Optimizing Berth Allocation in Maritime Transportation with Quay Crane Setup Times Using Reinforcement Learning

Abstract

1. Introduction

2. Literature Review

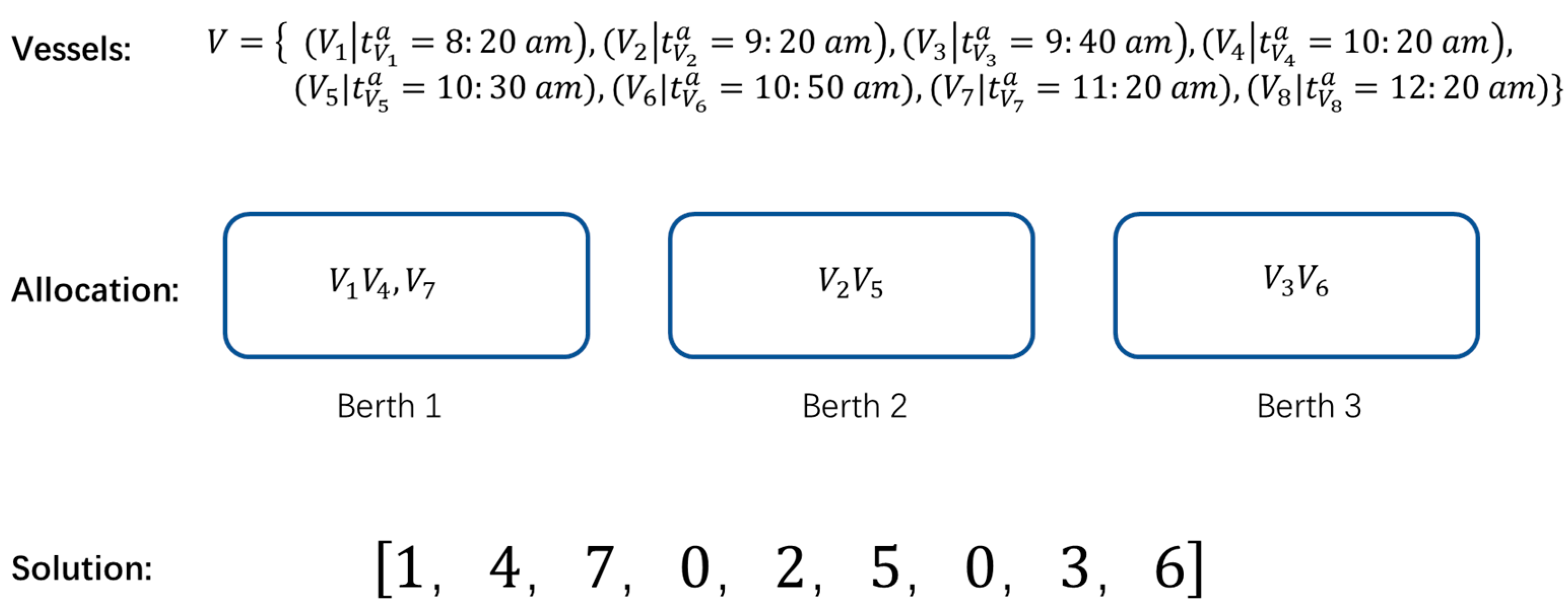

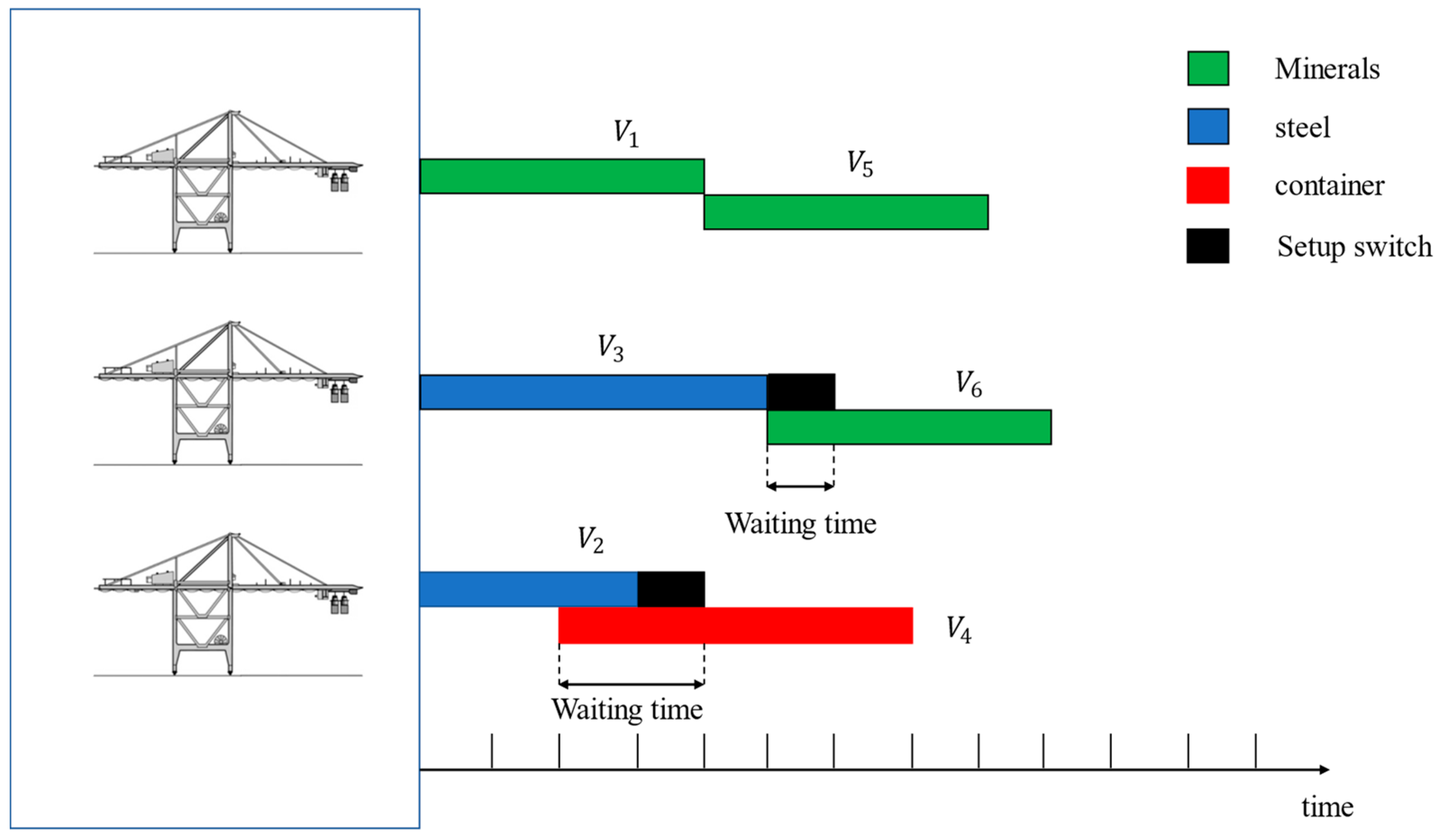

3. Problem Definition

4. Offline Case

4.1. Optimization Formulation

4.2. Greedy Insert Algorithm

| Algorithm 1. Greedy Insert |

| 1: Input: , 2: Initialize: 3: while or : 4: Randomly select with index 5: = 6: 7: end while 8: return x |

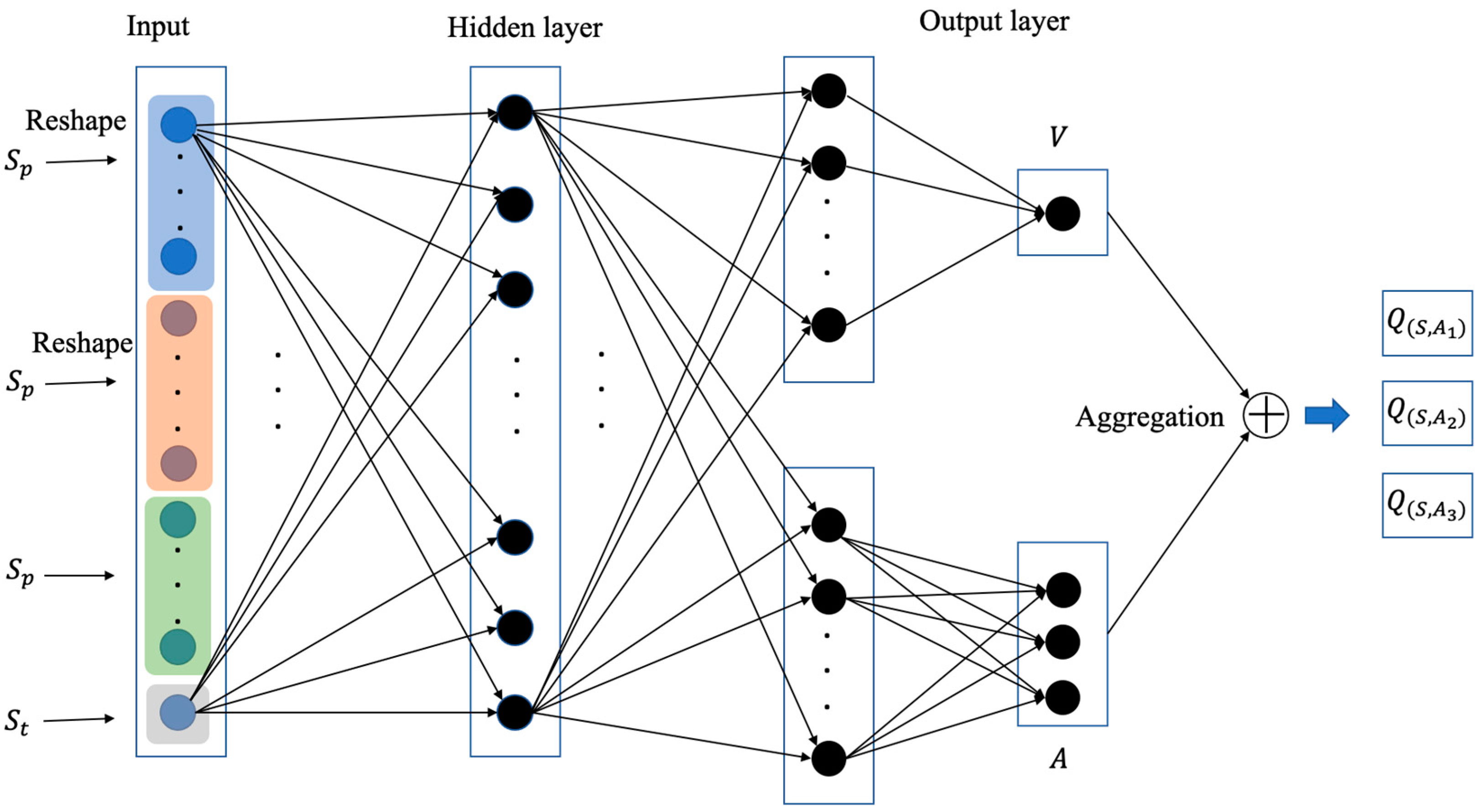

5. Online Case

5.1. MDP Formulation

- : The most important status is to describe the current working situation of the quay cranes of the corresponding berths. We define the matrix to represent the remaining working time of each berth. In , each row means a berth, and each column means a type of cargo; thus, the entries are the remaining time of a specific type of cargo processed in a specific berth;

- : To capture the history of the berths and the quay cranes, we define a matrix , which has a similar structure to but which represents the processed working time for each type of cargo at each berth;

- : We also define a vector to represent the service time of the arrival vessels that are being allocated into different berths;

- : A scalar represents the type of cargo that the arrival vessel carries.

5.2. Dueling-DQN-Based Algorithm

| Algorithm 2. DDQN Training |

| 1: Input: , 2: Initialize: Initialize the weight of network 3: for do 4: Initialize states 5: for do 6: select action a based on -greedy 7: Update state 8: Store transition in replay memory 9: Sample random minibatch of transitions from 10: Calculate value function and advantage function 11: Aggregate Q value 12: Perform a gradient descent step 13: end for 14: end for 15: return w |

6. Numerical Results

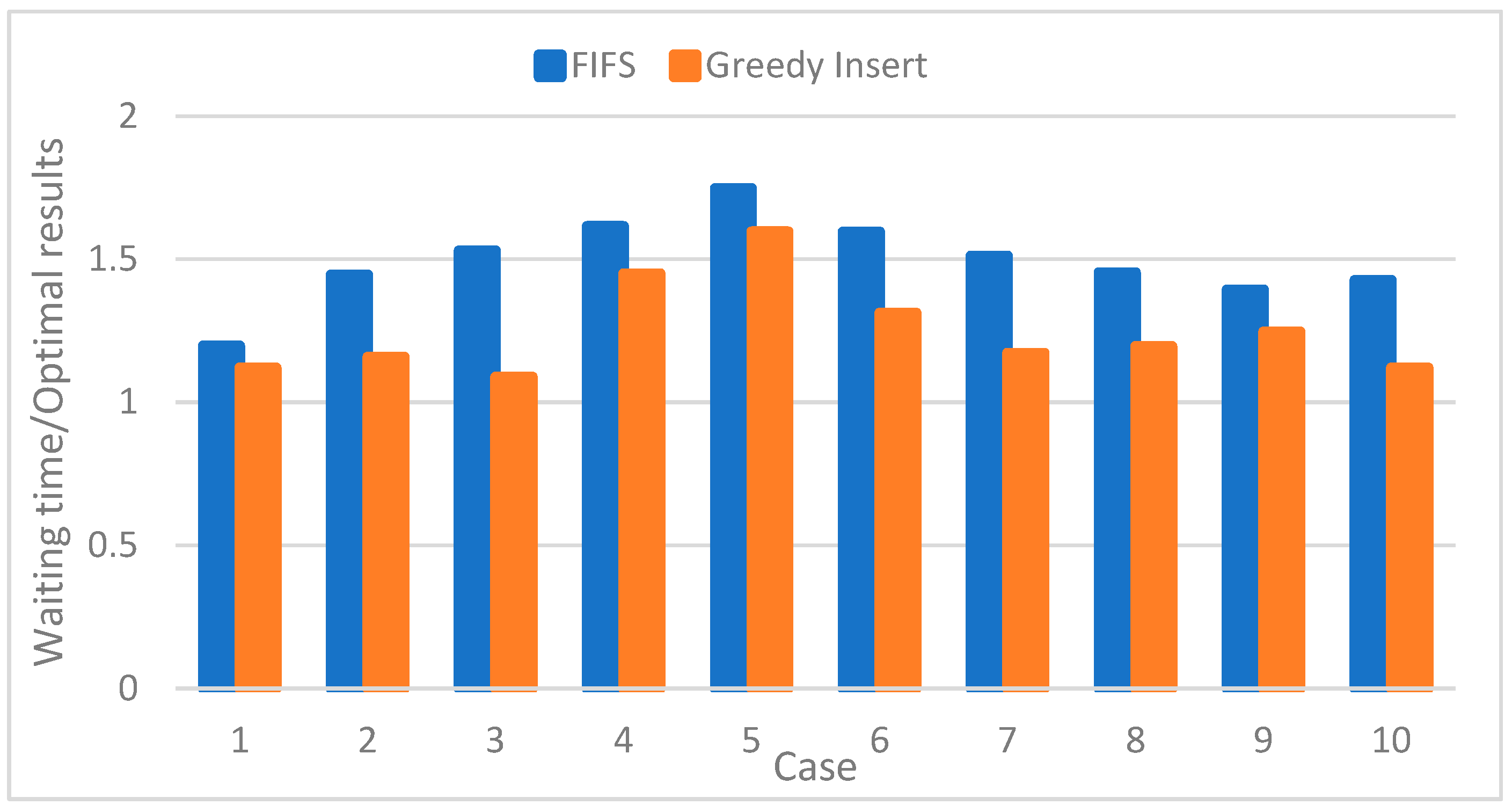

6.1. Offline Case

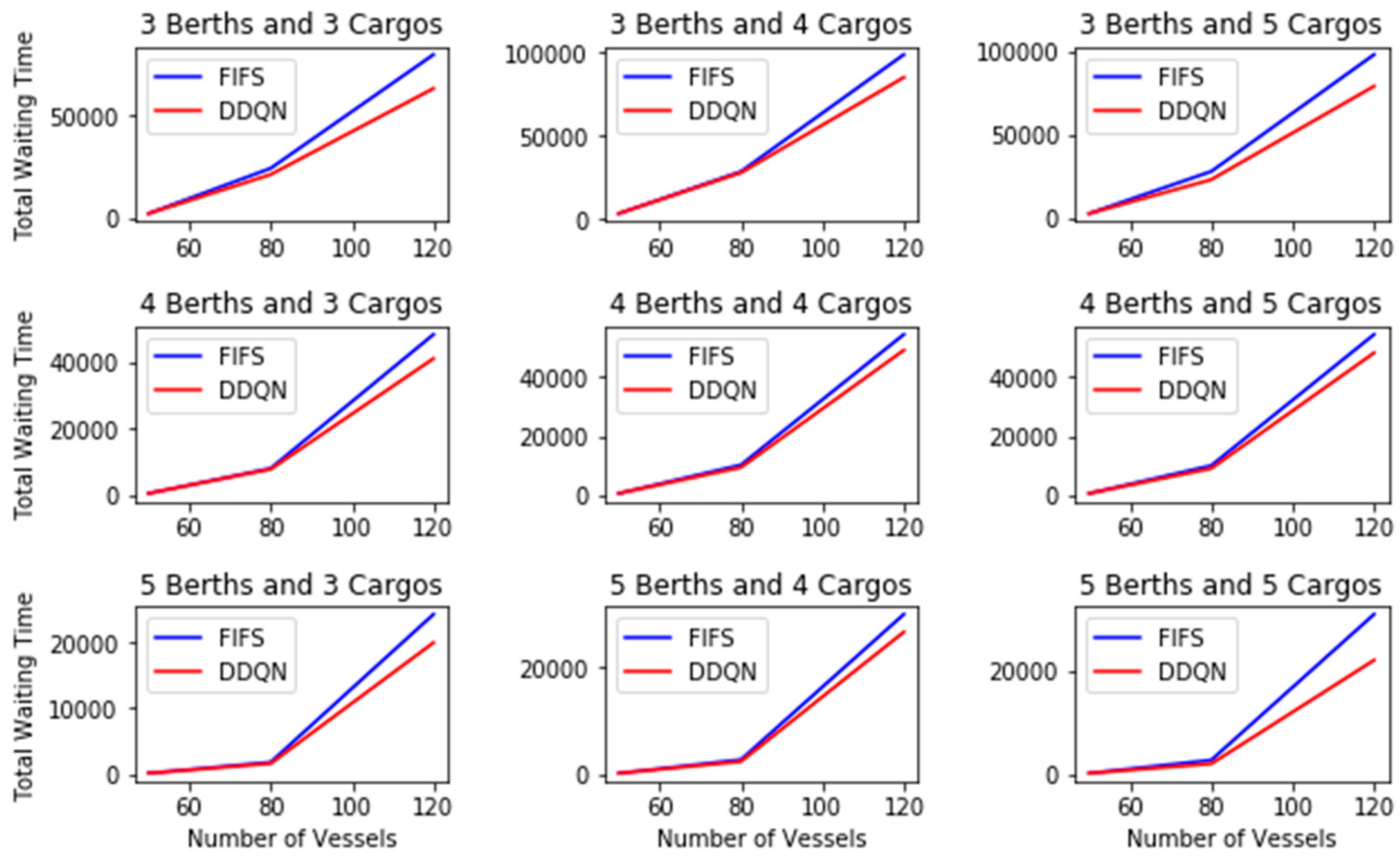

6.2. Online Case

7. Discussion and Conclusions

7.1. Discussion

7.2. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mnasri, S.; Alrashidi, M. A comprehensive modeling of the discrete and dynamic problem of berth allocation in maritime terminals. Electronics 2021, 10, 2684. [Google Scholar] [CrossRef]

- Iris, Ç.; Pacino, D.; Ropke, S.; Larsen, A. Integrated berth allocation and quay crane assignment problem: Set partitioning models and computational results. Transp. Res. Part E Logist. Transp. Rev. 2015, 81, 75–97. [Google Scholar] [CrossRef]

- Venturini, G.; Iris, Ç.; Kontovas, C.A.; Larsen, A. The multi-port berth allocation problem with speed optimization and emission considerations. Transp. Res. Part D Transp. Environ. 2017, 54, 142–159. [Google Scholar] [CrossRef]

- Lai, K.K.; Shih, K. A study of container berth allocation. J. Adv. Transp. 1992, 26, 45–60. [Google Scholar] [CrossRef]

- Kim, K.H.; Park, Y.M. A crane scheduling method for port container terminals. Eur. J. Oper. Res. 2004, 156, 752–768. [Google Scholar] [CrossRef]

- Iris, Ç.; Lam, J.S.L. Optimal energy management and operations planning in seaports with smart grid while harnessing renewable energy under uncertainty. Omega 2021, 103, 102445. [Google Scholar] [CrossRef]

- Bierwirth, C.; Meisel, F. A follow-up survey of berth allocation and quay crane scheduling problems in container terminals. Eur. J. Oper. Res. 2015, 244, 675–689. [Google Scholar] [CrossRef]

- Rodrigues, F.; Agra, A. Berth allocation and quay crane assignment/scheduling problem under uncertainty: A survey. Eur. J. Oper. Res. 2022, 303, 501–524. [Google Scholar] [CrossRef]

- Iris, Ç.; Lam, J.S.L. Recoverable robustness in weekly berth and quay crane planning. Transp. Res. Part B Methodol. 2019, 122, 365–389. [Google Scholar] [CrossRef]

- Xiang, X.; Liu, C. An expanded robust optimisation approach for the berth allocation problem considering uncertain operation time. Omega 2021, 103, 102444. [Google Scholar] [CrossRef]

- Gutierrez, F.; Lujan, E.; Asmat, R.; Vergara, E. Fuzziness in the berth allocation problem. In Recent Advances in Computational Optimization: Results of the Workshop on Computational Optimization WCO 2017; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 149–174. [Google Scholar]

- Lujan, E.; Vergara, E.; Rodriguez-Melquiades, J.; Jiménez-Carrión, M.; Sabino-Escobar, C.; Gutierrez, F. A fuzzy optimization model for the berth allocation problem and quay crane allocation problem (BAP + QCAP) with n quays. J. Mar. Sci. Eng. 2021, 9, 152. [Google Scholar] [CrossRef]

- Xiang, X.; Liu, C.; Miao, L. A bi-objective robust model for berth allocation scheduling under uncertainty. Transp. Res. Part E Logist. Transp. Rev. 2017, 106, 294–319. [Google Scholar] [CrossRef]

- Agra, A.; Oliveira, M. MIP approaches for the integrated berth allocation and quay crane assignment and scheduling problem. Eur. J. Oper. Res. 2018, 264, 138–148. [Google Scholar] [CrossRef]

- Tengecha, N.A.; Zhang, X. An Efficient Algorithm for the Berth and Quay Crane Assignments Considering Operator Performance in Container Terminal Using Particle Swarm Model. J. Mar. Sci. Eng. 2022, 10, 1232. [Google Scholar] [CrossRef]

- Lee, D.H.; Chen, J.H. An improved approach for quay crane scheduling with non-crossing constraints. Eng. Optim. 2010, 42, 1–15. [Google Scholar] [CrossRef]

- Liu, M.; Zheng, F.; Li, J. Scheduling small number of quay cranes with non-interference constraint. Optim. Lett. 2015, 9, 403–412. [Google Scholar] [CrossRef]

- de Andrade, J.L.M.; Menezes, G.C. A column generation-based heuristic to solve the integrated planning, scheduling, yard allocation and berth allocation problem in bulk ports. J. Heuristics 2023, 29, 39–76. [Google Scholar] [CrossRef]

- Guo, L.; Zheng, J.; Du, H.; Du, J.; Zhu, Z. The berth assignment and allocation problem considering cooperative liner carriers. Transp. Res. Part E Logist. Transp. Rev. 2022, 164, 102793. [Google Scholar] [CrossRef]

- Tang, M.; Ji, B.; Fang, X.; Yu, S.S. Discretization-strategy-based solution for berth allocation and quay crane assignment problem. J. Mar. Sci. Eng. 2022, 10, 495. [Google Scholar] [CrossRef]

- Lv, X.; Jin, J.G.; Hu, H. Berth allocation recovery for container transshipment terminals. Marit. Policy Manag. 2020, 47, 558–574. [Google Scholar] [CrossRef]

- Ji, B.; Tang, M.; Wu, Z.; Samson, S.Y.; Zhou, S.; Fang, X. Hybrid rolling-horizon optimization for berth allocation and quay crane assignment with unscheduled vessels. Adv. Eng. Inform. 2022, 54, 101733. [Google Scholar] [CrossRef]

- Iris, Ç.; Lalla-Ruiz, E.; Lam, J.S.L.; Voß, S. Mathematical programming formulations for the strategic berth template problem. Comput. Ind. Eng. 2018, 124, 167–179. [Google Scholar] [CrossRef]

- Zhao, S.; Zhao, X.; Farnell, C.; Mantooth, H.A.; Umuhoza, J.; Zhang, Y. A daily optimization method for a PV-battery microgrid considering the battery lifetime and time-of-use pricing. In Proceedings of the 2019 IEEE Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 17–21 March 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 3243–3250. [Google Scholar]

- Hu, X.; Ji, S.; Hua, H.; Zhou, B.; Hu, G. An Improved Genetic Algorithm for Berth Scheduling at Bulk Terminal. Comput. Syst. Sci. Eng. 2022, 43, 1285–1296. [Google Scholar] [CrossRef]

- Jiang, X.; Zhong, M.; Shi, J.; Li, W.; Sui, Y.; Dou, Y. Overall Scheduling Model for Vessels Scheduling and Berth Allocation for Ports with Restricted Channels That Considers Carbon Emissions. J. Mar. Sci. Eng. 2022, 10, 1757. [Google Scholar] [CrossRef]

- Yu, J.; Tang, G.; Song, X. Collaboration of vessel speed optimization with berth allocation and quay crane assignment considering vessel service differentiation. Transp. Res. Part E Logist. Transp. Rev. 2022, 160, 102651. [Google Scholar] [CrossRef]

- Fatemi-Anaraki, S.; Tavakkoli-Moghaddam, R.; Abdolhamidi, D.; Vahedi-Nouri, B. Simultaneous waterway scheduling, berth allocation, and quay crane assignment: A novel matheuristic approach. Int. J. Prod. Res. 2021, 59, 7576–7593. [Google Scholar] [CrossRef]

- Yu, F.; Shan, Q.; Xiao, Y.; Teng, F. Robust Low-Carbon Discrete Berth Allocation under Uncertainty. Int. Trans. Electr. Energy Syst. 2022, 2022, 5310004. [Google Scholar] [CrossRef]

- Liu, B.; Li, Z.C.; Wang, Y. A two-stage stochastic programming model for seaport berth and channel planning with uncertainties in ship arrival and handling times. Transp. Res. Part E Logist. Transp. Rev. 2022, 167, 102919. [Google Scholar] [CrossRef]

- Liu, B.; Li, Z.C.; Wang, Y.; Sheng, D. Short-term berth planning and ship scheduling for a busy seaport with channel restrictions. Transp. Res. Part E Logist. Transp. Rev. 2021, 154, 102467. [Google Scholar] [CrossRef]

- Iris, Ç.; Pacino, D.; Ropke, S. Improved formulations and an adaptive large neighborhood search heuristic for the integrated berth allocation and quay crane assignment problem. Transp. Res. Part E Logist. Transp. Rev. 2017, 105, 123–147. [Google Scholar] [CrossRef]

- Meisel, F.; Bierwirth, C. A framework for integrated berth allocation and crane operations planning in seaport container terminals. Transp. Sci. 2013, 47, 131–147. [Google Scholar] [CrossRef]

- Legato, P.; Trunfio, R. A local branching-based algorithm for the quay crane scheduling problem under unidirectional schedules. 4OR Q. J. Oper. Res. 2014, 12, 123–156. [Google Scholar] [CrossRef]

- Huang, Q.; Huang, R.; Hao, W.; Tan, J.; Fan, R.; Huang, Z. Adaptive power system emergency control using deep reinforcement learning. IEEE Trans. Smart Grid 2019, 11, 1171–1182. [Google Scholar] [CrossRef]

- Xiao, X.; Waddell, C.; Hamilton, C.; Xiao, H. Quality Prediction and Control in Wire Arc Additive Manufacturing via Novel Machine Learning Framework. Micromachines 2022, 13, 137. [Google Scholar] [CrossRef]

- Wan, Z.; Jiang, C.; Fahad, M.; Ni, Z.; Guo, Y.; He, H. Robot-assisted pedestrian regulation based on deep reinforcement learning. IEEE Trans. Cybern. 2018, 50, 1669–1682. [Google Scholar] [CrossRef]

- Xiao, X.; Joshi, S. Process planning for five-axis support free additive manufacturing. Addit. Manuf. 2020, 36, 101569. [Google Scholar] [CrossRef]

- Xiao, X.; Roh, B.M.; Hamilton, C. Porosity management and control in powder bed fusion process through process-quality interactions. CIRP J. Manuf. Sci. Technol. 2022, 38, 120–128. [Google Scholar] [CrossRef]

- Mnih, V.; Kavukcuoglu, K.; Silver, D.; Rusu, A.A.; Veness, J.; Bellemare, M.G.; Graves, A.; Riedmiller, M.; Fidjeland, A.K.; Ostrovski, G.; et al. Human-level control through deep reinforcement learning. Nature 2015, 518, 529–533. [Google Scholar] [CrossRef]

| Notation | Meaning |

|---|---|

| Set of vessels | |

| Set of berths | |

| Set of cargo types | |

| Service time of vessel v in berth b | |

| Start service time of vessel v | |

| Arrival time of vessel v | |

| Setup changing time between cargo types |

| Vessel | Arrival Time | Cargo Type | Service Time (min) |

|---|---|---|---|

| 8:20 a.m. | A | 140 | |

| 9:20 a.m. | A | 90 | |

| 9:40 a.m. | B | 100 | |

| 10:20 a.m. | C | 65 | |

| 10:30 a.m. | C | 70 | |

| 10:50 a.m. | B | 90 | |

| 11:20 a.m. | A | 120 |

| Notation | Meaning | Dimension |

|---|---|---|

| In-processing berth status | ||

| Processing history | ||

| Service time of the arrival vessel | ||

| Type of cargo | 1 |

| Case No. | Optimal | FIFS | Greedy Insert |

|---|---|---|---|

| Computation time | 225 s | 0.03 s | 1.1 s |

| 1 | 18,233 min | 21,823 min | 20,435 min |

| 2 | 19,338 min | 27,949 min | 22,391 min |

| 3 | 17,391 min | 26,596 min | 18,935 min |

| 4 | 19,476 min | 31,450 min | 28,234 min |

| 5 | 16,758 min | 29,273 min | 26,743 min |

| 6 | 17,698 min | 28,229 min | 23,210 min |

| 7 | 18,290 min | 27,652 min | 21,431 min |

| 8 | 24,210 min | 35,183 min | 28,947 min |

| 9 | 19,261 min | 26,832 min | 23,998 min |

| 10 | 18,992 min | 27,079 min | 21,284 min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Y.; Li, Z.; Wang, B. Optimizing Berth Allocation in Maritime Transportation with Quay Crane Setup Times Using Reinforcement Learning. J. Mar. Sci. Eng. 2023, 11, 1025. https://doi.org/10.3390/jmse11051025

Dai Y, Li Z, Wang B. Optimizing Berth Allocation in Maritime Transportation with Quay Crane Setup Times Using Reinforcement Learning. Journal of Marine Science and Engineering. 2023; 11(5):1025. https://doi.org/10.3390/jmse11051025

Chicago/Turabian StyleDai, Yonggai, Zongchen Li, and Boyu Wang. 2023. "Optimizing Berth Allocation in Maritime Transportation with Quay Crane Setup Times Using Reinforcement Learning" Journal of Marine Science and Engineering 11, no. 5: 1025. https://doi.org/10.3390/jmse11051025

APA StyleDai, Y., Li, Z., & Wang, B. (2023). Optimizing Berth Allocation in Maritime Transportation with Quay Crane Setup Times Using Reinforcement Learning. Journal of Marine Science and Engineering, 11(5), 1025. https://doi.org/10.3390/jmse11051025