Fatigue Strength of Structural Steel-Welded Connections with Arc-Sprayed Aluminum Coatings and Corrosion Behavior of the Corresponding Coatings in Sea Water

Abstract

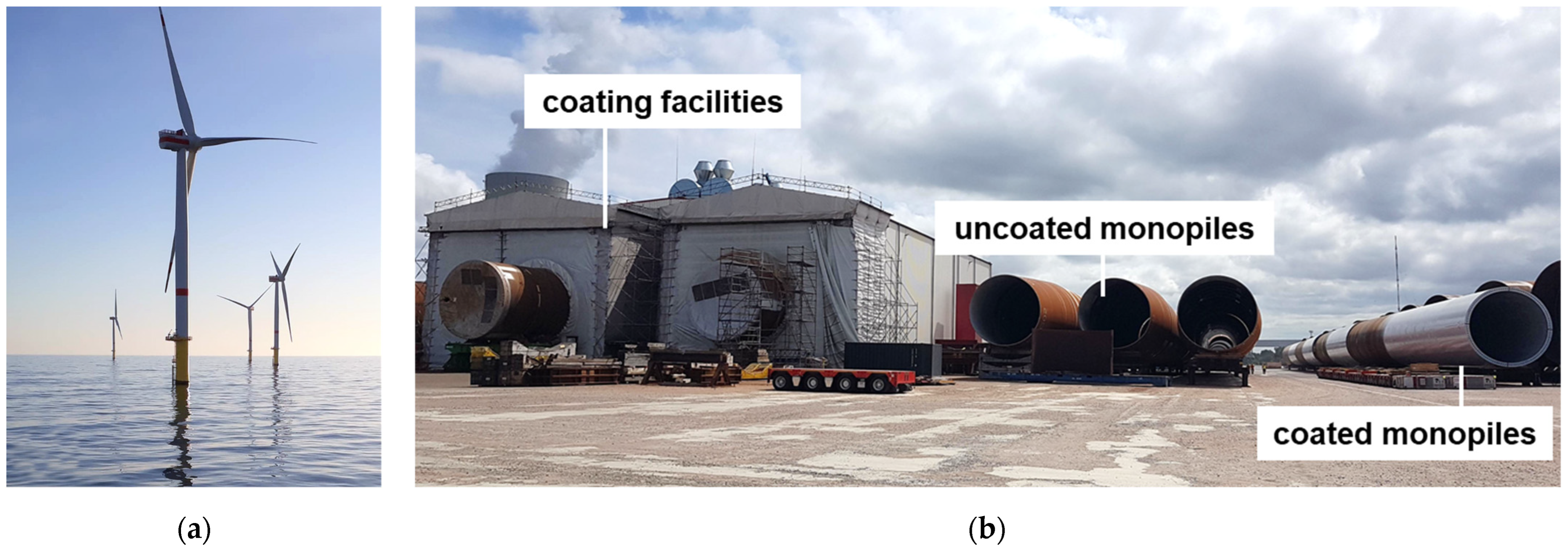

1. Introduction

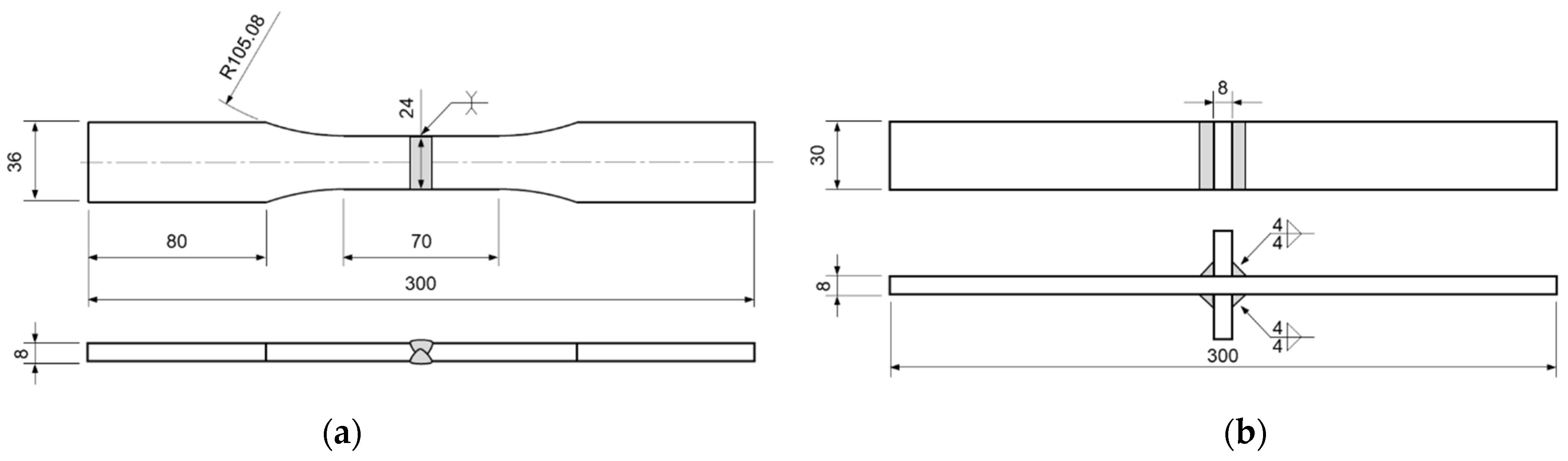

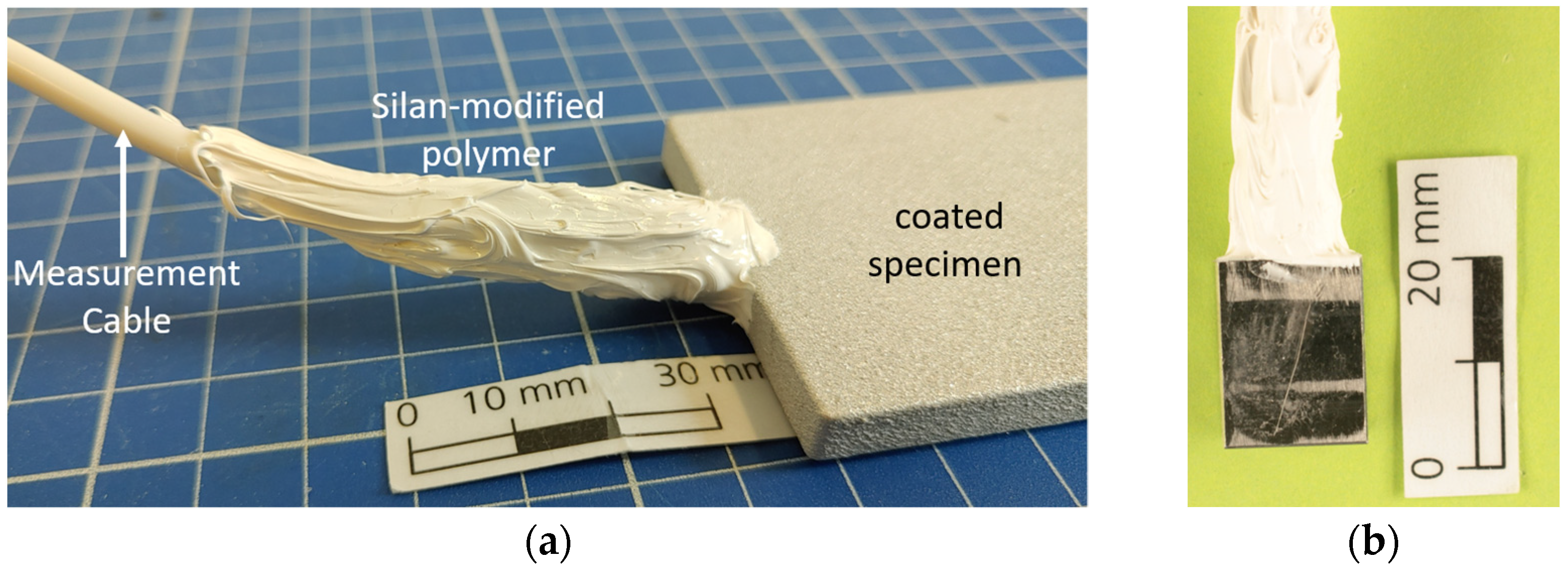

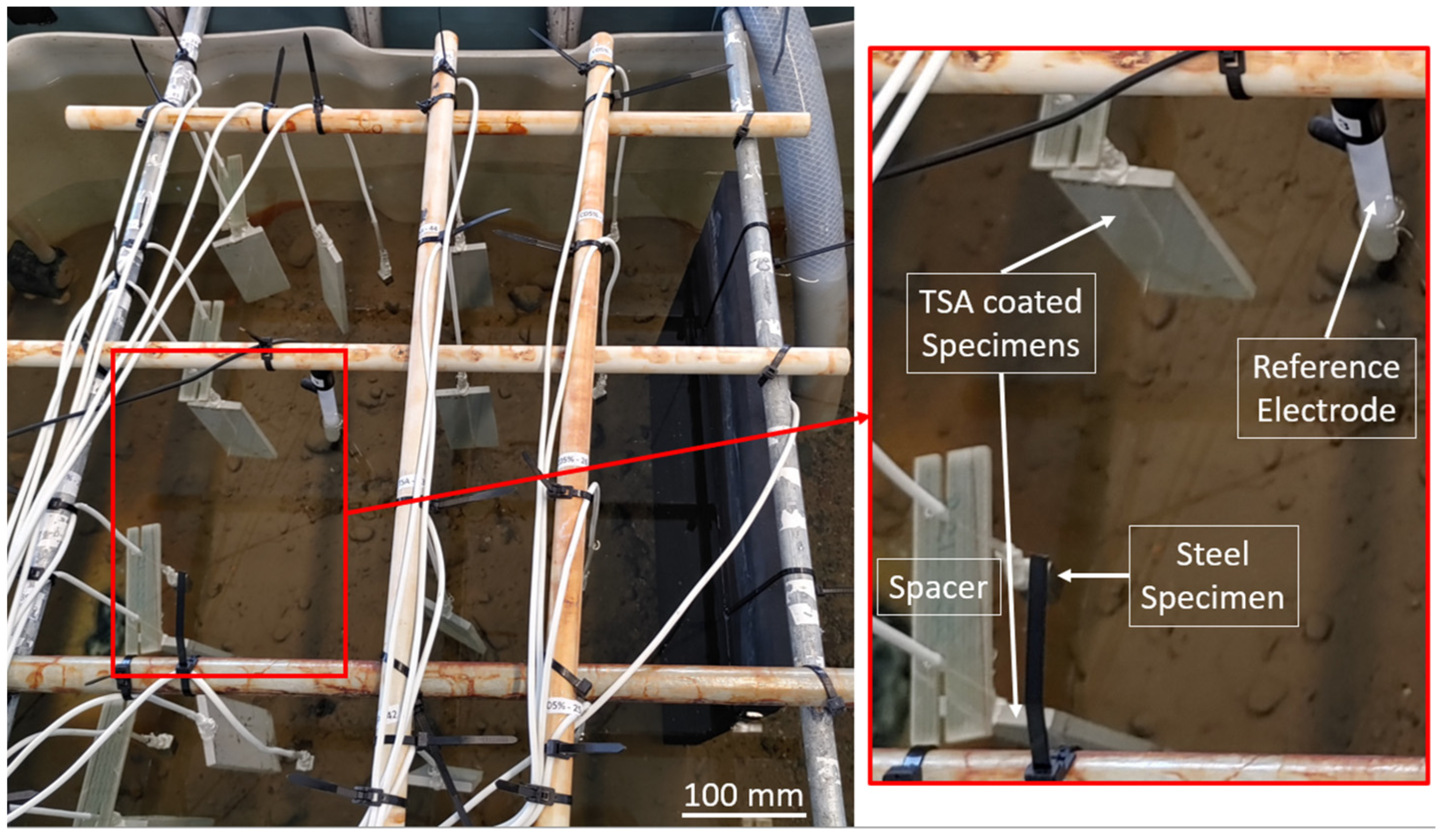

2. Materials and Methods

3. Results

3.1. Materials Characterization

3.1.1. Base Metal Properties

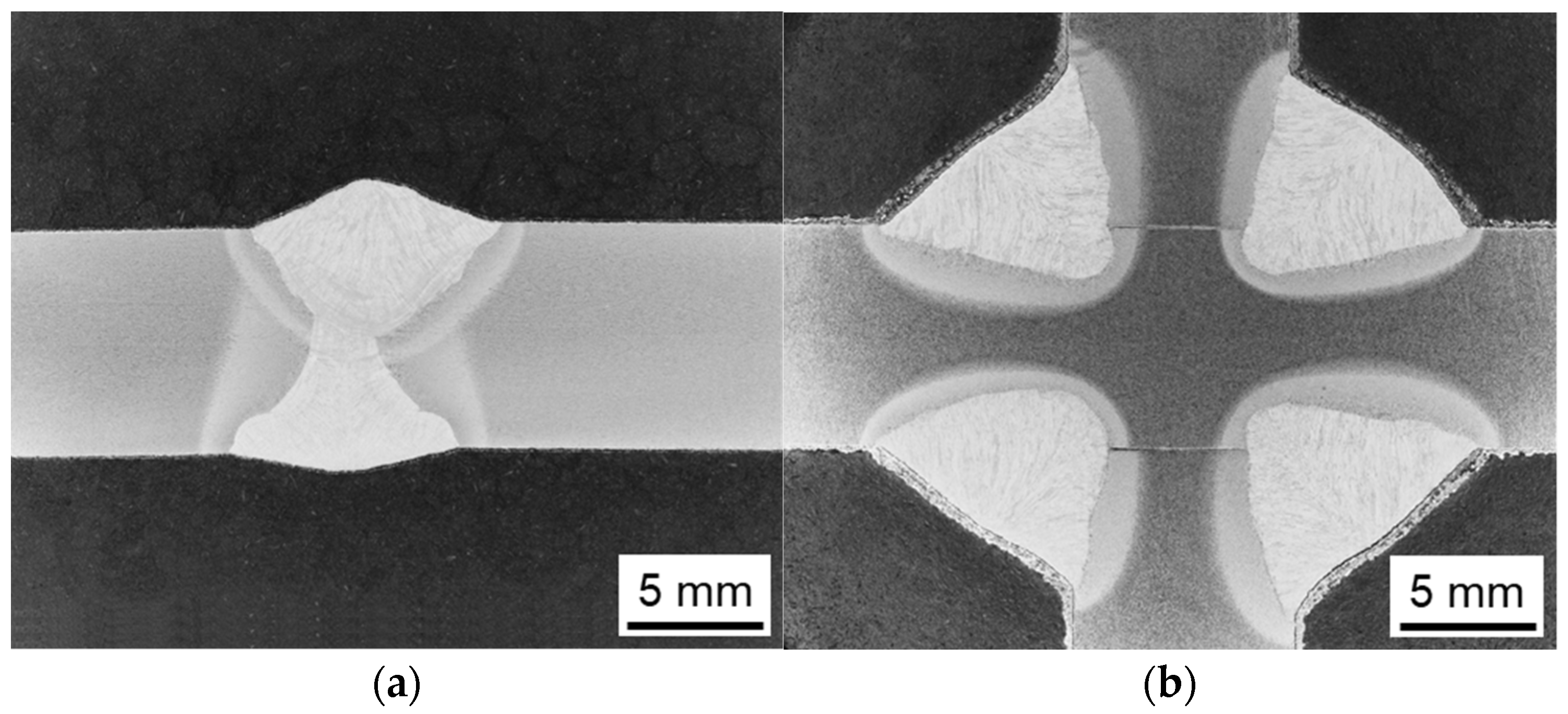

3.1.2. Weld Seam Quality

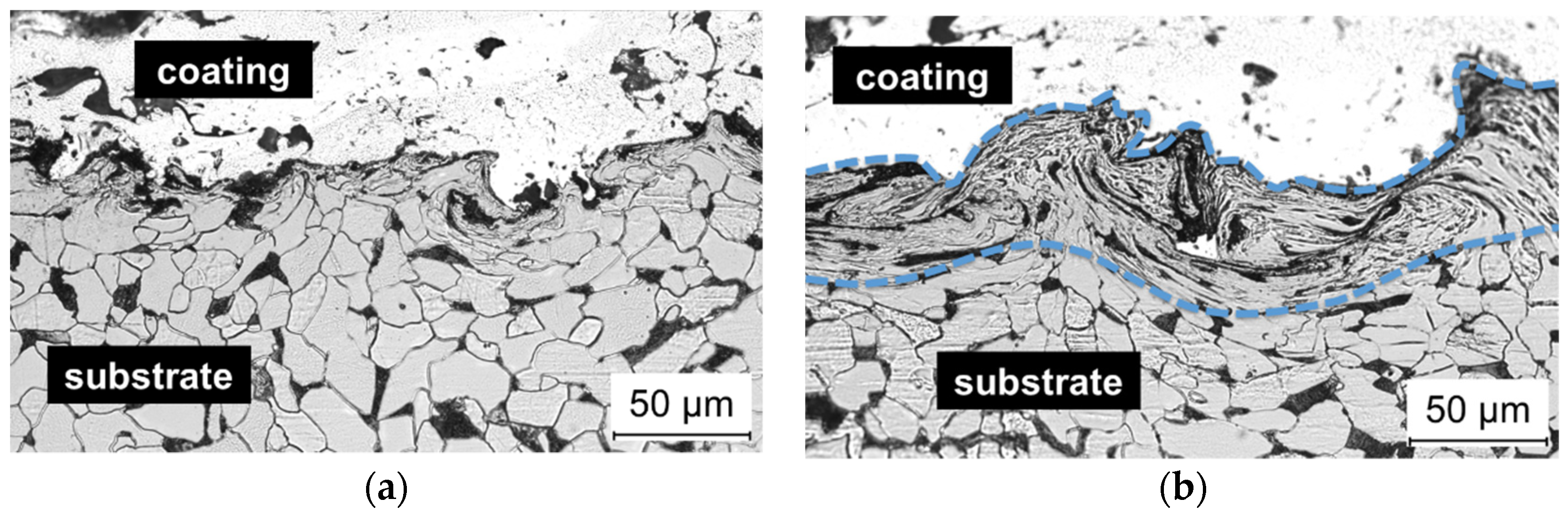

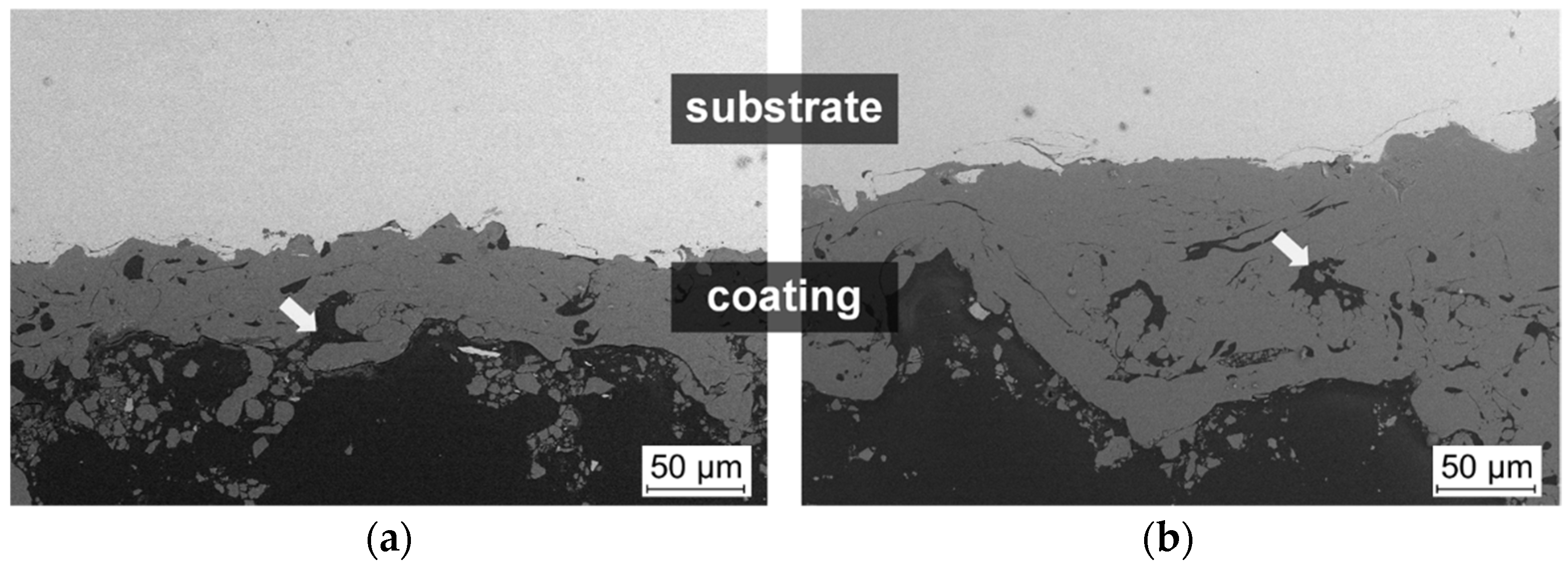

3.1.3. Surface and Coating Properties

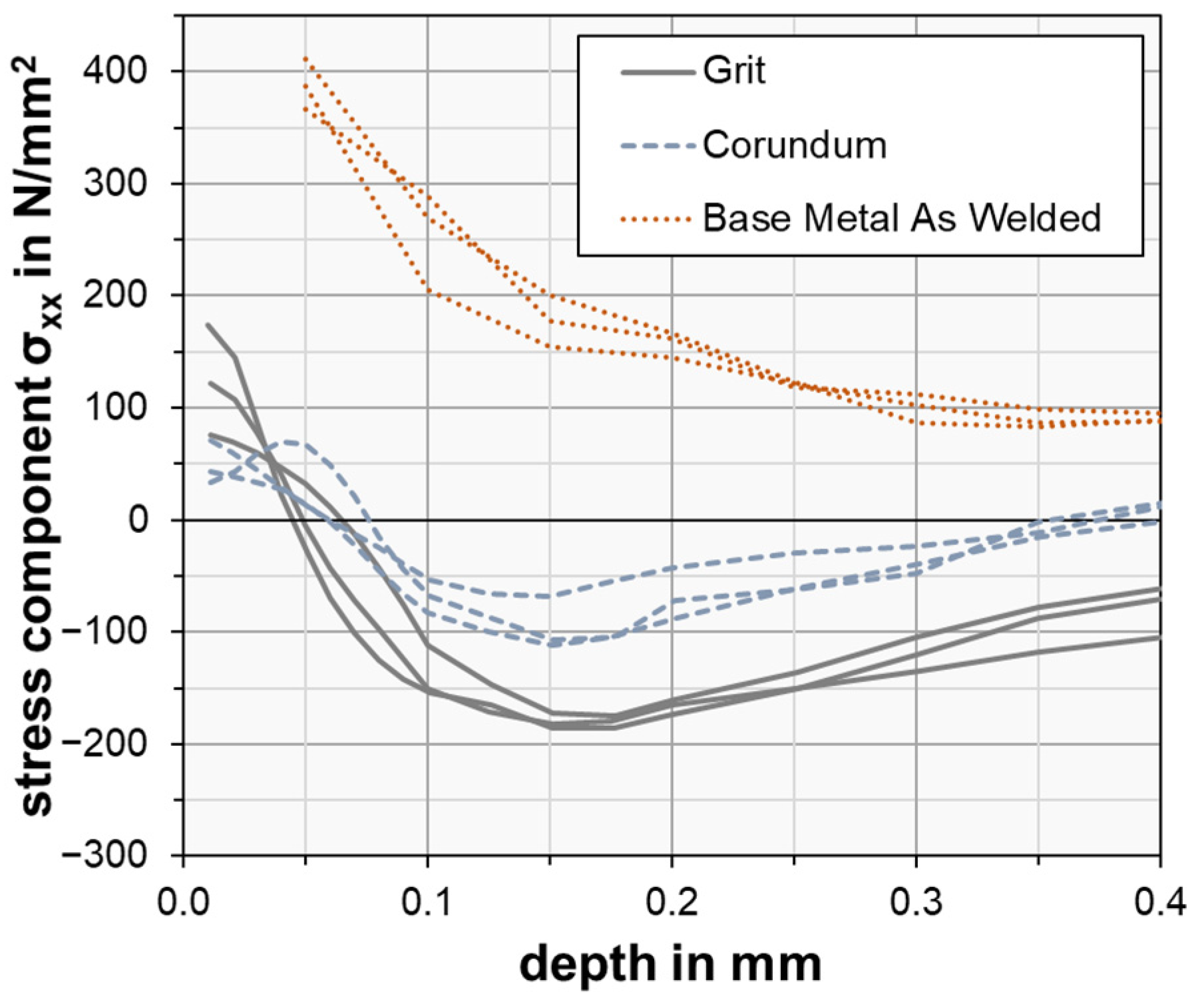

3.1.4. Residual Stress Measurements

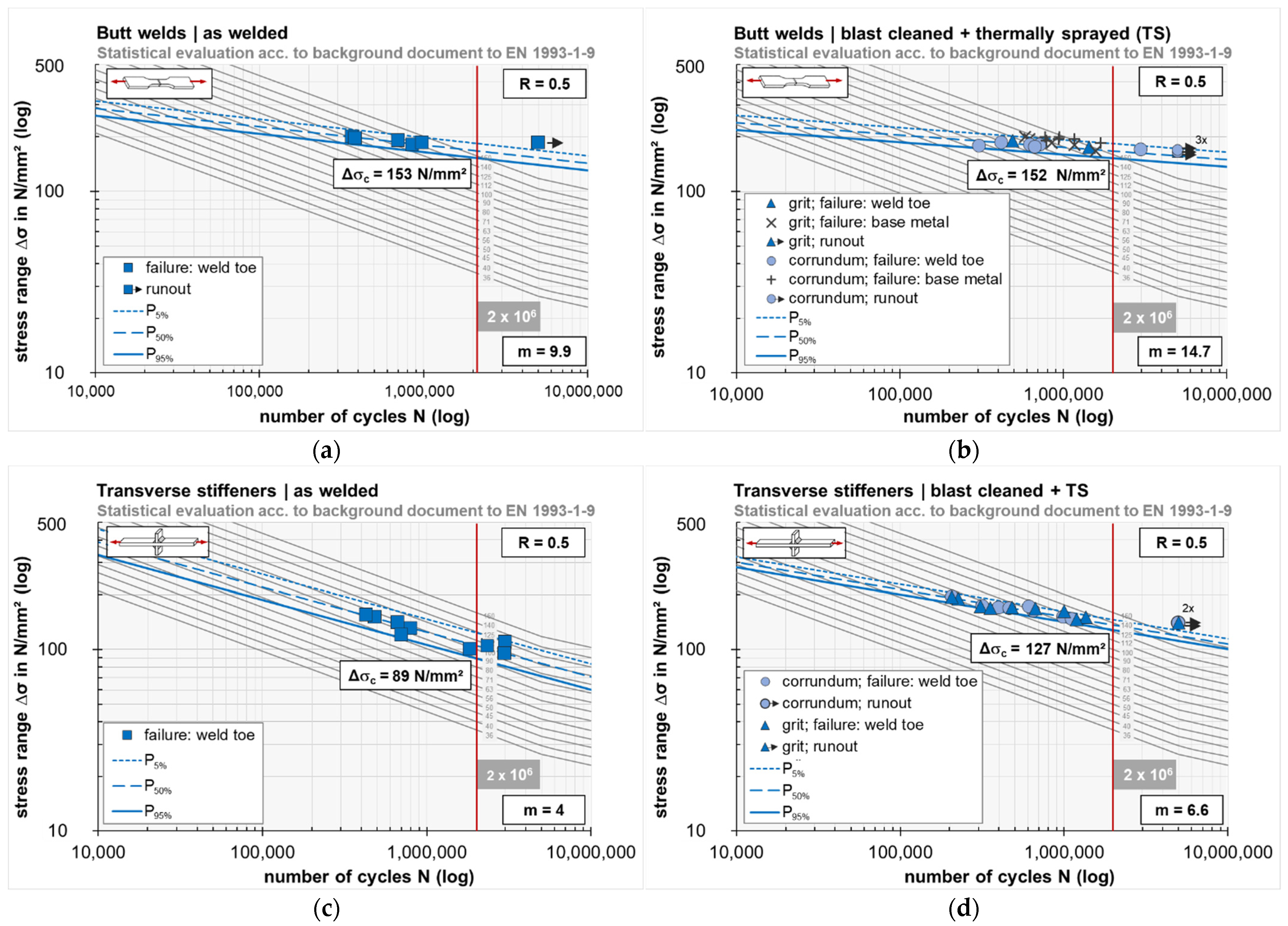

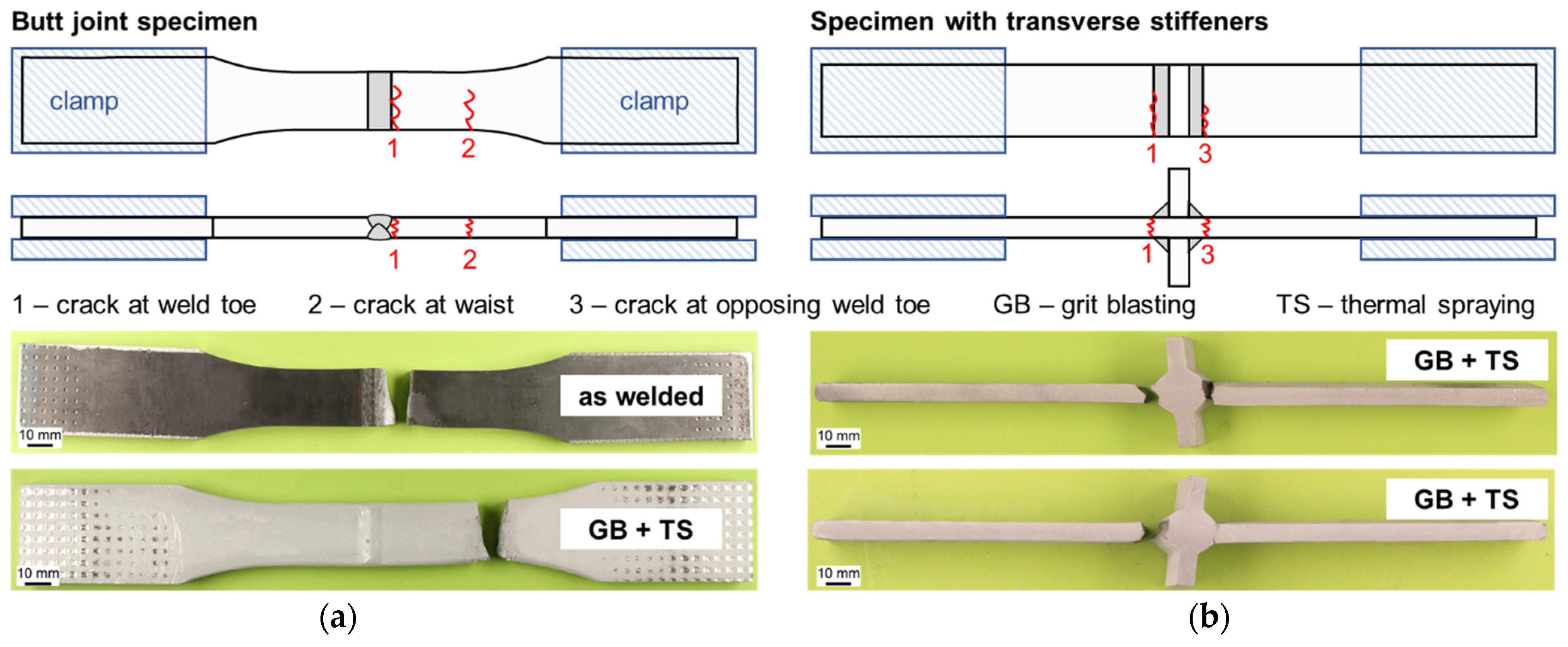

3.2. Fatigue Tests

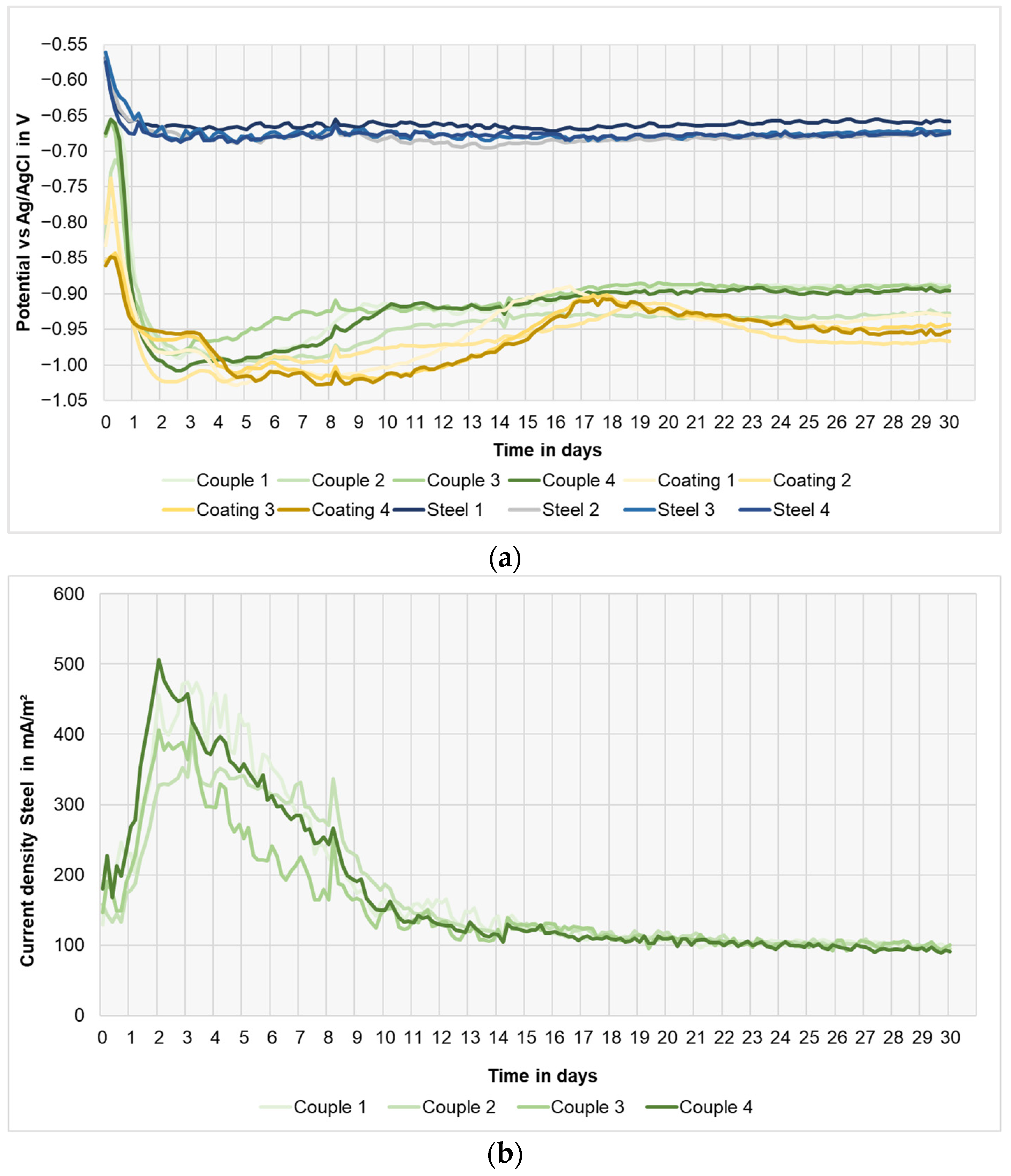

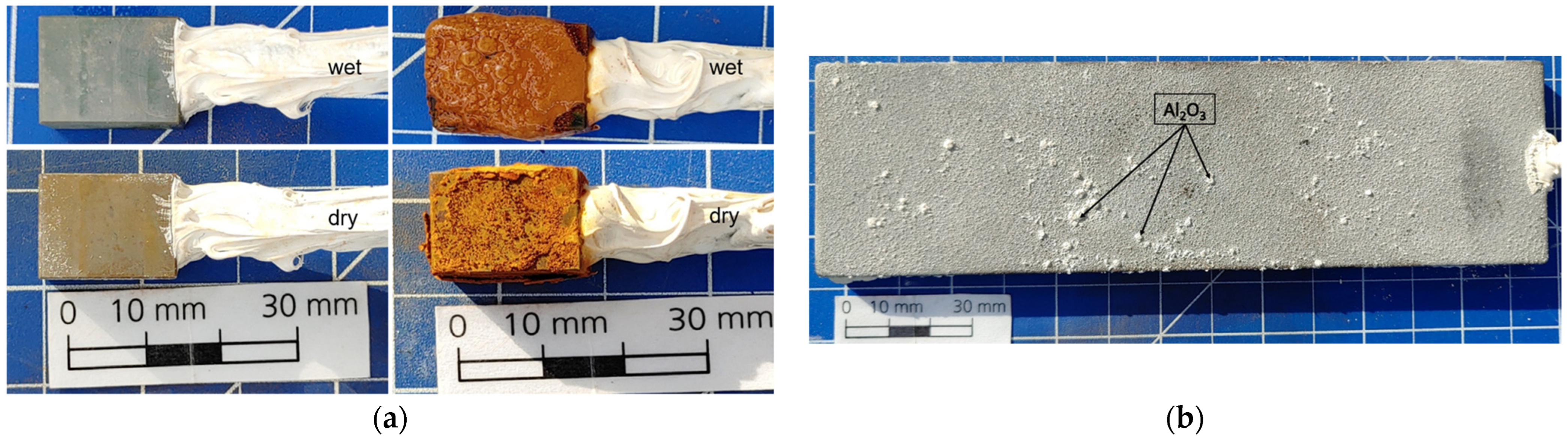

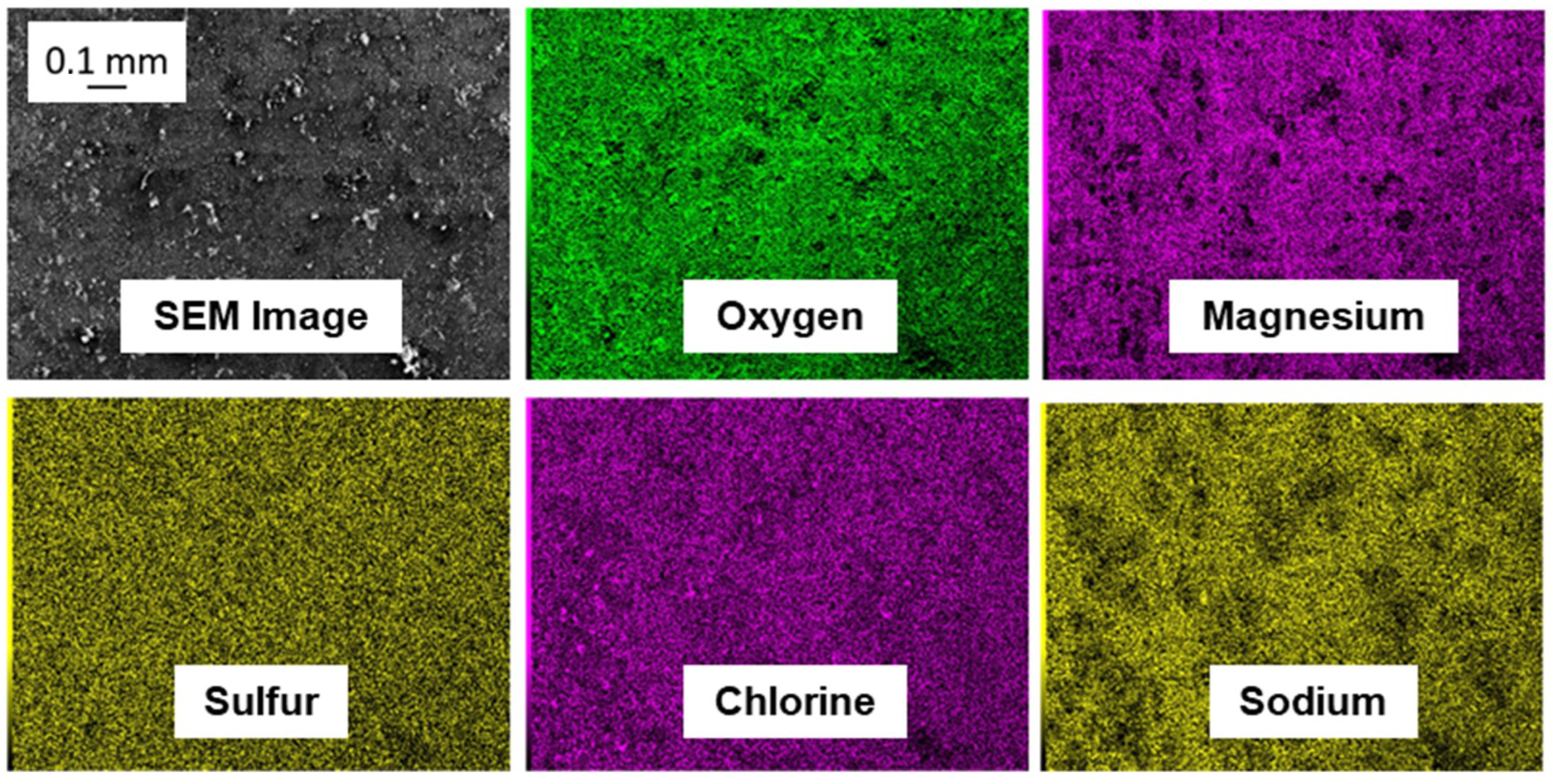

3.3. Corrosion Testing

4. Discussion

5. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- DIN EN 1993-1-9:2005+AC:2009; Eurocode 3: Design of Steel Structures—Part 1–9: Fatigue. DIN Deutsches Institut für Normung: Berlin, Germany, 2009. [CrossRef]

- Nikitas, G.; Arany, L.; Aingaran, S.; Vimalan, J.; Bhattacharya, S. Predicting long term performance of Offshore Wind Turbines using Cyclic Simple Shear apparatus. Soil Dyn. Earthq. Eng. 2017, 92, 678–683. [Google Scholar] [CrossRef]

- Hobbacher, A.F. Recommendations for Fatigue Design of Welded Joints and Components—IIW Document IIW-2259-15; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Haagensen, P.J.; Maddox, S.J. IIW Recommendations on Methods for Improving the Fatigue Strength of Welded Joints; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 4–12. [Google Scholar] [CrossRef]

- Hensel, J.; Eslami, H.; Nitschke-Pagel, T.; Dilger, K. Fatigue Strength Enhancement of Butt Welds by Means of Shot Peening and Clean Blasting. Metals 2019, 9, 744. [Google Scholar] [CrossRef]

- Glienke, R.; Wegener, F.; Gericke, A.; Hobbacher, A.; Henkel, K.; Marten, F.; Günther, H. Experimentelle und numerische Untersuchungen zur Schwingfestigkeit an Schweißdetails in Stahlrohrtürmen für Windenergieanlagen. Stahlbau 2019, 88, 968–987. [Google Scholar] [CrossRef]

- Gericke, A.; Glienke, R.; Brandenburg, K.; Walter, C.; Ripsch, B.; Henkel, K.; Frithjof, M. Untersuchung des Reinigungsstrahlens als Nahtnachbehandlungsmethode zur Verbesserung der Schwingfestigkeit Geschweißter Strukturen; DVS Berichte 2018—Band 344; DVS Media GmbH: Düsseldorf, Germany, 2018; pp. 350–357. [Google Scholar]

- Price, S.J.; Figueira, R.B. Corrosion Protection Systems and Fatigue Corrosion in Offshore Wind Structures: Current Status and Future Perspectives. Coatings 2017, 7, 25. [Google Scholar] [CrossRef]

- Kim, J.-H.; Lee, M.-H. A Study on Cavitation Erosion and Corrosion Behavior of Al-, Zn-, Cu-, and Fe-Based Coatings Prepared by Arc Spraying. J. Therm. Spray Technol. 2010, 19, 1224–1230. [Google Scholar] [CrossRef]

- Lang, F.; Krömmer, W. Economic and ecological benefits of using gas mixtures for arc spraying. In Proceedings of the 10th Colloquium High Velocity Oxy-Fuel Flame Spraying, Erding, Germany, 29–30 October 2015; pp. 79–88. [Google Scholar]

- GTV Verschleißschutz GmbH, Krebs Korrosionsschutz GmbH Rostock, EEW SPC GmbH. Available online: https://www.youtube.com/watch?v=O5v73kPugm0 (accessed on 19 July 2022).

- Barth, A. Application areas of arc spraying. In Proceedings of the Seminar “Modern Coating Technologies”, Dortmund, Germany, 5 November 2014. [Google Scholar]

- Voorwald, H.J.C.; Souza, R.C.; Pigatin, W.L.; Cioffi, C.O.H. Evaluation of WC–17Co and WC–10Co–4Cr thermal spray coatings by HVOF on the fatigue and corrosion strength of AISI 4340 steel. Surf. Coat. Technol. 2005, 190, 155–164. [Google Scholar] [CrossRef]

- Puchi-Cabrera, E.S.; Staia, M.H.; Ortiz-Mancilla, M.J.; La Barbera-Sosa, J.G.; Ochoa Pérez, O.C.; Villalobos-Gutiérrez, C.; Bellayer, S.; Traisnel, M.; Chicot, D.; Lesage, J. Fatigue behavior of a SAE 1045 steel coated with Colmonoy 88 alloy deposited by HVOF thermal spray. Surf. Coat. Technol. 2010, 205, 1119–1126. [Google Scholar] [CrossRef]

- McGrann, R.T.R.; Greving, D.J.; Shadley, J.R.; Rybicki, E.F.; Kruecke, T.L.; Bodger, B.E. The effect of coating residual stress on the fatigue life of thermal spray-coated steel and aluminum. Surf. Coat. Technol. 1998, 108–109, 59–64. [Google Scholar] [CrossRef]

- Kovářík, O.; Haušild, P.; Medřický, J.; Tomek, L.; Siegl, J.; Mušálek, R.; Curry, N.; Björklund, S. Fatigue Crack Growth in Bodies with Thermally Sprayed Coating. J. Therm. Spray Technol. 2016, 25, 311–320. [Google Scholar] [CrossRef]

- Yamaguchi, N.; Shiozaki, T.; Tamai, Y.; Okuda, K.; Ichikawa, Y.; Ogawa, K. Effect of cold spray deposition on fatigue strength of arc-welded ultra-high strength steel sheet. Int. J. Fatigue 2022, 161, 2411–2502. [Google Scholar] [CrossRef]

- Al-Fadhli, H.Y.; Stokes, J.; Hashmi, M.S.J.; Yilbas, B.S. HVOF coating of welded surfaces: Fatigue and corrosion behaviour of stainless steel coated with Inconel-625 alloy. Surf. Coat. Technol. 2006, 200, 4904–4908. [Google Scholar] [CrossRef]

- Chi, J.; Zhang, A.; Xie, S.; Jin, C. Process Optimization and Residual Stress Measurement for Arc Spraying Rapid Tooling. Acad. J. Xi’an Jiaotong Univ. 2014, 48, 126–130. [Google Scholar]

- Hauer, M.; Henkel, K.; Krebs, S.; Krömmer, W. Study of Traverse Speed Effects on Residual Stress State and Cavitation Erosion Behavior of Arc-Sprayed Aluminum Bronze Coatings. J. Therm. Spray Technol. 2017, 26, 217–228. [Google Scholar] [CrossRef]

- Sampath, S.; Jiang, X.Y.; Matejicek, J.; Prchlik, L.; Kulkarni, A.; Vaidya, A. Role of thermal spray processing method on the microstructure, residual stress and properties of coatings: An integrated study for Ni–5 wt.% Al bond coats. Mater. Sci. Eng. 2004, 364, 216–231. [Google Scholar] [CrossRef]

- Chen, Y.X.; Liang, X.B.; Liu, Y.; Wei, S.C.; Xu, B.S. Effect of heat treatment on microstructure and residual stress of wire arc sprayed high carbon steel coating. Surf. Eng. 2010, 26, 407–412. [Google Scholar] [CrossRef]

- Syrek-Gerstenkorn, B.; Paul, S.; Davenport, A.J. Sacrificial Thermally Sprayed Aluminium Coatings for Marine Environments: A Review. Coatings 2020, 10, 267. [Google Scholar] [CrossRef]

- Ryen, A.; Johnsen, R.; Iannuzzi, M.; Årtun, L. Cathodic protection by distributed sacrificial anodes—Performance at elevated Temperature and in mud. In Proceedings of the Corrosion Conference and Expo 2018, Phoenix, AZ, USA, 15–19 April 2018; pp. 2934–2948. [Google Scholar]

- Grinon-Echaniz, R.; Refait, P.; Jeannin, M.; Sabot, R.; Paul, S.; Thornton, R. Study of cathodic reactions in defects of thermal spray aluminium coatings on steel in artificial seawater. Corros. Sci. 2021, 187, 109514. [Google Scholar] [CrossRef]

- DIN EN 10025-2:2019-10; Hot Rolled Products of Structural Steels—Part 2: Technical Delivery Conditions for Non-Alloy Structural Steels. European Committee for Standardization: Brussels, Belgium, 2019. [CrossRef]

- DIN EN ISO 2553:2019-03; Welding and Allied Processes—Symbolic Representation on Drawings—Welded Joints. DIN Deutsches Institut für Normung: Berlin, Germany, 2019. [CrossRef]

- SAE J443:2017-08; Procedures for Using Standard Shot Peening Almen Test Strip. Society of Automotive Engineers: Warrendale, PA, USA, 2017. [CrossRef]

- SAE J442:2022-05; Test Strip, Holder, and Gage for Shot Peening. Society of Automotive Engineers: Warrendale, PA, USA, 2022. [CrossRef]

- ISO/TR 18491:2015-05; Welding and Allied Processes—Guidelines for Measurement of Welding Energies. International Organization for Standardization: Geneva, Switzerland, 2015.

- ISO/TR 17671-1:2002-02; Welding—Recommendations for Welding of Metallic Materials—Part 1: General Guidance for Arc Welding. International Organization for Standardization: Vernier, Switzerland, 2012.

- DIN EN ISO 11124-1:2018-12; Preparation of Steel Substrates before Application of Paints and Related Products—Specifications for Metallic Blast-Cleaning Abrasives—Part 1: General Introduction and Classification. DIN Deutsches Institut für Normung: Berlin, Germany, 2018. [CrossRef]

- FEPA-Standard 42-1:2006; Grains of Fused Aluminium Oxide, Silicon Carbide and Other Abrasive Materials for Bonded Abrasives and for General Applications Macrogrits F 4 to F 220. Federation of European Producers of Abrasives: Paris, France, 2006.

- DIN EN ISO 8501-1:2007-12; Preparation of Steel Substrates before Application of Paints and Related Products—Visual Assessment of Surface Cleanliness—Part 1: Rust Grades and Preparation Grades of Uncoated Steel Substrates and of Steel Substrates after Overall Removal of Previous Coatings. International Organization for Standardization: Geneva, Switzerland, 2007. [CrossRef]

- SAE J2277:2013-04; Shot Peening Coverage Determination. Society of Automotive Engineers: Warrendale, PA, USA, 2013. [CrossRef]

- DIN EN ISO 17632:2016-05; Welding Consumables—Tubular Cored Electrodes for Gas Shielded and Non-Gas Shielded Metal arc Welding of Non-Alloy and Fine Grain Steels—Classification. DIN Deutsches Institut für Normung: Berlin, Germany, 2016. [CrossRef]

- DIN EN ISO 5817:2014-06; Welding—Fusion-Welded Joints in Steel, Nickel, Titanium and Their Alloys (Beam Welding Excluded)—Quality Levels for Imperfections. DIN Deutsches Institut für Normung: Berlin, Germany, 2014. [CrossRef]

- DIN EN ISO 14175:2008-06; Welding Consumables—Gases and Gas Mixtures for Fusion Welding and Allied Processes. DIN Deutsches Institut für Normung: Berlin, Germany, 2008. [CrossRef]

- ISO/TR 14345:2012-06; Fatigue—Fatigue Testing of Welded Components—Guidance. International Organization for Standardization: Vernier, Switzerland, 2012.

- ECCS Technical Committee 6. Background Information on Fatigue Design Rules—Statistical Evaluation, 2nd ed.; European Convention for Constructional Steelwork: Brussels, Belgium, 2018. [Google Scholar]

- Stern, M.; Geary, A.L. Electrochemical Polarization: I. A Theoretical Analysis of the Shape of Polarization Curves. J. Electrochem. Soc. 1956, 104, 56–63. [Google Scholar] [CrossRef]

- DIN EN ISO 6892-1:2019-11; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. DIN Deutsches Institut für Normung: Berlin, Germany, 2019. [CrossRef]

- DIN EN 10027-1:2017-01; Designation Systems for Steels—Part 1: Steel Names. DIN Deutsches Institut für Normung: Berlin, Germany, 2017. [CrossRef]

- Leitner, M.; Stoschka, M.; Eichsleder, W. Fatigue Enhancement of Thin-Walled, High-Strength Steel Joints by High Frequency Mechanical Impact Treatment. Weld. World 2014, 58, 29–39. [Google Scholar] [CrossRef]

- Hauer, M.; Gärtner, F.; Krebs, S.; Klassen, T.; Watanabe, M.; Kuroda, S.; Kroemmer, W.; Henkel, K.-M. Process Selection for the Fabrication of Cavitation Erosion-Resistant Bronze Coatings by Thermal and Kinetic Spraying in Maritime Applications. J. Therm. Spray Technol. 2021, 30, 1310–1328. [Google Scholar] [CrossRef]

- DNV-RP-B401; Cathodic Protection Design. Det Norske Veritas: Bærum, Norway, 2010.

| Welding Parameter | Value | Blasting Parameters | Value |

|---|---|---|---|

| Arc Voltage | 27 V | Almen Intensity Steel Grit | 628 µmA (T = 2.5 s) |

| Welding Current | 300 A | Almen Intensity Corundum | 467 µmA (T = 18.2 s) |

| Wire feed rate | 10 m/min | Blasting Consumables | Type & Particle Size |

| Welding speed | 35 cm/min | Steel grit | ISO 11124 M/HCS/G100 [32] |

| Heat input | 1.1 kJ/mm | nominal particle size 1.0 mm | |

| Shielding gas flow rate | 12 L/min | Corundum | F24 (FEPA 42-1 [33]) |

| Electrode stickout | 18–22 mm | 600–850 µm | |

| Welding wire diameter | 1.2 mm | Blasting Quality Criteria | Requirement |

| Torch angle | 10° | Surface preparation grade | Sa3 (ISO 8501-01 [34]) |

| Travel direction | Push welding | Coverage | 100% (SAE J2277 [35]) |

| Welding Consumables | Designation | Welding Quality Criteria | Requirement |

| Welding wire | ISO 17632-A—T 46 6 M M21 1 [36] | General Quality Level | B (ISO 5817 [37]) |

| Shielding gas | ISO 14175—M21—ArC—18 [38] |

| Gas | Flow Rate in m3/h | pGas in Bar | Robot Speed in m/min | Robot Offset in mm | Stand-Off Distance in mm | Number of Passes | Voltage in V | Current in A | Wire Feed Rate in m/min |

|---|---|---|---|---|---|---|---|---|---|

| Air | 93.0 | 3.5 | 40 | 9 | 100 | 2 | 28 | 107 | 6.2 |

| Component | Sodium | Potassium | Calcium | Magnesium | Chloride | Bromide | Sulphate |

|---|---|---|---|---|---|---|---|

| Concentration in mg/L | 2906.9 | 99.6 | 227.4 | 480.6 | 6518.7 | 47.8 | 800.1 |

| Property | Salinity | pH | O2 | Temperature | |||

| Value | 0.81 g/L | 7.5 ± 0.1 | 7 ± 0.3 mg/L | 21 ± 1 °C |

| Steel | Content in % | C | Si | Mn | P | S | N | Cu | Ni | Cr | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S355J2+N acc. to [43] | Max. content acc. to [13] | 0.20 | 0.55 | 1.60 | 0.025 | 0.025 | - | 0.55 | 0.42 | 0.29 | 0.11 |

| 0.159 | 0.197 | 0.72 | 0.0085 | 0.0042 | 0.022 | 0.021 | 0.042 | 0.056 | 0.012 | ||

| 0.0083 | 0.0038 | 0.0040 | 0.0002 | 0.0001 | 0.0025 | 0.0001 | 0.0021 | 0.0009 | 0.0002 |

| Blasting Procedure | Coating Thickness in µm | Amount of Defects (Porosity, Cracks, Oxides) in % |

|---|---|---|

| Corundum | 78 ± 20 | 4.7 ± 2.3 |

| Grit | 97 ± 26 | 6.2 ± 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gericke, A.; Hauer, M.; Ripsch, B.; Irmer, M.; Nehlsen, J.; Henkel, K.-M. Fatigue Strength of Structural Steel-Welded Connections with Arc-Sprayed Aluminum Coatings and Corrosion Behavior of the Corresponding Coatings in Sea Water. J. Mar. Sci. Eng. 2022, 10, 1731. https://doi.org/10.3390/jmse10111731

Gericke A, Hauer M, Ripsch B, Irmer M, Nehlsen J, Henkel K-M. Fatigue Strength of Structural Steel-Welded Connections with Arc-Sprayed Aluminum Coatings and Corrosion Behavior of the Corresponding Coatings in Sea Water. Journal of Marine Science and Engineering. 2022; 10(11):1731. https://doi.org/10.3390/jmse10111731

Chicago/Turabian StyleGericke, Andreas, Michél Hauer, Benjamin Ripsch, Michael Irmer, Jonas Nehlsen, and Knuth-Michael Henkel. 2022. "Fatigue Strength of Structural Steel-Welded Connections with Arc-Sprayed Aluminum Coatings and Corrosion Behavior of the Corresponding Coatings in Sea Water" Journal of Marine Science and Engineering 10, no. 11: 1731. https://doi.org/10.3390/jmse10111731

APA StyleGericke, A., Hauer, M., Ripsch, B., Irmer, M., Nehlsen, J., & Henkel, K.-M. (2022). Fatigue Strength of Structural Steel-Welded Connections with Arc-Sprayed Aluminum Coatings and Corrosion Behavior of the Corresponding Coatings in Sea Water. Journal of Marine Science and Engineering, 10(11), 1731. https://doi.org/10.3390/jmse10111731