Analysis of Exhaust Pollutants from Four-Stroke Marine Diesel Engines Based on Bench Tests

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Engines

2.2. Emission Regulations

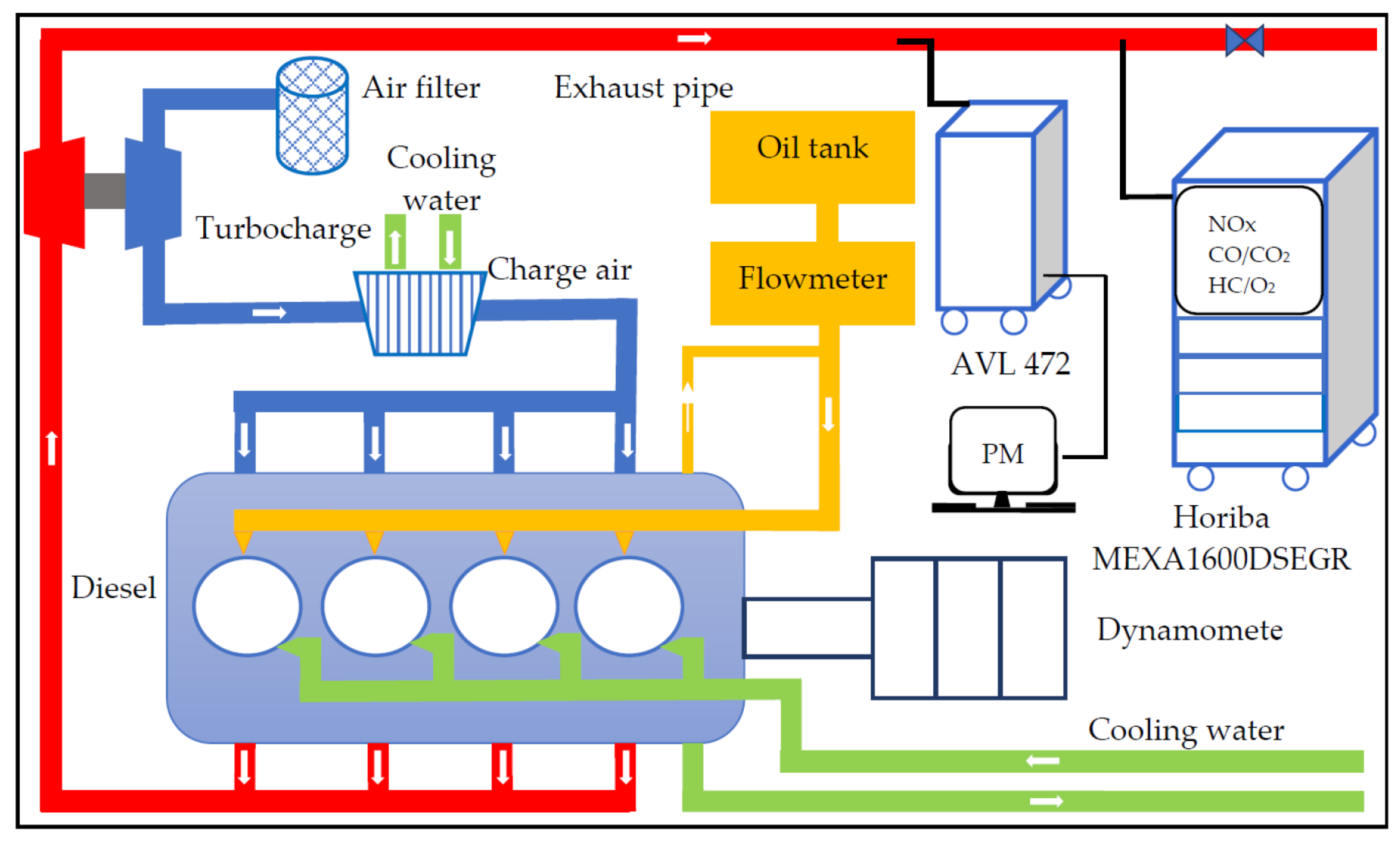

2.3. Test Measurement System and Bench Test

2.4. Calculation Method

2.5. Fuel Information

3. Results and Discussion

3.1. Fuel-Based Average Emission Factors

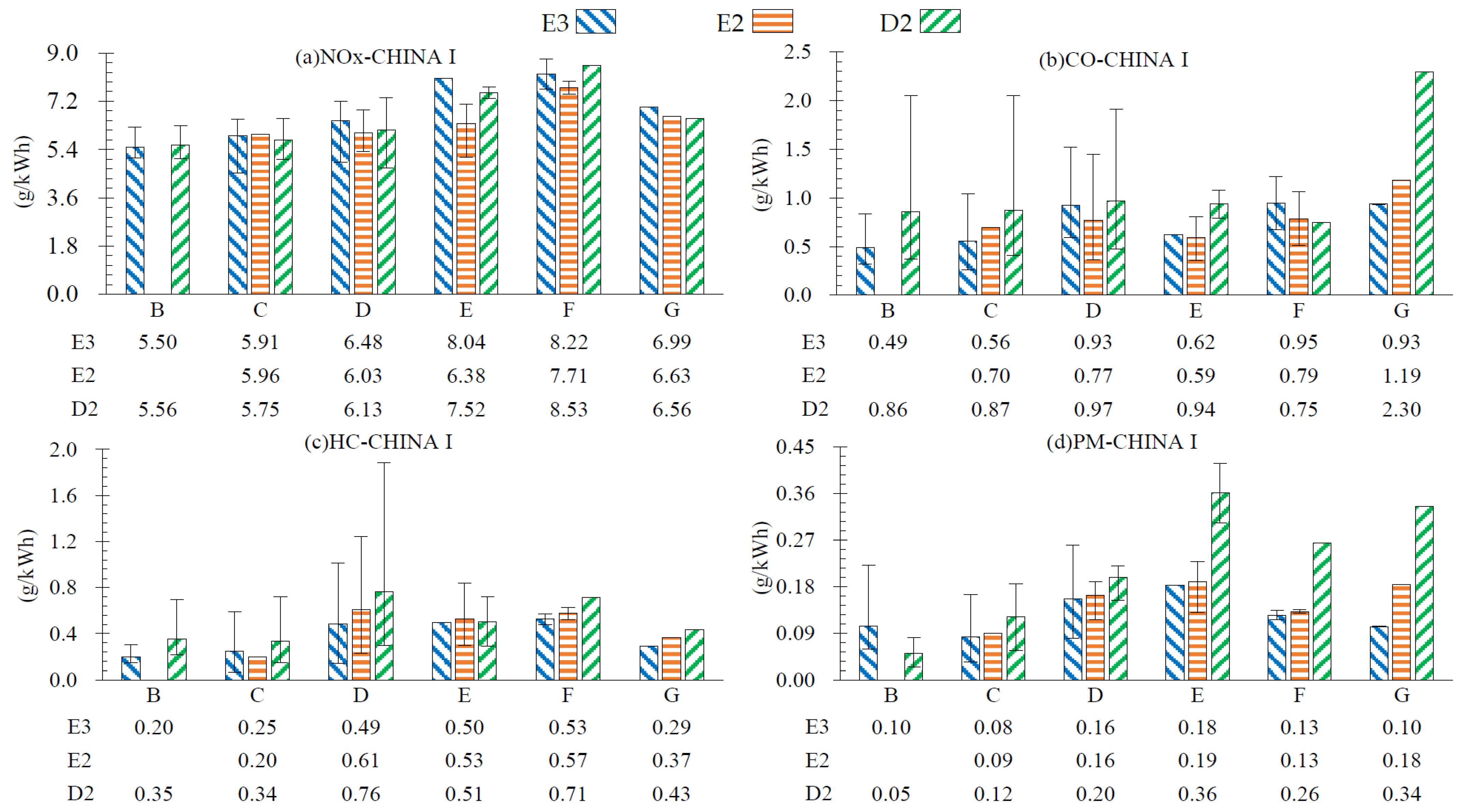

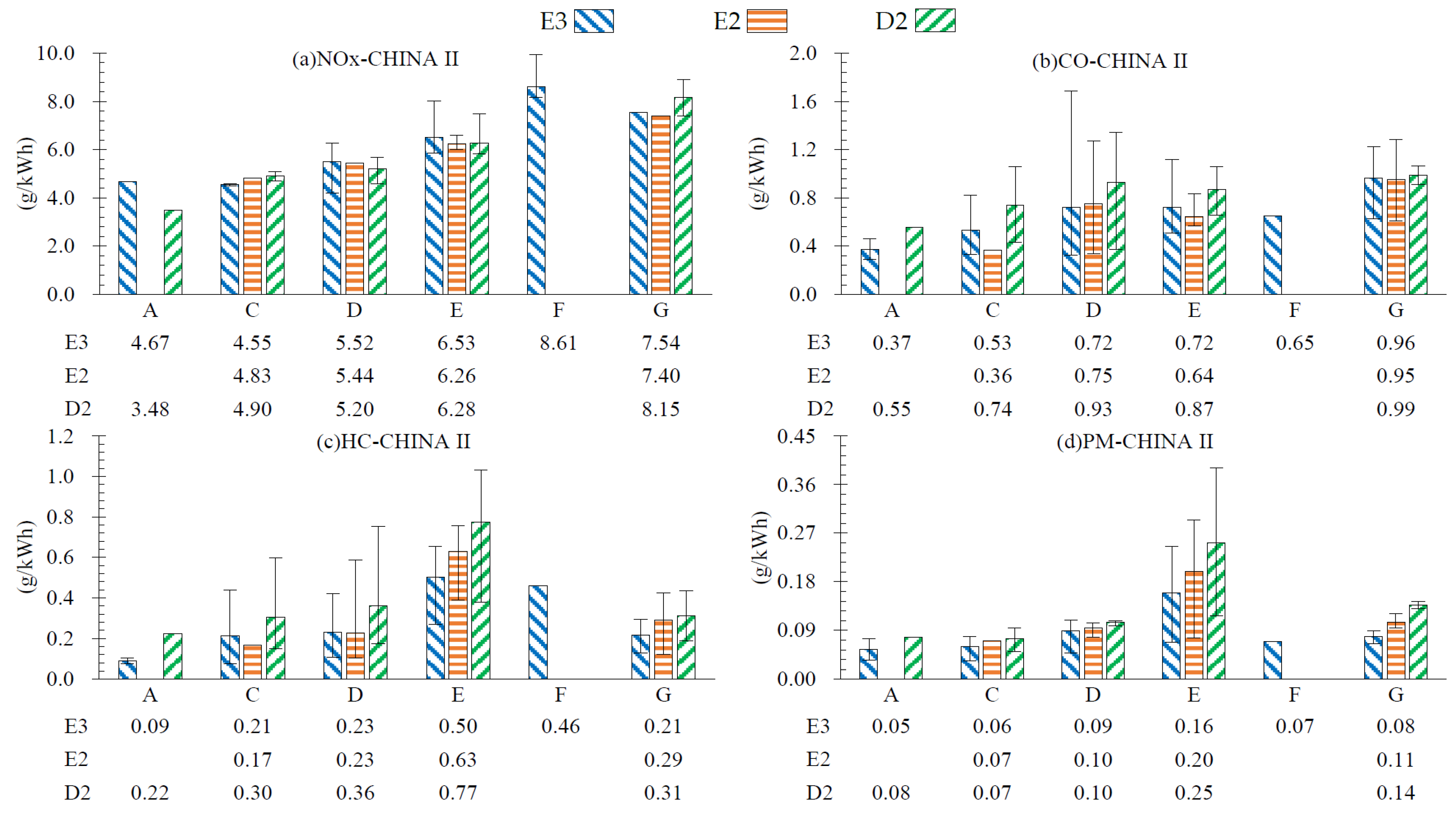

3.2. Energy-Based Average Emission Factors

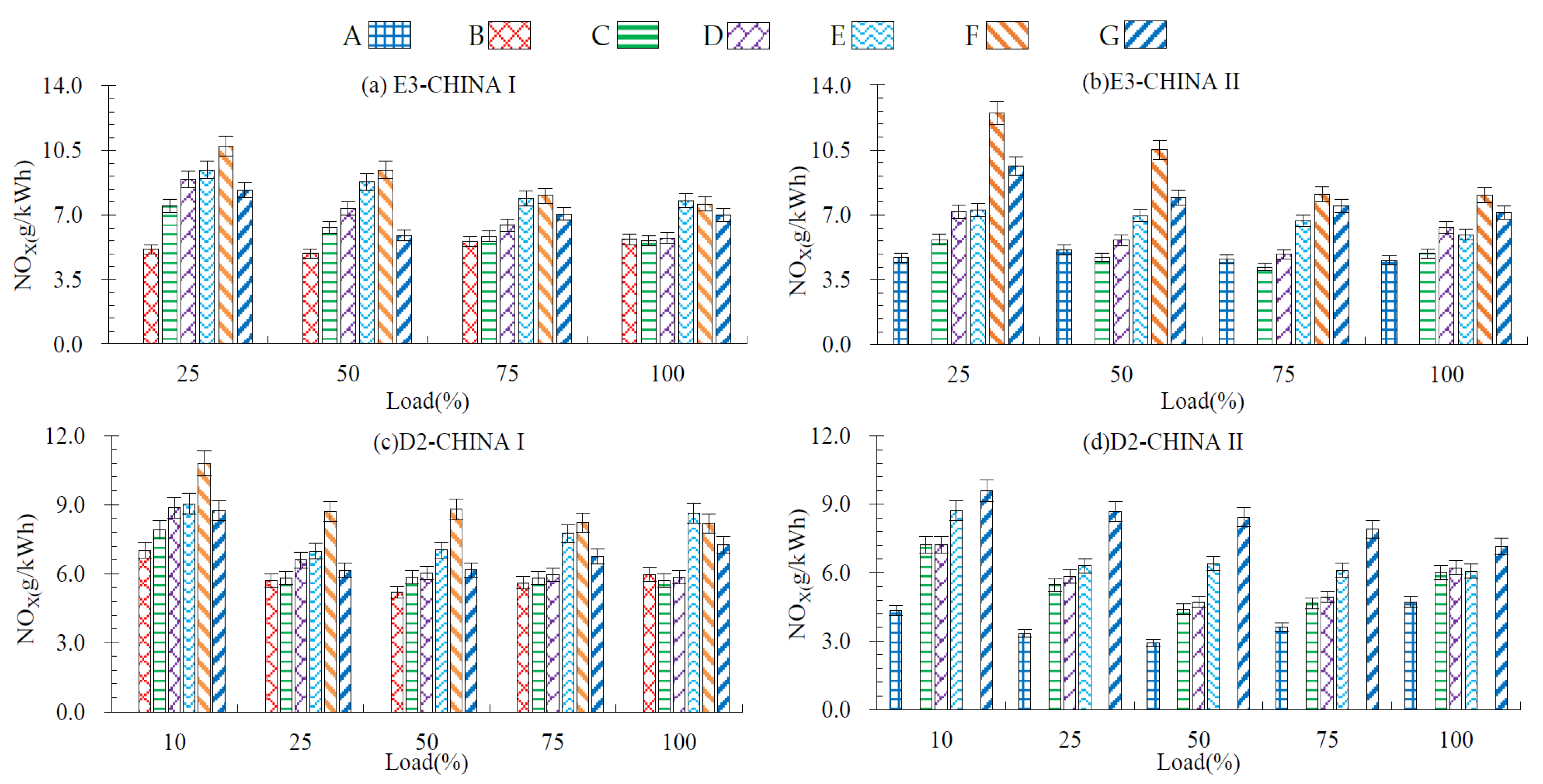

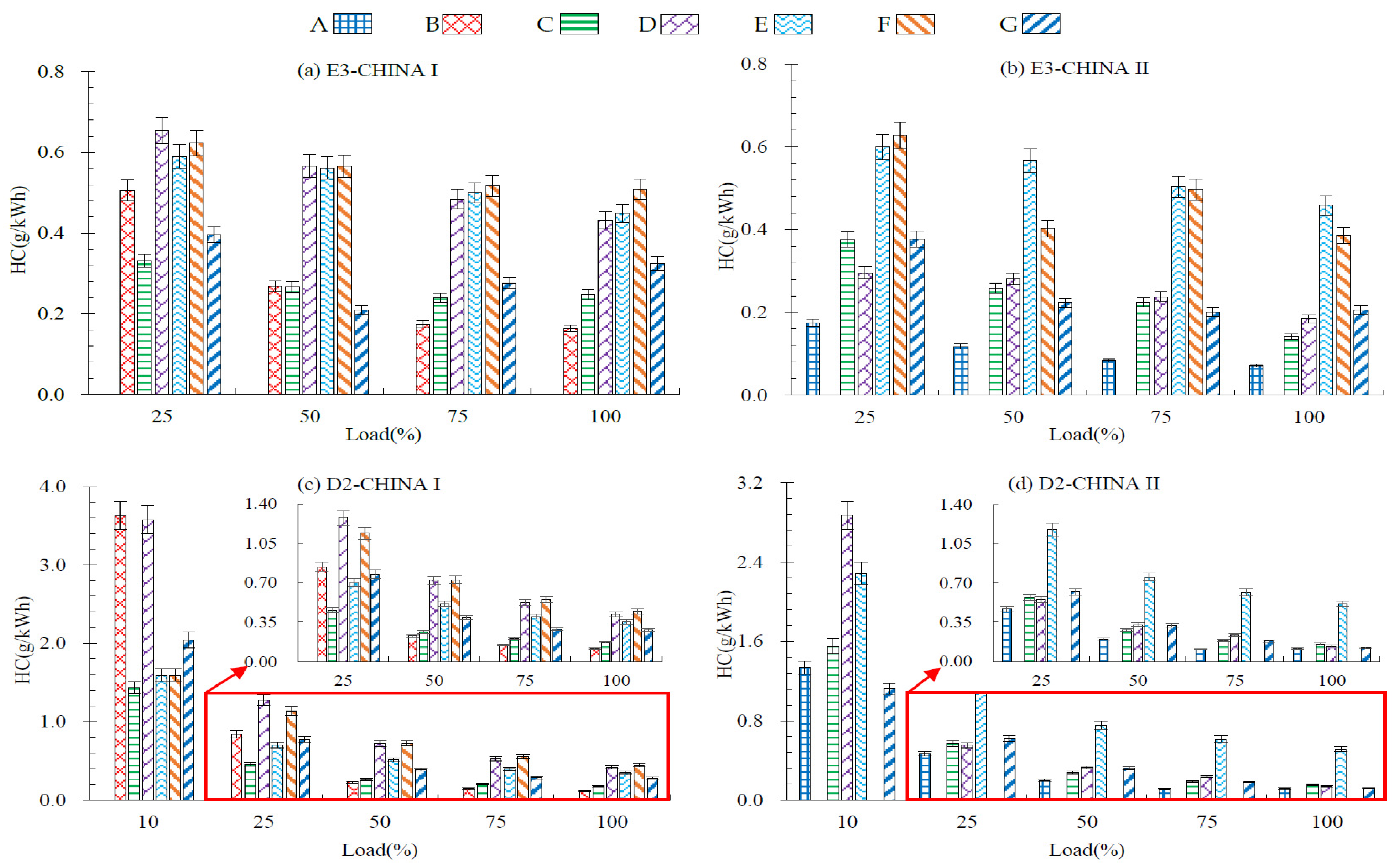

3.3. Energy-Based Emission Factors under Different Load Conditions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations and Definitions

| Term | Explanation | Term | Explanation |

| ME | Main Engine | g | Gram |

| AE | Auxiliary Engine | kg | Kilogram |

| NOX | Nitrogen Oxides | t | Tonne |

| HC | Hydrocarbon | NDIR | Non dispersive Infrared detection |

| CO | Carbon Monoxide | CLD | Chemi-uminescent detection |

| CO2 | Carbon Dioxide | MPD | Magnetic pneumatic detection |

| O2 | Oxygen | HFID | Heated flame ionization detection |

| PM | Particulate Matter | PT | Point |

| SO2 | Sulfur Dioxide | FS | Full Scale |

| CH4 | Methane | C | Carbon |

| kWh | Kilo Watt-hour | H | Hydrogen |

| SV | Single-cylinder displacement | O | Oxygenium |

| L | Volume unit, liter | N | Nitrogen |

| P | Power | S | Sulphur |

References

- Yusuf, A.A.; Yusuf, D.A.; Jie, Z.; Bello, T.Y.; Tambaya, M.; Abdullahi, B.; Muhammed-Dabo, I.A.; Yahuza, I.; Dandakouta, H. Influence of waste oil-biodiesel on toxic pollutants from marine engine coupled with emission reduction measures at various loads. Atmos. Pollut. Res 2022, 13, 101258. [Google Scholar] [CrossRef]

- Yusuf, A.A.; Inambao, F.L.; Ampah, J.D. Evaluation of biodiesel on speciated PM2.5, organic compound, ultrafine particle and gaseous emissions from a low-speed EPA Tier II marine diesel engine coupled with DPF, DEP and SCR filter at various loads. Energy 2022, 239, 121837. [Google Scholar] [CrossRef]

- Alanen, J.; Isotalo, M.; Kuittinen, N.; Simonen, P.; Martikainen, S.; Kuuluvainen, H.; Honkanen, M.; Lehtoranta, K.; Nyyss¨onen, S.; Vesala, H.; et al. Physical characteristics of particle emissions from a medium speed ship engine fueled with natural gas and low-sulfur liquid fuels. Environ. Sci. Technol. 2020, 54, 5376–5384. [Google Scholar] [CrossRef] [PubMed]

- Lang, J.; Zhou, Y.; Chen, D.; Xing, X.; Wei, L.; Wang, X.; Zhao, N.; Zhang, Y.; Guo, X.; Han, L.; et al. Investigating the contribution of shipping emissions to atmospheric PM2.5 using a combined source apportionment approach. Environ. Pollut. 2017, 229, 557–566. [Google Scholar] [CrossRef] [PubMed]

- Toscano, D.; Murena, F. Atmospheric ship emissions in ports: A review. Correlation with data of ship traffic. Atmos. Environ. X 2019, 4, 100050. [Google Scholar] [CrossRef]

- Jiang, H.; Wu, G.; Li, T.; He, P.; Chen, R. Characteristics of particulate matter emissions from a low-speed marine diesel engine at various loads. Environ. Sci. Technol. 2019, 53, 11552–11559. [Google Scholar] [CrossRef]

- Sommer, D.E.; Yeremi, M.; Son, J.; Corbin, J.C.; Gagn´e, S.; Lobo, P.; Miller, J.W.; Kirchen, P. Characterization and reduction of in-use CH4 emissions from a dual fuel marine engine using wavelength modulation spectroscopy. Environ. Sci. Technol. 2019, 53, 2892–2899. [Google Scholar] [CrossRef]

- Miola, A.; Ciuffo, B. Estimating air emissions from ships: Meta-analysis of modelling approaches and available data sources. Atmos. Environ. 2011, 45, 2242–2251. [Google Scholar] [CrossRef]

- IMO. Third IMO GHG Study 2014 Executive Summary and Final Report; IMO: London, UK, 2014; pp. 1–295. [Google Scholar]

- Nunes, R.A.O.; Alvim-Ferraz, M.D.C.; Martins, F.; Sousa, S. The activity-based methodology to assess ship emissions-A review. Environ. Pollut. 2017, 231, 87–103. [Google Scholar] [CrossRef]

- Xing, H.; Duan, S.; Huang, L.; Han, Z.; Liu, Q. Testbed-Based Exhaust Emission Factors for Marine Diesel Engines in China. Huan Jing Ke Xue Huanjing Kexue 2016, 37, 3750–3757. [Google Scholar]

- Chu-Van, T.; Ristovski, Z.; Pourkhesalian, A.; Rainey, T.; Garaniya, V.; Abbassi Jahangiri, S.; Enshaei, H.; Kam, U.; Kimball, R.; Yang, L.; et al. On-board measurements of particle and gaseous emissions from a large cargo vessel at different operating conditions. Environ. Pollut. 2018, 237, 832–841. [Google Scholar] [CrossRef] [PubMed]

- Reda, A.A.; Schnelle-Kreis, J.; Orasche, J.; Abbaszade, G.; Lintelmann, J.; Arteaga-Salas, J.M.; Stengel, B.; Rabe, R.; Harndorf, H.; Sippula, O.; et al. Gas phase carbonyl compounds in ship emissions: Differences between diesel fuel and heavy fuel oil operation. Atmos. Environ. 2015, 112, 370–380. [Google Scholar] [CrossRef]

- Ma, Z.; Yang, Y.; Sun, P.; Xing, H.; Duan, S.; Qu, H.; Zou, Y. Analysis of Marine Diesel Engine Emission Characteristics of Different Power Ranges in China. Atmosphere 2021, 12, 1108. [Google Scholar] [CrossRef]

- Fu, M.; Ding, Y.; Ge, Y.; Yu, L.; Yin, H.; Ye, W.; Liang, B. Real-world emissions of inland ships on the Grand Canal, China. Atmos. Environ. 2013, 81, 222–229. [Google Scholar] [CrossRef]

- Yin, H.; Ding, Y.; Ge, Y.; Ye, W.; Wang, J.; Bai, T.; Qian, L. Emissions characteristics of diesel engines for inland waterway vessels in China. Res. Environ. Sci. 2014, 27, 470–476. [Google Scholar]

- Huang, C.; Hu, Q.Y.; Wang, H.Y.; Qiao, L.P.; Jing, S.A.; Wang, H.L.; Zhou, M.; Zhu, S.H.; Ma, Y.G.; Lou, S.R.; et al. Emission factors of particulate and gaseous compounds from a large cargo vessel operated under real-world conditions. Environ. Pollut. 2018, 242, 667–674. [Google Scholar] [CrossRef]

- Wang, C.; Hao, L.; Ma, D.; Ding, Y.; Lv, L.; Zhang, M.; Wang, H.; Tan, J.; Wang, X.; Ge, Y. Analysis of ship emission characteristics under real-world conditions in China. Ocean Eng. 2019, 194, 106615. [Google Scholar] [CrossRef]

- Peng, W.; Yang, J.; Corbin, J.; Trivanovic, U.; Lobo, P.; Kirchen, P.; Rogak, S.; Gagn, S.; Miller, J.; Cocker, D. Comprehensive analysis of the air quality impacts of switching a marine vessel from diesel fuel to natural gas. Environ. Pollut. 2020, 266, 115404. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Y.; Tian, C.; Lou, D.; Li, J.; Zhang, G.; Matthias, V. Emission factors for gaseous and particulate pollutants from offshore diesel engine vessels in China. Atmos. Chem. Phys. 2016, 16, 6319–6334. [Google Scholar] [CrossRef]

- Cooper, D.A. Exhaust emissions from ships at berth. Atmos. Environ. 2003, 37, 3817–3830. [Google Scholar] [CrossRef]

- Agrawal, H.; Malloy, G.J.; Welch, W.A.; Miller, J.W.; Cocker, D.R. In-use gaseous and particulate matter emissions from a modern ocean-going container vessel. Atmos. Environ. 2008, 42, 5504–5510. [Google Scholar] [CrossRef]

- Hulskotte, J.H.J.; Denier van der Gon, H.A.C. Fuel consumption and associated emissions from seagoing ships at berth derived from an on-board survey. Atmos. Environ. 2010, 44, 1229–1236. [Google Scholar] [CrossRef]

- CCS. Limits and Measurement Methods for Exhaust Pollutants from Marine Engines (CHINA Ⅰ/Ⅱ); China Classification Society (CCS): Beijing, China, 2018; pp. 1–110. [Google Scholar]

- CCS. Technical Code on Control of Emission of Nitrogen Oxides from Marine Diesel Engines; China Classification Society (CCS): Beijing, China, 2020; pp. 1–100. [Google Scholar]

- Xing, H.; Stuart, C.; Spence, S.; Chen, H. Alternative fuel options for low carbon maritime transportation: Pathways to 2050. J. Clean. Prod. 2021, 297, 126651. [Google Scholar] [CrossRef]

- IMO. Initial IMO Strategy on Reduction of GHG Emissions from Ships; Resolution MEPC, 304 (72) adopted on 13 April 2018; IMO: London, UK, 2018. [Google Scholar]

- Peng, Z.; Ge, Y.; Tan, J.; Fu, M.; Wang, X.; Chen, M.; Yin, H.; Ji, Z. Emissions from several in-use ships tested by portable emission measurement system. Ocean Eng. 2016, 116, 260–267. [Google Scholar] [CrossRef]

- Winnes, H.; Fridell, E. Emissions of NOX and particles from manoeuvring ships. Transport. Res. Part D 2010, 15, 204–211. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Y.; Chen, Q.; Feng, Y.; Shang, Y.; Yang, X.; Gao, H.; Tian, C.; Li, J.; Zhang, G.; et al. Real-world emission factors of gaseous and particulate pollutants from marine fishing boats and their total emissions in China. Environ. Sci. Technol. 2018, 52, 4910–4919. [Google Scholar] [CrossRef]

- McCaffery, C.; Zhu, H.; Karavalakis, G.; Durbin, T.D.; Miller, J.W.; Johnson, K.C. Sources of air pollutants from a Tier 2 ocean-going container vessel: Main engine, auxiliary engine, and auxiliary boiler. Atmos. Environ. 2021, 245, 118023. [Google Scholar] [CrossRef]

- Bie, S.; Yang, L.; Zhang, Y.; Huang, Q.; Li, J.; Zhao, T.; Zhang, X.; Wang, P.; Wang, W. Source appointment of PM2.5 in Qingdao Port, East of China. Sci. Total Environ. 2021, 755, 142456. [Google Scholar] [CrossRef]

- Tan, J.; Song, Y.; Ge, Y.; Li, J.; Li, L. Emission inventory of ocean-going vessels in Dalian coastal area. Res. Environ. Sci. 2014, 27, 1426–1431. [Google Scholar]

| Test Cycle | Parameter | Test Power Point | ||||

|---|---|---|---|---|---|---|

| E3 | Power | 100% | 75% | 50% | 25% | - |

| Speed | 100% | 91% | 80% | 63% | - | |

| Weighting factor | 0.20 | 0.50 | 0.15 | 0.15 | - | |

| E2 | Power | 100% | 75% | 50% | 25% | - |

| Speed | 100% | 100% | 100% | 100% | - | |

| Weighting factor | 0.20 | 0.50 | 0.15 | 0.15 | - | |

| D2 | Power | 100% | 75% | 50% | 25% | 10% |

| Speed | 100% | 100% | 100% | 100% | 100% | |

| Weighting factor | 0.05 | 0.25 | 0.30 | 0.30 | 0.10 | |

| Single-Cylinder Displacement SV(L 1) | Rated Power (kW) | CO | HC + NOX | CH4 2 | PM |

|---|---|---|---|---|---|

| SV < 0.9 | P ≥ 37 | 5.0 | 7.5 | 1.5 | 0.40 |

| 0.9 ≤ SV < 1.2 | 5.0 | 7.2 | 1.5 | 0.30 | |

| 1.2 ≤ SV < 5 | 5.0 | 7.2 | 1.5 | 0.20 | |

| 5 ≤ SV < 15 | 5.0 | 7.8 | 1.5 | 0.27 | |

| 15 ≤ SV < 20 | P < 3300 | 5.0 | 8.7 | 1.6 | 0.50 |

| P ≥ 3300 | 5.0 | 9.8 | 1.8 | 0.50 | |

| 20 ≤ SV < 25 | 5.0 | 9.8 | 1.8 | 0.50 | |

| 25 ≤ SV < 30 | 5.0 | 11.0 | 2.0 | 0.50 | |

| Single-Cylinder Displacement SV(L 1) | Rated Power (kW) | CO | HC + NOX | CH4 2 | PM |

|---|---|---|---|---|---|

| SV < 0.9 | P ≥ 37 | 5.0 | 5.8 | 1.0 | 0.30 |

| 0.9 ≤ SV < 1.2 | 5.0 | 5.8 | 1.0 | 0.14 | |

| 1.2 ≤ SV < 5 | 5.0 | 5.8 | 1.0 | 0.12 | |

| 5 ≤ SV < 15 | P < 2000 | 5.0 | 6.2 | 1.2 | 0.14 |

| 2000 ≤ P < 3700 | 5.0 | 7.8 | 1.5 | 0.14 | |

| P ≥ 3700 | 5.0 | 7.8 | 1.5 | 0.27 | |

| 15 ≤ SV < 20 | P < 2000 | 5.0 | 7.0 | 1.5 | 0.34 |

| 2000 ≤ P < 3300 | 5.0 | 8.7 | 1.6 | 0.50 | |

| P ≥ 3300 | 5.0 | 9.8 | 1.8 | 0.50 | |

| 20 ≤ SV < 25 | P < 2000 | 5.0 | 9.8 | 1.8 | 0.27 |

| P ≥ 2000 | 5.0 | 9.8 | 1.8 | 0.50 | |

| 25 ≤ SV < 30 | P < 2000 | 5.0 | 11.0 | 2.0 | 0.27 |

| P ≥ 2000 | 5.0 | 11.0 | 2.0 | 0.50 | |

| Ingredient | Principle | Accuracy | Measuring Range |

|---|---|---|---|

| CO | NDIR | Within 2%PT or 0.3%FS | 0~3000 ppm |

| CO2 | NDIR | Within 2%PT or 0.3%FS | 0~16 vol.% |

| NOX | CLD | Within 2%PT or 0.3%FS | 0~5000 ppm |

| O2 | MPD | Within 2%PT or 0.3%FS | 0~25 vol.% |

| THC | HFID | Within 2%PT or 0.3%FS | 0~5000 ppm |

| Class | Single-Cylinder Displacement SV (L) | Class | Single-Cylinder Displacement SV (L) |

|---|---|---|---|

| A | SV < 0.9 | E | 15 ≤ SV < 20 |

| B | 0.9 ≤ SV < 1.2 | F | 20 ≤ SV < 25 |

| C | 1.2 ≤ SV < 5 | G | 25 ≤ SV < 30 |

| D | 5 ≤ SV < 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Du, T.; Duan, S.; Qu, H.; Wang, K.; Xing, H.; Zou, Y.; Sun, P. Analysis of Exhaust Pollutants from Four-Stroke Marine Diesel Engines Based on Bench Tests. J. Mar. Sci. Eng. 2023, 11, 413. https://doi.org/10.3390/jmse11020413

Ma Z, Du T, Duan S, Qu H, Wang K, Xing H, Zou Y, Sun P. Analysis of Exhaust Pollutants from Four-Stroke Marine Diesel Engines Based on Bench Tests. Journal of Marine Science and Engineering. 2023; 11(2):413. https://doi.org/10.3390/jmse11020413

Chicago/Turabian StyleMa, Zhongmin, Taili Du, Shulin Duan, Hongfei Qu, Kai Wang, Hui Xing, Yongjiu Zou, and Peiting Sun. 2023. "Analysis of Exhaust Pollutants from Four-Stroke Marine Diesel Engines Based on Bench Tests" Journal of Marine Science and Engineering 11, no. 2: 413. https://doi.org/10.3390/jmse11020413

APA StyleMa, Z., Du, T., Duan, S., Qu, H., Wang, K., Xing, H., Zou, Y., & Sun, P. (2023). Analysis of Exhaust Pollutants from Four-Stroke Marine Diesel Engines Based on Bench Tests. Journal of Marine Science and Engineering, 11(2), 413. https://doi.org/10.3390/jmse11020413