Corrosion Damage Evolution Study of the Offshore Cable-Stayed Bridge Anchorage System Based on Accelerated Corrosion Test

Abstract

1. Introduction

2. Tests

2.1. Accelerated Corrosion Test

| Number | Reagents Name | Specification | Technical Parameters | Quantity |

|---|---|---|---|---|

| 1 | NaCl | 500 g/bottle | AR | 40 |

| 2 | CuCl2·2H2O | 500 g/bottle | AR | 2 |

| 3 | CH3COOH | 500 mL/bottle | AR | 8 |

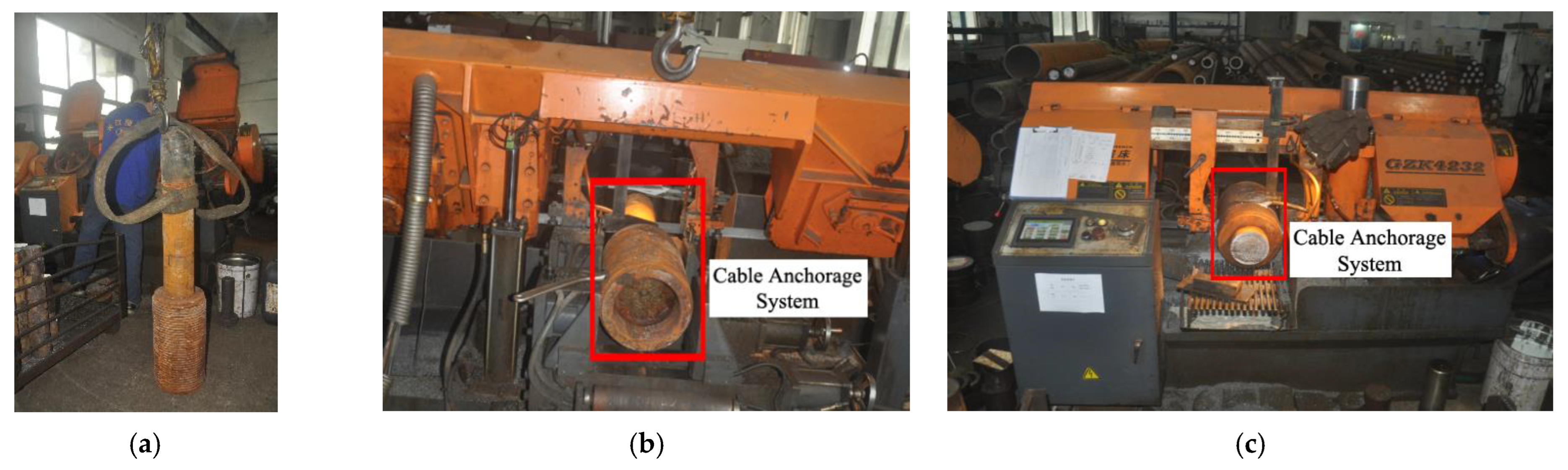

2.2. Anchorage System Dissection Test

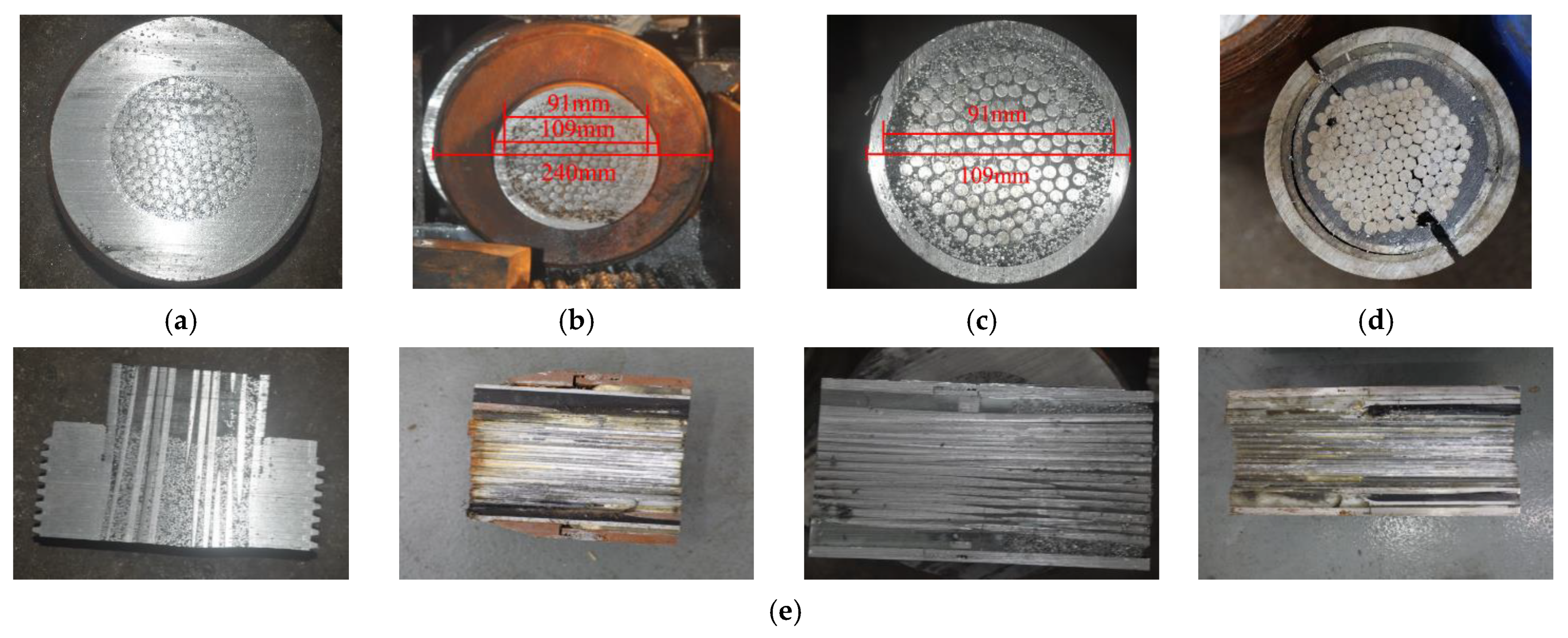

2.2.1. Basic Parameters

2.2.2. Dissection

3. Results and Analysis

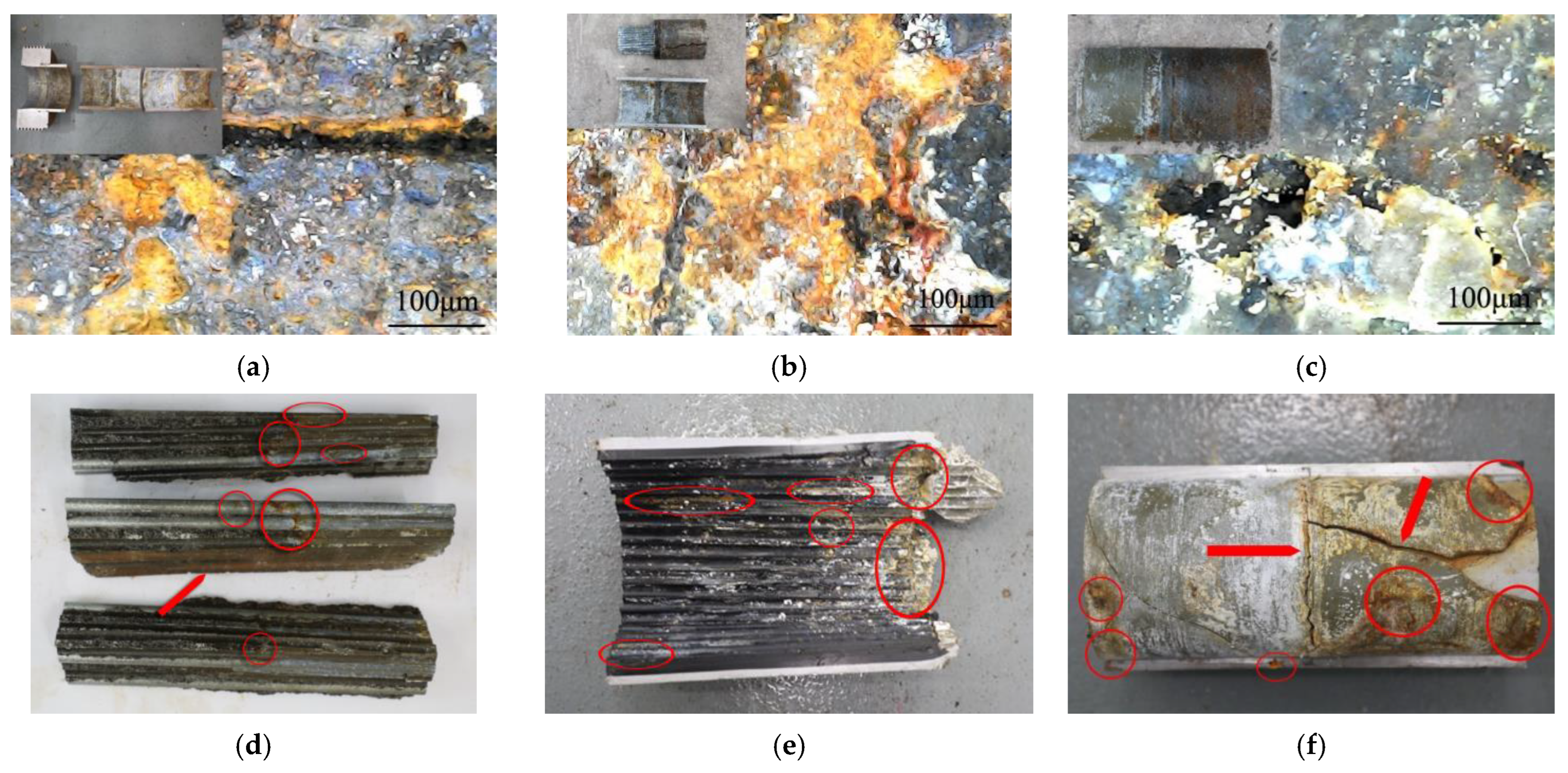

3.1. Anchor Cup, Connecting Barrel and Filling Medium

3.2. Corroded Cable Steel Wires

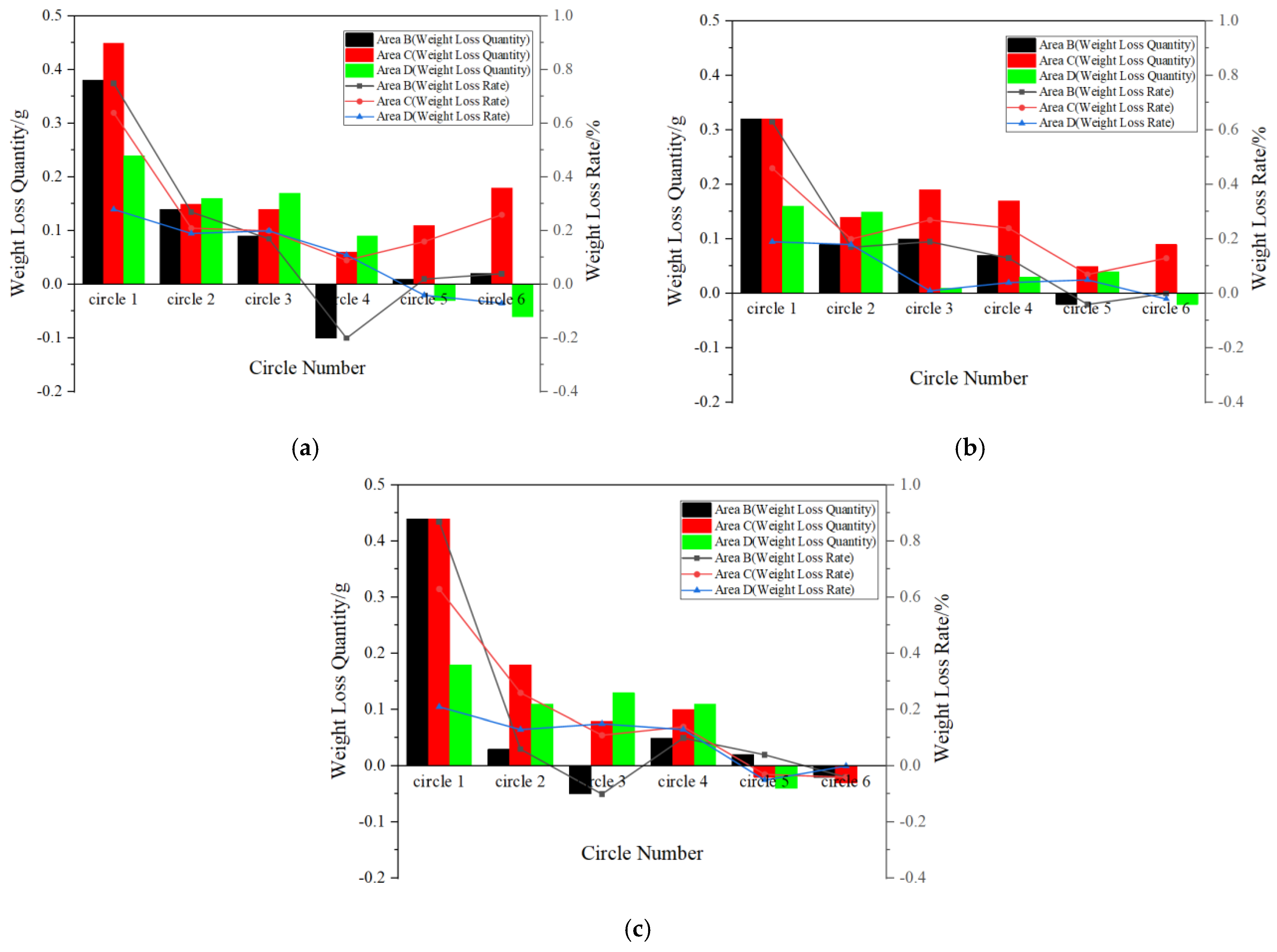

3.2.1. Morphology and Weight Loss

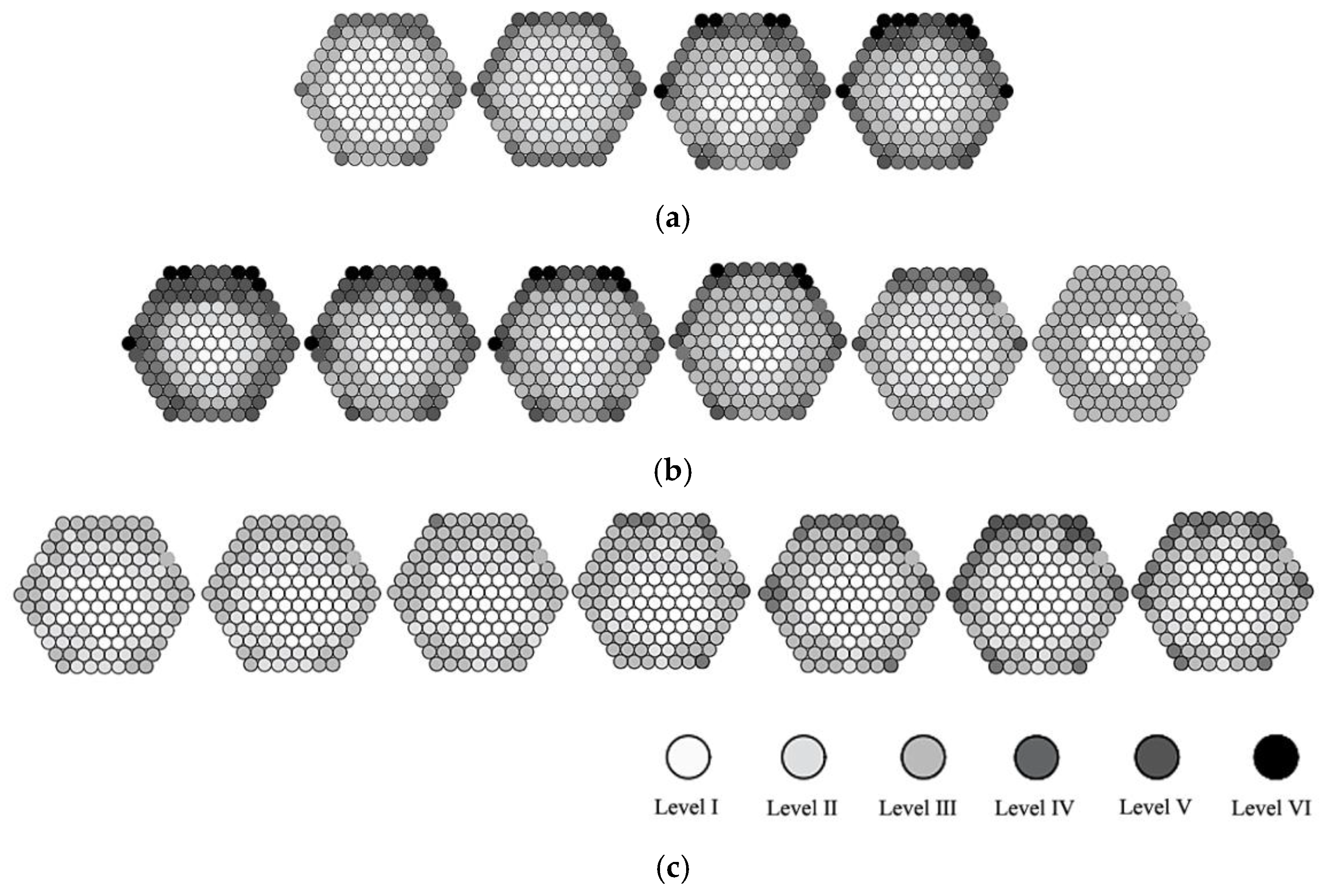

3.2.2. Space Distribution

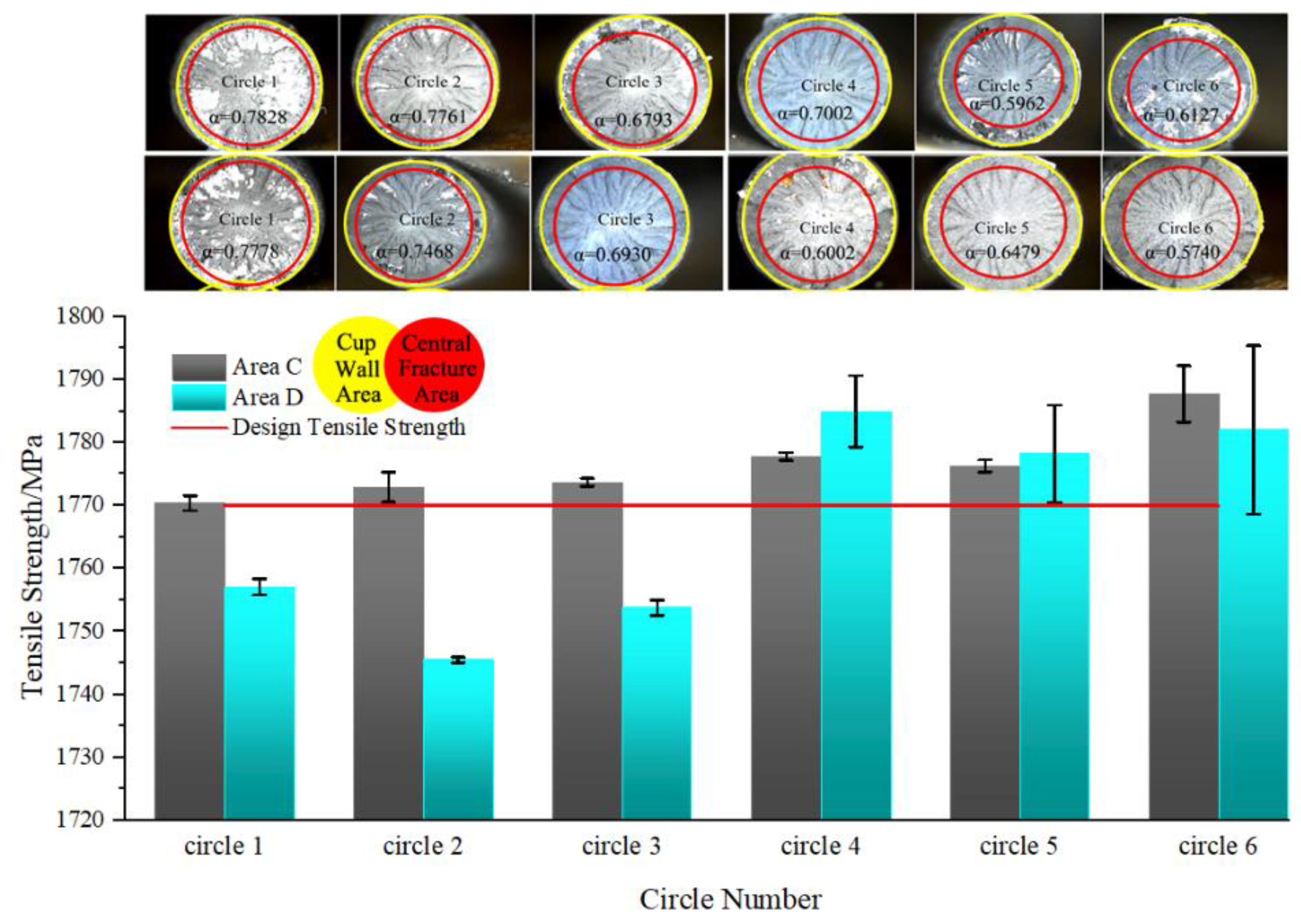

3.2.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, J.; Ruan, X.; Du, H. Design of the oblique saddle-type pylon anchorage system for cable-stayed bridges. Struct. Eng. 2014, 30, 19–24. [Google Scholar]

- Xu, J.; Chen, W. Behavior of wires in parallel wire stayed cable under general corrosion effects. J. Constr. Steel Res. 2013, 85, 40–47. [Google Scholar] [CrossRef]

- McTavish, S.; Raeesi, A.; D’Auteuil, A.; Yamauchi, K.; Sato, H. An investigation of the mechanisms causing large-amplitude wind-induced vibrations in stay cables using unsteady surface pressure measurements. J. Wind Eng. Ind. Aerodyn. 2018, 183, 19–34. [Google Scholar] [CrossRef]

- JT/T775-2016; Cable of Parallel Wires for Large-Span Cable-Stayed Bridge. China Communications Press: Beijing, China, 2016.

- Borchers, C.; Kirchheim, R. Cold-drawn pearlitic steel wires. Prog. Mater. Sci. 2016, 82, 405–444. [Google Scholar] [CrossRef]

- Gao, Z.; Ruan, H.; Qin, S.; Ma, R.; Mei, D. Technical status, challenges and solutions of marine bridge engineering. Strateg. Study CAE 2019, 21, 1–4. [Google Scholar] [CrossRef]

- Reza Kashyzadeh, K.; Amiri, N.; Maleki, E.; Unal, O. A Critical Review on Improving the Fatigue Life and Corrosion Properties of Magnesium Alloys via the Technique of Adding Different Elements. J. Mar. Sci. Eng. 2023, 11, 527. [Google Scholar] [CrossRef]

- Wang, D.; Song, D.; Xu, W.; Zhang, D. Effect of fretting frequency on tension-torsion fretting corrosion fatigue behavior of steel wire. Tribology 2021, 41, 964–973. [Google Scholar]

- He, X.; Guo, Z.; Xu, H. Vehicle impact effect of suspender in half-through arch bridge considering vehicle-bridge coupled vibration. Noise Vib. Control 2022, 42, 206–213. [Google Scholar]

- Editorial Department of China Journal of Highway and Transport. Review on China’s bridge engineering research: 2021. China J. Highw. Transp. 2021, 34, 1–97. [Google Scholar]

- Liao, H.; Li, M.; Ma, C.; Wang, Q.; Sun, Y.; Zhou, Q. State-of-the-art review of bridge wind engineering in 2019. J. Civ. Environ. Eng. 2020, 42, 56–66. [Google Scholar]

- Liu, Q.; Zheng, Y.; Bai, Y.; Shao, Q.; Liu, X.; Ma, W. Parametric optimization of aerodynamic anti-vibration measure for rain-wind induced vibration of cables. J. Vib. Shock 2015, 34, 31–35. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Zheng, Q.; Zhang, W. Study of combined effects of wind and thermal loads on Changtai Changjiang River Bridge. Bridge Constr. 2020, 50, 42–47. [Google Scholar]

- Hu, Z. Experimental Study on the Fatigue Properties and Time-Dependent Corrosion Model of Coastal Bridge Suspenders. MA.Eng. Thesis, Chongqing Jiaotong University, Chongqing, China, 2020. [Google Scholar]

- Chen, Y.; Xu, H.; Yu, Y. Accident analysis of lowered/half supported tied arch bridges and enlightments for bridge detection. J. Fujian Univ. Technol. 2013, 11, 213–217. [Google Scholar]

- Ye, J.; Zhong, J. Corrosion and protection of bridge cable systems. Steel Constr. 2005, 2, 85–89. [Google Scholar]

- Zhu, Z. Experimental Study on the Damage Mechanism of Parallel Wire Cable Under Coupling Load and Electrochemical Corrosion. MA.Eng. Thesis, Chongqing Jiaotong University, Chongqing, China, 2018. [Google Scholar]

- Hamilton, I.H.R.; Breen, J.E.; Frank, K.H. Bridge stay cable corrosion protection. II: Accelerated corrosion tests. J. Bridge Eng. 1998, 3, 72–81. [Google Scholar] [CrossRef]

- Barton, S.C.; Vermaas, G.W.; Duby, P.F.; West, A.C.; Betti, R. Accelerated corrosion and embrittlement of high-strength bridge wire. J. Mater. Civ. Eng. 2000, 12, 33–38. [Google Scholar] [CrossRef]

- Li, W. Experimental Research on Stress Corrosion and Corrosion Fatigue Under Salt Fog Environment and Loading. MA.Eng. Thesis, Chongqing Jiaotong University, Chongqing, China, 2015. [Google Scholar]

- Chen, X.; Tang, M. Corrosion rate of non-galvanized high-strength steel wires under different temperature and humidity conditions. J. Southwest Jiaotong Univ. 2018, 53, 253–259. [Google Scholar]

- Wu, G. Experimental Study on Stress Corrosion and Corrosion Fatigue of Stay Cables Under Acid Rain Condition. MA.Eng. Thesis, Chongqing Jiaotong University, Chongqing, China, 2015. [Google Scholar]

- Nakamura, S.I.; Suzumura, K.; Tarui, T. Mechanical properties and remaining strength of corroded bridge wires. Struct. Eng. Int. 2004, 14, 50–54. [Google Scholar] [CrossRef]

- Mayrbaurl, R.M.; Camo, S. Cracking and fracture of suspension bridge wire. J. Bridge Eng. 2001, 6, 645–650. [Google Scholar] [CrossRef]

- Marandi, L.; Sen, I. Effect of saline atmosphere on the mechanical properties of commercial steel wire. Metall. Mater. Trans. 2019, 50, 132–141. [Google Scholar] [CrossRef]

- Nakamura, S.I.; Suzumura, K. Hydrogen embrittlement and corrosion fatigue of corroded bridge wires. J. Constr. Steel Res. 2008, 65, 269–277. [Google Scholar] [CrossRef]

- Wang, Y.; Ye, H.; Duan, X. Hydrogen embrittlement and corrosion fatigue tests of corroded bridge cables. J. China Foreign Highw. 2014, 34, 110–116. [Google Scholar]

- Mang, Y.; Ye, J.; Zou, L.; Chen, Y. Analysis of corrosion and mechanical properties of steel wire of suspension bridge main cable. J. China Foreign Highw. 2008, 4, 144–149. [Google Scholar]

- Li, X.; Xie, X.; Pan, X.; Sun, W.; Zhu, H. Experimental study on fatigue performance of corroded high tensile steel wires of arch bridge hangers. China Civ. Eng. J. 2015, 48, 68–76. [Google Scholar]

- Nakamura, S.I.; Furuya, K.; Kitagawa, M.; Suzumura, K. Corrosion Performance of New Suspension Bridge Cable Protection; International Association for Bridge and Structural Engineering: Lucerne, Switzerland, 2000. [Google Scholar]

- Yao, G.; He, X.; Liu, J.; Guo, Z.; Chen, P. Test study of the bridge cable corrosion protection mechanism based on impressed current cathodic protection. Lubricants 2023, 11, 30. [Google Scholar] [CrossRef]

- Yuan, Y.; Liu, X.; Pu, G.; Wang, T.; Zheng, D. Temporal and spatial variability of corrosion of high-strength steel wires within a bridge stay cable. Constr. Build. Mater. 2021, 308, 15. [Google Scholar] [CrossRef]

- Betti, R.; West, A.C.; Vermaas, G.; Cao, Y. Corrosion and embrittlement in high-strength wires of suspension bridge cables. J. Bridge Eng. 2005, 10, 151–162. [Google Scholar] [CrossRef]

- Suzumura, K.; Nakamura, S.I. Environmental factors affecting corrosion of galvanized steel wires. J. Mater. Civ. Eng. 2004, 16, 1–7. [Google Scholar] [CrossRef]

- Yao, G.; Du, G.; Li, S. Corrosion Damage Research of Stayed Cable Under Coupling Salt Spray Environment and Loading; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Wu, J. A Novel Anchorage System of CFRP Cables and Its Performance. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2018. [Google Scholar]

- Cui, Q.; Zhu, M.; Zhang, H.; He, X. Experimental study on fire resistance performance of anchorage system for steel strand. Prog. Steel Build. Struct. 2019, 21, 107–113. [Google Scholar]

- Zhou, J.; Wang, X.; Peng, Z.; Wu, Z.; Zhu, Z. Evaluation of a large-tonnage FRP cable anchor system: Anchorage design and full-scale experiment. Eng. Struct. 2022, 251, 113551. [Google Scholar] [CrossRef]

- Feng, B. Study on Anchorage System and Its Long-Term Performance for Large Capacity FRP Cable. Ph.D. Thesis, Southeast University, Nanjing, China, 2019. [Google Scholar]

- Yao, G.; Li, S.; Chen, P.; Gu, L. A Kind of Bridge Cable Impressed Current Cathodic Protection Method, System and Device. Chinese Patent CN111593354B, 10 May 2022. [Google Scholar]

- Yao, G.; He, X.; Wu, Y.; Liu, J.; Li, S.; Jiang, E. Prestressed Flexible Sealing Device for Cable Anchorage System. Chinese Patent CN115418961A, 2 December 2022. [Google Scholar]

- Damiani, M.; Quadrino, A.; Nisticò, N. FRP cables to prestress RC beams: State of the art vs. a split wedge anchorage system. Buildings 2021, 11, 209. [Google Scholar] [CrossRef]

- Ai, P.; Feng, P.; Lin, H.; Zhu, P.; Ding, G. Novel self-anchored CFRP cable system: Concept and anchorage behavior. Compos. Struct. 2021, 263, 113736. [Google Scholar] [CrossRef]

- Li, C.; Guo, R.; Xian, G.; Li, H. Innovative compound-type anchorage system for a large-diameter pultruded carbon/glass hybrid rod for bridge cable. Mater. Struct. 2020, 53, 111966. [Google Scholar] [CrossRef]

- Zuo, X.; Li, Q.; Wen, P. Discussion on the design of cable tower grouping-anchorage system of cable-stayed bridge. J. Highw. Transp. Res. Dev. 2021, 15, 30–39. [Google Scholar] [CrossRef]

- Suzumura, K.; Nakamura, S.I.; Sakamoto, Y. A study on corrosion prevention paste of suspension bridge cable. Kou Kouzou Rombunshuu 2003, 10, 23–30. [Google Scholar]

- Suzumura, K.; Eguchi, T.; Sakamoto, Y.; Nakamura, S.I. Corrosion prevention of suspension bridge cables by S-shaped wire wrapping system. Kou Kouzou Rombunshuu 2003, 10, 31–38. [Google Scholar]

- GB/T 10125-2021; Corrosion Tests in Artificial Atmospheres-Salt Spray Tests. Standards Press of China: Beijing, China, 2021.

- GB/T 24195-2009; Corrosion of Metals and Alloys-Accelerated Cyclic Tests with Exposure to Acidified Salt Spray, “Dry” and “Wet” Conditions. Standards Press of China: Beijing, China, 2009.

- GB/T 20853-2007; Corrosion of Metals and Alloys-Corrosion in Artificial Atmosphere-Accelerated Corrosion Test Involving Exposure Under Controlled Conditions of Humidity Cycling and Intermittent Spraying of a Salt Solution. Standards Press of China: Beijing, China, 2007.

- Wang, Q. Experimental Study on Corrosion Damage Mechanism of the Bridge Cable Anchorage System Under Service Environment. MA.Eng. Thesis, Chongqing Jiaotong University, Chongqing, China, 2022. [Google Scholar]

- Yin, Q. Study on the Corrosion Mechanism of Zinc with Different Influence Factors in Simulated Atmosphere. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2019. [Google Scholar]

- Xu, J. Damage Evolution Mechanism and Remained Service Lives Evaluation of Stayed Cables. Ph.D. Thesis, Tongji University, Shanghai, China, 2006. [Google Scholar]

- Xiang, W. Experimental Study on Corrosion Damage of Stay Cable’s Anchorage System Under Salt Fog Environment. MA.Eng. Thesis, Chongqing Jiaotong University: Chongqing, China, 2020. [Google Scholar]

- Chen, J. Experimental Study on Corrosion Damage of HDPE System of Stayed Cables Under Environment and Loading. MA.Eng. Thesis, Chongqing Jiaotong University: Chongqing, China, 2020. [Google Scholar]

- GB/T 228.1-2021; Metallic Materials-Tensile Testing-Part 1, Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2021.

- GB/T 8358-2014; Steel Wire Ropes-Determination of Measured Breaking Force. Standards Press of China: Beijing, China, 2014.

| Number | Equipment Name | Model | Technical Parameters | Quantity |

|---|---|---|---|---|

| 1 | Salt spray test chamber | YC-200 | Geometric dimension: 2700 mm × 1500 mm × 1500 mm | 1 |

| 2 | Precision acidity measuring instrument | PHS-3C | 1 | |

| 3 | Air compressor | VB-0.2/8 | 2.2 kW | 1 |

| 4 | Electronic balance | SL500ZN | Precision: 0.01 g | 1 |

| 5 | Industrial digital microscope | SK2700H | 1 | |

| 6 | Digital camera | CANON EOS | 1 |

| Model of Anchorage | External Diameter of Anchor Cup | Length of Anchor Cup | External Diameter of Anchor Ring | Height of Anchor Ring | Weight of Anchorage |

|---|---|---|---|---|---|

| LM(1770)-7-127 | 240 mm | 450 mm | 310 mm | 135 mm | 140 kg |

| Model of Cable | External Diameter of the Cable | Thickness of Sheath | Unit Mass of Cable | Diameter of Naked Cable | Area of Naked Cable | Unit Mass of Naked Cable |

|---|---|---|---|---|---|---|

| LPES(1770)-7-127-Zn | 109 mm | 9 mm | 41.1 kg/m | 91 mm | 4888 mm2 | 38.4 kg/m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, G.; He, X.; Long, H.; Lu, J.; Wang, Q. Corrosion Damage Evolution Study of the Offshore Cable-Stayed Bridge Anchorage System Based on Accelerated Corrosion Test. J. Mar. Sci. Eng. 2023, 11, 896. https://doi.org/10.3390/jmse11050896

Yao G, He X, Long H, Lu J, Wang Q. Corrosion Damage Evolution Study of the Offshore Cable-Stayed Bridge Anchorage System Based on Accelerated Corrosion Test. Journal of Marine Science and Engineering. 2023; 11(5):896. https://doi.org/10.3390/jmse11050896

Chicago/Turabian StyleYao, Guowen, Xuanbo He, Hong Long, Jiangshan Lu, and Qianling Wang. 2023. "Corrosion Damage Evolution Study of the Offshore Cable-Stayed Bridge Anchorage System Based on Accelerated Corrosion Test" Journal of Marine Science and Engineering 11, no. 5: 896. https://doi.org/10.3390/jmse11050896

APA StyleYao, G., He, X., Long, H., Lu, J., & Wang, Q. (2023). Corrosion Damage Evolution Study of the Offshore Cable-Stayed Bridge Anchorage System Based on Accelerated Corrosion Test. Journal of Marine Science and Engineering, 11(5), 896. https://doi.org/10.3390/jmse11050896