Application of Artificial Intelligence in Marine Corrosion Prediction and Detection

Abstract

1. Introduction

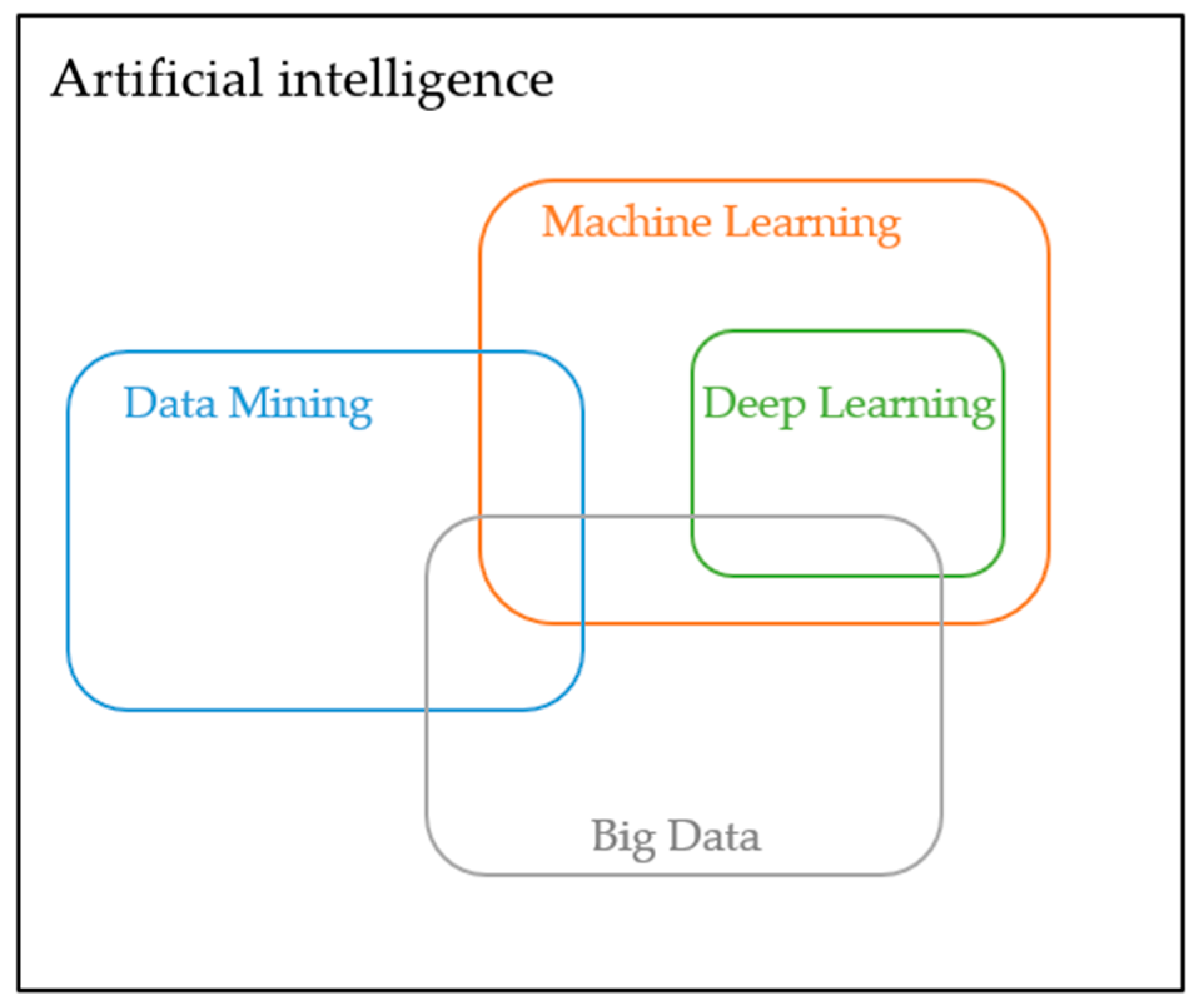

2. Artificial Intelligence

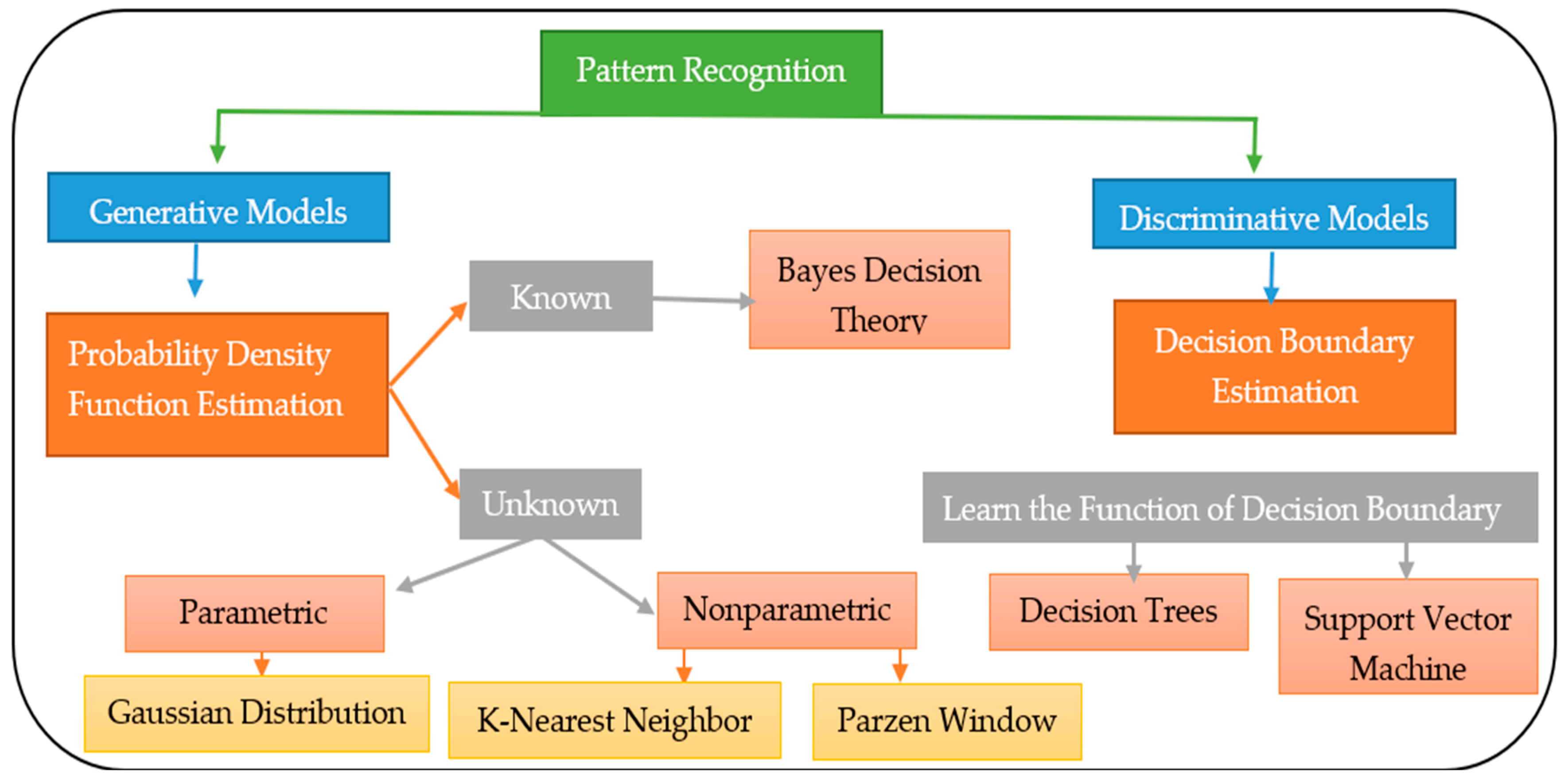

2.1. Pattern Recognition

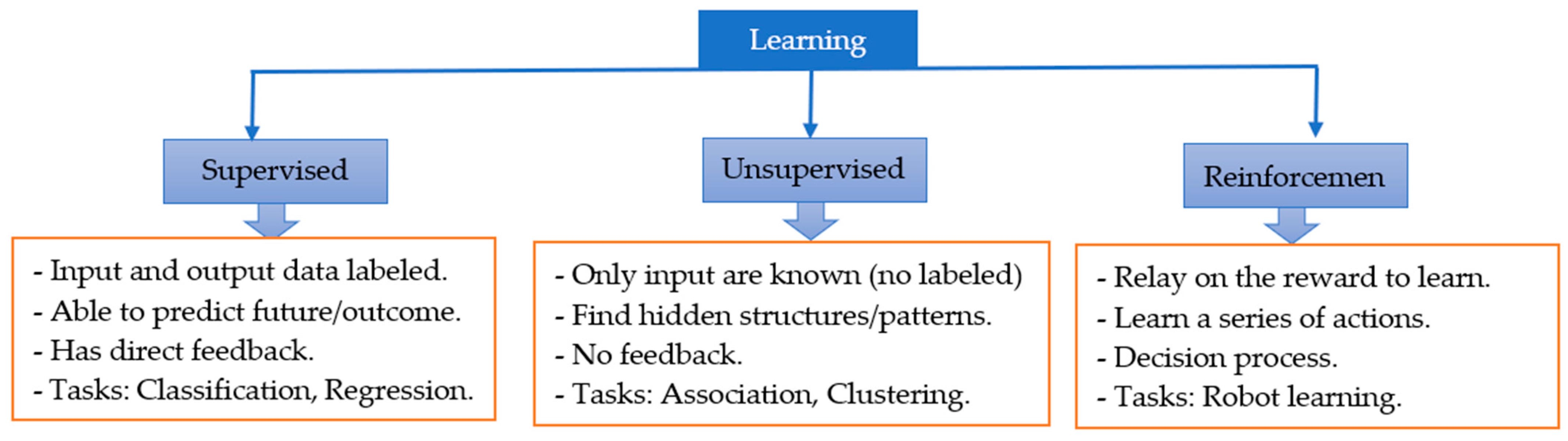

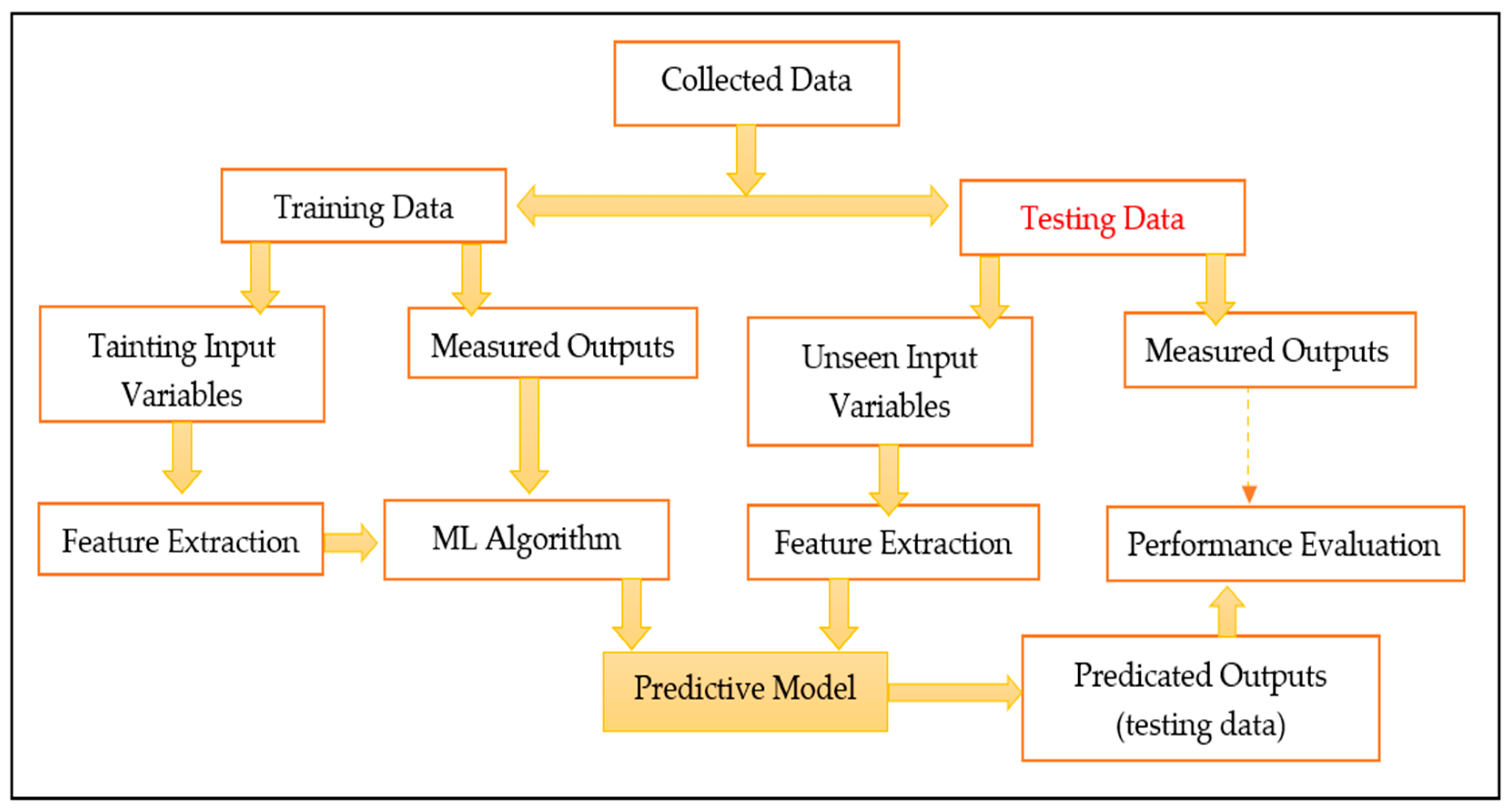

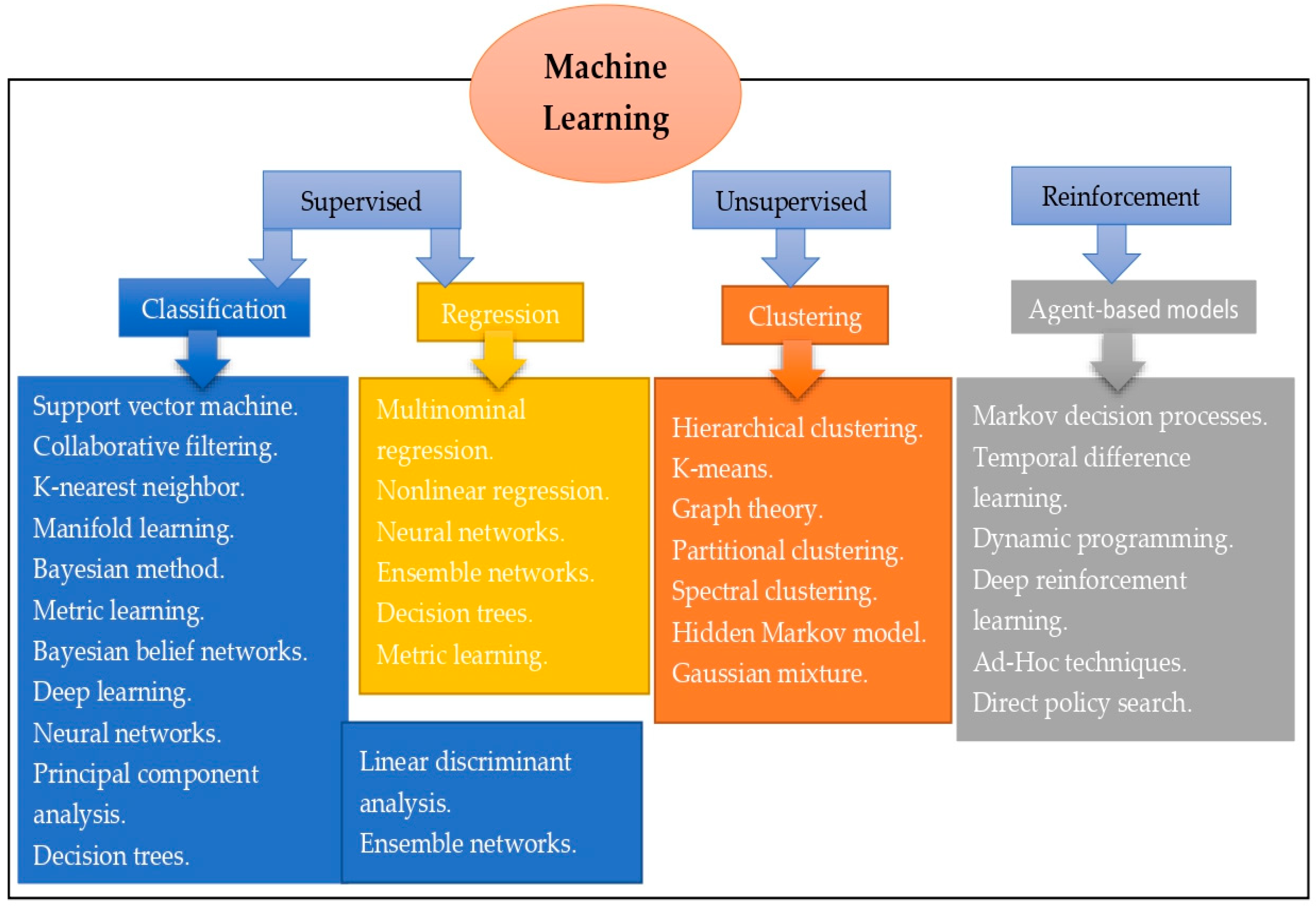

2.2. Machine Learning (ML)

2.2.1. Supervised Learning

2.2.2. Unsupervised Learning

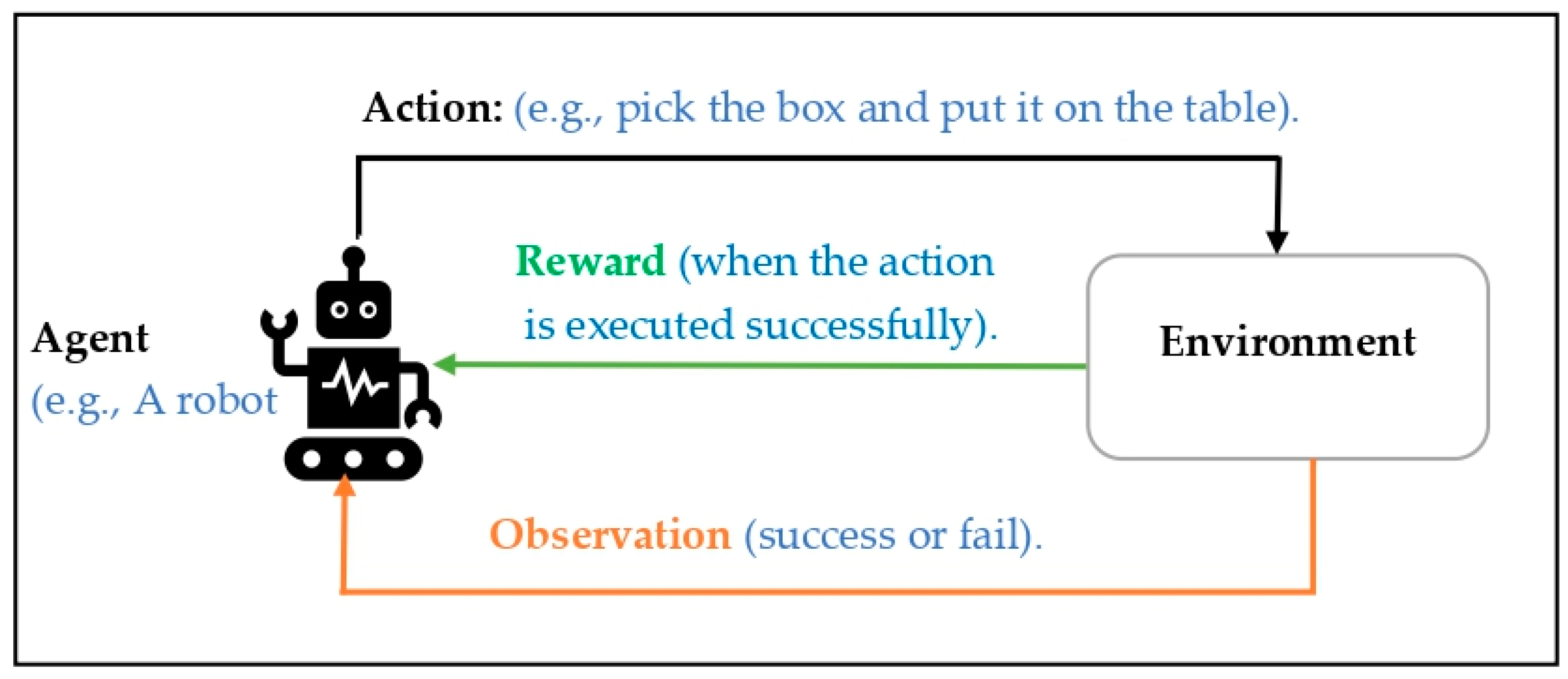

2.2.3. Reinforcement Learning

2.3. Deep Learning (DL)

3. Corrosion Detection Approaches

3.1. Predictive Maintenance Approaches for Corrosion Detection

3.1.1. PdM with Knowledge-Based Model

3.1.2. PdM with Physic-Based Model

3.1.3. PdM with Data-Based Model

3.1.4. PdM with Hybrid Model

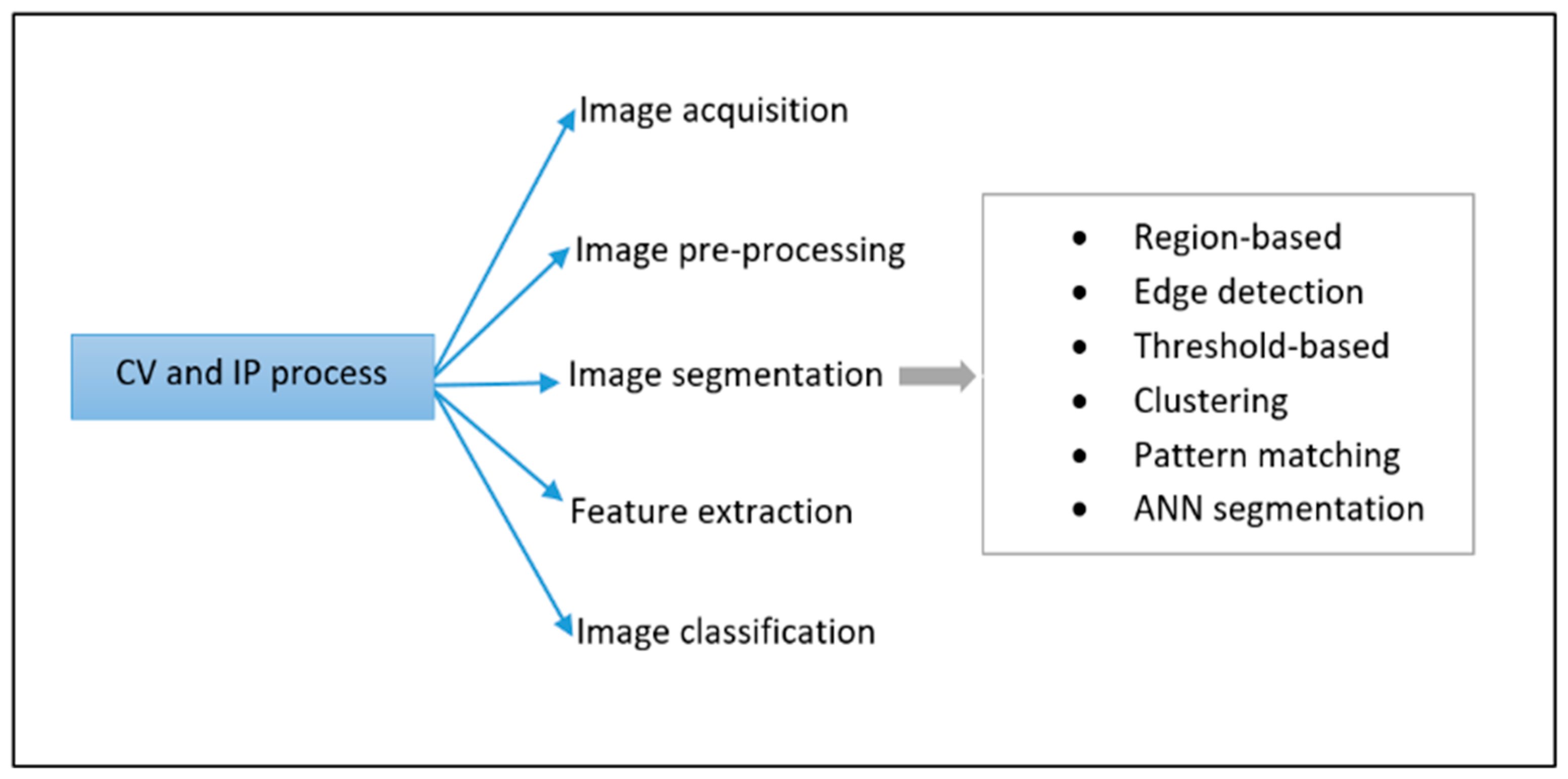

3.2. Computer Vision and Image Processing Approaches for Corrosion Detection

3.2.1. Infrared Thermography

3.2.2. Texture Analysis

3.2.3. Non-Destructive Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Muhammad, F.S.; Khurram, K.; Faheem, R.; Salman, S.; Hassan, Z.; Kashif, K. Corrosion detection and severity level prediction using acoustic emission and machine learning based approach. Ain Shams Eng. J. 2021, 12, 3891–3903. [Google Scholar] [CrossRef]

- Eric, J.; Michael, A.M.; Jeffrey, M.R. Corrosion of additively manufactured stainless steels—Process, structure, performance: A review. Corrosion 2021, 77, 484–503. [Google Scholar]

- Sun, P.; Wang, Z.; Lu, Y.; Shen, S.; Yang, R.; Xue, A.; Parker, T.; Wang, J.; Wang, Q. Analysis of the corrosion failure of a semiconductor polycrystalline distillation column. Process Saf. Environ. Prot. 2020, 135, 244–256. [Google Scholar] [CrossRef]

- NACE SP0294-2006; Standard Practice—Design, Fabrication, and Inspection of Storage Tank Systems for Concentrated Fresh and Process Sulfuric Acid and Oleum at Ambient Temperatures. National Association of Corrosion Engineers: Houston, TX, USA, 2006; 42p.

- Koch, G.; Varney, J.; Thopson, N.; Moghissi, O.; Gould, M.; Payer, J. International Measures of Prevention, Application, and Economics of Corrosion Technologies Study. NACE Int. 2016, 216, 1–216. [Google Scholar]

- Hansson, C.M. The impact of corrosion on society. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 2952–2962. [Google Scholar] [CrossRef]

- Baorong, H.; Xiaogang, L.; Xiumin, M.; Cuiwei, D.; Dawei, Z.; Meng, Z.; Weichen, X.; Dong-zhu, L.; Fubin, M. The cost of corrosion in China. Npj Mater. Degrad. 2017, 1, 1–10. [Google Scholar] [CrossRef]

- Nakai, T.; Matsushita, H.; Yamamoto, N. Effect of pitting corrosion on the ultimate strength of steel plates subjected to in-plane compression and bending. J. Mar. Sci. Technol. 2006, 11, 52–64. [Google Scholar] [CrossRef]

- Jamaludin, S.; Zainal, N.; Zaki, W.M.D.W. GPU implementation of sub-iris technique in iris recognition system. Pertanika J. Sci. Technol. 2017, 25, 263–274. [Google Scholar]

- Emi, H.; Yuasa, M.; Kumano, A.; Kumamoto, H.; Yamamoto, N.; Matsunaga, M. A study on life assessment of ships and off-shore structures: 2nd report: Risk assessment of fatigue failures of hull structures. Jpn. Soc. Nav. Archit. Ocean. Eng. 1992, 172, 627–635. [Google Scholar] [CrossRef] [PubMed]

- Khayatazad, M.; De-Pue, L.; De, W. Detection of corrosion on steel structures using automated image processing. Dev. Built Environ. 2020, 3, 100022. [Google Scholar] [CrossRef]

- Wu, D.; Birge, J.R. Risk intelligence in big data era: A review and introduction to special issue. IEEE Trans. Cybern. 2016, 46, 1718–1720. [Google Scholar] [CrossRef]

- Agarwala; Vinod, S.; Perry, L.; Reed; Siraj, A. Corrosion detection and monitoring—A review. NACE Int. 2000, 2000, 136664832. [Google Scholar]

- Schmitt, G.; Schütze, M.; Hays, G.F.; Burns, W.; Han, E.; Pourbaix, A.; Jacobson, G. Global needs for knowledge dissemination, research, and development in materials deterioration and corrosion control. World Corros. Organ. 2009, 38, 14. [Google Scholar]

- Sharon, A.; Itzhak, D. The environmental behavior of SAE 304L stainless steel sintered in the presence of a copper base additive. Mater. Sci. Eng. 1997, 1, 177–186. [Google Scholar] [CrossRef]

- Yuan, Y.; Yang, Y.; Yanpeng, W.; Xuefeng, Z. Artificial intelligence-based hull structural plate corrosion damage detection and recognition using convolutional neural network. Appl. Ocean Res. 2019, 90, 101823. [Google Scholar] [CrossRef]

- Patwardhan, R.S.; Hamadah, H.A.; Patel, K.M.; Hafiz, R.H.; Al-Gwaiz, M.M. Applications of advanced analytics at Saudi Aramco: A practitioners’ perspective. Ind. Eng. Chem. Res. 2019, 58, 11338–11351. [Google Scholar] [CrossRef]

- Jamaludin, S.; Zainal, N.; Zaki, W.M.D.W. A fast specular reflection removal based on pixels properties method. Bull. Electr. Eng. Inform. 2021, 9, 2358–2363. [Google Scholar] [CrossRef]

- Völker, C.; Kruschwitz, S.; Ebell, G. A machine learning-based data fusion approach for improved corrosion testing. Surv. Geophys. 2020, 41, 531–548. [Google Scholar] [CrossRef]

- Dral, P.O.; Von-Lilienfeld, O.A.; Thiel, W. Machine learning of parameters for accurate semiempirical quantum chemical calculations. J. Chem. Theory Comput. 2015, 11, 2120–2125. [Google Scholar] [CrossRef]

- Ser, C.T.; Zˇuvela, P.; Wong, M.W. Prediction of corrosion inhibition efficiency of pyridines and quinolines on an iron surface using machine learning-powered quantitative structure-property relationships. Appl. Surf. Sci. 2020, 512, 145612. [Google Scholar] [CrossRef]

- Hadi, S.; Rigoberto, B. Emerging artificial intelligence methods in structural engineering. Eng. Struct. 2018, 171, 170–189. [Google Scholar]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- LeCun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Li, Y.; Wang, G.; Nie, L.; Wang, Q.; Tan, W. Distance metric optimization driven convolutional neural network for age invariant face recognition. Pattern Rec. 2017, 75, 46. [Google Scholar] [CrossRef]

- Jaderberg, M.; Vedaldi, A.; Zisserman, A. Deep features for text spotting. Eur. Conf. Comput. 2014, 8692, 512–528. [Google Scholar]

- Aghdam, H.H.; Heravi, E.J.; Puig, D. A practical approach for detection and classification of traffic signs using convolutional neural networks. Robot. Auton. Syst. 2017, 84, 97–112. [Google Scholar] [CrossRef]

- Yammen, S.; Muneesawang, P. An Advanced Vision System for the Automatic Inspection of Corrosions on Pole Tips in Hard Disk Drives. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 1523–1533. [Google Scholar] [CrossRef]

- Liu, L.; Tan, E.; Yin, X.J.; Zhen, Y.; Cai, Z.Q. Deep learning for Coating Condition Assessment with Active perception. In Proceedings of the 2019 3rd High Performance Computing and Cluster Technologies Conference, ACM, Guangzhou, China, 22–24 June 2019; pp. 75–80. [Google Scholar]

- Bonnin-Pascual, F.; Ortiz, A. Corrosion Detection for Automated Visual Inspection. Developments in Corrosion Protection. InTech 2014, 25, 619–632. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, Z.; Guo, H.; Cheng, J. Multiresolution Analysis Driven Corrosion Detection on Metal Surface. In Proceedings of the 2011 International Conference on Multimedia and Signal Processing, IEEE, Aligarh, India, 17–19 December 2011; pp. 85–88. [Google Scholar]

- Petricca, L.; Moss, T.; Figueroa, G.; Broen, S. Corrosion Detection Using, A.I.: A Comparison of Standard Computer Vision Techniques and Deep Learning Model. Computer Science & Information Technology (CS & IT). In Proceedings of the Sixth International Conference on Computer Science, Engineering and Information Technology, Vienna, Austria, 21–22 May 2016; pp. 91–99. [Google Scholar]

- Katsamenis, I.; Protopapadakis, E.; Doulamis, A.; Doulamis, N.; Voulodimos, A. Pixel-Level Corrosion Detection on Metal Constructions by Fusion of Deep Learning Semantic and Contour Segmentation. In Proceedings of the ISVC 2020: 15th International Symposium on Visual Computing, San Diego, CA, USA, 5–7 November 2020; pp. 160–169. [Google Scholar]

- Bezdek, J. What is Computational Intelligence? Compuational Intelligence Imitating Life; Zurada, J.M., Marks, R.J., II, Robinson, C.J., Eds.; IEEE Press: Piscataway, NJ, USA, 1994; pp. 1–12. [Google Scholar]

- Nils, J.N. Artificial Intelligence: A New Synthesis; Elsevier: Amsterdam, The Netherlands, 1998. [Google Scholar] [CrossRef]

- David, P.; Alan, K.M.; Randy, G. Computational Intelligence: A Logical Approach; Oxford University Press: New York, NY, USA, 1998. [Google Scholar] [CrossRef]

- Kurzweil, R. The Age of Spiritual Machines: When Computers Exceed Human Intelligence; Penguin Books: New York, NY, USA, 2000. [Google Scholar]

- Jamaludin, S.; Ayob, A.F.M.; Norzeli, S.M.; Mohamed, S.B. Adaptive initial contour and partly-normalization algorithm for iris segmentation of blurry iris images. J. Inf. Commun. Technol. 2022, 21, 411–435. [Google Scholar] [CrossRef]

- Rafael, A.G.; Mauricio, S.S.; Felipe, M. Pattern recognition techniques implementation on data from In-Line Inspection (ILI). J. Loss Prev. Process Ind. 2016, 44, 735–747. [Google Scholar] [CrossRef]

- Giorgio, L.; Pierluigi, T.; Paola, L. Applications of chemometric tools in corrosion studies. Corros. Sci. 2010, 52, 2750–2757. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, X.; Amp, T.J. Laboratory-scale identification of corrosion mechanisms by a pattern recognition system based on electrochemical noise measurements. J. Electrochem. Soc. 2019, 166, C284. [Google Scholar] [CrossRef]

- Legat, A.; Doleček, V. Corrosion Monitoring System based on measurement and analysis of Electrochemical Noise. Corrosion 1995, 51, 295–300. [Google Scholar] [CrossRef]

- Ali, A.; Albasir, A.; Ramahi, O.M. Microwave sensor for imaging corrosion under coatings utilizing pattern recognition. In Proceedings of the IEEE International Symposium on Antennas and Propagation (APSURSI), Fajardo, Puerto Rico, 26 June–1 July 2016; pp. 951–952. [Google Scholar] [CrossRef]

- Liu, L.; Tan, E.; Zhen, Y.; Yin, X.J.; Cai, Z.Q. AI-facilitated coating corrosion assessment system for productivity enhancement. In Proceedings of the 13th IEEE Conference on Industrial Electronics and Applications (ICIEA), Wuhan, China, 31 May–2 June 2018; pp. 606–610. [Google Scholar] [CrossRef]

- Reich, Y. Machine learning techniques for civil engineering problems. Comput.-Aided Civ. Infrastruct. Eng. 1997, 12, 295–310. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Sun, F.; Zhang, W. A comparison study of machine learning based algorithms for fatigue crack growth calculation. Materials 2017, 10, 543. [Google Scholar] [CrossRef]

- Bekkerman, R.; Bilenko, M.; Langford, J. Scaling up Machine Learning: Parallel and Distributed Approaches; Cambridge University Press: Cambridge, UK, 2012; pp. 1–22. [Google Scholar]

- Cherkassky, V.; Mulier, F.M. Learning from Data: Concepts, Theory, and Methods; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Taffese, W.Z.; Sistonen, E. Machine learning for durability and service-life assessment of reinforced concrete structures: Recent advances and future directions. Autom. Constr. 2017, 77, 1–14. [Google Scholar] [CrossRef]

- Imran, M.H.M.; Ayob, A.F.; Jamaludin, S. Applications of artificial intelligence in ship berthing: A review. Indian J. Geo-Mar. Sci. 2022, 50, 855–863. [Google Scholar]

- Zibo, P.; Dawei, Z.; Yuanjie, Z.; Tao, Y.; Lulu, J.; Dongmei, F.; Xuequn, C.; Herman, A.T.; Johannes, M.C.M.; Xiaogang, L. Towards understanding and prediction of atmospheric corrosion of an Fe/Cu corrosion sensor via machine learning. Corros. Sci. 2020, 170, 108697. [Google Scholar] [CrossRef]

- Duda, R.O.; Hart, P.E.; Stork, D.G. Pattern Classification, 2nd ed.; WileyInterscience: New York, NY, USA, 2000. [Google Scholar]

- Theodoridis, S.; Koutroumbas, K. Pattern Recognition, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Karbhari, V.; Lee, L.S.W. Vibration-Based Damage Detection Techniques for Structural Health Monitoring of Civil Infrastructure Systems, Structural Health Monitoring of Civil Infrastructure Systems; Elsevier: Amsterdam, The Netherlands, 2009; pp. 77–212. [Google Scholar]

- Murphy, K.P. Machine Learning: A Probabilistic Perspective; MIT Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Bishop, C. Pattern Recognition and Machine Learning; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Yupeng, D.; Luchun, Y.; Kewei, G. Improvement of the machine learning-based corrosion rate prediction model through the optimization of input features. Mater. Des. 2021, 198, 109326. [Google Scholar] [CrossRef]

- Takeda, A.; Kanamori, T. Using financial risk measures for analyzing generalization performance of machine learning models. Neural Netw. 2014, 57, 29–38. [Google Scholar] [CrossRef]

- Kim, M.J.; Kang, D.K. Ensemble with neural networks for bankruptcy prediction. Expert Syst. Appl. 2010, 37, 3373–3379. [Google Scholar]

- Di, K.; Li, W.; Yue, Z.; Sun, Y.; Liu, Y. A machine learning approach to crater detection from topographic data. Adv. Space Res. 2014, 54, 2419–2429. [Google Scholar] [CrossRef]

- Dede, G.; Sazlı, M.H. Speech recognition with artificial neural networks. Digit. Signal Process. 2010, 20, 763–768. [Google Scholar] [CrossRef]

- Vaughan, A.; Bohac, S.V. Real-time, adaptive machine learning for nonstationary, near chaotic gasoline engine combustion time series. Neural Netw. 2015, 70, 18–26. [Google Scholar] [CrossRef]

- Kialashaki, A.; Reisel, J.R. Development and validation of artificial neural network models of the energy demand in the industrial sector of the United States. Energy 2014, 76, 749–760. [Google Scholar] [CrossRef]

- Chau, K.W.; Wu, C. A hybrid model coupled with singular spectrum analysis for daily rainfall prediction. J. Hydroinform. 2010, 12, 458–473. [Google Scholar] [CrossRef]

- Chen, X. Hydrologic connections of a stream–aquifer-vegetation zone in southcentral Platte River valley, Nebraska. J. Hydrol. 2007, 333, 554–568. [Google Scholar] [CrossRef]

- Che, D.; Liu, Q.; Rasheed, K.; Tao, X. Decision tree and ensemble learning algorithms with their applications in bioinformatics. Adv. Exp. Med. Biol. 2011, 696, 91–199. [Google Scholar] [CrossRef]

- Zhang, S.; Chau, K.W. Dimension reduction using semi-supervised locally linear embedding for plant leaf classification. In International Conference on Intelligent Computing; Springer: Berlin/Heidelberg, Germany, 2009; pp. 948–955. [Google Scholar]

- Al-Jamimi, H.A.; Sadam, A.A.; Tawfik, A.S. Supervised machine learning techniques in the desulfurization of oil products for environmental protection: A review. Process Saf. Environ. Prot. 2018, 120, 57–71. [Google Scholar] [CrossRef]

- Zhang, D.; Tsai, J.J.P. Machine learning and software engineering. Softw. Qual. J. 2003, 11, 87–119. [Google Scholar] [CrossRef]

- Zhang, D.; Tsai, J.J.P. Machine Learning Applications in Software Engineering; World Scientific: Singapore, 2005. [Google Scholar] [CrossRef]

- Al-Jamimi, H.A.; Ahmed, M. Machine learning-based software quality pre-diction models: State of the art. In Proceedings of the Information Science and Applications (ICISA) International Conference, Suwon, Republic of Korea, 24–26 June 2013; pp. 1–4. [Google Scholar]

- Al-Jamimi, H.A.; Ahmed, M.A. Machine learning approaches for predict-ing software maintainability: A fuzzy-based transparent model. IET Softw. 2013, 7, 317–326. [Google Scholar] [CrossRef]

- Cussens, J.; Page, D.; Muggleton, S.; Srinivasan, A. Using Inductive Logic Pro-Gramming for Natural Language Processing; University of Economics: Prague, Czech Republic, 1997. [Google Scholar]

- Helmy, T.; Al-Azani, S.; Bin-Obaidellah, O. A machine learning-based approachto estimate the CPU-burst time for processes in the computational grids. In Proceedings of the AIMS 2015. 3rd International Conference on Artificial Intelligence, Modelling and Simulation, Kota Kinabalu, Malaysia, 2–4 December 2015; pp. 3–8. [Google Scholar] [CrossRef]

- IBM Cloud Education. What is Unsupervised Learning? IBM. Available online: https://www.ibm.com/cloud/learn/unsupervised (accessed on 20 October 2022).

- Han, J.; Pei, J.; Kamber, M. Data Mining: Concepts and Techniques; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Jamaludin, S.; Ayob, A.F.M.; Akhbar, M.F.A.; Ali, A.A.I.M.; Imran, M.M.H.; Norzeli, S.M.; Mohamed, S.B. Efficient, accurate and fast pupil segmentation for pupillary boundary in iris recognition. Adv. Eng. Softw. 2023, 175, 103352. [Google Scholar] [CrossRef]

- Rosten, E.; Drummond, T. Machine learning for high-speed corner detection. In Proceedings of the 9th European Conference on Computer Vision, Graz, Austria, 7–13 May 2006; Springer: Berlin/Heidelberg, Germany, 2006; Volume 3951, pp. 430–443. [Google Scholar] [CrossRef]

- Lézoray, O.; Charrier, C.; Cardot, H.; Lefèvre, S. Machine learning in image processing. EURASIP J. Adv. Signal Process. 2008, 2008, 927950. [Google Scholar] [CrossRef][Green Version]

- Bradski, G.; Kaehler, A. Learning Open CV: Computer Vision with the Open CV library; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2008. [Google Scholar]

- Duygulu, P.; Barnard, K.; Freitas, J.F.; Forsyth, D.A. Object Recognition as Machine Translation: Learning a Lexicon for a Fxed Image Vocabulary; Springer: Berlin/Heidelberg, Germany, 2002; pp. 97–112. [Google Scholar]

- Harris, T. Credit scoring using the clustered support vector machine. Expert Syst. Appl. 2015, 42, 741–750. [Google Scholar] [CrossRef]

- Sharma, N.; Sharma, P.; Irwin, D.; Shenoy, P. Predicting solar generation from weather forecasts using machine learning. In Proceedings of the 2011 IEEE international conference on smart grid communications (SmartGridComm), Brussels, Belgium, 17–20 October 2011; pp. 528–533. [Google Scholar]

- Marvuglia, A.; Messineo, A. Monitoring of wind farms’ power curves using machine learning techniques. Appl. Energy 2012, 98, 574–583. [Google Scholar] [CrossRef]

- Hinton, G.; Deng, L.; Yu, D.; Dahl, G.; Mohamed, A.; Jaitly, N.; Senior, A.; Vanhoucke, V.; Nguyen, P.; Sainath, T.N.; et al. Deep neural networks for acoustic modeling in speech recognition: The shared views of four research groups. IEEE Signal Process. Mag. 2012, 29, 82–97. [Google Scholar] [CrossRef]

- Deng, L.; Hinton, G.; Kingsbury, B. New types of deep neural network learning for speech recognition and related applications: An overview. In Proceedings of the 2013 IEEE International Conference on Acoustics, Speech and Signal Processing, Vancouver, Canada, 26–31 May 2013; pp. 8599–8603. [Google Scholar] [CrossRef]

- Graves, A.; Mohamed, A.; Hinton, G. Speech recognition with deep recurrent neural networks. In Proceedings of the 2013 IEEE international conference on acoustics, speech and signal processing, Vancouver, Canada, 26–31 May 2013; pp. 6645–6649. [Google Scholar] [CrossRef]

- Michalski, R.S.; Carbonell, J.G.; Mitchell, T.M. Machine Learning: An Artificial Intelligence Approach; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Alpaydin, E. Introduction to Machine Learning; MIT Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Robert, C. Machine learning, a probabilistic perspective. Chance 2014, 27, 62–63. [Google Scholar] [CrossRef]

- Jamaludin, S.; Zainal, N.; Zaki, W.M.D.W. The removal of specular reflection in noisy iris image. J. Telecommun. Electron. Comput. Eng. 2016, 8, 59–64. [Google Scholar]

- Tong, S.; Chang, E. Support Vector Machine Active Learning for Image Retrieval; ACM Press: New York, NY, USA, 2001; Volume 107, pp. 107–118. [Google Scholar] [CrossRef]

- Sebe, N. Machine Learning in Computer Vision; Springer: Berlin/Heidelberg, Germany, 2005; p. 29. [Google Scholar]

- Deng, L.; Li, X. Machine learning paradigms for speech recognition: An overview. IEEE Trans. Audio Speech Lang. Process. 2013, 21, 1060–1089. [Google Scholar] [CrossRef]

- LeBaron, B. Agent-based computational finance. Handb. Comput. Econ. 2006, 2, 1187–1233. [Google Scholar]

- Brabazon, A.; O’Neill, M. Natural Computing in Computational Finance; Springer: Berlin/Heidelberg, Germany, 2008; p. 100. [Google Scholar]

- Wan, C.; Xu, Z.; Pinson, P.; Dong, Z.Y.; Wong, K.P. Probabilistic forecasting of wind power generation using extreme learning machine. IEEE Trans. Power Syst. 2014, 29, 1033–1044. [Google Scholar] [CrossRef]

- Needham, C.J.; Bradford, J.R.; Bulpitt, A.J.; Westhead, D.R. A primer on learning in Bayesian networks for computational biology. PLoS Comput. Biol. 2007, 3, 129. [Google Scholar] [CrossRef] [PubMed]

- IBM Cloud Education. What is Deep Learning? IBM. Available online: https://www.ibm.com/cloud/learn/deeplearning# (accessed on 20 October 2022).

- Fentaye, A.D.; Ul-Haq Gilani, S.I.; Baheta, A.T.; Li, Y.G. Performance-based fault diagnosis of a gas turbine engine using an integrated support vector machine and artificial neural network method. Proceedings of the Institution of Mechanical Engineers. J. Power Energy Syst. 2019, 233, 786–802. [Google Scholar] [CrossRef]

- Zhang, C.; Lim, P.; Qin, A.K.; Tan, K.C. Multi objective deep belief networks ensemble for remaining useful life estimation in prognostics. IEEE Trans. Neural Netw. Learn. Syst. 2016, 28, 23062318. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W.; Ding, Q. Deep learning based remaining useful life estimation of bearings using multi-scale feature extraction. Reliab. Eng. Syst. 2019, 182, 208–218. [Google Scholar] [CrossRef]

- Peng, X.; Anyaoha, U.; Liu, Z.; Tsukada, K. Analysis of Magnetic-Flux Leakage (MFL) Data for Pipeline Corrosion Assessment. IEEE Trans. Magn. 2020, 56, 1–15. [Google Scholar] [CrossRef]

- Soomro, A.; Ainul, M.; Jundika, C.K.; Huimin, L.; Najeebullah, L.; Chico, S. Deep Learning-Based Reliability Model for Oil and Gas Pipeline Subjected to Stress Corrosion Cracking: A Review and Concept. Hunan Daxue Xuebao J. Hunan Univ. Nat. Sci. 2021, 48, 10. [Google Scholar]

- Ren, C.Y.; Qiao, W.; Tian, X. Natural gas pipeline corrosion rate prediction model based on BP neural network. Adv. Intell. Syst. Comput. 2012, 147, 449–455. [Google Scholar] [CrossRef]

- Chamkalani, A.; Nareh’ei, M.A.; Chamkalani, R.; Zargari, M.H.; Dehestaniardakani, M.R.; Farzam, M. Soft computing method for prediction of CO2 corrosion in flow lines based on neural network approach. Chem. Eng. Commun. 2013, 200, 731–747. [Google Scholar] [CrossRef]

- Gabetta, G.; De, M.G.; Gentile, M.; Vichi, R.; Scapin, M. Pipeline Internal Damage Prediction by Deterministic Models and Neural Networks. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 10–13 November 2014. SPE-171919MS. [Google Scholar] [CrossRef]

- Shaw, B.; Kelly, R. What is corrosion? Electrochem. Soc. Interface 2006, 15, 24. [Google Scholar] [CrossRef]

- Shi, L.; Song, Y.; Zhao, P.; Wang, H.; Dong, K.; Shan, D.; Han, E.H. Variations of galvanic currents and corrosion forms of 2024/Q235/304 tri-metallic couple with multivariable cathode/anode area ratios: Experiments and modeling. Electrochim. Acta 2020, 359, 136947. [Google Scholar] [CrossRef]

- Bitenc, J.; Lindahl, N.; Vizintin, A.; Abdelhamid, M.E.; Dominko, R.; Johansson, P. Concept and electrochemical mechanism of an Al metal anode–organic cathode battery. Energy Storage Mater. 2020, 24, 379–383. [Google Scholar] [CrossRef]

- Goyal, M.; Kumar, S.; Bahadur, I.; Verma, C.; Ebenso, E.E. Organic corrosion inhibitors for industrial cleaning of ferrous and non-ferrous metals in acidic solutions: A review. J. Mol. Liq. 2018, 256, 565–573. [Google Scholar] [CrossRef]

- Ng, D.Q.; Lin, J.K.; Lin, Y.P. Lead release in drinking water resulting from galvanic corrosion in three-metal systems consisting of lead, copper and stainless steel. J. Hazard. Mater. 2020, 398, 122936. [Google Scholar] [CrossRef]

- Liu, C.; Deng, Y.; Chen, J.; Zou, D.; Su, W. Integrated process to recover NiMH battery anode alloy with selective leaching and multistage extraction. Ind. Eng. Chem. Res. 2017, 56, 7551–7558. [Google Scholar] [CrossRef]

- Han, X.; Yang, D.Y.; Frangopol, D.M. Probabilistic life-cycle management framework for ship structures subjected to coupled corrosion–fatigue deterioration processes. J. Struct. Eng. 2019, 145, 4019116. [Google Scholar] [CrossRef]

- Selcuk, S. Predictive maintenance, its implementation and latest trends, Proceedings of the Institution of Mechanical Engineers. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2017, 231, 1670–1679. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Ye, Y.; Zhang, C.; Wei, Y. A hybrid predictive maintenance approach for CNC machine tool driven by Digital Twin. Robot Comput. Integr. Manuf. 2020, 65, 101974. [Google Scholar] [CrossRef]

- Filom, S.; Amiri, A.M.; Razavi, S. Applications of machine learning methods in port operations–A systematic literature review. Transp. Res. E-Log. 2022, 161, 102722. [Google Scholar] [CrossRef]

- Jimenez, J.J.M.; Schwartz, S.; Vingerhoeds, R.; Grabot, B.; Salaün, M. Towards multi-model approaches to predictive maintenance: A systematic literature survey on diagnostics and prognostics. J. Manuf. Syst. 2020, 56, 539–557. [Google Scholar] [CrossRef]

- Rossouw, E.; Doorsamy, W. Predictive Maintenance Framework for Cathodic Protection Systems Using Data Analytics. Energies 2021, 14, 5805. [Google Scholar] [CrossRef]

- Canca, A.; Kökkülünk, G. Is existing maintenance system adequate for sulphur 2020 amendments? J. ETA Marit. Sci. 2020, 8, 302–308. [Google Scholar] [CrossRef]

- Vu, V.T.; Dong, D.T. Hull girder ultimate strength assessment considering local corrosion. J. Mar. Sci. Appl. 2020, 19, 693–704. [Google Scholar] [CrossRef]

- Bicen, S.; Celik, M. A RAM extension to enhance ship planned maintenance system. Aust. J. Marit. Ocean Aff. 2022, 2022, 1–20. [Google Scholar] [CrossRef]

- Abbas, M.; Shafiee, M. An overview of maintenance management strategies for corroded steel structures in extreme marine environments. Mar. Struct. 2020, 71, 102718. [Google Scholar] [CrossRef]

- Bhat, J.; Bhapkar, U.; Desai, M. Condition based predictive maintenance of worm gearbox using DR ferrography. Mater. Today Proc. 2022, 52, 2210–2212. [Google Scholar] [CrossRef]

- Gong, C.; Frangopol, D.M. System reliability of corroded ship hull girders. Struct. Infrastruct. Eng. 2020, 16, 1302–1310. [Google Scholar]

- Woloszyk, K.; Garbatov, Y. An enhanced method in predicting tensile behaviour of corroded thick steel plate specimens by using random field approach. Ocean Eng. 2020, 213, 107803. [Google Scholar] [CrossRef]

- Pourabdollah, K. Fouling formation and under deposit corrosion of boiler firetubes. J. Environ. Chem. Eng. 2021, 9, 104552. [Google Scholar] [CrossRef]

- Raadnui, S. Spur gear wear analysis as applied for tribological based predictive maintenance diagnostics. Wear 2019, 426, 1748–1760. [Google Scholar]

- Bouzaffour, K.; Lescop, B.; Talbot, P.; Gallée, F.; Rioual, S. Development of an embedded UHF-RFID corrosion sensor for monitoring corrosion of steel in concrete. IEEE Sens. J. 2021, 21, 12306–12312. [Google Scholar] [CrossRef]

- Melchers, R.E. Predicting long-term corrosion of metal alloys in physical infrastructure. NPJ Mater. Degrad. 2019, 3, 4. [Google Scholar] [CrossRef]

- Lampe, J.; Hamann, R. Probabilistic model for corrosion degradation of tanker and bulk carrier. Mar. Struct. 2018, 61, 309–325. [Google Scholar] [CrossRef]

- Tinga, T.; Tiddens, W.W.; Amoiralis, F.; Politis, M. Predictive maintenance of maritime systems: Models and challenges. In Proceedings of the 27th European Safety and Reliability Conference (ESREL 2017), Portoroz, Slovenia, 18–22 June 2017; pp. 1–9. [Google Scholar]

- Tinga, T.; Loendersloot, R. Physical model-based prognostics and health monitoring to enable predictive maintenance. In Predictive Maintenance in Dynamic Systems; Springer: Berlin/Heidelberg, Germany, 2019; pp. 313–353. [Google Scholar]

- Ayyub, B.M.; Stambaugh, K.A.; McGill, W.L. End-of-life corrosion estimation and profile of ship hull structure: Nonparametric statistical analysis of medium endurance cutters. ASCE-ASME J. Risk Uncertain. Eng. Syst. B Mech. Eng. 2022, 8, 31203. [Google Scholar] [CrossRef]

- Gong, C.; Frangopol, D.M.; Cheng, M. Risk-based decision-making on corrosion delay for ship hull tankers. Eng. Struct. 2020, 212, 110455. [Google Scholar] [CrossRef]

- Yarveisy, R.; Khan, F.; Abbassi, R. Data-driven predictive corrosion failure model for maintenance planning of process systems. Comput. Chem. Eng. 2022, 157, 107612. [Google Scholar] [CrossRef]

- Kim, K.; Lee, G.; Park, K.; Park, S.; Lee, W.B. Adaptive approach for estimation of pipeline corrosion defects via Bayesian inference. Reliab. Eng. Syst. 2021, 216, 107998. [Google Scholar] [CrossRef]

- Cheliotis, M.; Lazakis, I.; Theotokatos, G. Machine learning and data-driven fault detection for ship systems operations. Ocean Eng. 2020, 216, 107968. [Google Scholar] [CrossRef]

- Makridis, G.; Kyriazis, D.; Plitsos, S. Predictive maintenance leveraging machine learning for time-series forecasting in the maritime industry. In Proceedings of the 2020 IEEE 23rd International Conference on Intelligent Transportation Systems (ITSC). IEEE, Rhodes, Greece, 20–23 September 2020; pp. 1–8. [Google Scholar]

- Kim, D.K.; Wong, E.W.C.; Cho, N.K. An advanced technique to predict time-dependent corrosion damage of onshore, offshore, nearshore and ship structures. Int. J. Nav. Archit. 2020, 12, 657–666. [Google Scholar] [CrossRef]

- Ivošević, Š.; Bauk, S. The use of information technology in the assessment of the corrosion damage on ship hull. In Proceedings of the 23rd International Scientific-Professional Conference on Information Technology (IT), IEEE, Zabljak, Montenegro, 19–24 February 2018; pp. 1–4. [Google Scholar]

- Gautam, M.; Ramu, V.S.; Sinha, S.; Reddy, P.K.; Kondur, M.; Kumar, S.S. Augmenting the existing CBPM maintenance philosophy currently in use in the marine sector with intelligent predictive—CBPM philosophy. In Proceedings of the International Conference on Recent Trends in Machine Learning, IoT, Smart Cities and Applications, Hyderabad, India, 28–29 March 2021; Springer: Berlin/Heidelberg, Germany, 2021; pp. 553–560. [Google Scholar]

- Gong, C.; Frangopol, D.M. Time-variant hull girder reliability considering spatial dependence of corrosion growth, geometric and material properties. Reliab. Eng. Syst. 2020, 193, 106612. [Google Scholar] [CrossRef]

- Liu, Y.; Frangopol, D.M.; Cheng, M. Risk-informed structural repair decision making for service life extension of aging naval ships. Mar. Struct. 2019, 64, 305–321. [Google Scholar] [CrossRef]

- Jimenez, V.J.; Bouhmala, N.; Gausdal, A.H. Developing a predictive maintenance model for vessel machinery. J. Ocean Eng. Sci. 2020, 5, 358–386. [Google Scholar] [CrossRef]

- Silionis, N.E.; Anyfantis, K.N. On the detection of thickness loss in ship hull structures through strain sensing. In European Workshop on Structural Health Monitoring; Springer: Berlin/Heidelberg, Germany, 2023; pp. 207–216. [Google Scholar]

- Cullum, J.; Binns, J.; Lonsdale, M.; Abbassi, R.; Garaniya, V. Risk-based maintenance scheduling with application to naval vessels and ships. Ocean Eng. 2018, 148, 476–485. [Google Scholar] [CrossRef]

- Simion, D.; Purcărea, A.; Cotorcea, A.; Nicolae, F. Maintenance onboard ships using computer maintenance management system. Sci. Bull. Mircea Cel Batran Nav. Acad. 2020, 23, 134–141. [Google Scholar] [CrossRef]

- Anyfantis, K.N. An abstract approach toward the structural digital twin of ship hulls: A numerical study applied to a box girder geometry. Proc. Inst. Mech. Eng. M J. Eng. Marit. Environ. 2021, 235, 718–736. [Google Scholar] [CrossRef]

- Hassan, S.I.; Dang, L.M.; Mehmood, I.; Im, S.; Choi, C.; Kang, J.; Park, Y.S.; Moon, H. Underground sewer pipe condition assessment based on convolutional neural networks. Autom. Constr. 2019, 106, 102849. [Google Scholar] [CrossRef]

- Yin, X.; Chen, Y.; Bouferguene, A.; Zaman, H.; Al-Hussein, M.; Kurach, L. A deep learning-based framework for an automated defect detection system for sewer pipes. Autom. Constr. 2020, 109, 102967. [Google Scholar] [CrossRef]

- Cheng, J.C.; Wang, M. Automated detection of sewer pipe defects in closed-circuit television images using deep learning techniques. Autom. Constr. 2018, 95, 155–171. [Google Scholar] [CrossRef]

- Vince, P. Advances in condition assessment of water pipelines. Corrosion 2020, 76, 511–519. [Google Scholar] [CrossRef]

- Bastian, B.T.; Jaspreeth, N.; Ranjith, S.K.; Jiji, C.V. Visual inspection and characterization of external corrosion in pipelines using deep neural network. NDT E Int. 2019, 107, 102134. [Google Scholar] [CrossRef]

- Amaya-Gómez, R.; Riascos-Ochoa, J.; Muñoz, F.; Bastidas-Arteaga, E.; Schoefs, F.; Sánchez-Silva, M. Modeling of pipeline corrosion degradation mechanism with a Lévy process based on ILI (In-Line) inspections. Int. J. Press. Vessel. Pip. 2019, 172, 261–271. [Google Scholar] [CrossRef]

- Aryai, V.; Baji, H.; Mahmoodian, M.; Li, C.Q. Time-dependent finite element reliability assessment of cast-iron water pipes subjected to spatio-temporal correlated corrosion process. Reliab. Eng. Syst. 2020, 197, 106802. [Google Scholar] [CrossRef]

- Zhang, M.; Song, H.; Lim, S.; Akiyama, M.; Frangopol, D.M. Reliability estimation of corroded RC structures based on spatial variability using experimental evidence, probabilistic analysis and finite element method. Eng. Struct. 2019, 192, 30–52. [Google Scholar] [CrossRef]

- Zhang, M.; Akiyama, M.; Shintani, M.; Xin, J.; Frangopol, D.M. Probabilistic estimation of flexural loading capacity of existing RC structures based on observational corrosion-induced crack width distribution using machine learning. Struct. Saf. 2021, 91, 102098. [Google Scholar] [CrossRef]

- Hoang, N.D. Image processing-based pitting corrosion detection using metaheuristic optimized multilevel image thresholding and machine-learning approaches. Math. Probl. Eng. 2020, 2020, 6765274. [Google Scholar] [CrossRef]

- Wang, K.; Li, C.; Lu, J.; Nan, C.; Zhang, Q.; Zhang, H. Intelligent evaluation of marine corrosion of q420 steel based on image recognition method. Coatings 2022, 12, 881. [Google Scholar] [CrossRef]

- Milimonfared, R.; Oskouei, R.H.; Taylor, M.; Solomon, L.B. An intelligent system for image-based rating of corrosion severity at stem taper of retrieved hip replacement implants. Med. Eng. Phys. 2018, 61, 13–24. [Google Scholar] [CrossRef]

- Karimi, A.M.; Fada, J.S.; Parrilla, N.A.; Pierce, B.G.; Koyutürk, M.; French, R.H.; Braid, J.L. Generalized and mechanistic PV module performance prediction from computer vision and machine learning on electroluminescence images. IEEE J. Photovolt. 2020, 10, 878–887. [Google Scholar] [CrossRef]

- Perumal, P.; Ramanathan, K.; Ganesan, L.; Subramanian, B.; Ganesh, V.; Stalin, B. Investigation of TiN coating uniformity and its corrosion behaviour using image process. Mater. Res. Express 2019, 6, 46411. [Google Scholar] [CrossRef]

- Dong, B.; Ding, W.; Qin, S.; Fang, G.; Liu, Y.; Dong, P.; Han, S.; Xing, F.; Hong, S. 3D visualized tracing of rebar corrosion-inhibiting features in concrete with a novel chemical self-healing system. Constr. Build. Mater. 2018, 168, 11–20. [Google Scholar] [CrossRef]

- Bado, M.F.; Tonelli, D.; Poli, F.; Zonta, D.; Casas, J.R. Digital twin for civil engineering systems: An exploratory review for distributed sensing updating. Sensors 2022, 22, 3168. [Google Scholar] [CrossRef]

- Abbas, M.H.; Norman, R.; Charles, A. Neural network modelling of high-pressure CO2 corrosion in pipeline steels. Process Saf. Environ. Prot. 2018, 119, 36–45. [Google Scholar] [CrossRef]

- Florindo, J.B.; Metze, K. A cellular automata approach to local patterns for texture recognition. Expert Syst. Appl. 2021, 179, 115027. [Google Scholar] [CrossRef]

- Venketeswaran, A.; Lalam, N.; Wuenschell, J.; Ohodnicki, P.R., Jr.; Badar, M.; Chen, K.P.; Lu, P.; Duan, Y.; Chorpening, B.; Buric, M. Recent advances in machine learning for fiber optic sensor applications. Adv. Intell. Syst. 2022, 4, 2100067. [Google Scholar] [CrossRef]

- Nash, W.; Drummond, T.; Birbilis, N. A review of deep learning in the study of materials degradation. NPJ Mater. Degrad. 2018, 2, 37. [Google Scholar] [CrossRef]

- Doshvarpassand, S.; Wu, C.; Wang, X. An overview of corrosion defect characterization using active infrared thermography. Infrared Phys. Technol. 2019, 96, 366–389. [Google Scholar] [CrossRef]

- Zhang, X.; Saniie, J.; Heifetz, A. Detection of defects in additively manufactured stainless steel 316L with compact infrared camera and machine learning algorithms. JOM 2020, 72, 4244–4253. [Google Scholar] [CrossRef]

- Omar, T.; Nehdi, M.L.; Zayed, T. Infrared thermography model for automated detection of delamination in RC bridge decks. Constr. Build. Mater. 2018, 168, 313–327. [Google Scholar] [CrossRef]

- Zhao, Y.; Addepalli, S.; Sirikham, A.; Roy, R. A confidence map-based damage assessment approach using pulsed thermographic inspection. NDT E Int. 2018, 93, 86–97. [Google Scholar] [CrossRef]

- Park, J.; Han, H.S.; Park, J.; Seo, H.; Edwards, J.; Kim, Y.C.; Ok, M.R.; Seok, H.K.; Jeon, H. Corrosion behavior of biodegradable Mg-based alloys via femtosecond laser surface melting. Appl. Surf. Sci. 2018, 448, 424–434. [Google Scholar] [CrossRef]

- Wang, L.; Dai, L.; Bian, H.; Ma, Y.; Zhang, J. Concrete cracking prediction under combined prestress and strand corrosion. Struct. Infrastruct. Eng. 2019, 15, 285–295. [Google Scholar] [CrossRef]

- Nair, R.B.; Arora, H.S.; Grewal, H.S. Microwave synthesized complex concentrated alloy coatings: Plausible solution to cavitation induced erosion-corrosion. Ultrason. Sonochem. 2019, 50, 114–125. [Google Scholar] [CrossRef]

- Karimi, A.M.; Fada, J.S.; Hossain, M.A.; Yang, S.; Peshek, T.J.; Braid, J.L.; French, R.H. Automated pipeline for photovoltaic module electroluminescence image processing and degradation feature classification. IEEE J. Photovolt. 2019, 9, 1324–1335. [Google Scholar] [CrossRef]

- Ayob, A.F.M.; Jalal, N.I.; Hassri, M.H.; Rahman, S.A.; Jamaludin, S. Neuroevolutionary autonomous surface vehicle simulation in restricted waters. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2020, 14, 865–873. [Google Scholar] [CrossRef]

- Atha, D.J.; Jahanshahi, M.R. Evaluation of deep learning approaches based on convolutional neural networks for corrosion detection. Struct. Health Monit. 2018, 17, 1110–1128. [Google Scholar] [CrossRef]

- Prithivirajan, S.; Narendranath, S.; Desai, V. Analysing the combined effect of crystallographic orientation and grain refinement on mechanical properties and corrosion behaviour of ECAPed ZE41 Mg alloy. J. Magnes. Alloy. 2020, 8, 1128–1143. [Google Scholar] [CrossRef]

- Bondada, V.; Pratihar, D.K.; Kumar, C.S. Detection and quantitative assessment of corrosion on pipelines through image analysis. Procedia Comput. Sci. 2018, 133, 804–811. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Shi, L.; Lan, J. Imaging feature analysis-based intelligent laser cleaning using metal color difference and dynamic weight dispatch corrosion texture. Photonics 2020, 7, 130. [Google Scholar] [CrossRef]

- Li, M.; Duan, Y.; He, X.; Yang, M. Image positioning and identification method and system for coal and gangue sorting robot. Int. J. Coal Prep. Util. 2022, 42, 1759–1777. [Google Scholar] [CrossRef]

- Ramkumar, G. Hybrid model for detection of corrosion in water pipeline images using CNN and comparing accuracy with SVM. ECS Trans. 2022, 107, 13861. [Google Scholar]

- Hong, X.; Huang, L.; Gong, S.; Xiao, G. Shedding damage detection of metal underwater pipeline external anticorrosive coating by ultrasonic imaging based on HOG + SVM. J. Mar. Sci. 2021, 9, 364. [Google Scholar] [CrossRef]

- Lv, Y.J.; Wang, J.W.; Wang, J.; Xiong, C.; Zou, L.; Li, L.; Li, D.W. Steel corrosion prediction based on support vector machines. Chaos Solit. Fractals 2020, 136, 109807. [Google Scholar] [CrossRef]

- Li, X.; Guo, Y.; Li, Y. Particle swarm optimization-based SVM for classification of cable surface defects of the cable-stayed bridges. IEEE Access 2019, 8, 44485–44492. [Google Scholar] [CrossRef]

- Yang, J.; Li, R.; Chen, L.; Hu, Y.; Dou, Z. Research on equipment corrosion diagnosis method and prediction model driven by data. Process Saf. Environ. Prot. 2022, 158, 418–431. [Google Scholar] [CrossRef]

- Le, M.; Luong, V.S.; Nguyen, D.K.; Le, D.K.; Lee, J. Auto-detection of hidden corrosion in an aircraft structure by electromagnetic testing: A machine-learning approach. Appl. Sci. 2022, 12, 5175. [Google Scholar] [CrossRef]

- Deng, L.; Guo, Y.; Chai, B. Defect detection on a wind turbine blade based on digital image processing. Processes 2021, 9, 1452. [Google Scholar] [CrossRef]

- Blitz, J. Electrical and Magnetic Methods of Non-Destructive Testing; Springer: Berlin/Heidelberg, Germany, 2012; Volume 3. [Google Scholar]

- Jamaludin, S.; Zainal, N.; Zaki, W.M.D.W. Sub-iris technique for non-ideal iris recognition. Arab. J. Sci. Eng. 2018, 43, 7219–7228. [Google Scholar] [CrossRef]

- Grosse, C.U.; Ohtsu, M. Acoustic Emission Testing; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Carpinteri, A.l.; Lacidogna, G.; Pugno, N. Structural damage diagnosis and life-time assessment by acoustic emission monitoring. Eng. Fract. Mech. 2007, 74, 273–289. [Google Scholar] [CrossRef]

- Carpinteri, A.G.; Lacidogna, M.C.; Battista, E.D. Cracking and crackling in concrete-like materials: A dynamic energy balance. Eng. Fract. Mech. 2016, 155, 130–144. [Google Scholar] [CrossRef]

- Mohamad, G.D.; Nadimul, H.F.; Fraser, O.; John, A.S.; Mohamed, E.S. Acoustic emission method for defect detection and identification in carbon steel welded joints. J. Constr. Steel Res. 2017, 134, 28–37. [Google Scholar] [CrossRef]

- Wu, K.; Jung, W.S.; Byeon, J.W. Acoustic emission of hydrogen bubbles on the counter electrode during pitting corrosion of 304 stainless steel. Mater. Trans. 2015, 56, 587–592. [Google Scholar] [CrossRef]

- Jamaludin, S.; Zainal, N.; Zaki, W.M.D.W. Iris recognition based on the modified Chan-Vese active contour. J. Teknol. 2016, 78, 13–17. [Google Scholar] [CrossRef]

- Patil, S.; Shweta, G.; Bilavari, K. Performance evaluation of accelerated corrosion techniques using electrochemical measurements and acoustic emission parameters. In Proceedings of the 2016 IEEE International Conference on Prognostics and Health Management (ICPHM), Ottawa, Canada, 20–22 June 2016. [Google Scholar]

- Gloria, N.B.S.; Areiza, M.C.L.; Miranda, I.V.J.; Rebello, J.M.A. Development of a magnetic sensor for detection and sizing of internal pipeline corrosion defects. NDT E Int. 2009, 42, 669–677. [Google Scholar] [CrossRef]

- Van, D.V.P. Internal corrosion in small-diameter, heavy-wall pipelines: A critical phenomenon and how to measure it. Corros. Prev. Control. 2000, 47, 103–106. [Google Scholar]

- Raghavan, A.; Cesnik, C.E.S. Review of guided-wave structural health monitoring. Shock. Vibr. Dig. 2007, 39, 91–116. [Google Scholar] [CrossRef]

- Mokhles, M.; Ghavipanjeh, C.; Tamimi, A. The use of ultrasonic guided waves for extended pipeline qualification prediction. In Proceedings of the Singapore International NDT Conference & Exhibition, Marina Bay Sands, Singapore, 19–20 July 2013. [Google Scholar]

- Kim, D.; Udpa, L.; Udpa, S. Remote field eddy current testing for detection of stress corrosion cracks in gas transmission pipelines. Mater. Lett. 2004, 58, 2102–2104. [Google Scholar] [CrossRef]

- Shi, X.; Nguyen, T.A.; Kumar, P.; Liu, Y. A phenomenological model for the chloride threshold of pitting corrosion of steel in simulated concrete pore solutions. Anti-Corros. Methods Mater. 2011, 58, 179–189. [Google Scholar] [CrossRef]

- Ali, H.; Amir, B.; Davood, M.; Seyed, M.M.; Kasra, R. Implementing ANN to minimize sewage systems concrete corrosion with glass beads substitution. Constr. Build. Mater. 2017, 138, 441–454. [Google Scholar] [CrossRef]

- Wen, Y.F.; Cai, C.Z.; Liu, X.H.; Pei, J.F.; Zhu, X.J.; Xiao, T.T. Corrosion rate prediction of 3C steel under different seawater environment by using support vector regression. Corros. Sci. 2009, 51, 349–355. [Google Scholar] [CrossRef]

- Liao, K.; Quanke, Y.; Xia, W.; Wenlong, J. A Numerical Corrosion Rate Prediction Method for Direct Assessment of Wet Gas Gathering Pipelines Internal Corrosion. Energies 2012, 5, 3892–3907. [Google Scholar] [CrossRef]

- Jian, L.; Weikang, K.; Shi, J.; Wang, K.; Weikui, W.; Weipu, Z.; Zhoumo, Z. Determination of Corrosion Types from Electrochemical Noise by Artificial Neural Networks. Int. J. Electrochem. Sci. 2013, 8, 2365–2377. [Google Scholar]

- Giulia, D.M.; Manuela, G.; Roberta, V.; Roberto, B.; Giovanna, G. Machine learning approach to corrosion assessment in subsea pipelines. In Proceedings of the Oceans 2015 Genova Conference & Exhibition, Genova, Italy, 18–21 May 2015. [Google Scholar]

- Qifang, L.; Ray, K.L.; Su, A. Wasserstein distance-based analogous method to predict distribution of non-uniform corrosion on reinforcements in concrete. Constr. Build. Mater. 2019, 226, 965–975. [Google Scholar] [CrossRef]

- Medeiros, F.N.S.; Ramalho, G.L.B.; Bento, M.P.; Medeiros, L.C.L. On the evaluation of texture and color features for nondestructive corrosion detection. EURASIP J. Adv. Signal Process. 2010, 2010, 817473. [Google Scholar] [CrossRef]

- Russakovsky, O.; Deng, J.; Su, H.; Krause, J.; Satheesh, S.; Ma, S.; Huang, Z.; Karpathy, A.; Khosla, A.; Bernstein, M.; et al. Imagenet large scale visual recognition challenge. Int. J. Comput. Vis. 2015, 115, 211–252. [Google Scholar] [CrossRef]

- Zeiler, M.D.; Fergus, R. Visualizing and Understanding Convolutional Networks; Springer: Berlin/Heidelberg, Germany, 2014; pp. 818–833. [Google Scholar]

- Szegedy, C.; Liu, W.; Jia, Y.; Sermanet, P.; Reed, S.; Anguelov, D.; Erhan, D.; Vanhoucke, V.; Rabinovich, A. Going deeper with convolutions. In Proceedings of the IEEE conference on computer vision and pattern recognition, Boston, MA, USA, 7–12 June 2015. [Google Scholar]

- Tada, Y.; Miura, T.; Nakamura, H. Detection method of corrosion area of rebar and corrosion induced internal crack by using electromagnetic wave radar. In Bridge Maintenance, Safety, Management, Life-Cycle Sustainability and Innovations; CRC Press London: Boca Raton, FL, USA, 2021; pp. 1672–1679. [Google Scholar]

- Li, D.; Tan, M.; Zhang, S.; Ou, J. Stress corrosion damage evolution analysis and mechanism identification for prestressed steel strands using acoustic emission technique. Struct. Control Health Monit. 2018, 25, e2189. [Google Scholar] [CrossRef]

- Shanbi, P.; Zhe, Z.; Enbin, L.; Wei, L.; Weibiao, Q. A new hybrid algorithm model for prediction of internal corrosion rate of multiphase pipeline. J. Nat. Gas Eng. 2021, 85, 103716. [Google Scholar] [CrossRef]

- Rudling, P.; Strasser, A.; Garzarolli, F.; Van, S.L. Welding of Zirconium Alloys; IZNA7 Special Topic Report; Advanced Nuclear Technology International: Krongjutarvagen, Sweden, 2007. [Google Scholar]

- Ossai, C.I. A data-driven machine learning approach for corrosion risk assessment—A comparative study. Big Data Cogn. Comput. 2019, 3, 28. [Google Scholar] [CrossRef]

- Abdur, R.M.F.; Yong-Bin, K.; Prem, P.J.; Kewen, L.; Rohit, K.; Graham, M.; Rajiv, R.; Samir, S. CorrDetector: A framework for structural corrosion detection from drone images using ensemble deep learning. Expert Syst. Appl. 2022, 193, 116461. [Google Scholar] [CrossRef]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Jui-Sheng, C.; Ngoc-Tri, N.; Chong, W.K. The use of artificial intelligence combiners for modeling steel pitting risk and corrosion rate. Eng. Appl. Artif. Intell. 2017, 65, 471–483. [Google Scholar] [CrossRef]

- Hasan, T.; Jamaludin, S.; Wan Nik, W.B. Analysis of intelligent solar ICU water ambulance to optimize energy. Ann. Med. Surg. 2022, 2022, 104141. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Sato, T.; Iai, S.; Hutchinson, T. A pattern recognition technique for structural identification using observed vibration signals: Linear case studies. Eng. Struct. 2008, 30, 1439–1446. [Google Scholar] [CrossRef]

| Subject | Description |

|---|---|

| Database | Web of Science, Scopus, Science Direct, IEEE |

| Keywords | ‘’Artificial intelligence + corrosion+ detection,’’ “Predictive + maintenance + corrosion,” “Artificial + intelligence” and “current + trends,” “Computer vision + corrosion + monitoring,” “Image processing + corrosion + monitoring.” |

| Publication type | Journal and conference paper |

| Language | English |

| Time interval | 2017–2022 |

| Element | Supervised Learning | Unsupervised Learning |

|---|---|---|

| Input data | Labeled | Unlabeled |

| Feedback mechanism | Have | Don’t have |

| Data classified | Based on the training dataset | Assigns properties of given data to classify it. |

| Division | Regression and classification | Clustering and association |

| Application | For prediction | For analysis |

| Algorithm | Logistic regressions, decision trees, support vector machine | Hierarchical clustering, K-means clustering, apriori algorithm. |

| Class number | Known | Unknown |

| Models | Descriptions | Applications |

|---|---|---|

| Knowledge-Based Model | Used artificial intelligence to predict the progress of corrosion from images and videos. | -Automated sewer inspection [149,150]. -Combination of CCTV and machine learning [151,152,153]. |

| Probabilistic Model | Used for corrosion detection when the real-time data and historical data are insufficient. Require in-depth knowledge and expertise in physic and mathematics to develop a sophisticated mathematical model. Quite difficult to develop. | -Gamma distribution [154]. -Gamma process and copulas of Spatio-temporal [155]. -Probabilistic model and finite element [156]. -Monte Carlo finite element [157,158]. |

| Statistical Model | Used statistical analysis to predict and detect the corrosion progress based on historical data. The historical data can be collected from the installed CCTV in the gas pipeline, sewer, and many more. | -Markov chain with gray level co-occurrence method [159,160]. -Polynomial regression [161] and linear regression [162,163]. |

| Deterministic Model | The relationships between variables or parameters of corroded material are studied from the field experiments via images and videos. Easier to develop and could be inaccurate in terms of extrapolation results [164]. | -Structural health monitoring (SHM) and digital twin [165]]. -Texture descriptors with cellular automata [166]. -Others [167,168]. |

| Methods | Advantages | Limitations |

|---|---|---|

| Vision-Based Inspection (VSI) | Inexpensive and consistent monitoring. | Off-line processing. Costly in terms of computation. Concerns with minimal access. |

| Magnetic Flux Leakage (MFK) | Inexpensive, rapid inspection of the surface and subsurface. Active type. | Restricted to ferromagnetic substances. It is required to align the magnetic flux and flaws. |

| Guided waves-based inspection | On-line monitoring and active type. | Ultrasonics with a high frequency. Waves are necessary. Crosstalk problems. Expensive. |

| Radiographic inspection | Not constrained by material kind, precise, trustworthy, active type. | Safety risks are pricey. Required results interpretation. |

| Acoustic emission | Inexpensive. On-line monitoring, passive type. | It’s crucial to interpret AE. |

| References | Methods | Descriptions |

|---|---|---|

| [203,204,205,206] | Artificial neural network | Concrete corrosion monitoring in the sewage system. Investigate pitting corrosion in steel-reinforced concrete. |

| [207] | Hybrid machine learning Algorithms | Find the corrosion rate in a gas pipeline. |

| [92] | ANN and image processing | Detect the corrosion level of the concrete structure of reinforced steel. |

| [95] | Tomographic acoustic micro imaging (TAMI) | Evaluate the pitted region and corrosion depth in the scanning acoustic microscopy (SAM) images. |

| [208] | Electrochemical noise (EN) | Find pitting, uniform, and passivation corrosion rates. |

| [97,209] | Magnetic resonance imaging (MRI) | For corrosion analysis. |

| [210] | Fitting neural network (FNN) | Investigate the corrosion rate in the pipelines. |

| [94] | Thermal spraying method | Assess the corrosion mechanism and coatings. |

| [211] | A Wasserstein distance-based analogous method | Predict the non-uniform deterioration of reinforcing materials. |

| [93] | Fourier transform and Gaussian filter | Monitor and predict the corrosion degree. |

| [83] | Synchrotron radiation computed tomography (SRCT) | Tested for corrosion rate measurement, composite failure analysis, and electrochemical reaction visualization. |

| [33] | A python-based deep learning approach | Automatic metal corrosion (rust) detection. |

| [30,212] | Two weak classifiers | Automatically detecting corrosion on pipelines, storage tanks, and other containers. |

| [46] | HSI (Hue, Saturation, and Intensity) | Applied for corrosion detection. |

| [45] | The hybrid wavelet packet transforms | Carbon-steel pipeline corrosion detection. |

| [213] | Wavelet image coefficient | Determine the atmospheric corrosion characteristics. |

| [66] | HSV color space | Locate the corroded and non-corroded regions. |

| [214] | 2D-wavelet filtering | Identify structural damage. |

| [47] | Backpropagation method, radial basis function, and extreme learning machine | Predict stress corrosion cracking. |

| [215] | SOM (Self Organizing Map) | Investigate the deterioration of corrosion-induced crack and rebar corrosion. |

| [216] | SOM-based neural network | Analysis of the progression of corrosion in prestressed steel and identification of the process. |

| [217] | The hybrid intelligent algorithm method | Predicts the corrosion rate of the multiphase flow pipeline. |

| [218] | CNN | Hull structural plate corrosion damage detection. |

| [219] | Tree-based ensemble, kernel-based technique | 85% accuracy with the kernel-based technique and 81% accuracy using ensemble techniques for predicting corrosion and stress corrosion cracking. |

| [220] | Principal component analysis-gradient boosting machine, feed-forward ANN | Predict corrosion in offshore pipelines. |

| [221] | CorrDetector | Structural corrosion detection from drone images. |

| [1] | Machine learning algorithm | Prevent pipeline corrosion. |

| [222] | Wavelet analysis | Determine the effect of nitrogen on pitting corrosion. |

| [223] | Hybrid metaheuristic regression model | Monitoring corrosion in steel rebar in real-time. |

| [224] | Automated method | Determine the cause of corrosion by collecting a set of historical data. |

| [225] | Single support vectors regression (SVR) | Estimate the 3C steel corrosion rate in five distinct marine conditions. |

| [30] | Phenomenological model | Determine pitting corrosion of steel in concrete. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imran, M.M.H.; Jamaludin, S.; Ayob, A.F.M.; Ali, A.A.I.M.; Ahmad, S.Z.A.S.; Akhbar, M.F.A.; Suhrab, M.I.R.; Zainal, N.; Norzeli, S.M.; Mohamed, S.B. Application of Artificial Intelligence in Marine Corrosion Prediction and Detection. J. Mar. Sci. Eng. 2023, 11, 256. https://doi.org/10.3390/jmse11020256

Imran MMH, Jamaludin S, Ayob AFM, Ali AAIM, Ahmad SZAS, Akhbar MFA, Suhrab MIR, Zainal N, Norzeli SM, Mohamed SB. Application of Artificial Intelligence in Marine Corrosion Prediction and Detection. Journal of Marine Science and Engineering. 2023; 11(2):256. https://doi.org/10.3390/jmse11020256

Chicago/Turabian StyleImran, Md Mahadi Hasan, Shahrizan Jamaludin, Ahmad Faisal Mohamad Ayob, Ahmad Ali Imran Mohd Ali, Sayyid Zainal Abidin Syed Ahmad, Mohd Faizal Ali Akhbar, Mohammed Ismail Russtam Suhrab, Nasharuddin Zainal, Syamimi Mohd Norzeli, and Saiful Bahri Mohamed. 2023. "Application of Artificial Intelligence in Marine Corrosion Prediction and Detection" Journal of Marine Science and Engineering 11, no. 2: 256. https://doi.org/10.3390/jmse11020256

APA StyleImran, M. M. H., Jamaludin, S., Ayob, A. F. M., Ali, A. A. I. M., Ahmad, S. Z. A. S., Akhbar, M. F. A., Suhrab, M. I. R., Zainal, N., Norzeli, S. M., & Mohamed, S. B. (2023). Application of Artificial Intelligence in Marine Corrosion Prediction and Detection. Journal of Marine Science and Engineering, 11(2), 256. https://doi.org/10.3390/jmse11020256