Optimization Design and Experiment of Soil-Covering Device for Astragalus Mulching Transplanting Machine

Abstract

1. Introduction

2. Materials and Methods

2.1. Whole Machine Structure and Working Principle

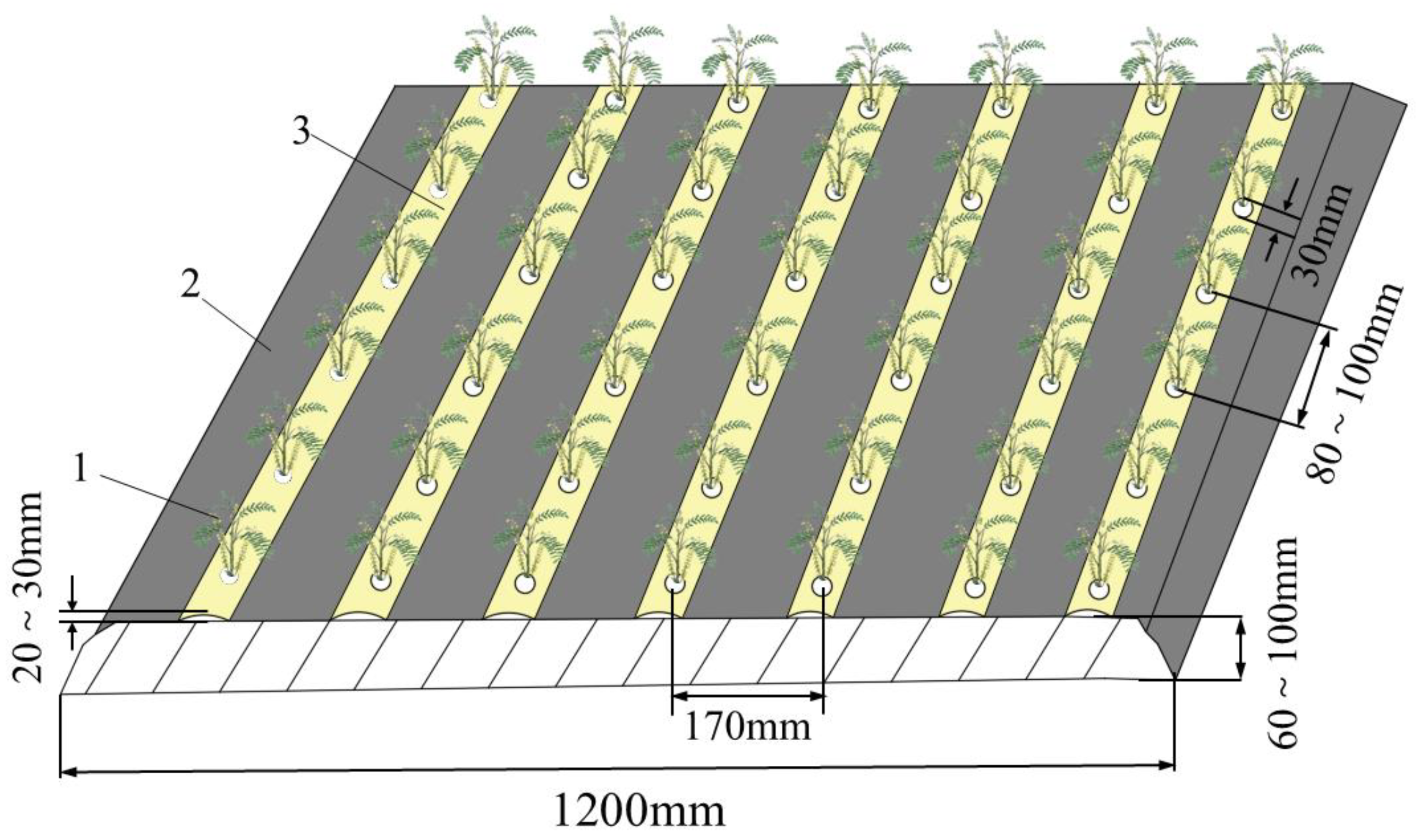

2.1.1. Agricultural Requirements for the Cultivation of Astragalus Film-Covered Outcrop

2.1.2. Structure and Main Technical Parameters of Astragalus Transplanter

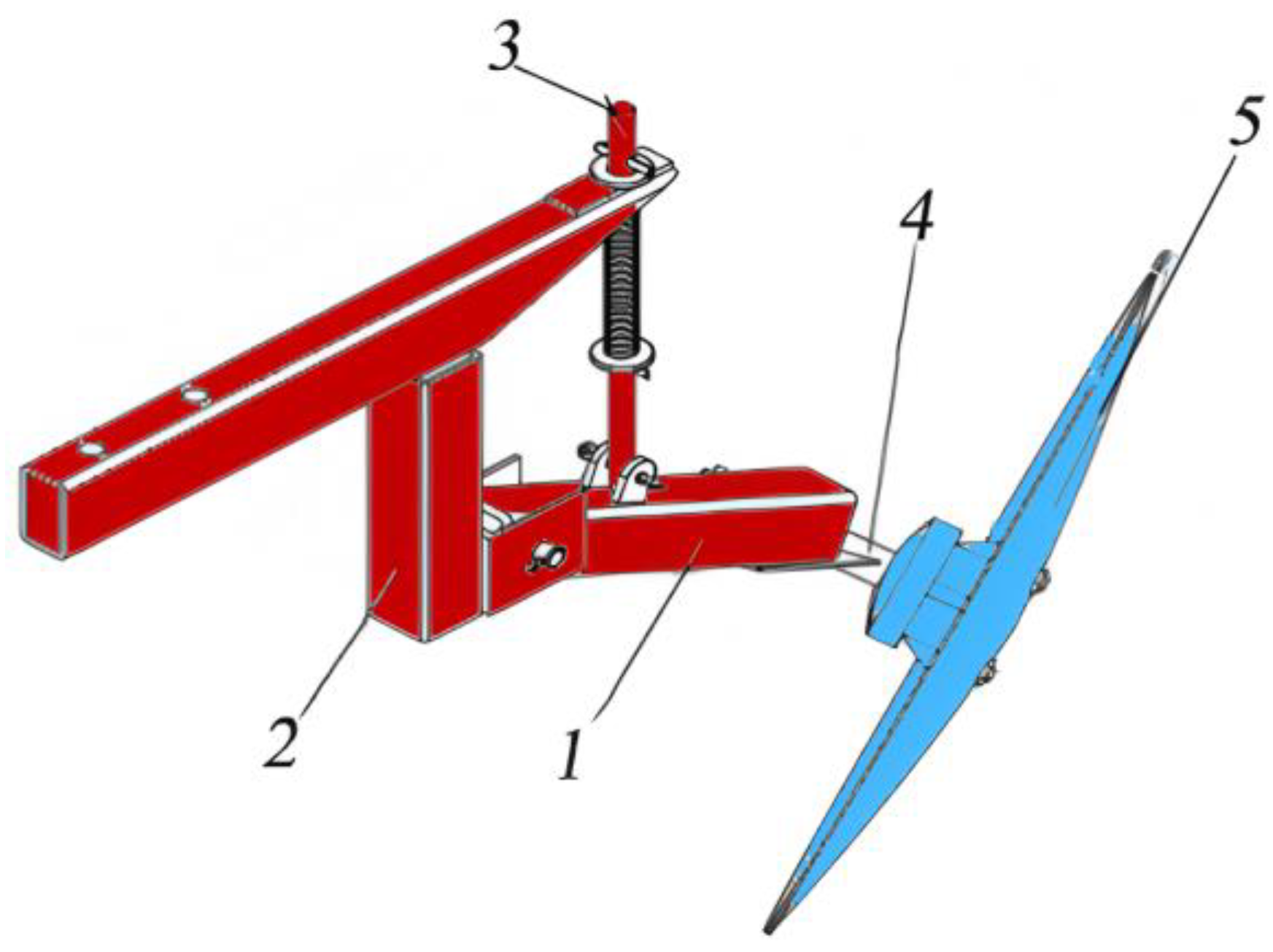

2.1.3. Structure and Working Principle of Soil-Covering Device

2.2. Design and Analysis of Soil-Covering Device

2.2.1. Design of Soil-Covering Disc

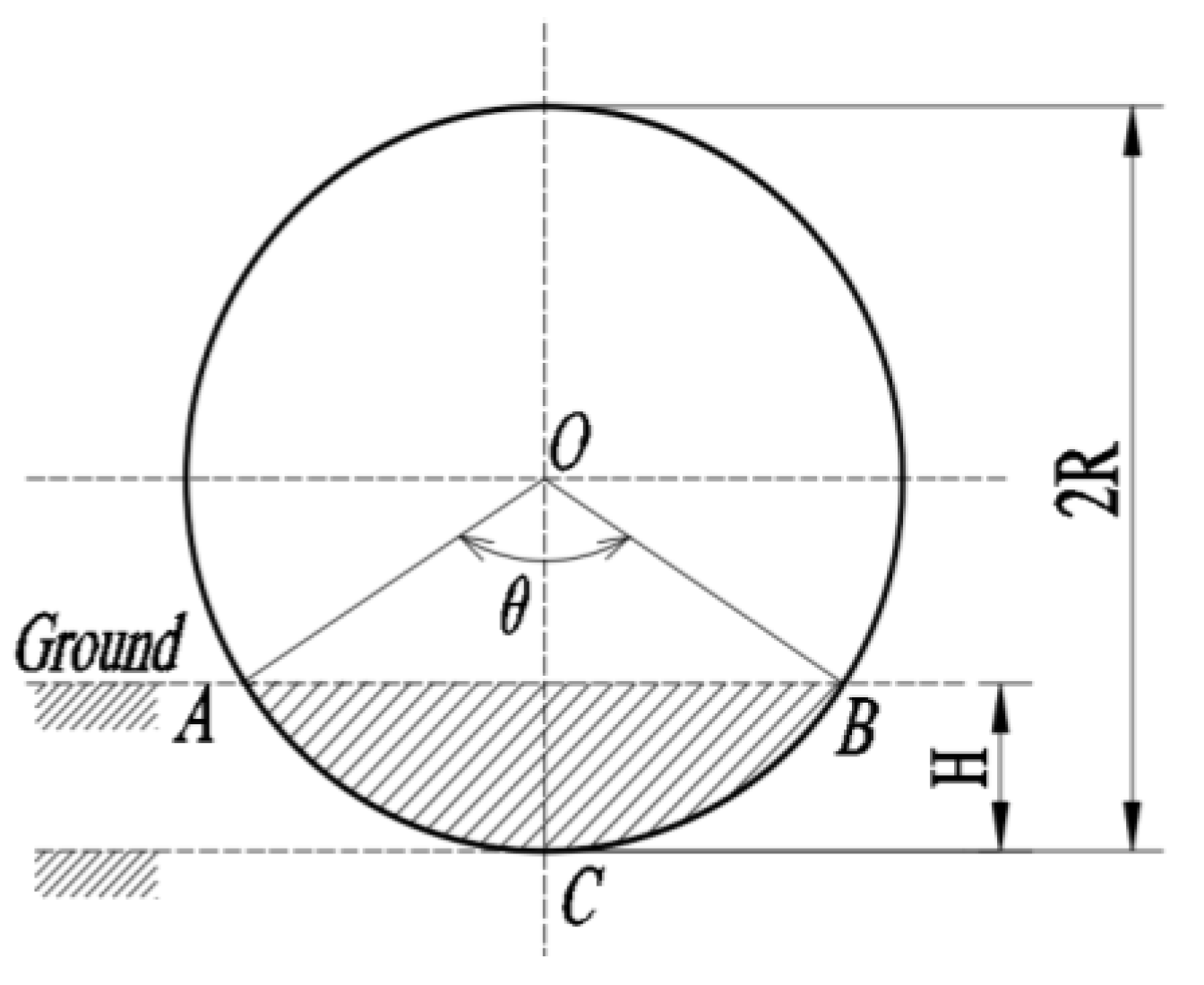

- (1)

- Analysis of the circular disc soil extraction process

- (2)

- Disk Structure Parameters

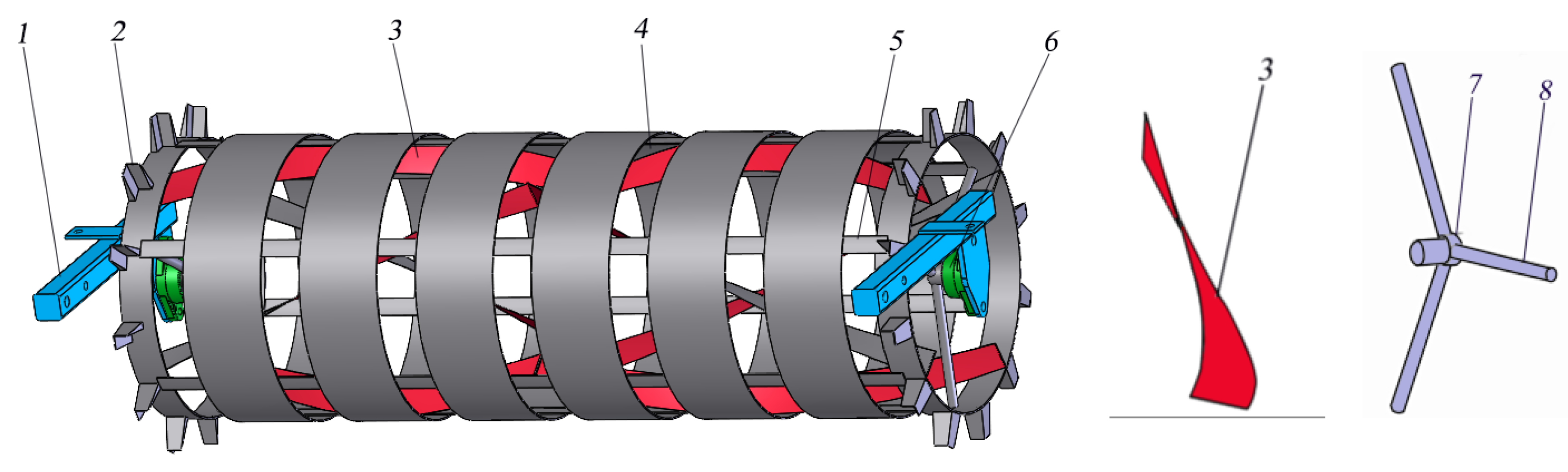

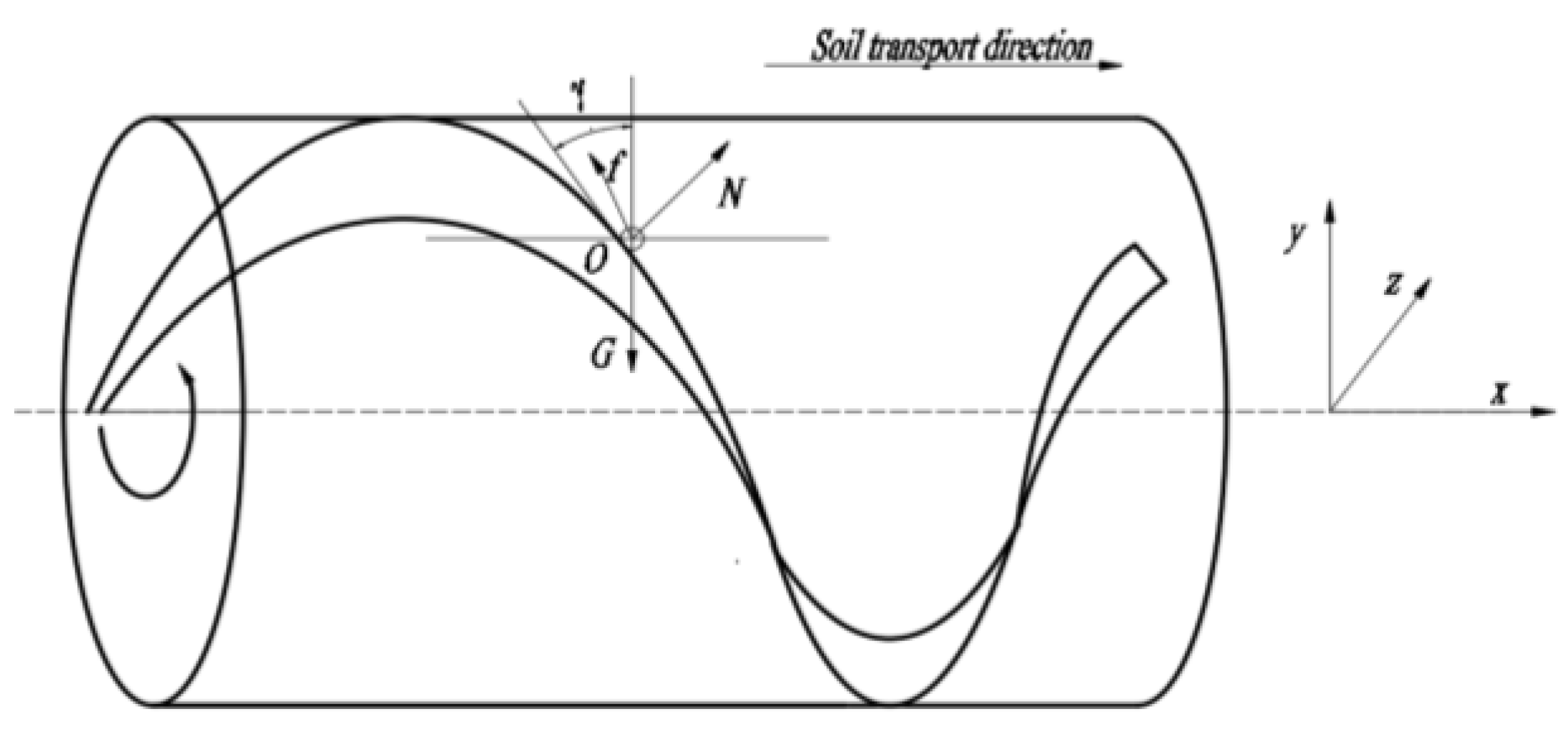

2.2.2. Design of Soil-Covering Drum

- (1)

- Analysis of Soil Transport Model with Soil-Covering Drum

- (2)

- Structural Parameters of Soil-Covering Drum

2.3. Test Materials

2.4. Test Methods

2.4.1. Quantity of Soil Cover (Q)

2.4.2. Variation Coefficient of Soil Cover Quantity Uniformity (QCV)

2.5. Test Results

3. Results and Discussion

3.1. Regression Model Establishment and Significance Analysis

3.1.1. Significance Analysis of the Quantity of Soil Cover

3.1.2. Significance Analysis of the Variation Coefficient of Soil Cover Quantity Uniformity

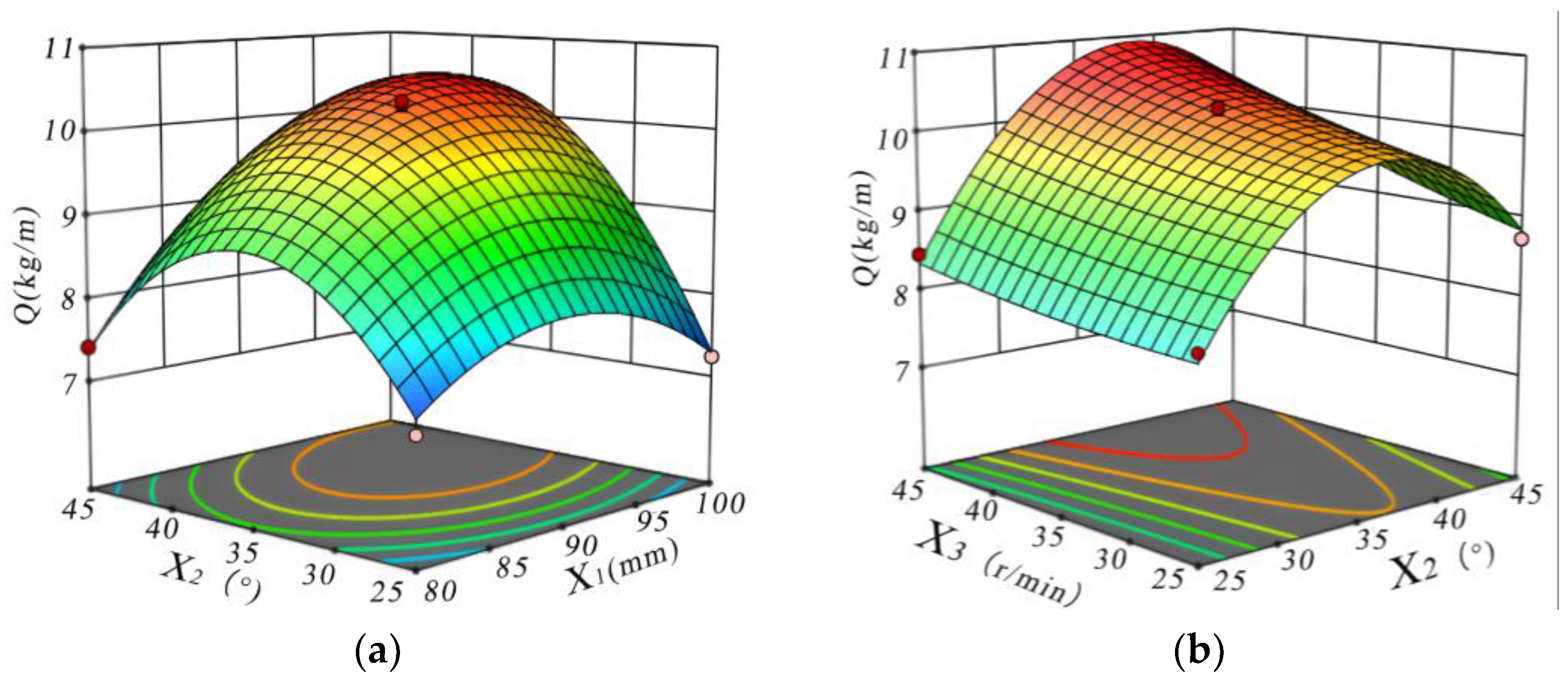

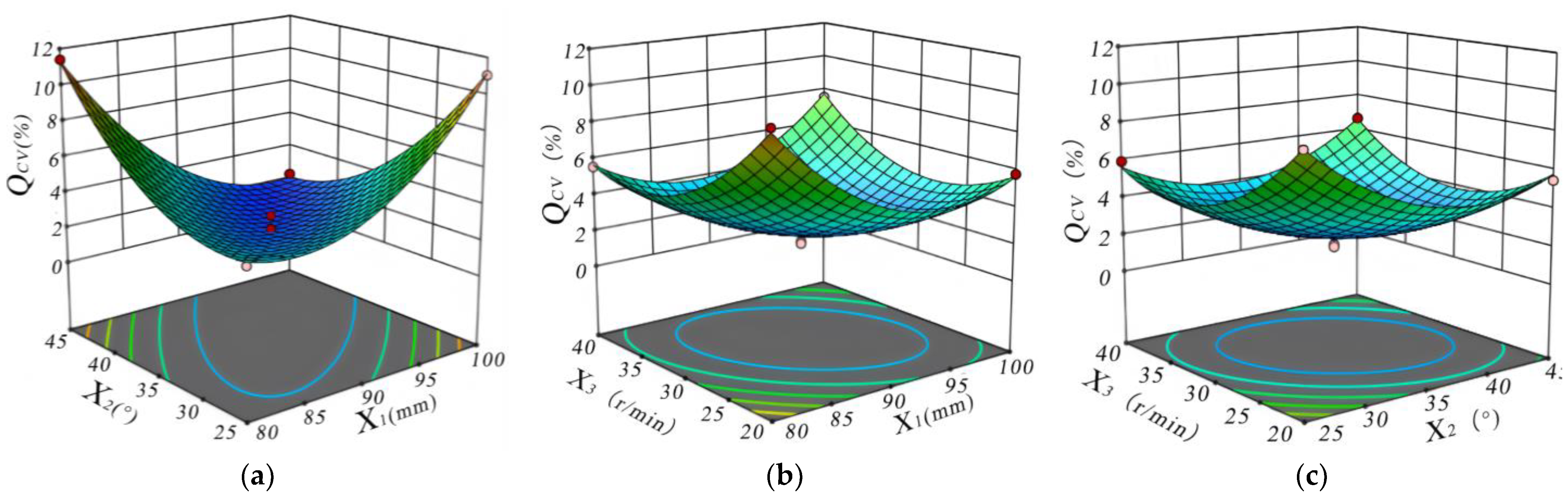

3.2. Response Surface Analysis

3.2.1. Analysis of the Effect Pattern of Interaction Factors on the Quantity of Soil Cover

3.2.2. Analysis of the Pattern of Interaction Factors on the Variation Coefficient of Soil Cover Quantity Uniformity

3.3. Parameter Optimization

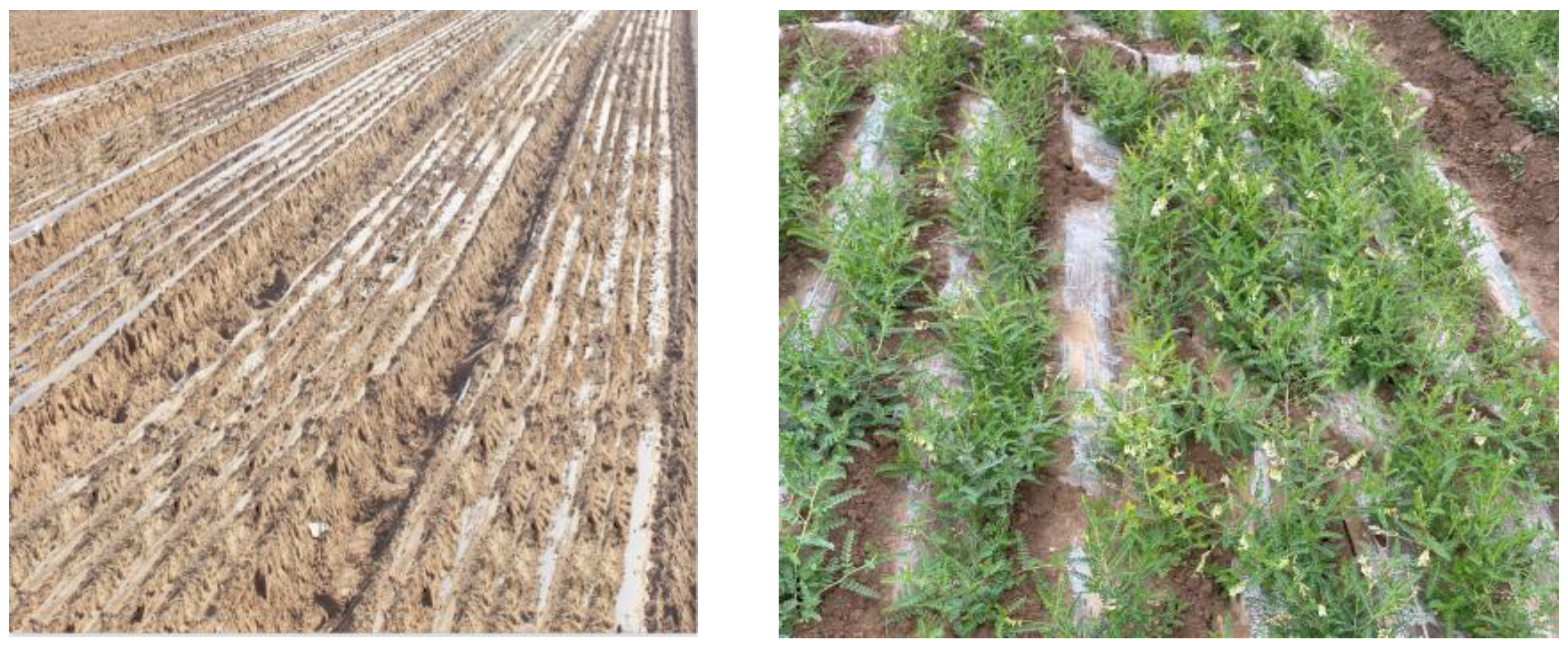

3.4. Field Validation Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Li, B.; Geng, G. Research Progress on the Chemical Composition and Pharmacological Effects of Astragalus. Chin. W. Med. Res. 2022, 14, 262–264. [Google Scholar]

- Hu, J. Comparative Experiment on Seedling Raising with Different Sowing Amounts of Astragalus Seeds. Agric. Sci. Technol. Inf. 2020, 5, 20–21. [Google Scholar]

- Zhao, J.; Wang, Y.; Wang, Y.; Deng, A.; Nan, T.; Kang, L.; Zhan, Z. Comparative Study of Transplanted and Wild-Simulated Astragalus Based on Traditional Quality Evaluation. Chin. Exp. Formul. J. 2024, 30, 21–30. [Google Scholar]

- Gao, S.; Li, K.; Qin, X.; Li, Z.; Li, A.; Liu, Y.; Du, G.; Zhang, X. Comparative Study on the Quality of Wild and Transplanted Astragalus Based on Absolute Growth Age. Chin. Herb. Med. 2018, 49, 2248–2257. [Google Scholar]

- Cao, Z.; Sun, X.; Pan, F.; Li, R.; Wu, Y.; Li, Z.; Wang, L.; Huang, X. Effect of Transplantation Methods on the Growth and Yield of a New Variety of Astragalus, Xiqi No. 1. Gansu Agric. Sci. Technol. 2021, 52, 58–60. [Google Scholar]

- Li, W.; Tang, X.; Wang, C. Standardized, High-Quality, and Efficient Cultivation Techniques for Astragalus. Agric. Technol. Equip. 2023, 3, 182–184. [Google Scholar]

- Chen, X.; Lü, Z.; Xue, X.; Xin, L.; Yu, Q.; Yu, Y.; Zhao, Y. Development and Performance Experiment of Wireless Remote Control Walking Rice Transplanter. Trans. Chin. Soc. Agric. Eng. 2017, 33, 10–17. [Google Scholar]

- Khadatkar, A.; Mathur, S.M. Design and Development of an Automatic Vegetable Transplanter Using a Novel Rotating Finger Device with Push-Type Mechanism for Plug Seedlings. Int. J. Veg. Sci. 2022, 28, 121–131. [Google Scholar] [CrossRef]

- Ramirez-Castro, E.; Shkiliova, L. Technological and Operational Evaluation of Agricultural Units in Mechanized Tobacco Cultivation. Rev. Cienc. Técnicas Agropecu. 2021, 30, 33–45. [Google Scholar]

- Xu, G.; Liu, H.; Jian, S.; Shi, C.; He, T. Design and Experiment of a Five-Bar Mechanism for the Transplantation of Salvia miltiorrhiza on Film. Trans. Chin. Soc. Agric. Eng. 2018, 49, 55–65. [Google Scholar]

- Lu, D. Design and Experimental Research on Seedling Placement Device of American Ginseng Transplanting Machine. Master’s Thesis, Jilin Agricultural University, Changchun, China, 2022. [Google Scholar]

- Sun, W. Design and Experiment of a Directional Transplanting Device for Panax Notoginseng Seedlings Based on Object Detection. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2023. [Google Scholar]

- Ma, X.; Zhang, L.; Liu, P.; Li, S. Design and Field Testing of a Combined Film Mulching and Soil Covering Machine for Dangshen Cultivation. Agric. Mech. Res. 2024, 46, 82–88. [Google Scholar]

- Liu, K.; Lin, Z.; Cai, L. Design and Study of a Dense Planting Transplanting Machine for Ophiopogon japonicus. Agric. Technol. Equip. 2024, 2, 1–4+7. [Google Scholar]

- Zuo, S.; Ding, X.; Kong, D.; Liu, Q.; Zuo, S. Design and Experiment of a Fully Automatic Ginseng Transplanting Machine. Agric. Mechanization Res. 2025, 47, 127–132. [Google Scholar]

- Xiao, X.; Wang, X.; Zeng, L.; Yang, Y. Effect of Plastic Film Mulching on the Cultivation of Chinese Medicinal Materials. Spec. Econ. Anim. Plants 2024, 27, 166–171+175. [Google Scholar]

- Shen, L.; Chen, W.; Teng, S.; Gu, X. Design and Testing of Key Components of a Slot-Wheel Astragalus Transplanting Machine. Chin. J. Agric. Mech. Chem. 2024, 45, 71–78. [Google Scholar]

- Li, S.; Ma, X.; Zhang, L.; Liu, P. Design and Experiment of Ridge Raising, Film Covering, and Soil Covering Transplanting Machine for Rhizome Chinese Medicinal Materials. J. Agric. Mech. Res. 2025, pp. 1–8, (Online debut version). Available online: http://kns.cnki.net/kcms/detail/23.1233.S.20250116.1312.004.html (accessed on 30 March 2025).

- Bai, Y. Design and Performance Testing of an Integrated Machine for Transplanting Astragalus with Film and Drip Irrigation. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2023. [Google Scholar]

- Wang, Y.; Zheng, S.; Kang, Q.; Zhao, J.; Liu, P. Design and experiment of a combined operation machine for mulching, fertilization, and transplanting of Codonopsis pilosula. Agric. Mech. Res. 2025, 47, 192–196. [Google Scholar]

- Zhu, P.; Cao, X.; Li, X.; Zhang, F.; Liu, P.; Zhang, L. Design and Experiment of a Seedling Transplanting Machine for Astragalus with Ridging and Mulching. Agric. Mech. Res. 2024, 46, 83–89. [Google Scholar]

- Liu, F.; Gao, X.; Jia, X.; Huang, Y.; Zhang, C. Design and Test of Archimedean Spiral Curved Double tooth Disc Soil Covering Device for High speed Precision Seeding Machine. J. Agric. Mach. 2024, 55, 91–100+120. [Google Scholar]

- Lü, J.; Zhang, X.; Zhu, X.; Li, J.; Yang, D.; Sun, Q. Design and Testing of Key Components for a Large-Row Double-Line Potato Mulching Machine. J. Northeast Agric. Univ. 2023, 54, 88–96. [Google Scholar]

- Li, H. Research on Rice Plastic Film Mulching Dry Direct Seeding Technology and Equipment. Master’s Thesis, Jilin University, Changchun, China, 2021. [Google Scholar]

- Wang, J.; Liu, X.; Han, M.; Hou, H.; Liu, F. Optimization Design of a Double-Disc Soil-Covering Device. Chin. J. Agric. Mech. Chem. 2016, 37, 37–39. [Google Scholar]

- Mei, Z.; Li, H.; Qi, X.; Hu, T.; Li, C. Testing and Analysis of the Mechanical Properties of Sandy Soil. J. Shenyang Agric. Univ. 2018, 49, 605–612. [Google Scholar]

- Zhang, X.; Li, Y.; Yang, J. Parameter Optimization and Analysis of the Seed-Covering Drum of a Sowing Machine Based on Discrete Element Method. Chin. J. Agric. Mech. Chem. 2020, 41, 43–48. [Google Scholar]

- Fan, Y.; Yang, R.; Chai, H.; Guo, T. Design and Experimental Research on a Film Mulching Device for Seedling Transplanting. Chin. J. Agric. Mech. Chem. 2014, 35, 5–8. [Google Scholar]

- Zhao, J.; Zhao, W.; Tian, S.; Zhang, Q.; Song, J.; Li, Y.; Han, X. Simulation and Experimental Study of the Soil-Covering Component for Fritillaria. Agric. Mech. Res. 2023, 45, 24–31. [Google Scholar]

- JB/T 10291-2013; Dryland Planting Machinery. Ministry of Industry and Information Technology of the People’s Republic of China Machinery Industry Press: Beijing, China, 2014.

- NY/T 987-2006; Quality of Film Mulching Hole-Seeding Machines. Ministry of Agriculture and Rural Affairs of the People’s Republic of China. China Agricultural Press: Beijing, China, 2006.

- Wang, Y. Experimental Study and Parameter Optimization of Soil Compaction Device for Cotton Seeder. Master’s Thesis, Shihezi University, Shihezi, China, 2023. [Google Scholar]

- He, W.; Xue, W.; Tang, B. Optimization Experimental Design Methods and Data Processing; Chemical Industry Press: Beijing, China, 2012. [Google Scholar]

- Ge, Y.; Liang, Q.; Wang, G. Experimental Design Methods and the Application of Design-Expert Software; Harbin Institute of Technology Press: Harbin, China, 2015. [Google Scholar]

| Item | Parameter |

|---|---|

| Machine dimensions (length × width × height)/mm | 2450 × 1565 × 1080 |

| Machine weight/kg | 160 |

| Power/kW | 29.42~51.48 |

| Machine forward speed/(km/h) | 1.8~2.1 |

| suspension mode | three-point suspension |

| Machine working width/mm | 1400 |

| Transplanting depth/mm | 50~150 |

| Number of rows transplanted/(rows) | 7 |

| Row spacing/mm | 170 |

| Plastic film width/mm | 1400 |

| Thickness of plastic film/mm | 0.01 |

| Thickness of soil cover for planting/mm | 20~50 |

| Working efficiency/(hm2/h) | 0.13~0.15 |

| Code | Depth of Disc Extraction X1 (mm) | Disc Deflection Angle X2 (°) | Rotation Speed of Soil-Covering Drum X3 (r/min) |

|---|---|---|---|

| −1 | 80 | 25 | 20 |

| 0 | 90 | 35 | 30 |

| 1 | 100 | 45 | 40 |

| Test | X1 | X2 | X3 | Quantity of Soil Cover Q (kg/m) | Variation Coefficient of Soil Cover Quantity Uniformity QCV (%) |

|---|---|---|---|---|---|

| 1 | 0 | −1 | 1 | 8.45 | 5.93 |

| 2 | 0 | 1 | 1 | 10.11 | 6.66 |

| 3 | −1 | 0 | −1 | 8.47 | 10.32 |

| 4 | −1 | 1 | 0 | 7.41 | 11.40 |

| 5 | 0 | 0 | 0 | 10.33 | 1.65 |

| 6 | −1 | −1 | 0 | 7.13 | 4.04 |

| 7 | 0 | 1 | −1 | 8.73 | 5.46 |

| 8 | 0 | 0 | 0 | 10.05 | 2.29 |

| 9 | 0 | 0 | 0 | 10.24 | 1.76 |

| 10 | 1 | 1 | 0 | 10.16 | 2.23 |

| 11 | 0 | 0 | 0 | 10.31 | 2.32 |

| 12 | 0 | −1 | −1 | 8.09 | 8.82 |

| 13 | −1 | 0 | 1 | 9.47 | 5.56 |

| 14 | 1 | −1 | 0 | 7.24 | 11.05 |

| 15 | 1 | 0 | 1 | 10.53 | 7.55 |

| 16 | 1 | 0 | −1 | 9.76 | 5.81 |

| 17 | 0 | 0 | 0 | 10.36 | 3.04 |

| Source | Quantity of Soil Cover Q (kg/m) | Variation Coefficient of Soil Cover Quantity Uniformity QCV (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| Sum of Square | df | F-Value | p-Value | Sum of Square | df | F-Value | p-Value | |

| Model | 23.24 | 9 | 92.32 | <0.0001 ** | 171.84 | 9 | 81.90 | <0.0001 ** |

| X1 | 3.39 | 1 | 121.33 | <0.0001 ** | 2.74 | 1 | 11.74 | 0.0110 * |

| X2 | 3.78 | 1 | 135.21 | <0.0001 ** | 2.09 | 1 | 8.97 | 0.0201 * |

| X3 | 1.54 | 1 | 55.07 | 0.0001 | 2.77 | 1 | 11.89 | 0.0107 * |

| X1X2 | 1.74 | 1 | 62.31 | <0.0001 ** | 65.45 | 1 | 280.74 | <0.0001 ** |

| X1X3 | 0.0132 | 1 | 0.4729 | 0.5138 | 10.56 | 1 | 45.31 | 0.0003 ** |

| X2X3 | 0.2601 | 1 | 9.30 | 0.0186 | 4.18 | 1 | 17.94 | 0.0039 ** |

| 2.56 | 1 | 91.66 | <0.0001 ** | 32.55 | 1 | 139.61 | <0.0001 ** | |

| 9.38 | 1 | 335.50 | <0.0001 ** | 20.15 | 1 | 86.44 | <0.0001 ** | |

| 0.0268 | 1 | 0.9576 | 0.3604 | 22.62 | 1 | 97.02 | <0.0001 ** | |

| Residual | 0.1958 | 7 | 1.63 | 7 | ||||

| Lack of fit | 0.1339 | 3 | 2.88 | 0.1663 | 0.4084 | 3 | 0.4451 | 0.7340 |

| Pure error | 0.0619 | 4 | 1.22 | 4 | ||||

| Total | 23.43 | 16 | 173.47 | 16 | ||||

| Item | Depth of Disc Extraction X1 (mm) | Disc Deflection Angle X2 (°) | Rotation Speed of Soil-Covering Drum X3 (r/min) | QCV/% | Q/kg/m |

|---|---|---|---|---|---|

| Before optimization | 94.91 | 39.67 | 29.88 | 1.89 | 10.53 |

| After optimization | 95 | 40 | 30 | 1.79 | 10.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, B.; Sun, W.; Xin, S.; Wang, G.; Lv, W.; Wang, J. Optimization Design and Experiment of Soil-Covering Device for Astragalus Mulching Transplanting Machine. Agriculture 2025, 15, 769. https://doi.org/10.3390/agriculture15070769

Feng B, Sun W, Xin S, Wang G, Lv W, Wang J. Optimization Design and Experiment of Soil-Covering Device for Astragalus Mulching Transplanting Machine. Agriculture. 2025; 15(7):769. https://doi.org/10.3390/agriculture15070769

Chicago/Turabian StyleFeng, Bin, Wei Sun, Shanglong Xin, Guanping Wang, Wenjing Lv, and Junzeng Wang. 2025. "Optimization Design and Experiment of Soil-Covering Device for Astragalus Mulching Transplanting Machine" Agriculture 15, no. 7: 769. https://doi.org/10.3390/agriculture15070769

APA StyleFeng, B., Sun, W., Xin, S., Wang, G., Lv, W., & Wang, J. (2025). Optimization Design and Experiment of Soil-Covering Device for Astragalus Mulching Transplanting Machine. Agriculture, 15(7), 769. https://doi.org/10.3390/agriculture15070769