Abstract

The results of the research work on biofuel’s impact on the environmental and economic performance of marine diesel engines are presented. During the research, a fuel mixture was used that consisted of the diesel fuel RMA10 and FAME biofuel. The objective of the research was to determine the optimal concentration of biofuel mixed with diesel fuel. The research work was carried out on three of the same type of marine medium-speed diesel engine, 6N165LW Yanmar. One of the diesel engines only operated on diesel fuel, and the other two operated on a mixture of diesel fuel and 5–20% biofuel. During the experiment, the diesel engines operated at a load of 50–80% of the rated value. Experimentally, it was found that using biofuel improved the environmental friendliness of diesel engines: the emission of nitrogen oxides in exhaust gases was reduced by 8.7–23.4%, and the emission of carbon oxides in exhaust gases was reduced by 3.1–24%. However, when using biofuel, the economic efficiency of diesel operation decreased as the specific effective fuel consumption increased by 0.5–9.3%. The highest environmental efficiency was achieved when using a fuel mixture that included 10–15% biofuel in an 80% diesel load. In this case, the emission of nitrogen oxides was reduced by 21–23.5%, the emission of carbon oxides was reduced by 16.5–19.2%, and the magnification of the specific useful consumption of the diesel engine was 1–1.55%.

1. Introduction

European countries are constantly developing transportation and infrastructure, including sea and inland water transport. Shipping companies in Europe (such as Maersk, Copenhagen, Denmark; Mediterranean Shipping Company, Geneva, Switzerland; and CMA CGM, Paris, France) build or order modern ships from Asian shipyards that meet the requirements of American and European classification societies and are able to operate in any water area of the world’s oceans [1,2]. The output of the power plants of these ships can reach 80,000–100,000 kW, and the speed can be 25–27 knots. On sea and inland water transport ships, turbine units, gas turbine units, and internal combustion plants are used as heat engines [3,4]. Steam turbine plants (which include a steam boiler and a steam turbine) are installed on sea tankers and LNG-type (liquid natural gas carrier/tanker) and LPG-type (liquid petroleum gas carrier/tanker) vessels with a deadweight of 75,000–80,000 tons and above. Gas turbine units are usually used on passenger ships and perform the functions of auxiliary engines, providing electrical energy to ship consumers. On all the ships, with no exceptions, diesel engines are installed, irrespective of their type and deadweight, and they serve as both main and auxiliary engines [5,6]. In the first case, their power ensures the movements of the ship; in the second case, their useful mechanical energy is converted into electrical energy by generators, ensuring the functioning of the ship’s auxiliary mechanisms and systems [7,8].

Receiving energy and useful work from heat engines is impossible without the use of liquid fuel [9,10,11]. The introduction of modern scientific technologies that are directed at the use of wind and solar energy in sea transport can be used only partially. Installing solar panels on open decks requires their continuous disassembly and reassembly before and after cargo operations. Wind generators, rigid sails, and skate sails increase aerodynamic drag when hydrometeorological conditions change, and in the case of critical weather deterioration (which occurs constantly in sea and ocean conditions), they lose their ability to control [12]. Using the storage batteries on transport ships requires a constant recharging of their capacity, which is impossible in the conditions of long sea crossings [13]. The use of gaseous fuels is possible only on limited types of ships (gas carriers and some tankers), on which this fuel is transported as cargo, and also on some very large cruise ships that are powered by methane [14]. In this way, liquid fuel will remain the main energy source for marine power installations for the foreseeable future. However, the global request for fuel increases all the time, natural resources decrease every year, mining volumes are regulated by manufacturing countries, the cost of transportation to consumer countries is constantly increasing, and price dynamics are subject to abrupt changes. It should also be taken into account that consumer countries buy crude oil as “liquid fuel”. To obtain diesel or heavy fuel oil, crude oil is subjected to heating, evaporation, and thermal or catalytic cracking. These operations not only require additional financial costs but also contribute to air and water pollution.

At the same time, requirements are applied to the environmental indicators of the power of marine ships: the sulfur content in the fuel is limited [15], the emissions of nitrogen oxides in exhaust gases [16] are regulated, and the emissions of carbon monoxide are limited [17].

This stimulates the development and use of alternative fuel in ship power plants. The main types of alternative fuels are natural gas [18,19], liquefied petroleum gas [20,21], hydrogen [22,23], alcohol mixtures with petroleum fuels (methanol and ethanol) [24,25], vegetable oils [26,27], and artificial liquid fuel of biological origin (biofuel) [28,29,30].

The use of alternative fuels is gaining ground in road and rail transport. For sea and inland water transport power plants, the use of alternative fuels has not been substantially developed. The task of studying the effect of alternative fuels on the energy and environmental performance of marine diesel engines (the main type of heat engines for marine vessels) does not differ in its systematic approach and is at the stage of initial studies. The solution to this task and finding the optimal modes of operation for diesel engines on alternative fuel will contribute to improving the environmental indicators of the working quality of marine vessels.

The use of alternative fuels (including biofuels) in the power plants of sea vessels is regulated by the recommendations of the manufacturers of the fuel. In this case, only the minimum and maximum concentrations of biofuel in the fuel mixture are indicated, at which combustion is ensured. The efficiency of its use directly depends on the competence of the ship’s crew and the availability of recommendations on the technology of using biofuel in various operating modes of the diesel engine.

In this regard, the main objective of the research work was to experimentally determine the optimal concentration of biofuel in a diesel fuel mixture in marine diesel engines. At the same time, the environmental friendliness of the diesel engine should be ensured (in particular, the minimum levels of emissions of nitrogen oxides and carbon oxides), with a minimal increase in specific fuel consumption.

2. Literature Review

At the moment, the following alternative fuels are used and actively promoted on marine vessels.

Natural gas ranks in first place among alternative fuels in stationary energy. Modern liquefied natural gas consists of 85–95% methane CH4, and the remaining 5% includes ethane, propane, butane, and nitrogen. The lower caloric value is about 50,000 kJ/kg. With the stoichiometric ratio 5–19, when its upper limit is exceeded, the gas will not be enough to start a fire; if the stoichiometric ratio is less than 5, there will be less oxygen in the mixture. The liquefied natural gas can be used after regasification—evaporation without air access. As a result, its specific volume increases—this (due to the need for additional fuel tanks) limits the possibility of its use on sea vessels. The best option for using liquefied natural gas is LNG-type vessels, on which it is transported as cargo. The density of the gas phase is fundamentally different from the density of the liquid petroleum fuel and at 20 °C is 0.7 kg/m3. This forces the use of the separate nozzles and a special supply system to direct it to the diesel cylinder [31,32,33,34].

Petroleum gas is a mixture of light hydrocarbons which is liquefied under pressure. The main components are propane C3H8 and butane C4H10. The lower caloric value is 47,500–48,500 kJ/kg, and the gas-phase density at 20 °C is 1.8–2.5 kg/m3. It is similar to liquefied natural gas, when the use of liquefied petroleum gas is necessary to change the design of the fuel system, using the special nozzles. As a rule, the use of natural and petroleum gases as fuel occurs on the ships that are carrying them. Due to the fact that they are not only a source of energy, but are also the part of the transported cargo, diesel operation on these types of alternative fuel is possible only when the vessel is moving in one direction. In the case of a ballast passage, the operation of the power plant should be taken on fuel of petroleum origin. In addition, if the temperature or pressure changes in the gas supply system to the diesel cylinder, their partial or complete condensation may occur. This leads to deterioration or the impossibility of spraying gas from the fuel injector [35,36,37,38].

The use of hydrogen as a fuel was proposed for various types of transport: road, rail, and aviation. Hydrogen is an environmentally friendly fuel—reacting with oxygen in the air, it forms only water vapor. The combustion of hydrogen is accompanied by the release of a large amount of energy; the lower caloric value is 120,000–140,000 kJ/kg. Combustion in the diesel cylinder turns into detonation, which increases the mechanical load on the parts of the cylinder group, bearings, and the crankshaft. Hydrogen, when mixed with air, forms an explosive mixture—explosive gas. It must be stored in special gas cylinders. All this limits the use of hydrogen on ships of sea transport [39,40,41,42].

Mixtures of alcohols with diesel fuel (methanol and ethanol) have a density of 790–800 kg/m3 at 20 °C. This allows for their supply to the diesel cylinder using fuel pumps and nozzles designed to inject the main (diesel) fuel. At the same time, in their purest form, methanol and ethanol are extremely dangerous flammable liquids with a flash point of 7–10 °C and an ignition temperature of 12–15 °C. The lower caloric value of methanol is 22,500–23,000 kJ/kg; its losses (compared to diesel fuel) are compensated by high combustion rate, completeness of combustion, and reduction in heat losses. However, pure methanol and ethanol are used as fuel only in automotive diesel engines. Methanol/ethanol and petroleum fuel blends must be subject to permanent hydrodynamic treatment and used immediately after preparation. The storage of such mixtures leads to their stratification and, when used, causes uneven combustion, and increases the uneven speed of the diesel engine [43,44,45,46].

The most widespread among vegetable oils when used as an alternative fuel is rapeseed. The density of rapeseed oil at 20 °C is 900–920 kg/m3 and the flash point is 55–60 °C. This allows the use of rapeseed oil without changing or upgrading the design of the diesel fuel system. The use of rapeseed oil significantly reduces CO2 emissions in exhaust gases. Rapeseed oil contains up to 0.02% suphur, which also improves the environmental performance of a diesel engine. The negative characteristic of rapeseed oil is its reduced lower caloric value (up to 37,000–37,500 kJ/kg), as well as increased smoke during combustion. In addition, the higher (compared to diesel fuel) density of rapeseed oil forces it to be used in a mixture with ethyl alcohol. The density of such a mixture (with an alcohol content of up to 30%) decreases to 880–890 kg/m3; however, the lower caloric value decreases to 34,000–35,000 kJ/kg [47,48,49,50].

One of the promising and widespread types of alternative fuel is artificial liquid fuel of biological origin (biofuel). Biodiesel fuel (or FAME—fatty acid methyl ester, methyl esters of fatty acids) is made from various products, in particular from rapeseed, plants, and used cooking oil. The advantage of biodiesel fuel is that raw materials are available in large volumes. Biodiesel can be blended with diesel or used pure [51,52,53,54].

It should also be noted that the use of alternative fuels for high-power marine diesel engines (with a cylinder diameter of more than 0.4–0.42 m and a rated power of more than 5000 kW) is limited due to the fact that the following occur: uncontrolled deterioration of environmental performance (due to fluctuations in the fuel–air ratio) [55], a reduction in torque (due to the drop in the maximum cycle pressure) [56], and a decrease in effective power at the rated load (due to the change in the period of fuel supply) [57].

The above literature review confirms that the study of the possibility of using alternative fuels (including biodiesel) in marine diesel engines is a high-priority task, the solution of which has not yet been found. In this case, it is necessary to:

- Establish optimal configuration schemes for marine fuel systems, in which the use of alternative fuel is possible;

- Define the criteria for evaluating the efficiency of using alternative fuels;

- Set the optimal concentration of alternative fuel in a mixture with diesel fuel.

The characteristics of alternative fuels are given in Table 1.

Table 1.

Some characteristics of alternative fuels.

3. Materials and Methods

The use of biodiesel fuel on ships of sea and inland water transport is limited by the following causes:

- The navigation autonomy and the impossibility of unhindered refueling (including alternative) [58];

- High output of the ship power plant and, accordingly, high fuel consumption [59].

The proper work and technical conditions of a fuel system are monitored by qualification societies [60].

The main disadvantage of using biodiesel fuel is that it has low calorific value; so, the normal operation of a diesel engine is impossible with only biofuel [61,62]. For this reason, we should use a mix of diesel fuel and biofuel where diesel fuel, the main component, is 70–80% and biofuel is 20–30% of all volume. Diesel and biofuel have the same main characteristics (density, viscosity, and flash point), so to make a mix of it will not be a hard task and it can be made onboard vessels without additional equipment.

The composition of diesel fuel (compared to biofuels) includes an increased content of sulfur and nitrogen. When they are burned, toxic components are formed—sulfur oxides (SOX) and nitrogen (NOX), which have a negative effect on the environment and humans. In accordance with the requirements of Annex VI MARPOL:

- The sulfur content of marine fuel must not exceed 0.5% by weight;

- In special areas, to control SOX emissions, the sulfur content in the marine fuel supplied to the ship and used on it should not exceed 0.10% by weight;

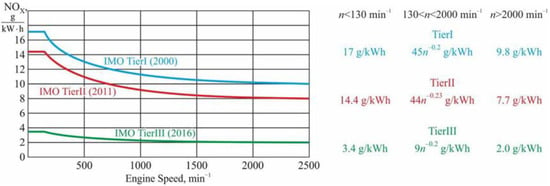

- The emissions of nitrogen oxides in exhaust gases must comply with Tier-I, Tier-II, Tier-III standards (which apply to diesel engines of ships built after 2000, 2011, and 2016), but the maximum amount of NOX in exhaust gases depends on the speed of the diesel engine and should not exceed the values determined by special expressions (Figure 1) [60,63,64].

Figure 1. Requirements Annex VI MARPOL to quantify NOX in the exhaust gases of marine diesel engines [36,60].

Figure 1. Requirements Annex VI MARPOL to quantify NOX in the exhaust gases of marine diesel engines [36,60].

Harmful emissions released into the atmosphere with the exhaust gases of marine diesel engines also include carbon oxides—CO and CO2. At the same time, CO (carbon monoxide) is a toxic gas and causes the poisoning of living organisms; CO2 (carbon dioxide) is a greenhouse gas and causes thermal pollution of the atmosphere.

The problem of reducing the concentration of sulfur oxides in exhaust gases was solved by using fuel in diesel engines with a sulfur content of 0.5% (and in some areas up to 0.1%) [4].

Today, much attention is paid to the reduction in substances which can be harmful, for example, carbon oxides and especially nitrogen oxides in combustion products [17,60]. We have primary and secondary methods of reducing these emissions, especially of nitrogen oxides. The primary method is the reduction in NOX in a diesel cylinder during the combustion of fuel. One more method of reducing nitrogen oxides in exhaust gases is using alternative fuels. The use of various types of alternative fuels is one of the general recommendations for determining its optimal concentration in diesel fuel. Additionally, there are no recommendations as for the economic and environmental efficiency of using a mixture of diesel fuel and biofuel in various diesel operating modes.

The best variant is to use alternative fuels in marine medium-speed diesel engines with a power of 400–700 kW as auxiliary engines. In this case, with a total mean load of 250–550 kW on the ship power plant, the daily fuel consumption is 1200–2500 kg/day. At 20–30% alternative fuel concentration in the fuel mixture, its daily consumption should not exceed 500–750 kg/day. With an autonomy of navigation of up to 30 days, current volumes are possible to be delivered in different seaports and can be stored on board [65].

This research used FAME biofuel as an alternative fuel with the following main characteristics:

- Content of biodiesel fuel—99.7%;

- Diesel fuel content—0.3%;

- Diesel fuel class—ultra-low-sulfur diesel fuel;

- Sulfur content in diesel fuel—0.02%;

- Viscosity at 40 °C—15 sSt;

- Density at 15 °C—850 kg/m3.

RMA10 fuel was used as diesel fuel, which complies with the international fuel standard ISO 8217 and has the following main characteristics:

- Viscosity at 40 °C—12 sSt;

- Density at 15 °C—865 kg/m3;

- Sulfur content—0.09%.

If the analyzed values of viscosity and density of fuel RMA10 and FAME biofuels are guaranteed, we can ensure that a stable fuel mixture can be made [66,67]. Diesel fuel RMA10 will be used as the main component of the fuel mixture. Biofuel in the fuel mixture content will be nearly 5–25% of the total volume.

The research was carried out on marine medium-speed diesel engines 6N165LW Yanmar with the following characteristics (Table 2).

Table 2.

Main characteristics of diesel engines 6N165LW Yanmar.

The objective of the research was to determine the optimal concentration of FAME biodiesel fuel mixed with RMA10 diesel fuel. At the same time, a simultaneous maximum increase in environmental and minimum decrease in the economic parameters of the operation of a marine diesel engine should be ensured.

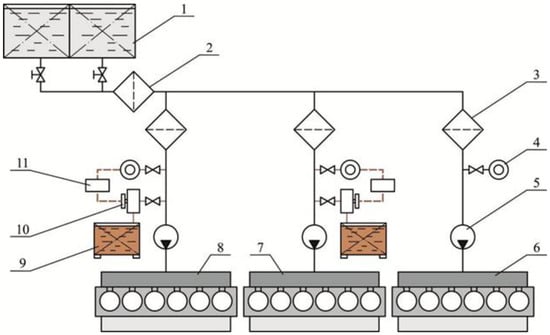

The research was carried out on three identical marine medium-speed diesel engines 6N165LW Yanmar, which served as auxiliary engines (diesel generators). A fragment of the diesel fuel feed system is shown in Figure 2.

Figure 2.

Fragment of the fuel feed system of marine diesel engines 6N165LW Yanmar: 1—service tank of diesel fuel RMA10; 2—first-stage fuel filter; 3—second-stage fuel filter; 4—flow meter; 5—fuel pump; 6, 7, and 8—auxiliary diesel 6N165LW; 9—service tank biodiesel fuel FAME; 10—dispenser; 11—microcontroller.

The composition of the fuel system included the following equipment: a service tank of diesel fuel 1; common first-stage fuel filter 2; separate second-stage fuel filter 3 for each diesel engine; separate electronic flow meter 4 for each diesel engine; separate fuel pump 5 for each diesel engine; and diesels 6, 7, and 8.

The operation of the fuel system occurred as follows. From service tank 1, the RMA10 diesel fuel through first-stage fuel filter 2 and second-stage fuel filter 3 (located in the contour of each diesel engine 6, 7, and 8) was supplied to fuel pumps 5 and then sent to the diesel engines. The amount of fuel supplied to diesel engines 6, 7, and 8 was portioned by flow meters 4 (located in the contour of each diesel engine). The fuel supply loop to diesel 6 was not altered; the diesel was operated on RMA10 fuel. A service tank was additionally installed in the contours of diesel engines 7 and 8 biodiesel fuel 9, dispenser 10, and microcontroller 11. These diesel engines were operated on a mixture of diesel fuel and biofuel. The required amount of biofuel in the fuel mixture was provided using microcontroller 11. At the same time, depending on the consumption of diesel fuel, the amount of biofuel that was supplied to the fuel system from tank 9 through dispenser 10 changed. Tank 1 was replenished automatically. The replenishment of tank 9 was performed in a manual mode. The installation and operating rules of additional equipment (biodiesel service tanks, dispensers, and microcontrollers) were agreed with the technical management department of the company that owned the vessel [65].

We have two main ways for how to prepare fuel mixtures: the cyclic method or the continuous way. In the cyclic method, we need equipment that will ensure the preparation of the mixture operates periodically. The current method consists of adding biofuel directly to the service tank or additional mix tank. When the biofuel is added to the cylinder during injection, it is the continuous method. The mixture of diesel fuel and FAME biodiesel prepared using the continuous method when we performed the experiment is shown in Figure 2. In the main engine, the fuel mixture was in the range of 5, 10, 15, and 20%.

To evaluate the efficiency of the use of biofuel, as well as to determine the optimal concentration of biofuel in a mixture with diesel fuel, environmental and economic criteria were used. The main environmental criterion is the concentration of carbon monoxide CO and nitrogen oxides NOx.

The specific effective fuel consumption be was used as an economic criterion.

Using the gas analyzer Testo340, the concentration of nitrogen oxides NOX and the volumetric content of carbon monoxide CO were monitored in the exhaust gases. The gas analyzer can be used for measurements in the temperature range up to 1000 °C. This Testo340 gas analyzer complies with the requirements of the Continuous Emission Monitoring System (CEMS) of the Environmental Protection Agency (EPA) [60]. In accordance with the requirements of the NOx Technical Code, the analysis of exhaust gases was carried out in the gas outlet line at a distance of 10 m from the place where gases exited the gas turbine of the diesel turbocharger. As a result, the measurement error of NOX and CO emissions by the Testo340 gas analyzer was ±1.0% in the exhaust gases.

The ship flow meter installed on the fuel supply line to the diesel engine (item 4 in Figure 2) with and a timer; the specific fuel oil consumption be was calculated by the ratio:

where Gh—hourly fuel consumption, kg/h, determined by the equation:

- Vf—the amount of fuel that has passed through the flow meter, m3;

- ρ—density of the fuel at the appropriate temperature, kg/m3;

- t—the time during which the experiment was carried out in the corresponding operating mode of the diesel engine, h;

- Nework—power of the diesel in different modes of operation, kW.

The value of Nework was determined in the central control room by means of electronic equipment.

Additionally, thanks to engine power meters, it was possible to measure in the range of 0–700 kW with a guaranteed accuracy of ±1 kW.

The fuel consumption was determined using NMG electromagnetic flowmeters installed on the fuel supply and return lines. The flow meter provides measurement in the temperature range of −20–+70 °C with visualization of the values on the touch screen.

The time of the experiment was recorded by means of an electronic timer. Taking into account the duration of the experiment (more than an hour in each of the modes), the error in measuring the time was not considered.

At the same time, the determination of fuel consumption did not exceed ±2.5%.

During the research, in order to provide consumers with power, a diesel engine was operated, the fuel system of which was not altered (diesel 5 in Figure 2). Its operation was carried out on RMA10 diesel fuel. Additionally, along the experiments, one or two diesel engines were used (6 and 7 in Figure 2), in the fuel system of which additional equipment was installed (service tank biodiesel fuel 9, dispenser 10, and microcontroller 11—Figure 2). This ensured the operation of diesel engines on a fuel mixture with different concentrations of FAME biofuel.

The diesel engines where we performed the experiment worked on continuous load and supplied the same group of consumers. Depending on the experiment modes, the continuous power was 265 kW, 320 kW, 370 kW, and 425 kW. This matched the loads of 50, 60, 70, and 80% of the rated power of the diesel Nenom.

Prior to the experiment, all diesel engines had fuel equipment, cylinder group parts, and motion bearings of the same service life and technical condition [59].

By switching consumer groups, the diesel engines were operated at the same load defined before the experiment. When we changed the number of consumers and power which was required for the operation, the extra load was redistributed to other engines which did not participate in the experiment.

However, on the diesel engines on which we performed the experiment, the load was stable and constant. At the same time, all axillary systems such as lubrication and cooling were working in stable mode with the same operation temperature [47].

The main parameters and engine load were stable during the experiment which took place from 1.0 to 1.5 h. All that we pointed out earlier showed that experiment was correct and all measurements were carried out on different load and different engines.

4. Results

The research was carried out on a sea vessel of the general cargo type with a deadweight of 14,800 tons during an ocean passage between the ports of South America. In each port, the possibility of obtaining biofuels was provided. At the same time (due to the absence of cargo and mooring operations), the operation of 6N165LW Yanmar marine diesel engines took place without abrupt changes in loads. List, trim, and other outer effects did not influence the measured parameters and the process of preparing a mixture of FAME biofuel and RMA10 diesel fuel. The duration of the cycle of experimental studies was 7–8 h.

The results of the experiment to determine the emission of nitrogen oxides NOX (per g/(kWh)) and the emission of carbon oxides CO (per volumetric percent) in the exhaust gases, as well as the results the specific useful fuel consumption be, are given in Table 3.

Table 3.

Results of the experiment.

The concentration of NOX in the exhaust gases of marine diesel engines is regulated by the requirements of MARPOL Annex VI [2,36,65]. In accordance with these requirements, the 6N165LW Yanmar marine diesel engine is classified as Tier II. For such diesel engines, the concentration of NOX in the exhaust gases must not exceed the value determined by the expression:

where n—diesel engine speed, min–1.

In accordance with (3) for marine diesel 6N165LW Yanmar:

Additionally, we need to say that the concentration of nitrogen oxides which was determined by expression (3) in all operation modes should not exceed the needed value.

Thus, during the experiment, the operation of the diesel engines 6N165LW Yanmar was carried out in compliance with the requirements of Annex VI MARPOL [36,60].

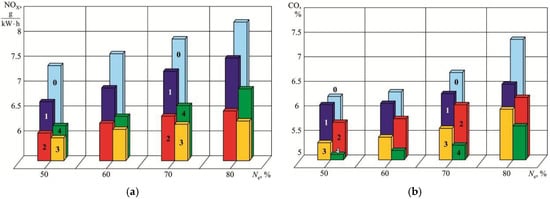

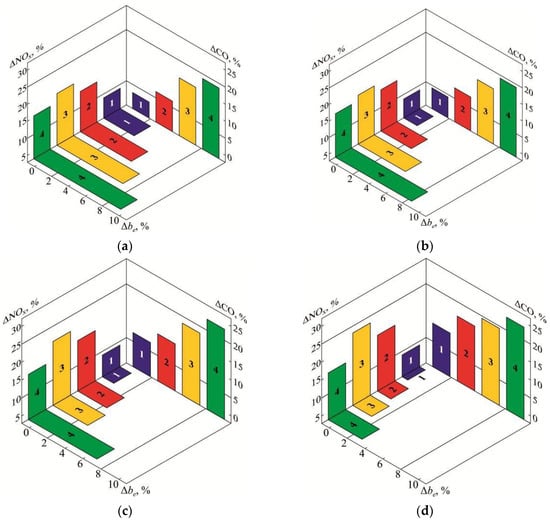

As well as for a comprehensive evaluation of the results given in Table 3, nomograms were built (Figure 3a–c) for a clearer perception and understanding, and better visualization. At the same time, the nomograms separately show the change in the controlled parameters relative to the load of the diesel engine and the content of biofuel in the fuel mixture. This makes it possible to evaluate the efficiency of using the fuel mixture with different biofuel content at different diesel loads.

Figure 3.

Comparative characteristics 6N165LW Yanmar on the different load when using fuel of different blends: (a)—emission of nitrogen oxides; (b)—emission of carbon oxide; (c)—specific useful fuel consumption; 0—RMA10; 1—RMA10 + 5% biofuel; 2—RMA10 + 10% biofuel; 3—RMA10 + 15% biofuel; 4—RMA10 + 20% biofuel.

The effective fuel consumption was increased no matter the content of FAME biofuel in the mixture. At the same time, NOX and CO emissions were decreased.

The relative changes in the emission of nitrogen oxides ∆NOX and the emission of carbon monoxide ∆CO in exhaust gases, as well as specific useful fuel consumption ∆be, were calculated according to the equations:

- where —emission of nitrogen oxide during diesel operation on RMA10 fuel and the mixture of RMA10 fuel with FAME biofuel, g/(kWh);

- —emission of carbon during diesel operation on RMA10 fuel and the mixture of RMA10 fuel with FAME biofuel, %;

- —the specific useful diesel fuel consumption during diesel operation on RMA10 fuel and the mixture of RMA10 fuel with FAME biofuel, g/(kWh).

The received values are summarized in Table 4.

Table 4.

Change in the relative performance of the 6N165LW Yanmar diesel engine.

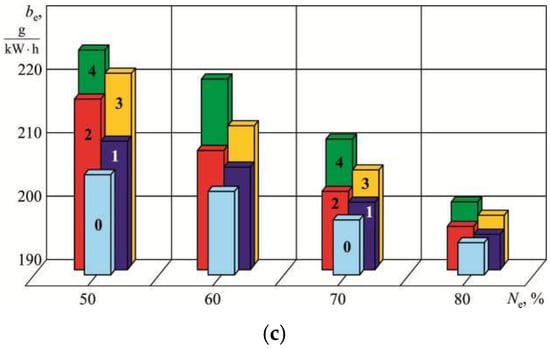

For a better visualization of the results given in Table 4, their perception and understanding, as well as for their comprehensive assessment, nomograms were constructed (Figure 4a–d). At the same time, the change in the controlled parameters relative to the diesel load is separately collected in the nomograms. This makes it possible to perform a comprehensive assessment of the environmental friendliness and economy of using a fuel mixture with different biofuel content.

Figure 4.

The performance variation of the 6N165LW Yanmar diesel engine when using different fuel blend: (a)—load 50%; (b)—load 60%; (c)—load 70%; (d)—load 80%; 1—RMA10 + 5% biofuel; 2—RMA10 + 10% biofuel; 3—RMA10 + 15% biofuel; 4—RMA10 + 20% biofuel.

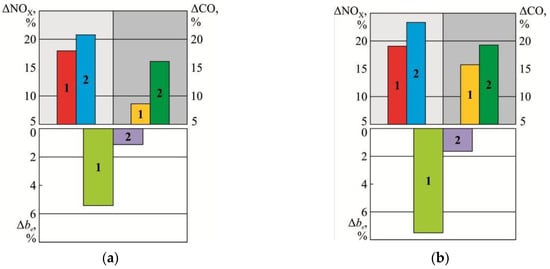

The efficiency of using a mixture of biofuel and diesel fuel should be expedient to carry out using an integrated method. A reduction in nitrogen oxides in tandem with increasing specific fuel consumption is the main target. The other target is a decrease in carbon monoxides. The emission of carbon monoxide (due to its toxicity) is also an important indicator. In this regard, a mixture containing 10 and 15% of biofuel counts as the optimal composition of the fuel mixture. The nomograms revealing the change in environmental and economic performance of the 6N165LW Yanmar marine diesel engine under such conditions are shown in Figure 5. In this case (similar to Table 4 and Figure 4), the values ∆NOX and ∆CO match the reduction in the emission of nitrogen oxides and carbon oxides in exhaust gases; the value ∆be shows an increase in the specific effective fuel consumption.

Figure 5.

Optimal use of FAME biofuels in marine diesel 6N165LW Yanmar: (a)—RMA10 + 10% biofuel; (b)—RMA10 + 15% biofuel; 1—load 50%; 2—load 80%.

Fuel mixtures containing 10–15% of biofuels provided more than a 20% reduction in nitrogen oxide emissions and 15–20% reduction in carbon oxide emissions. The smallest decrease in the efficiency of the operation of a marine diesel engine when using biofuel (up to 1–1.5%) was achieved at a diesel load of 80%. When the load decreased, the value of the specific effective fuel consumption increased. At 50% load, this increase could exceed 7%. Therefore, the use of fuel mixtures during diesel operation at such loads reduces its economic efficiency.

5. Discussion

The internal combustion engines of marine vessels do not only provide power to the ship and her auxiliary machinery, but also release toxic components into the atmosphere. In addition, the use of petroleum fuel in marine diesel engines reduces its global reserves. An option that, on the one hand, contributes to reducing the emission of toxic components and, on the other hand, reduces the consumption of natural oil resources, is the use of alternative fuels. For marine diesels, FAME biodiesel fuel can be used as an alternative fuel. These fuel grades are produced in many EU countries, as well as in the USA, Brazil, and China. This gives an opportunity of bunkering biofuel at worldwide ports. Using the mixture of biodiesel and diesel fuel can improve ecologic and economic characteristics.

At the main point, it showed a decrease in the emission of nitrogen and carbon oxides. In our opinion, this is due to the lower (compared to diesel fuel) flash point of biofuel, as well as the increased content of hydrogen in it. This reduces the maximum temperature in the diesel cylinder and interrupts the chain reaction of NOX and CO formation. This is especially important considering new regulations of international and national conventions [68,69,70].

The optimal concentration of biofuel in the fuel mixture (at which the maximum reduction in NOX and CO emissions is provided) depends on the stoichiometric ratio and can be determined experimentally for each diesel engine load.

The use of alternative types of fuel in ship power plants can reduce the consumption of the general types of fuel. The production of biofuel can be performed in regions where natural fuel is limited. Additionally, using the production of biofuel means less dependence on countries and major oil suppliers. The performance characteristics of biofuels (viscosity, density, flash point, and calorific value) must be comparable to those of diesel fuel. The discrepancy in the density of biofuel and diesel fuel can lead to the stratification of their mixture, the violation of homogeneous fuel injection, an uneven speed of rotation of a diesel engine, and an increase in the temperature stress on the cylinders and the gas exhaust system of the diesel engine. This limits the possibility of using some types of biofuels [71,72,73]. The lower (compared to diesel fuel) calorific value of biofuel is the reason for the increase in specific fuel consumption. This is explained as follows: reducing heat generation in the cylinder reduces the torque on the diesel shaft, while the automatic control system proportionally increases the fuel supply.

On existing vessels, we also need to equip the new type of fuel system. For this purpose, we need to redesign fuel systems and all power plants’ equipment regarding the rules and requirements of the register of class. On the other hand, the equipment for biofuel can be used on any type of engine. Additionally, all works on the re-equipment of the fuel system can be made by the ship crew based on the technological scheme which was prepared by a special organization.

The obtained results are in good agreement with the data provided in a number of papers devoted to similar research [65,74,75,76,77].

6. Conclusions

The main conclusions resulting from the research can be formulated as follows.

- The fuel mixture can be based on the diesel fuel which it contains (80–95%); the rest will take place in the form of biodiesel. It is easier to make a mixture with diesel and biodiesel directly before injection using a special dosing unit. The needed proportion of biodiesel will be automatically added to the system and the mixture will be ready directly before injection. The close or equal viscosity and density of diesel fuel and biofuel allow the injection of the fuel mixture through a common nozzle. It does not require the installation of an additional biofuel supply system to the diesel engine cylinder.

- It is advisable to carry out, on the basis of environmental and economic criteria, the efficient use of a fuel mixture consisting of diesel fuel and biofuel. It is also necessary to calculate the specific effective fuel consumption as an economic criterion.

- The best proportion between biodiesel and diesel can be found during the test and experiment for each type of diesel engine.

- During the experimental research performed on 6N165LW Yanmar marine medium-speed diesel engines in the range of their operating loads of 50–80% with a fuel mixture that included 80–95% RMA10 diesel fuel and 5–20% FAME biofuel, the environmental friendliness of marine diesel operation was shown to increase. At the same time (depending on the diesel load and the content of biofuel in the fuel mixture), the emission of nitrogen oxides within exhaust gases was reduced by 8.7–23.4% and the emission of carbon oxides within exhaust gases was reduced by 3.1–24%. It was also found that when using biofuels, the efficiency of diesel operation was reduced. At the same time (depending on the load of the diesel engine and the content of biofuel in the fuel mixture), the specific effective fuel consumption increased by 0.5–9.3%.

- The concentration of biofuel in the fuel mixture has an optimal value. It has been experimentally established that the highest environmental efficiency was achieved when using a fuel mixture which includes 10–15% of biofuel. At the same time, in the modes of 80% of the diesel load, the emission of nitrogen oxides decreased (by 21–23.5%) and the emission of carbon oxides decreased (by 16.5–19.2%). The increase in the specific effective consumption for the specified composition of the fuel mixture and diesel load was 1–1.55%.A fuel mixture containing 20% of biofuel significantly reduced the efficiency of a diesel engine. At the same time, at loads of 50–60% (the most common range of operating conditions for marine auxiliary engines), the specific fuel consumption increased by 8.46–9.31%. Despite an almost twenty percent reduction in carbon oxide emissions and an almost sixteen percent reduction in nitrogen oxide emissions, the operation of marine diesel engines with such a fuel mixture composition is not advisable. The highest economic efficiency for any concentration of biofuel in the fuel mixture belongs to the modes of 70–80% of the load. At the same time, at the load of 70%, the specific effective fuel consumption increased by 1–6.6%; at the load of 80%, it showed an increase of 0.5–3.1%. The fuel mixture containing 5% biofuel only provided the minimum environmental efficiency of the diesel engine—the emission of nitrogen oxides was reduced by 8.7–9.6%, and the emission of carbon oxides was reduced by 3.0–12.3% (relative to the diesel load). In this regard, the operation of diesel engines using such a fuel mixture can only be performed in certain cases (for example, with a small amount of biofuel on board).

- The proposed option for using biofuel in marine medium-speed diesel engines is based on practical experience. Taking into account that bunkering by biofuel is not possible in all ports, it is better to bunker in a convenient port with the needed quantity of biofuel to reach the next convenient port.

Recommendations for the use of biofuels in marine diesel engines are not limited to the results presented. It is advisable to devote further research to determining the optimal angles of fuel supply to the cylinder, as well as the possibility of controlling exhaust gases. In addition, the issues of increasing the stability of the fuel mixture (biofuel and diesel fuel) during its storage and transportation on sea vessels require research. The study of the temperature state of a diesel engine (primarily exhaust gas temperature) in the case of using fuel mixtures with different biofuel concentrations is also subject to further research. In addition, it is necessary to evaluate the efficiency of using different types/grades of biofuels, as well as the compatibility of different types of biofuels with diesel fuel.

The growth of biofuel production in EU countries, a significant shortage of energy resources in Europe, and the rising prices for petroleum products allow us to conclude that the further use of biofuels in marine diesel engines has good prospects.

Author Contributions

Conceptualization, S.S.; methodology, S.S., I.T. and S.K.; validation, V.M., A.S., T.S. and I.T.; data curation, A.S., T.S. and I.T.; writing, original draft preparation, A.S., I.T. and S.K.; writing, review, and editing, S.S., V.M., A.S. and S.K.; visualization, S.S. and A.S.; investigation, S.S., A.S., T.S. and I.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Smyshlyaeva, K.I.; Rudko, V.A.; Kuzmin, K.A.; Povarov, V.G. Asphaltene genesis influence on the low-sulfur residual marine fuel sedimentation stability. Fuel 2022, 328, 125291. [Google Scholar] [CrossRef]

- Sagin, S.; Kuropyatnyk, O.; Sagin, A.; Tkachenko, I.; Fomin, O.; Píštěk, V.; Kučera, P. Ensuring the Environmental Friendliness of Drillships during Their Operation in Special Ecological Regions of Northern Europe. J. Mar. Sci. Eng. 2022, 10, 1331. [Google Scholar] [CrossRef]

- Sagin, S.; Madey, V.; Sagin, A.; Stoliaryk, T.; Fomin, O.; Kučera, P. Ensuring Reliable and Safe Operation of Trunk Diesel Engines of Marine Transport Vessels. J. Mar. Sci. Eng. 2022, 10, 1373. [Google Scholar] [CrossRef]

- Kaminski, P. Experimental Investigation into the Effects of Fuel Dilution on the Change in Chemical Properties of Lubricating Oil Used in Fuel Injection Pump of Pielstick PA4V185 Marine Diesel Engine. Lubricants 2022, 10, 162. [Google Scholar] [CrossRef]

- Maryanov, D. Development of a method for maintaining the performance of drilling fluids during transportation by Platform Supply Vessel. Technol. Audit. Prod. Reserves 2021, 5, 15–20. [Google Scholar] [CrossRef]

- Maryanov, D. Control and regulation of the density of technical fluids during their transportation by sea specialized vessels. Technol. Audit. Prod. Reserves 2022, 1, 19–25. [Google Scholar] [CrossRef]

- Lovska, A.; Fomin, O.; Pistek, V.; Kucera, P. Dynamic load modelling within combined transport trains during transportation on a railway ferry. Appl. Sci. 2020, 10, 5710. [Google Scholar] [CrossRef]

- Gorb, S.; Levinskyi, M.; Budurov, M. Sensitivity Optimisation of a Main Marine Diesel Engine Electronic Speed Governor. Sci. Horiz. 2021, 24, 9–19. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Li, J.; Wang, S.; Zhong, Y.; Dong, R.; Gao, S.; Cao, C.; Tan, D. Investigation on combustion, performance and emission characteristics of a diesel engine fueled with diesel/alcohol/n-butanol blended fuels. Fuel 2022, 320, 123975. [Google Scholar] [CrossRef]

- Komać, A.; Mohović, Đ.; Strabić, M. Impact of High Speed of Vessels on Narrow and Shallow Waterways with Reference to the Adriatic Sea. Naše more 2022, 69, 84–91. [Google Scholar] [CrossRef]

- Ren, H.; Ding, Y.; Sui, C. Influence of EEDI (Energy Efficiency Design Index) on Ship-Engine-Propeller Matching. J. Marit. Sci. Eng. 2019, 7, 425. [Google Scholar] [CrossRef]

- Lu, R.; Ringsberg, J.W. Ship energy performance study of three wind-assisted ship propulsion technologies including a parametric study of the Flettner rotor technology. Ships Offshore Struct. 2020, 15, 249–258. [Google Scholar] [CrossRef]

- Öztürk, E.; Can, Ö. Effects of EGR, injection retardation and ethanol addition on combustion, performance and emissions of a DI diesel engine fueled with canola biodiesel/diesel fuel blend. Energy 2020, 244, 123129. [Google Scholar] [CrossRef]

- Aditya, N.D.; Sandhya, K.G.; Harikumar, R. Development of small vessel advisory and forecast services system for safe navigation and operations at sea. J. Oper. Oceanogr. 2020, 15, 52–67. [Google Scholar] [CrossRef]

- Shen, F.; Li, X. Effects of fuel types and fuel sulfur content on the characteristics of particulate emissions in marine low-speed diesel engine. Environ. Sci. Pollut. Res. 2020, 27, 37229–37236. [Google Scholar] [CrossRef]

- Sagin, S.V.; Kuropyatnyk, O.A. The Use of Exhaust Gas Recirculation for Ensuring the Environmental Performance of Marine Diesel Engines. Naše More Int. J. Marit. Sci. Technol. 2018, 65, 78–86. [Google Scholar] [CrossRef]

- Van, T.G.; Ramirez, J.; Ristovskim, Z.; Brown, R.J. Global impact of recent IMO regulation on marine fuel oil refining processes and ship emissions. Transp. Res. Part D Transp. Environ. 2019, 70, 123–134. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S.; Mickevicius, T. Experimental investigation of biodiesel-n-butanol fuels blends on performance and emissions in a diesel engine. Combust. Engines 2022, 188, 90–95. [Google Scholar] [CrossRef]

- Ingaldi, M.; Klimecka-Tatar, D. People’s Attitude to Energy from Hydrogen—From the Point of View of Modern Energy Technologies and Social Responsibility. Energies 2020, 13, 6495. [Google Scholar] [CrossRef]

- Fomin, O.; Lovska, A.; Kučera, P.; Píštěk, V. Substantiation of Improvements for the Bearing Structure of an Open Car to Provide a Higher Security during Rail/Sea Transportation. J. Mar. Sci. Eng. 2021, 9, 873. [Google Scholar] [CrossRef]

- Maryanov, D.M. Maintaining the efficiency of drilling fluids when they are transported by platform supply vessels class offshore vessels. Austrian J. Tech. Nat. Sci. Sci. J. 2021, 7–8, 22–28. [Google Scholar] [CrossRef]

- Karthic, S.; Kumar, M. Experimental investigations on hydrogen biofueled reactivity controlled compression ignition engine using open ECU. Energy 2021, 229, 120787. [Google Scholar] [CrossRef]

- Sahar, M.; Kassem, H.; Driss, Z.; Abid, M. Effects of hydrogen enrichment and injection location on in-cylinder flow characteristics, performance and emissions of gaseous LPG engine. Energy 2021, 150, 92–108. [Google Scholar] [CrossRef]

- Zincira, B.; Deniz, C.; Tunér, M. Investigation of environmental, operational and economic performance of methanol partially premixed combustion at slow speed operation of a marine engine. J. Clean. Prod. 2019, 235, 1006–1019. [Google Scholar] [CrossRef]

- Chen, C.; Yao, A.; Yao, C.; Wang, D.; Lu, H.; Fen, J. Study of the characteristics of PM and the correlation of soot and smoke opacity on the diesel methanol dual fuel engine. Appl. Therm. Eng. 2019, 148, 391–403. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Xie, G.; Li, J.; Xu, W.; Jiang, F.; Huang, Y.; Tan, D. Investigation on the combustion and emission characteristics of diesel engine fueled with diesel/methanol/n-butanol blends. Fuel 2022, 314, 123088. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Dong, R.; Zou, Z.; Gao, S.; Tan, D. Performance, combustion and emission characteristics investigations on a diesel engine fueled with diesel/ethanol/n-butanol blends. Energy 2022, 249, 123733. [Google Scholar] [CrossRef]

- Madey, V.V. Usage of biodiesel in marine diesel engines. Austrian J. Tech. Nat. Sci. Sci. J. 2021, 7–8, 18–21. [Google Scholar] [CrossRef]

- Tabatabaeiab, M.; Aghbashlo, M.; Dehhaghice, M.; Kazem, H.; Panahic, S.; Mollahosseini, A.; Hosseini, M.; Soufiya, M. Reactor technologies for biodiesel production and processing. Prog. Energy Combust. Sci. 2019, 74, 239–303. [Google Scholar] [CrossRef]

- Melnyk, O.; Onishchenko, O.; Onyshchenko, S.; Voloshyn, A.; Kalinichenko, Y.; Rossomakha, O.; Naleva, G.; Rossomakha, O. Autonomous Ships Concept and Mathematical Models Application in their Steering Process Control. TransNav 2022, 16, 553–559. [Google Scholar] [CrossRef]

- Alanen, J.; Saukko, E.; Lehtoranta, K.; Murtonen, T. The formation and physical properties of the particle emissions from a natural gas engine. Fuel 2015, 162, 155–161. [Google Scholar] [CrossRef]

- Povarov, V.G.; Efimov, I.; Smyshlyaeva, K.I.; Rudko, V.A. Application of the UNIFAC Model for the Low-Sulfur Residue Marine Fuel Asphaltenes Solubility Calculation. J. Mar. Sci. Eng. 2022, 10, 1017. [Google Scholar] [CrossRef]

- Likhanov, V.A.; Lopatin, O.P. Dynamics of soot formation and burnout in a gas diesel cylinder. IOP Conf. Ser. Mater. Sci. Eng. 2020, 862, 062033. [Google Scholar] [CrossRef]

- Lopez, J.A.; Alvarez, P.; Onur, B.; Kiliciris, A.; Vis, F.A. An inventory control policy for liquefied natural gas as a transportation fuel. Omega 2020, 90, 101985. [Google Scholar] [CrossRef]

- Chen, C.; Yao, A.; Yao, C.; Wang, H.; Liu, M.; Li, Z. Selective catalytic reduction of nitrogen oxides with methanol over the (Cobalt-Molybdenum)/Alumina dual catalysts under the diesel methanol dual fuel conditions. Chem. Eng. Sci. 2020, 211, 115320. [Google Scholar] [CrossRef]

- Kuropyatnyk, O.A.; Sagin, S.V. Exhaust Gas Recirculation as a Major Technique Designed to Reduce NOx Emissions from Marine Diesel Engines. Naše More Int. J. Marit. Sci. Technol. 2019, 66, 1–9. [Google Scholar] [CrossRef]

- Sagin, S.V. Decrease in mechanical losses in high-pressure fuel equipment of marine diesel engines. Mater. Int. Conf. Sci. Res. SCO Ctries. Synerg. Integr. 2019, 1, 139–145. [Google Scholar] [CrossRef]

- Jalava, P.I.; Aakko-Saksa, P.; Murtonen, T.; Happo, M.S.; Markkanen, A.; Yli-Pirilä, P.; Hakulinen, P.; Hillamo, R.; Mäki-Paakkanen, J.; Salonen, R.O.; et al. Toxicological properties of emission particles from heavy duty engines powered by conventional and bio-based diesel fuels and compressed natural gas. Part Fibre Toxicol. 2012, 9, 37. [Google Scholar] [CrossRef]

- Millo, F.; Vlachos, T.; Piano, A. Physicochemical and mutagenic analysis of particulate matter emissions from an automotive diesel engine fuelled with fossil and biofuel blends. Fuel 2021, 285, 119092. [Google Scholar] [CrossRef]

- Kowalska, M.; Wegierek-Ciuk, A.; Brzoska, K.; Wojewodzka, M.; Meczynska-Wielgosz, S.; Gromadzka-Ostrowska, J.; Mruk, R.; Øvrevik, J.; Kruszewski, M.; Lankoff, A. Genotoxic potential of diesel exhaust particles from the combustion of first- and second-generation biodiesel fuels—The Fuel Health project. Environ. Sci. Pollut. Res. 2017, 24, 24223–24234. [Google Scholar] [CrossRef]

- Ju, H.-J.; Jeon, S.-K. Analysis of Characteristic Changes of Blended Very Low Sulfur Fuel Oil on Ultrasonic Frequency for Marine Fuel. J. Mar. Sci. Eng. 2022, 10, 1254. [Google Scholar] [CrossRef]

- Vilke, S.; Tadic, F.; Ostović, I.; Debelić, B. The use of hydrogen as an alternative fuel in urban transport. Sci. J. Marit. Res. 2020, 34, 376–386. [Google Scholar] [CrossRef]

- Likhanov, V.A.; Lopatin, O.P.; Yurlov, A.S.; Anfilatova, N.S. Simulation of soot formation in a tractor diesel engine running on rapeseed oil methyl ether and methanol. IOP Conf. Ser. Earth Environ. Sci. 2021, 839, 052057. [Google Scholar] [CrossRef]

- Wanderley Neto, A.O.; Rodrigues, D.V.; De Oliveira Freitas, J.C.; Da Silva, V.L.; Ribeiro, L.S.; Nunes Da Silva, D.N. A novel oil-in-water microemulsion as a cementation flushing fluid for removing non-aqueous filter cake. J. Pet. Sci. Eng. 2020, 184, 106536. [Google Scholar] [CrossRef]

- Zablotsky, Y.V.; Sagin, S.V. Maintaining Boundary and Hydrodynamic Lubrication Modes in Operating High-pressure Fuel Injection Pumps of Marine Diesel Engines. Indian J. Sci. Technol. 2016, 9, 208–216. [Google Scholar] [CrossRef]

- Chena, Z.; Chena, H.; Wang, L.; Geng, L.; Zen, K. Parametric study on effects of excess air/fuel ratio, spark timing, and methanol injection timing on combustion characteristics and performance of natural gas/methanol dual-fuel engine at low loads. Energy Convers. Manag. 2020, 210, 112742. [Google Scholar] [CrossRef]

- Sagin, S.V.; Semenov, O.V. Motor Oil Viscosity Stratification in Friction Units of Marine Diesel Motors. Am. J. Appl. Sci. 2016, 13, 200–208. [Google Scholar] [CrossRef]

- Kneba, Z.; Stepanenko, D.; RudnickiI, J. Numerical methodology for evaluation the combustion and emissions characteristics on WLTP in the light duty dual-fuel diesel vehicle. Combust. Engines 2022, 189, 94–102. [Google Scholar] [CrossRef]

- Temizer, I.; Cihan, O.; Eskici, B. Numerical and experimental investigation of the effect of biodiesel/diesel fuel on combustion characteristics in CI engine. Fuel 2020, 270, 117523. [Google Scholar] [CrossRef]

- Yadav, P.; Athanassiadis, D.; Yacout, D.; Tysklind, M.; Upadhyayula, V. Environmental Impact and Environmental Cost Assessment of Methanol Production from wood biomass. Environ. Pollut. 2020, 265, 114990. [Google Scholar] [CrossRef]

- Kuropyatnyk, O.A. Reducing the emission of nitrogen oxides from marine diesel engines. Int. Conf. Sci. Res. SCO Ctries. Synerg. Integr. 2020, 154–160. [Google Scholar] [CrossRef]

- Likhanov, V.A.; Lopatin, O.P.; Yurlov, A.S.; Anfilatova, N.S. Investigation of the effective performance of diesel engines running on methanol and rapeseed oil methyl ether. J. Phys. Conf. Ser. 2021, 1889, 042067. [Google Scholar] [CrossRef]

- Sagin, S.V.; Solodovnikov, V.G. Estimation of Operational Properties of Lubricant Coolant Liquids by Optical Methods. Int. J. Appl. Eng. Res. 2017, 12, 8380–8391. [Google Scholar]

- Popovskii, Y.M.; Sagin, S.V.; Khanmamedov, S.A.; Grebenyuk, M.N.; Teregerya, V.V. Designing, calculation, testing and reliability of machines: Influence of anisotropic fluids on the operation of frictional components. Russ. Eng. Res. 1996, 16, 1–7. [Google Scholar]

- Sagin, S.V.; Solodovnikov, V.G. Cavitation Treatment of High-Viscosity Marine Fuels for Medium-Speed Diesel Engines. Mod. Appl. Sci. 2015, 9, 269–278. [Google Scholar] [CrossRef]

- Kondrasheva, N.K.; Rudko, V.A.; Kondrashev, D.O.; Shakleina, V.S.; Smyshlyaeva, K.I.; Konoplin, R.R.; Shaidulina, A.A.; Ivkin, A.S.; Derkunskii, I.O.; Dubovikov, O.A. Application of a ternary phase diagram to describe the stability of residual marine fuel. Energy Fuels 2019, 33, 4671–4675. [Google Scholar] [CrossRef]

- Sagin, S.V.; Semenov, O.V. Marine Slow-Speed Diesel Engine Diagnosis with View to Cylinder Oil Specification. Am. J. Appl. Sciences. 2016, 13, 618–627. [Google Scholar] [CrossRef]

- Sagin, S.; Madey, V.; Stoliaryk, T. Analysis of mechanical energy losses in marine diesels. Technol. Audit. Prod. Reserves 2021, 5, 26–32. [Google Scholar] [CrossRef]

- Zablotsky, Y.V.; Sagin, S.V. Enhancing Fuel Efficiency and Environmental Specifications of a Marine Diesel When using Fuel Additives. Indian J. Sci. Technol. 2016, 9, 353–362. [Google Scholar] [CrossRef]

- Sagin, S.V.; Kuropyatnyk, O.A.; Zablotskyi, Y.V.; Gaichenia, O.V. Supplying of Marine Diesel Engine Ecological Parameters. Naše More Int. J. Marit. Sci. Technol. 2022, 69, 53–61. [Google Scholar] [CrossRef]

- Strus, M.; Poprawski, W. Efficiency of the Diesel engine fuelled with the advanced biofuel Bioxdiesel. Combust. Engines 2021, 186, 89–95. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Y.; Wang, J.; Tan, D.; Zhang, Z.; Yang, D. Effects of Different Biodiesel-Diesel Blend Fuel on Combustion and Emission Characteristics of a Diesel Engine. Processes 2021, 9, 1984. [Google Scholar] [CrossRef]

- Dhyani, V.; Subramanian, K.A. Control of backfire and NOX emission reduction in a hydrogen fueled mylti-cylinder spark ignition engine using cooled EGR and water injection strategies. Int. J. Hydrogen Energy 2019, 44, 6287–6298. [Google Scholar] [CrossRef]

- Husnain, N.; Wang, E.; Li, K.; Anwar, M.T. Iron oxide based catalysts for low temperature selective catalytic reduction NOX with NH3. Rev. Chem. Eng. 2019, 35, 239–264. [Google Scholar] [CrossRef]

- Madey, V. Assessment of the efficiency of biofuel use in the operation of marine diesel engines. Technol. Audit. Prod. Reserves 2022, 2, 34–41. [Google Scholar] [CrossRef]

- Hunicz, J.; Krzaczek, P.; Gęca, M.; Rybak, A.; Mikulski, M. Comparative study of combustions and emission of diesel engine fuelled with FAME and HVO. Combust. Engines 2021, 184, 72–78. [Google Scholar] [CrossRef]

- Jiaqi, H.; Helin, X.; Xiaolong, Y.; Fengyun, G.; Xiuqing, H. Effects of methanol blending on combustion characteristics and various emissions of a diesel engine fueled with soybean biodiesel. Fuel 2020, 15, 118734. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Xie, G.; Tan, D.; Qin, B.; Huang, Y.; Cui, S. Effects of Different Diesel-Ethanol Dual Fuel Ratio on Performance and Emission Characteristics of Diesel Engine. Processes 2021, 9, 1135. [Google Scholar] [CrossRef]

- Wang, Y.; Wright, L.A. A Comparative Review of Alternative Fuels for the Maritime Sector: Economic, Technology, and Policy Challenges for Clean Energy Implementation. World 2020, 2, 29. [Google Scholar] [CrossRef]

- Smyshlyaeva, K.I.; Rudko, V.A.; Povarov, V.G.; Shaidulina, A.A.; Efimov, I.; Gabdulkhakov, R.R.; Pyagay, I.N.; Speight, J.G. Influence of Asphaltenes on the Low-Sulphur Residual Marine Fuels’ Stability. J. Mar. Sci. Eng. 2021, 9, 1235. [Google Scholar] [CrossRef]

- Feng, C.; Deng, Y.; Chen, L.; Han, W.; Jiaqiang, E.; Wei, K.; Han, D.; Zhang, B. Hydrocarbon emission control of a hydrocarbon adsorber and converter under cold start of the gasoline engine. Energy 2022, 239, 122138. [Google Scholar] [CrossRef]

- Cruz-Peragón, F.; Torres-Jiménez, E.; Lešnik, L.; Arma, O. Methodology improvements to simulate performance and emissions of engine transient cycles from stationary operating modes. A case study applied to biofuels. Fuel 2022, 312, 122977. [Google Scholar] [CrossRef]

- Lee, T.; Cho, J.; Lee, J. Mixing Properties of Emulsified Fuel Oil from Mixing Marine Bunker-C Fuel Oil and Water. J. Mar. Sci. Eng. 2022, 10, 1610. [Google Scholar] [CrossRef]

- Abdu Ahmed, S.; Zhou, S.; Yuanqing, Z.; Yongming, F.; Adil, M.; Naseem, A. Influence of Injection Timing on Performance and Exhaust Emission of CI Engine Fuelled with Butanol-Diesel Using a 1D GT-Power Model. Processes 2019, 7, 299. [Google Scholar] [CrossRef]

- Aydın, S. Detailed evaluation of combustion, performance and emissions of ethyl proxitol and methyl proxitol-safflower biodiesel blends in a power generator diesel engine. Fuel 2020, 270, 117492. [Google Scholar] [CrossRef]

- Likhanov, V.A.; Lopatin, O.P.; Vylegzhanin, P.N. Calculation of geometric parameters of diesel fuel ignition flares. IOP Conf. Ser. Mater. Sci. Eng. 2020, 862, 062074. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Robbins, C. Review of the effects of biodiesel on NOx emissions. Fuel Process. Technol. 2012, 96, 237–249. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).