Abstract

In Korea, fishing boats account for 65,452 out of 71,174 coastal ships, and aging ships are a leading cause of environmental problems and economic loss. To solve this problem, the government has enacted a policy to promote the development and distribution of environmental vessels. Electric propulsion systems and hybrid systems are suggested as alternatives. However, to study whether this hybrid system is environmentally friendly, a system for measuring the performance of conventional diesel-powered ships was developed and measured. A case study applying the battery hybrid system was analyzed through a Matlab/Simulink simulation, and the effect of reducing the carbon dioxide emissions by 7.6% was verified. In addition, comparing with a case where the load-sharing optimal control was introduced, we proved that the carbon dioxide reduction with the controller was 10.7%. By applying the results of this study to various countries with different fuel production processes through the LCA technique, it was confirmed that the battery hybrid system is eco-friendly from the energy production stage, rather than unconditionally, according to the national power production method. Additional research is needed to reflect the aging trend of the entire fleet and to create a detailed category classification through future research.

1. Introduction

1.1. Background

Various efforts are being made to solve the problem of air pollution around the world. According to the “Fourth IMO Greenhouse Gas Study” report issued by the International Maritime Organization (IMO), greenhouse gas emissions from ships increased from 2.76% in 2012 to 2.89% in 2018 compared to the total greenhouse gas emissions in all sectors []. To reduce emissions, the International Maritime Organization adopted an initial strategy to reduce total greenhouse gas emissions from all ships by 50% or more by 2050 compared to 2008 at the 76th meeting of the MEPC, held in June 2021 [].

The Korean government established the 2050 Carbon Neutrality and Green Growth Commission under the President’s direct control to transform the country into a carbon neutral society to respond to the climate crisis, and set a goal of reducing total emissions by 40% by 2030 compared to 2018 []. To achieve this carbon neutrality goal, the Ministry of Oceans and Fisheries, which oversees the entire maritime and fishery sector in Korea, enacted and implemented the “Act on the Promotion of Development and Distribution of Environmentally Friendly Vessels” []. In addition, the government is making efforts at the government level to supply eco-friendly ships to reduce greenhouse gas emissions by implementing an “eco-friendly public ship conversion project” [] and an “eco-friendly ship certification system” []. As of 2021, this applied to 65,452 fishing vessels out of 71,174 coastal ships; most fishing vessels are driven by aging gasoline and diesel engines. As a result of analyzing fishing vessels of less than 10 tons, which account for 99.4% of the fishing vessels in coastal waters, we found that the outboard type of gasoline engine is mainly applied to small fishing boats of 3 tons or less. Fishing boats weighing 3–10 tons with diesel engines account for about 87.7% of the total [].

Mechanical propulsion systems, such as gasoline and diesel, are applied in most fishing vessels. To achieve the carbon neutrality goal in the marine and fishery sector, it is essential to prepare countermeasures to reduce greenhouse gas emissions from fishing boats through the application of an eco-friendly propulsion system.

Various methods have been proposed as an alternative to power aging fishing vessels. Among them, an electric propulsion system can be used for coastal vessels, but rather than an all-electric propulsion system, a battery hybrid system that uses both an engine and a battery is used to retrofit an existing vessel. Moreover, it seems to be suitable as a propulsion system for the building of new fishing boats.

To verify the effectiveness of the battery hybrid system based on the data obtained from the diesel ship, we also study the economic and environmental effects of introducing an optimal load sharing controller, ECMS (energy consumption minimization strategy).

This study presents results on the environmental characteristics and economic feasibility in the hybrid system’s case with the ECMS methodology. In addition, we conduct simulations and experiments to determine whether the proposed battery hybrid system is eco-friendly through an environmental analysis using the LCA technique.

1.2. Past Research

Research on emissions reduction has mainly been conducted on large vessels engaged in international voyages, considering hybrid or electric propulsion systems, the improvement of emissions reduction through to a blending of fuel being used in the engine of the existing mechanical propulsion system, and engines, such as scrubber or EGR types. Various studies have been conducted on the conversion of large ships via the existing mechanical propulsion system being applied to a hybrid or propulsion system. However, most fishing boat research is limited to a small area or not based on actual data from fishing vessels. A study on the selection of optimal capacity and specifications [], a study on the improvement of eco-friendliness due to emissions reduction, and a study on the effect on fuel consumption and emissions by various propulsion modes of a hybrid propulsion system in a large cargo ship were conducted [].

Between a study showing the results for emissions, such as SOx, NOx, CO2, and PM according to the characteristics of diesel fuel, mainly used as engine fuel for existing mechanical propulsion systems by adding various additives [], and a study showing the results according to the blending ratio of diesel fuel and liquefied natural gas (LNG), a large amount of research has been carried out on the application of new fuels, such as liquefied petroleum gas (LPG) []. Environmental analyses of hydrogen and ammonia fuel have been carried out through a simulation by Bicer et al. [], a comparison of lifecycle environmental performance according to fuel by Brynolf et al. [], and biodiesel mixing fire by Ogunkunle et al. []. Various studies, such as a performance and emission analysis of the used diesel engine, were conducted. In addition, Yu et al. [] researched deriving an optimal route through an analysis of exhaust gas, while Ma et al.’s [] research established a ship speed and route optimization model, considering the existence of ECA. Studies on reduction measures have taken into account emissions from specific ports, such as in Croatia and China. It can be seen that prior research related to reducing ship’s exhaust gas has mainly focused on large ships sailing the ocean.

We overlook the fact that pollutants emitted by coastal fishing boats that do not fall within the scope of domestic and foreign regulations have a large impact on the air environment, and research in this field is insufficient. In Korea’s maritime and fisheries sector, the impact of a fishing vessel may be small in terms of the size of a single vessel, but if the output standard that sums up the total capacity is applied, the proportion of the fishing vessel is very large. In light of these points, it can be confirmed that few environmental and economic analyses based on actual data on existing fishing vessels have been conducted. In addition, in the case of fishing boats, the emissions based on a single output are large because the focus is on the maximum operating speed, rather than the economical results due to the supply of duty-free oil. Since low-cost investment and preventive maintenance are not carried out periodically, an increase in fuel consumption and the amount of exhaust gas is clearly occurring due to a deterioration in performance.

Therefore, it is essential to apply an appropriate eco-friendly propulsion system according to an analysis of the vessel’s operating profiles in order to reduce the emissions generated from such coastal fishing vessels.

In this research, we would like to answer the following questions:

- If the battery hybrid system is applied to fishing boats as one of the eco-friendly propulsion systems, what economic and environmental benefits could be achieved?

- Additionally, if these results were applied to the entire Korean fishing boat fleet, what kind of environmental benefit would be achieved from a national perspective?

- Due to the differences in electricity energy production methods in other countries, can it be said that this method is eco-friendly?

In order to answer these fundamental questions, it is necessary to investigate the fishing vessels that account for the majority of coastal vessels operating in Korea, and to select the most representative type of fishing boats. To calculate the carbon dioxide emissions based on the performance and fuel consumption of the selected representative ship, it is necessary to analyze the economic and environmental characteristics based on the ship’s actual performance. Based on the measured load profile of the diesel direct propulsion system, it is crucial to find the reduction in emissions when applied to the battery hybrid system. Furthermore, it is necessary to determine the environmental benefits to a country when a battery hybrid system is applied based on the results of representative ships. Finally, based on these results, we would like to consider the results of applying them to countries with different electricity energy production methods.

Through this analysis, the question “Why is it necessary to study the application of hybrid electric propulsion systems to fishing boats?” can be answered decisively.

2. Methodology

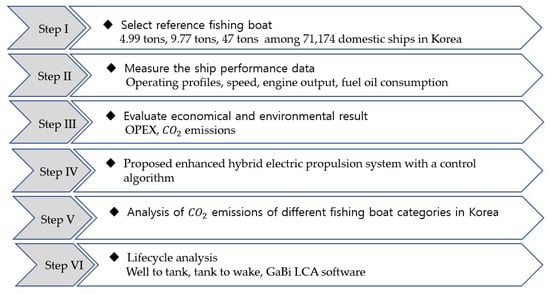

Through the process shown in Figure 1, we carried out an empirical experiment with fishing boat data in Korea. First, a target ship was selected from among the 70,000 ships in Korea. Three ships that represent the majority were chosen for the application of the battery hybrid system. Ship performance data were measured through rpm and fuel oil flow, with the calculation of SFOC (specific fuel oil consumption) through the total fuel consumption according to the engine output amount. After measuring the flow rate 30 times per second using a noncontact flow meter, the average value was converted to [L/min]. By accumulating over time, the total fuel consumption was calculated. Based on this, it was possible to calculate the OPEX and fuel cost as shown in the following formula:

Figure 1.

Methodology.

Carbon dioxide emissions estimations can be calculated using the following formula based on the measured fuel consumption:

where the CF value represents the carbon dioxide emission coefficient according to the fuel consumption according to the type of oil. The diesel/gas oil used in this experiment, ISO 8217 grade and with a CF value of 3.206, was applied to the conversion of carbon dioxide emissions.

To verify emissions reduction with the battery hybrid electric propulsion system compared to a conventional diesel ship, a simulation system was implemented using Matlab/Simulink (Natick, Massachusetts, USA). This is an analysis tool used to confirm the economic and environmental impact of the ship. The possibility of environmental improvement for diesel-powered fishing boats was confirmed through a comparative verification with the battery hybrid system with the ECMS control. The research results were applied to all fishing ships in Korea to calculate the total CO2 emissions.

To apply the research results of using the battery hybrid system and the ECMS control method to all fishing ships in Korea, Equation (3) was applied to calculate the annual fuel consumption. Here, represents the yearly fuel consumption (tons), is the correction factor to correct the error with the actual measurement, is the maximum engine power of the target ship (kW), is the fuel consumption based on one voyage of the reference ship (tons), is the maximum engine power (kW) of the reference ship, and represents the number of voyages per year. Annual carbon dioxide emissions and annual fuel costs were calculated using Equations (1) and (2), respectively.

The annual total fuel consumption () of the number of ships of 3 tons or more that can be applied to battery hybrid electric propulsion ships can be obtained from the following formula:

Furthermore, in this paper, to analyze the lifecycle analysis, which considers the well-to-tank (WTT) and tank-to-wake (TTW) environmental impacts, GaBi LCA software (Sphera, Chicago, IL, USA) version 2021 was used. This software creates lifecycle models of systems, energies, products, etc. This software is linked with an LCA database that has data on emissions and energy consumption for thousands of lifecycle activities. Key emissions data were retrieved from the GaBi database. The analysis was conducted based on the country and region.

The proposed LCA model was developed in the GaBi user interface, which is directly linked to the GaBi LCA database. Using this database, the inputs (generally, energies, resources, and materials) and outputs (generally, emissions) of the individual processes were determined. The quantification of those inputs and outputs of the holistic LCA process was represented as a lifecycle inventory analysis. Then, the quantified emissions were converted into global warming potential by means of CML 2001, which is a method to convert CO2, CO, and CH4 into global warming potential (GWP 100 years) by proposing normalization factors of 1 for CO2, 3 for CO, and 25 for CH4.

3. Results

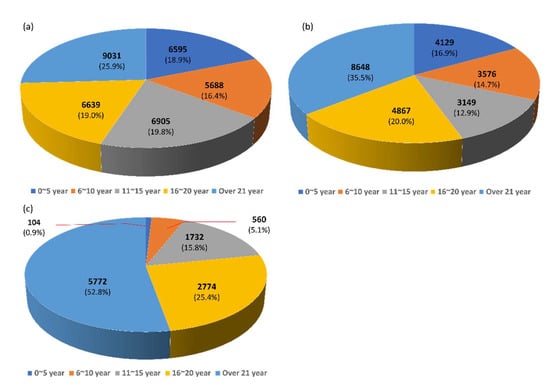

3.1. Step I: Select Reference Fishing Boats

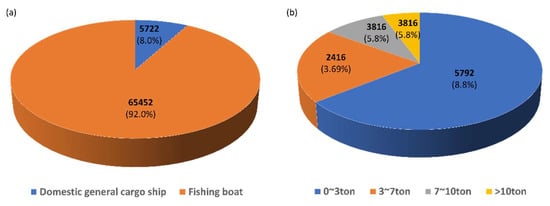

Among the 71,174 coastal ships in Korea, the registered fishing ships are shown in Figure 2a; as of October 2020, there were 65,452 ships (92%). More than 85% of these registered fishing ships are coastal composite or gill net fishing ships.

Figure 2.

Domestic ships and fishing boats in Korea: (a) number of domestic cargo ships and fishing boats; (b) domestic fishing boats by weight in tons.

As shown in Figure 2b, most fishing ships are coastal composite or gill net fishing ships of 10 tons or more. A large proportion of fishing boats undertake jig fishing, for which 436 are registered in the 47 ton class.

To verify the effectiveness of carbon dioxide emission reduction from Korean coastal ships when the proposed battery hybrid system and ECMS controller are applied to a fishing ship with a diesel propulsion engine, the target ship was a coastal composite and gill net fishing ship, or a jig fishing ship. The 4.99 ton class and 9.77 ton class fishing boats and the 47 ton class fishing boats presented in Figure 3 were selected.

Figure 3.

Reference fishing boats: (a) 4.99 tons, (b) 9.77 tons, and (c) 47 tons.

3.2. Step II: Measure the Ship Performance Data

3.2.1. Load Profile

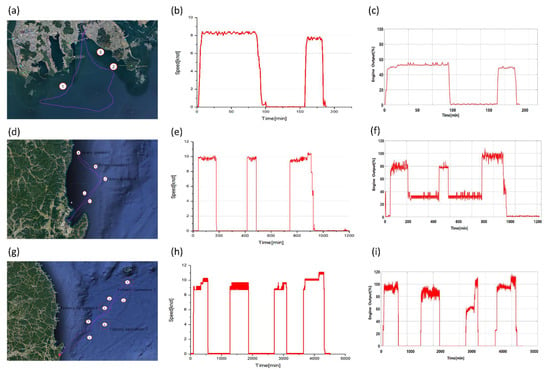

To verify the operating profile and performance of the fishing ship, the output of the propulsion system was calculated as shown in Figure 4.

Figure 4.

Operating profile of fishing ships: (a) voyage route of Sujeong-ho, (b) speed of Sujeong-ho, (c) engine output of Sujeong-ho, (d) voyage route of Yuil-ho, (e) speed of Yuil-ho, (f) engine output of Yuil-ho, (g) voyage route of Eunjin-ho, and (h) speed of Eunjin-ho, (i) engine output of Eunjin-ho.

3.2.2. Fuel Oil Consumption

Table 1 shows the fuel consumption ratio according to the voyage and operation of each fishing ship. Depending on the ship’s fishing activity characteristics, the difference in operating time is significant. The fuel consumption varies greatly depending on whether the engine is used as a power source for fishing or as an additional generator engine operation during sailing. This analysis makes it possible to find the potential for emission reduction through efficient operation.

Table 1.

Fuel oil consumption, fuel cost, and CO2 emissions of reference fishing boats.

3.3. Step III: Evaluate the Economic and Environmental Results

3.3.1. Method to Calculate OPEX

Table 1 indicates the fuel cost based on the fuel consumption for each ship during sailing. For a relative fuel price comparison, the MGO price of 864.50 USD/mt in Hong Kong was used as the standard as of March 1, 2022 (BUNKER, 2022).

3.3.2. Method to Calculate CO2 Emissions

As shown in Table 1, this represents the carbon dioxide emissions calculated by the fuel consumption according to the output of the fishing vessel and the operating characteristics, and it serves as basic data for calculating the total carbon dioxide emissions of fishing vessels in Korea.

3.4. Step IV: Proposed Enhanced Hybrid Electric Propulsion System with a Control Algorithm

3.4.1. System Configuration

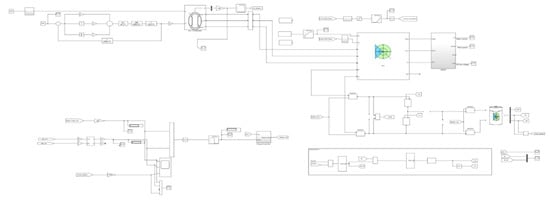

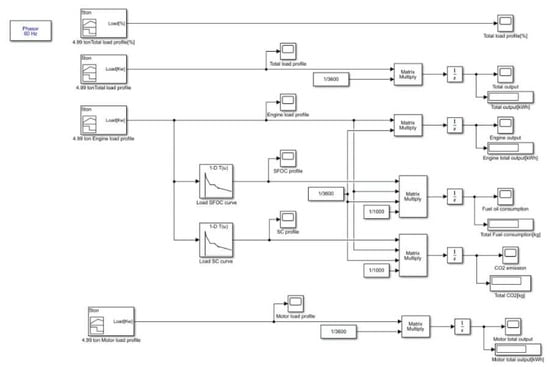

In Figure 5, a hybrid electric propulsion system was modeled with Matlab/Simulink. In addition, for a comparative analysis of the economic feasibility and environmental characteristics by introducing the hybrid system with the ECMS control method, the model in Figure 6 was modeled through Matlab/Simulink.

Figure 5.

Matlab modeling of a battery hybrid system.

Figure 6.

Economic and environmental analysis tool.

3.4.2. Proposed Solution Benefit for Fuel Savings and CO2 Reduction

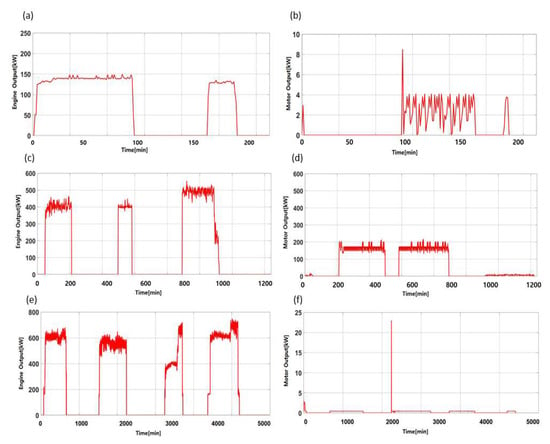

By applying the hybrid system shown in Figure 7, the operation is performed in the electric propulsion method using the battery charged from the shore power source during operation and idling.

Figure 7.

Load profile of battery hybrid system: (a) engine load of 4.99 tons, (b) motor load of 4.99 tons, (c) engine load of 9.77 tons, (d) motor load of 9.77 tons, (e) engine load of 47 tons, and (f) motor load of 47 tons.

This can prevent low efficiency at low load, avoid energy consumption during idling, and reduce carbon dioxide emissions. Table 2 shows the load on the engine and battery-motor when the hybrid system is applied, and Table 3 shows the reduced fuel consumption and carbon dioxide amount.

Table 2.

Output of proposed battery hybrid fishing boats in idling and fishing.

Table 3.

CO2 emission reduction in proposed battery hybrid fishing boats in idling and fishing.

3.4.3. Fuel Saving and CO2 Reduction with ECMS

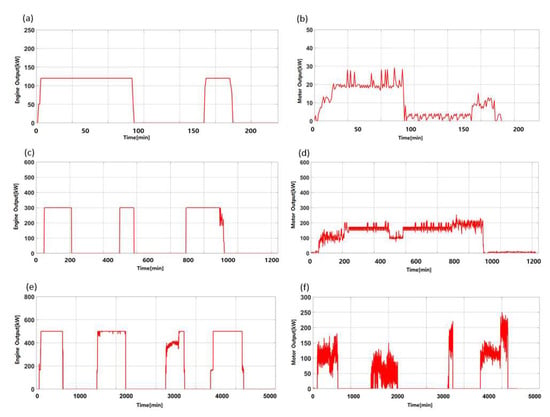

In the previous case study, only idling and fishing operations were considered; in the case of Figure 8, a section with improved SFOC was selected based on ECMS control, and the engine was operated at a setting equal to the load output, while a motor drove the remaining output.

Figure 8.

Outputs of engine and motor in battery hybrid system with ECMS control: (a) engine output of 4.99 tons, (b) motor output of 4.99 tons, (c) engine output of 9.77 tons, (d) motor output of 9.77 tons, (e) engine output of 47 tons, and (f) motor output of 47 tons.

Table 4 shows the load on the engine and battery motor of the hybrid system to which ECMS control is applied, and Table 5 shows the reduced fuel consumption and carbon dioxide reduction.

Table 4.

Output of proposed battery hybrid fishing boats with ECMS control in idling and fishing.

Table 5.

CO2 emissions of proposed battery hybrid fishing boats ECMS in idling and fishing.

3.5. Step V: CO2 Emissions Estimation from Fishing Boats of Different Categories

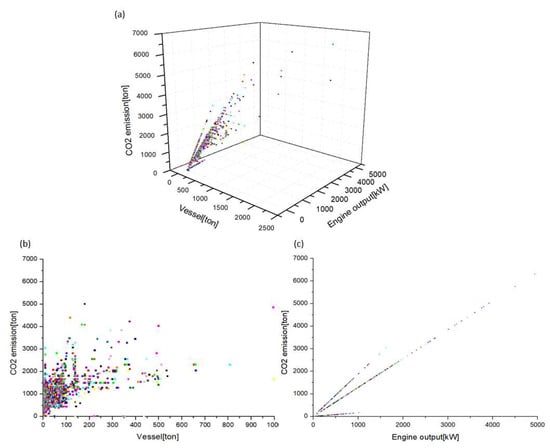

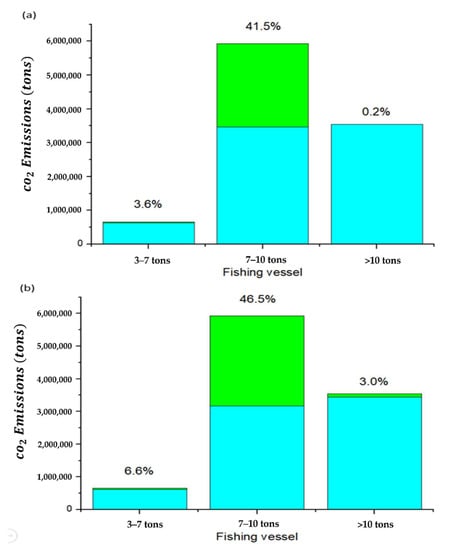

Fishing boats were classified into four types according to the ship’s tonnage, as follows: 0–3 tons (42,111 ships), 3–7 tons (13,524 ships), 7–10 tons (6113 ships), and 10 tons or over (3704 ships). The annual distribution of carbon dioxide emissions according to the tonnage and kW of 23,341 coastal ships to which the battery hybrid electric propulsion was applied is shown in Figure 9.

Figure 9.

Carbon dioxide emissions according to the tonnage and output of fishing boats: (a) annual carbon dioxide emissions compared to the tonnage and engine output in fishing ships; (b) annual carbon dioxide emissions by tonnage; (c) annual carbon dioxide emissions by engine output.

Table 6 shows the annual fuel consumption, fuel cost, and calculated carbon dioxide emissions of ships in Korea that use diesel engines as their main propulsion engines.

Table 6.

Fishing boat yearly operating results in Korea.

Table 7 and Figure 10 show the annual CO2 emission reduction for 23,341 ships applying the battery hybrid electric propulsion system among domestic coastal ships (2,491,841 tons), with 2,907,461 tons as the ECMS control. From this we can calculate the fuel savings at 777,242 tons. This saving can be increased to 906,881 tons with ECMS control. Accordingly, the fuel cost is reduced by about 672 million USD with a battery hybrid system, while 784 million USD is saved with ECMS control. If the operating environment is diversified, idling is frequent, and the operation time is longer, the carbon dioxide emissions can be significantly reduced if the combined electric propulsion system is applied, as in the case of 7–10 tons ships. In addition, by applying the ECMS control, it is possible to improve efficiency by using the propulsion system’s optimal efficiency.

Table 7.

Battery hybrid fishing boat with ECMS control algorithm operating results for Korea.

Figure 10.

Annual carbon dioxide emissions reduction, by tonnage, of fishing boats in Korea: (a) battery hybrid electric propulsion system; (b) battery hybrid electric propulsion system with ECMS control.

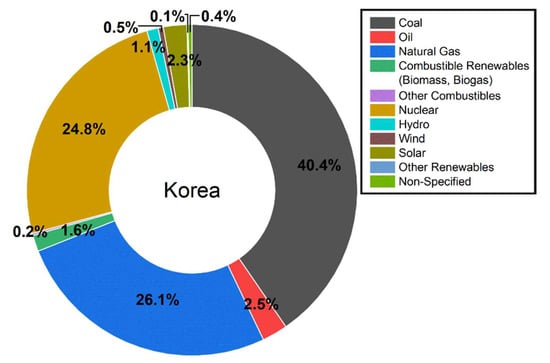

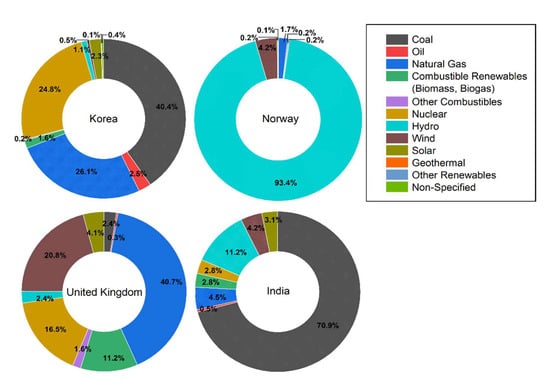

3.6. Step VI: Lifecycle Analysis

Emissions from fuel used in ships can be classified and categorized into global warming potential (GWP), acidification potential (AP), eutrophication potential (EP), and photochemical ozone creation potential (POCP) through the LCIA step of the LCA process. Based on the above four categories, a lifecycle analysis was performed to prove the environmental superiority of the hybrid electric propulsion system proposed in this study using the confirmed fuel consumption results. Table 8 shows the environmental factors of MGO and electricity, which are fuels used in ships in this study and produced in Korea. In the case of MGO, using the data from the study of Hwang et al. [,], the functional units of MGO when importing crude oil from Saudi Arabia to South Korea, refining it in Korea, and supplying it to ships were summarized. In the case of electricity, as shown in Figure 11, the environmental factors per 1 kWh were calculated based on Korea’s national grid electricity production method, surveyed by the International Energy Agency (IEA) []. At this time, the data from Gabi software and the environmental factors generated during the production of electric energy from each source material used in producing electricity, such as coal, oil, and nuclear, as investigated by Jeong et al. [], were also considered.

Table 8.

Functional units of fuels used in ships made in Korea.

Figure 11.

The proportion of resources used to generate national electricity in Korea.

Based on Table 8, the daily environmental impact of each energy supply method for each ship from the viewpoint of the lifecycle is summarized in Table 9 below.

Table 9.

Daily emissions from each type of ship.

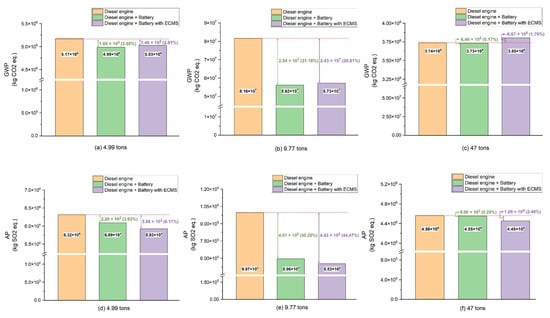

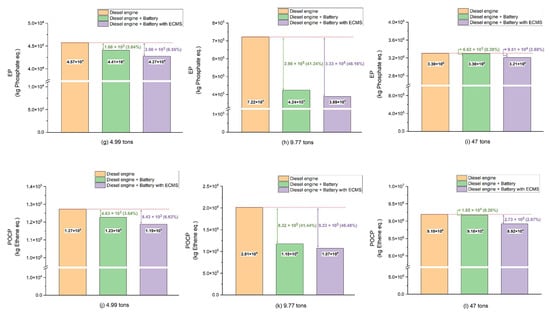

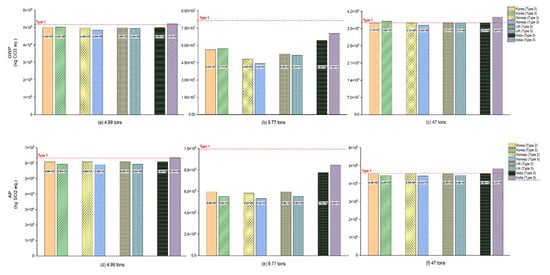

Based on Table 9, and assuming that the lifespan of the ship is 30 years and calculating the emission by type per ship, the results shown in Figure 12 can be obtained.

Figure 12.

Environmental impacts during the lifespan of each ship.

The results show how environmentally superior the engine was that operated at optimal efficiency based on ECMS; the remaining output was covered by the electric propulsion system (Type 3), which supplied power from the battery, compared to the case that used only the existing diesel engine. In addition, the case with the electric propulsion system that supplies power from the battery during fishing and idling (Type 2) also had better environmental impacts than using only the diesel engine. In particular, the 9.77 ton ship showed a significant reduction in emissions for all environmental impact areas compared to ships of other sizes.

In this study, GWP was different from other environmental impact categories, such as AP, EP, and POCP. In particular, in the 47 ton ship, when Type 3, which controls the diesel engine and battery system with ECMS, was applied, 6.67 × 106 kg CO2 equivalent more (1.79% higher) was generated than by Type 1 using only the diesel engine. In the 4.99 ton and 9.77 ton ships, Type 3 showed more negligible GWP than Type 1, but it caused 0.6–1.3% higher emissions than Type 2.

On the other hand, in terms of AP, EP, and POCP, when Type 3 was applied to all three sizes of ships, the lowest emissions were achieved. In the case of Type 2, in which the electric propulsion system was combined with the diesel system, the emission reduction effect was 3.6% or more in the 4.99 ton ship, more than 40.2% in the 9.77 ton ship, and 0.2% in the 47 ton ship compared to using the existing Type 1. However, when Type 3 was applied to the ships, there was an environmental improvement effect of at least 2.2% compared to when Type 2 was used. In particular, a POCP-saving effect of about 5% was seen in the 9.77 ton ship, which was the greatest reduction.

4. Discussion

4.1. Research Novelty

Although the total amount of carbon dioxide emissions from 70,000 coastal ships in Korea is huge, the emission regulations on coastal ships are weak compared to international merchant ships. However, although the government pursued a carbon dioxide emissions strategy by introducing the Act on the Promotion of the Development and Distribution of Green Ships, empirical research related to countermeasure technology is lacking. Previous research is insufficient to analyze fishing ships’ economic and environmental characteristics, and the development of economic and environmental analysis systems for propulsion systems for fishing ships is rare and expensive. This study measures real ship performance and presents the economic and environmental benefits of the battery hybrid system to which the ECMS control method is applied.

In environmental research on the maritime sector, due to the difficulty of securing accurate operational data, most lifecycle assessment (LCA) studies have been performed based on the maximum output of the ship. However, in this study, various devices were installed on the ships to measure the actual operational data, and the results made it possible to perform accurate LCA. As claimed by Park et al. [], the LCA study, through the use of these more realistic and accurate data, makes the results of the environmental evaluation of this study more reliable than the results of the conventional LCA method. The significance of this study is that it can provide more accurate and applicable information in terms of the environmental impact based on the data generated from actual experiments rather than the predictions and assumptions. Based on the sufficiently high reliability, these holistic environmental results can present a basis for introducing new technologies to stakeholders in the future and can be a valuable reference to policymakers for setting policy directions.

This is an important study because it not only presents reliable environmental impact information based on accurate data, but also confirms how much fuel can be saved and by how much emissions can be reduced by incorporating the electric propulsion system and a control system called ECMS. By introducing the electric propulsion system and by changing the propulsion system according to the engine load, it was proven that fuel and energy consumption can be reduced, and more efficient and eco-friendly operations are possible. However, it was also clearly verified through the results of GWP from the 47 ton ship that simply increasing electricity consumption by lowering the diesel engine utilization rate and increasing the electric propulsion system utilization rate to reduce the use of fossil fuels is not an eco-friendly method.

As argued by Park et al. [], it is important to consider how the electricity used as fuel in an electric propulsion system is produced from a lifecycle perspective. As their research results show, the electric propulsion system using electricity produced in some countries causes more emissions than the diesel system using fossil fuels. Therefore, simply introducing the electric propulsion system without considering electrical energy from a lifecycle point of view can be the wrong decision and might actually harm the environment.

Therefore, in analyzing the results of this study, we must take into account the electricity production method. Since the case ships are engaged in international services, they are highly likely to receive bunker oil from various nations; thus, the analysis was extended to several countries to observe their environmental gaps.

The results of this analysis are meaningful in that they do not target only the ships selected in this study, but they can suggest a direction for Korea’s energy policy and technology development in terms of regulations and environmental aspects of future ships. In Korea, coal power generation accounts for 40.4% of the national electricity generation system. This means that a relatively large amount of GHGs are generated in the production of electrical energy in Korea compared to countries using more renewable energy for their national grid, considering the environmental impact of each electric power generation source. This proves that, when using an electric propulsion system with electricity produced in Korea as a power source, the environmental improvement effect may not be significant in terms of GWP compared to a system that uses fossil fuels to obtain power.

As can be seen from Figure 13, India’s coal power generation ratio exceeds 70%, while Norway generates about 98% of its national electricity through renewable energy sources. In the UK, the proportion of coal power generation is very low at 2.4%, and the proportion of electricity produced through renewable energy sources is much higher than that of Korea. As a result, the environmental impact due to the difference in energy production method shows a large difference per 1 kWh of electrical energy, as shown in Table 10.

Figure 13.

The proportion of electricity generation sources in four countries that have different percentages of resources used for national electricity generation.

Table 10.

Functional units of electricity produced in other sample countries.

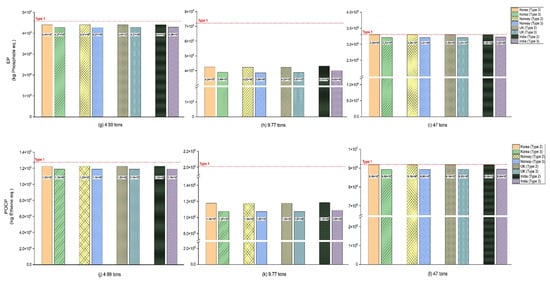

By applying these environmental functional units to the three case ships selected in this study, we examined how environmentally different they were when using electricity produced in Korea and in three other countries.

As shown in Figure 14, if the share of renewable energy in Korea’s national electricity production system increases further, such as in Norway or the UK, further environmental improvement effects can be obtained. In particular, when using electricity produced in Korea, the GWP result of the 47 ton ship was not as good environmentally as Type 1, which was propelled using only MGO as fuel when Type 3 was applied. However, when using electricity produced in Norway, when Type 3 was applied, the GWP reduction effect was about 2.6% compared to the Type 1 system. It is possible to reduce the GWP by about 4.5% compared to Type 3 by using electricity produced in Korea. Even when using electricity produced in the UK, when Type 3 was applied, GWP was reduced by about 4.5% in the 4.99 ton ship compared to Type 1, and by 0.3% in the 47 ton ship. Even when the same Type 3 was applied, GWP reductions of 1.7% and 2.0%, respectively, were seen compared to when electricity produced in Korea was used.

Figure 14.

Environmental impacts during the lifespan of each ship using electricity produced in four different countries.

On the other hand, when the electricity was produced in India, where the proportion of coal power generation is very high, the opposite pattern was seen. When using electricity produced in other countries, including Korea, when Type 3 was applied to a 4.99 ton ship, all emissions reduced compared to Type 1, but when electricity produced in India was used, it increased by approximately 0.9% of GWP and about 0.5% of AP. In addition, the results show that GWP, AP, EP, and POCP all increased compared to when electricity produced in Korea was used; in particular, 7.1% more AP was generated. In the case of the 47 ton ship, the environmental impact was 6.4% worse in terms of GWP.

In this study, due to each ship’s set energy and propulsion system application concept and operation characteristics, the reduction in MGO use through the introduction of the electric propulsion system for 4.99 ton and 47 ton ships was not large. For this reason, the difference in environmental impact results according to the applied propulsion system is not clear from the size of the ship. However, in the case of a 9.77 ton ship, which was able to significantly reduce MGO consumption by applying the electric propulsion system, when Type 2 was applied, it reduced MGO by about 41.5%. Furthermore, when sailing with a Type 3 system, about 46.6% of fossil fuel consumption was reduced, and electric energy replaced it.

When using electricity produced in Norway, which is considered to have the highest proportion of renewable energy, GWP was reduced by about 41% in Type 2 and 46% in Type 3 compared to the emissions generated by applying Type 1. Moreover, 14.2% and 22.7% GWP decreases could be confirmed, respectively, compared to when using electricity produced in Korea. Even when using electricity produced in the UK, AP, EP, and POCP were reduced by more than 40%, including 35.6% and 37.0% GWP reductions, respectively, when Type 2 and Type 3 were applied compared to when Type 1 was used.

However, when electricity from India’s national grid was used, and Type 2 and Type 3 were applied, the GWP was only reduced by 21.3% and 13.8%, which is less than when using electricity from other countries.

Furthermore, those results show that GWP was 22.2% and 36.9% higher than when using electricity produced in the UK and 33.3% and 58.9% more than when using electricity generated in Norway.

Through these results, two significantly important messages of this paper can be determined. The first is the importance of appropriate energy use and a propulsion system suitable for the operating characteristics of a ship. The 9.77 ton ship uses more energy for fishing and idling than other ships. It is clear that it is possible to save a considerable amount of fuel when an electric propulsion system is applied.

It was confirmed that a huge environmental improvement effect, e.g., a 13.8–46% reduction in GWP, is possible depending on the electricity production method. Therefore, based on this study, we suggest to stakeholders that a propulsion system be installed by closely examining a ship’s operational profile and reflecting on the ship’s expected operating scenarios when building ships in future.

The second important finding of this study is the direction of change in the production method of electric energy. To overcome the global climate crisis, many countries and companies are making efforts to reduce pollutant emissions. Comparing the electricity production methods of the four countries and the environmental impact of applying the electric propulsion system to three sample ships, there is no doubt that the eco-friendliness of the electricity production method is a meaningful way to overcome climate change. Currently, the Korean government is carrying out a Green New Deal policy to continuously and efficiently promote carbon neutrality by 2050. This study is in support of this policy. Electric propulsion ships operating on the coast of Korea can become greener ships, similar to those operated in the UK and Norway. This study can serve as important policy guidance so that more environmentally friendly policies can be actively established and promoted.

Furthermore, in the current situation, where electric vehicles are leading the global market, the results of this study are not limited to ships, but can be the basis for the conclusion that simply replacing conventional internal combustion engine vehicles with electric vehicles in all countries will never be a perfect solution from an environmental point of view. There is novelty in this study in that we found that the production method of the electric energy used in electric vehicles is more important than vehicle replacement.

4.2. Limitations and Future Study

To ensure the accuracy of the data in this study, we tried to compare engine performance data from an engine design company with our measurement data but, due to the age of the ships selected for the study, we could only utilize performance data from similar new engines. As shown in Figure 15, the types of engines used for each tonnage of ship are diverse with different fuels, but this study deals with MGO only.

Figure 15.

The proportion of ships by tonnage in different engine types: (a) gasoline engine; (b) diesel engine; (c) diesel engine vehicle.

Through our research, we measured ships’ performance based on actual data and could calculate the output, fuel consumption, and carbon dioxide emissions according to the load profile. To compare the economic feasibility of all ships in Korea and other countries, not only fuel price but also an in-depth, comparative analysis of the OPEX and CAPEX fields (as follows) is required.

For CAPEX, research should focus on the following:

- Different system prices between diesel propulsion system and battery hybrid propulsion system with installation cost.

For OPEX, research should focus on the following:

- Fuel price scenario;

- Different tax on fuel oil in different countries;

- Electricity cost scenario;

- Electricity consumption by auxiliary machinery;

- Maintenance costs.

Therefore, these limitations on the research should be addressed in future study.

However, this study has produced meaningful results on fuel consumption and emissions reduction through the use of a battery hybrid system and ECMS control. In future research, the decrease in the performance of the power source due to the aging of fishing ships will be regarded as a factor in the decrease in the amount of carbon dioxide. This study aims to investigate total carbon dioxide emissions through fuel consumption of representative ships by category for the entire coastline, not just three types of ships studied here. In addition, in the study of fishing ships, additional research is required on the specifications of applicable ships because there are a large number of small ships that cannot apply the battery hybrid system due to their size. Additionally, we intend to conduct a verification study of carbon dioxide reduction in propulsion systems using various control methodologies.

5. Conclusions

During this study, three representatives (4.99 ton, 9.77 ton, and 47 ton) of the 70,000 coastal ships were selected and their performance and operating profiles were analyzed. Therefore, we represented various operation modes, which are an important factor in designing the capacity of the battery motor and has a great influence on the amount of power used by the battery. If the electricity charged by the battery reduces the carbon dioxide emissions, this indicates that carbon dioxide emissions can be reduced through motor operation in the idling and fishing sections. On average, this was reduced to 7.6%, and it was confirmed that the reduction was 10.7% in the case of applying the ECMS that operates the power generation source at the optimum load. Based on this, we calculated the fuel price and carbon dioxide emissions compared to the expected fuel consumption based on the diesel propulsion engine operation standard for the 23,341 Korean coastal ships suitable for hybrid energy. Comparing the results of applying the battery hybrid ship and the ECMS, we found that 2,491,841 tons of carbon dioxide and 2,907,461 tons of carbon dioxide can be avoided, respectively. However, assuming that the electric power used in the battery is charged from the shore, in the case of Korea, the proposed battery hybrid system method is effective compared to the conventional diesel propulsion system in AP, EP, and POCP. However, in terms of carbon dioxide emissions (4.99 tons and 9.77 tons), reducing emissions is effective due to the existence of various idling and fishing sections. However, in the case of the 47 ton ship, if the battery motor use section is negligible due to the operational characteristics of the ship, similar results to diesel propulsion are seen, but the efficiency of the generator is only achieved by using ECMS, which increases the battery motor operating time and carbon dioxide emissions.

In addition, the type and amount of emissions vary greatly depending on the power source in each country. In India and Korea, which have large power sources using fossil fuels (compared to Norway and the UK, which use eco-friendly power sources), a battery hybrid system was applied, and when the battery usage time increased, the carbon dioxide emissions increased from 4.99 ton ships in India and 47 ton ships in India and Korea.

The operating profiles of fishing boats were divided into three main categories, as follows: idling, fishing, and sailing. In the case of sailing, fishing boats operate at full speed, so if the battery motor operation section is unnecessary or used, it can serve as a booster mode only. In the idling and fishing sections, it is very important to analyze the operational characteristics of the actual ship because it is necessary to design a battery motor operation area. Renovation or new building is required to reduce carbon dioxide due to the aging of the fishing vessels. In this case, if the battery hybrid system is considered an eco-friendly propulsion source, the power supply network and supply cost for fishing vessels at the national level, and the eco-friendliness of the electric power production method, should be considered with an LCA analysis. A simple introduction of a battery system can reduce the operating time of a diesel engine, but the emissions generated by the generation of a power source charged from the shore will be another issue. An eco-friendly propulsion system for fishing vessels will become possible by analyzing an actual ship’s load profile, designing a battery motor suitable for it, and performing ECMS operations in consideration of the optimal efficiency of the engine.

Author Contributions

J.K.: Funding acquisition, Project administration, Resources, Conceptualization. H.J.: Software, Writing—review & editing, Supervision. S.K.: Data curation, Formal analysis, Investigation, Methodology, Validation, Visualization, Writing-original draft. C.P.: Data curation, Formal analysis, Methodology, Writing—review & editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Korea Institute of Marine Science & Technology Promotion (KIMST), funded by the Ministry of Oceans and Fisheries (NO. 20210369).

Data Availability Statement

Data presented in this article is available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- IMO. Fourth Greenhouse Gas Study 2020; IMO: London, UK, 2021. [Google Scholar]

- IMO. Proceedings of the 76th Session of the Marine Environment Protection Committee, MEPC 76, London, UK, 10–17 June 2021.

- The 2050 Carbon Neutrality and Green Growth Commission. National Greenhouse Gas Reduction Goals. Available online: https://www.2050cnc.go.kr/eng/main/view (accessed on 26 August 2021).

- Ministry of Oceans and Fisheries. Change to an Eco-Friendly Ship and Receive Government Subsidies. Available online: https://www.mof.go.kr/iframe/article/view.do?articleKey=38581&boardKey=10¤tPageNo=1 (accessed on 25 April 2021).

- Ministry of Oceans and Fisheries. Introduction of Eco-Friendly Public Ships? It’s Not Difficult. Available online: https://www.mof.go.kr/article/view.do?boardKey=10&menuKey=971¤tPageNo=1&articleKey=34799 (accessed on 26 July 2020).

- Korea Maritime Transportation Safety Authority. Eco-Friendly Ship&Equipment Certification System. Available online: https://www.komsa.or.kr/kor/sub02_0406.do;jsessionid=9BE624A4DF8D345FA63D880398F92452 (accessed on 15 May 2021).

- National Institute of Environmental Research. A Study on the Development of Air Pollutant and Greenhouse Gases Emission Factor and Emission Estimation from the Domestic Coastal Shipping. Available online: https://nier.go.kr/NIER/kor/research/getResearchResultList.do?menuNo=12007 (accessed on 12 April 2022).

- Sui, C.; de Vos, P.; Stapersma, D.; Visser, K.; Ding, Y. Fuel consumption and emissions of ocean-going cargo ship with hybrid propulsion and different fuels over voyage. J. Mar. Sci. Eng. 2020, 8, 588. [Google Scholar] [CrossRef]

- Nguyen, H.P.; Hoang, A.T.; Nizetic, S.; Nguyen, X.P.; Le, A.T.; Luong, C.N.; Chu, V.D.; Pham, V.V. The electric propulsion system as a green solution for management strategy of CO2 emission in ocean shipping: A comprehensive review. Int. Trans. Electr. Energy Syst. 2021, 31, e12580. [Google Scholar] [CrossRef]

- Deng, J.; Wang, X.; Wei, Z.; Wang, L.; Wang, C.; Chen, Z. A review of NOx and SOx emission reduction technologies for marine diesel engines and the potential evaluation of liquefied natural gas fuelled vessels. Sci. Total Environ. 2021, 766, 144319. [Google Scholar] [CrossRef] [PubMed]

- Moldanová, J.; Fridell, E.; Popovicheva, O.; Demirdjian, B.; Tishkova, V.; Faccinetto, A.; Focsa, C. Characterisation of particulate matter and gaseous emissions from a large ship diesel engine. Atmos. Environ. 2009, 43, 2632–2641. [Google Scholar] [CrossRef]

- Bicer, Y.; Dincer, I. Clean fuel options with hydrogen for sea transportation: A life cycle approach. Int. J. Hydrogen Energy 2018, 43, 1179–1193. [Google Scholar] [CrossRef]

- Brynolf, S.; Fridell, E.; Andersson, K. Environmental assessment of marine fuels: Liquefied natural gas, liquefied biogas, methanol and bio-methanol. J. Clean. Prod. 2014, 74, 86–95. [Google Scholar] [CrossRef]

- Ogunkunle, O.; Ahmed, N.A. Exhaust emissions and engine performance analysis of a marine diesel engine fuelledwith Parinari polyandra biodiesel–diesel blends. Energy Rep. 2020, 6, 2999–3007. [Google Scholar] [CrossRef]

- Yu, H.; Fang, Z.; Fu, X.; Liu, J.; Chen, J. Literature review on emission control-based ship voyage optimization. Transp. Res. Part D Transp. Environ. 2021, 93, 102768. [Google Scholar] [CrossRef]

- Ma, D.; Ma, W.; Jin, S.; Ma, X. Method for simultaneously optimizing ship route and speed with emission control areas. Ocean. Eng. 2020, 202, 107170. [Google Scholar] [CrossRef]

- Hwang, S.; Jeong, B.; Jung, K.; Kim, M.; Zhou, P. Life cycle assessment of LNG fueled vessel in domestic services. J. Mar. Sci. Eng. 2019, 7, 359. [Google Scholar] [CrossRef] [Green Version]

- International Energy Agency (IEA). Monthly OECD Electricity Statistics. Available online: https://www.iea.org/data-and-statistics/data-product/monthly-electricity-statistics#monthly-electricity-statistics (accessed on 19 May 2021).

- Jeong, B.; Jeon, H.; Kim, S.; Kim, J.; Zhou, P. Evaluation of the lifecycle environmental benefits of full battery powered ships: Comparative analysis of marine diesel and electricity. J. Mar. Sci. Eng. 2020, 8, 580. [Google Scholar]

- Park, C.; Jeong, B.; Zhou, P.; Jang, H.; Kim, S.; Jeon, H.; Nam, D.; Rashedi, A. Live-Life cycle assessment of the electric propulsion ship using solar PV. Appl. Energy 2022, 309, 118477. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).