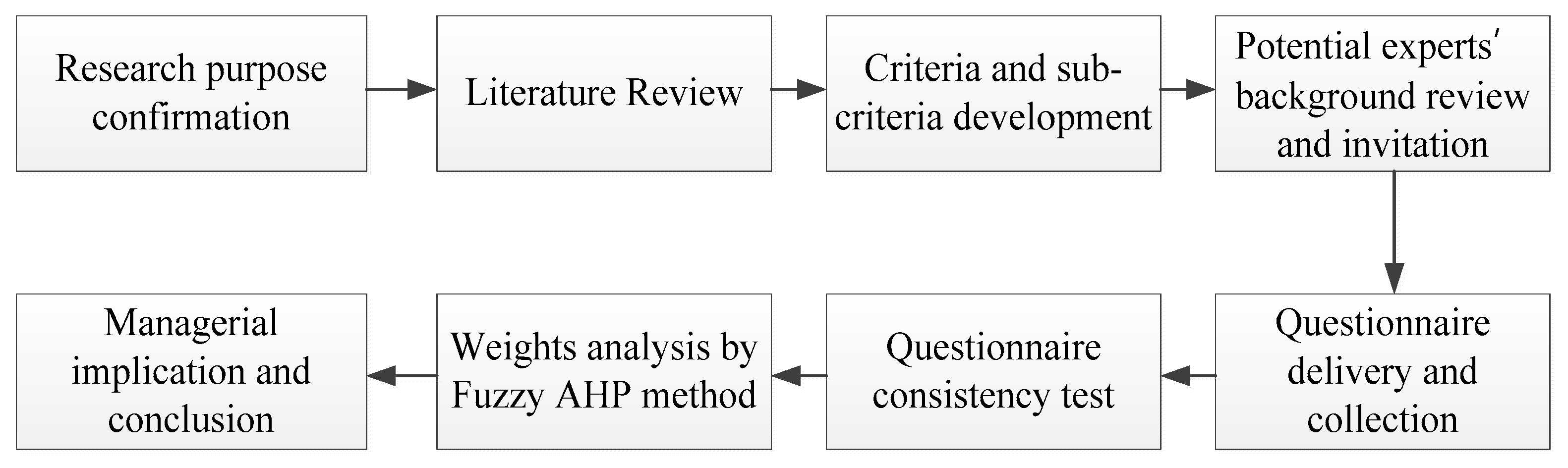

The research method framework of this paper is shown in

Figure 3. After confirming the research purpose, the safety assessment and the relevant literature reviews were conducted in order to establish the research criteria and sub-criteria. Then, the potential questionnaire experts’ backgrounds were reviewed and their intention to participate in the study was confirmed. The questionnaires were sent to qualified experts, with whom we conducted the surveys and collection works. Before the data analysis, the questionnaire consistency was tested to ensure its validity. The valid questionnaires were analyzed by fuzzy AHP methods and weights analysis based on sensitivity analysis. Finally, the managerial implications and conclusions are provided based on the research findings.

4. Results

A total of 25 valid questionnaires were drawn upon for this study out of the total of 30 questionnaires from potentially qualified experts (e.g., sufficient work experience and good knowledge about this research topic) who were contacted by one of the authors, and the raw data were later transferred for analysis through the use of fuzzy equations in Excel. This number is sufficient for such an analysis and is, indeed, higher than the number of experts consulted in other AHP analyses (e.g., 10 in Chen et al. [

1]). We note that, here, we complement previous work by outlining and identifying the key criteria of what constituted an ‘expert’ in the context of this paper (see

Table 2 below) with regard to their qualifications, positions, and experience. This is not something often done in previous research (e.g., Chen et al. [

1]) but is arguably key in illustrating the validity of the data (Baker et al. [

30]). After confirming their participation intention, a total of 30 questionnaires were delivered by mail by one of the authors with postage-paid return envelopes on 2 June 2023. By the cut-off date (16 June 2023), 28 questionnaires had been received. The results indicated that three questionnaires with CI > 0.1 and CR > 0.1 were highly inconsistent [

28] and were consequently discarded. The overall response rate was 83.3% (=25/30) and their profiles are shown in

Table 2. The majority of the respondents were male (92%) and their ages were between 51–60 (48%). Regarding their education level, the Ph.D. was the main degree (36%), followed by the Bachelor’s degree (32%) and the Master’s degree. (24%). Regarding their job type, most were governmental officials (28%), followed by employees of shipping companies (24%), port operators (24%), and academic scholars (24%). The majority of the experts served as managers (40%), followed by division directors (20%), captains (12%), and assistant general managers (8%). The majority of the experts (52%) had 21 years of related experience, enhancing the study’s reliability.

As shown in

Table 3, the results indicate that the detection capability is the most important criterion (0.296), followed by the rescue capability (0.244), the recovery capability (0.239), and the resistance capability (0.221). It is argued that most experts thought the practitioner’s detection capability should be emphasized, since effective monitoring works can help avoid potential operational risk. Moreover, “terminal operators’ safety awareness/familiarization training”, “proper isolation measures around the port”, “emergency evacuation and rescue operation”, and “updating applicable regulations” were perceived to be the most important sub-criteria with respect to each criterion in relation to the detection capability, resistance capability, rescue capability, and recovery capability, respectively. Further, the global weights were synthesized from the second level drawn by multiplying the local weights and the corresponding criteria in the level above. The results revealed that the top three important sub-criteria were proper isolation measures around the port (0.0810), terminal operators’ safety awareness/familiarization training (0.0778), and shippers’ safety awareness (0.0748), respectively.

In the context of enhancing the reliability and validity of data analysis in the context of the FAHP, sensitivity analysis is a key tool. The sensitivity analysis is used to identify the weight change situation under a variety of scenarios. Then, the decision-maker can understand the scenario changes and subsequently adopt effective resource allocations when changing certain criteria’s weight value.

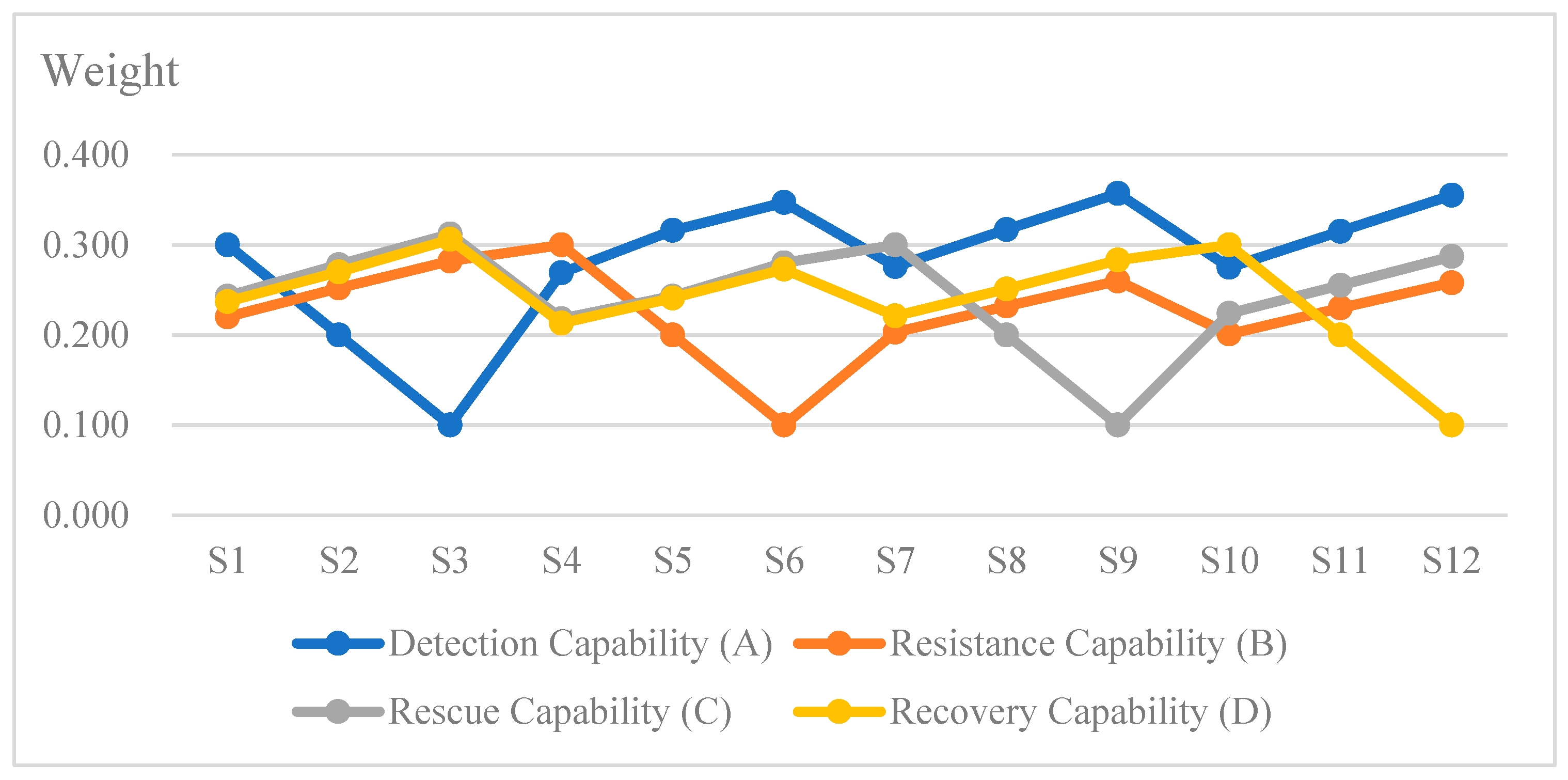

Figure 4 shows the results of the sensitivity analysis through 12 scenarios for four criteria. Scenario 1~3 means the detection capability’s weight is 0.3, 0.2, and 0.1, respectively. Scenario 4~6 means the resistance capability’s weight is 0.3, 0.2, and 0.1, respectively. Scenario 7~9 means the rescue capability’s weight is 0.3, 0.2, and 0.1, respectively. Scenario 10~12 means the recovery capability’s weight is 0.3, 0.2, and 0.1, respectively. The results show that the rescue capability criteria show higher weight values in most scenarios, especially in the scenario where the other three criteria’s weight values are set as 0.1 (see S6, S9, and S12). This phenomenon means most experts think the authorities should provide sufficient resources to develop detection capabilities. When the resources for detection capabilities are insufficient (e.g., weight values are 0.2 or 0.1), the authorities should provide nearly the same resource for the other three criteria (resistance capabilities, rescue capabilities, and recovery capabilities).

5. Discussion

Based on the analysis results, the detection capability is the most important criterion, and this means the practitioner’s professional abilities should be improved in advance. This would avoid a domino effect of an initial mistake leading to further and potentially more disastrous ones and is something that can also be explained by the Swiss Cheese theory [

31]. In other words, if a practitioner’s unsafe acts (e.g., mistaken cargo segregation or inappropriate dangerous goods declaration, etc.) can be effectively avoided, this can, then, consequently reduce the possibility of a future accident [

25]. However, in reality, for practical and short-term financial reasons [cf. 8], shippers might not frankly state their cargo content due to possible reasons such as reducing maritime freight, or reducing custom tax or the possibility of time delays through a sampling check by customs, or even due to a lack of professional knowledge on dangerous goods. The ranks of rescue capability, recovery capability, and resistance capability are second, third, and fourth, respectively. Their weight scores are close when compared to the detection capability. This means they are perceived to be relatively unimportant according to the experts’ opinions. However, these criteria still should be carefully considered and further developed when creating any sequence of organized work processes to prevent and reduce potential casualties and losses.

Although we can only state so hypothetically, it is possible that shipping operators or port operators, for similar reasons as to those outlined immediately above, might not strictly obey the IMDG Code to conduct the carriage of dangerous goods. Indeed, many incidents in transportation operations are attributed to the poor packaging of cargo transport units (for example, the inadequate securing of cargo within the cargo transport units, incorrect declaration of contents, incorrect cargo loading/discharge, and overloading [

2,

4]). Thus, and according to many of the questionnaire experts concerned, the terminal operators’ safety awareness/familiarization training and shippers’ safety awareness were ranked high priorities within all sub-criteria. Thus, sufficient safety education and the necessary dangerous goods certificates should be regularly reviewed for shipping and port operators in order to reduce the probability of a hazardous accident occurrence and the severity of the consequences. In the Tianjin port accident case, the Ruihai Company did not observe port safety laws and regulations and lacked emergency response plans (Zhang et al. [

25]). In addition, various accident cases and training materials should be regularly updated to enhance practitioners’ risk awareness [

22].

Thus, although the above results show the paramount role of the detection capability—i.e., the determining of, in relation to dangerous goods—the other stages of rescue, recovery, and resistance are also key. However, in relation to the idea of a domino effect, the paramount importance of the ‘detection capability’ means that, if the failure occurs at this stage, then this ‘domino’ may fall and then impact the others. Of course, analogously, the others may fall later of their own accord, which is why they are also key, but it is the first one that is perceived to be of paramount importance by the 25 experts interviewed here. What, then, of the reasons why shippers might not frankly state the nature of their goods—the fact that dangerous goods require more room and space, may require more tax to be paid, cause time delays through customs checks, or remain undetected due to a lack of knowledge or training? Each one of these possible reasons relates to the fundamental aspect of resources or profit, but, here, there is a trade-off in the focus on short-term profit at the expense of a possible medium- or long-term severe loss. In other words, it is true that, in the short term, if a freight company is able to transport ‘dangerous’ goods as standard goods, it will be able to transport more of them, and they will require less time to be checked in, and they may be subject to reduced tax and to few customs checks. It will also cost a shipping company significantly less to employ staff who do not have qualifications in such areas. However, should an accident occur, the medium- and long-term costs are severe, easily outweighing any short-term savings that had been gained. Arguably, a key question here is who should pay to help with the detection and determining of dangerous goods. This, itself, is a question for future research, but, at an IMO level, one key procedure is undoubtedly to stipulate regulations for the determining of dangerous goods. At the same time, it is arguable that such regulations require global legal acceptance and enforcement, and, further, that they require support in terms of resources in order to ensure that they are followed. Such resources would be able to ensure that time, space, tax, and so on were not issues for shipping companies, and would also ensure staff could be properly qualified in the detection and identification of dangerous goods.

This, in turn, leads to a subsequent question of where the money should come from. Should it be the case that the IMO adopts a funding model for dangerous goods similar to the European Union funding model, for example, where larger countries (by economic size) contribute more to a pool of resources, which is then distributed according to those who need it the most? Such questions are not ones that are within the scope of this paper and are arguably ones that are suitable for future research. Nevertheless, we argue that they do, in many ways, constitute an ‘elephant in the room’, in that they constitute the key issue in relation to all aspects of the way dangerous goods are handled and approached in a port context, in that, without resources dedicated to the handling and transport of dangerous goods, the danger will always exist of another Beirut or another Tianjin. This, we note, is in addition to the many other, less severe accidents that occur as a result of dangerous goods in port contexts.

Having said all this, were such funding to exist, and we know that ports do have resources to fund projects, then the model we develop here (represented in

Figure 3 and

Figure 4) we argue can serve as a guide for how to handle and transport dangerous goods. Such a model can be used alongside and as a complement to the other procedures and recommendations developed in other research (e.g., [

1,

2,

4]). The results can help decision-makers adopt strategic planning to carry out resource allocation in the preparation and recovery activities for taking precautions and avoiding dangerous goods accidents, especially in resource constraint scenarios.

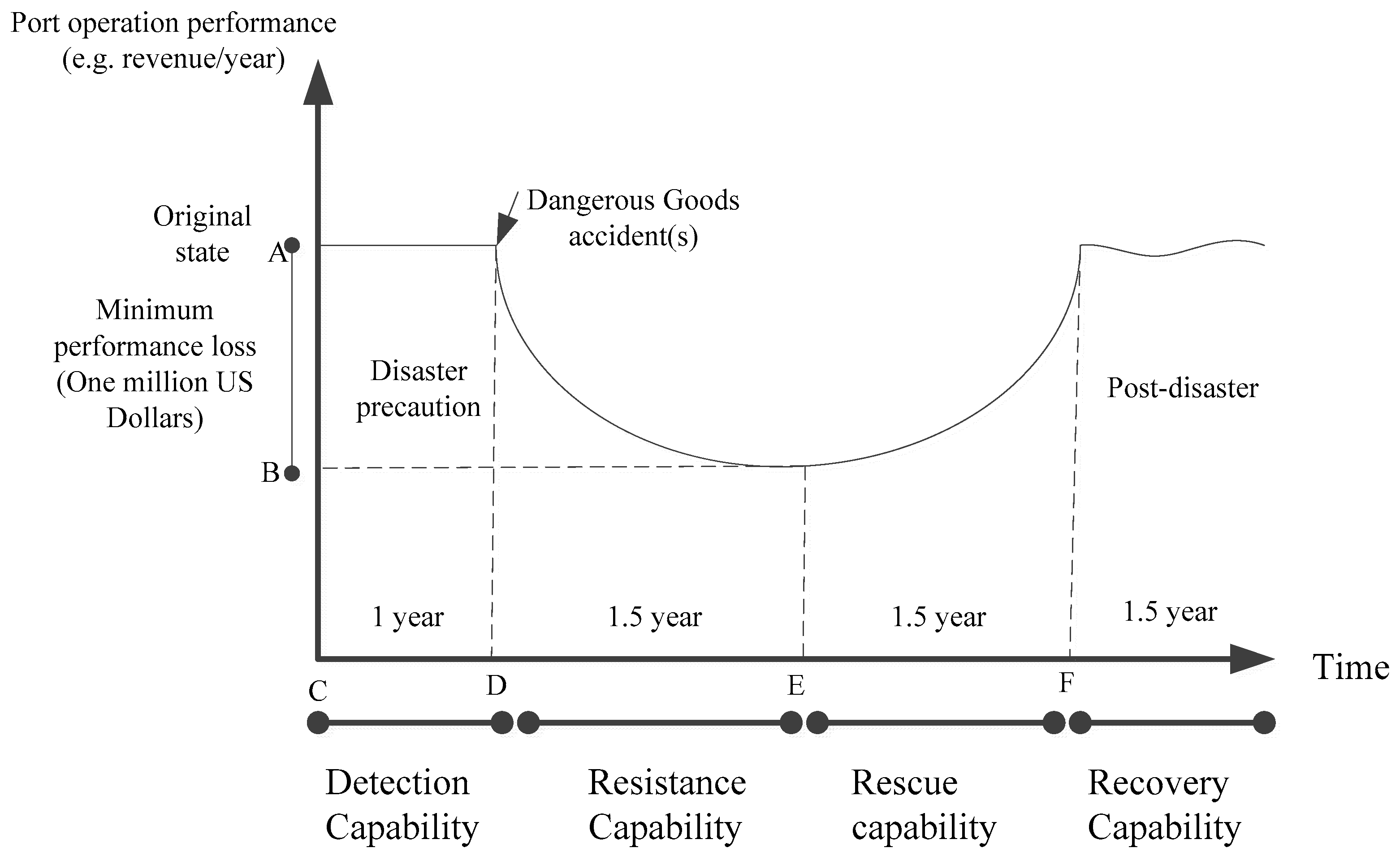

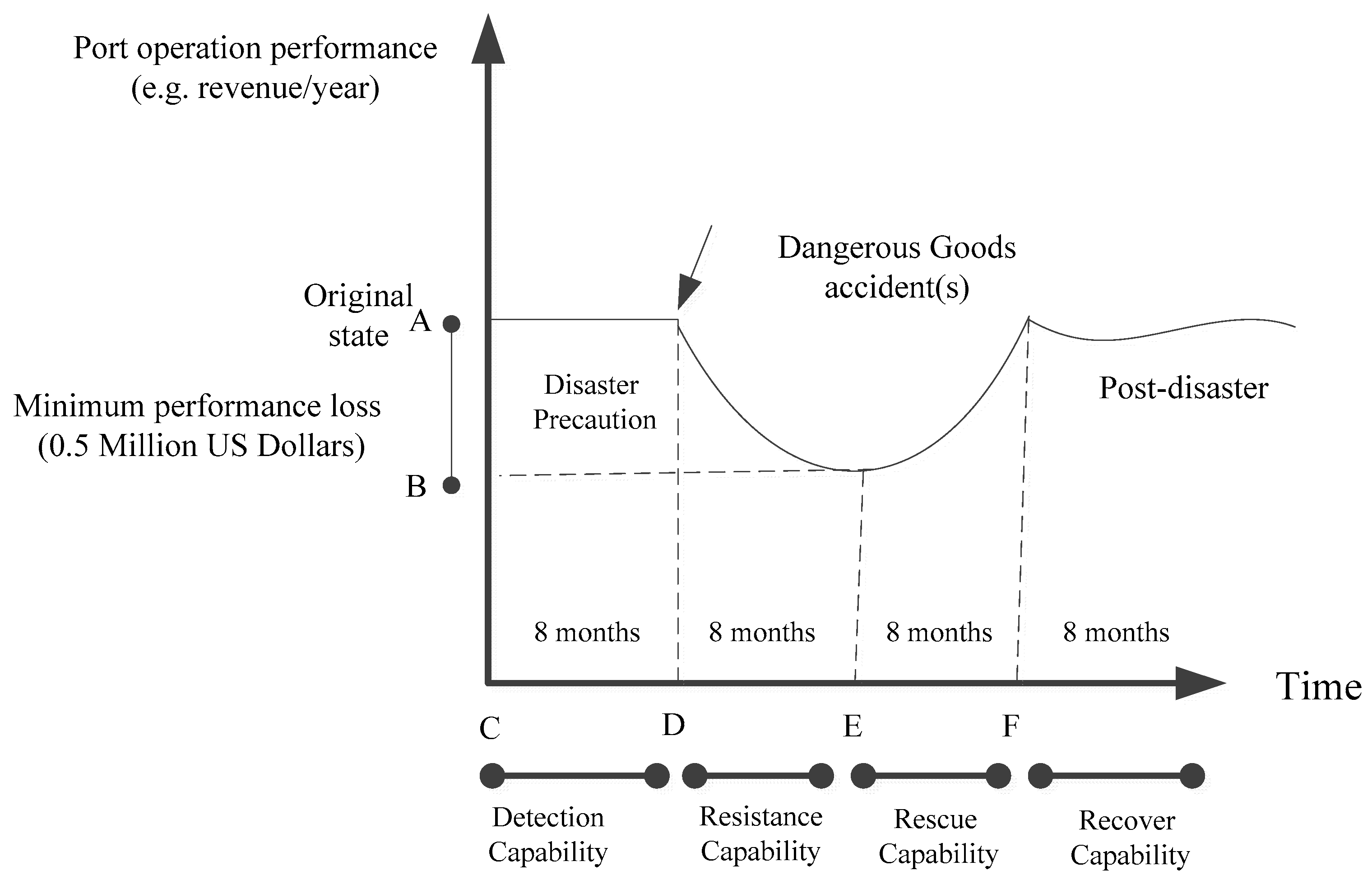

As shown in the model in

Figure 3, and based on our findings, it is expected that the port authorities and relevant stakeholders would adopt damage loss strategies to reduce the economic losses, casualties, and external costs when dangerous goods accidents occur. This means that, when a dangerous goods accident occurs, this model attempts to reduce the minimum performance loss (assuming one million US dollars, the distance between point A and point B) in one year (see

Figure 5), and then achieve point F eventually. By promising resource allocation and constructing thorough port resilience capabilities, as shown in the revised model in

Figure 6, the detection time of finding dangerous goods accidents (the distance between point C and point D) will be effectively shortened, possibly to the extent of avoiding accidents occurring at the beginning stage. If, unfortunately, dangerous goods accidents do occur, it can still shorten the time of the performance cost (assuming 8 months, the distance between point D and point F) and reduce the performance loss (assuming 0.5 million US dollars, the distance between A and point B) through developing effective resistance capabilities and rescue capabilities, and make the curve quickly achieve point A (original operation performance stage) even more effectively (see

Figure 6).

6. Conclusions

This paper used an FAHP analysis to prioritize the key criteria and sub-criteria of dangerous goods in port operations based on questionnaires with 25 experts that were created after an initial literature review. The ranked criteria were detection capability, rescue capability, recovery capability, and resistance capability. Sensitivity analysis was used to identify the weight value change under 12 scenarios. The research findings can help improve decision-making policies and resource allocations for dangerous goods safety management regarding shipping operators, port operators, and other stakeholders by prioritizing this detection capability stage. For port authorities, it is suggested that they should effectively monitor high-risk transport companies or shippers by introducing an increasing penalty for unsafe behavior (e.g., stowage or segregation mistakes). Consequently, this could help provide potential preventative measures to avert dangerous goods accidents and reduce any dangers to humans and the environment based on our assessment model. Regarding shipping operators, port operators, and relevant stakeholders who take charge of dangerous goods (e.g., import and export companies), the staff should be well-trained and pass the dangerous-goods-related certificates in order to ensure each person has the ability to take charge of dangerous goods works. These results were represented in the above-suggested model (

Figure 4 and

Figure 5) for approaching the handling of dangerous goods in the port. It is hoped such a model can be practically used alongside and as a complement to existing research and suggestions for the handling of dangerous goods in ports to ensure a lower possibility of any accidents occurring. Our research limitation is that the research area of the expert questionnaire survey is Taiwan. Another similar study involving a field expert in a non-Taiwan area can be further investigated in the future.

Finally, future researchers could adopt various methodologies to investigate similar topics based on these research findings. One area of potential research, as discussed above, is that of the aspect of resourcing the handling and transport of dangerous goods. Here, qualitative approaches could help gain the views of key stakeholders regarding their perspectives as to how best to approach any funding models and, indeed, what funding models and legal models could be adopted. In addition, quantitative work could study how to ascertain what costs are involved, and, importantly, attempt to quantify the short-term gains made by not frankly declaring dangerous goods compared to the medium- and longer-term losses incurred by accidents resulting from fires, explosions, and other accidents in relation to dangerous goods. In addition, in the area of dangerous goods themselves, the above study suggests a number of areas for future research. For example, quantitatively, the research could adopt the Technique for Order Preferences by Similarity to an Ideal Solution (TOPSIS) to conduct the criteria and alternative evaluations. From a qualitative perspective, it could adopt expert interviews based on grounded theory to explore the dangerous goods detail issues, for example in relation to stowage, segregation, package, loading/unloading, temperature control, intermodal transport, fire-fighting, insurance, law and regulation revisions, supply chain operator co-operation, and other factors.