3.1. Simulation Results of Seed Potato Posture Adjustment

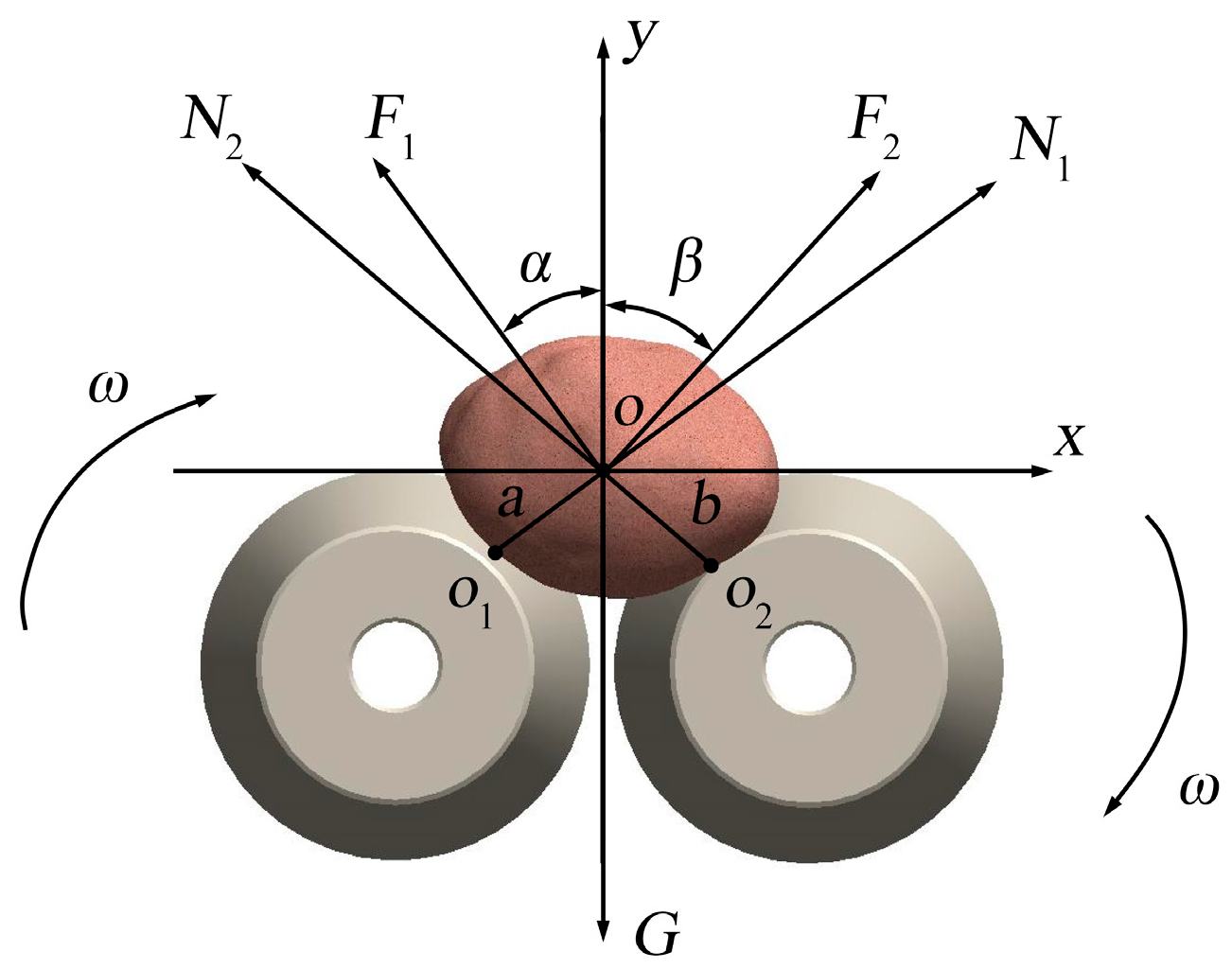

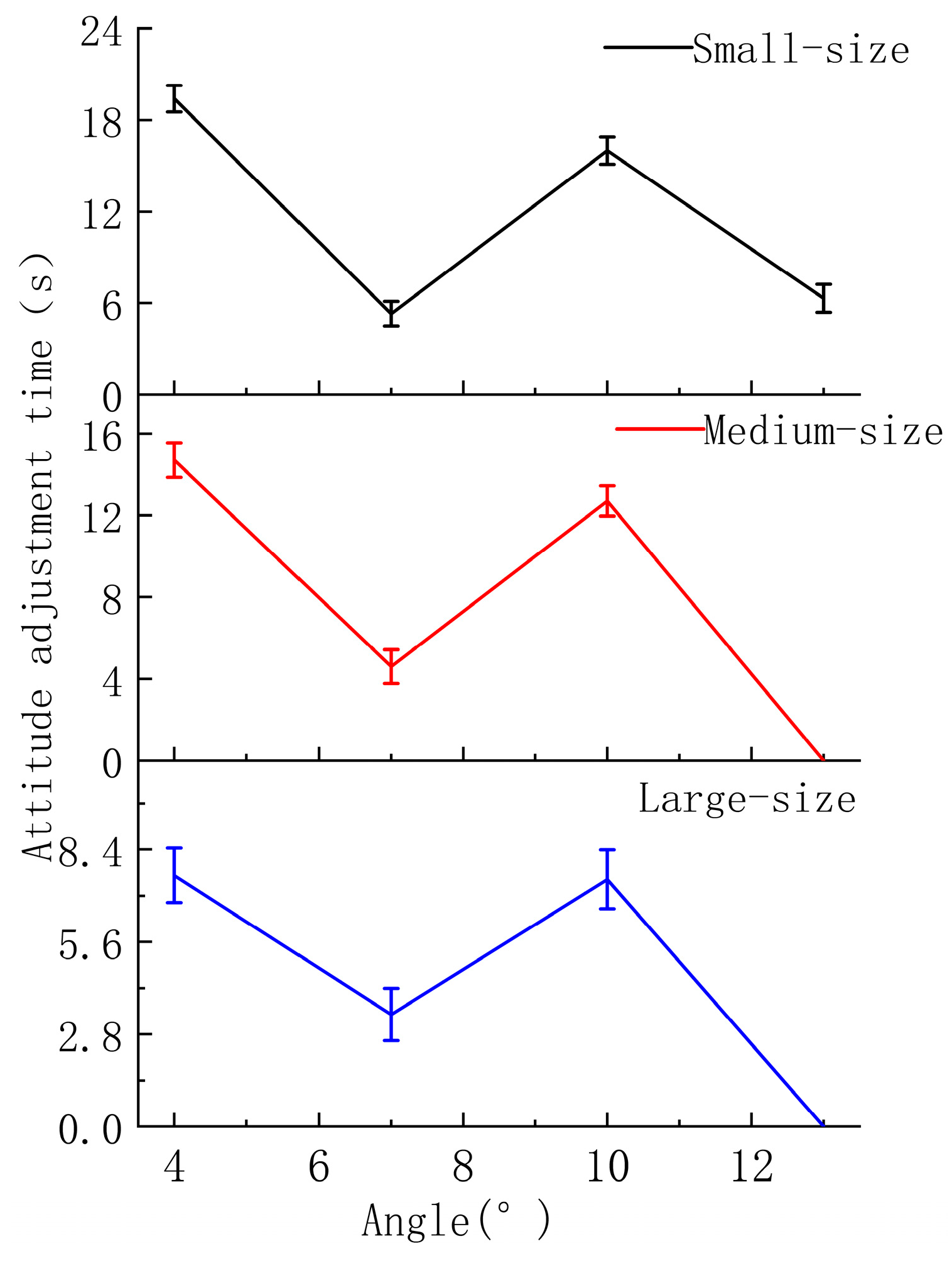

The simulation results are presented in

Figure 10. When the bevel taper of the conical roller is 4°, the taper is insufficient, preventing the seed potato from aligning with the central axis of the symmetrical roller during rotation, and thus failing to achieve proper positioning. At a bevel taper of 7°, the posture adjustment time for all types of seed potatoes is shorter, and the performance is more effective. When the bevel taper is increased to 10°, although all types of seed potatoes can complete their positioning and posture adjustment operations, the time required is excessively long. At a bevel taper of 13°, the gap between adjacent rollers becomes too large, causing small- and medium-sized seed potatoes to fall into the gap during rotation, which prevents successful posture adjustment. Therefore, a bevel taper of 7° is selected for the conical roller in the design, as it yields optimal experimental results.

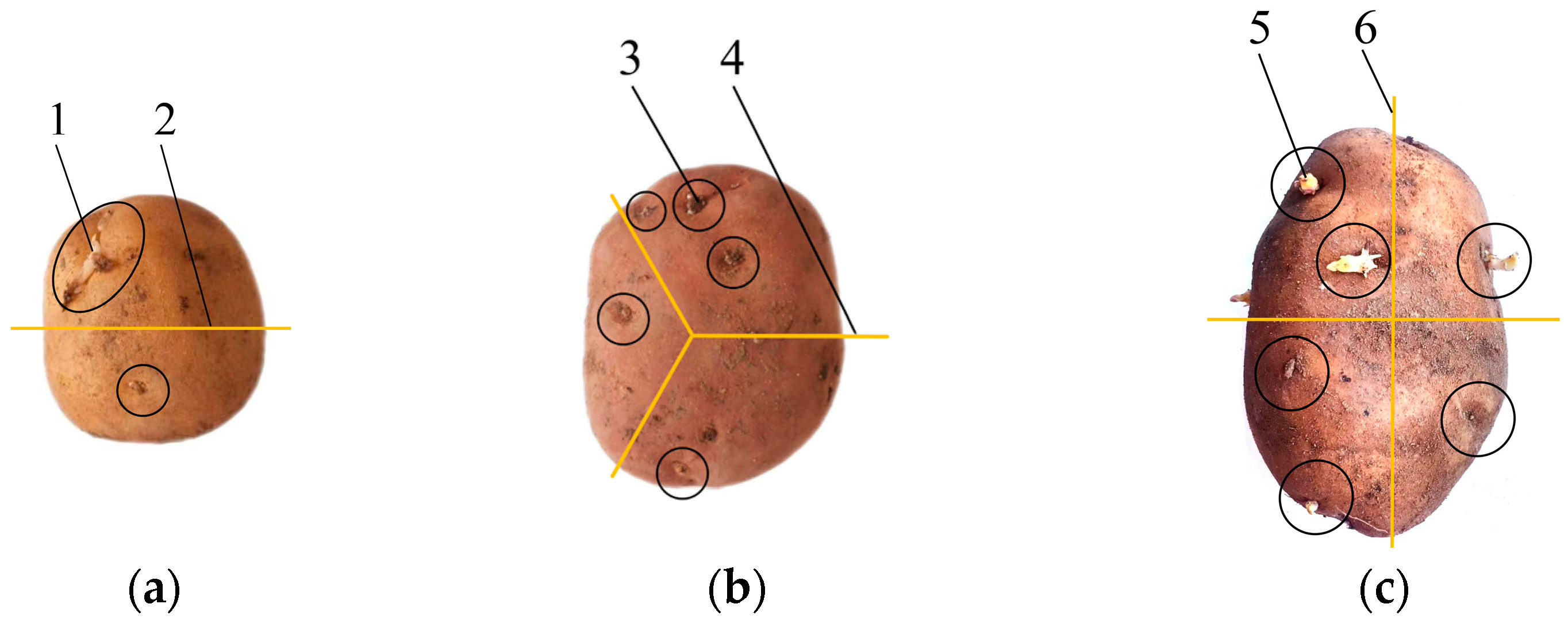

There is little research in the literature on the posture adjustment of seed potatoes in cutting machines. Liu employed a conical roller as the conveying and posture adjusting device in their potato cutting machine [

27]. By configuring the structural parameters of the conical roller, using D

1 = 124 mm, D

2 = 20 mm, L

1 = 30 mm, L

2 = 30 mm, and α = 12° (refer to

Figure 3), they achieved the transportation and posture adjustment of potatoes weighing between 100 and 300 g. However, the study only qualitatively described the ability of the conical roller to adjust the posture of potatoes during transmission, without conducting any related simulation analysis.

Zhu developed a potato seed cutting machine that utilized a coordinated operation of longitudinal disc cutter sets and transverse cutter sets [

28]. This machine employed conical rubber rollers to adjust the orientation of potatoes, which were then fed into the longitudinal disc cutter in a fixed orientation. After the initial longitudinal cutting, oversized potato pieces were directed by a deflector plate to the transverse cutter for secondary cutting. However, the indeterminate positioning of seed potatoes on the conical rubber rollers resulted in random orientations when entering the disc cutter, leading to irregular sizes and shapes of the cut seed potatoes. This randomness often caused the densely budded tops of the seed potatoes to be sliced, resulting in significant seed loss.

3.2. Simulation Results of Seed Potato Dropping

The simulation process of seed potato dropping is illustrated in

Figure 11. The simulation results indicate that when the rotation speed ratio between the roller and the baffle is maintained at 5:8, the secondary baffle conveyor mechanism can smoothly receive the potato seed tubers. Specifically, when the rotating speed of the cone table roller is set to 20 r/min and the baffle’s rotating speed is set to 36 r/min, no bouncing or throwing phenomena of the seed potatoes are observed. However, when the rotating speed of the cone table roller exceeds 25 r/min, the initial velocity of the seed potatoes falling into the secondary baffle becomes too high, causing the potatoes to rebound and altering their posture. This prevents the potatoes from landing in the correct position, significantly affecting the qualified rate of potato cutting and the blind eye rate in the tuber pieces.

From the simulation of the seed potato conveying and posture adjustment process, it is evident that when the speed ratio is 5:8 and the rotating speed of cone table roller does not exceed 25 r/min, the initial positions of the roller and the baffle can be determined, to ensure that all three types of seed potatoes (small, medium, and large) fall smoothly into the secondary baffle mechanism without any change in posture.

3.3. Bench Test Results

To achieve the objectives of a high qualified rate of potato cutting and a low blind eye rate in the potato pieces, preliminary single-factor experiments were conducted. These experiments analyzed the influence of the conical roller speed, the number of cone rollers, and the cutting angle of the cutter on the qualified rate of potato cutting and the blind eye rate. The results indicated that within the ranges of 10–16 rpm for the conical roller speed, 36–44 for the number of cone rollers, and 0–10° for the cutting angle of the cutter, the qualified rate of potato cutting was higher, and the blind eye rate was lower.

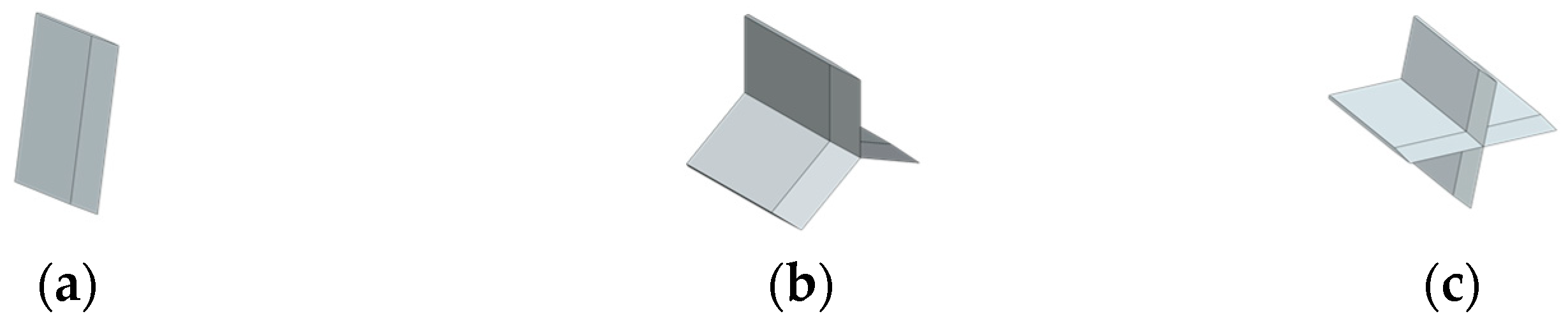

In accordance with an L

9(3

4) orthogonal table, a three-factor, three-level, orthogonal test was designed. Orthogonal tests were conducted using three types of cutters: straight-shaped, Y-shaped, and cross-shaped. The factors and levels for the orthogonal tests of the cutting performance of the seed potato cutting machine are presented in

Table 3. The test results for the cutting performance of the three types of cutters are summarized in

Table 4, while

Figure 12 illustrates the potato tubers cut by the different cutter types.

As shown in

Table 5, there is a significant relationship between the three factors (number of conical rollers, cutting angle, and rotational speed) and the two performance indicators (qualified rate of potato cutting and blind eye rate of potato tubers) in the straight-shaped cutter test. The optimal working combination for maximizing the qualified rate and minimizing the blind eye rate is B

3C

1A

2, which corresponds to 44 conical rollers, a cutting angle of 0°, and a rotational speed of 12 r/min. Under these conditions, the qualified rate of potato cutting reaches 89.1%, and the blind eye rate of the potato tubers is 1.3%. Similarly, in the Y-shaped cutter test, a significant relationship exists between the three factors and the two performance indicators. The optimal working combination is B

3C

2A

3, which includes 44 conical rollers, a cutting angle of 5°, and a rotational speed of 14 r/min. This configuration achieves a qualified rate of 89.6% and a blind eye rate of 1.8%. For the cross-shaped cutter test, the number of conical rollers and the cutting angle significantly affect the qualified rate of potato cutting, while the rotational speed of the conical rollers has no significant impact. However, the rotational speed exhibits a highly significant effect on the blind eye rate. The optimal working combination for this cutter type is C

1B

3A

2, which consists of a cutting angle of 0°, 44 conical rollers, and a rotational speed of 14 r/min. This setup yields a qualified rate of 89.6% and a blind eye rate of 1.4%.

Wang et al. developed a combined positioning and cutting device for segmenting potato seed tubers, utilizing the qualified cutting rate and blind eye rate as evaluation metrics. The experiment was designed as a three-factor, three-level response surface test, with the central distance of the conical roller set, the chain conveyor speed, and a V-shaped blade angle as the experimental factors [

29]. The experimental results were analyzed using the Design-Expert 12.0.3 software for variance analysis and the interaction effects. The qualified cutting rate ranged from 87.52% to 98.35%, while the blind eye rate ranged from 1.17% to 3.08% under various factor combinations. The variance analysis revealed that the factors influencing the qualified cutting rate, in descending order of significance, were the V-shaped blade angle, the chain conveyor speed, and the central distance of the conical roller set. For the blind eye rate, the order of significance was the central distance of the conical roller set, the V-shaped blade angle, and the chain conveyor speed. The software optimization module identified the optimal parameter combination as a central distance of 100.83 mm for the conical roller set, a chain conveyor speed of 0.019 m/s, and a V-shaped blade angle of 49.50°.

In a separate study, Wang et al. designed and constructed a directional alignment and cross-cutting machine for potato seed tubers [

17]. The experiment employed the intermediate motor speed, the central distance between the upper and lower rubber rollers, and the installation angle of the potato cutting comb as experimental factors, with the qualified tuber rate, blind eye rate, and seed tuber loss rate as evaluation metrics. A multi-factor response surface experiment revealed that the central distance between the upper and lower rubber rollers had a significant impact on the qualified tuber rate and blind eye rate, with the order of influence being the central distance, intermediate motor speed, and installation angle of the potato cutting comb. The intermediate motor speed significantly affected the seed tuber loss rate, with the order of influence being the intermediate motor speed, installation angle of the potato cutting comb, and central distance between the upper and lower rubber rollers. Using the Design-Expert 8.0.6 software to analyze the experimental data, the qualified cutting rate ranged from 71.23% to 95.25%, the blind eye rate ranged from 1.37% to 5.89%, and the seed tuber loss rate ranged from 9.25% to 15.02% under various factor combinations.

3.4. Verification Test

Based on the results of the orthogonal test, the optimal operating parameters for each type of cutter were determined, as presented in

Table 6.

Under the optimal operating parameters, the performance of the seed potato cutting machine was validated. The results are presented in

Table 7. For the straight-shaped cutter, the qualified rate of potato cutting was 90.3% and the blind eye rate of the potato tubers was 1.86%. For the Y-shaped cutter, the qualified rate of potato cutting was 87.9% and the blind eye rate of the potato tubers was 2.86%. For the cross-shaped cutter, the qualified rate of potato cutting was 87.1% and the blind eye rate of the potato tubers was 3.80%. These results meet the agronomic requirements for seed potato processing.

Wang et al. conducted a series of experiments on the segmented cutting of potato seed tubers using a combined positioning and cutting mechanism. Based on variance analysis, the experimental validation demonstrated that when the central distance of the conical roller set was 101.60 mm, the chain conveyor speed was 0.019 m/s, and the V-shaped blade angle was 49.50°, the qualified cutting rate reached 90.56%, with a blind eye rate of 1.27%. The relative error compared to the optimized values was less than 5% [

29].

In another study, Wang et al. performed experiments on a directional alignment and cross-cutting machine for potato seed tubers. The results indicated that under the optimal parameter combination, where the intermediate motor speed was 965.76 r/min, the central distance between the upper and lower rubber rollers was 315 mm, and the installation angle of the potato-cutting comb was 104.61°, the qualified tuber rate was 92.13%, the blind eye rate was 1.91%, and the seed tuber loss rate was 10.21%. Compared to the predicted values, the relative errors for the qualified tuber rate, blind eye rate, and seed tuber loss rate were 2.88%, 3.80%, and 5.04%, respectively [

17].