2.1. Theoretical Frameworks

Productivity and efficiency are the two most important concepts for measuring performance and are frequently used interchangeably. The productivity of a firm is defined either as the ratio of output to input or as total factor productivity. Efficiency represents either the ability of a firm to minimize the inputs used in production for a given output vector or the ability of the firm to maximize output from a given input vector [

10].

The literature on the measurement of the port efficiency and productivity using frontier models has considerably grown since the first empirical studies were published in the 1990s. As a consequence, these studies can be divided into two main categories with respect to the methods used to estimate the frontier. In fact, the first category uses non-parametric methods, in particular the DEA method, while the second uses parametric techniques, such as the stochastic frontier analysis (SFA).

The DEA method was first tried in the port industry by Roll and Hayuth [

11] where, to measure the efficiency of twenty ports in two regions, they used three inputs, such as number of workers, capital, and cargo homogeneity, and four outputs, including the handled tonnage, the level of service, the satisfaction of the users, and the number of ship calls. There are principally two DEA models frequently used in the literature, which are the DEA-CCR (or Charnes, Cooper, and Rhodes) model proposed by Charnes et al. [

12], and the DEA-BCC (or Banker, Charnes, and Cooper) model proposed by Banker et al. [

13].

For instance, Martinez-Budria et al. [

14] estimated the efficiency of 26 Spanish ports over the 1993–1997 period, which they classified into three harmonized groups (large, medium, and small) by applying complexity criteria and taking into account the size of the seaport and the types of the handled goods. More precisely, they examined the efficiency of these ports using the DEA-BCC to evaluate pure technical efficiency under the assumption of variable returns to scale (VRS). The results found showed that large ports are the most efficient and have the largest efficiency improvements. On the other hand, Tongzon [

15] used both the DEA-CCR and the DEA-additive models to estimate and compare the efficiency of four Australian container ports and twelve other international container ports for 1996. He argued that port size is not the main determinant of port efficiency. However, these results contradict those of Bonilla et al. [

16] and Gonzalez and Trujillo [

17], who reported that the most efficient ports include both large and small ports, and that they are similar to the least efficient ones.

For his part, Barros [

18] applied the DEA-CCR and DEA-BCC models to assess the efficiency achieved by some Portuguese ports in order to get an idea of the role of the incentives established by the Portuguese regulations. He came to the conclusion that the improvements made by the Portuguese port authorities have positioned these ports beyond the efficiency frontier. However, he acknowledged that due to the small sample size and the heterogeneity of the ports in the study, the results should be taken with caution. For their part, Barros and Athanassiou [

19] also recognized the same problem in their research when they used the DEA-CCR and DEA-BCC models to assess the efficiency of two Greek and four Portuguese ports. Their study ranked ports and identified the ones that achieved remarkable improvements in efficiency. They suggested that scale efficiency is a primary objective for the defined ports.

Rodriguez-Alvarez et al. [

20] evaluated the technical and allocative efficiency of the three main container terminals in the port of Las Palmas in Spain. On the other hand, Alonso and Bofarull [

21] applied the DEA method to measure the efficiency of the ports of Bilbao and Valencia in Spain in order to find out to what extent investments have improved efficiency and whether this improvement has enhanced the attractiveness of the ports. In fact, their results revealed that investment is not the only factor that can improve the technical efficiency of ports.

Regarding Hung et al. [

22], they used the DEA method to examine the overall technical efficiency (pure technical and scale efficiency) of 31 Asian container ports. For this reason, they used 4 inputs, such as the terminal area, the container gantries on the quay, the number of berth and the terminal length, and 1 output, which is the container throughput. Their conclusion can be summarized as follows: (1) the technical inefficiency of the Asian container ports is due to pure technical inefficiency rather than to scale inefficiency caused by inefficient management practices; (2) in terms of increasing returns to scale (IRS), the container ports need to consider their expansion; and (3) the East Asian container ports are more efficient than the ports in other Asian regions (Northeast Asia and Southeast Asia). Furthermore, Choi [

23] presented an empirical analysis on the efficiency of 13 container ports in Northeast Asia during the 2005–2007 period. Their study analyzed empirical results on the efficiency of major ports using the DEA-CCR, DEA-BCC, Malmquist index, and Tobit regression models. The obtained results revealed that most ports have higher scores in pure technical efficiency but low scores in scale efficiency. Furthermore, the study concluded that investments in infrastructure do not improve efficiency. On the other hand, Fu et al. [

24] applied the Malmquist DEA-based productivity index to measure the relative efficiency of ten major container ports in China between 2001 and 2006.

In contrast, Barros [

25] used DEA models and the Malmquist index to assess the changes in efficiency and productivity in seaports located in Angola, Nigeria, and Mozambique during the period 2004–2010, while Wilmsmeier et al. [

26] analyzed and compared, for the period 2005–2011, the evolution of port productivity and efficiency for 20 terminals in ten countries in Latin America, the Caribbean, and Spain, using the Malmquist productivity index.

In another study, Yuen et al. [

27] examined the effect of intraport and interport competition on the efficiency of container terminals in China and neighboring countries. In fact, the technical efficiency of the sampled container terminals was measured using the DEA method for the period from 2003 to 2007. Furthermore, regression analysis was used to examine the elements that affect the efficiency of container terminals. The study concluded that the Chinese port ownership could improve the efficiency of the container terminals. Furthermore, it was found that intra- and interport competition could improve the efficiency of these container ports.

On the other hand, Schøyen and Odeck [

28] applied the Malmquist productivity index to measure productivity changes in the UK Nordic container ports and the six largest container ports in Norway. For their part, Shaheen and Elkalla [

29] conducted an efficiency analysis of Middle Eastern container ports using both the DEA-CCR and BCC models and found that 80% of the ports considered showed increasing returns to scale. As for Seth and Feng [

30], they applied the DEA method to calculate the efficiency scores of 15 U.S. container ports by comparing them to better ones.

Wang et al. [

3] applied a hybrid approach that combines the DEA Malmquist method and the epsilon-based measure to assess the efficiency of a sample of 14 seaport companies in Vietnam during 2015–2020. Jeh et al. [

1] applied DEA and a Malmquist index analysis to study 21 global terminal operators to determine the characteristic that showed the highest efficiency and productivity. Very recently, some researchers have integrated the environmental analysis aspect, as a basic component of sustainable development, into the evaluation of seaport performance, such as in He et al. [

2], Gan et al. [

31], and Castelló-Taliani et al. [

32].

The above literature review shows that the DEA method is a technique used to measure efficiency and productivity in the port industry. All these authors have emphasized the advantages of this approach. Nevertheless, several authors have proposed a combination of the DEA axiom with other parametric techniques such as Tobit regression. These combinations allow us to highlight the determinants of port performance or the influence of environmental variables. Noting the need to measure changes in productivity over time and to analyze the influence of policy changes, several authors have also combined the DEA method with Malmquist indices. With these, it is possible to see how total port productivity changes over a period of time and which factors influence this movement (technological progress, improvements in technical efficiency or scale efficiency). As far as developing countries are concerned, our literature review shows that studies dealing with the port system and the DEA method are still rare or very recent. Other studies have investigated the differences in efficiency between ports in different countries.

Most studies measuring efficiency and productivity in the port sector have been conducted in container terminals in Asian, European, and Latin American countries. There is a need to explore these aspects further in Africa and especially in Tunisia, as there are no published studies that have examined the efficiency of Tunisian seaports with both DEA and IPM-DEA methods. In fact, Tunisia is one country located in North Africa that is accessible via Mediterranean Sea. Like many other developing countries, Tunisia’s economic situation is in a fragile state. In January 2011, after a 28-day civil resistance campaign, a revolution took place in Tunisia. This manifestation, also called the Jasmine revolution, was to replace the longtime president Zine El Abidine Ben Ali by a democratic political state.

2.3. Data Envelopment Analysis (DEA)

Unlike the regression analysis, which gives us the average profile of the DMUs, the DEA method involves using linear programming to construct a piecewise frontier, which represents, in economic terms, the revolved frontier (or envelope) of the best production practices. By projecting each DMU onto the frontier, it is possible to determine the level of inefficiency by comparing a single reference DMU or a convex combination to other reference DMUs. The projection refers to a “virtual DMU”, which is a convex combination of one or more efficient DMUs. Therefore, the projected point may not itself be an initial DMU.

The non-parametric approach relies on linear programming to construct the production frontier. This approach imposes no restrictions on the functional form of the production frontier. In fact, the most common method is the DEA developed by Charnes et al. [

12] in 1978 and Banker et al. [

13] in 1984. This method estimates the frontier of a set of production units and is applied in a multi-input, multi-output technology framework.

Unlike a regression analysis, which gives us an average profile of DMUs, the DEA method consists of using linear programming to construct a piecewise frontier, which represents in economic terms the revolved (or enveloped) frontier of best production practices. By projecting each DMU onto the frontier, it is possible to determine the level of inefficiency by comparing a single reference DMU or a convex combination with other reference DMUs. The projection refers to a “virtual DMU”, which is a convex combination of one or more efficient DMUs. Thus, the projected point may not itself be an initial DMU.

More specifically, the DEA method calculates the efficiency of a DMU with respect to resource allocation among alternative uses. When one wants to determine the minimum possible level of inputs needed to produce a given set of outputs, this is an input orientation, or to determine the maximum possible level of outputs by consuming a given set of inputs, this is an output orientation. Thus, the DEA method identifies relationships between inputs and outputs, single or multiple, from the perspective of relative efficiency. The latter term is used because the efficiency of each DMU is estimated relative to the other DMUs in the sample. In the literature, the two most widely used DEA models are the CCR model presented by Charnes et al. [

12], which assumes constant returns to scale (CRS), and the BCC model proposed by Banker et al. [

13], which assumes variable returns to scale (VRS). The evaluation of returns to scale can occur in three situations: constant returns to scale, increasing returns to scale (IRS), and decreasing returns to scale (DRS). The first refers to the case where the output increases in line with the input levels, the second refers to the case where the output production increases above the input levels, and the third represents the case where the output production increases below the input levels.

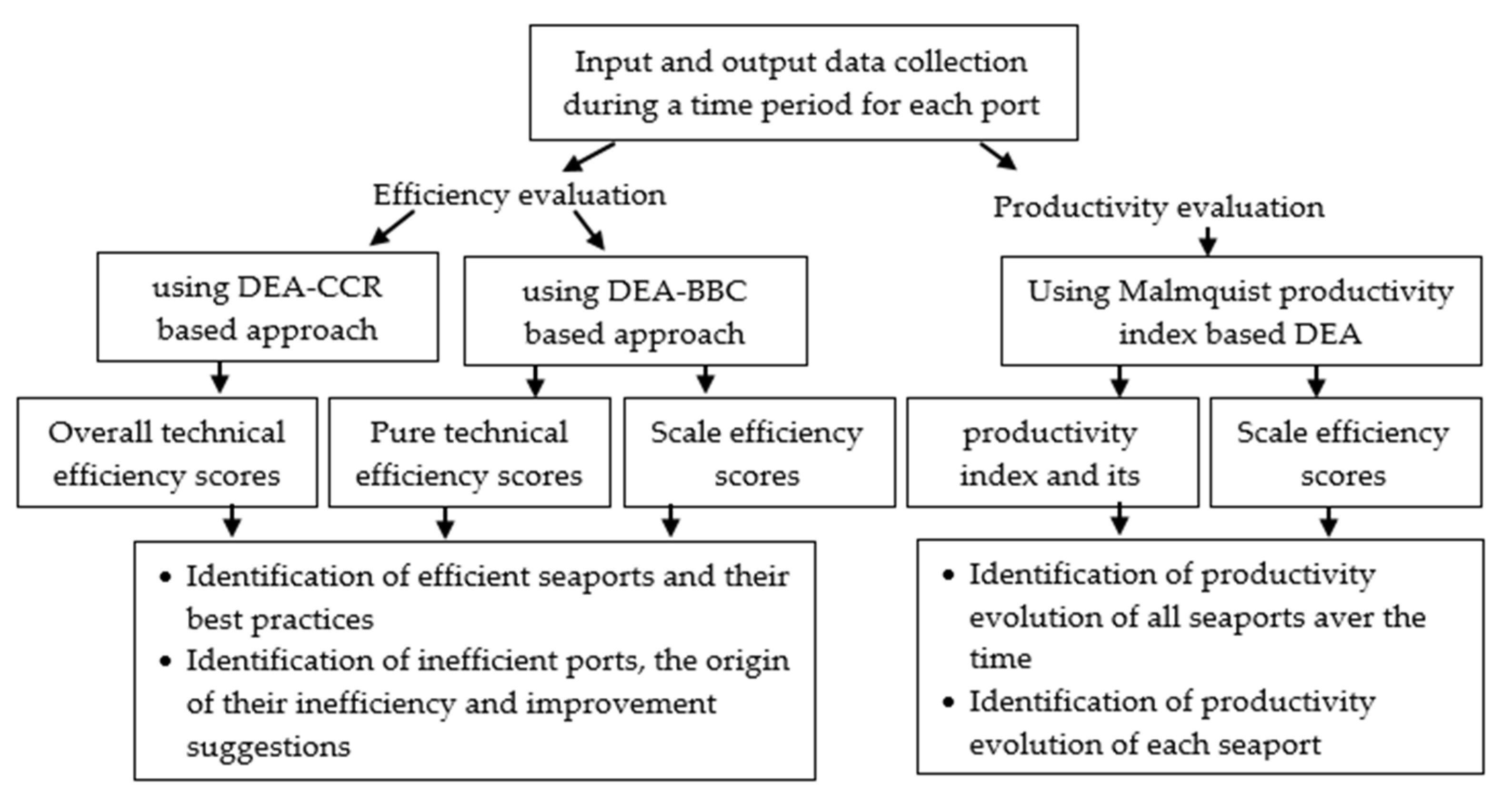

In this study, the two models DEA-CCR and DEA-BCC were selected to measure the technical efficiency of the Tunisian ports. The choice in favor of these two types of models is justified by the fact that the CCR model enables us to visualize the overall technical efficiency of the sample, while the BCC model helps us divide the overall efficiency into pure technical efficiency and scale efficiency.

The following parameters and variables are used in the following models.

ϕ: efficiency score;

yr0: the observed quantities of output “r” from the port, the efficiency of which is measured, with r = 1;

xi0: the observed quantities of input “i” from the port whose efficiency is measured, with i = 1, 2, 3;

yrj: the observed quantities of output r from port “j”, with j = 1, 2 ,… n;

xij: the observed quantities of input “i” from port “j”;

λj: the weighting coefficients;

OSr: the difference variables in output “r”;

ISi: the difference variables in input “i”.

The two output-oriented models that we have retained in our analysis are the DEA-CCR output-oriented model and DEA-BCC output-oriented model. Note that all λj, OSr, ISi, and ϕ should be positives.

2.3.1. The DEA-CCR Output-Oriented Model

The output-oriented model aims to maximize the outputs while not exceeding the observed input levels.

subject to

2.3.2. The DEA-BCC Output-Oriented Model

The objective in the BCC model is to maximize the output production while not exceeding the actual input level. It has the same formulation as the CCR model with a supplementary constraint indicated in Equation (4):

2.4. The Malmquist Productivity Index

In fact, ports generally have different outputs (container handling, liquid bulk, dry bulk, general cargo, etc.) and inputs (cranes, labor, terminal facilities, etc.). Therefore, a simple ratio between an output and an input may not correctly represent the reality of a port. For this reason, we need to use methodologies that take into account all the inputs needed to produce one or more outputs, which is called total factor productivity (TFP). Thus, a wide range of methodologies have been implemented in recent decades, mainly based on the estimation of a production frontier, to determine the TFP, which is a methodology that enables decomposing the TFP into different components through panel data on different ports.

The main advantage of this approach is that it reveals exactly where the differences in impact on productivity and efficiency changes over time can be found for the six Tunisian ports. In addition, although efficiency is a short-term concept evaluated each year, productivity evaluates changes over time and therefore is more like a long-term concept.

Furthermore, the Malmquist Productivity Index (MPI) can be used to measure changes in the total factor productivity between two points by calculating the ratio of the distances of each data point from a common technology. As a result, the MPI has become a standard approach in measuring productivity over time. Being first introduced by Malmquist [

33] in 1953 and later developed by other authors, such as Caves et al. [

34] and Fare et al. [

35], this index has been widely used over the past decade in the literature dealing with ports.

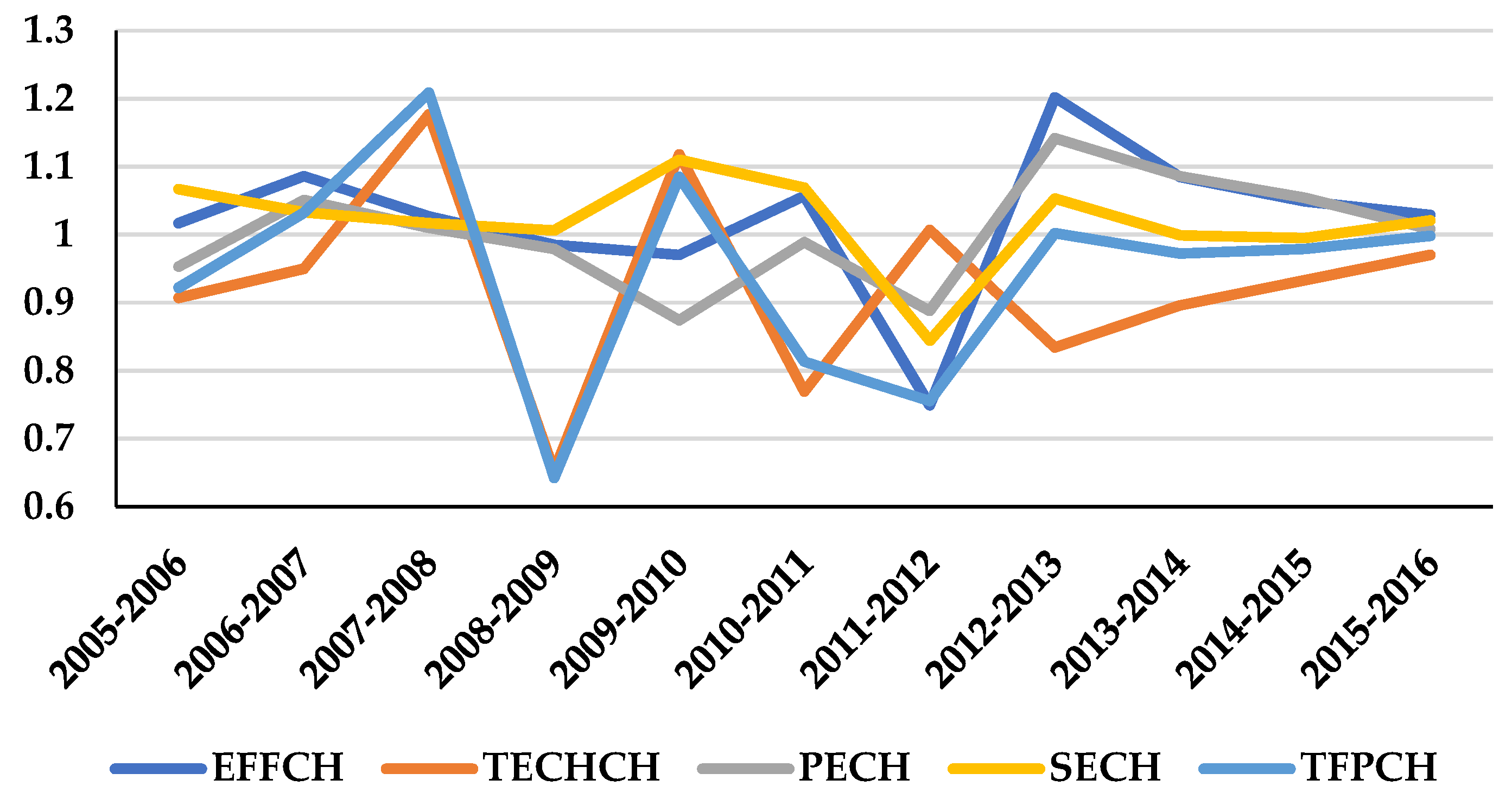

Furthermore, the main merit of the MPI is its ability to decompose the change in productivity into the total technical efficiency change (EFFCH), which captures the catch-up effect (i.e., the movement towards or away from the best practice frontier), and the technological change (TECHCH), which reflects the frontier shift effect over time. In addition, EFFCH can be further decomposed into pure technical efficiency change (PECH) and scale efficiency change (SECH). The former term is related to the optimal use of resources by managers, while the latter refers to the appropriate size of the ports.

For their part, Fare et al. [

35] specify such output-oriented Malmquist indices as presented in Equation (5):

where

yt, yt+1: the vectors of the observed quantities of outputs, respectively in periods t and t + 1;

xt, xt+1: the vectors of the observed quantities of inputs respectively in periods t and t + 1;

: the output-oriented distance function in period t;

: the distance function that measures the maximum proportional change in output required to make, relative to the technology of period t.

On the other hand, if the period technology is used as a reference, the Malmquist total productivity index can be written as presented in Equation (6):

where:

: the distance function, which measures the maximum proportional change in the output required to make relative to the technology in period t + 1;

): the output-oriented distance function in period t + 1.

Therefore, a value of the Malmquist total productivity index greater than 1 indicates a percentage improvement in the total factor productivity in both periods t and t + 1, while a value less than 1 shows a regression in the TFP. However, in order to avoid arbitrarily choosing a benchmark, Fare et al. [

35] proposed an index, which is the geometric mean value of the two Malmquist productivity indices as mentioned in Equation (7) and equivalently in Equation (8).

From Equation (8), we observe that the ratio outside the square brackets measures the change in the output-oriented technical efficiency between periods t and t + 1, while the geometric mean of the two ratios between the brackets reflects the technological change represented by a change in the production frontier in period t + 1 relative to period t.

Fare et al. [

35] subsequently proposed a decomposition to measure scale efficiency. They reuse the technical efficiency term (EFFCH), which represents the ratio of two distance functions at constant returns to scale (CRS), and decompose it into a pure technical efficiency change term (PECH), measured relative to the frontier assuming variable returns to scale (VRS), and a scale efficiency change term (SECH). The index of change of pure technical efficiency (PECH) is expressed as shown in Equation (9).

By utilizing both CRS and VRS, the DEA frontiers to estimate the distance functions in Equation (8), the technical efficiency can be decomposed into scale efficiency and pure technical efficiency components. A scale efficiency change (SECH) is given in Equation (10).