Abstract

Food safety and traceability in dairy processing plants are essential for public health and industry sustainability. This study provides an empirical assessment of food safety and traceability practices among artisanal and semi-automated dairy processors in Fier, Albania, which is the country’s leading milk-producing region. Based on structured interviews with 18 dairy processors, we examined practices related to supplier management, quality control, facility conditions, staff hygiene, and equipment sanitation. The results reveal significant gaps in milk supplier inspections, biochemical testing, and traceability systems. The majority of processors lack barcode systems, regulated contracts with farmers, and formalized product tracking mechanisms, decreasing the chances of market formalization. Moreover, none of the dairies in this study have ISO certification, which restricts access to international markets. This paper also compares food safety practices between semi-automated and artisanal processors, with the former having slightly better compliance in certain key areas such as milk supply monitoring and biochemical testing. However, both groups face major challenges in complying with food safety standards due to weak regulatory enforcement, limited financial resources, and insufficient training. Implementing stricter food safety measures and modern traceability systems is not only a regulatory necessity but a strategic step toward improving public health, market access, and the long-term sustainability of Albania’s dairy sector.

1. Introduction

Food safety is a critical concern for both public health and economic sustainability, particularly in the dairy industry, where contamination risks can compromise consumer health and industry reputation. Dairy products are highly perishable and vulnerable to biological, chemical, and physical hazards throughout the supply chain [1]. Therefore, their quality can change very quickly. In addition, foods are prone to adulteration and fraudulent activities, mostly because of financial gain motives, jeopardizing consumer health [2]. Milk, in particular, is identified as one of the most frequently adulterated food products, along with beverages and meat, and the adulteration of these products primarily occurs during the manufacturing process [3]. In developing economies such as Albania, milk fraud is a common problem. Water is the most common adulterant used in milk, decreasing its nutritional value and posing serious health risks for consumers [4]. Hazards related to dairy products are one of the most notable hazards reported at the Rapid Alert System for Food and Feed (RASFF) [5].

A series of studies was conducted on the quality of the different food categories in Albania; these studies have reported cases of contaminated and unsafe products, such as vegetables [6], eggs [7], cheese [8], seafood [9], wild animals [10], ground beef [11], chicken [12,13], fresh milk [14], water [15], meat [16], infant formula [17], etc. Other studies that analyzed samples from milk [18] and meat processing plants [12,13] showed that these food categories pose a significant risk to consumers because of their quality. This has led to growing concerns among consumers and authorities regarding the need for stricter regulations, enforcement, and improved food safety measures within the food industry in Albania.

The dairy sector is a vital source of income, particularly in rural areas, as most families living there rely on agriculture. Dairy products are the main products of the Albanian household consumer basket. Albania is actually the eighth largest milk consumer in the world, with a consumption of 305.94 kg/capita [19]. The dairy sector is considered a priority sector by the government of Albania due to its importance for employment in rural areas and its contribution to the agricultural sector and GDP. The sector still faces various challenges, including compliance with quality and safety standards [20]. Food quality and safety challenges in the milk sector are related to limited farmer awareness about animal diseases and food safety standards, gaps in the supply chain, weak law enforcement, inadequate infrastructure, and a legislative framework that is not in compliance with EU standards [21]. Moreover, the sector has experienced a decline in production in recent years [22]. Subsequently, most of the milk is destined to fulfill the increasing domestic demand, and only a small part is exported, mostly to Kosovo [23].

Despite the growing importance of food safety regulations, no prior studies have systematically examined the compliance among dairy processors in Albania. This study bridges this gap by assessing compliance levels and identifying critical weaknesses in traceability systems.

The objectives of this study are as follows:

- To examine the extent to which artisanal and semi-automated dairy processors comply with food safety and traceability standards;

- To identify key challenges in implementing food safety protocols;

- To compare food safety practices between artisanal and semi-automated processors to determine whether processing technology influences compliance levels;

- To evaluate the extent of formalization and integration of the actors within the supply chain with regard to food safety.

1.1. The Role of Milk Processing Plants in Assuring Food Safety

Milk processing plants are facilities where raw milk is processed into various dairy products, such as cheese, yogurt, butter, and ice cream. They play a crucial role in the dairy industry by ensuring the safety, quality, and availability of dairy products for consumers worldwide. These plants receive raw milk from dairy farms and then undergo several processing steps to transform it into consumer-ready products. The typical process in a milk processing plant involves several stages, as follows: reception and testing, separation, pasteurization, homogenization, standardization, processing, packaging, and distribution [24].

Errors and milk adulteration can occur at any point along the value chain due to either unintentional mistakes or intentional actions by the actors involved. There are three main groups of hazards that can occur during milk production: chemical, microbiological, and physical. Chemical hazards, such as aflatoxin M1, dioxins, antibiotics, and residues of veterinary drugs, as well as physical hazards such as metal, glass, and plastic particles, are significant concerns [25,26]. Microbiological hazards, such as Listeria monocytogenes, Staphylococcus aureus, Salmonella, and pathogenic Escherichia coli, are frequently encountered in dairy products.

Food safety is ensured through a combination of good manufacturing practices, sanitation procedures, heat treatment, hazard analysis and critical control points (HACCP), training, hygiene standards, traceability systems, and quality assurance measures to prevent contamination and ensure product safety [27,28,29]. Following good practice adequately can significantly minimize the environmental, social, and economic impacts associated with milk production and consumption. Table 1 presents the possible stages that are prone to contamination along the supply chain.

Table 1.

Contamination points along the dairy supply chain (adopted from Ntuli et al., 2023 [29]).

Numerous factors contribute to the production of low-quality dairy products in processing plants. Obviously, this begins with good-quality milk from dairy farmers. However, this study focuses specifically on practices related to processors only. Therefore, among the most critical issues related to this are health and hygiene conditions. Clean and sanitary conditions are basic to the preservation of the quality of dairy products. Dairy production must adhere to rigid controls and criteria that are specified by law. Potential threats include errors in pasteurization, consumption of raw milk products, contamination of milk products by emerging heat-resistant pathogens, emergence of antimicrobial resistance in zoonotic pathogens, chemical adulteration of milk, transmission of zoonotic pathogens to humans through animal contact, and foodborne disease related to cull dairy cows [29].

Food handlers play a significant role in possible cross-contamination. Various researchers have shown that two of the major causes of microbial contamination and growth in food products are dirty food contact surfaces and poor personal hygiene practices among food handlers [30]. Other challenges include the need for continuous staff training and adherence to protocols by workers. Therefore, investments in infrastructure and hygiene practices are crucial for these improvements [31].

Plant layout and construction affect microbial contamination and the overall wholesomeness of the product. It is especially important to ensure that clean air and water are available and that surfaces in contact with dairy foods do not react with the products. The facility should be well-designed in order to minimize contamination risks by ensuring the proper airflow, drainage, and separation of raw and finished products.

Innovations in dairy processing, including pasteurization, cleaning, and sanitation, have dramatically enhanced the safety, nutrition, and sustainability of milk over the last century [32]. Food safety systems in small dairy processing establishments are essential but difficult to establish. Small-scale dairies tend to have challenges with compliance with hygienic practices, resulting in lower microbial quality than in large plants [30]. Research has shown that the implementation of hazard analysis critical control points (HACCP) and good manufacturing practices (GMPs) can significantly improve microbial quality and safety [33,34].

The scale of production also influences the microbiological performance of dairy processing plants. Large plants have better adherence to food safety standards and produce safer products compared to smaller plants, which can have issues related to manual operations and a lack of system documentation [30].

1.2. Requirements of Safe Milk

All processing plants are required to obtain a license to operate their activities. During the production process, hygiene, sanitary, veterinary, and technological standards must be strictly followed. According to Law № 9441, dated 11 November 2005, ‘On the production, collection, processing, and trade of milk and milk by-products’, milk intended for consumption must meet specific safety requirements, such as fat content (not less than 3%), dry content (up to 8.5%), protein content (not less than 28 g/L, freezing point (not higher than −0.520 degrees), and density (approximately 1.025 g/L). Residues such as antibiotics, pesticides, and detergents must not exceed the limits defined by current legislation. Milk tankers and refrigerated trucks must be registered with the Regional Directorate of Agriculture and are strictly prohibited from transporting anything other than food products. Farm animals and dairy farms are subject to veterinary inspections, while milk collectors and processors are periodically monitored by the National Food Authority. Milk processors must also implement self-control systems and internal audits, such as HACCP. According to the same law, the requirements for imported milk and milk by-products must be equal to or stricter than those defined for domestic production.

Raw milk that is collected from dairy farms should come from animals that are free of diseases, such as tuberculosis or brucellosis. It should be checked regularly with random samples for bacterial contamination, antibiotic residues, somatic cell count, aflatoxins, and added chemicals. It should also be tested for water content, acidity, and nutritional standards such as fat and protein levels. When transporting raw milk from the dairy farm directly to a processing center, samples should be taken when the milk is collected from the farm in order to avoid adulteration during transport.

Traceability must be established at all levels of production. Processing plants are required to create a system for maintaining records that allows for identification at any time. Additionally, they are obliged to implement the HACCP system. HACCP procedures should be reviewed and modified whenever there is a change in the product, process, or any other production stage, as per the guidelines.

2. Materials and Methods

2.1. Questionnaire Design

The methodology used in this study was primarily qualitative. To meet the objectives of this study, 18 face-to-face questionnaires were conducted with milk processing plants. Similar studies that have been conducted by various authors in different countries [34,35], with legislation in place, and expert opinions from the field from the Agricultural University of Tirana were consulted in order to construct the questionnaire. This was divided into four main sections: the first section gathered data on the general activity of the firm; the second section collected information on staff training regarding food safety standards; the third section provided insights into food safety practices followed by the processing plant; and the fourth section comprised questions related to the traceability system and product recall.

The first two sections primarily included multiple-choice questions. The third section contained 15 questions based on a five-point Likert scale, measured from ‘Never’ to ‘Always’. These questions were divided into five categories of practices: supplies management, quality control of final products, building and environment, staff practices, and equipment. The fourth section was focused on the traceability system and included 10 Yes/No questions and several multiple-choice items related to product recall.

Interviews were conducted between December 2024 and January 2025 in the Fier region. Meetings were scheduled in advance via phone. Initially, two pilot interviews were conducted to test and improve the questionnaire. Each interview lasted approximately 45 min, on average. Additionally, on-site observations and informal conversations were carried out as part of the data collection process in order to minimize response bias. The questionnaire was designed using the QuestionPro website, then exported to Excel, and later into the R Studio version 4.4.2 program for further analysis.

2.2. Study Area and Population

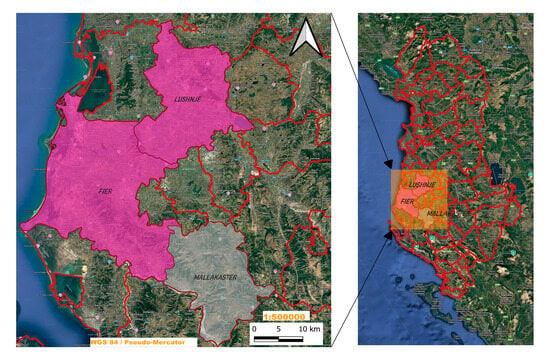

Albania is divided into 12 counties. Fier County was selected as the study area as it is the largest milk producer in the country. It includes the districts of Fier, Lushnja, and Mallakastra. According to the Institute of Statistics (INSTAT), Fier produced 154,894 tons of cow milk in 2023, from a total production of 765,347 tons, which accounts for 20% of the total country production. Fier is characterized by productive agricultural land, which creates better conditions for producing animal feed and supporting milk production. Mallakastra is oriented toward small ruminants’ milk, which is not the focus of this study and was therefore excluded (Figure 1).

Figure 1.

Study area.

A list of milk processors was provided by the National Food Authority. There are a total of 29 milk processors within the study area. The inclusion criterion for the selection of milk processing plants in this study focused on artisanal and semi-automated plants. Due to their small to medium size, these processors operate primarily at the local level. By setting this criterion, this study aimed to concentrate on plants that reflect the typical challenges and practices of the majority of milk processors within the study area, ensuring that the findings are more applicable to the local dairy industry.

To achieve this, this study excluded three large processing plants that are fully automated. These facilities possess greater resources and standardized practices, which differ significantly from smaller operators. Large processors often meet international regulatory and compliance standards, which could mask the variability and issues prevalent among smaller processors. Large processors are also better in terms of technology, scale of production, and market share. These three large plants, however, could later be examined separately as case studies to provide additional insights into how large-scale operations manage food safety and traceability, thereby complementing the overall analysis.

As a result, 18 out of 26 small to medium processors (70%) were randomly selected and included in this study. This sample reflects a substantial portion of the total number of small and medium dairy processors operating in the study area. The diversity in plant size, technology, and legal structure allowed for a balanced representation. In food safety research, studies often have small sample sizes due to challenges such as limited access to participants, low respondent willingness, and confidentiality concerns. Milk processors are monitored by regulating bodies; therefore, some of them are unwilling to disclose details about their food safety practices, non-compliance, or weaknesses, especially if they fear regulatory consequences or reputational harm. The structure of the questionnaire, as well as follow-up informal conversations and on-site observations, allowed for a detailed assessment of food safety and traceability practices, compensating to some extent for the limited sample size of this study.

3. Results

3.1. General Characteristics of the Respondents

A total of 18 interviews were conducted, of which 8 were in Fier and 10 in Lushnja. The interviews were conducted with dairy owners (78%) or with one of their employee-family members (22%). In 88% of cases, the owner was also the manager. The majority of the interviewees were male (88%). Since this study focused on small to medium-sized dairies, most family members were actively involved in the business. The dairy operations began between 1994 and 2004, which explains the relatively high average age of 53.7 years, ranging from 26 to 65 years (SD = 11.7). Regarding their educational level, 50% of respondents had secondary education, 39% had a high school level education, and only 11% had obtained an undergraduate degree.

3.2. General Characteristics of the Processing Plant

Fifteen dairies are registered as sole proprietorships, one as a partnership, and two as limited liability companies (Fier, Albania) (LLCs). The number of employees, excluding the owner, ranged from two to eleven, with an average of four employees. Based on the interviews, there are no formal skill requirements for employment. Most workers are either relatives or come from the same village as the owner; this is typical, given that all dairies are located in rural areas. Training is usually undertaken on the job by the owner or manager, who often has many years of experience and a background in the field.

Daily production capacity varied between two and twenty tons. However, due to the decline in dairy farms, reductions in livestock numbers, and labor shortages, all the dairies were operating below capacity (Table 2 and Table 3). The processors are connected to an average of 68 dairy farmers, the majority of whom own up to 5 cows. The farm gate price of milk is around ALL 60–65 per liter.

Table 2.

Sampling of milk processors.

Table 3.

General characteristics of the processing plants.

Regarding milk collection, all units use refrigerated trucks for milk collection. However, due to the local nature of operations and proximity to farmers, some farmers deliver milk directly to the dairies. Milk collection is conducted 1–2 times per day, depending on the number of supplying farmers or the season (once per day in winter and twice per day in summer). An additional reason for collecting milk twice daily is to prevent fraud by farmers, such as skimming milk fat overnight.

The range of dairy products includes yogurt, different types of cheese (white cheese, feta cheese, cottage cheese, mozzarella, and kashkaval), butter, and sour cream. Artisanal dairies produce mostly white cheese and some kashkaval, which are mostly distributed within their operating area, including the cities of Fier and Lushnja. In contrast, semi-automated dairies, due to their larger capacity, produce a wider range of products, which are also distributed to other regions, such as Tirana, Vlora, and Durrës.

Farmers that distribute milk to artisanal dairies do not have written contracts, primarily because they own a very small number of livestock and, as a result, cannot guarantee milk delivery on a daily basis. Only one artisanal dairy has partially implemented written contracts with some larger dairy farms. The geographical distance between farmers and processors can be very small; therefore, some farmers deliver the milk themselves. Semi-automated units are supplied by both small and large dairy farmers, but they only have written contracts with the latter.

One of the main reasons for the small production scale of dairy processors in Albania is the significant decline in national milk production over recent years. According to INSTAT, in 2023, milk production was approximately 19.13% lower compared to 2019. Furthermore, only a small portion of total production is directed toward formal processing. On average, just 10% of total milk production is collected by processing plants. For instance, in 2023, only around 80,000 tons of milk were delivered to processors out of a national production of 765,000 tons. Moreover, the number of milk processors is also decreasing.

3.3. Assessment of Food Safety Practices

In order to assess the level of food safety practices in processing plants, a total of 15 5-point Likert scale questions were asked of the interviewees. These questions were grouped into five categories, as follows: supplies management, quality control of final products, building and environment, staff practices, and equipment.

The findings show that most plants have clear criteria for selecting milk suppliers, but direct inspections of suppliers’ farms and the biochemical testing of raw milk are not conducted regularly. Sensory characteristics such as taste, smell, and appearance are often considered when selecting milk. Cold storage monitoring is strictly followed, as dairy products can spoil very quickly. Testing of the final product quality is inconsistent due to financial constraints. Final products are analyzed every few months or only when authorities do their regular checking.

The processing environment is generally well maintained, with the exception of a few dairies. Certain plants require improvements in their buildings and lighting. Personnel hygiene is well managed, with staff wearing hair caps and uniforms. Equipment sanitation is also well maintained. Most plants have a designated hygiene supervisor, who is typically the manager. However, sanitation procedures are not reviewed regularly.

A comparative analysis of food safety practices was conducted across two distinct groups of milk processors: artisanal and semi-automated. To assess the differences between these two groups, descriptive statistics were utilized, including the calculation of means and standard deviations for each food safety practice. Likert scale data, which is ordinal in nature, generally does not meet the strict assumptions required for normal distribution. Therefore, we applied the non-parametric Mann–Whitney U test (also known as the Wilcoxon rank-sum test or W-statistic) to determine if there were significant differences in the practices between the two groups, using a p-value threshold of 0.05 to assess statistical significance (Table 4). Cliff’s Delta effect sizes for each food safety practice were calculated in order to quantify the magnitude of differences between artisanal and semi-automated processors. Cliff’s Delta values were medium to large for the practices, except for QC2, EQ2, and EQ3. These practices had a small effect size and non-significant p-value, suggesting only minor differences.

Table 4.

Comparison of food safety practices in artisanal and semi-automated milk processing.

The differences between artisanal and semi-automated processors in terms of food safety practices are noticeable in only some areas. The lack of significant differences in other areas suggests similar practices across the two groups, regardless of their technological approach.

As expected, semi-automated plants generally score higher across most food safety practices, with means often reaching 5.00 (indicating full compliance). Artisanal plants still maintain some essential safety standards. Semi-automated plants implement stricter supplier controls than artisanal ones. While both plant types monitor cold storage and test final products, semi-automated plants perform more quality checks during production. Hygiene control at facility entry points is stricter in semi-automated plants. Uniforms and protective clothing are more rigorously enforced in semi-automated plants. Equipment sanitation and hygiene monitoring are relatively similar in both plant types. However, on-site observations revealed some discrepancies between reported practices and actual conditions (Figure 2).

Figure 2.

On-site observation (left, artisanal, and right, semi-automated).

3.4. Traceability Systems

Current food safety management and traceability practices reflect some of the biggest challenges facing the dairy industry as a whole. In many dairies, food safety practices are underdeveloped or inconsistently applied, causing risks to milk quality and consumer safety. The lack of a structured traceability system is one of the main problems. In most cases, dairies keep records on paper, without a standardized manual or electronic system that can ensure proper monitoring of the source and quality of the milk. This makes it especially difficult to identify and separate the milk by origin at the farm gate and increases the chance that contamination will spread throughout the containers.

Another concerning practice is the collection and storage of milk in the same tank without segregation, making it impossible to identify potential problems and link them to specific farmers. In addition, testing for harmful substances, such as antibiotics, is not carried out every day, but only when there are doubts. Dairies are often forced to buy milk with antibiotics, which they then report having to discard, but this process is not properly documented and is not always widespread. In many cases, farmers do not report these problems, causing an environment of uncertainty and lack of transparency.

To improve this situation, it is necessary to create an advanced system of traceability and quality control. The implementation of barcode codification systems for each product, the separation of milk according to origin, and the use of technologies for quality monitoring would contribute to better management of food safety. Furthermore, it is important that farmers and dairies increase their capacity for regular testing and educate themselves on the best food safety practices.

3.5. Challenges of Sector Formalization

Although the demand for good-quality dairy products is increasing, a large part of the industry continues to operate informally, causing challenges in food security, market competition, and economic development. It is estimated that only 11–15% of the total milk production in the country is delivered to processors [22]. While dairy processors often report high compliance standards, the reality is that they frequently struggle to produce high-quality dairy products. As a result, these products fail to meet the criteria for entry into the European market and remain less competitive than imported alternatives, such as those from Serbia.

Some of the key challenges are related to the sector formalization, as follows:

- Low compliance with food safety standards—A large number of dairies continue to follow traditional practices without implementing the proper rules of hygiene, pasteurization, and storage, increasing the risk of microbial contamination and antibiotic residues in their products. This is especially true for small dairies that have limited (financial) resources.

- Lack of traceability systems—Many dairies and farms do not implement structured mechanisms for milk traceability. Milk from different sources is often mixed at the same collection point, making it difficult to identify contamination or problems and link them to specific suppliers. Almost all farmers do not own a record-keeping book.

- Paper record-keeping—Many dairy producers record information manually on paper, rather than using digital systems, making it difficult to track data and monitor quality.

- Lack of barcoding—Most small producers do not use barcodes for their products, limiting access to formal markets such as supermarkets and exports. It is important to note that barcodes, where used, serve retail purposes only; such as EAN-13 barcodes, which are used for product identification and sales in supermarkets. They are not linked to internal batch tracking or traceability systems.

- Irregular testing—Instead of regularly testing milk quality, many dairies only test when they suspect problems, reducing the level of quality control.

- Lack of regulated contracts between farmers and dairies—In many cases, farmers sell milk informally without documented contracts, making it difficult to ensure a fair price, quality control, and accountability in the supply chain. There are only a few cases where there is a contract between the farmer and the processor.

- None of the dairies in this study held ISO certification, such as ISO 22000.

4. Discussion and Conclusions

This study focused on identifying the key food safety challenges faced by artisanal and semi-automated dairies in the Fier region of Albania. The results showed that while basic hygiene and cold storage practices are generally maintained, significant improvements are needed in areas such as supplier inspections, biochemical testing, and regular updates to hygiene protocols. Artisanal dairies have a lower food safety compliance level compared to semi-automated ones. Experience from other countries also shows that small dairies often struggle to meet food safety standards due to limited resources and trained staff [36,37]. Upgrading buildings, equipment, and processes requires significant investment, which is hard to justify at a small production scale. Many lack the capacity to manage the full cold chain from milk collection to storage and distribution. In most cases, one person handles both management and production tasks, making it difficult to properly supervise and document every step of the activity. Limited training in smaller plants often results in poor hygiene practices and inadequate HACCP compliance. Although HACCP implementation is a legal requirement for food business operators, challenges remain in effectively implementing food safety standards in dairies. Effective food safety practices require comprehensive training for all staff, including management, technical staff, and temporary workers.

Globally, food safety in the dairy sector is shaped by a combination of regulatory frameworks, market-driven standards, and public health priorities. The Codex Alimentarius outlines the core principles of hygiene, hazard control, and traceability that serve as the foundation for national food safety systems worldwide. In high-income and EU countries, compliance is typically enforced through structured systems, such as HACCP, ISO certification, and digital traceability. In contrast, countries with fragmented agriculture and lower institutional capacity, including many in Eastern Europe prior to EU accession, as well as parts of Africa and South Asia, have faced challenges implementing such systems. Studies from Poland, Romania, and Serbia show that the process of aligning with EU standards led to the closure or consolidation of small farms and dairies, but also created opportunities through cooperative models and targeted investment [38,39].

As an EU candidate country, Albania faces similar pressures to align its dairy sector with EU food safety standards. The country’s dairy industry shares structural characteristics with Eastern European countries before their accession, especially fragmented production, limited infrastructure, and underdeveloped traceability systems. Without targeted support, such as training, subsidies, cooperative models, or shared infrastructure, many small producers may struggle to adapt. A combination of supporting short supply chains for traditional products and encouraging more organized production for broader distribution could be key to long-term improvements. Furthermore, continued harmonization of national legislation with EU food safety standards is essential for enabling compliance and competitiveness.

Traceability systems continue to be one of the basic challenges in the industry, as both traceability systems and frequent quality control checks are absent. The lack of these exposes the dairy system to higher risks of contamination and makes it hard to identify and recall unsafe products from the market. The lack of effective traceability systems, such as batch barcodes, creates challenges in tracing food safety problems, which is a threat to consumer health and also to the reputation of the dairy sector. Moreover, incomplete reporting by dairies and farmers regarding issues with products indicates the lack of transparency and fear of the consequences of full reporting.

Small milk processors in Albania operate sustainably within short supply chains, especially for traditional products. These niche products such as feta, kashkaval, and fresh white cheese are culturally valued and often preferred by local consumers [40]. Proximity between farmers, producers, and consumers helps reduce traceability risks and improve transparency. However, for broader improvements in food safety, more centralized milk production models are needed.

To address the challenges identified in this study, several practical policy recommendations are proposed. First, simplified HACCP and ISO certification procedures are needed, which are designed specifically for small processors in order to make compliance more achievable. Second, support from the government is needed to create training programs focused on hygiene, record-keeping, and traceability and to build capacity across the sector. Third, financial incentives such as reductions in taxes, equipment grants, or loans with lower interest rates could help processors invest in food safety improvements.

In 2023, the Albanian government revised its agricultural subsidy policy, increasing the minimum number of cows required for farmers to receive financial support from five to more than ten. This change, introduced under the National Agriculture Scheme, aims to encourage larger-scale farming and improve productivity. However, it poses challenges for small-scale farmers who now struggle to qualify for subsidies, limiting their ability to invest in herd expansion, infrastructure, and food safety compliance. As a result, the number of small dairy farms is decreasing and raw milk prices at the farm gate are rising, which threatens the sustainability of artisanal dairies.

On the other side, interest rates for agricultural business loans can be as high as 20%, which burdens more small milk processors and limits their investments in food safety. Another suggestion would be increasing local-level technical support and inspections; this would improve enforcement while offering guidance rather than penalties. Together, these policies could significantly improve food safety standards without placing an unrealistic burden on small dairies.

In conclusion, adopting advanced technologies in production and traceability systems, conducting regular supplier inspections, and implementing biochemical testing are necessary steps toward improving milk safety in dairies. However, such improvements cannot be performed without supportive and stronger food safety legislation and investment in infrastructure. Furthermore, increasing production capacity is vital to sustain the dairy sector and reduce dependence on imported dairy products. To achieve this, the formalization of Albania’s dairy sector is crucial, as this will improve food safety, traceability, and fair competition. These changes will not only benefit the sector but also provide families with safer, higher-quality dairy products.

Author Contributions

Conceptualization, P.T., M.L. and I.K.; methodology, P.T.; software, P.T.; validation, P.T., M.L. and I.K.; formal analysis, P.T.; investigation, P.T.; resources, P.T.; data curation, P.T.; writing—original draft preparation, P.T.; writing—review and editing, P.T., M.L. and I.K.; visualization, P.T.; supervision, I.K.; project administration, P.T.; funding acquisition, P.T. and M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Deutsche Bundesstiftung Umwelt (DBU).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gallo, M.; Ferrara, L.; Calogero, A.; Montesano, D.; Naviglio, D. Relationships between food and diseases: What to know to ensure food safety. Food Res. Int. 2020, 137, 109414. [Google Scholar] [CrossRef]

- Rizzuti, A. Food Crime: A Review of the UK Institutional Perception of Illicit Practices in the Food Sector. Soc. Sci. 2020, 9, 112. [Google Scholar] [CrossRef]

- Soon, J.; Wahab, I. A Bayesian Approach to Predict Food Fraud Type and Point of Adulteration. Foods 2022, 11, 328. [Google Scholar] [CrossRef]

- Handford, C.; Campbell, K.; Elliott, C. Impacts of Milk Fraud on Food Safety and Nutrition with Special Emphasis on Developing Countries. Compr. Rev. Food Sci. Food Saf. 2016, 15, 130–142. [Google Scholar] [CrossRef] [PubMed]

- Pigłowski, M.; Nogales, A.; Śmiechowska, M. Hazards in Products from Northern Mediterranean Countries Reported in the Rapid Alert System for Food and Feed (RASFF) in 1997–2021 in the Context of Sustainability. Sustainability 2025, 17, 889. [Google Scholar] [CrossRef]

- Çoku, A.; Lika, M.; Hajdini, M.; Bani, R. Microbiological examination of frozen fruits and vegetables sold in Tirana markets. J. Int. Environ. Appl. Sci. 2011, 6, 518–520. [Google Scholar]

- Shehu, F.; Maci, R.; Nexhipi, E.; Memoci, H.; Xinxo, A.; Bijo, B. Occurrence of Salmonella spp. in chicken eggs in Albania. Special edition. In Proceedings of the Conference ICOALS 2018, Tirana, Albania, 7–9 May 2018; pp. 188–191. [Google Scholar]

- Allaraj, Y.; Biba, N.; Coku, A.; Çuka, E. Quality Assessment of Cheese in Markets of Tirana City. Albanian J. Agric. Sci. 2014, 13, 82–85. [Google Scholar]

- Lufo, L.; Beli, E.; Kaba, E. Listeria spp. and L. monocytogenes prevalence in shrimps from the seafood industry in Albania. Albanian J. Agric. Sci. 2023, 22, 22–29. [Google Scholar]

- Korro, K.; Mema, K. Initial data on Albania regarding the urgency of implementing “One Wildlife, One Food Safety”. Albanian J. Agric. Sci. 2023, 22, 19–25. [Google Scholar]

- Çoçoli, S.; Andoni, E.; Kika, T. Antimicrobial resistance of Salmonella spp. isolated from ground beef in Tirana market. Int. J. Adv. Nat. Sci. Eng. Res. 2023, 7, 302–304. [Google Scholar]

- Daҫi, A.; Shehdula, D.; Ozuni, L. Staphylococcus aureus and Listeria spp. in Chicken Meat in Slaughterhouses and at Retail Shops in Tirana. J. Multidiscip. Eng. Sci. Technol. 2016, 3, 4115–4121. [Google Scholar]

- Daçi, A.; Shehdula, D.; Ozuni, L.E. coli in chicken meat in slaughterhouses and at retail shops in Tirana. J. Multidiscip. Eng. Sci. Technol. 2016, 3, 43–52. [Google Scholar]

- Sulaj, K.; Terpollari, J.; Kongoli, R.; Korro, K.; Duro, S.; Selami, F.; Kumbe, I.; Bizhga, B. Incidence of coagulase positive Staphylococcus aureus in raw cow milk produced by cattle farms in Fieri Region in Albania. J. Life Sci. 2013, 7, 390–394. [Google Scholar]

- Bakalli, M.; Selamaj, J. Quality of water used in bakery. J. Hyg. Eng. Des. 2022, 38, 18–22. [Google Scholar]

- Nexhipi, E.; Beli, E. Assessment of the process hygiene and safety meat products RTE, produced in the region of Tirana. Albanian J. Agric. Sci. 2014, 499–503. [Google Scholar]

- Maçi, R.; Bija, B.; Xinxo, A.; Shehu, F.; Memoçi, H. Prevalence of Salmonella spp. in imported powdered infant formula (PIF). Albanian J. Agric. Sci. 2015, 14, 236–240. [Google Scholar]

- Postoli, I.; Shehu, F. Evaluation of the microbial parameters and hygiene status of dairy establishments in Tirana region. Eur. Acad. Res. 2018, 6, 1815–1830. [Google Scholar]

- World Population Review. Milk Consumption by Country. 2024. Available online: https://worldpopulationreview.com/country-rankings/milk-consumption-by-country (accessed on 15 February 2025).

- Imami, D.; Valentinov, V.; Skreli, E. Food Safety and Value Chain Coordination in the Context of a Transition Economy. Int. J. Commons 2021, 15, 21–34. [Google Scholar]

- Skreli, E.; Imami, D. Milk Sector Study; Technical Report Prepared for EBRD AASF Project; AASF Project Office: Tiranë, Albania, 2019. [Google Scholar]

- INSTAT. Statistikat e Blegtorisë. 2024. Available online: https://databaza.instat.gov.al:8083/pxweb/sq/DST/START__BL/NewBL0012/ (accessed on 16 February 2025).

- Gjeci, G.; Bicoku, Y.; Imami, D. Awareness about food safety and animal health standards–the case of dairy cattle in Albania. Bulg. J. Agric. Sci. 2016, 22, 339–345. [Google Scholar]

- Achaw, O.-W.; Danso-Boateng, E. Chemical and Process Industries: With Examples of Industries in Ghana; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar] [CrossRef]

- Asselt, E.; Fels-Klerx, H.; Marvin, H.; Veen, H.; Groot, M. Overview of Food Safety Hazards in the European Dairy Supply Chain. Compr. Rev. Food Sci. Food Saf. 2017, 16, 59–75. [Google Scholar] [CrossRef]

- Montgomery, H.; Haughey, S.; Elliott, C. Recent food safety and fraud issues within the dairy supply chain (2015–2019). Glob. Food Secur. 2020, 26, 100447. [Google Scholar] [CrossRef]

- Opiyo, B.A.; Wangoh, J.; Njage, P.M. Microbiological performance of dairy processing plants is influenced by scale of production and the implemented food safety management system: A case study. J. Food Prot. 2013, 76, 975–983. [Google Scholar] [CrossRef]

- Nada, S.; Ilija, D.; Igor, T.; Jelena, M.; Ruzica, G. Implication of food safety measures on microbiological quality of raw and pasteurized milk. Food Control 2012, 25, 728–731. [Google Scholar] [CrossRef]

- Ntuli, V.; Sibanda, T.; Elegbeleye, J.A.; Mugadza, D.T.; Seifu, E.; Buys, E.M. Dairy production: Microbial safety of raw milk and processed milk products. In Present Knowledge in Food Safety; Academic Press: Cambridge, MA, USA, 2023; pp. 439–454. [Google Scholar] [CrossRef]

- Rankin, S.; Bradley, R.; Miller, G.; Mildenhall, K. A 100-Year Review: A century of dairy processing advancements-Pasteurization, cleaning and sanitation, and sanitary equipment design. J. Dairy Sci. 2017, 100, 9903–9915. [Google Scholar] [CrossRef] [PubMed]

- Cusato, S.; Gameiro, A.; Corassin, C.; Sant’Ana, A.; Cruz, A.; Faria, J.; Oliveira, C. Food safety systems in a small dairy factory: Implementation, major challenges, and assessment of systems’ performances. Foodborne Pathog. Dis. 2013, 10, 6–12. [Google Scholar] [CrossRef]

- Zacharski, K.A.; Southern, M.; Ryan, A.; Adley, C.C. Evaluation of an Environmental Monitoring Program for the Microbial Safety of Air and Surfaces in a Dairy Plant Environment. J. Food Prot. 2018, 81, 1108–1116. [Google Scholar] [CrossRef]

- Owusu-Kwarteng, J.; Akabanda, F.; Agyei, D.; Jespersen, L. Microbial Safety of Milk Production and Fermented Dairy Products in Africa. Microorganisms 2020, 8, 752. [Google Scholar] [CrossRef]

- Karaman, A. Food safety practices and knowledge among Turkish dairy businesses in different capacities. Food Control 2012, 26, 125–132. [Google Scholar] [CrossRef]

- Tesfaye, M.; Beze, A.; Degefa, K. Assessment of good manufacturing practices in Ethiopia Dairy Industry. Nutr. Food Sci. J. 2020, 10, 5557778. [Google Scholar] [CrossRef]

- Njage, P.M.K.; Opiyo, B.; Wangoh, J.; Wambui, J. Scale of production and implementation of food safety programs influence the performance of current food safety management systems: Case of dairy processors. Food Control 2018, 85, 85–97. [Google Scholar]

- Djekić, I.; Smigic, N.; Miloradovic, Z.; Aleksic, B.; Maslovarić, M.; Jovanović, R.; Tolimir, N.; Pudja, P.; Miocinovic, J. Level of Adoption of Hygiene Practices in Small-Scale Dairy Plants in Serbia. Foods 2024, 13, 2470. [Google Scholar] [CrossRef] [PubMed]

- Czubak, W.; Pawłowski, K.; Wiza-Augustyniak, P.; Arion, F. Polish and Romanian Dairy Farms Using eu Investment Support: A Comparative Study. Ann. Pol. Assoc. Agric. Agrobus. Econ. 2019, XXI, 64–75. [Google Scholar] [CrossRef]

- Grace, D. Food Safety in Low- and Middle-Income Countries. Int. J. Environ. Res. Public Health 2015, 12, 10490–10507. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Imami, D.; Skreli, E.; Zhllima, E.; Canavari, M.; Chan Halbrendt, C.; Cela, A. Analysis of consumers’ preferences for typical local cheese in Albania applying conjoint analysis. New Medit 2016, 15, 49–55. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).