Study on Distribution Law of Gas Phase and Cavitation in the Pressurization Unit of Helical Axial Flow Multiphase Pump

Abstract

1. Introduction

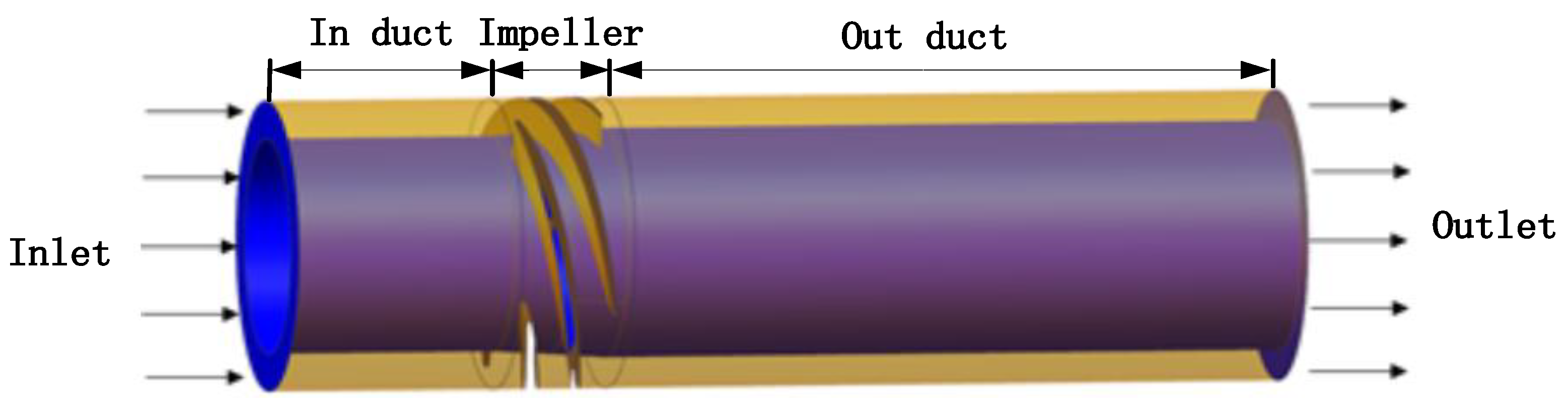

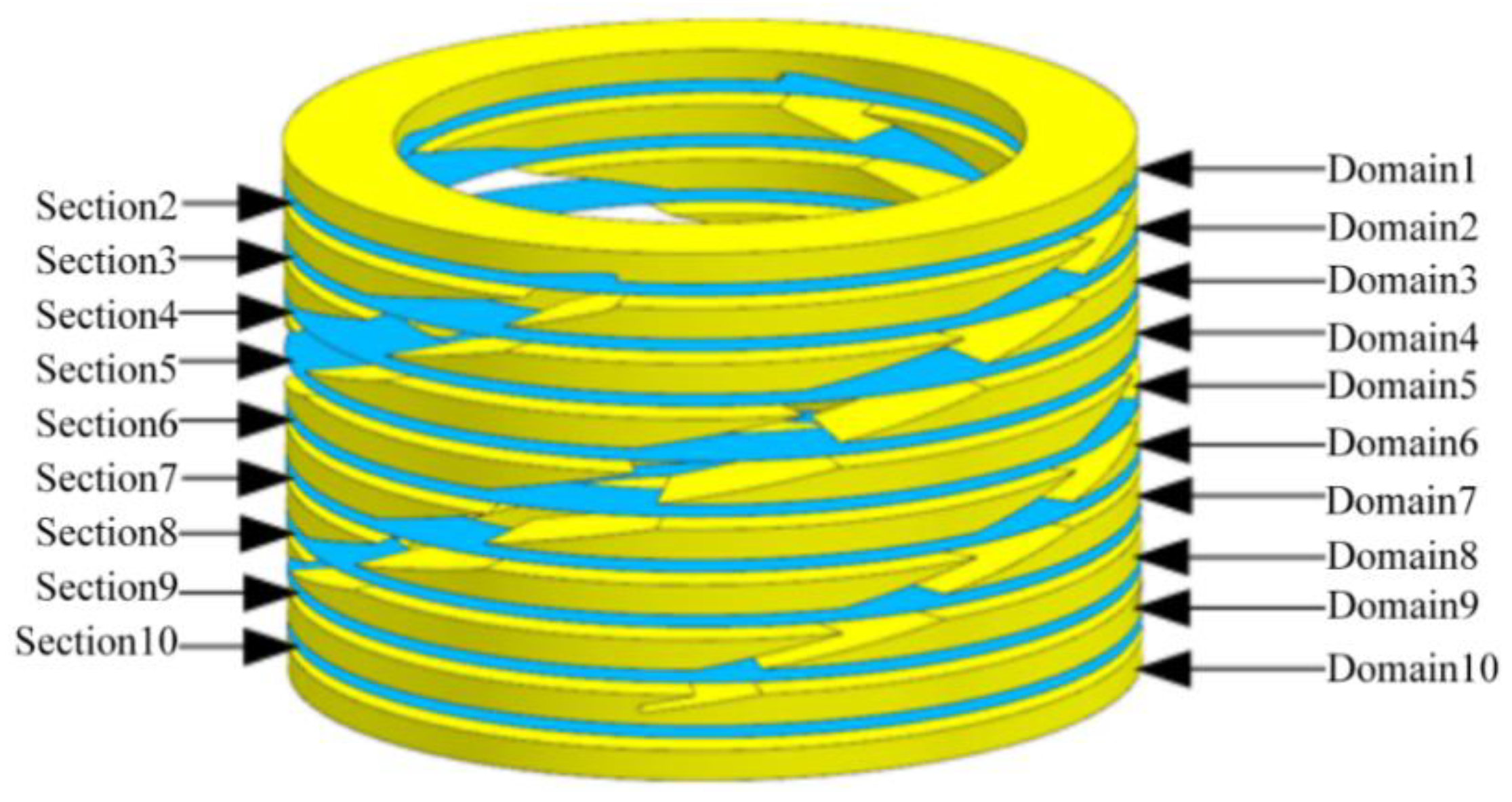

2. Introduction of the Multiphase Pump Model

3. Fundamental Equation

3.1. The Governing Equation

- 1.

- The mass conservation equation

- 2.

- The momentum conservation equation

- 3.

- The energy conservation equation

3.2. The Cavitation Model

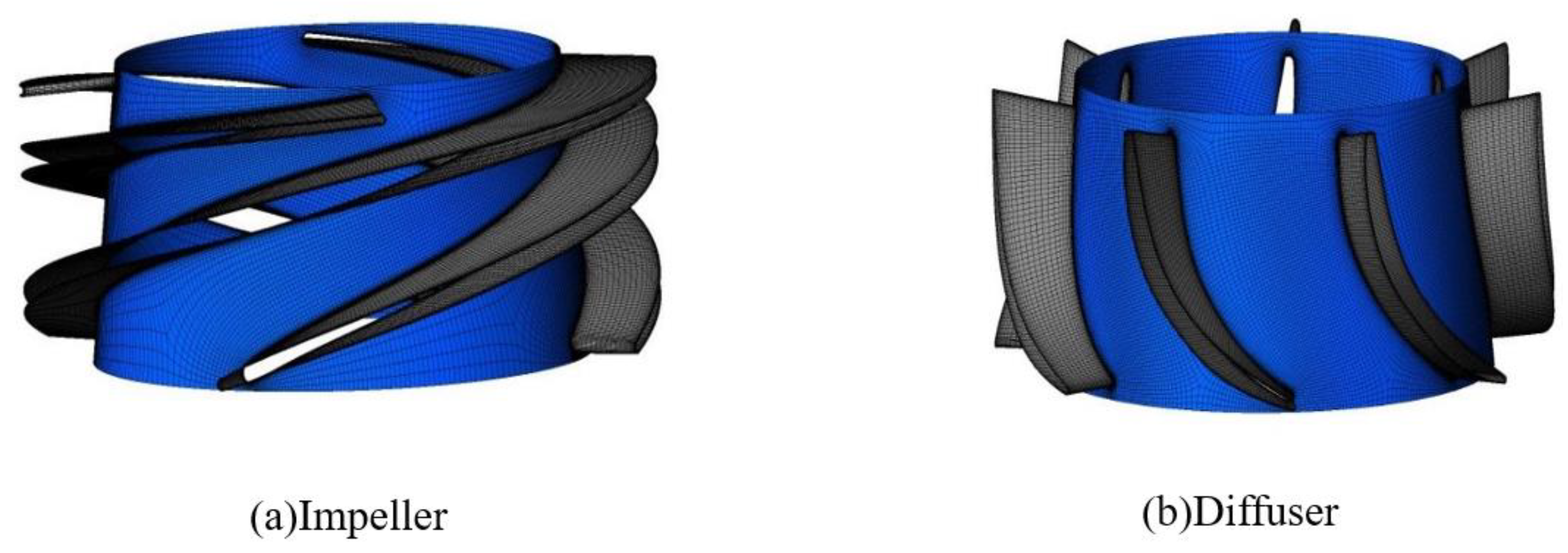

4. Mesh Partitioning and Independent Verification

4.1. The Mesh Generation

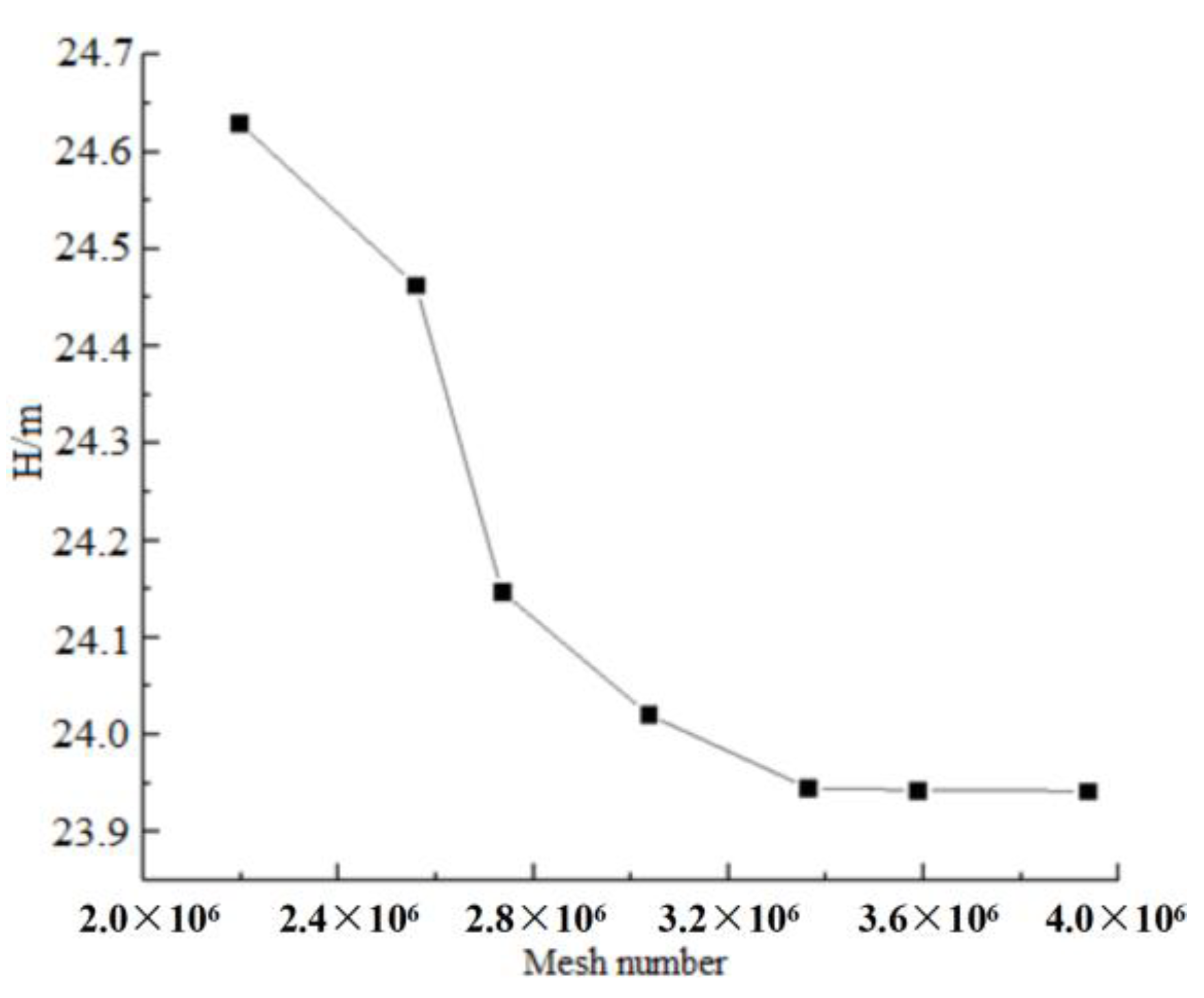

4.2. Mesh Independence Validation

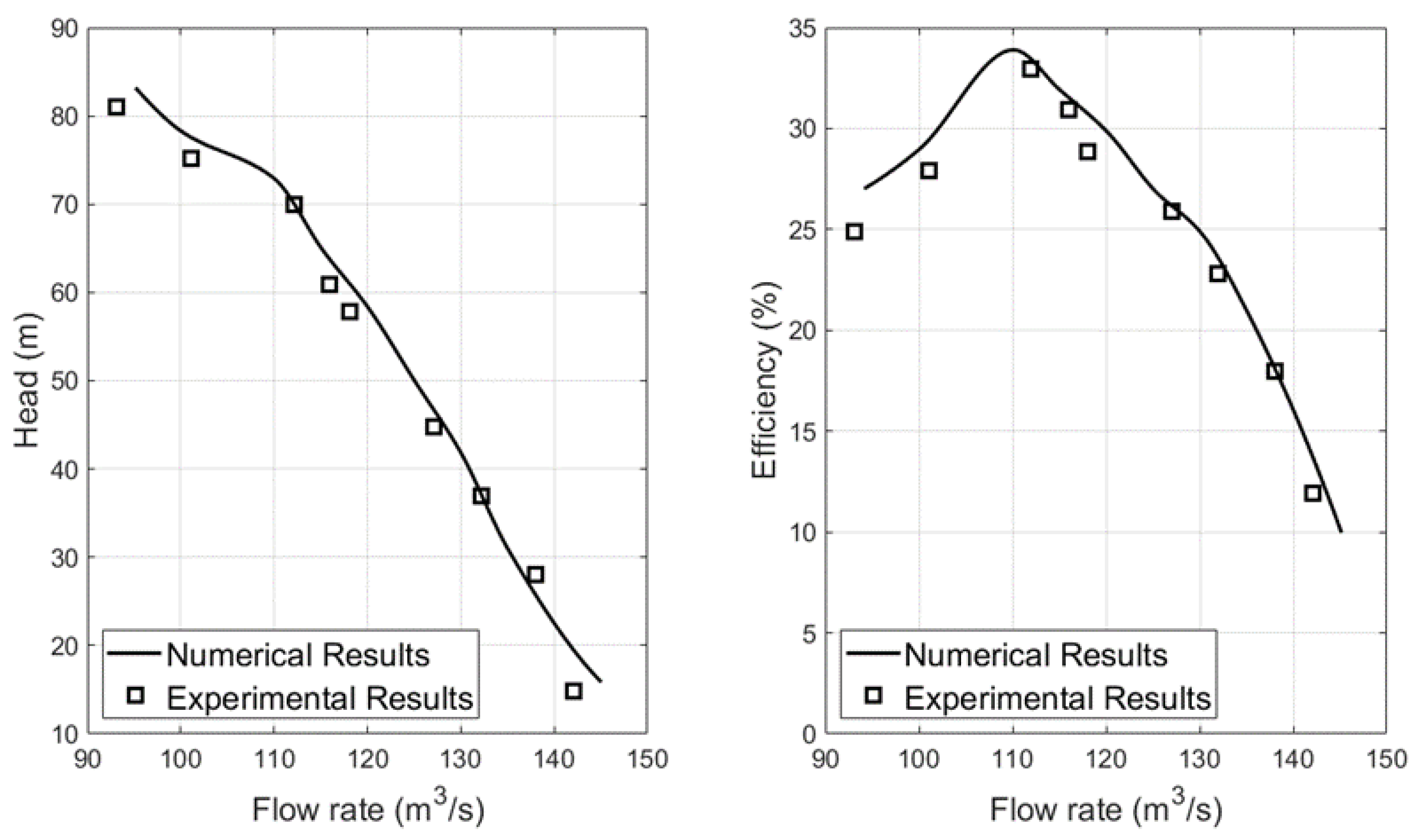

5. Experimental Verification

6. Results Analysis

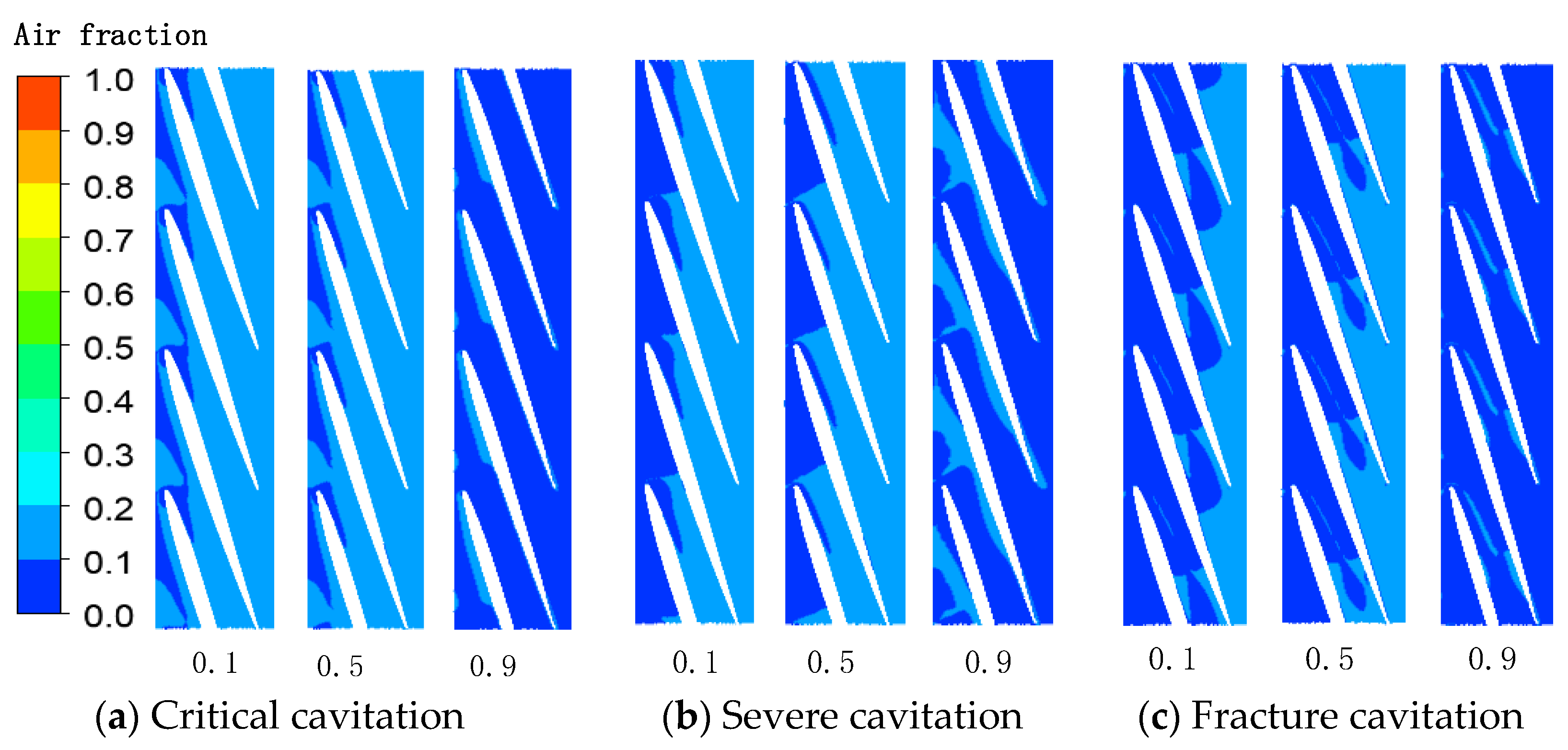

6.1. Distribution of Gas Phase in Impeller Passage at Different Spans

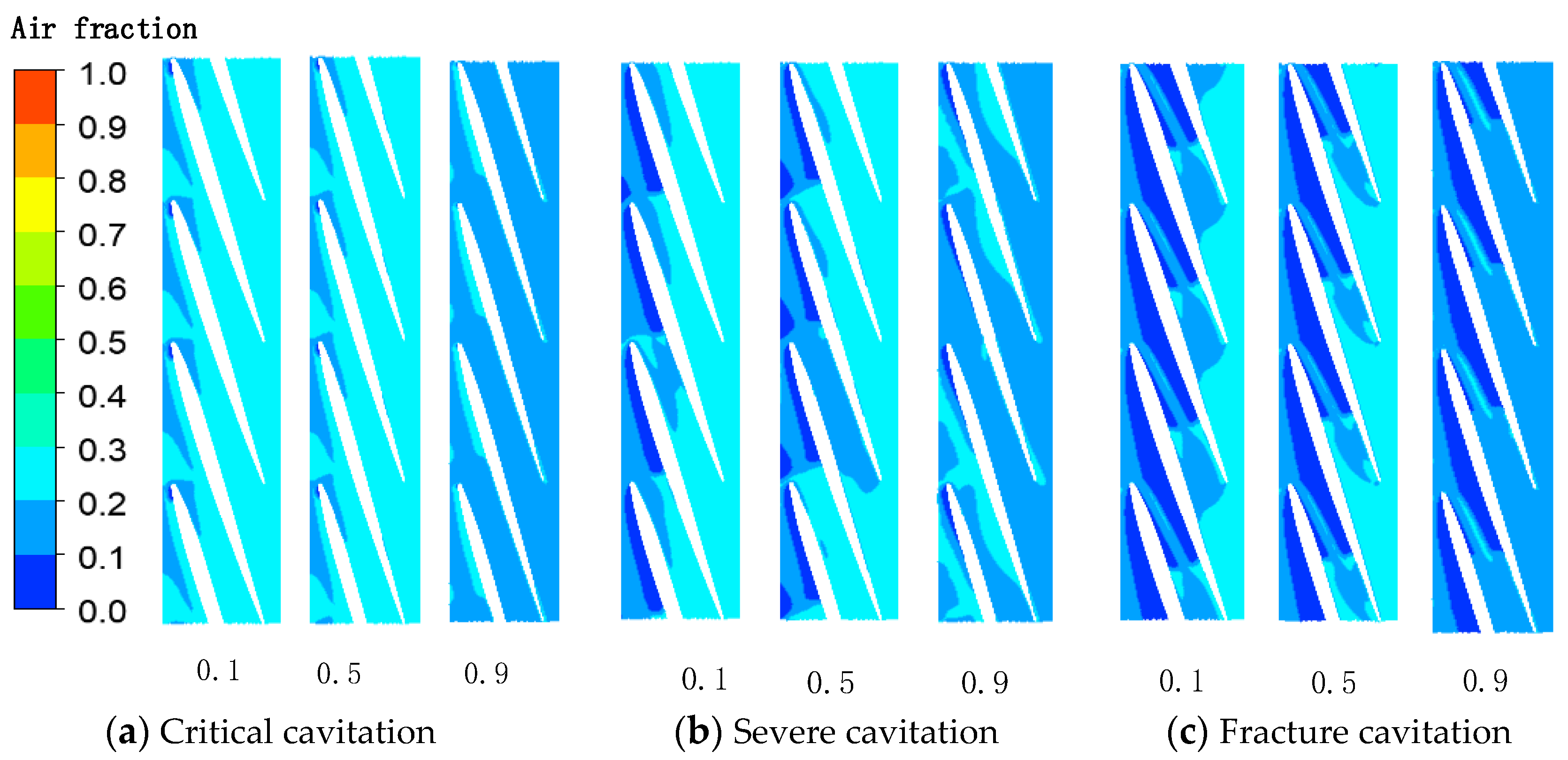

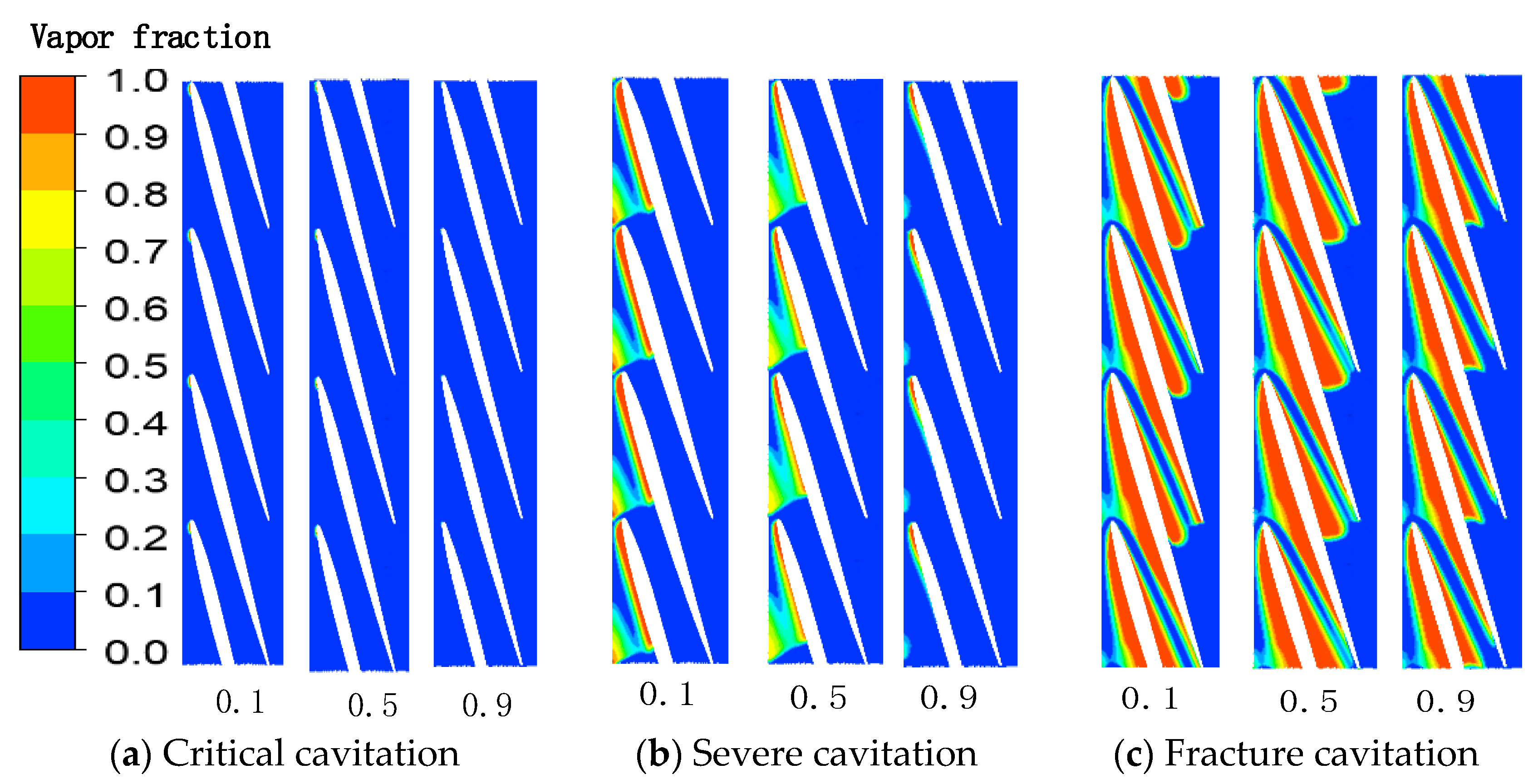

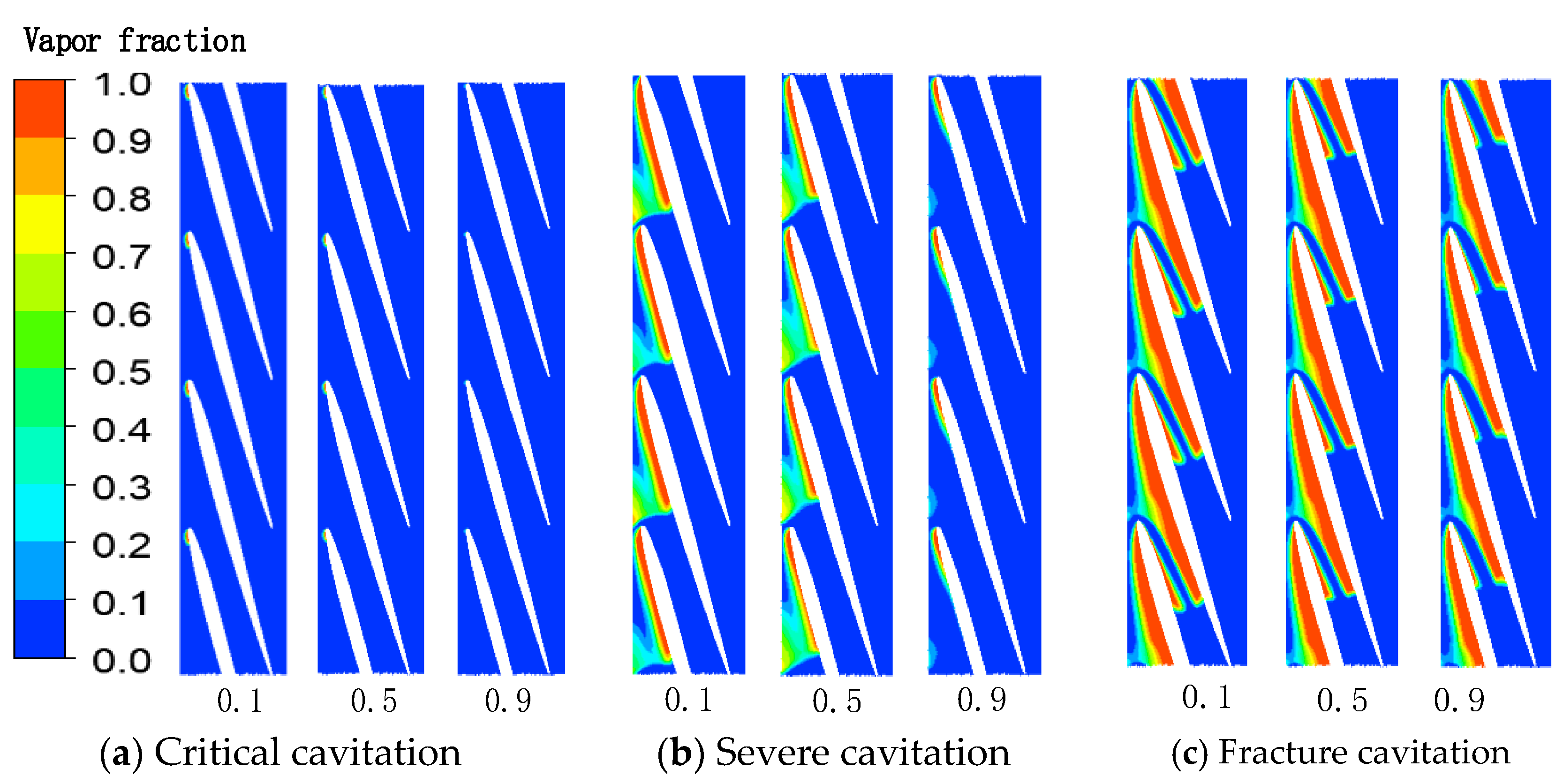

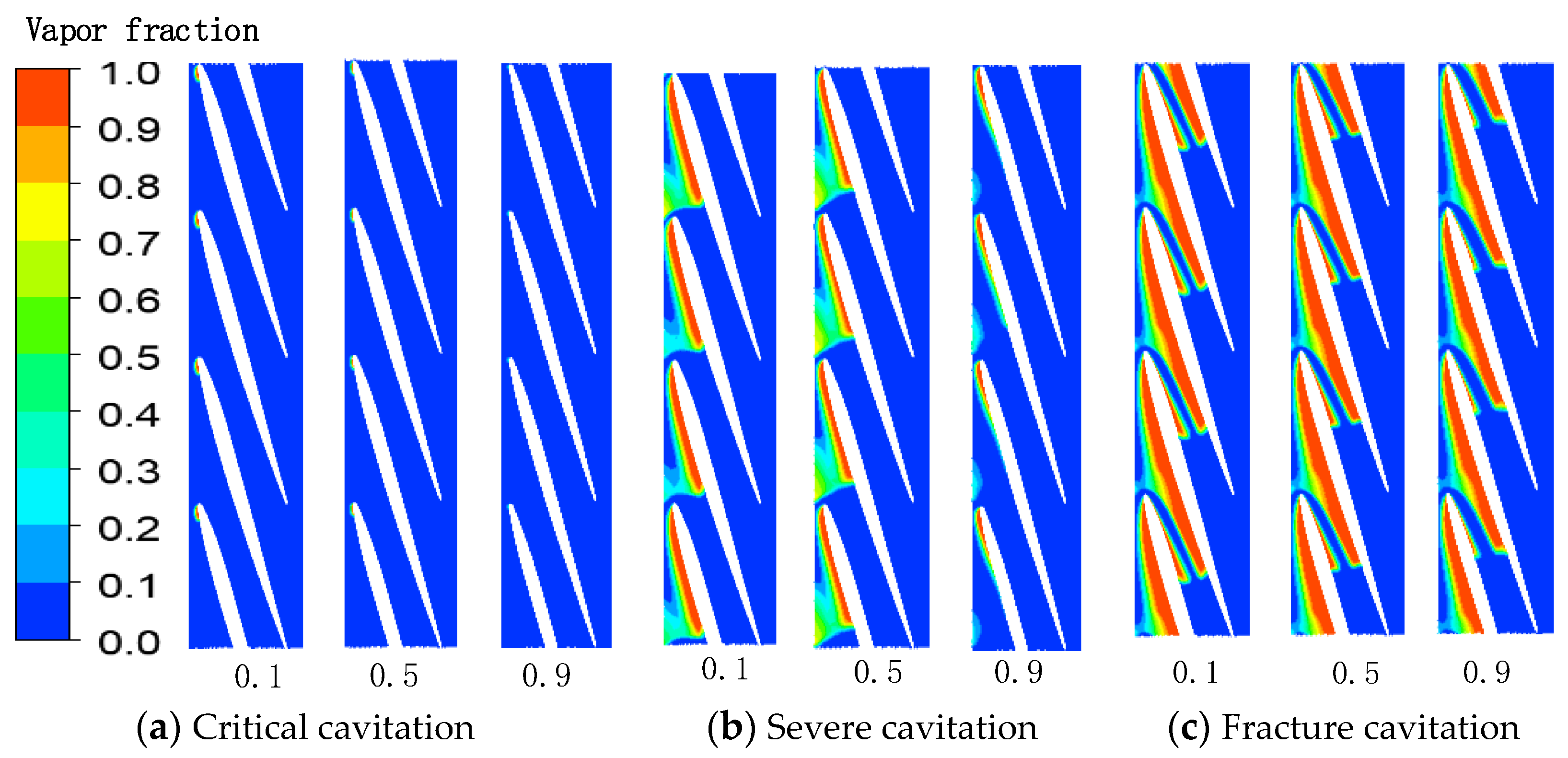

6.2. Cavitation Distribution in Impeller Passage at Different Blade Heights

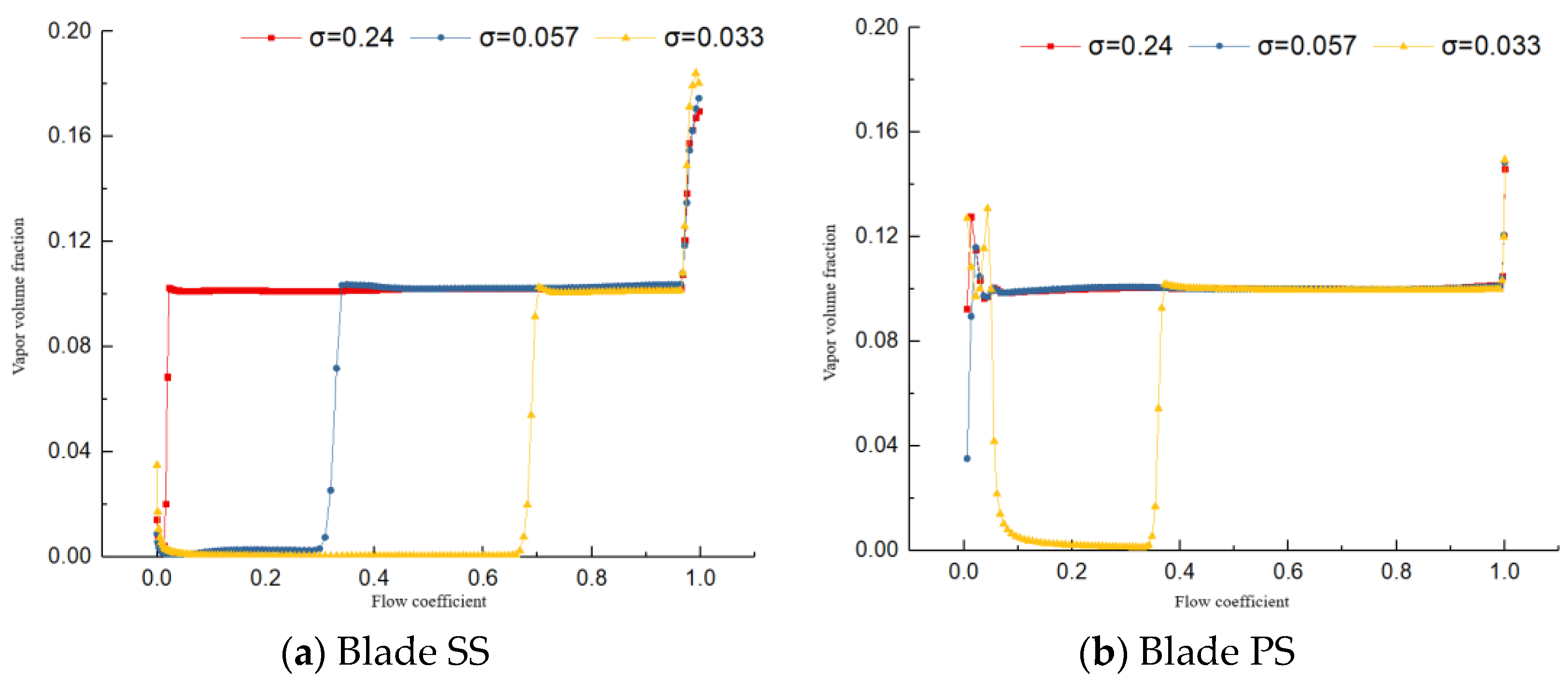

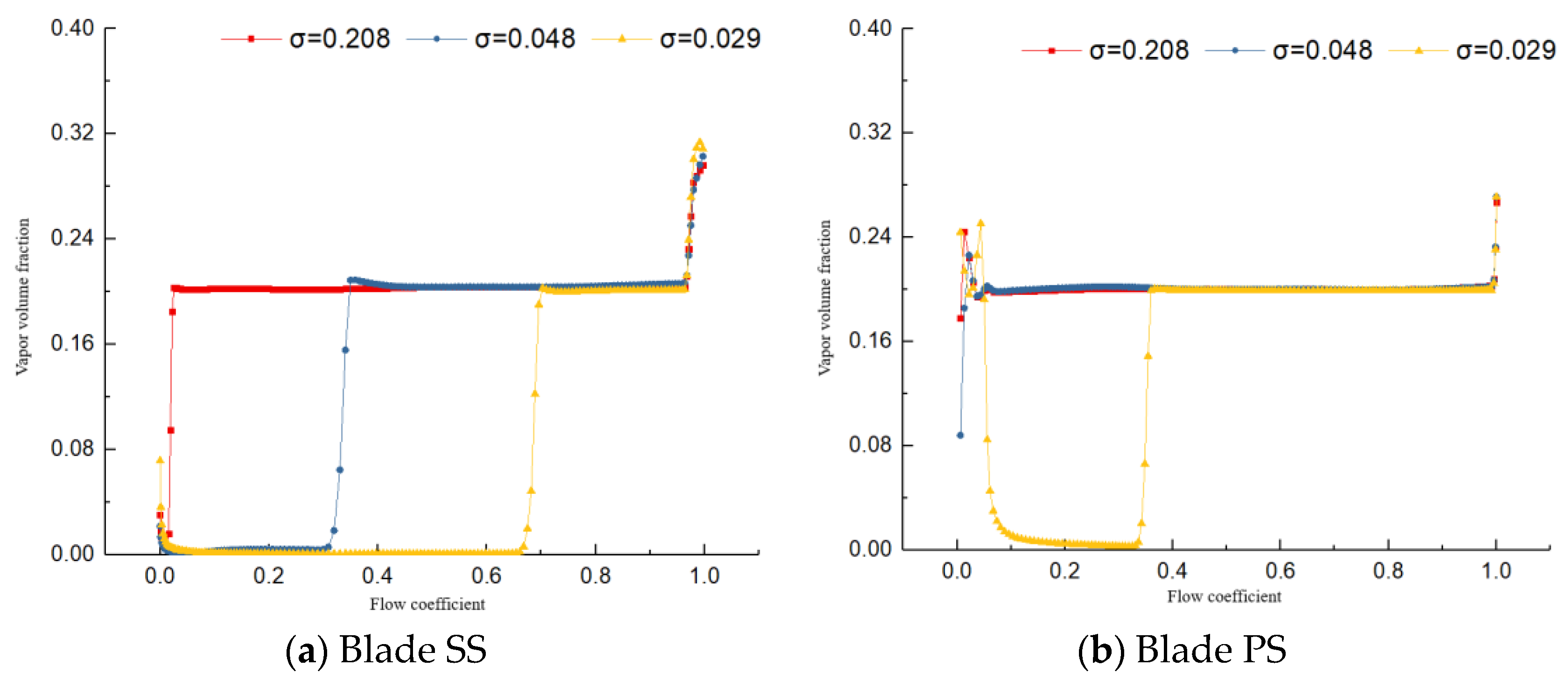

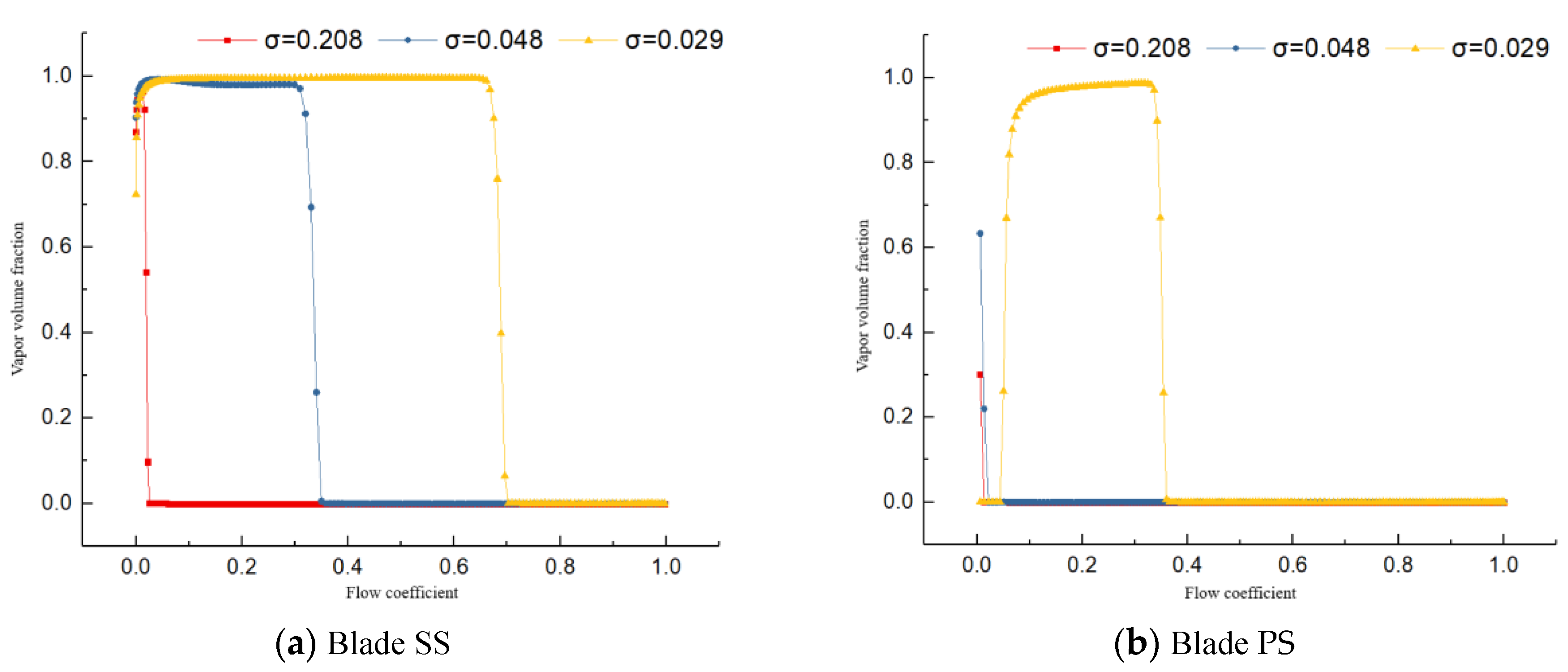

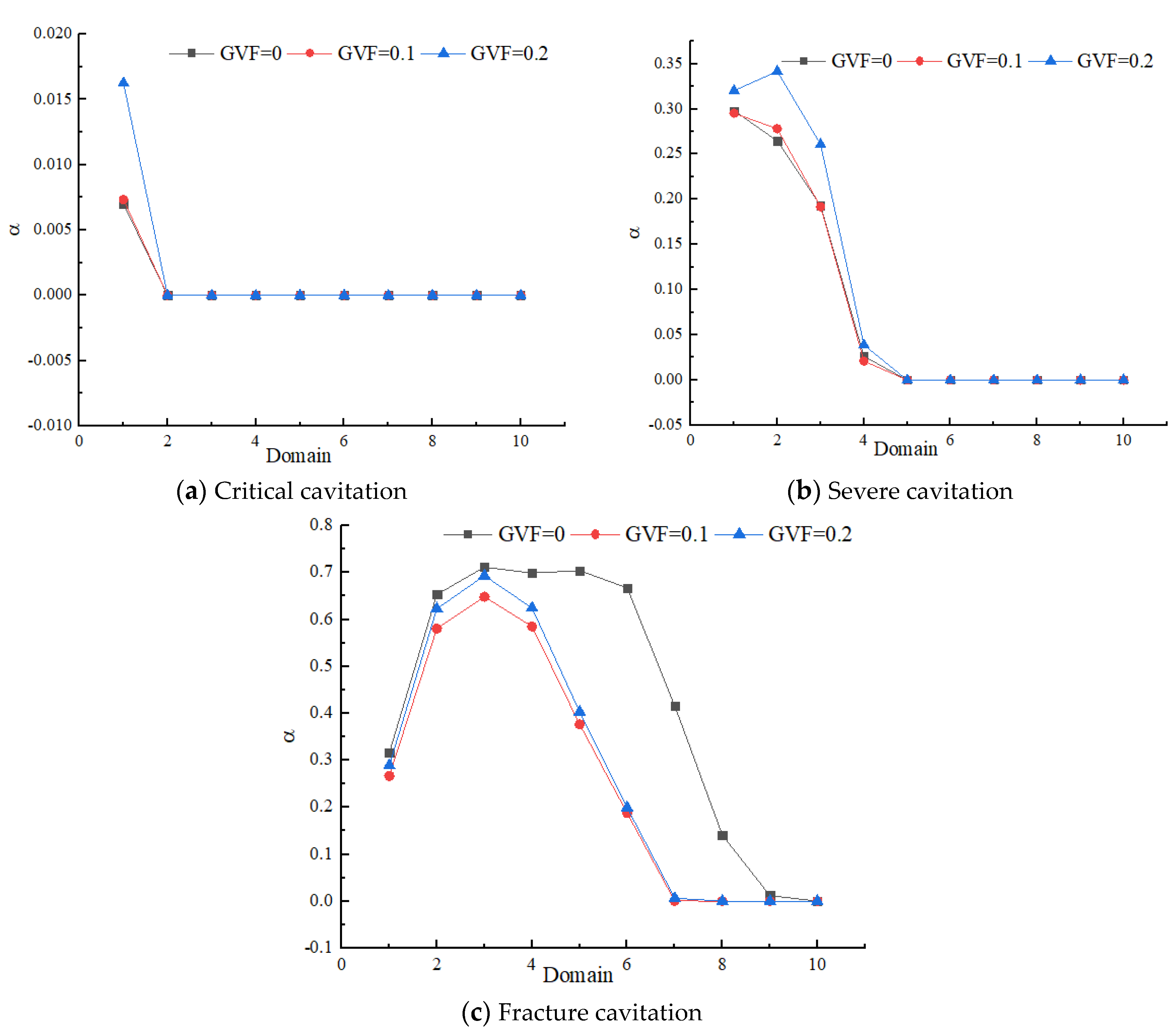

6.3. Influence of GVF on the Volume Fraction of Cavitation in Impeller Fluid Domain

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Barbosa, Y.M.; da Silva, J.A.M.; de Junior, S.O.; Torres, E.A. Deep seawater as efficiency improver for cogeneration plants of petroleum production units. Energy 2019, 177, 29–43. [Google Scholar] [CrossRef]

- Viet, N.; Xie, X.; Liew, K.; Banthia, N.; Walng, Q. Energy harvesting from ocean waves by a floating energy harvester. Energy 2016, 112, 1219–1226. [Google Scholar] [CrossRef]

- Stuart, S. Multiphase pumping addressed a wide range of operating problems. Oil Gas J. 2009, 101, 59–71. [Google Scholar]

- Kim, J.H.; Lee, H.C.; Kim, J.H.; Choi, Y.S.; Yoon, J.Y.; Yoo, I.S.; Choi, W.C. Improvement of hydrodynamic performance of a multiphase pump using design of experiment techniques. J. Fluids Eng. 2015, 137, 081301. [Google Scholar] [CrossRef]

- Xiao, W.; Tan, L. Design method of controllable velocity moment and optimization of pressure fluctuation suppression for a multiphase pump. Ocean Eng. 2020, 220, 108402. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Cao, S. Method of dynamic mode decomposition and reconstruction with application to a three-stage multiphase pump. Energy 2020, 208, 118344. [Google Scholar] [CrossRef]

- Shi, Y.; Zhu, H. Proposal of a stage-by-stage design method and its application on a multi-stage multiphase pump based on numerical simulations. Adv. Mech. Eng. 2021, 13, 1687814020987317. [Google Scholar] [CrossRef]

- Suh, J.; Kim, J.; Choi, Y.; Zhang, J.; Zhao, J. Experiment and numerical study of a new generation three-stage multiphase pump. J. Pet. Sci. Eng. 2018, 169, 471–484. [Google Scholar]

- Suh, J.; Kim, J.; Choi, Y.; Kim, J.; Joo, W.; Lee, K. Development of numerical Eulerian-Eulerian models for simulating multiphase pumps. J. Pet. Sci. Eng. 2018, 162, 588–601. [Google Scholar] [CrossRef]

- Meerakaviyad, D.; Keville, T.; Prakash, A.; Sajid, A.; Hamad, F. Recent progress in multiphase flow simulation through multiphase pumps. Heat Transf. 2020, 49, 2849–2867. [Google Scholar] [CrossRef]

- Yu, Y. Analysis of the Model Selection and Application of Oil-gas Multiphase pump. Mod. Chem. Res. 2016, 12, 27–28. [Google Scholar]

- Han, W.; Yuan, S.-f.; Quan, H. Analysis on mixed transport characteristics of oil-gas pump. J. Lanzhou Univ. Technol. 2021, 47, 41–46. [Google Scholar]

- Liu, M.; Tan, L.; Cao, S. Influence of viscosity on energy performance and flow field of a multiphase pump. Renew. Energy 2020, 162, 1151–1160. [Google Scholar] [CrossRef]

- Shi, G.; Liu, Z.; Xiao, Y.; Li, H.; Liu, X. Tip leakage vortex trajectory and dynamics in a multiphase pump at off-design condition. Renew. Energy 2020, 150, 703–711. [Google Scholar] [CrossRef]

- Ge, Q. Influence of Different Blade Thickening Method on the Performance of Oil-gas Multiphase Pump. Chin. Hydraul. Pneum. 2020, 158–161. [Google Scholar]

- Sano, T.; Wakai, T.; Reclari, M.; Xu, Y.; Cao, S.L. Investigation of internal flow pattern of a multiphase axial pump. IOP Conf. Ser. Earth Environ. Sci. 2019, 240, 062058. [Google Scholar] [CrossRef]

- Wang, Q.; Shi, G.; Liu, Z.; Wang, Y. Effect of Flow Rate on Gas Distribution on the First-Stage Impeller of Multiphase Pump. China Pet. Mach. 2021, 49, 75–80. [Google Scholar]

- Zhang, J.; Tan, L. Energy Performance and Pressure Fluctuation of a Multiphase Pump with Different Gas Volume Fractions. Energies 2018, 11, 1216. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, S.; Hongwu, Z.; Zhang, Y. Experimental investigation of the flow at the entrance of a rotodynamic multiphase pump by visualization. J. Pet. Sci. Eng. 2015, 126, 254–261. [Google Scholar] [CrossRef]

- Shi, G.; Liu, Z.; Xiao, Y.; Wang, Z.; Luo, Y.; Luo, K. Energy conversion characteristics of multiphase pump impeller analyzed based on blade load spectra. Renew. Energy 2020, 157, 9–23. [Google Scholar] [CrossRef]

- Shi, J.; Tao, S.; Shi, G.; Song, W. Effect of Gas Volume Fraction on the Energy Loss Characteristics of Multiphase Pumps at Each Cavitation Stage. Water 2021, 13, 2293. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, S.; Li, Y.; Zhu, H.; Zhang, Y. Visualization study of gas–liquid two-phase flow patterns inside a three-stage rotodynamic multiphase pump. Exp. Therm. Fluid Sci. 2016, 70, 125–138. [Google Scholar] [CrossRef]

- Patil, A.; Gudigopuram, S.; Ayyildiz, B.; Delgado, A.; Morrison, G. Performance Evaluation and Dimensional Analysis of Multistage Helico-axial Pump for Two-Phase Flow. Int. J. Turbomach. Propuls. Power 2019, 4, 22. [Google Scholar] [CrossRef]

- Xu, Y.; Cao, S.; Sano, T.; Wakai, T.; Reclari, M. Experimental Investigation on Transient Pressure Characteristics in a Helico-Axial Multiphase Pump. Energies 2019, 12, 461. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Cai, S.J.; Zhu, H.; Yang, K.; Qiang, R. Numerical Investigation of Compessible Flow in a Three-stage Helico-axial Multiphase Pump. Trans. Chin. Soc. Agric. Mach. 2014, 45, 89–95. [Google Scholar]

- Zheng, X.; Liu, L.; Guo, P.; Hong, F. Numerical investigation of three-dimensional cavitating performance of NACA66 hydrofoil base on different cavitation models. Chin. J. Hydrodyn. 2018, 33, 199–206. [Google Scholar]

- Leroux, J.; Astolfi, J.; Billard, J. An experimental study of unsteady partial cavitation. J. Fluids Eng. 2004, 126, 94–101. [Google Scholar] [CrossRef]

- Liu, X.; Hu, Q.; Shi, G.; Zhao, Q. Cavitation characteristic of multiphase pump at low flow rate. J. Drain. Irrig. Mach. Eng. 2018, 36, 15–20. [Google Scholar]

| Parameters | Symbol | Value | Unit |

|---|---|---|---|

| Design flow rate | Qd | 110 | m3/h |

| Design speed | N | 3000 | rpm |

| Inlet hub ratio | 0.79 | (-) | |

| Outlet hub ratio | 0.74 | (-) | |

| Impeller diameter | D | 230.5 | mm |

| Blade number | Z | 4 | (-) |

| Blade wrap angle | 179.6 | ° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Gui, Z.; Li, X.; Tao, S.; Shi, G.; Gu, C. Study on Distribution Law of Gas Phase and Cavitation in the Pressurization Unit of Helical Axial Flow Multiphase Pump. J. Mar. Sci. Eng. 2022, 10, 1795. https://doi.org/10.3390/jmse10111795

Xiao Y, Gui Z, Li X, Tao S, Shi G, Gu C. Study on Distribution Law of Gas Phase and Cavitation in the Pressurization Unit of Helical Axial Flow Multiphase Pump. Journal of Marine Science and Engineering. 2022; 10(11):1795. https://doi.org/10.3390/jmse10111795

Chicago/Turabian StyleXiao, Yexiang, Zhonghua Gui, Xuesong Li, Sijia Tao, Guangtai Shi, and Chunwei Gu. 2022. "Study on Distribution Law of Gas Phase and Cavitation in the Pressurization Unit of Helical Axial Flow Multiphase Pump" Journal of Marine Science and Engineering 10, no. 11: 1795. https://doi.org/10.3390/jmse10111795

APA StyleXiao, Y., Gui, Z., Li, X., Tao, S., Shi, G., & Gu, C. (2022). Study on Distribution Law of Gas Phase and Cavitation in the Pressurization Unit of Helical Axial Flow Multiphase Pump. Journal of Marine Science and Engineering, 10(11), 1795. https://doi.org/10.3390/jmse10111795