Research on the Enhancement of the Separation Efficiency for Discrete Phases Based on Mini Hydrocyclone

Abstract

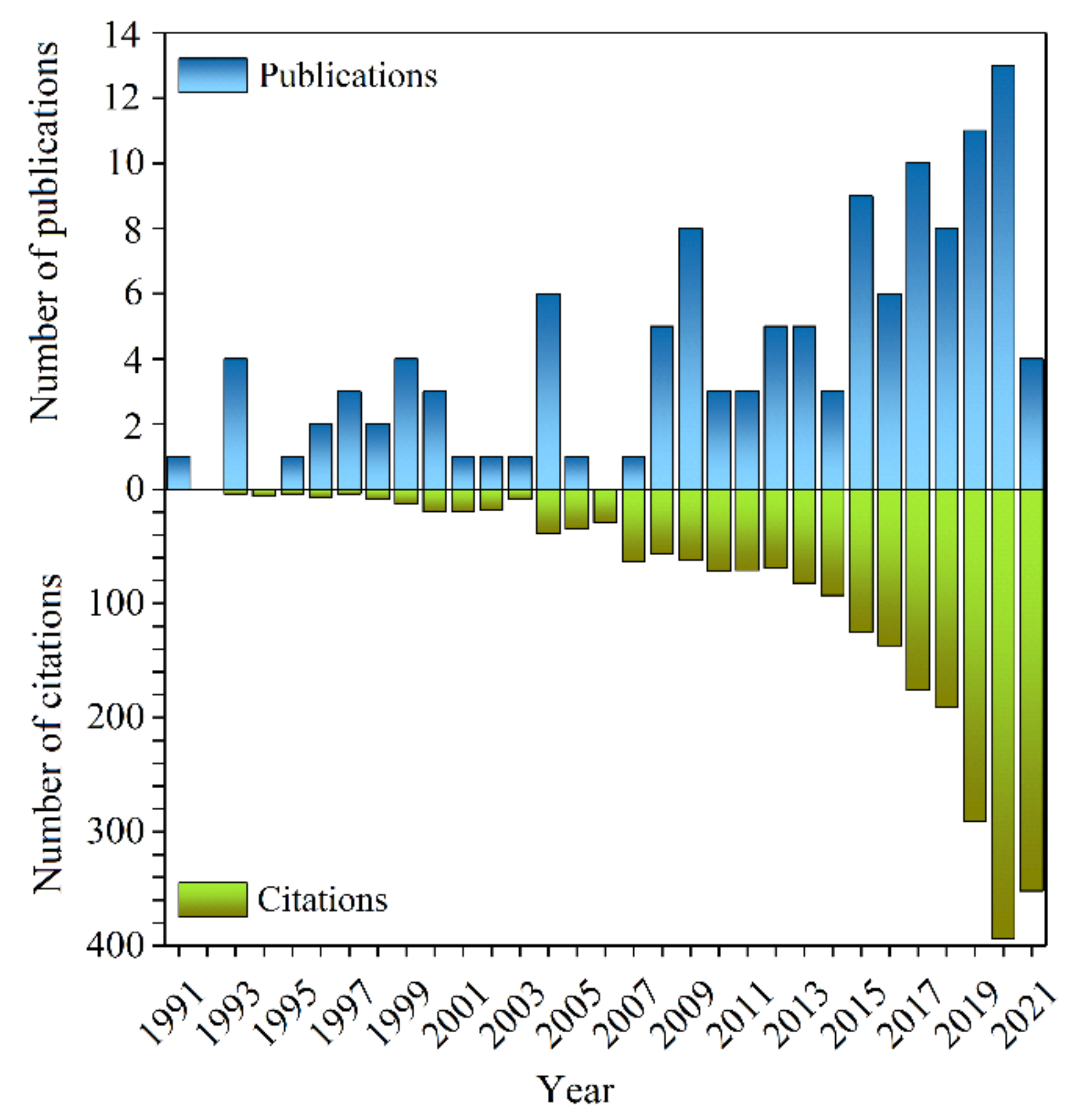

1. Introduction

2. Materials and Methods

2.1. Simulation of Oil–Water Separation

2.1.1. Structural Parameters of Hydrocyclone

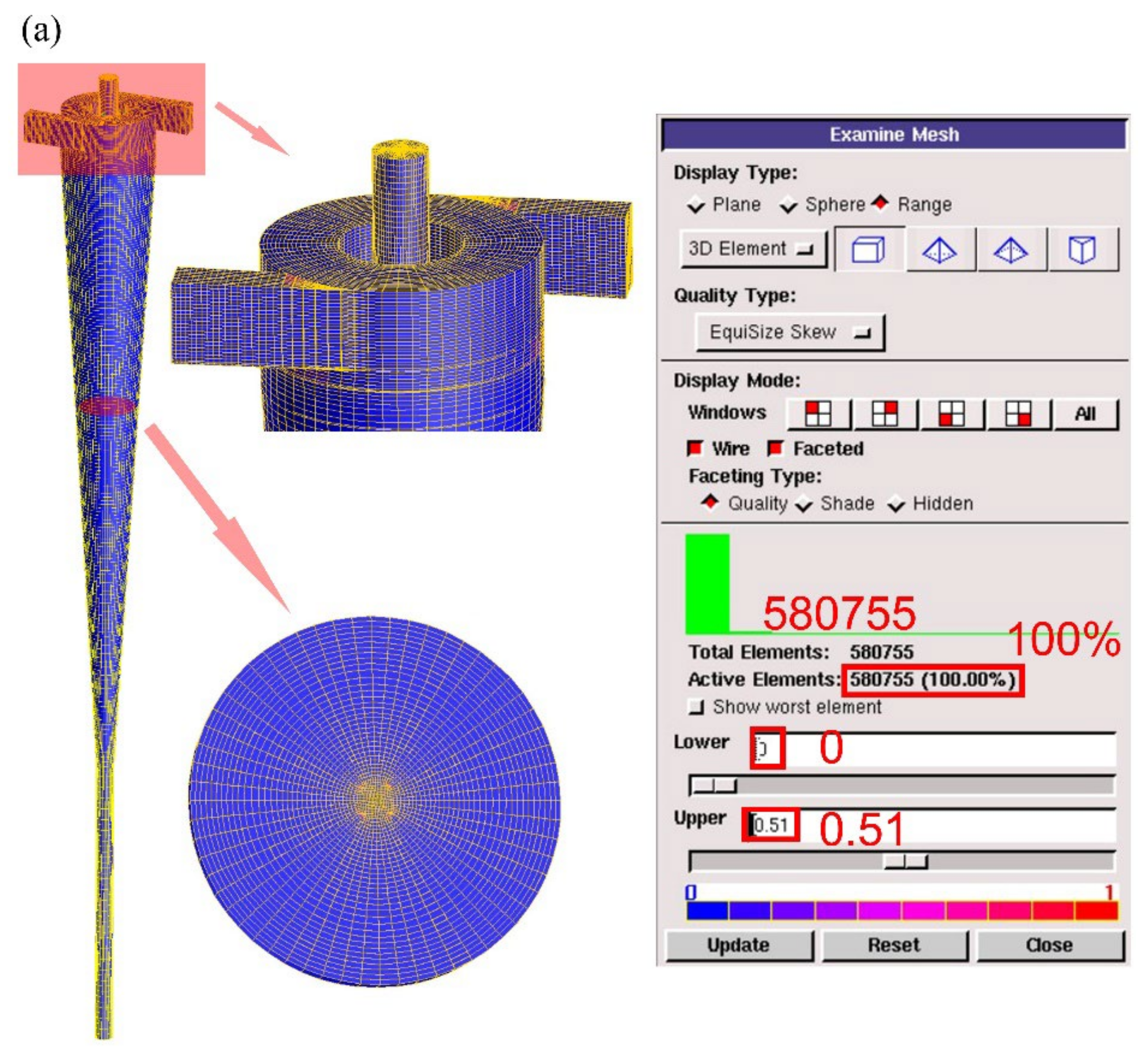

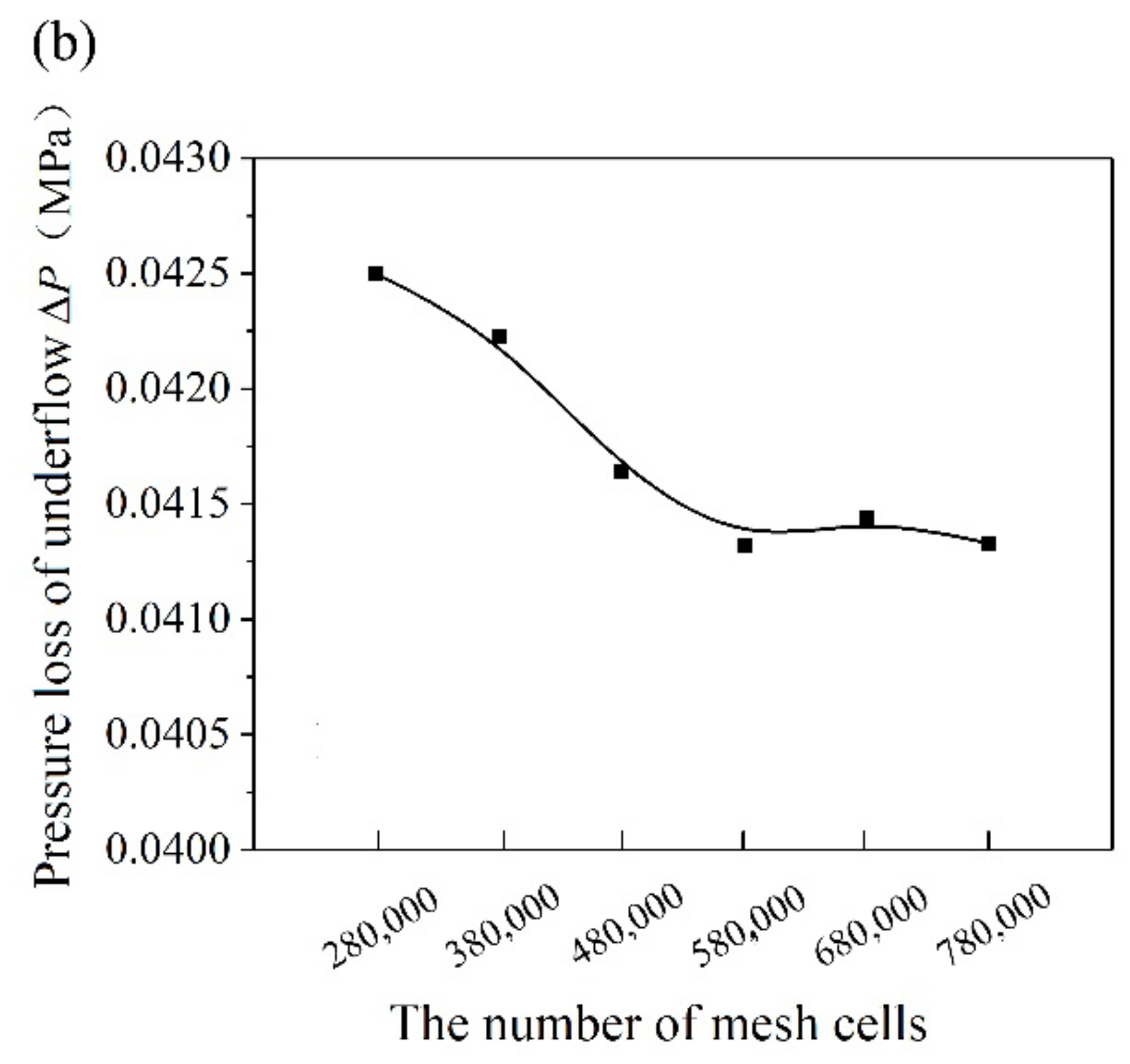

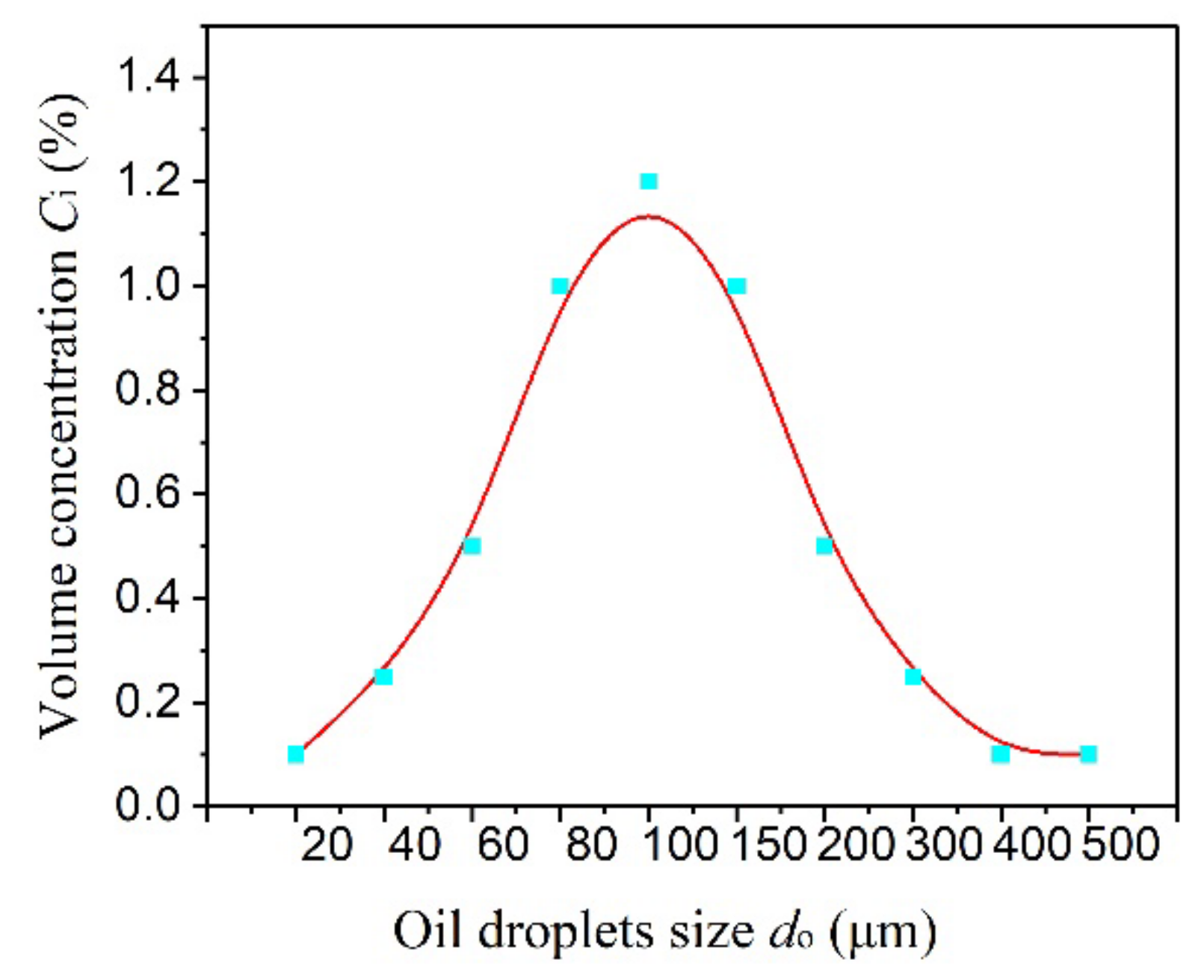

2.1.2. Preprocessing of Simulations

2.1.3. Simulation Method and Settings

2.2. Simulation of Silica Particle and Water Separation

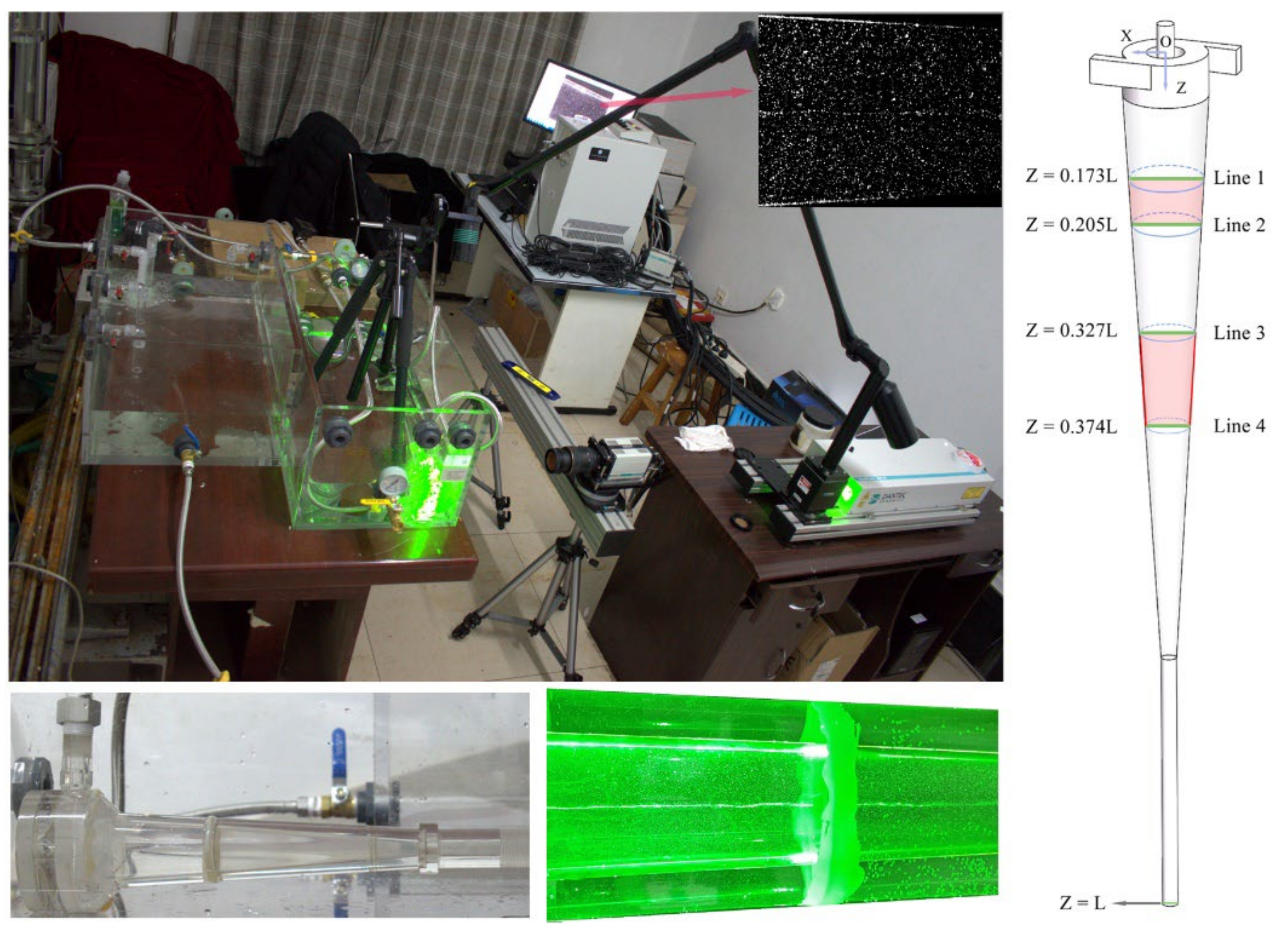

2.3. Particle Image Velocimetry (PIV) Experiment

3. Results and Discussion

3.1. Oil-Water Separation

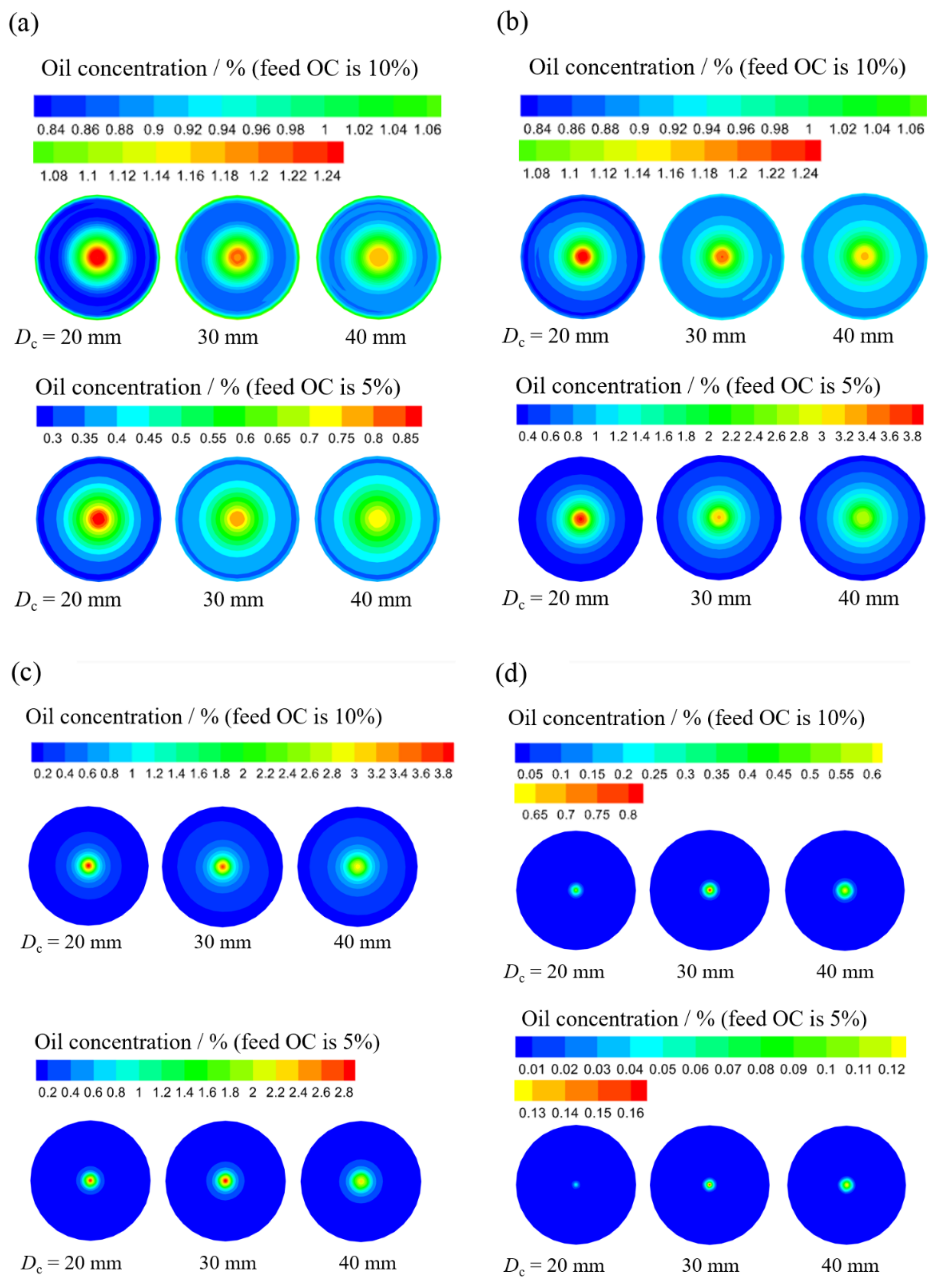

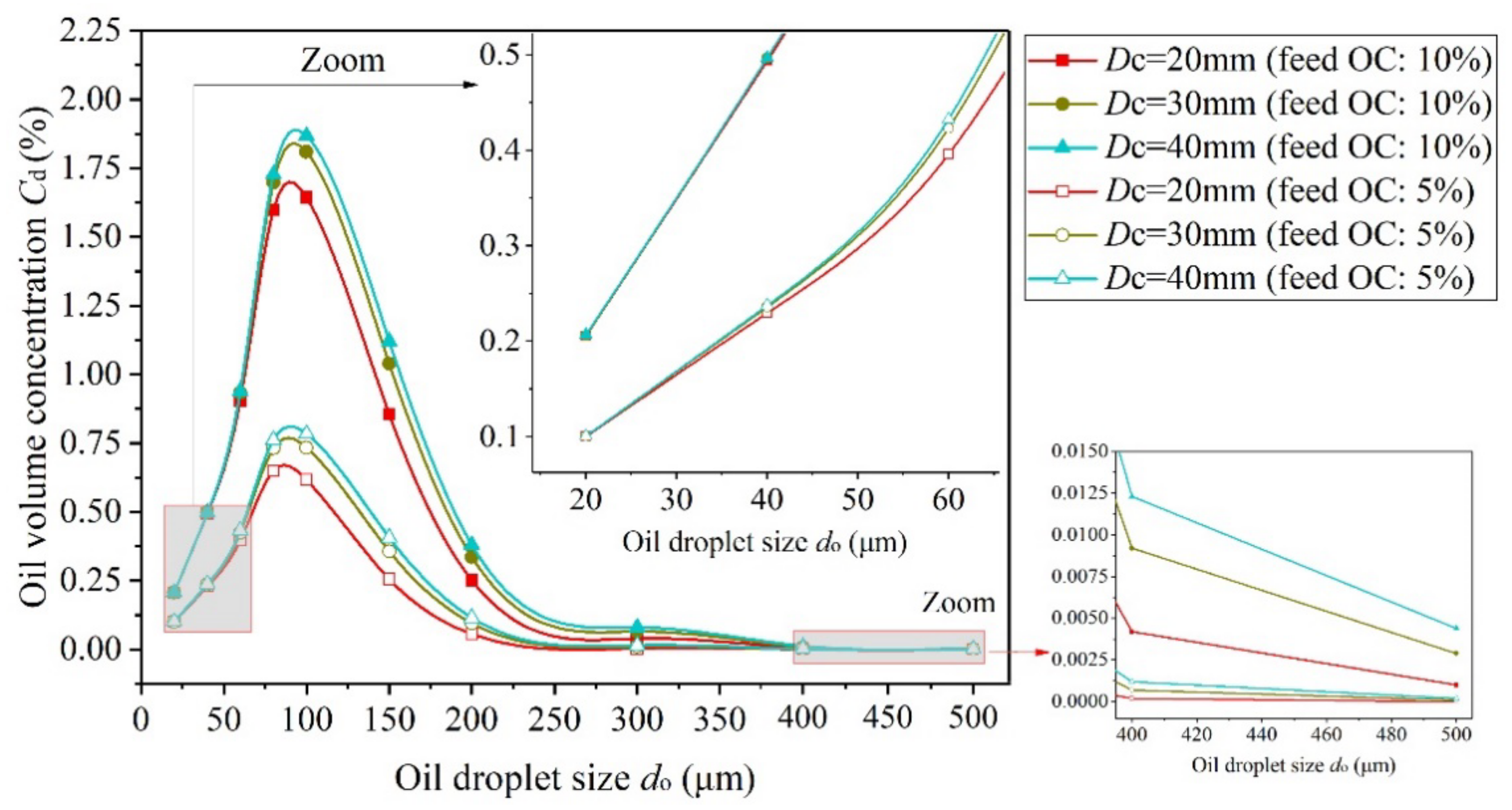

3.1.1. Oil Concentration Analysis

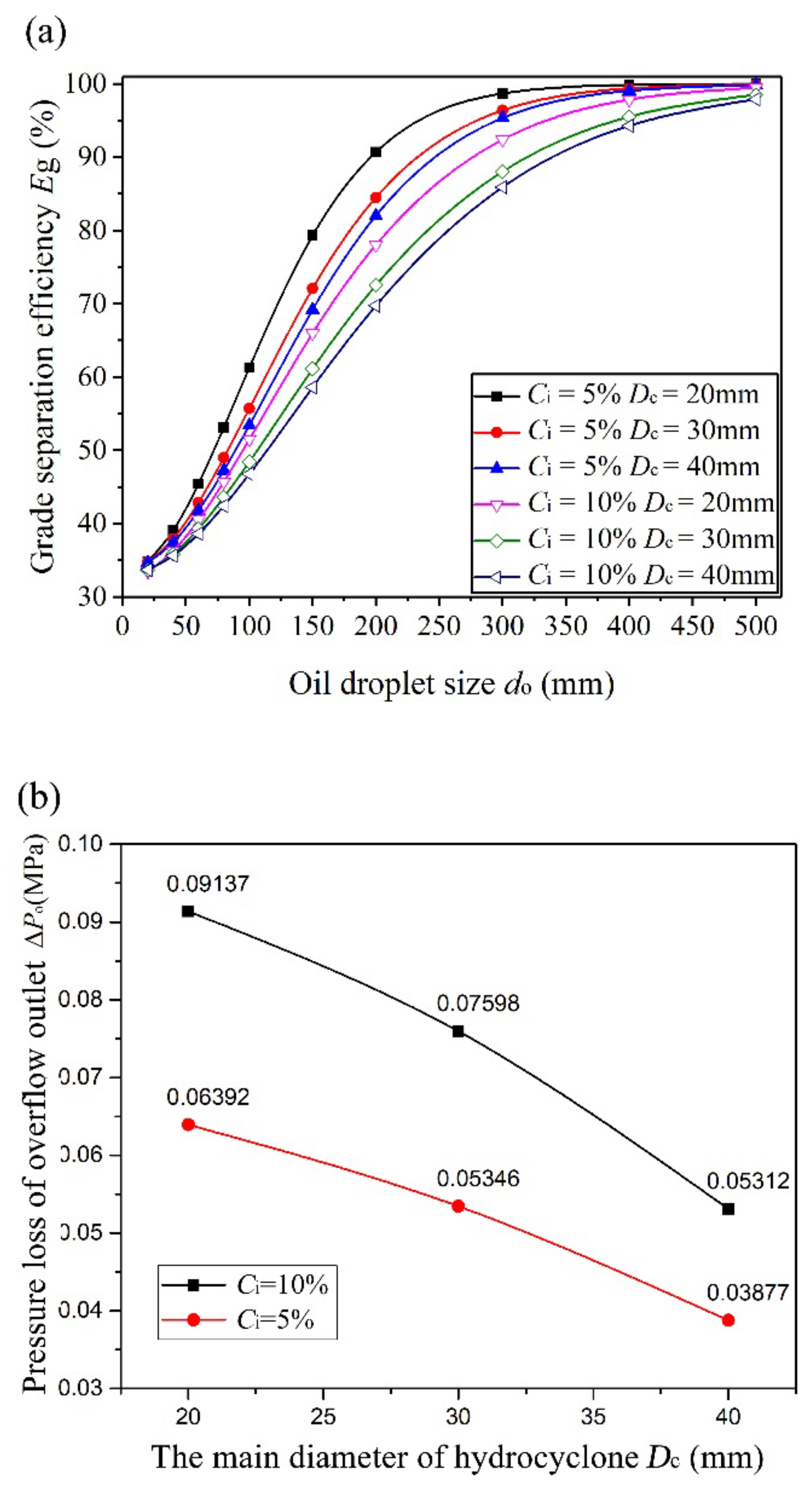

3.1.2. Grade Separation Efficiency and Pressure Loss

3.2. Silica Particle and Water Separation

3.2.1. Particle Concentration Distribution

3.2.2. Grade Separation Efficiency and Pressure Loss

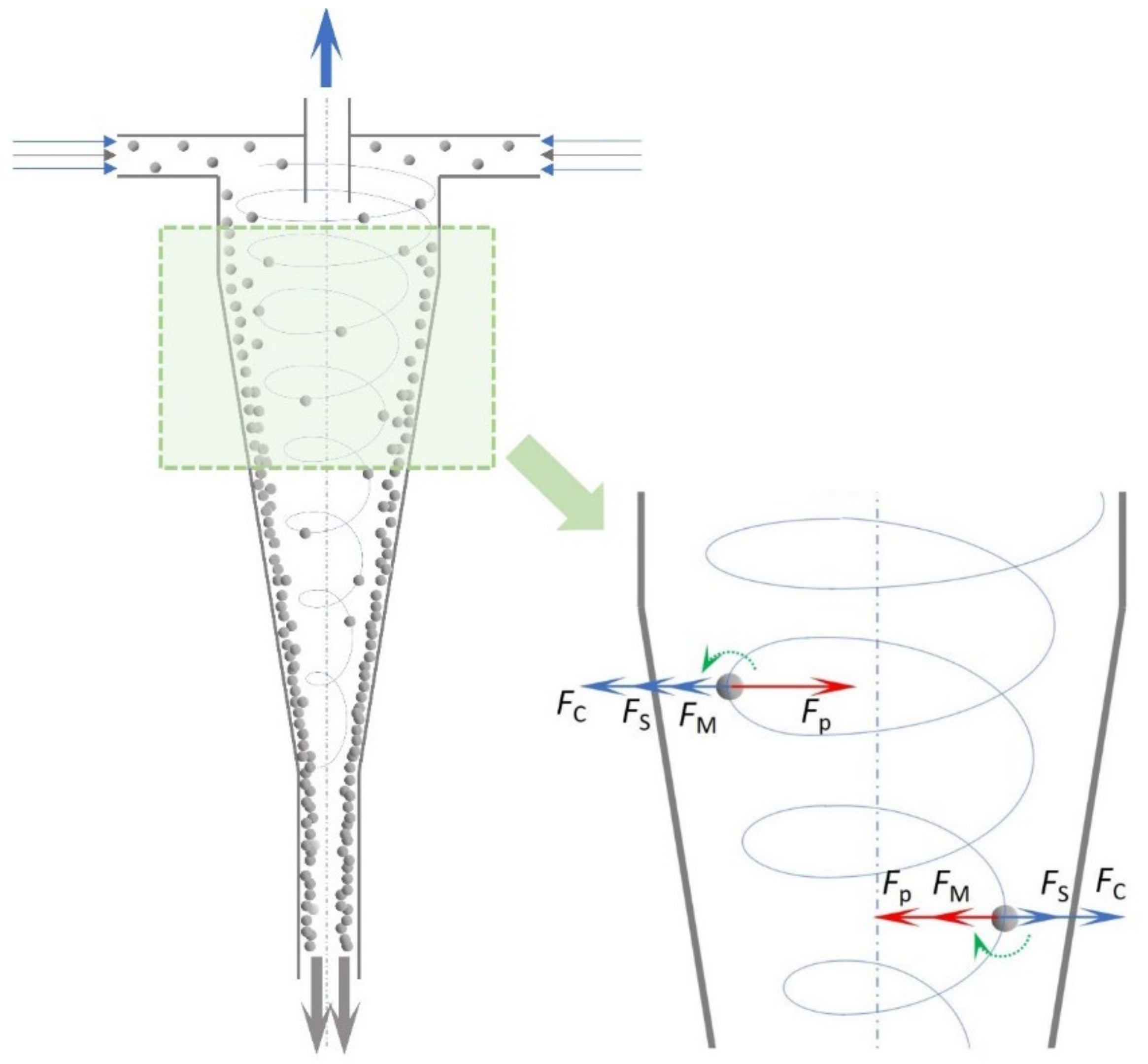

3.3. Analysis and Discussion of Efficiency Enhancement of MHC

3.3.1. Efficiency Enhancement Analysis

3.3.2. Discussion

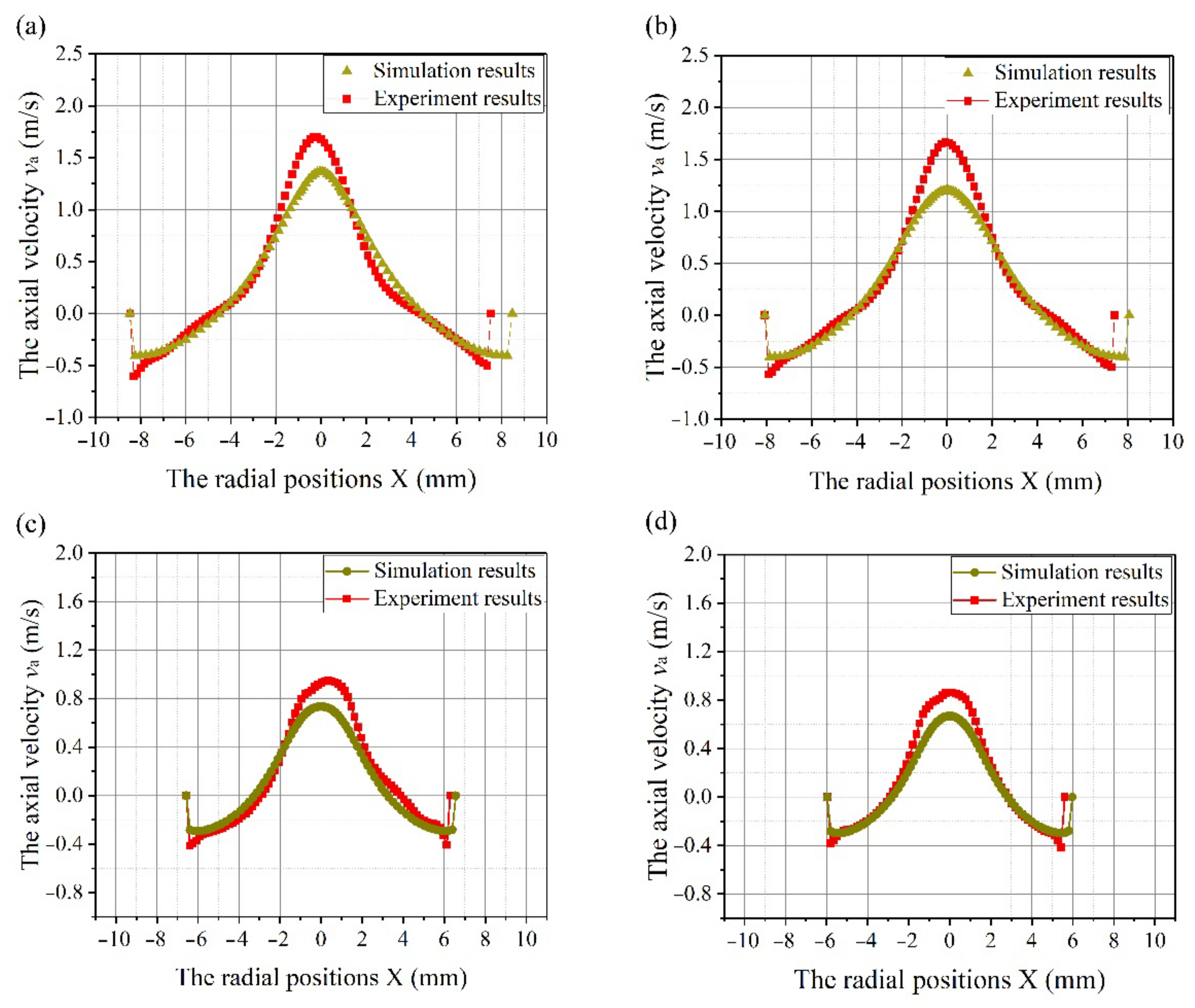

3.4. Verification of the Accuracy of Numerical Simulations

4. Conclusions

- (1)

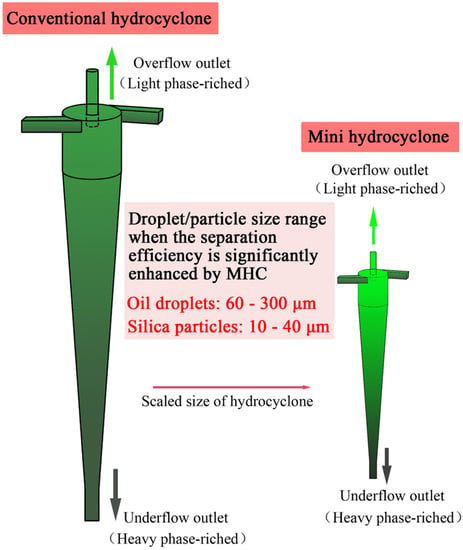

- The separation performance of the oil–water separation by hydrocyclone with different main diameters (Dc) was studied. Results show that the separation efficiency of MHC is higher than that of the conventional hydrocyclone (CHC) under the same feed flow velocity, and it is suitable for the situation of both high and low feed oil concentrations. When the oil droplet size is between 60 and 300 μm, the effect of efficiency enhancement of MHC is more obvious. For the oil droplet size below 20 μm and over 400 μm, the enhancement effect of MHC on the separation efficiency is not significant.

- (2)

- Through the research on silica–water separation, the corresponding particle size range is 10–40 μm when the separation efficiency of MHC is significantly enhanced compared with CHC, which is lower than the optimal particle size range for oil–water separation. When the particle size is larger than 60 μm, the separation efficiency for MHC is comparable to that of MHC. CHC cannot separate particles as small as 5 μm, while MHC still provides separation. Additionally, the efficiency enhancement of MHCs was explained from the perspective of force analysis of discrete phase in MHC and CHC.

- (3)

- The pressure loss of MHC is higher than that of CHC for both oil–water and silica–water separations. Connecting the CHC with MHC in series could ensure the high separation efficiency of particles while avoiding the high energy consumption and clogging problems caused by using the MHC alone.

Nomenclature or Abbreviations

| Nomenclature | |

| a and b | The height and width of the tangential inlet of hydrocyclone |

| d50 | Cut size, means the particle/droplet size when the grade efficiency equals 50% |

| do | Oil droplet size |

| dp | Particle size |

| Ci | Feed concentration |

| Dc | The main diameter of hydrocyclone |

| Do | Diameter of overflow outlet |

| Du | Diameter of underflow outlet |

| Eg | Grad separation efficiency |

| Lc | Length of the cylindrical section |

| Ld | Length of underflow pipe |

| Lv | Length of vortex finder |

| Re | Reynolds number |

| Rf | Split ratio |

| θ | Angle of cone section |

| ρo | Oil density |

| ηo | Oil viscosity |

| Abbreviations | |

| CHC | Conventional hydrocyclone |

| GSE | Grade separation efficiency |

| MHC | Mini hydrocyclone |

| OC | Oil concentration |

| PC | Particle concentration |

| PIV | Particle image velocimetry |

| PW | Produced water |

| RSM | Reynolds stress model |

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qiu, R.; Li, Z.; Zhang, Q.; Yao, X.; Xie, S.; Liao, Q.; Wang, B. A Realistic and Integrated Model for Evaluating Offshore Oil Development. J. Mar. Sci. Eng. 2022, 10, 1155. [Google Scholar] [CrossRef]

- Yacovitch, T.I.; Daube, C.; Herndon, S.C. Methane Emissions from Offshore Oil and Gas Platforms in the Gulf of Mexico. Environ. Sci. Technol. 2020, 54, 3530–3538. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Lu, H.; Li, Y.; Xu, H.; Pan, Z.; Dai, P.; Wang, H.; Yang, Q. A Review of Treatment Technologies for Produced Water in Offshore Oil and Gas Fields. Sci. Total Environ. 2021, 775, 145485. [Google Scholar] [CrossRef] [PubMed]

- Tanudjaja, H.J.; Hejase, C.A.; Tarabara, V.V.; Fane, A.G.; Chew, J.W. Membrane-Based Separation for Oily Wastewater: A Practical Perspective. Water Res. 2019, 156, 347–365. [Google Scholar] [CrossRef]

- Mccormack, P.; Jones, P.; Hetheridge, M.J.; Rowland, S.J. Analysis of Oilfield Produced Waters and Production Chemicals by Electrospray Ionisation Multi-Stage Mass Spectrometry (ESI-MSn). Water Res. 2001, 35, 3567–3578. [Google Scholar] [CrossRef]

- Jimenez, S.; Mico, M.M.; Arnaldos, M.; Medina, F.; Contreras, S. State of the Art of Produced Water Treatment. Chemosphere 2018, 192, 186–208. [Google Scholar] [CrossRef]

- Lu, H.; Liu, Y.-Q.; Cai, J.-B.; Xu, X.; Xie, L.-S.; Yang, Q.; Li, Y.-X.; Zhu, K. Treatment of Offshore Oily Produced Water: Research and Application of a Novel Fibrous Coalescence Technique. J. Pet. Sci. Eng. 2019, 178, 602–608. [Google Scholar] [CrossRef]

- Mousa, H.; Fahmy, H.; Ali, G.; Abdelhamid, H.; Ateia Ibrahim, M. Membranes for Oil/Water Separation: A Review. Adv. Mater. Interfaces 2022, 9, 2200557. [Google Scholar] [CrossRef]

- Mousa, H.M.; Fahmy, H.S.; Abouzeid, R.; Abdel-Jaber, G.T.; Ali, W.Y. Polyvinylidene Fluoride-Cellulose Nanocrystals Hybrid Nanofiber Membrane for Energy Harvesting and Oil-Water Separation Applications. Mater. Lett. 2022, 306, 130965. [Google Scholar] [CrossRef]

- Mousa, H.M.; Hamdy, M.; Yassin, M.A.; El-Sayed Seleman, M.M.; Abdel-Jaber, G.T. Characterization of Nanofiber Composite Membrane for High Water Flux and Antibacterial Properties. Colloids Surf. A Physicochem. Eng. Asp. 2022, 651, 129655. [Google Scholar] [CrossRef]

- Mousa, H.M.; Alfadhel, H.; Ateia, M.; Abdel-Jaber, G.T.; Gomaa, A.A. Polysulfone-Iron Acetate/Polyamide Nanocomposite Membrane for Oil-Water Separation. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100314. [Google Scholar] [CrossRef]

- Pedersen, S.; Bram, M.V. The Impact of Riser-Induced Slugs on the Downstream Deoiling Efficiency. J. Mar. Sci. Eng. 2021, 9, 391. [Google Scholar] [CrossRef]

- Mognon, J.L.; da Silva, J.M.; Bicalho, I.C.; Ataíde, C.H.; Duarte, C.R. Modular Mini-Hydrocyclone Desilter Type of 30 Mm: An Experimental and Optimization Study. J. Pet. Sci. Eng. 2015, 129, 145–152. [Google Scholar] [CrossRef]

- Mognon, J.L.; Bicalho, I.C.; Ataíde, C.H. Mini-Hydrocyclones Application in the Reduction of the Total Oil-Grease (TOG) in a Prepared Sample of Produced Water. Sep. Sci. Technol. 2016, 51, 370–379. [Google Scholar] [CrossRef]

- Huang, Y.; Li, J.-P.; Zhang, Y.-H.; Wang, H.-L. High-Speed Particle Rotation for Coating Oil Removal by Hydrocyclone. Sep. Purif. Technol. 2017, 177, 263–271. [Google Scholar] [CrossRef]

- Mognon, J.L.; da Silva, J.M.; Bicalho, I.C.; Ataíde, C.H.; Duarte, C.R. Mini-Hydrocyclones Applied to the Removal of Solids from Non-Newtonian Fluids and Analysis of the Scale-Up Effect. J. Pet. Sci. Eng. 2016, 146, 255–263. [Google Scholar] [CrossRef]

- Vakamalla, T.R.; Mangadoddy, N. Numerical Simulation of Industrial Hydrocyclones Performance: Role of Turbulence Modelling. Sep. Purif. Technol. 2017, 176, 23–39. [Google Scholar] [CrossRef]

- Chu, L.Y.; Chen, W.M.; Lee, X.Z. Effect of Structural Modification on Hydrocyclone Performance. Sep. Purif. Technol. 2000, 21, 71–86. [Google Scholar] [CrossRef]

- Zhao, L.; Li, Y.; Xu, B.; Jiang, M. Design and Numerical Simulation Analysis of an Integrative Gas-Liquid-Solid Separation Hydrocyclone. Chem. Eng. Technol. 2015, 38, 2146–2152. [Google Scholar] [CrossRef]

- Abdollahzadeh, L.; Mazraeno, M.S.; Hosseini, S.N.; Fazlali, A.; Soury, E.; Habibian, M.; Khatami, M. Numerical and Experimental Biomass Separation from Fermentation Process ByMinihydrocyclones. Chem. Eng. Technol. 2021, 44, 23–30. [Google Scholar] [CrossRef]

- Kyriakidis, Y.N.; Silva, D.O.; Barrozo, M.A.S.; Vieira, L.G.M. Effect of Variables Related to the Separation Performance of a Hydrocyclone with Unprecedented Geometric Relationships. Powder Technol. 2018, 338, 645–653. [Google Scholar] [CrossRef]

- Motin, A.; Tarabara, V.V.; Petty, C.A.; Bénard, A. Hydrodynamics within Flooded Hydrocyclones during Excursion in the Feed Rate: Understanding of Turndown Ratio. Sep. Purif. Technol. 2017, 185, 41–53. [Google Scholar] [CrossRef]

- Shakeel Syed, M.; Rafeie, M.; Henderson, R.; Vandamme, D.; Asadnia, M.; Ebrahimi Warkiani, M. A 3D-Printed Mini-Hydrocyclone for High Throughput Particle Separation: Application to Primary Harvesting of Microalgae. Lab Chip 2017, 17, 2459–2469. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Jiang, M.; Wang, Y. Experimental Study of a Hydrocyclone under Cyclic Flow Conditions for Fine Particle Separation. Sep. Purif. Technol. 2008, 59, 183–189. [Google Scholar] [CrossRef]

- Endres, E.; Dueck, J.; Neesse, T. Hydrocyclone Classification of Particles in the Micron Range. Miner. Eng. 2012, 31, 42–45. [Google Scholar] [CrossRef]

- Xing, L.; Jiang, M.; Zhao, L.; Gao, J.; Liu, L. Design and Analysis of De-Oiling Coalescence Hydrocyclone. Sep. Sci. Technol. 2021, 57, 749–767. [Google Scholar] [CrossRef]

- Lv, W.J.; Huang, C.; Chen, J.Q.; Liu, H.L.; Wang, H.L. An Experimental Study of Flow Distribution and Separation Performance in a UU-Type Mini-Hydrocyclone Group. Sep. Purif. Technol. 2015, 150, 37–43. [Google Scholar] [CrossRef]

- He, F.; Zhang, Y.; Wang, J.; Yang, Q.; Wang, H.; Tan, Y. Flow Patterns in Mini-Hydrocyclones with Different Vortex Finder Depths. Chem. Eng. Technol. 2013, 36, 1935–1942. [Google Scholar] [CrossRef]

- Huang, C.; Wang, J.G.; Wang, J.Y.; Chen, C.; Wang, H.L. Pressure Drop and Flow Distribution in a Mini-Hydrocyclone Group: UU-Type Parallel Arrangement. Sep. Purif. Technol. 2013, 103, 139–150. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, J.; Bai, Z.; Wang, J.; Wang, H. Experimental Investigation of Various Inlet Section Angles in Mini-Hydrocyclones Using Particle Imaging Velocimetry. Sep. Purif. Technol. 2015, 149, 156–164. [Google Scholar] [CrossRef]

- Pinto, R.C.V.; Medronho, R.A.; Castilho, L.R. Separation of CHO Cells Using Hydrocyclones. Cytotechnology 2008, 56, 57–67. [Google Scholar] [CrossRef] [PubMed]

- Moradinejad, S.; Vandamme, D.; Glover, C.M.; Seighalani, T.Z.; Zamyadi, A. Mini-Hydrocyclone Separation of Cyanobacterial and Green Algae: Impact on Cell Viability and Chlorine Consumption. Water 2019, 11, 1473. [Google Scholar] [CrossRef]

- Yang, Q.; Wang, H.; Wang, J.; Li, Z.; Liu, Y. The Coordinated Relationship between Vortex Finder Parameters and Performance of Hydrocyclones for Separating Light Dispersed Phase. Sep. Purif. Technol. 2011, 79, 310–320. [Google Scholar] [CrossRef]

- Wang, J.; Priestman, G.H.; Tippetts, J.R. Modelling of Strongly Swirling Flows in a Complex Geometry Using Unstructured Meshes. Int. J. Numer. Methods Heat Fluid Flow 2006, 16, 910–926. [Google Scholar] [CrossRef]

- Grady, S.A.; Wesson, G.D.; Abdullah, M.; Kalu, E.E. Prediction of 10-Mm Hydrocyclone Separation Efficiency Using Computational Fluid Dynamics. Filtr. Sep. 2003, 40, 41–46. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, L.; Sun, Y.; Gao, S.; Jiang, M.; Jiang, M.; Rosso, D. Separation Performance of Hydrocyclones with Medium Rearrangement Internals. J. Environ. Chem. Eng. 2021, 9, 105642. [Google Scholar] [CrossRef]

- Hwang, K.-J.; Chou, S.-P. Designing Vortex Finder Structure for Improving the Particle Separation Efficiency of a Hydrocyclone. Sep. Purif. Technol. 2017, 172, 76–84. [Google Scholar] [CrossRef]

- Bai, Z.S.; Wang, H.L. Numerical Simulation of the Separating Performance of Hydrocyclones. Chem. Eng. Technol. 2006, 29, 1161–1166. [Google Scholar] [CrossRef]

- Medronho, R.A.; Schuetze, J.; Deckwer, W.D. Numerical Simulation of Hydrocyclones for Cell Separation. Lat. Am. Appl. Res. 2005, 35, 1–8. [Google Scholar]

- Wu, S.E.; Hwang, K.J.; Cheng, T.W.; Hung, T.C.; Tung, K.L. Effectiveness of a Hydrocyclone in Separating Particles Suspended in Power Law Fluids. Powder Technol. 2017, 320, 546–554. [Google Scholar] [CrossRef]

- Moud, A.; Poisson, J.; Hudson, Z.; Hatzikiriakos, S. Yield Stress and Wall Slip of Kaolinite Networks. Phys. Fluids 2021, 33, 53105. [Google Scholar] [CrossRef]

- Abbasi Moud, A.; Piette, J.; Danesh, M.; Georgiou, G.C.; Hatzikiriakos, S.G. Apparent Slip in Colloidal Suspensions. J. Rheol. 2022, 66, 79–90. [Google Scholar] [CrossRef]

- Hatzikiriakos, S.G. Wall Slip of Molten Polymers. Prog. Polym. Sci. 2012, 37, 624–643. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, B.; Su, Y. Flow Pattern and Pressure Drop for Small Long-Cylinder Cyclones Operating at High Flow Rates. Chem. Eng. Technol. 2019, 42, 1960–1969. [Google Scholar] [CrossRef]

- Patra, G.; Velpuri, B.; Chakraborty, S.; Meikap, B.C. Performance Evaluation of a Hydrocyclone with a Spiral Rib for Separation of Particles. Adv. Powder Technol. 2017, 28, 3222–3232. [Google Scholar] [CrossRef]

- Hwang, K.-J.; Hwang, Y.-W.; Yoshida, H.; Shigemori, K. Improvement of Particle Separation Efficiency by Installing Conical Top-Plate in Hydrocyclone. Powder Technol. 2012, 232, 41–48. [Google Scholar] [CrossRef]

- Bagdi, P.; Bhardwaj, P.; Sen, A.K. Analysis and Simulation of a Micro Hydrocyclone Device for Particle Liquid Separation. J. Fluids Eng. Trans. ASME 2012, 134, 021105. [Google Scholar] [CrossRef]

- Liu, L.; Sun, Y.; Kleinmeyer, Z.; Habil, G.; Yang, Q.; Zhao, L.; Rosso, D. Microplastics Separation Using Stainless Steel Mini-Hydrocyclones Fabricated with Additive Manufacturing. Sci. Total Environ. 2022, 840, 156697. [Google Scholar] [CrossRef]

- Zhao, L.; Li, F.; Ma, Z.; Hu, Y. Theoretical Analysis and Experimental Study of Dynamic Hydrocyclones. J. Energy Resour. Technol. 2010, 132, 429011–429016. [Google Scholar] [CrossRef]

- Bradley, D. The Hydrocyclone: International Series of Monographs in Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2013; Available online: https://www.elsevier.com/books/the-hydrocyclone/bradley/978-0-08-010399-0 (accessed on 20 September 2022).

- Schütz, S.; Gorbach, G.; Piesche, M. Modeling Fluid Behavior and Droplet Interactions during Liquid–Liquid Separation in Hydrocyclones. Chem. Eng. Sci. 2009, 64, 3935–3952. [Google Scholar] [CrossRef]

- Rietema, K.; Maatschappij, S.I.R. Performance and Design of Hydrocyclones—I: General Considerations. Chem. Eng. Sci. 1961, 15, 298–302. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, L.; Reifsnyder, S.; Gao, S.; Jiang, M.; Huang, X.; Jiang, M.; Liu, Y.; Rosso, D. Analysis of Hydrocyclone Geometry via Rapid Optimization Based on Computational Fluid Dynamics. Chem. Eng. Technol. 2021, 44, 1693–1707. [Google Scholar] [CrossRef]

- Bai, Z.S.; Wang, H.L.; Tu, S.T. Removal of Catalyst Particles from Oil Slurry by Hydrocyclone. Sep. Sci. Technol. 2009, 44, 2067–2077. [Google Scholar] [CrossRef]

- Tue Nenu, R.K.; Yoshida, H. Comparison of Separation Performance between Single and Two Inlets Hydrocyclones. Adv. Powder Technol. 2009, 20, 195–202. [Google Scholar] [CrossRef]

- Abdollahzadeh, L.; Habibian, M.; Etezazian, R.; Naseri, S. Study of Particle’s Shape Factor, Inlet Velocity and Feed Concentration on Mini-Hydrocyclone Classification and Fishhook Effect. Powder Technol. 2015, 283, 294–301. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, L.; Yang, X.; Wang, Y.; Xu, B.; Liang, B. Innovative Design and Study of an Oil-Water Coupling Separation Magnetic Hydrocyclone. Sep. Purif. Technol. 2019, 213, 389–400. [Google Scholar] [CrossRef]

- Lv, W.-J.; Chen, J.-Q.; Chang, Y.-L.; Liu, H.-L.; Wang, H.-L. UU-Type Parallel Mini-Hydrocyclone Group Separation of Fine Particles from Methanol-to-Olefin Industrial Wastewater. Chem. Eng. Process. Process Intensif. 2018, 131, 34–42. [Google Scholar] [CrossRef]

- Chen, C.; Wang, H.L.; Gan, G.H.; Wang, J.Y.; Huang, C. Pressure Drop and Flow Distribution in a Group of Parallel Hydrocyclones: Z-Z-Type Arrangement. Sep. Purif. Technol. 2013, 108, 15–27. [Google Scholar] [CrossRef]

- Song, T.; Tian, J.; Ni, L.; Shen, C.; Yao, Y. Experimental Study on Liquid Flow Fields in De-Foulant Hydrocyclones with Reflux Ejector Using Particle Image Velocimetry. Sep. Purif. Technol. 2020, 240, 116555. [Google Scholar] [CrossRef]

- He, F.; Wang, H.; Wang, J.; Li, S.; Fan, Y.; Xu, X. Experimental Study of Mini-Hydrocyclones with Different Vortex Finder Depths Using Particle Imaging Velocimetry. Sep. Purif. Technol. 2020, 236, 116296. [Google Scholar] [CrossRef]

| Do/Dc | Du/Dc | Lc/Dc | Lv/Dc | Ld/Dc | a/Dc; b/Dc | θ |

|---|---|---|---|---|---|---|

| 0.2 | 0.25 | 1.06 | 0.16 | 9.63 | 0.18; 0.32 | 5.8° |

| Physical Parameters | Values |

|---|---|

| Density ρo | 889 kg/m3 |

| Oil droplet size in feed liquid do (μm) | 20, 40, 60, 80, 100, 150, 200, 300, 400, 500 |

| Oil volume concentration in feed liquid | Case 1: 5% and Case 2: 10% |

| Oil viscosity ηo | 1.006 Pa·s |

| Do/Dc | Du/Dc | Lc/Dc | Lv/Dc | Ld/Dc | a/Dc; b/Dc | θ |

|---|---|---|---|---|---|---|

| 0.2 | 0.18 | 0.52 | 0.38 | 3 | 0.15; 0.3 | 7° |

| Physical Parameters | Values |

|---|---|

| Density ρo | 2200 kg/m3 |

| Silica particles in feed liquid dp (μm) | 5, 10, 20, 40, 60, 80, 100 |

| Feed particle volume concentration | 0.7% (each particle size accounts for 0.1%) |

| % | 5 μm | 10 μm | 20 μm |

|---|---|---|---|

| Dc = 2.5 mm | 0.087 | 0.049 | 6.34 × 10−4 |

| Dc = 10 mm | 0.094 | 0.076 | 0.019 |

| Dc = 40 mm | 0.099 | 0.093 | 0.073 |

| Types | Formula | Direction |

|---|---|---|

| Centrifugal force/FC | Opposite to the axis | |

| Radial pressure gradient force/FP | To the axis | |

| Stokes resistance/FS | Opposite to the axis | |

| Magnus force/FM | Determined by the direction of autorotation |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, L.; Zhao, L.; Wang, Y.; Zhang, S.; Song, M.; Huang, X.; Lu, Z. Research on the Enhancement of the Separation Efficiency for Discrete Phases Based on Mini Hydrocyclone. J. Mar. Sci. Eng. 2022, 10, 1606. https://doi.org/10.3390/jmse10111606

Liu L, Zhao L, Wang Y, Zhang S, Song M, Huang X, Lu Z. Research on the Enhancement of the Separation Efficiency for Discrete Phases Based on Mini Hydrocyclone. Journal of Marine Science and Engineering. 2022; 10(11):1606. https://doi.org/10.3390/jmse10111606

Chicago/Turabian StyleLiu, Lin, Lixin Zhao, Yahong Wang, Shuang Zhang, Minhang Song, Xueqiang Huang, and Zhongrun Lu. 2022. "Research on the Enhancement of the Separation Efficiency for Discrete Phases Based on Mini Hydrocyclone" Journal of Marine Science and Engineering 10, no. 11: 1606. https://doi.org/10.3390/jmse10111606

APA StyleLiu, L., Zhao, L., Wang, Y., Zhang, S., Song, M., Huang, X., & Lu, Z. (2022). Research on the Enhancement of the Separation Efficiency for Discrete Phases Based on Mini Hydrocyclone. Journal of Marine Science and Engineering, 10(11), 1606. https://doi.org/10.3390/jmse10111606