Collision Avoidance Strategy for Unmanned Surface Vessel Considering Actuator Faults Using Kinodynamic Rapidly Exploring Random Tree-Smart and Radial Basis Function Neural Network-Based Model Predictive Control

Abstract

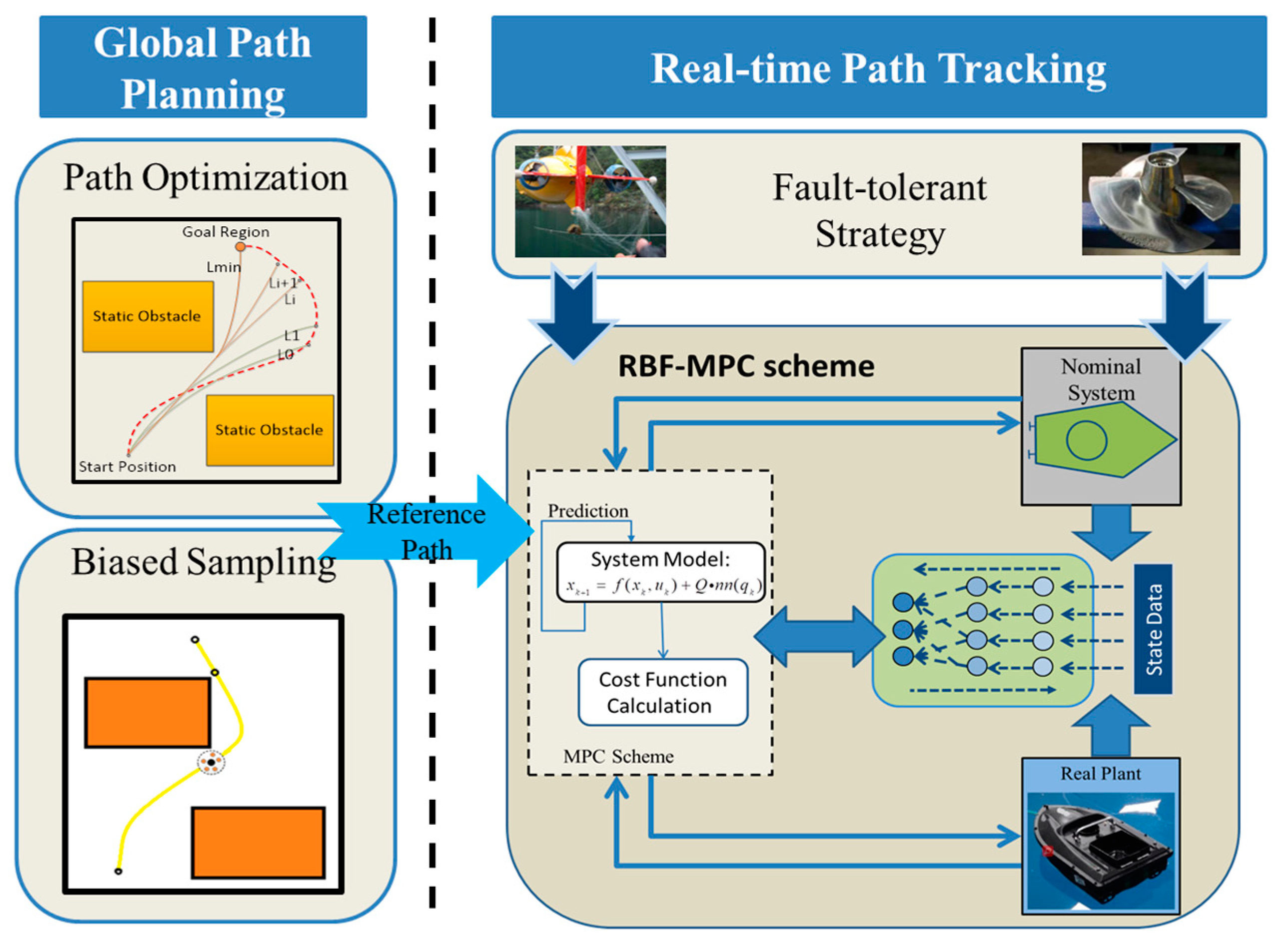

1. Introduction

2. Collision Avoidance Path Generation

2.1. Preliminaries

2.2. State Equations and Control Inputs

2.3. Kindynamic RRT*-Smart Algorithm

| Algorithm 1 Kinodynamic RRT*-Smart | |

| Input: Goal, Map, K | |

| Output: The feasible path | |

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | V ← V ∪ {xnew}, E ← E ∪ {Vnearest,xnew} |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 |

| Algorithm 2 Path_Optimization | |

| Tree2(V2,E2) | |

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | end |

| 12 | |

| 13 |

| Algorithm 3 Rewiring Edges | |

| Input: | |

| Output: The feasible path | |

| 1 | |

| 2 | |

| 3 | |

| 4 | |

| 5 | |

| 6 | Snew = IntelligentBiasedSampling(Send) |

| 7 | |

| 8 | |

| 9 | |

| 10 | |

| 11 | |

| 12 | |

| 13 | |

| 14 | |

| 15 | |

| 16 | |

| 17 | |

| 18 | |

| 19 | |

| 20 |

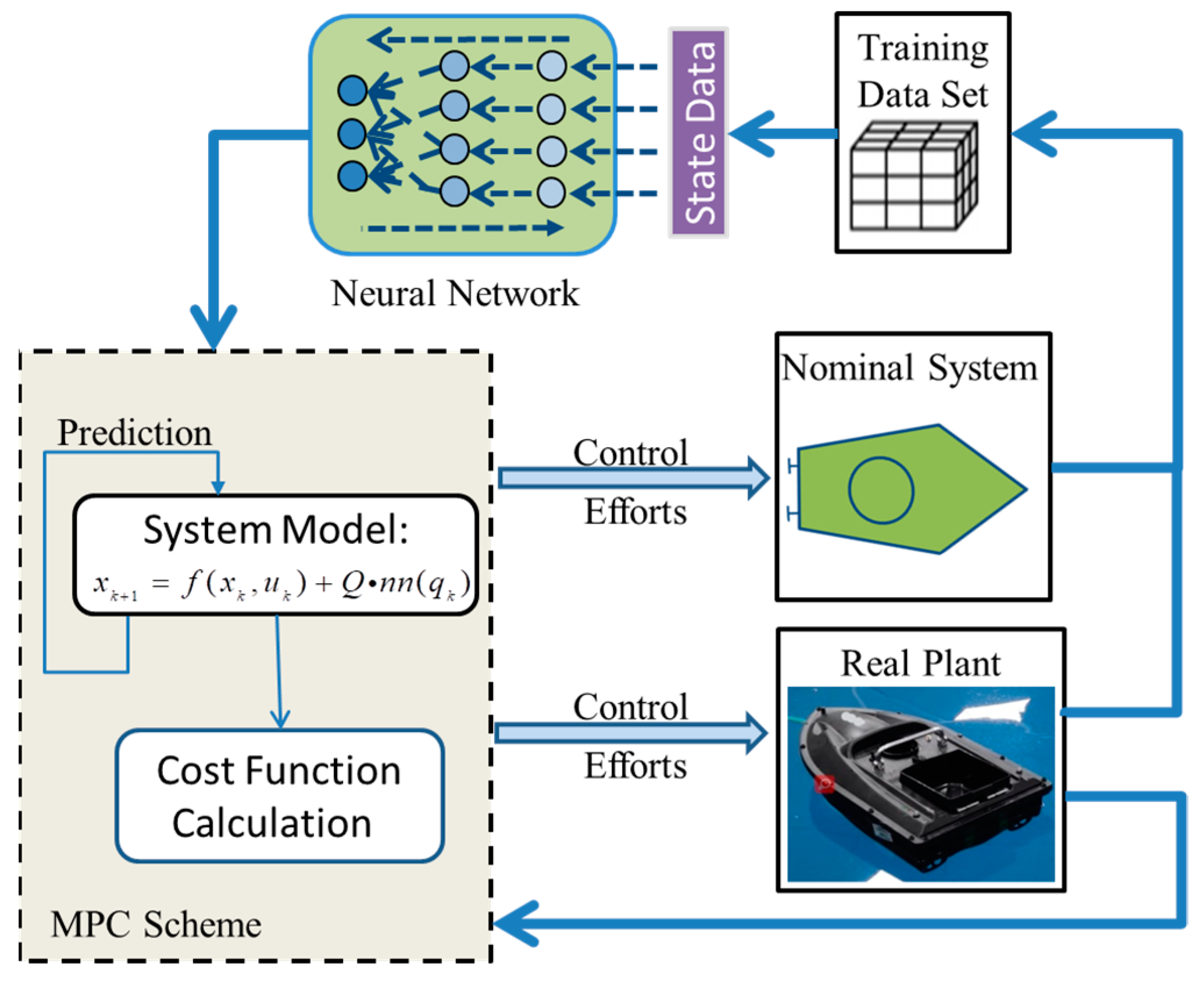

3. RBF-MPC for USV with Actuator Faults

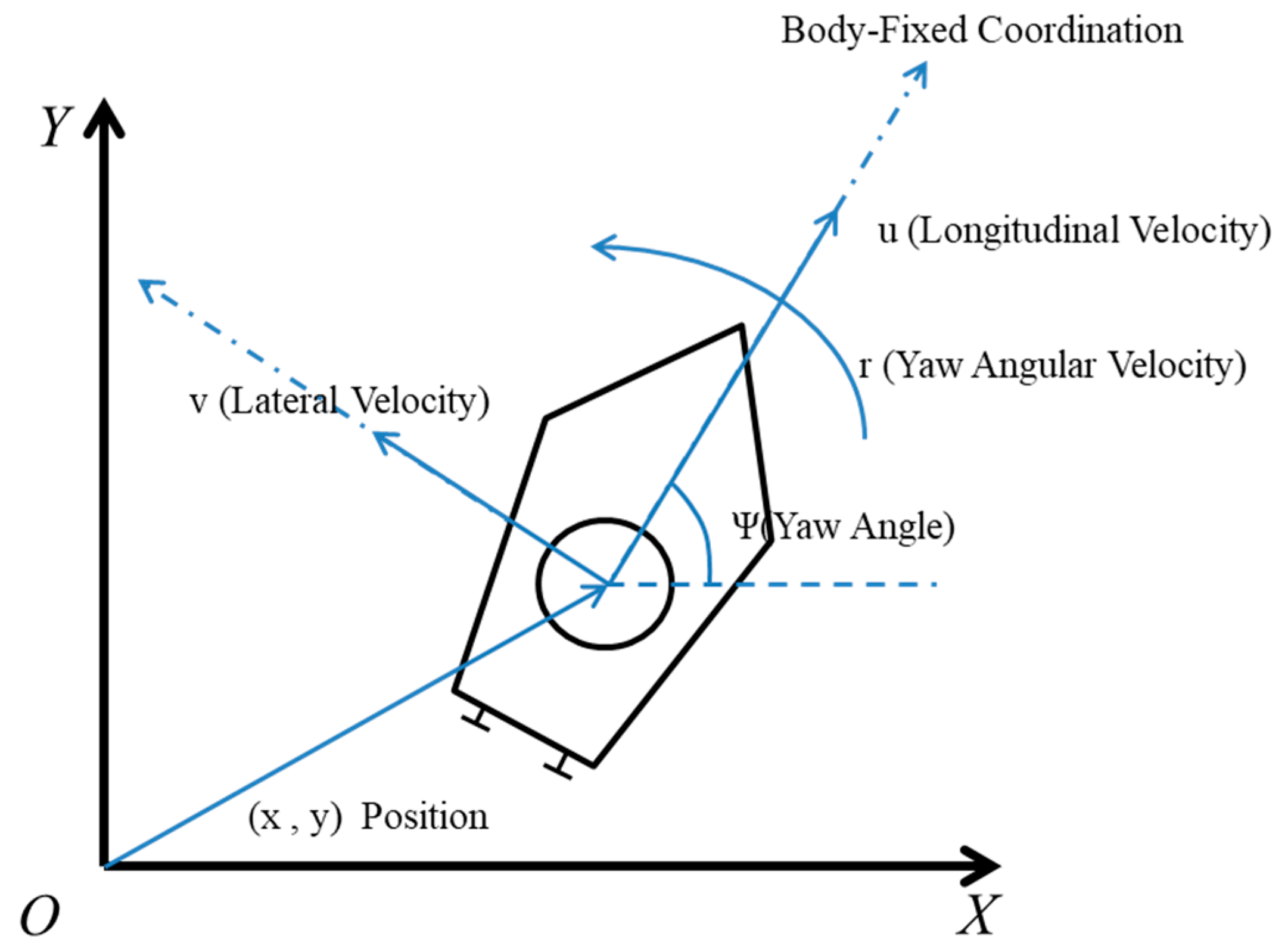

3.1. Assumptions

- Neglecting roll, pitch, and heave motion: The motion of the USV in the roll, pitch, and heave directions is disregarded for simplicity.

- Neutral buoyancy and body-fixed coordinate: The USV is assumed to have neutral buoyancy, and the origin of the body-fixed coordinate system is positioned at the center of mass of the USV.

- Three planes of symmetry: The USV possesses three planes of symmetry, which aid in simplifying the analysis and modeling process.

3.2. Vehicle Kinematic Model and Dynamic Model

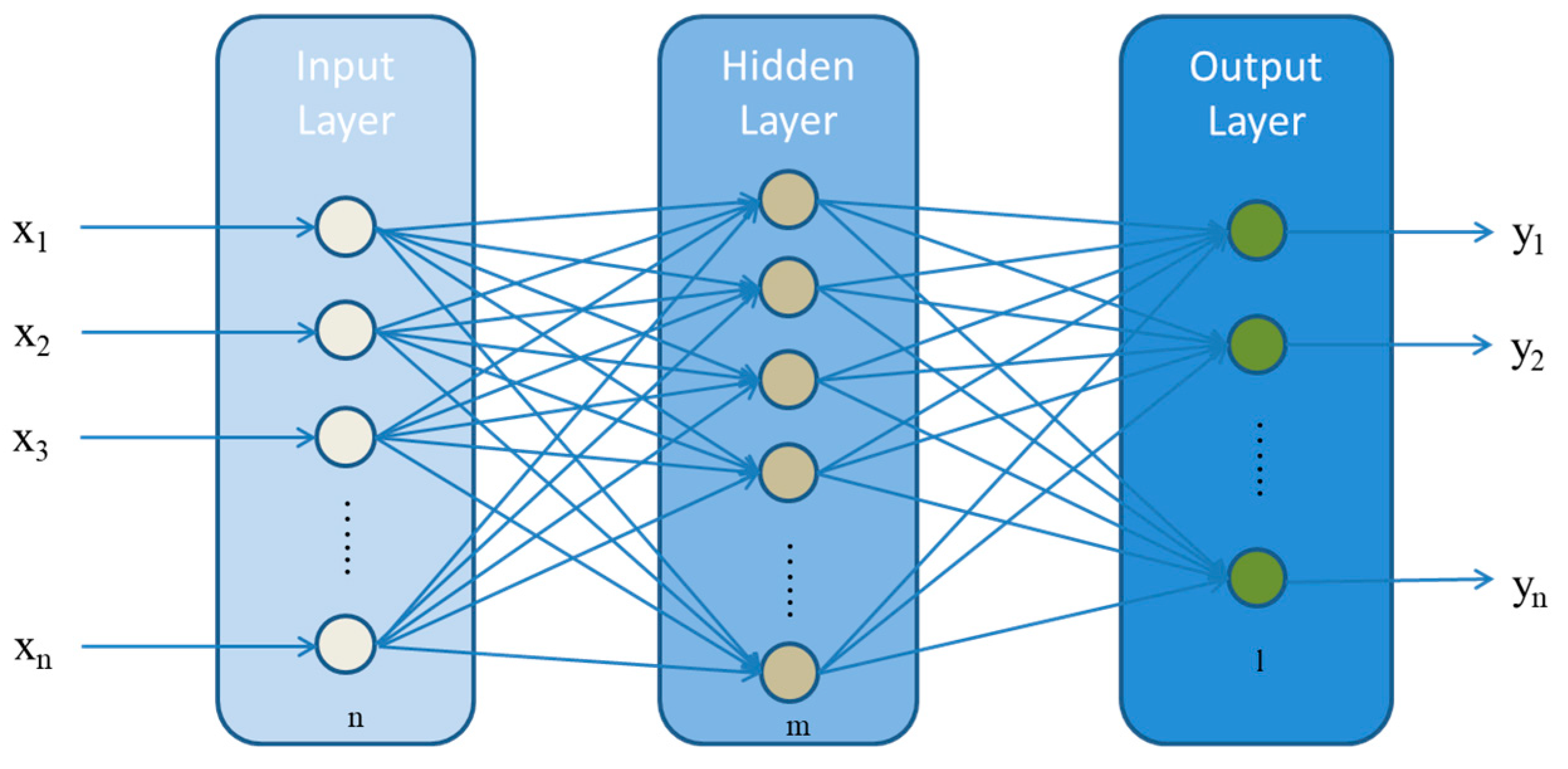

3.3. RBF Neural Network-Based Model Predictive Control

3.4. Fault-Tolerance Strategy

4. Simulation Results

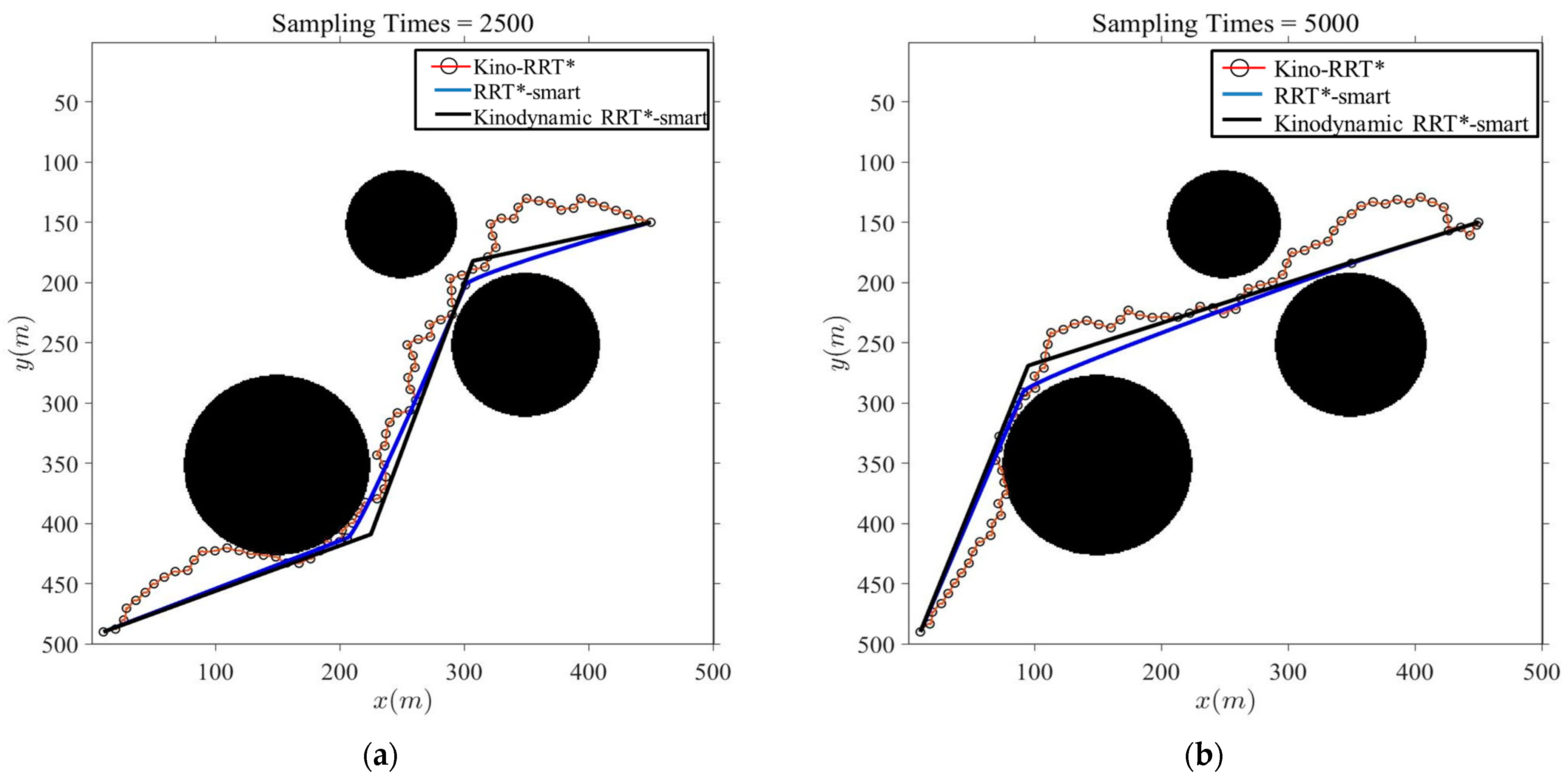

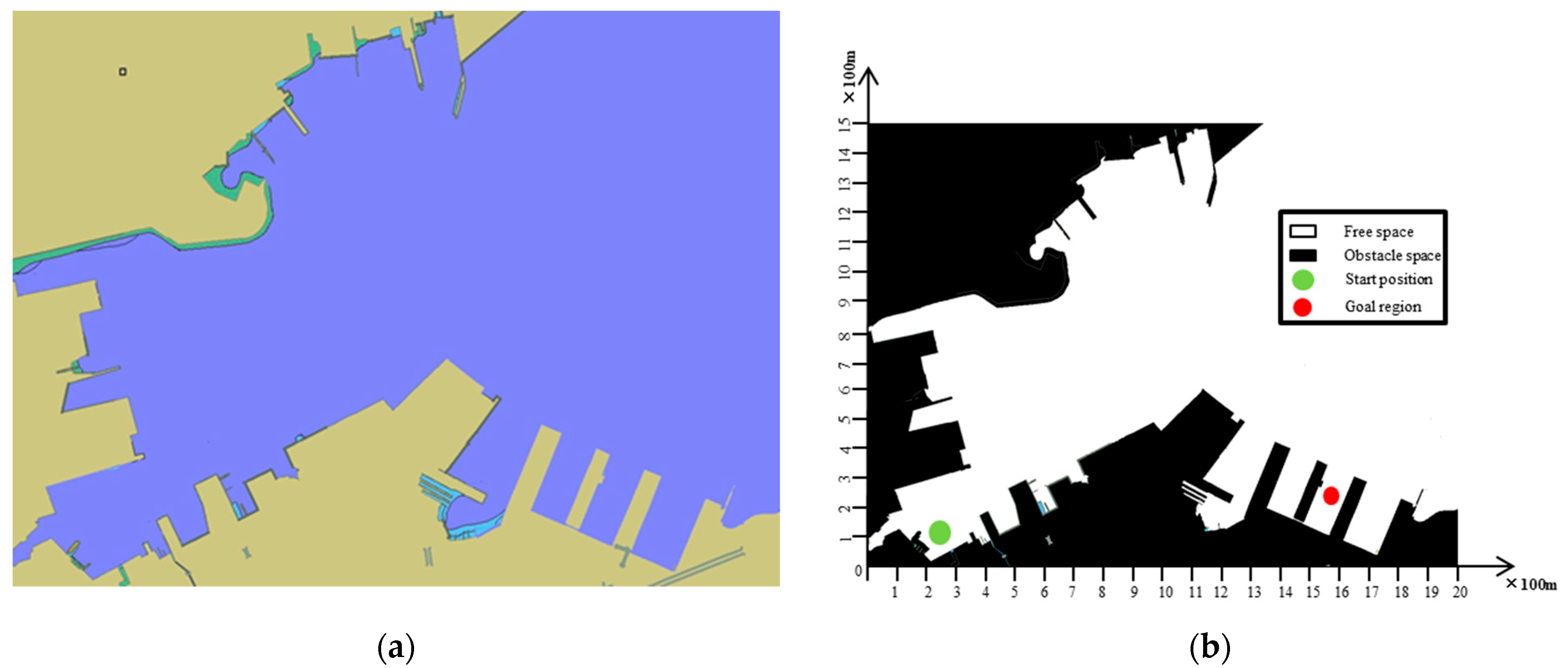

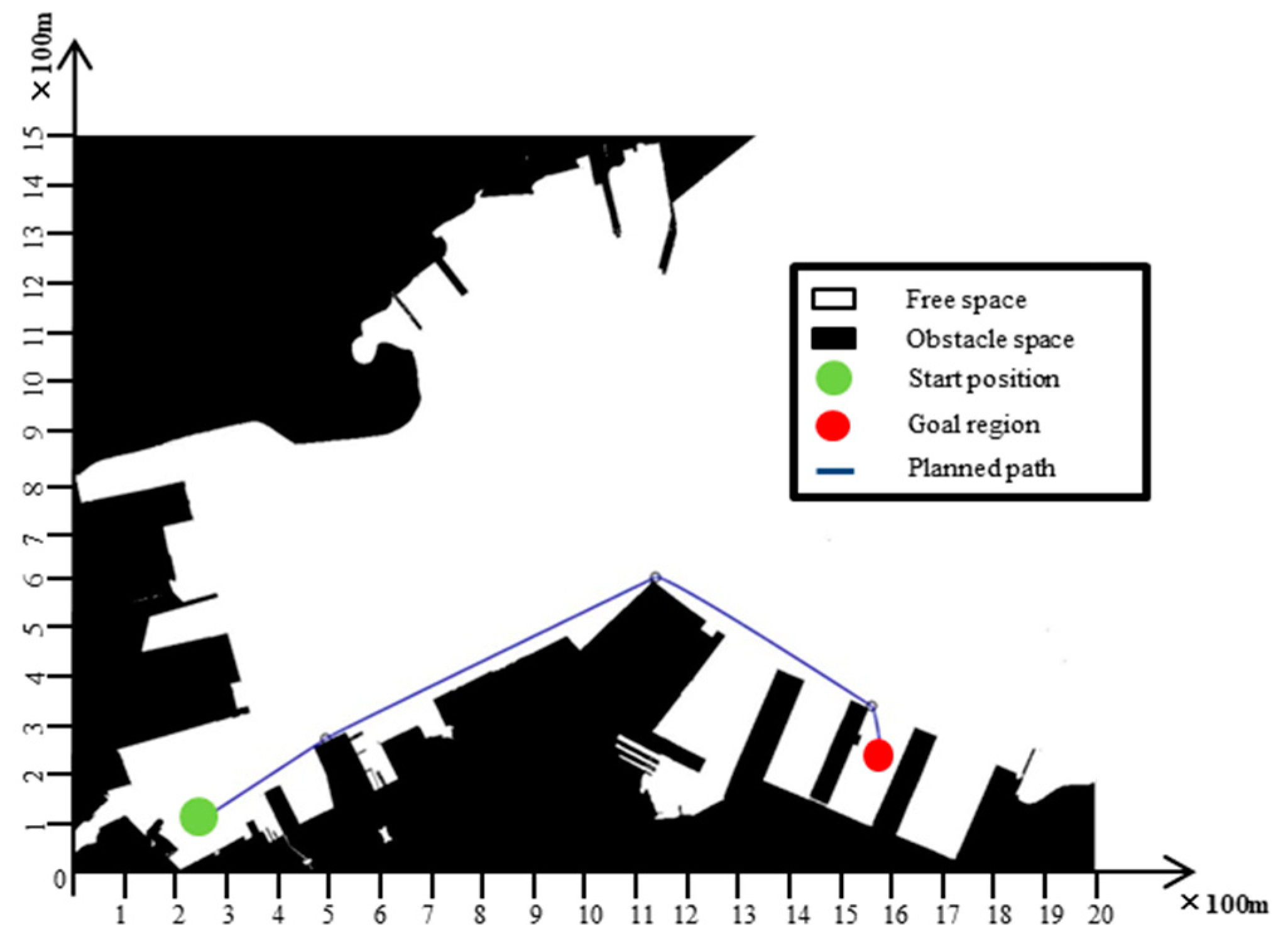

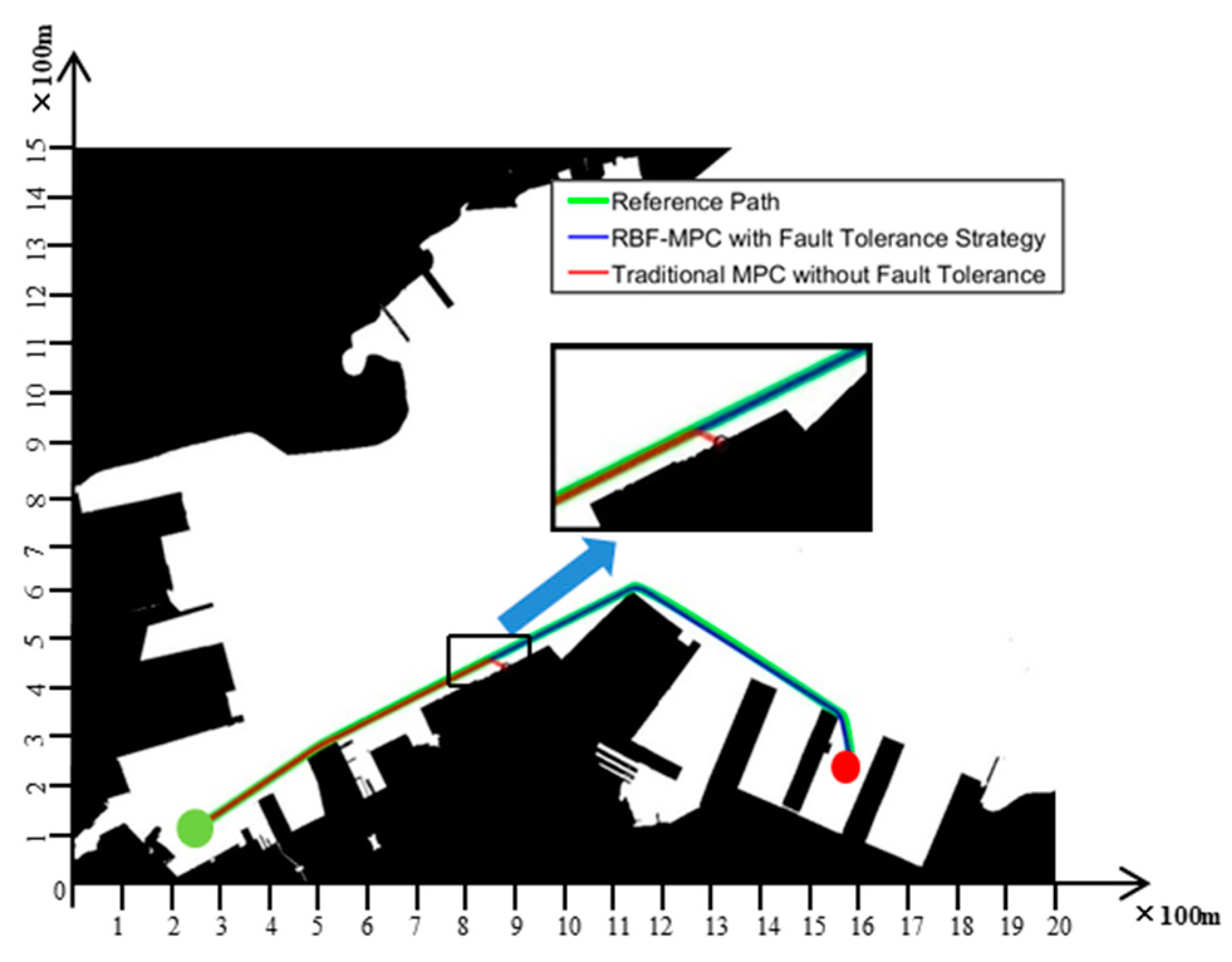

4.1. Collision Avoidance Path Performance Comparison in Simulation Studies

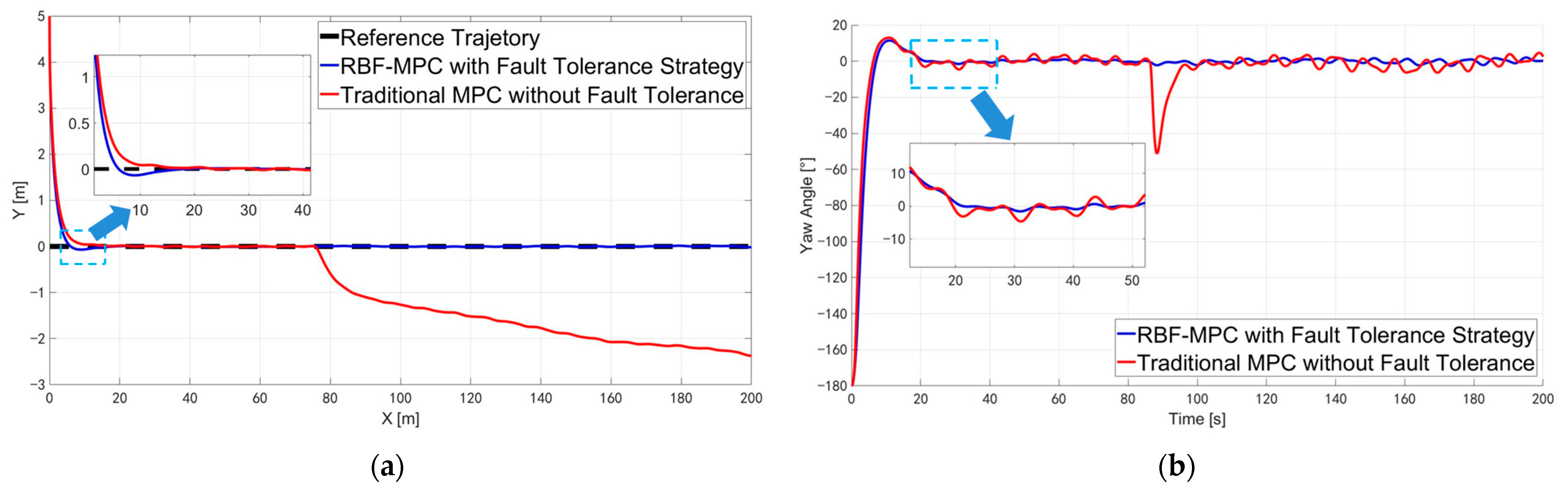

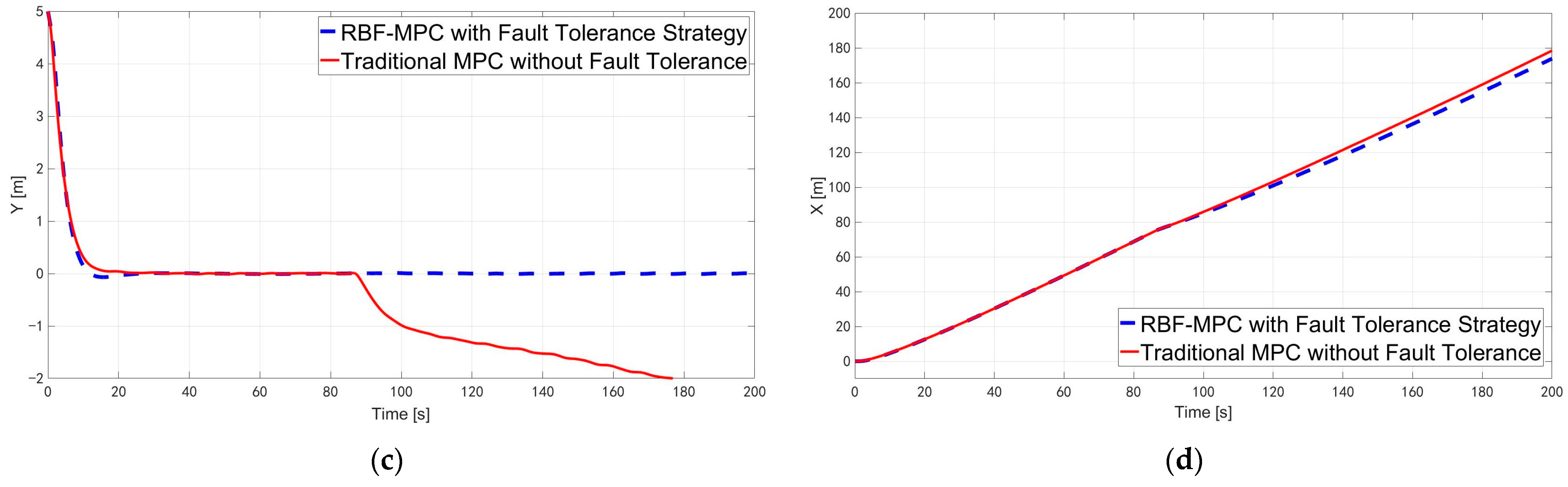

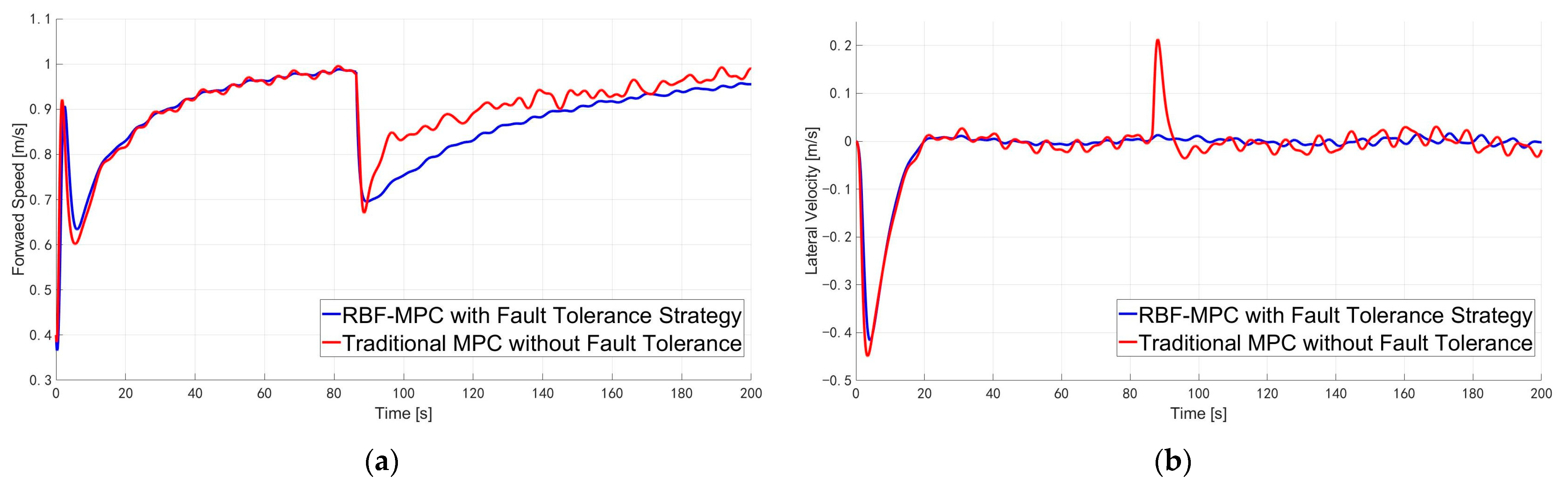

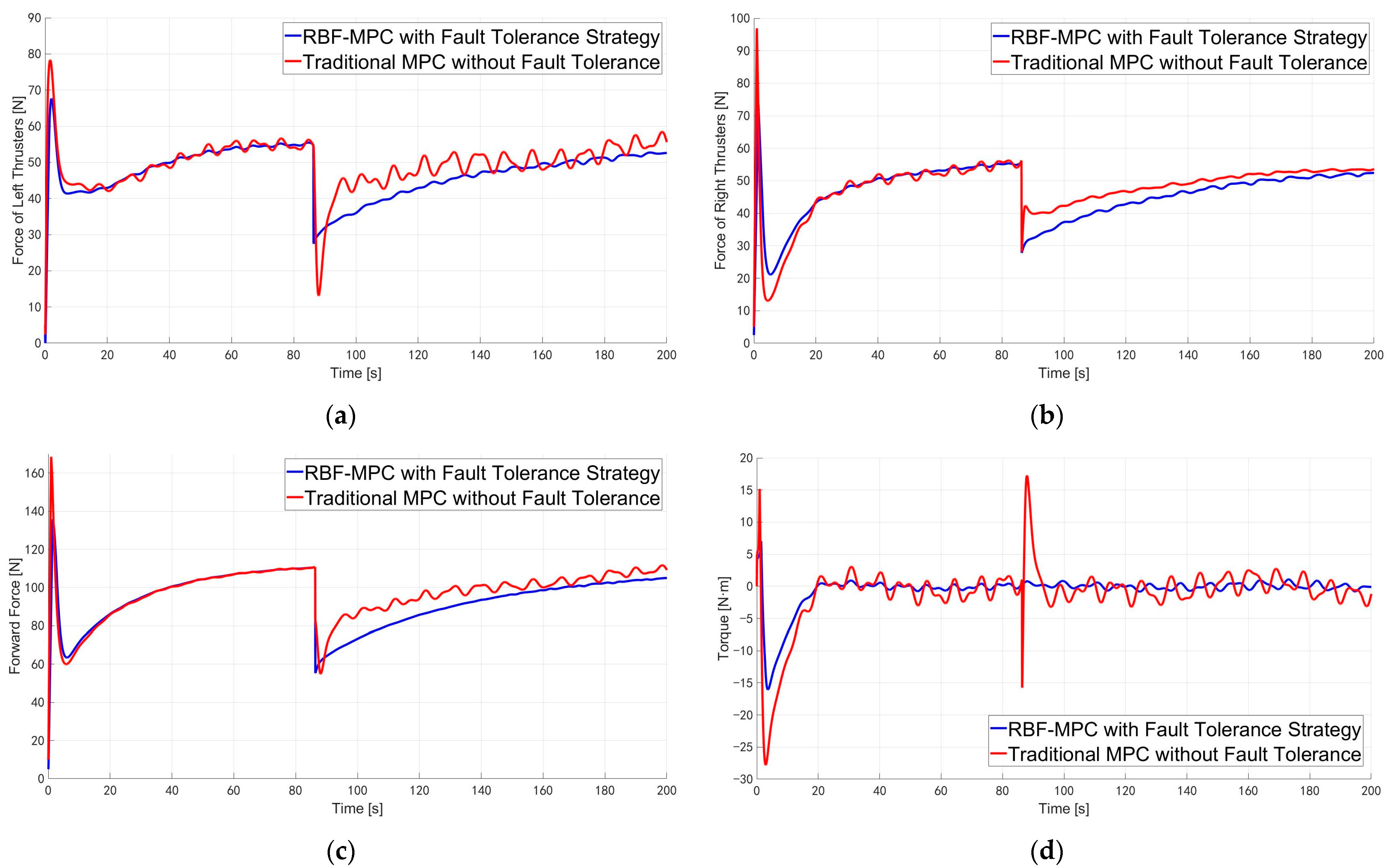

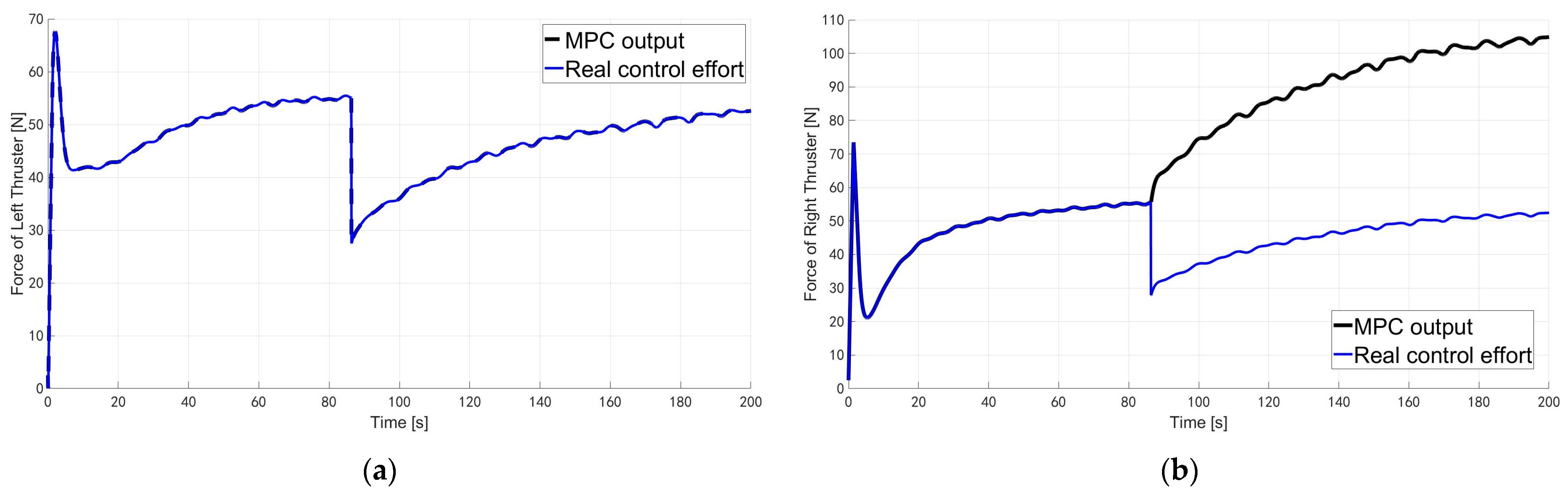

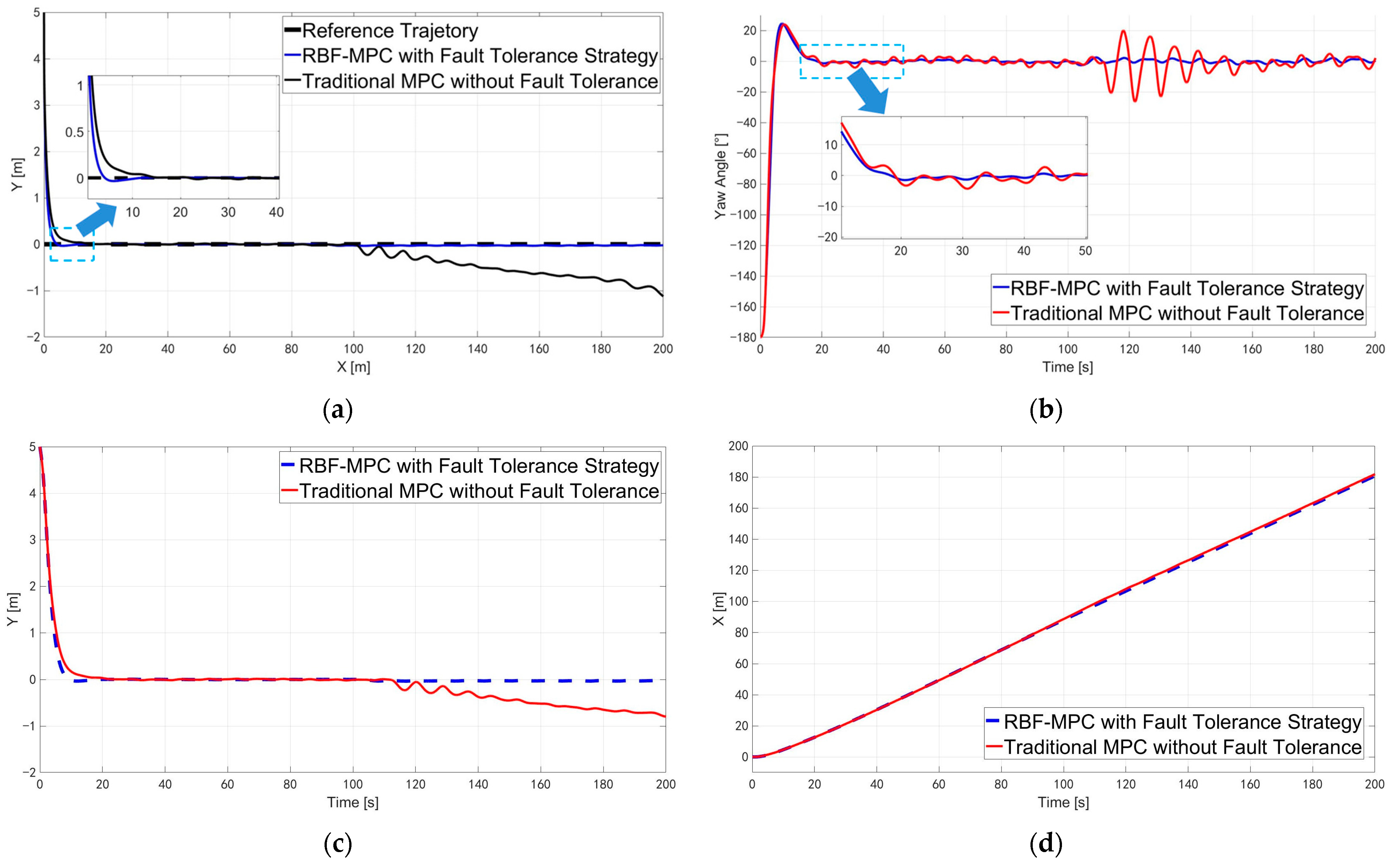

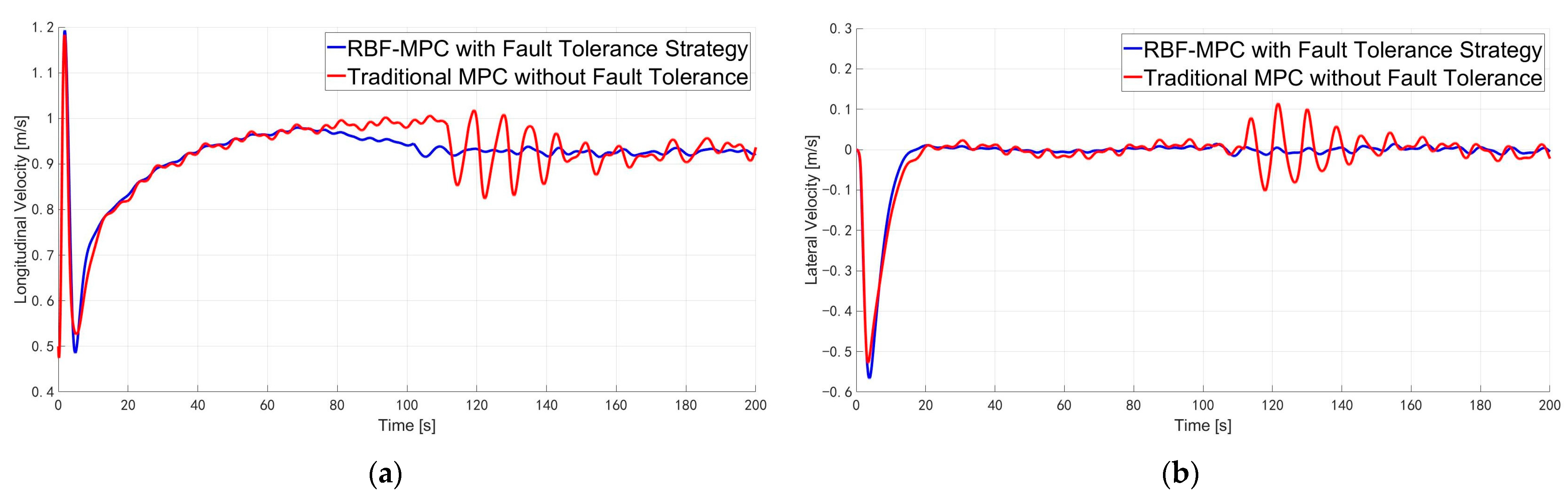

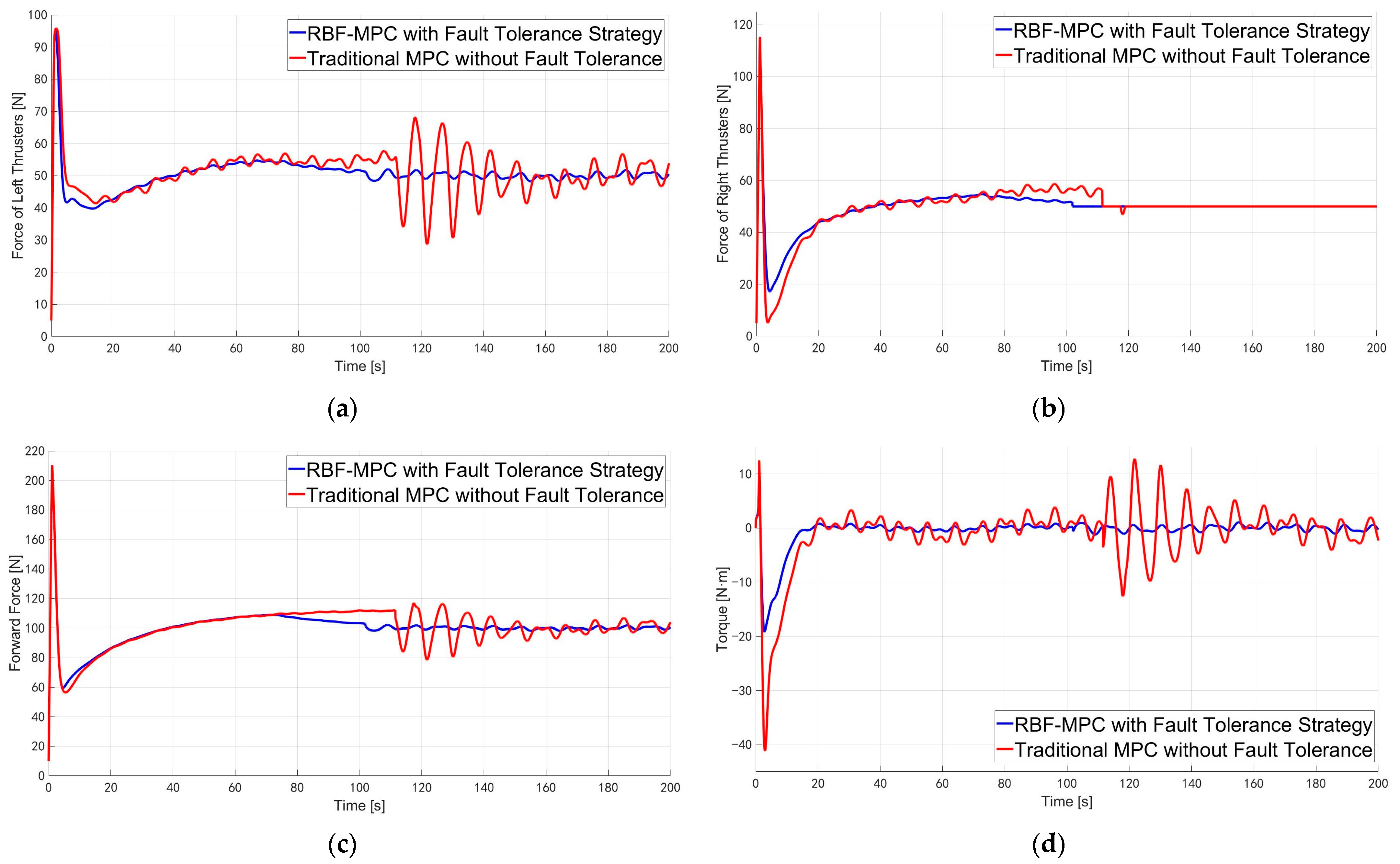

4.2. RBF-MPC with Fault-Tolerance Strategy Performance Comparison in Simulation Studies

5. Conclusions

- (1)

- Application to a USV physical platform: We aim to implement and validate the effectiveness of the proposed method on an actual USV physical platform through experimentation.

- (2)

- Learning-based MPC: We will develop the learning-based MPC algorithm that obviates the need for explicit fault-tolerant strategy design. By leveraging the power of neural networks, we aim to approximate the changes in the USV dynamic model induced by faults, thereby circumventing the task of fault-tolerant strategy design.

- (3)

- Optimization of sampling strategy: We will delve deeper into the optimization of the sampling strategy employed in our path planning algorithm. Additionally, we will try to provide evidence of the algorithm’s probability completeness and asymptotic optimality.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, M.; Liu, Z.; Cai, W.; Yan, Q. Design of Low-cost Unmanned Surface Vessel for Water Surface Cleaning. In Proceedings of the 2021 China Automation Congress (CAC), Beijing, China, 22–24 October 2021; pp. 2290–2293. [Google Scholar]

- Mun, A.; Long, C.; Shen, K.; An, O.; Nugroho, H.; Rusydi, M.I. Fuzzy-based Control System of Unmanned Surface Vehicle (USV) for Floating Garbage Collection. In Proceedings of the 2022 IEEE International Conference on Artificial Intelligence in Engineering and Technology (IICAIET), Kota Kinabalu, Malaysia, 13–15 September 2022; pp. 1–6. [Google Scholar]

- Ntakolia, C.; Lyridis, D.V. Path Planning in the Case of Swarm Unmanned Surface Vehicles for Visiting Multiple Targets. J. Mar. Sci. Eng. 2023, 11, 719. [Google Scholar] [CrossRef]

- Mishra, R.; Koay, T.B.; Chitre, M.; Swarup, S. Multi-USV Adaptive Exploration Using Kernel Information and Residual Variance. Front. Robot. AI 2021, 8, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.; Jeong, S.-K.; Ji, D.-H.; Tran, N.-H.; Vu, M.T.; Choi, H.-S. Study on Control System of Integrated Unmanned Surface Vehicle and Underwater Vehicle. Sensors 2020, 20, 2633. [Google Scholar] [CrossRef] [PubMed]

- Hart, P.E.; Nilsson, N.J.; Raphael, B. A Formal Basis for the Heuristic Determination of Minimum Cost Paths. IEEE Trans. Syst. Sci. Cybern. 1968, 4, 100–107. [Google Scholar] [CrossRef]

- Stentz, A. Optimal and efficient path planning for partially-known environments. In Proceedings of the 1994 IEEE International Conference on Robotics and Automation, San Diego, CA, USA, 8–13 May 1994; pp. 3310–3317. [Google Scholar]

- LaValle, S.M. Randomized Kinodynamic Planning. Int. J. Robot. Res. 2001, 20, 378–400. [Google Scholar] [CrossRef]

- LaValle, S.M. On the Relationship Between Classical Grid Search and Probabilistic Roadmaps. Int. J. Robot. Res. 2004, 23, 673–692. [Google Scholar] [CrossRef]

- Karaman, S.; Frazzoli, E. Sampling-based Algorithms for Optimal Motion Planning. Int. J. Robot. Res. 2011, 30, 846–894. [Google Scholar] [CrossRef]

- Webb, D.J.; Berg, J. Kinodynamic RRT*: Asymptotically optimal motion planning for robots with linear dynamics. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 5054–5061. [Google Scholar]

- Li, Y.; Littlefield, Z.; Bekris, K.E. Asymptotically Optimal Sampling-based Kinodynamic Planning. Int. J. Robot. Res. 2016, 35, 528–564. [Google Scholar] [CrossRef]

- Li, Y.; Cui, R.; Li, Z.; Xu, D. Neural Network Approximation Based Near-Optimal Motion Planning with Kinodynamic Constraints Using RRT. IEEE Trans. Ind. Electron. 2018, 65, 8718–8729. [Google Scholar] [CrossRef]

- Zheng, D.; Tsiotras, P. Accelerating Kinodynamic RRT* Through Dimensionality Reduction. In Proceedings of the 2021 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Prague, Czech Republic, 27 September–October 2021; pp. 3674–3680. [Google Scholar]

- Mao, S.; Yang, P.; Gao, D.; Bao, C.; Wang, Z. A Motion Planning Method for Unmanned Surface Vehicle Based on Improved RRT Algorithm. J. Mar. Sci. Eng. 2023, 11, 687. [Google Scholar] [CrossRef]

- Wen, N.; Zhang, R.; Liu, G. Online planning low-cost paths for unmanned surface vehicles based on the artificial vector field and environmental heuristics. Int. J. Adv. Robot. Sys. 2020, 17, 846–894. [Google Scholar] [CrossRef]

- Wen, N.; Zhang, R.; Wu, J. Online planning for relative optimal and safe paths for USVs using a dual sampling domain reduction-based RRT* method. Int. J. Mach. Learn. Cyber. 2020, 11, 2665–2687. [Google Scholar] [CrossRef]

- Han, S.; Wang, Y.; Wang, L.; He, H. Automatic berthing for an underactuated unmanned surface vehicle: A real-time motion planning approach. Ocean Eng. 2021, 235, 109352. [Google Scholar] [CrossRef]

- Esfahani, H.N.; Szlapczynski, R. Model Predictive Super-Twisting Sliding Mode Control for an Autonomous Surface Vehicle. Polish Mar. Res. 2019, 26, 163–171. [Google Scholar] [CrossRef]

- Liang, X.; Qu, X.; Hou, Y.; Li, Y.; Zhang, R. Distributed coordinated tracking control of multiple unmanned surface vehicles under complex marine environments. Ocean Eng. 2020, 205, 107328. [Google Scholar] [CrossRef]

- Qu, X.; Liang, X.; Hou, Y. Fuzzy State Observer-Based Cooperative Path-Following Control of Autonomous Underwater Vehicles with Unknown Dynamics and Ocean Disturbances. Int. J. Fuzzy Syst. 2021, 23, 1849–1859. [Google Scholar] [CrossRef]

- Kabzan, J.; Hewing, L.; Liniger, A.; Zeilinger, M.N. Learning-Based Model Predictive Control for Autonomous Racing. IEEE Robot. Autom. Lett. 2019, 4, 3363–3370. [Google Scholar] [CrossRef]

- Vu, M.T.; Le, T.-H.; Thanh, H.L.N.N.; Huynh, T.-T.; Van, M.; Hoang, Q.-D.; Do, T.D. Robust Position Control of an Over-actuated Underwater Vehicle under Model Uncertainties and Ocean Current Effects Using Dynamic Sliding Mode Surface and Optimal Allocation Control. Sensors 2021, 21, 747. [Google Scholar] [CrossRef]

- Ning, C.; You, F. Online learning based risk-averse stochastic MPC of constrained linear uncertain systems. Automatica 2021, 125, 109402. [Google Scholar] [CrossRef]

- Xia, L.; Shao, C.; Li, H.; Cui, Y. Robust Model-based Reinforcement Learning USV System Guided by Lyapunov Neural Networks. In Proceedings of the 2022 IEEE International Conference on Robotics and Biomimetics (ROBIO), Jinghong, China, 5–9 December 2022; pp. 1976–1981. [Google Scholar]

- Shen, H.; Lv, Y.; Zhou, J.; Wang, L. An Online Parameter Estimation Method Based on Adaptive Unscented Kalman Filter for Unmanned Surface Vessel. In Proceedings of the 2022 34th Chinese Control and Decision Conference (CCDC), Hefei, China, 15–17 August 2022; pp. 2584–2589. [Google Scholar]

- Qu, X.; Liang, X.; Hou, Y. Path-following control of unmanned surface vehicles with unknown dynamics and unmeasured velocities. J. Mar. Sci. Technol. 2021, 26, 395–407. [Google Scholar] [CrossRef]

- Choo, K.-B.; Cho, H.; Park, J.-H.; Huang, J.; Jung, D.; Lee, J.; Jeong, S.-K.; Yoon, J.; Choo, J.; Choi, H.-S. A Research on Fault Diagnosis of a USV Thruster Based on PCA and Entropy. Appl. Sci. 2023, 13, 3344. [Google Scholar] [CrossRef]

- Yu, X.; Hao, L.; Wang, X. Fault Tolerant Control for an Unmanned Surface Vessel Based on Integral Sliding Mode State Feedback Control. Int. J. Control Autom. Syst. 2022, 20, 2514–2522. [Google Scholar] [CrossRef]

- Tanakitkorn, K.; Phoemsapthawee, S. Impacts of thruster configurations on the task performance of an unmanned surface vehicle. Ocean Eng. 2022, 256, 111465. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, B.; Wu, Z.-G.; Xie, S.; Peng, Y. Adaptive Sliding Mode Fault-Tolerant Fuzzy Tracking Control with Application to Unmanned Marine Vehicles. IEEE Trans. Syst. Man Cybern. 2021, 51, 6691–6700. [Google Scholar] [CrossRef]

- Guo, W.; Lin, X.; Wang, Y. Predictive Fault-tolerant Control for Trajectory Tracking of Unmanned Surface Vehicle. In Proceedings of the 2021 CAA Symposium on Fault Detection, Supervision, and Safety for Technical Processes (SAFEPROCESS), Chengdu, China, 17–18 December 2021; pp. 1–6. [Google Scholar]

- Ding, X.; Zhu, D.; Yan, M. Research on static fault-tolerant control method of thruster based on MPC. J. Mar. Sci. Technol. 2021, 26, 861–871. [Google Scholar] [CrossRef]

- Zhang, G.; Chu, S.; Zhang, W.; Liu, C. Adaptive Neural Fault-Tolerant Control for USV With the Output-Based Triggering Approach. IEEE Trans. Veh. Technol. 2022, 71, 6948–6957. [Google Scholar] [CrossRef]

- Nan, F.; Sun, S.; Foehn, P.; Scaramuzza, D. Nonlinear MPC for Quadrotor Fault-Tolerant Control. IEEE Robot. Autom. Lett. 2022, 7, 5047–5054. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, J. In-Wheel-Motor-Driven Electric Vehicles Motion Control Methods Considering Motor Thermal Protection. J. Dyn. Syst. Meas. Control 2019, 141, 011015. [Google Scholar] [CrossRef]

- Nasir, J.; Islam, F.; Malik, U. RRT*-Smart: A rapid convergence implementation of RRT*. Int. J. Adv. Robot. Syst. 2013, 10, 299–310. [Google Scholar] [CrossRef]

- Chi, W.; Wang, C.; Wang, J.; Meng, M.Q.-H. Risk-DTRRT-Based Optimal Motion Planning Algorithm for Mobile Robots. IEEE Trans. Autom. Sci. Eng. 2019, 16, 1271–1288. [Google Scholar] [CrossRef]

- Vu, M.T.; Van, M.; Bui, D.H.P.; Do, Q.T.; Huynh, T.-T.; Lee, S.-D.; Choi, H.-S. Study on Dynamic Behavior of Unmanned Surface Vehicle-Linked Unmanned Underwater Vehicle System for Underwater Exploration. Sensors 2020, 20, 1329. [Google Scholar] [CrossRef] [PubMed]

| Sampling Times | Algorithm | Running Time | Path Cost | Path Length |

|---|---|---|---|---|

| 2500 | RRT*-smart | 0.45 | × | 608.73 |

| Kino-RRT* | 0.67 | 748.65 | 752.49 | |

| proposed method | 0.56 | 534.57 | 612.31 | |

| 5000 | RRT*-smart | 0.63 | × | 572.46 |

| Kino-RRT* | 1.34 | 647.55 | 698.65 | |

| proposed method | 0.92 | 455.93 | 555.58 |

| Parameter | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Model | 141.85 | 197.75 | 15.6 | −45.6 | −67.26 | −29.54 | −73.85 | −10.71 | −5.59 |

| Real Plant | 153.65 | 204.35 | 18.2 | −40.3 | −67.26 | −30.54 | −70.25 | −10.71 | −5.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Chen, Y.; Gao, J.; Wang, Y.; Pan, G. Collision Avoidance Strategy for Unmanned Surface Vessel Considering Actuator Faults Using Kinodynamic Rapidly Exploring Random Tree-Smart and Radial Basis Function Neural Network-Based Model Predictive Control. J. Mar. Sci. Eng. 2023, 11, 1107. https://doi.org/10.3390/jmse11061107

Song Y, Chen Y, Gao J, Wang Y, Pan G. Collision Avoidance Strategy for Unmanned Surface Vessel Considering Actuator Faults Using Kinodynamic Rapidly Exploring Random Tree-Smart and Radial Basis Function Neural Network-Based Model Predictive Control. Journal of Marine Science and Engineering. 2023; 11(6):1107. https://doi.org/10.3390/jmse11061107

Chicago/Turabian StyleSong, Yunxuan, Yimin Chen, Jian Gao, Yazhou Wang, and Guang Pan. 2023. "Collision Avoidance Strategy for Unmanned Surface Vessel Considering Actuator Faults Using Kinodynamic Rapidly Exploring Random Tree-Smart and Radial Basis Function Neural Network-Based Model Predictive Control" Journal of Marine Science and Engineering 11, no. 6: 1107. https://doi.org/10.3390/jmse11061107

APA StyleSong, Y., Chen, Y., Gao, J., Wang, Y., & Pan, G. (2023). Collision Avoidance Strategy for Unmanned Surface Vessel Considering Actuator Faults Using Kinodynamic Rapidly Exploring Random Tree-Smart and Radial Basis Function Neural Network-Based Model Predictive Control. Journal of Marine Science and Engineering, 11(6), 1107. https://doi.org/10.3390/jmse11061107