Abstract

To address the low shelling rate and high seed breakage in existing oil tea fruit shelling devices, a novel laser scoring device was designed for fresh Camellia oleifera fruits. Experimental studies were conducted to optimize the key parameters of the custom-built laser scoring machine, aiming to improve scoring qualification rates. Through single-factor tests and response surface methodology, a regression model was developed to characterize the relationship between the scoring qualification rate and the following three variables: conveyor speed (12 mm/s), laser power (97 W), and defocusing distance (10 mm). The study revealed interactive effects among these parameters. After optimization and verification under ideal conditions, the device achieved a peak average qualification rate of 85.6%.

1. Introduction

Camellia oleifera, an endemic woody oil-bearing species indigenous to China [1], boasts a cultivation history spanning more than 2000 years [2]. The seed-derived oil from this species, colloquially termed “Oriental olive oil” due to its exceptional nutritional profile [3], is predominantly harvested through either manual collection or mechanized systems [4,5]. Notably, vibrational harvesting technology has established itself as the industry-standard methodology in mechanized operations, leveraging targeted mechanical oscillations to optimize fruit detachment [6,7]. Post-harvest protocols systematically progress through four critical phases: initial solar dehydration, mechanical pericarp removal, automated impurity separation, and controlled thermal processing. This sequential pretreatment cascade precedes the mechanical expression of crude oil, which subsequently undergoes multistage refinement processes to meet stringent edible oil quality standards. The fruit consists of three components: a cellulose-rich, oil-free shell, seed, and septum [8]. The shell’s fibrous structure adversely affects oil processing and equipment performance, necessitating removal [9]. With expanding cultivation, the demand for mechanical shelling has increased significantly. Current methods include extrusion-rubbing [10,11], centrifugal-impact [12], flexible roller-beating [13], and shear mechanisms [14], supplemented by thermal bursting [15,16] and enzymatic approaches. While most shellers combine single/multiple principles for shell-seed separation [17], the following challenges remain: a high kernel breakage rate, broken seeds, and post-shelling separation difficulties [18].

Extensive studies indicate that pretreatment enhances Camellia oleifera shelling efficiency. Li et al. [19] designed a dehulling machine specifically for Camellia oleifera fruits with rotor blades combining shearing, impacting, and tearing actions. The shelling mechanism utilizes rotating cutter blades for repeated cutting and impacting the shelling chamber, but high-speed rotation causes significant seed damage. Xiao et al. [20] developed a mechanical scoring device using vertically movable spring blades to create circumferential scores on shells without damaging seeds, followed by roller crushing. This scoring pretreatment reduces seed damage and produces uniformly sized shell fragments for efficient separation. Xiao [21] designed a laser chestnut scoring machine, achieving a 98% bursting rate (the success rate of shell cracking was measured precisely along laser scores) through gas-jet impact after scoring. Jin et al. [22] applied laser scoring to peanut pods, reducing compressive fracture force and deformation while improving the shelling rate and kernel integrity. Chou et al. [23] developed a laser scoring device optimized for walnuts. The defocusing amount (which refers to the distance between the laser focus and the walnut surface, and this distance affects the energy distribution and effect of the laser on the walnut shell) has an important impact on the laser scoring effect. At a conveyor speed of 25 mm/s, a laser power of 130 W, and a defocusing distance of 2 mm in the laser scoring process, the ratio of walnuts whose shells are not fully penetrated (i.e., the scratching rate) reaches 7%; the ratio of walnuts whose shells are penetrated without damaging the kernels (i.e., the scoring qualification rate) reaches 91%; and the ratio of walnuts whose shells are penetrated but the kernels are damaged (i.e., the kernel damage rate) is 2%. This parameter combination demonstrates the optimal balance between processing efficiency and product quality. Zhang [24] combined compression tests and finite element simulations to study walnut fragmentation, achieving a 99.6% shelling rate (the ratio of walnuts with fully removed shells) and an 88.1% intact kernel rate (the proportion of undamaged kernels) with laser scoring. Compared to mechanical methods, laser scoring enables precise depth control, avoids inconsistent cuts caused by uneven tool pressure or wear, eliminates mechanical compression, reduces kernel damage risks, and offers higher controllability and automation. Additionally, laser scoring requires only positioning without clamping, ensuring smoother operation.

While laser scoring has been studied for walnuts, chestnuts, and peanuts, Camellia oleifera presents unique challenges due to its complex shell structure (e.g., irregular fiber alignment and uneven thickness) and mechanical variability. Current issues include unstable scoring depth control and high seed damage risks. Systematic research on laser parameters (power, conveyor speed, defocusing distance) and their interaction with shells is essential to overcome traditional mechanical method limitations (high damage and low efficiency), bridge theoretical and technological gaps in laser-based shelling, and advance high-efficiency and low-damage processing in equipment development. This effort will also promote laser technology applications in agricultural processing.

This study applies laser scoring technology to Camellia oleifera. A dedicated laser scoring device was developed to investigate the effects of scoring speed, laser power, and defocusing distance on scoring quality. Through experimental optimization, we aim to establish optimal shelling parameters that ensure efficient scoring without seed damage, improve shelling quality, surpass single-mechanism methods, and provide theoretical foundations for advanced laser scoring equipment.

2. Materials and Methods

2.1. General Structure and Operating Principle

2.1.1. Working Principle

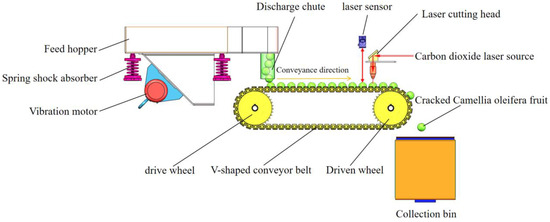

Figure 1 illustrates the working principle of the device. The working principle of the Camellia oleifera fruit laser scoring device is as follows: The Camellia oleifera fruits are initially loaded into the hopper and transported into the conveyor tube under the vibration of a motor-driven vibration motor. Through this tube, the fruits are transferred onto the specialized conveyor system, where precise single-file alignment is achieved via the geometric constraints of the belt’s V-shaped guiding channels. When the fruits are conveyed to the laser processing module (cutting station), the laser sensor triggers the control circuit by detecting the reflected signal from the fruit surface, instantly activating the focused laser beam to generate uniform circumferential grooves through controlled ablation. Once the fruit exits the focal zone of the laser cutting head, the laser beam automatically deactivates to minimize energy consumption. Finally, the processed fruits move to the downstream section of the conveyor system and drop into the collection bin, completing the automated processing.

Figure 1.

Working principle of Camellia oleifera laser scoring device.

2.1.2. General Structure

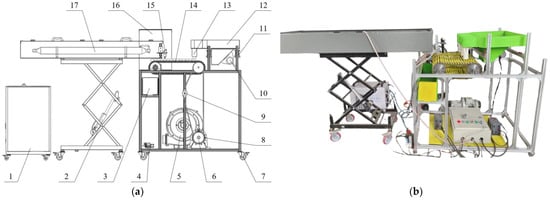

The laser scoring device for Camellia oleifera fruit (Figure 2) is a homemade apparatus that incorporates a vibration feeding device, a conveying device, and a laser scoring device. The vibration feeding device comprises a hopper, a vibration motor, a spring shock absorber, and other components. The conveying device consists of a sprocket, a drive shaft, a “V” conveyor belt, a drive mechanism, and other components. The laser scoring module consists of four core components: the CO2 laser, laser cutting head, electric lifter, and chiller system.

Figure 2.

The Camellia oleifera fruit laser scoring device. (a) Structural diagram of Camellia oleifera fruit laser scoring device. 1. Chiller; 2. electric lifter; 3. collection bin; 4. electromagnetic air pump; 5. blower; 6. belt pulley; 7. caster; 8. drive motor; 9. belt tensioner pulley; 10. vibration motor; 11. spring shock absorber; 12. feed hopper; 13. discharge chute; 14. V-shaped conveyor belt; 15. laser cutting head; 16. laser cutting protective cover; and 17. CO2 laser. (b) Physical prototype of Camellia oleifera laser scoring device.

The component types and parameters of the Camellia oleifera fruit laser scoring device are listed in Table 1. The conveyor speed is controlled by adjusting the motor’s rotational speed via a frequency converter. The laser output power is regulated by tuning the supply current through the laser power source, with real-time calibration based on ammeter readings. The defocusing distance is adjusted by vertically positioning the laser using an electric lifter. The controller and control strategies are implemented as follows: The frequency converter utilizes a V/f controller (constant voltage-to-frequency ratio controller) with an open-loop control strategy; the laser power supply is regulated by an analog controller operating in the open-loop mode; and the electric lifter is controlled via a wired manual controller under an open-loop strategy.

Table 1.

Component types and parameters of a laser scoring machine for Camellia oleifera fruits.

2.2. Key Component Design

2.2.1. Laser Generator

Lasers are categorized into five types by an active medium: solid-state, gas, liquid, semiconductor, and free electron media. Gas lasers excel in their structural simplicity, low cost, superior beam quality, and long-term stable operation. CO2 lasers generate 10.6 μm mid-infrared radiation through gas tube glow discharge, offering dual continuous/pulsed modes with stable power output and strong environmental resistance (operating range: 9–18 μm), making them dominant in industrial welding and cutting applications.

Based on preliminary research and pre-experiments, a moisture analyzer measured the average moisture content of unopened Camellia oleifera fruit shells at approximately 75%. To ensure the laser’s power level sufficiently meets the scoring requirements for Camellia fruits, a CO2 laser with 140 W power and 10.6 μm wavelength was selected.

Laser reflecting mirrors, as core components of the optical path system, directly determine scoring efficiency and quality through three key factors: efficient energy transmission, thermal stability assurance, and optical precision control. Silicon mirrors exhibit advantages in high-power laser systems (>100 W) due to their low cost, durability, and thermal stability. Their reflectivity exceeds 98%, their energy loss is below 2%, and their surface roughness is significantly lower than molybdenum mirrors. Although molybdenum mirrors tolerate harsh environments and have longer lifespans, their high impurity content and poor compactness limit their application to sub-100 W scenarios. After a comprehensive evaluation of performance and cost, a silicon-based reflecting mirror with 20 mm diameter and 3 mm thickness was selected.

The optical focusing lens concentrates the laser beam axially onto the workpiece. The relationships between the laser focusing spot diameter d, depth of focus b, and power density Pf at the focus are as follows [25]:

This design employs a CO2 laser with three key parameters: 140 W power output, 1.06 × 10−5 m wavelength, and 5 × 10−3 m beam diameter. The selected focusing lens has a 63.5 mm focal length and 20 mm diameter. Calculations based on Equations (1)–(3) yield a focal spot diameter of 2.05 × 10−4 m, a depth of focus of 1.69 × 10−2 m, and laser power density at the focal point of 4.2 × 109 W/m2.

During Camellia oleifera fruit scoring, graded fruits exhibit dimensional variations ≤10 mm. The 16.9 mm depth of focus, thus, accommodates scoring requirements for different-sized graded fruits. Compared to steel cutting, which requires 108–109 W/m2 power density, the achieved power of 4.2 × 109 W/m2 sufficiently ablates the Camellia oleifera shells.

2.2.2. Vibratory Feeders

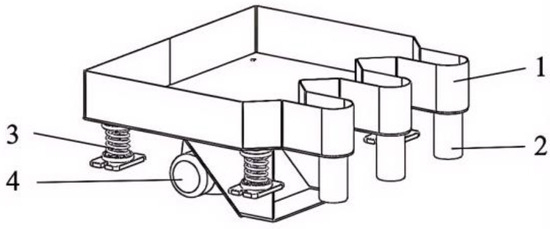

The fresh Camellia oleifera fruit vibration feeding system comprises a feed hopper, conveying tube, vibration motor, and damping springs. Four damping springs were installed below the feed hopper to reduce the noise and wear caused by the vibration motor operation. The hopper contains three channels where fruits enter the feeding passages through motor-induced vibrations and then fall onto the lower conveyor belt via the conveying tube in an orderly manner. The structural schematic diagram of the vibration feeding device is shown in Figure 3.

Figure 3.

Camellia oleifera fruit vibratory feeder. 1. Feed hopper; 2. discharge chute; 3. spring shock absorber; and 4. vibrating motor.

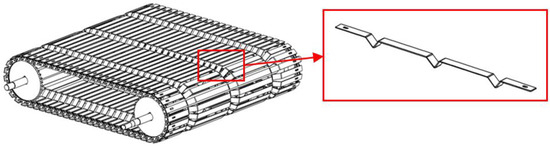

2.2.3. V-Shaped Conveyor Belt

The key to the laser scoring technology for Camellia oleifera fruits lies in achieving the ordered alignment and positioning of fruits with varying sizes and shapes prior to scoring. Based on morphological studies of the fruits, a “V”-shaped positioning and conveying plate was designed, as shown in Figure 4. This system consists of multiple “V”-shaped positioning plates and a conveyor chain. Each plate has openings at both ends and is mounted onto the chain via bolts, forming a complete “V”-shaped positioning and a conveying belt. This ensures that fruits remain centered within the grooves of the “V”-shaped plates during transport. To prevent interference between adjacent plates, the plate width is set to 18 mm. The upper opening of the “V”-shaped groove is 40–45 mm wide, with a 90-degree angle between its walls. Since the safety distance between adjacent lasers must be no less than 150 mm, the spacing between “V”-shaped grooves is set to 160 mm. To withstand the laser’s intensity and prevent the penetration or ablation/melting of the plates, metal materials are used for fabrication.

Figure 4.

V-shaped Camellia oleifera fruit orientation and conveyor system.

2.3. Experimental Conditions and Equipment

2.3.1. Single-Factor Test Method

This experiment was conducted at the Shuangfeng County Agricultural Machinery Group in Loudi City, Hunan Province, from November to December 2024. This experiment selected fresh Camellia oleifera fruits with intact shells (approximately 35 mm in diameter). The size variation among individual fruits was controlled within 1 mm. Through manual adjustments, the defocusing distance for each fruit was maintained within ±1 mm. The influence of factors such as moisture content and fruit shape was disregarded. Conveyor speed (A, mm/s, equivalent to laser scoring speed), laser output power (B, W), and defocusing distance (C, mm) were selected as the three experimental factors.

The experimental design involved a single-factor approach, with one test factor systematically varying while holding other factors constant at their respective level averages. This approach was employed to ascertain the influence of A, B, and C on the index of the scoring qualification rate of oil tea fruit scoring. Under each parameter condition, 50 oil tea fruits were selected for testing, with each experiment replicated three times, and the average values were calculated to ensure data reliability. The factor level coding tables for the single-factor experiments of conveyor speed, laser power, and defocusing distance are shown in Table 2, Table 3, and Table 4, respectively.

Table 2.

Table showing the factor level coding for the single-factor experiment of conveyor speed.

Table 3.

Table showing the factor level coding for the single-factor experiment of laser power.

Table 4.

Table showing the factor level coding for the single-factor experiment of defocusing distance.

2.3.2. Multi-Factor Test Method

The experimental materials used in the single-factor and multi-factor experiments are consistent. In the subsequent analysis, the response surface experimental design was built upon the findings of the single-factor test. The three-factor, three-level Box–Behnken method was employed for experimental design, with each influencing factor designated as the lowest, middle, and highest of these three levels, coded as −1, 0, and +1, respectively, and incorporated into the test. The range of values for each influencing factor was formulated based on the results of the one-factor test, as illustrated in Table 5.

Table 5.

Table showing the factor-level coding for multi-factor tests.

2.3.3. Experimental Indicator

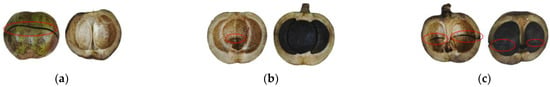

The key criteria for evaluating laser scoring quality are scoring effectiveness (whether the shell is fully penetrated) and seed integrity (the absence of damage to Camellia oleifera seeds). We referred to the definition of notching quality for walnuts in Reference [23] and extended it to define the notching quality criteria for Camellia oleifera fruits. Fruits with non-penetrated shells are classified as scratches; those with fully penetrated shells and intact seeds as valid notches; and those with penetrated shells but damaged seeds as damaged notches. A notch refers to structured incisions (e.g., V/U-shaped) penetrating the shell without kernel damage, formed by laser or mechanical processing; Scratches denote non-penetrative unstructured surface damage (e.g., abrasions). A schematic diagram illustrating these scoring quality categories is presented in Figure 5. The scoring qualification rate (η) is adopted as the evaluation metric, where a higher η value indicates superior scoring quality.

Figure 5.

Laser scratching quality diagram of camellia fruit. (a) Scratch; (b) valid notch; and (c) dam-aged notch.

In this context, n denotes the number of oil tea fruits that have been scratched through but not injured, whereas N signifies the total number of oil tea fruits that have been scratched.

3. Results

3.1. Analysis of Single-Factor Test Result

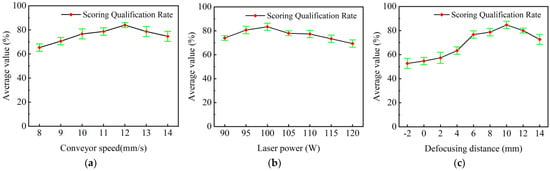

The results of the single-factor tests are shown in Figure 6. As shown in Figure 6a, the scoring qualification rate of Camellia oleifera fruits first increases and then decreases with higher conveyor speed. At a conveyor speed of 12 mm/s, the scoring qualification rate reaches its maximum value of 84%, with the lowest damage rate (4%). At 8 mm/s, the damage rate peaks at 24%. When the conveyor speed is 14 mm/s, the scoring failure rate reaches its highest value of 18%. The damage rate first decreases and then increases with the increasing conveyor speed while the scoring failure rate gradually increases. Thus, the scoring qualification rate declines when the conveyor speed exceeds 14 mm/s or falls below 8 mm/s.

Figure 6.

Single–factor experiment results. (a) Influence of conveyor speed on scoring quality; (b) influence of laser power on scoring quality; and (c) influence of defocusing distance on scoring quality.

As shown in Figure 6b, the qualification scoring rate initially rises and then declines with increasing laser output power. At 100 W, the scoring qualification rate peaks at 83%, with the lowest damage rate (5%). The scoring failure rate gradually decreases with higher laser power, peaking at 19% and 90 W. The damage rate first decreases and then increases with laser power, reaching a maximum of 20% at 120 W. When the laser power is below 90 W, the scoring failure rate increases, and above 120 W, the damage rate increases. According to the single-factor experiment results, when other factors remained constant, as the laser power increased from 90 W to 100 W, the scoring qualification rate gradually increased; when the laser power exceeded 100 W, the scoring qualification rate began to decrease; and when the laser power surpassed 110 W, the decline accelerated. Therefore, the laser power range of 90 W–110 W is considered appropriate.

As shown in Figure 6c, the scoring qualification rate first increases and then decreases with a higher defocusing distance. At a defocusing distance of 0 mm, the highest number of oil tea fruits are damaged due to the intense concentration of laser energy. A positive defocusing distance optimizes the laser energy distribution on the Camellia oleifera shell surface, significantly improving the scoring qualification rate. When the defocusing distance reaches 10 mm, the scoring qualification rate peaks at 84.6%.

3.2. Analysis of Multi-Factor Test Results

3.2.1. Multi-Factor Test Results

The Box-Behnken design method was employed in Design-Expert 13 software to construct a three-factor experimental design with three coded levels. The design comprised 17 experimental runs, including 12 factorial points for model establishment and 5 center points for curvature check and pure error estimation. When inputting each factor with its corresponding level values sequentially into the system, it generates an experimental plan table (Table 6). The experiments were conducted according to this plan, with the results recorded for each factor combination and entered into the designated columns.

Table 6.

Protocol and results of multi-factor test.

3.2.2. Establishment and Significance Testing of the Regression Model

Analysis of variance (ANOVA) for the regression model was performed on the experimental data from Table 6, yielding Table 7. Using Design Expert 13 software, multiple regression analysis was performed on the data from Table 7, yielding the following quadratic regression model for the scoring qualification rate (η):

η = 83.2 − A − 4.5B + 3.5C + 2.5AB − 5.5AC + 1.5BC − 8.35A2 − 7.35B2 − 5.35C2

Table 7.

ANOVA of the regression model.

Equation (5) is a quadratic regression model with which to determine the scoring qualification rate (η), derived from multiple regression analysis of the data in Table 7 using Design Expert 13 software. The exclusion of the ABC term (third-order interaction) aims to balance model complexity and practicality: third-order interactions would significantly increase the computational burden and statistical risks (e.g., overfitting and the reduced interpretability of parameters). In practical engineering applications, such higher-order interaction effects are generally statistically insignificant or lack theoretical justification based on physical mechanisms. The p-value measures the significance of a parameter’s impact on the model. A p-value below 0.01 indicates a highly significant effect on the model, while a p-value between 0.01 and 0.05 suggests a significant effect. As shown in Table 7, the p-value for the scoring qualification rate (η) is less than 0.01, indicating an extremely significant impact on the regression model. In contrast, the lack-of-fit term has a non-significant p-value of 0.6276, demonstrating that the regression model for the scoring qualification rate exhibits a satisfactory goodness of fit. Furthermore, the analysis of the influence of experimental factors on the response revealed that the interaction term AB has a significant impact on the scoring qualification rate (η), whereas the interaction term AC and the quadratic terms A2, B2, and C2 exhibit highly significant effects. The order of influence of the factors on the scoring qualification rate (η) is C (defocusing distance) > A (conveyor speed) > B (laser power).

3.2.3. Analysis of the Effect of Interaction Factors on the Performance of Laser Scoring Devices

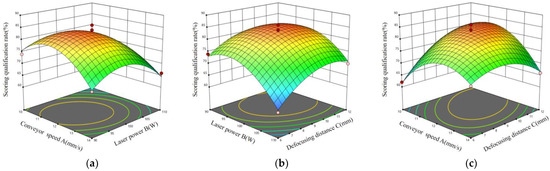

Figure 7 presents a three-dimensional response surface plot that describes the interaction of conveyor speed, laser power, and defocusing distance on the scoring qualification rate (%) of the cuts.

Figure 7.

Interactive effects of factors on scoring qualification rate. (a) Effect of conveyor speed and laser power on scoring qualification rate; (b) effect of laser power and defocusing distance on scoring qualification rate; and (c) effect of conveyor speed and defocusing distance on scoring qualification rate. The color gradient represents the magnitude of the response variable scoring qualification rate (%), with warmer hues (red) corresponding to higher values and cooler hues (blue) denoting lower values.

The laser power and defocusing distance in the experiment are described in Figure 7a. Figure 7a illustrates the effects of conveyor speed and laser power on the scoring qualification rate. The elliptical contour lines of factors A (conveyor speed) and B (laser power) indicate a significant interaction effect between them. The elliptical contour lines between these two factors indicate a significant interaction effect. The overall trend indicates that as the conveyor speed and laser power increase, the scoring qualification rate initially increases and subsequently decreases. The influence of conveyor speed is more pronounced than that of laser power. The conveyor speed and defocusing distance are shown in Figure 7b. Figure 7b demonstrates the influence of the laser power and defocusing distance on the scoring qualification rate. Although factors B (laser power) and C (defocusing distance) exhibit elliptical contour lines, their interaction effect is not statistically significant. Conveyor speed and laser power are shown in Figure 7c. Figure 7c shows the impact of the conveyor speed and defocusing distance on the scoring qualification rate. The elliptical contour lines of factors A (conveyor speed) and C (defocusing distance) suggest a significant interaction effect between these two parameters. The overall trend suggests that as both conveyor speed and defocusing distance increase, the scoring qualification rate first increases and then decreases. The effect of conveyor speed is more dominant compared to the defocusing distance.

3.3. Optimization of Working Parameters

It is known from the response surface analysis that the conveyor speed, laser power, and defocusing distance are all related to the scoring qualification rate η. Optimized by Design-Expert 13 software, the final optimization results are as follows: when the conveyor speed is 11.52 mm/s, the laser power is 96.94 W, and when the defocusing distance is 10.22 mm, the scoring qualification rate is 84.72%. Considering the simplicity of the actual operation, the optimal parameters are adjusted to a conveyor speed of 12 mm/s, a laser power of 97 W, and a defocusing distance of 10 mm.

3.4. Field Experiment Validation

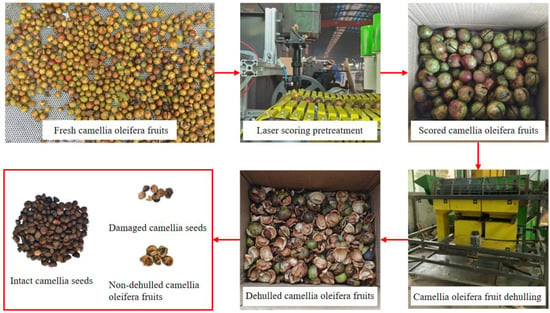

To validate the robustness of the regression model, verification experiments were conducted using the optimized parameter combination derived from the response surface methodology. The selected parameters included the following factors: conveyor speed (12 mm/s), laser power (97 W), and defocusing distance (10 mm), corresponding to the predicted optimal condition. Five independent replicates were performed, and the mean values of the experimental results (with standard deviations) are summarized in Table 8. The experimental results demonstrated a mean scoring qualification rate of 85.6% under optimized conditions (relative error 1.04%, p > 0.05), showing no statistically significant deviation from the predicted value. This confirms the validity of response surface methodology (RSM)-optimized parameters for Camellia oleifera laser scoring, establishing a reliable reference for industrial-scale processing. The verification of the experiment is shown in Figure 8. Fresh Camellia oleifera fruits were treated by a laser scoring device, including the remaining 14.4% unqualified fruit. All the scored fruits were then mechanically dehulled. The dehulled products were manually sorted into damaged camellia seeds, non-dehulled fruits, and intact camellia seeds, followed by the statistical calculation of the dehulling rate and kernel breakage rate. Mechanical dehulling was performed on 3 kg of Camellia oleifera fruits pretreated with laser scoring, with five experimental replicates. The statistical results were averaged, yielding an average dehulling rate (the proportion of fruits with fully removed shells) of 96.9% and an average seed breakage rate (the proportion of seeds damaged during dehulling) of 2.32%. A Camellia oleifera fruit dehuller with adjustable dehulling clearance achieved a dehulling rate of 96.91% with a seed breakage rate of 3.38% [11]. A compression-shearing Camellia oleifera fruit shelling machine achieved a dehulling rate of 91.5% with a seed breakage rate of 2.0% [26]. The experimental results demonstrate that laser scoring pretreatment effectively improves the mechanical dehulling efficiency of Camellia oleifera fruits.

Table 8.

The result of the verification experiment.

Figure 8.

Verification experiment.

4. Discussion

As a unique woody oil crop endemic to China, Camellia oleifera fruits are primarily processed for tea oil extraction. The growing market demand, driven by tea oil’s recognized health benefits, has accelerated the development of tea oil processing industries in recent years. However, the shelling process remains a critical bottleneck in tea oil production. Existing shelling machinery fails to adequately meet growers’ requirements, with conventional equipment exhibiting the following dual deficiencies: low shelling efficiency and high kernel breakage rates. The critical challenge lies in reducing the shell-breaking force during processing to enhance the efficiency of shelling while minimizing kernel damage.

This study developed a compact laser scoring machine for Camellia oleifera fruits, demonstrating broad applicability for nut pre-processing. Orthogonal experiments revealed differentiated impacts of three operational parameters on scoring performance. Defocusing distance exerted the most significant impact on the slotting qualification rate, followed by conveyor speed, with laser power showing minimal influence. The defocusing distance—the gap between the laser focal point and the material surface—determines laser energy density distribution through precise adjustment. At zero defocusing distance, excessive energy concentration caused shell perforation and kernel damage. Single-factor tests demonstrated improved qualification rates with positive defocusing values. Optimal performance requires parameter coordination: maintaining lower laser power while increasing conveyor speed achieves both higher qualification rates and processing efficiency. The 85.6% qualification rate indicates that most fruits met the laser scoring criteria, which is currently considered sufficient. The scoring qualification rate of 85.6% indicates that the majority of Camellia oleifera fruits (85.6%) met the laser notching standards and proceeded to the subsequent dehulling process. The remaining 14.4% of non-compliant fruits included both unscratched and scratched fruits. As the scratched fruits had minimal impact, all notched fruits underwent dehulling. While the scoring qualification rate of 85.6% was achieved, the gap compared to walnuts (91% in Reference [23]) primarily stems from the higher anisotropy of Camellia oleifera shells. Further optimization of experimental methods and parameters is required to achieve a higher scoring qualification rate.

Two technical bottlenecks emerged: First, natural variations in ellipsoidal fruit morphology present a challenge due to the inconsistency of their maintenance during processing, directly affecting scoring quality stability. To address this, developing a novel conveying system with precise positional control is proposed to ensure parameter consistency. Second, the economic constraints of CO2 laser systems (high initial investment and operational costs) necessitate subsequent research, focusing on the adaption of cost-effective semiconductors or fiber lasers. Notably, while laser scoring faces dual challenges regarding cost efficiency, technological innovations like dynamic parameter adaptation can enhance economic viability. The developed solution not only addresses Camellia processing needs but also provides transferable methodologies for the mechanized processing of other nut crops, offering valuable references for the intelligent upgrading of agricultural processing equipment.

Furthermore, varietal differences in Camellia fruits may influence machine performance. Practical implementation requires parameter optimization (conveyor speed, laser power, and defocusing distance) based on specific operational conditions.

5. Conclusions

- (1)

- A laser scoring device for pre-processing Camellia oleifera fruits was developed. Theoretical analysis and structural design were performed on key components, including the vibratory conveying device and the laser scoring system. Through single-factor experiments, the influence trends of conveyor speed, laser output power, and defocusing distance on the qualification rate of scoring were preliminarily explored, and reasonable parameter ranges for each factor were determined.

- (2)

- To achieve the highest qualification rate of scoring, a mathematical model describing the relationship between each factor and the qualification rate was established using the response surface methodology. The model’s lack-of-fit and F-value were analyzed to validate its accuracy. The degree of influence of each factor on the qualification rate was ranked as follows: A (conveyor speed) = C (defocusing distance) > B (laser power). Both conveyor speed and defocusing distance had significant effects on the qualification rate, and a significant interaction was observed between the conveyor speed (A) and laser power (B).

- (3)

- Using Design-Expert 13 software, the experimental results were optimized and validated. The optimal operating parameters for the laser scoring device were determined as follows: a conveyor speed of 12 mm/s, laser power of 97 W, and defocusing distance of 10 mm. Under these conditions, the qualification rate of scoring reached 85.6%.

Future improvements in the scoring qualification rate can be achieved by optimizing laser parameters (e.g., laser power, conveyor speed, and defocusing distance), integrating real-time monitoring and feedback systems, and upgrading processing equipment.

Author Contributions

Conceptualization, Z.W.; methodology, X.L.; software, X.L. and Y.C.; investigation, X.L., Y.C., G.H., X.Y. and Z.W.; resources, X.L.; writing—original draft preparation, X.L.; writing—review and editing, Z.W.; supervision, Z.W.; project administration, Z.W.; funding acquisition, Z.W. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Project of a Full-Process Mechanization Research Base for Special Oil Crops (Camellia oleifera) by the Department of Agricultural Mechanization Management, Ministry of Agriculture and Rural Affairs, of the People’s Republic of China: 2022-21.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jiang, X.; Zhao, J.P.; Liu, P.; Wang, K.; Xu, J.M.; Jiang, J. Research Progress on Fatty Acid Composition, Purification, and Applications of Woody Oils. Biomass Chem. Eng. 2022, 56, 60–68. [Google Scholar]

- Chen, Y.Z.; Deng, S.H.; Chen, L.S.; Ma, L.; He, H.; Wang, X.; Peng, S.; Liu, C.; Wang, R.; Xu, Y.; et al. New Perspectives on the Development of the Camellia oleifera Industry. J. Nanjing For. Univ. 2020, 44, 1–10. [Google Scholar]

- Luan, F.; Zeng, J.; Yang, Y.; He, X.; Wang, B.; Gao, Y.; Zeng, N. Recent advances in Camellia oleifera Abel: A review of nutritional constituents, biofunctional properties, and potential industrial applications. J. Funct. Foods 2020, 75, 104242. [Google Scholar] [CrossRef]

- Wang, J.P.; He, M.; Zhen, Q.G.; Hu, H.; Yuan, F.; Chen, S.; Fang, C. Vibration Picking Point Localization Method for Camellia oleifera Fruits Based on Improved UNet Model. Trans. Chin. Soc. Agric. Eng. 2024, 40, 171–178. [Google Scholar]

- Peng, Y.X.; Liao, K.; Xu, S.Y.; Chen, F.; Li, L.; Tang, G.; Luo, H. Development of a Wheel-Integrated Camellia oleifera Fruit Harvester for Hilly and Mountainous Areas. Trans. Chin. Soc. Agric. Eng. 2024, 40, 31–38. [Google Scholar]

- Tong, W.; Liao, K.; Li, L.; Gao, Z.; Chen, F.; Luo, H. Optimization of the Camellia oleifera Fruit Harvester Engine Compartment Heat Dissipation Based on Temperature Experiments and Airflow Field Simulation. Agriculture 2024, 14, 1640. [Google Scholar] [CrossRef]

- Gao, Q.; Han, J.; Zeng, S.; Wang, Y.; Wei, W.; Wang, D.; Ye, H.; Lu, J.; Zeng, H. Performance Analysis and Operation Parameter Optimization of Shaker-Type Harvesting for Camellia Fruits. Agriculture 2024, 14, 1989. [Google Scholar] [CrossRef]

- Liang, W.J.; Xiao, P.; Cui, M.; Fu, Y.; Luo, L. Dynamics of Fruit and Seed Development in Camellia oleifera. J. Nanchang Univ. 2019, 43, 46–52. [Google Scholar] [CrossRef]

- Tian, X.X.; Fang, X.Z.; Liu, S.H.; Du, M. Effects of Shelling Treatment on Nutritional Quality and Antioxidant Capacity of Camellia oleifera Seed Oil. J. Chin. Cereals Oils Assoc. 2020, 35, 98–103. [Google Scholar]

- Shi, M.C.; Liu, M.Z.; Li, C.H.; Cao, C.; Li, X. Design and Experiment of a Cam-Rocker Bidirectional Extrusion Walnut Shelling Device. Trans. Chin. Soc. Agric. Mach. 2022, 53, 140–150. [Google Scholar]

- Zhu, G.F.; Ren, J.J.; Wang, Z.; Xiang, H.; Mu, R.; Li, S. Design and Parameter Optimization of a Camellia oleifera Fruit Shelling Machine. Trans. Chin. Soc. Agric. Eng. 2016, 32, 19–27. [Google Scholar]

- Tang, X.; Xie, F.P.; Li, X.; Liu, D.; Wang, X.; Mao, L. Design and Experiment of a Camellia oleifera Fruit Shelling Device. J. Hunan Agric. Univ. 2014, 40, 665–668. [Google Scholar] [CrossRef]

- Ding, R.; Cao, C.M.; Zhan, C.; Lou, S.; Sun, S. Design and Experiment of a Biomimetic Percussive Hickory Nut Shelling Machine. Trans. Chin. Soc. Agric. Eng. 2017, 33, 257–264. [Google Scholar]

- Liu, M.Z.; Li, C.H.; Zhang, Y.B.; Yang, M.; Hou, Y.; Gao, L. Mechanism Analysis and Performance Test of Flexible Belt Shearing-Extrusion Walnut Shelling. Trans. Chin. Soc. Agric. Mach. 2016, 47, 266–273. [Google Scholar]

- Xiao, Z.; Tang, X.; Ai, Z.; Liu, M.; Deng, G.; Xu, H.; Tong, J.; Li, T. Experimental Study on the Characteristics of Camellia oleifera Fruit Shell Explosion by Hot Air Drying. Agriculture 2024, 14, 1242. [Google Scholar] [CrossRef]

- Huang, J.J.; Guo, Z.Y.; Li, S.T.; Zhang, Y.; Li, C.; Li, T.; Li, C. Heat-Mass Transfer Characteristics and Drying Process Optimization of Camellia oleifera Seeds After Hot-Air Bursting. Trans. Chin. Soc. Agric. Eng. 2024, 40, 332–341. [Google Scholar]

- Xu, K.S.; Du, P.D.; Tang, J.Y.; Wang, D.; Wu, H.; Zhang, Y. Equipment and Development Trends for Camellia oleifera Fruit Preprocessing. For. Mach. Woodwork. Equip. 2021, 49, 8–14. [Google Scholar] [CrossRef]

- Wu, J.Y.; Wang, Y.; Xiong, P.Y.; Ruan, J.; Liao, Z. Research Status and Prospects of Mechanized Shelling Devices for Camellia oleifera Fruits. Food Mach. 2023, 39, 208–217. [Google Scholar] [CrossRef]

- Li, S.M. Design of a Green Camellia oleifera Fruit Peeling and Seed-Shell Separation Device. Master’s Thesis, Wuhan Polytechnic University, Wuhan, China, 2016. [Google Scholar]

- Xiao, B.G.; Hu, S.F.; Deng, Y.J.; Lai, Q.F.; Liu, B.; Zhang, L.; Cao, X.; Li, H.; Guo, Y.; Weng, X.; et al. Design of a Grooving-Shelling Device for Camellia oleifera Fruits. South. Agric. Mach. 2021, 52, 17–19. [Google Scholar]

- Xiao, H.W.; Lin, H.; Gao, Z.J.; Zhang, L.Q.; Pang, C.L.; Wang, H. Design of a Laser Grooving Machine for Chestnuts. Trans. Chin. Soc. Agric. Mach. 2010, 41, 138–141. [Google Scholar]

- Jin, T.T.; Liu, L.; Liu, D.Q.; Dong, T.; Wang, D.; Li, X. Experimental Study and Analysis on Compressive Fracture Mechanics of Laser-Cut Peanut Pods. J. Agric. Mech. Res. 2022, 44, 147–152. [Google Scholar] [CrossRef]

- Chou, W.X.; Zheng, X.; Ma, R.; Tian, X.; Cen, H.; Zhang, E. Design and Experiment of a Laser Grooving Device for Walnuts. J. Gansu Agric. Univ. 2019, 54, 198–203+210. [Google Scholar] [CrossRef]

- Zhang, R. Study on Walnut Crushing Method Based on Laser Grooving Pretreatment. Master’s Thesis, Tarim University, Alar, China, 2023. [Google Scholar] [CrossRef]

- Hamasaki, M. Practical Laser Processing; China Machine Press: Beijing, China, 1992. [Google Scholar]

- Liu, L.L. Design and Experiment of a Press-Peeling Type Camellia oleifera Fruit Shelling Machine. Master’s Thesis, Hubei University of Technology, Wuhan, China, 2017. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).