Promising Strategies for the Reduction of Pollutant Emissions from Working Vessels in Offshore Wind Farms: The Example of Taiwan

Abstract

:1. Introduction

2. Alternative Fuel Strategies for Improving the Air Quality in Offshore Wind Farms

2.1. Scheme of Strategy ULSD

2.2. Scheme of Strategy PEMFC

3. Calculation Methods for the Emissions and Costs of the Implemented Strategy

3.1. Calculation Method for the Total Incremental Cost of Strategy ULSD

3.2. Calculation Method for the Total Incremental Cost of Strategy PEMFC

3.3. Calculation Method for the Pollutant Emissions

| SOx | NOx | HC | PM | CO2 |

|---|---|---|---|---|

| 1.02 | 1.02 | 1.04 | 1.06 | 1.02 |

3.4. Calculation Method for the Cost–Benefit Ratio

4. Results and Discussion

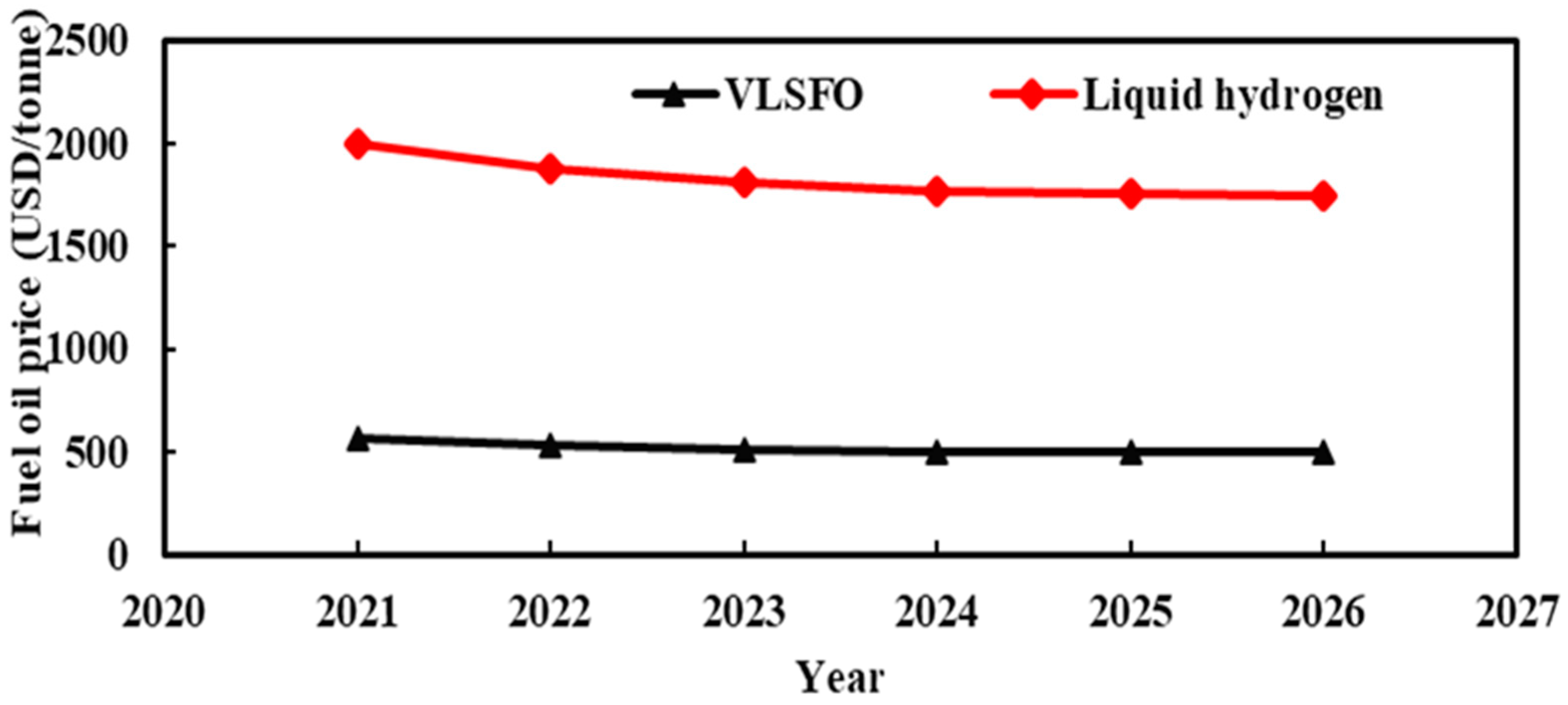

4.1. Comparison of Incremental Costs between Strategies

4.2. Comparison of Pollutant Emission Reductions between Strategies

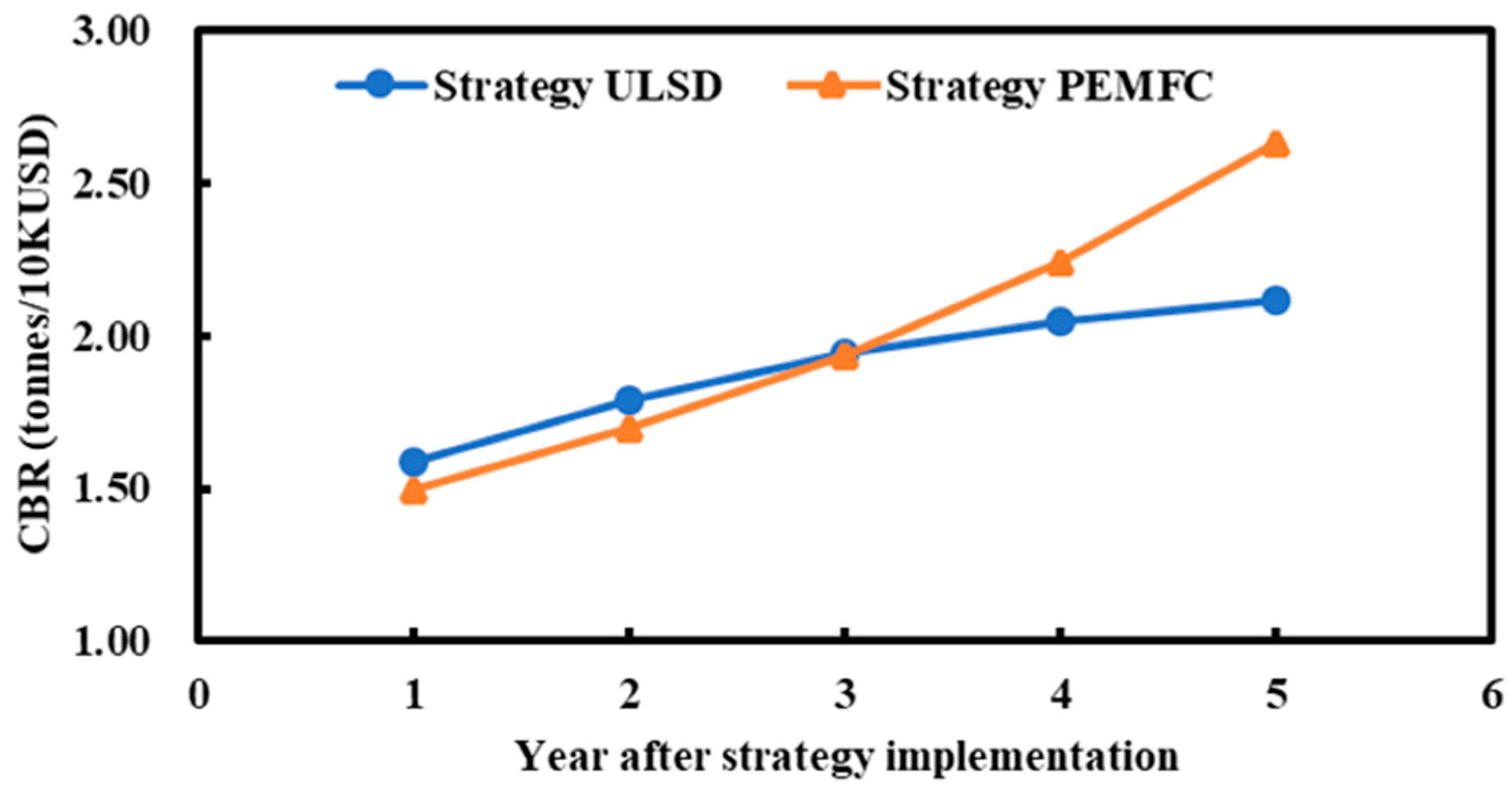

4.3. Comparison of Cost–Benefit Ratios between Strategies

5. Conclusions

- (1)

- The total incremental costs under Strategies ULSD and PEMFC increase by 7.5% and 51.2% over five years, respectively, as compared with the total cost of using VLSFO.

- (2)

- Strategy ULSD reduced the SOx, NOx, and PM emissions by 80.3%, 12%, and 60.5%, respectively, over the five-year period, but the amount of HC emitted was 24% higher compared with VLSFO.

- (3)

- Strategy PEMFC will bring more environmental benefits and reduced the SOx, NOx, HC, PM, and CO2 emissions by 100%, 97.4%, 91.8%, 81%, and 81.6%, respectively, which are much higher values than those of Strategy ULSD.

- (4)

- Five years after the adoption of Strategies ULSD and PEMFC, compared with the total CO2 emissions from VLSFO combustion, the emission reduction rates of Strategies ULSD and PEMFC were −14.6% and 81.6%, respectively, with a difference of 96.2%.

- (5)

- The cost–benefit analysis shows that both Strategy PEMFC and Strategy ULSD have promising advantages over VLSFO.

- (6)

- The cost–benefit ratios of Strategy ULSD are likely to increase slowly over the first five years. Therefore, as its long-term cost–benefit ratios are lower than those of Strategy PEMFC, we recommend that it be used as a short-term improvement strategy (i.e., for a period of less than three years). If the IMO’s carbon reduction regulations are implemented in the future, Strategy ULSD will become completely uncompetitive due to its higher carbon content.

- (7)

- PEMFCs are renewable power sources that can help ship owners have positive social perceptions. The cost–benefit ratios of Strategy PEMFC increased significantly over the five years. The initial capital expenditures of Strategy PEMFC are higher than those of Strategy ULSD. Therefore, we recommend that it be used as a medium- and long-term improvement plan (i.e., for a period of more than three years).

- (8)

- A cost–benefit analysis for vessels working in offshore wind farms that are powered by other low or zero-carbon sources of alternative energy, such as solar photovoltaic energy, electric power, wind energy, and ammonia or methanol fuel, should be performed in future research work.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AFC | Alkaline Fuel Cell |

| BoilerC | Boiler’s incremental cost |

| CAPEX | Capital expenditure |

| CBA | Cost–benefit analysis |

| CBR | Cost–benefit ratio |

| CO2 | Carbon dioxide |

| C.S.R | Continuous service rating |

| CTV | Crew transportation vessel |

| DF | Deterioration factor |

| DNV | Det Norske Veritas |

| EF | Emission factor |

| FC | Fuel cell |

| FCC | Fuel cell incremental cost |

| FCR | Fuel consumption rate |

| Fuel cell replacement | Annual shared incremental cost of replacing fuel cells |

| FIC | Fuel incremental cost |

| FP | Fuel price |

| GHG | Greenhouse Gas |

| HFO | Heavy fuel oil |

| IMO | International Maritime Organization |

| LCPA | Life Cycle Performance Assessment |

| LH2 | Liquid hydrogen |

| LNG | Liquefied Natural Gas Carrier |

| MCAE | Maintenance cost of auxiliary equipment for the fuel cell |

| MCFC | Molten carbonate fuel cell |

| MDO | Marine diesel oil |

| ME | Marine diesel engine |

| MGO | Marine gas oil |

| M&R | Maintenance and repair cost |

| M&RIC | Maintenance and repair incremental cost |

| MLC | Maritime Labor Convention |

| MoU | Memorandum of Understanding |

| NASA | National Aeronautics and Space Administration |

| non-diesel engine M&R | Maintenance incremental costs not related to diesel engines |

| NOx | Oxides of nitrogen |

| OPEX | Operating expenditure |

| MEP | Main engine power output |

| PAFC | Phosphoric acid fuel cell |

| PC | Personnel incremental cost |

| PEM | Proton exchange membrane |

| PM PPE | Particulate matter Personal protective equipment |

| PSC | Port State Control |

| Refuel | Incremental cost of refueling equipment |

| ROV | Remotely operated vehicle |

| SEA | Seafarers Employment Agreement |

| SOFC | Solid oxide fuel cell |

| SOx | Sulfur oxides |

| STCW | International Convention on Standards of Training, Certification and Watchkeeping for Seafarers |

| Storage | Incremental cost of liquid hydrogen storage equipment |

| TC | Cruise hours per year |

| TIC | Total incremental cost |

| ULSD | Ultra-low-sulfur diesel |

| VLSFO | Very-low-sulfur fuel oil (0.50 wt. % sulfur or less by mass) |

References

- Cranmer, A.; Baker, E. The global climate value of offshore wind energy. Environ. Res. Lett. 2020, 15, 054003. [Google Scholar] [CrossRef]

- 4C Offshore Company. Global Offshore Wind Farm Database. Available online: https://www.4coffshore.com/windfarms (accessed on 20 January 2022).

- Lu, S.-M. A review of renewable energies in Taiwan. Int. J. Eng. Sci. Res. Technol. 2010, 1, 405. [Google Scholar] [CrossRef]

- Department of Information Services (Taiwan). Offshore Wind-Power Generation. Available online: https://english.ey.gov.tw/News3/9E5540D592A5FECD/34ff3d6b-412e-458d-afe9-01737d2da52d (accessed on 10 January 2022).

- Łebkowski, A. Analysis of the use of electric drive systems for crew transfer vessels servicing offshore wind farms. Energies 2020, 13, 1466. [Google Scholar] [CrossRef] [Green Version]

- Whittaker, K.; Young, C.N. Status Review Report of the Taiwanese Humpback Dolphin Sousa chinensis taiwanensis. In National Marine Fisheries Service; National Oceanic and Atmospheric Administration, United States Department of Commerce: Washionton, DC, USA, 2018; pp. 7–12. [Google Scholar]

- Paterson, J.; D’Amico, F.; Thies, P.R.; Kurt, R.; Harrison, G. Offshore wind installation vessels– A comparative assessment for UK offshore rounds 1 and 2. Ocean Eng. 2018, 148, 637–649. [Google Scholar] [CrossRef]

- Arvesen, A.; Birkeland, C.; Hertwich, E.G. The importance of ships and spare parts in LCAs of offshore wind power. Environ. Sci. Technol. 2013, 47, 2948–2956. [Google Scholar] [CrossRef] [Green Version]

- Viana, M.; Rizza, V.; Tobías, A.; Carr, E.; Corbett, J.; Sofiev, M.; Karanasiou, A.; Buonanno, G.; Fann, N. Estimated health impacts from maritime transport in the Mediterranean region and benefits from the use of cleaner fuels. Environ. Int. 2020, 138, 105670. [Google Scholar] [CrossRef]

- Knudsen, D.B. Is the Shipping Industry still Sulfuring?—A Study of Compliance Factors from the IMO 2020 Sulfur Cap. Master’s Thesis, Lund University, Lund, Sweden, 2021. [Google Scholar]

- Joung, T.-H.; Kang, S.-G.; Lee, J.-K.; Ahn, J. The IMO initial strategy for reducing Greenhouse Gas (GHG) emissions, and its follow-up actions towards 2050. J. Int. Marit. Saf. Environ. Aff. Ship. 2020, 4, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Psaraftis, H.N.; Qi, J. Paradox of international maritime organization’s carbon intensity indicator. Commun. Transp. Res. 2021, 1, 100005. [Google Scholar] [CrossRef]

- Van, T.C.; Ramirez, J.; Rainey, T.; Ristovski, Z.; Brown, R.J. Global impacts of recent IMO regulations on marine fuel oil refining processes and ship emissions. Transp. Res. D Transp. Environ. 2019, 70, 123–134. [Google Scholar] [CrossRef]

- Fridell, E.; Winnes, H.; Eklund, V. Emission Factors for Shipping in Scenarios; Swedish Meteorological and Hydrological Institute: Norrköping, Sweden, 2020; pp. 11–20. [Google Scholar]

- Morales, J. The Impact of IMO’s Global Sulphur Cap the Shipping Industry and the Latter’s Countermeasure. Master’s Thesis, World Maritime University, Malmö, Sweden, August 2019. [Google Scholar]

- Ben-Hakoun, E.; Van De Voorde, E.; Shiftan, Y. Marine environmental emission reduction policy in the liner shipping the economic impact from trade lane perspective. Marit. Policy Manag. 2021, 48, 725–753. [Google Scholar] [CrossRef]

- Adland, R.; Cariou, P.; Jia, H.; Wolff, F.C. The energy efficiency effects of periodic ship hull cleaning. J. Clean. Prod. 2018, 178, 1–13. [Google Scholar] [CrossRef]

- Farkas, A.; Degiuli, N.; Martić, I.; Vujanović, M. Greenhouse gas emissions reduction potential by using antifouling coatings in a maritime transport industry. J. Clean. Prod. 2021, 295, 126428. [Google Scholar] [CrossRef]

- Traut, M.; Gilbert, P.; Walsh, C.; Bows, A.; Filippone, A.; Stansby, P.; Wood, R. Propulsive power contribution of a kite and a Flettner rotor on selected shipping routes. Appl. Energy 2014, 113, 362–372. [Google Scholar] [CrossRef]

- Castro, M.; Mestemaker, B.; van den Heuvel, H. Towards zero emission work vessels: The case of a dredging vessel. In Proceedings of the 2nd International Conference on Modelling and Optimisation of Ship Energy Systems (MOSES2019), Glasgow, UK, 8–10 May 2019; pp. 8–10. [Google Scholar]

- van Biert, L.; Godjevac, M.; Visser, K.; Aravind, P. A review of fuel cell systems for maritime applications. J. Power Sources 2016, 327, 345–364. [Google Scholar] [CrossRef] [Green Version]

- Klebanoff, L.E. The Zero-V: Feasibility of a Liquid Hydrogen Fueled Coastal Research Vessel; Sandia National Laboratory: Livermore, CA, USA, 2019. [Google Scholar]

- Gianni, M.; Pietra, A.; Taccani, R. Outlook of future implementation of PEMFC and SOFC onboard cruise ships. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; p. 04004. [Google Scholar]

- Tronstad, T.; Åstrand, H.H.; Haugom, G.P.; Langfeldt, L. Study on the Use of Fuel Cells in Shipping; DNV GL Maritime: Hamburg, Germany, 2017. [Google Scholar]

- Chiche, A.; Andruetto, C.; Lagergren, C.; Lindbergh, G.; Stenius, I.; Peretti, L. Feasibility and impact of a Swedish fuel cell-powered rescue boat. Ocean Eng. 2021, 234, 109259. [Google Scholar] [CrossRef]

- McKinlay, C.; Turnock, S.; Hudson, D. Fuel cells for shipping: To meet on-board auxiliary demand and reduce emissions. Energy Rep. 2021, 7, 63–70. [Google Scholar] [CrossRef]

- Guaitolini, S.V.M.; Yahyaoui, I.; Fardin, J.F.; Encarnação, L.F.; Tadeo, F. A review of fuel cell and energy cogeneration technologies. In Proceedings of the 2018 9th International Renewable Energy Congress (IREC), Hammamet, Tunisia, 20–22 March 2018; pp. 1–6. [Google Scholar]

- Felseghi, R.-A.; Carcadea, E.; Raboaca, M.S.; Trufin, C.N.; Filote, C. Hydrogen fuel cell technology for the sustainable future of stationary applications. Energies 2019, 12, 4593. [Google Scholar] [CrossRef] [Green Version]

- Sazali, N.; Wan Salleh, W.N.; Jamaludin, A.S.; Mhd Razali, M.N. New perspectives on fuel cell technology: A brief review. Membranes 2020, 10, 99. [Google Scholar] [CrossRef]

- Inal, O.; Deniz, C. Fuel cell availability for merchant ships. In Proceedings of the 3rd International Naval Architecture and Maritime Symposium, Istanbul, Turkey; 2018; pp. 907–916. [Google Scholar]

- Suraparaju, S.K.; Natarajan, S.K.; Karthikeyan, P. A succinct review on fuel cells. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; p. 012012. [Google Scholar]

- McKinlay, C.J.; Turnock, S.R.; Hudson, D.A. Route to zero emission shipping: Hydrogen, ammonia or methanol? Int. J. Hydrogen Energy 2021, 46, 28282–28297. [Google Scholar] [CrossRef]

- Uyanık, T.; Karatuğ, Ç.; Arslanoğlu, Y. Machine learning approach to ship fuel consumption: A case of container vessel. Transp. Res. Part D Transp. Environ. 2020, 84, 102389. [Google Scholar] [CrossRef]

- Thomas, J.F.; Sluder, C.S.; Kass, M.D.; Theiss, T. A guide to Fuel, Lubricant, and Engine Concerns Relative to the IMO 2020 Fuel Oil Sulfur Reduction Mandate; Report number ORNL/SPR-2019/1406; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2019; pp. 10–22. [Google Scholar]

- Saleh, T.A. Characterization, determination and elimination technologies for sulfur from petroleum: Toward cleaner fuel and a safe environment. Trends Environ. Anal. Chem. 2020, 25, e00080. [Google Scholar] [CrossRef]

- Chinese Petroleum Corporation. Test Report of Super-low Sulfur Diesel; Chinese Petroleum Corporation: Kaohsiung, Taiwan, 2021. [Google Scholar]

- Kayfeci, M.; Keçebaş, A.; Bayat, M. Hydrogen production. In Solar Hydrogen Production; Academic Press: Cambridge, MA, USA, 2019; pp. 45–83. [Google Scholar]

- Zhang, F.; Zhao, P.; Niu, M.; Maddy, J. The survey of key technologies in hydrogen energy storage. Int. J. Hydrogen Energy 2016, 41, 14535–14552. [Google Scholar] [CrossRef]

- Chen, W.; Gao, R.; Sun, J.; Lei, Y.; Fan, X. Modeling of an isolated liquid hydrogen droplet evaporation and combustion. Cryogenics 2018, 96, 151–158. [Google Scholar] [CrossRef]

- Pratt, J.W.; Klebanoff, L.E. Feasibility of the SF-Breeze: A Zero-Emission, Hydrogen Fuel Cell, High-Speed Passenger Ferry; Report number SAND2016-9719; Sandia National Laboratories: Livermore, CA, USA, 2016; pp. 41–69. [Google Scholar]

- Kierczynski, O.K.; Towers, J.A.; Jankowski, K.A. Evaluation of a Large Zero-Emission High-Speed Passenger Vessel. In Proceedings of the SNAME International Conference on Fast Sea Transportation, Providence, RI, USA, 26–27 October 2021. [Google Scholar]

- DNV AS. Handbook for Hydrogen-Fuelled Vessels. Available online: https://www.iims.org.uk/wp-content/uploads/2021/07/Handbook_for_hydrogen-fuelled_vessels.pdf (accessed on 12 December 2021).

- Ching Fu Shipbuiding Corporation Ltd. Particulars of the 7000M3 Hopper Suction Dredger; Ching Fu Shipbuiding Corporation Ltd.: Kaohsiung, Taiwan, 2012. [Google Scholar]

- Beijing Avespeed Commercial & Trading Corporation Ltd. Made-in-China Connecting Buyers with Chinese Suppliers. Available online: https://m.made-in-china.com/product/600kw-1350rpm-Convenient-Operation-Marine-Diesel-Engine-for-Tugboats-689959132.html (accessed on 8 October 2021).

- Qingdao Kaineng Environmental Protection Technology Corporation Ltd. Made-in-China Connecting Buyers with Chinese Suppliers. Available online: https://knboiler.en.made-in-china.com/product/VXJEWhkPgspL/China-Lzy-Vertical-Thread-Tube-Oil-Fired-Exhaust-Gas-Marine-Composite-Boiler.html (accessed on 27 September 2021).

- Xiao, Y.; Wang, G.; Lin, K.-C.; Qi, G.; Li, K.X. The effectiveness of the new inspection regime for port state control: Application of the Tokyo MoU. Mar. Policy 2020, 115, 103857. [Google Scholar] [CrossRef]

- Knoema Corporation. Crude Oil Price Forecast; Knoema Corporation: New York, NY, USA, 2022; Available online: https://knoema.com/infographics/yxptpab/crude-oil-price-forecast-2021-2022-and-long-term-to-2050 (accessed on 20 September 2021).

- Chinese Petroleum Corporation. Super-low Sulfur Diesel Fuel Price; Chinese Petroleum Corporation: Kaohsiung, Taiwan; Available online: https://www.cpc.com.tw/ (accessed on 20 September 2021).

- Ship & Bunker World Bunker Prices. Available online: https://shipandbunker.com/ (accessed on 20 September 2021).

- Ching Fu Shipbuiding Corporation Ltd. Drawing of Initial Calculation of Machinery for 7000M3 Hopper Suction Dredger; Ching Fu Shipbuiding Corporation Ltd.: Kaohsiung, Taiwan, 2010. [Google Scholar]

- Marbun, H.F.L. Wages of Seafarers: Legal Rights, Protections, and Remedies under the Perspectives of International Conventions. Master’s Thesis, University of Oslo, Oslo, Norway, March 2019. [Google Scholar]

- Aguda, O.O. Maritime labour convention 2006: Implications for seafarers after a decade. Nnamdi Azikiwe Univ. J. Int. Law Jurisprud. 2017, 8, 125–134. [Google Scholar]

- National Chinese Seamen’s Union. News and Events. Available online: http://www.ncsu.org.tw/news_1.php?id=1147 (accessed on 20 August 2021).

- Budak, Y.; Devrim, Y. Investigation of micro-combined heat and power application of PEM fuel cell systems. Energy Convers. Manag. 2018, 160, 486–494. [Google Scholar] [CrossRef]

- Durmaz, M.; Kalender, S.S.; Ergin, S. Experimental study on the effects of ultra-low sulfur diesel fuel to the exhaust emissions of a ferry. Fresenius Environ. Bull. 2017, 26, 5833–5840. [Google Scholar]

- Ji, C.; El-Halwagi, M.M. A data-driven study of IMO compliant fuel emissions with consideration of black carbon aerosols. Ocean Eng. 2020, 218, 108241. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, J.; Wang, W.; Peng, Y.; Wu, X.; Feng, X. Inland port vessel emissions inventory based on Ship Traffic Emission Assessment Model- Automatic Identification System. Adv. Mech. Eng. 2017, 9, 1687814017712878. [Google Scholar] [CrossRef]

- Zhang, Q.; Fan, J.; Yang, W.; Ying, F.; Bao, Z.; Sheng, Y.; Lin, C.; Chen, X. Influences of accumulated mileage and techno-logical changes on emissions of regulated pollutants from gasoline passenger vehicles. J. Environ. Sci. 2018, 71, 197–206. [Google Scholar] [CrossRef]

- California Air Resources Board. Appendix B: Emissions Estimation Methodology for Commercial Harbor Craft Operating in California. 2012. Available online: https://ww3.arb.ca.gov/msei/chc-appendix-b-emission-estimates-ver02-27-2012.pdf (accessed on 15 October 2021).

- Al-Ghussain, L. Global warming: Review on driving forces and mitigation. Environ. Prog. Sustain. Energy 2019, 38, 13–21. [Google Scholar] [CrossRef] [Green Version]

| Strategy | Description |

|---|---|

| ULSD | Replacing VLSFO with ULSD (S ≤ 10 ppm) |

| PEMFC | Using a PEMFC as an alternative power source to VLSFO |

| Cost Item | Strategy | |

|---|---|---|

| ULSD | PEMFC | |

| CAPEX | 1. Boiler’s incremental cost. | 1. Incremental cost of the fuel cell; |

| 2. Incremental cost of the refueling equipment; | ||

| 3. Incremental cost of the storage equipment for liquid hydrogen; | ||

| 4. Incremental cost of the boiler. | ||

| OPEX | 1. Incremental cost of ULSD; | 1. Incremental cost of liquid hydrogen fuel; |

| 2. Incremental cost of maintenance and repair. | 2. Incremental cost of the crew’s payroll; | |

| 3. Incremental cost of maintenance and repair. | ||

| Pipe and Manifold | Permit and License Fee | On-Site Storage Tank |

|---|---|---|

| 770,000 | 200,000 | 625,000 |

| LH2 | ULSD | |

|---|---|---|

| Total | 1,595,000 | 338,000 |

| Fuel Type | SOx | NOx | CO2 | HC | PM |

|---|---|---|---|---|---|

| VLSFO (S < 0.5 wt. %) | 0.51 | 13.54 | 533 | 0.5 | 0.2 |

| ULSD (S ≤ 10 ppm) | 0.1 | 11.91 | 611.14 | 0.62 | 0.07 |

| PEMFC | 0 | 0.34 | 98 | 0.02 | 0.03 |

| Year | Boiler Cost | Refueling Equipment Cost | FPVLFSO | M&RICVLFSO | PCVLFSO | Engine Cost | Total Cost |

|---|---|---|---|---|---|---|---|

| 1st | 1.85 | 61.45 | 3296.44 | 228.23 | 1390.18 | 89.23 | 5067.38 |

| 2nd | 1.69 | 55.31 | 3172.15 | 228.23 | 1390.18 | 81.79 | 4929.36 |

| 3rd | 1.54 | 49.16 | 3104.74 | 228.23 | 1390.18 | 74.36 | 4848.21 |

| 4th | 1.38 | 43.02 | 3073.08 | 228.23 | 1390.18 | 66.92 | 4802.81 |

| 5th | 1.23 | 36.87 | 3062.53 | 228.23 | 1390.18 | 59.49 | 4778.53 |

| Total | - | - | - | - | - | - | 24,426.28 |

| Year | CAPEX | OPEX | TICULSD | ||

|---|---|---|---|---|---|

| BoilerC | FICULSD | M&RICULSD | PCULSD | ||

| 1st | −1.85 | 1055.15 | −456.45 | −180.72 | 416.13 |

| 2nd | −1.69 | 1015.37 | −456.45 | −180.72 | 376.51 |

| 3rd | −1.54 | 993.79 | −456.45 | −180.72 | 355.08 |

| 4th | −1.38 | 983.66 | −456.45 | −180.72 | 345.11 |

| 5th | −1.23 | 980.28 | −456.45 | −180.72 | 341.88 |

| Total | - | - | - | - | 1834.71 |

| Year | CAPEX | OPEX | TICPEMFC | |||||

|---|---|---|---|---|---|---|---|---|

| FCC | Refuel | Storage | BoilerC | FICPEMFC | M&RICPEMFC | PCPEMFC | ||

| 1st | 1203.86 | 228.55 | 1384.53 | −1.85 | 421.91 | −451.66 | 305.84 | 3091.18 |

| 2nd | 1081.06 | 205.69 | 1246.07 | −1.69 | 406.00 | −451.66 | 305.84 | 2791.31 |

| 3rd | 958.26 | 182.84 | 1107.62 | −1.54 | 397.37 | −451.66 | 305.84 | 2498.73 |

| 4th | 835.45 | 159.98 | 969.17 | −1.38 | 393.32 | −451.66 | 305.84 | 2210.72 |

| 5th | 712.65 | 137.13 | 830.72 | −1.23 | 391.97 | −451.66 | 305.84 | 1925.41 |

| Total | - | - | - | - | - | - | - | 12,517.34 |

| Pollutant | EFVLSFO (g/kWh) | EFULSD (g/kWh) | EmissionVLSFO (Tonnes) | EmissionULSD (Tonnes) | Emission Reduction (Tonnes) | Total Pollutant Emission Reduction (Tonnes) |

|---|---|---|---|---|---|---|

| SOx | 0.51 | 0.1 | 16.47 | 3.23 | 13.24 | 65.93 |

| NOx | 13.54 | 11.91 | 436.62 | 384.06 | 52.56 | - |

| HC | 0.5 | 0.62 | 16.48 | 20.44 | −3.95 | - |

| PM | 0.2 | 0.07 | 6.74 | 2.66 | 4.07 | - |

| Pollutant | EFVLSFO (g/kWh) | EFPEMFC (g/kWh) | EmissionVLSFO (Tonnes) | EmissionPEMFC (Tonnes) | Emission Reduction (Tonnes) | Total Pollutant Emission Reduction (Tonnes) |

|---|---|---|---|---|---|---|

| SOx | 0.51 | 0.0 | 16.47 | 0 | 16.47 | 463.07 |

| NOx | 13.54 | 0.34 | 436.62 | 11.09 | 425.53 | - |

| HC | 0.5 | 0.02 | 16.48 | 0.88 | 15.60 | - |

| PM | 0.2 | 0.03 | 6.74 | 1.28 | 5.45 | - |

| Strategy | Year of Implementation | ||||

|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | 5th | |

| ULSD | 65.93 | 67.43 | 68.987 | 70.57 | 72.21 |

| PEMFC | 463.07 | 473.44 | 484.06 | 494.94 | 506.08 |

| Pollutant | Power Source | Total Emission over Five Years | Total Pollutant Emission Reduction over Five Years | Total Pollutant Emission Reduction Rate over Five Years (%) |

|---|---|---|---|---|

| SOx | VLSFO | 86.27 | - | - |

| ULSD | 16.91 | 69.35 | 80.3 | |

| PEMFC | 0.00 | 86.27 | 100 | |

| NOx | VLSFO | 2276.77 | - | - |

| ULSD | 2002.69 | 274.08 | 12 | |

| PEMFC | 57.84 | 2218.93 | 97.4 | |

| HC | VLSFO | 90.01 | - | - |

| ULSD | 111.61 | −21.60 | −24 | |

| PEMFC | 7.32 | 82.69 | 91.8 | |

| PM | VLSFO | 38.529 | - | - |

| ULSD | 15.219 | 23.310 | 60.5 | |

| PEMFC | 7.320 | 31.208 | 81 |

| Strategy | Year the Strategy Was Implemented | ||||

|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | 5th | |

| ULSD | −2468 | −2530 | −2593 | −2658 | −2724 |

| PEMFC | 13,739 | 14,083 | 14,435 | 14,795 | 15,165 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Lin, C.-Y. Promising Strategies for the Reduction of Pollutant Emissions from Working Vessels in Offshore Wind Farms: The Example of Taiwan. J. Mar. Sci. Eng. 2022, 10, 621. https://doi.org/10.3390/jmse10050621

Yang H, Lin C-Y. Promising Strategies for the Reduction of Pollutant Emissions from Working Vessels in Offshore Wind Farms: The Example of Taiwan. Journal of Marine Science and Engineering. 2022; 10(5):621. https://doi.org/10.3390/jmse10050621

Chicago/Turabian StyleYang, Hsuan, and Cherng-Yuan Lin. 2022. "Promising Strategies for the Reduction of Pollutant Emissions from Working Vessels in Offshore Wind Farms: The Example of Taiwan" Journal of Marine Science and Engineering 10, no. 5: 621. https://doi.org/10.3390/jmse10050621

APA StyleYang, H., & Lin, C.-Y. (2022). Promising Strategies for the Reduction of Pollutant Emissions from Working Vessels in Offshore Wind Farms: The Example of Taiwan. Journal of Marine Science and Engineering, 10(5), 621. https://doi.org/10.3390/jmse10050621