1. Introduction

Planting leguminous green manure in summer or winter in rotation with the main crop is a way of making full use of fallow fields. Also, it benefits the growth and development of leguminous green manure itself, as well as the subsequent main crop [

1]. Previous studies have shown that leguminous green manure can increase N supply, improve N-use efficiency, and maintain the N balance in a crop rotation system through its biological N fixation, thus increasing the yield of the main crop and reducing the application rate of N chemical fertilizers [

2,

3,

4]. As a high-quality source of organic fertilizer, Chinese milk vetch (CMV,

Astragalus sinicus L.) can be planted to reduce soil erosion, optimize the soil’s physical structure, and increase the soil’s nutrient content to a certain extent [

5,

6].

When chemical fertilizers are applied to a field, the nutrients are rapidly released. After incorporation, the CMV decomposes at a fast rate during the early stage and at a slow rate during the later stage, so CMV and chemical fertilizers can be applied together to ensure both a high demand for nutrients in the early growth stage of a crop, and the supply of nutrients in the later stage [

7]. Studies have shown that the biological N fixation by CMV ranged from 60 to 115 kg ha

−1 [

8]. In southern China, the incorporation of CMV can replace 20–40% of N fertilizer without reducing the rice (

Oryza sativa L.) yield [

3].

It has been pointed out that returning straw to the soil may result in adverse effects [

9,

10]. When the C/N ratio of straw exceeds the demand of soil microorganisms, the addition of organic carbon will promote microbial reproduction, which causes N competition between microorganisms and crops [

11,

12,

13]. Therefore, the incorporation of crop residues with an appropriate C/N ratio is essential for soil fertility and crop growth. Recently, the incorporation of green manure and rice straw has become a hot spot in research. The C/N ratio of rice straw (generally 50~70:1) is much higher than that of CMV (10~20:1); thus, the combination of them is helpful for the optimization of the C/N ratio [

14]. The incorporation of CMV and rice straw promotes the activities of β-glucosidase and cellulose hydrolase, thus enhancing the decomposition of rice straw and nutrient release [

15].

The N released through mineralization after the incorporation of CMV and rice straw into a field can replenish the soil’s N pool [

16]. Combined with that, an appropriate amount of N fertilizer will meet the N demand of rice for the whole growth period. Previous studies have mostly focused on the nutrient release of CMV and rice straw when they are incorporated into a field alone. There is a lack of data on the N cycle during each growing stage of rice after incorporating both of them. The objective of the present study was to compare the N-supplying capacity of soils after the incorporation of CMV alone with that after the incorporation of CMV and rice straw at both 60% and 100% of the conventional N fertilizer application rate.

2. Materials and Methods

2.1. Overview of the Field Trial

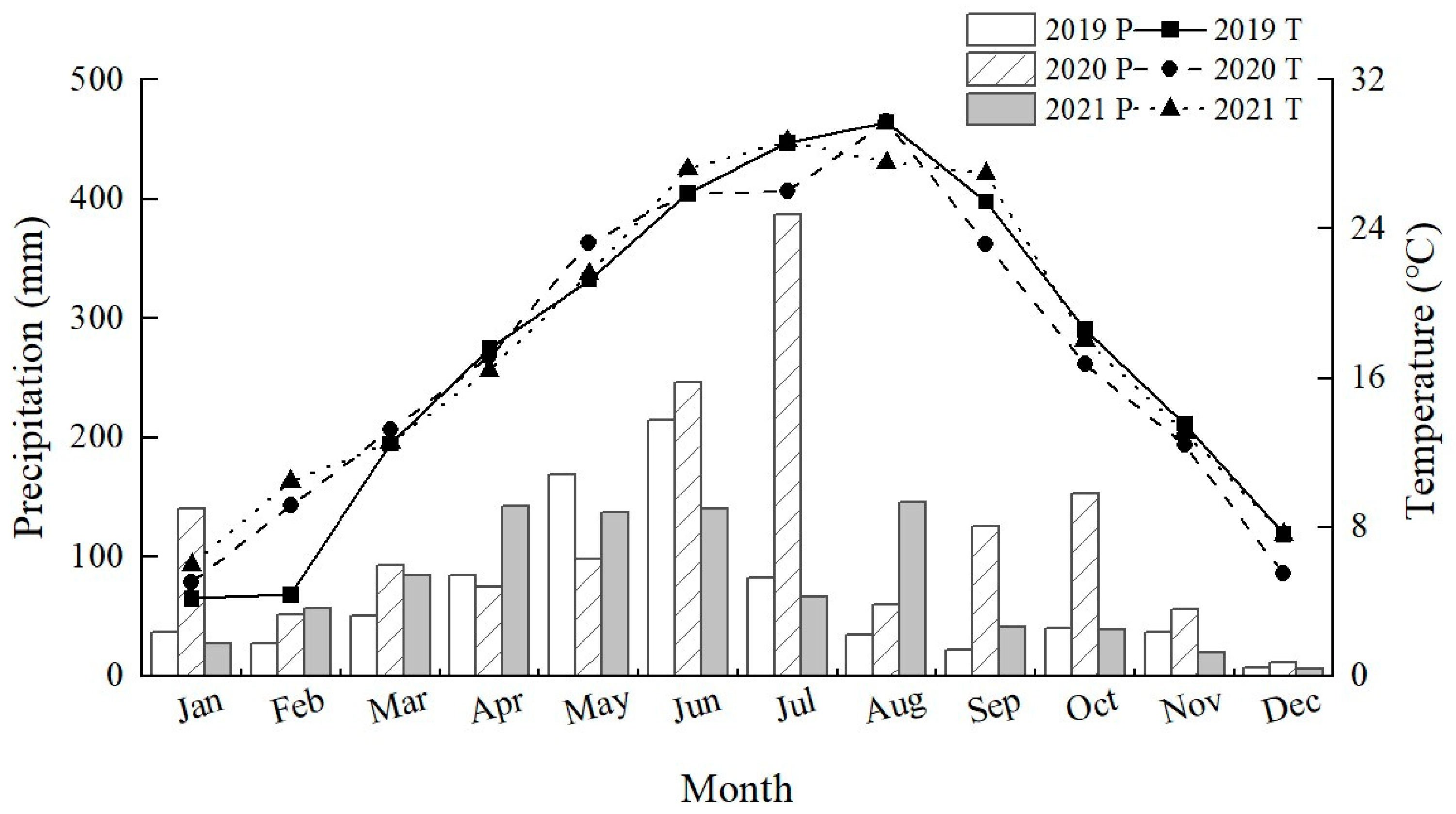

The present study was conducted at Taihu farm, Jianghan Plain, Hubei Province (N 30°22′1″, E 112°2′57″; altitude: 44.6 m), where the local climate was subtropical monsoon, with a monthly average temperature of 17.6 °C and an annual average precipitation of 1069 mm, during the 2019–2021 growing seasons (

Figure 1). The paddy soil was developed from alluvial deposits with the following properties (0–20 cm): pH of 7.6, organic matter of 22.4 g kg

−1, total N of 2.0 g kg

−1, available phosphorus of 10.6 mg kg

−1, and available potassium of 156.0 mg kg

−1. The local traditional crop rotation pattern was mid-season rice, grown from May to September of every year, followed by a winter fallow.

The field trial was established in the fall of 2018. There were seven treatments, and these included two treatments with N fertilizer application rates of 0 (N0) and 165 kg ha

−1 (100% of local conventional rate, N100), without the addition of crop residues. With the other three treatments, only CMV was incorporated, and N fertilizer was applied at 0 (MN0), 99 (60% of conventional rate, MN60), and 165 kg ha

−1 (MN100). The remaining two treatments involved the incorporation of CMV and rice straw, with N fertilizer application rates of 99 (SMN60) and 165 kg ha

−1 (SMN100). The total N input of each treatment is shown in

Table 1. Phosphorus and potassium were applied at 60 kg ha

−1 of P

2O

5 and 90 kg ha

−1 of K

2O for all the treatments.

Treatments were arranged in a randomized complete block design with three replications and were applied to the same plot every year. Each plot was 4 m wide and 5 m long and was spaced with 30 cm-wide ridges. For the rice straw treatments, all the rice straws were incorporated into the soil after rice grain harvest; otherwise they were removed from the plots. The CMV seeds were sown in the first week of October at a rate of 30 kg ha−1, with biomass incorporated on the spot during the full blooming stage (around 15 April in the following year). After CMV incorporation (with a depth of 10–15 cm), the field was subject to flooding for 4–5 weeks. The rice variety was “Fengliangyou No. 2” and 400 rice hills were transplanted for each plot. No fertilizers were added in the CMV growing season, with urea, calcium superphosphate, and potassium chloride applied in the rice season. On the day of rice transplantation, 70% of the total N fertilizers and all phosphorus and potassium fertilizers were spread on the surface of each plot. The remaining N fertilizers were applied at 13 and 70 days after transplantation (DAT). The pest control and irrigation management followed local practices.

2.2. Plant Sampling and Analysis

Before incorporation into soil, the aboveground fresh weight of CMV in the whole plot was measured; subsamples were randomly taken to measure the dry weight and N concentration. In the rice growing season, the aboveground biomasses of five hills per plot were collected in the tillering, shooting, grain filling, and maturity stages (i.e., approximately 30, 60, 90, and 120 DAT). In the latter two stages, grain and shoot were separated to measure dry weight individually. During the maturity stage, rice grains in the whole plot were harvested and the yield was determined after air-drying. In this study, rice yield data were from 2019 to 2021, and the rest of the data were from 2020 to 2021.

All plant samples were oven-dried at 105 °C for 30 min and then at 65 °C to a constant weight. After drying, they were ground to pass a 0.84 mm sieve and digested by H

2SO

4-H

2O

2. The N concentration was measured using the semi-micro Kjeldahl method [

17]. Plant N uptake was calculated by multiplying N concentration by dry weight.

2.3. Soil Sampling and Analysis

Soil samples were taken one day before rice transplantation (18 May 2020 and 20 May 2021) and in the rice tillering, shooting, and maturity stages. Five subsamples were collected at a depth of 0 to 20 cm from each plot. The soil samples were air-dried, ground, and passed through a 2 mm sieve for the measurement of microbial biomass N (MBN), ammonium-N (NH

4+-N), and nitrate-N (NO

3−-N) contents. The MBN content was measured by the chloroform fumigation–UV spectrophotometer method [

18]. Soil NH

4+-N and NO

3−-N were extracted by 1 mol L

−1 KCl and determined using an AA3 Continuous Flow Injection Analyzer (SEAL Analytical, Norderstedt, Germany).

2.4. Water Sampling and Analysis

Field surface water samples were taken by syringe before fertilizer application, and at 3, 6, 13, 16, and 28 DAT in 2020 and 2, 8, 13, 15, and 29 DAT in 2021. Five subsamples were randomly collected in each plot and mixed as one sample. These samples were sent to the laboratory in ice boxes, filtered through a 0.45 μm membrane, and stored in a 4 °C refrigerator before analysis. The NH4+-N and NO3−-N concentrations in water samples were determined by an AA3 Continuous Flow Injection Analyzer.

2.5. Statistical Analysis

The data from each year were analyzed separately because of the different weather conditions. One-way analysis of variance was performed through SAS (Version 9.2). Duncan’s Multiple Range Test was used to compare the significance of differences at the p < 0.05 level.

4. Discussion

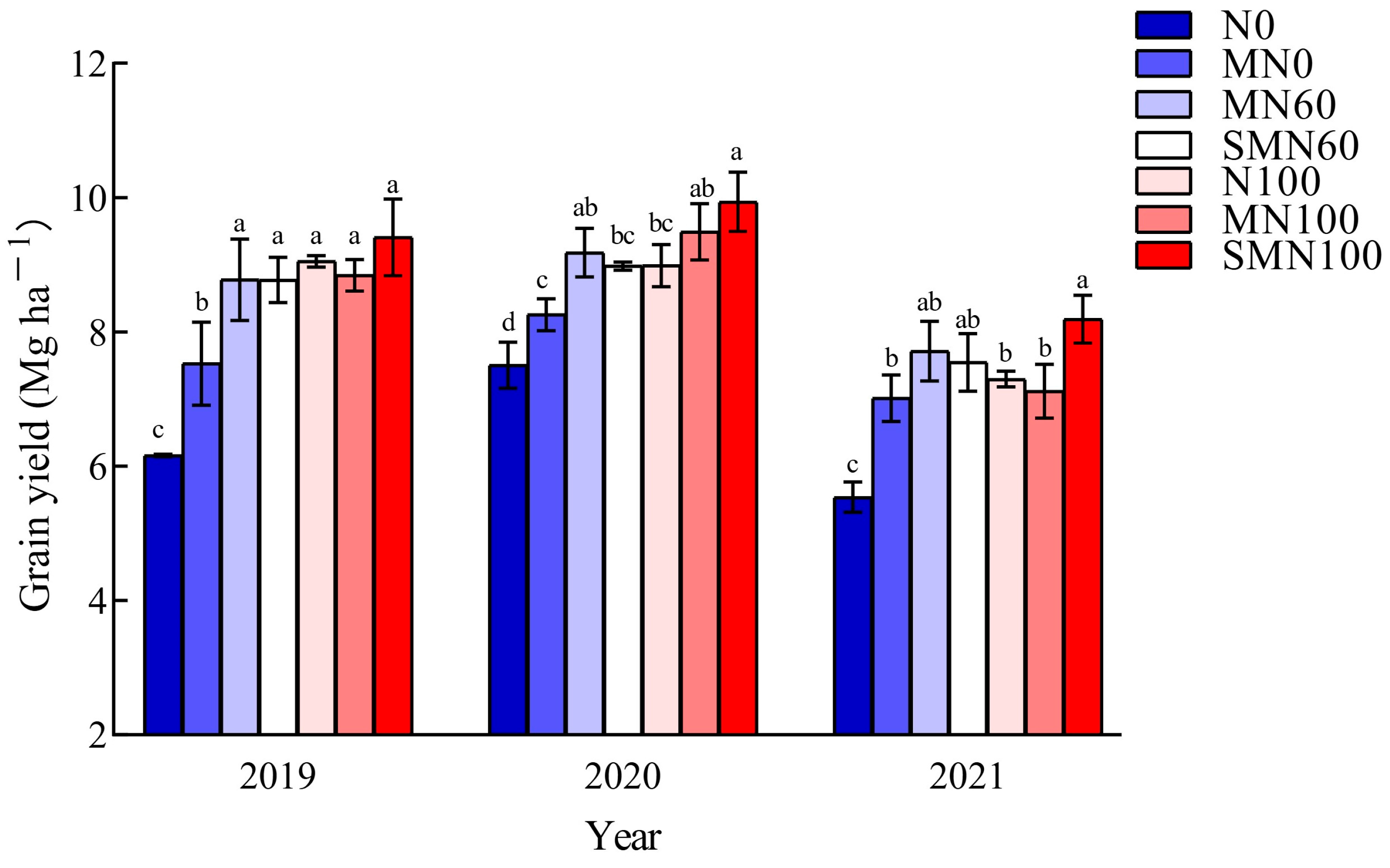

The present study found that the treatments incorporating CMV alone or combined with rice straw and with 60% of N fertilizer did not reduce rice grain yield compared with N100. This is consistent with the previous results, which showed that planting CMV could replace 20–40% of N fertilizer in the paddy fields in southern China [

3,

19]. The CMV, as a type of leguminous green manure, released a large amount of N after incorporation, which met the N demand of rice in the early growth stage and thus replaced the partial N fertilizer [

20,

21]. In addition, the C sources provided by the fresh organic residues increased the biomass and activity of soil microorganisms, leading to a positive priming effect and organic N mineralization [

22]. When organic materials were incorporated, the treatments with the conventional N application rate did not significantly increase rice grain yield compared with the N-reduced treatments, but significantly increased the N uptake in the rice plant.

The results show that the plant N uptake increased with increasing N application rate. However, the N uptakes under the treatments with a 40% reduction in N fertilizer (MN60 and SMN60) were not significantly different from that under N100. This confirms that the incorporation of CMV alone or in combination with rice straw could replace 40% of N fertilizers. Comparing with CMV alone, the incorporation of both CMV and rice straw with chemical fertilizers could harmonize the supply and demand of N nutrient, promoting rice growth [

20,

23]. The incorporation of CMV and rice straw at the conventional N application rate promoted the N uptake in rice straw and grain, but did not significantly improve rice grain yield. Thus, such a high amount of N accumulation in rice plants could be considered as surplus uptake. Abe et al. [

24] found that excessive N fertilizer application even reduced rice grain yield. Therefore, a proper application rate of N fertilizer is crucial for improving rice grain yield and minimizing the waste of resources and environmental risk.

In the tillering and shooting stages, the incorporation of CMV and rice straw with a 40% reduction in N fertilizer did not significantly reduce the soil inorganic N content compared with the N100 treatment. The input of nutrients from CMV and rice straw increased the soil organic N pool and promoted the mineralization of organic matter, which increased N release and thus the inorganic N concentration [

25]. In addition, the incorporation of CMV and rice straw optimized the C/N ratio of the inputs [

26], increasing the activity of soil microorganisms and the MBN content [

27].

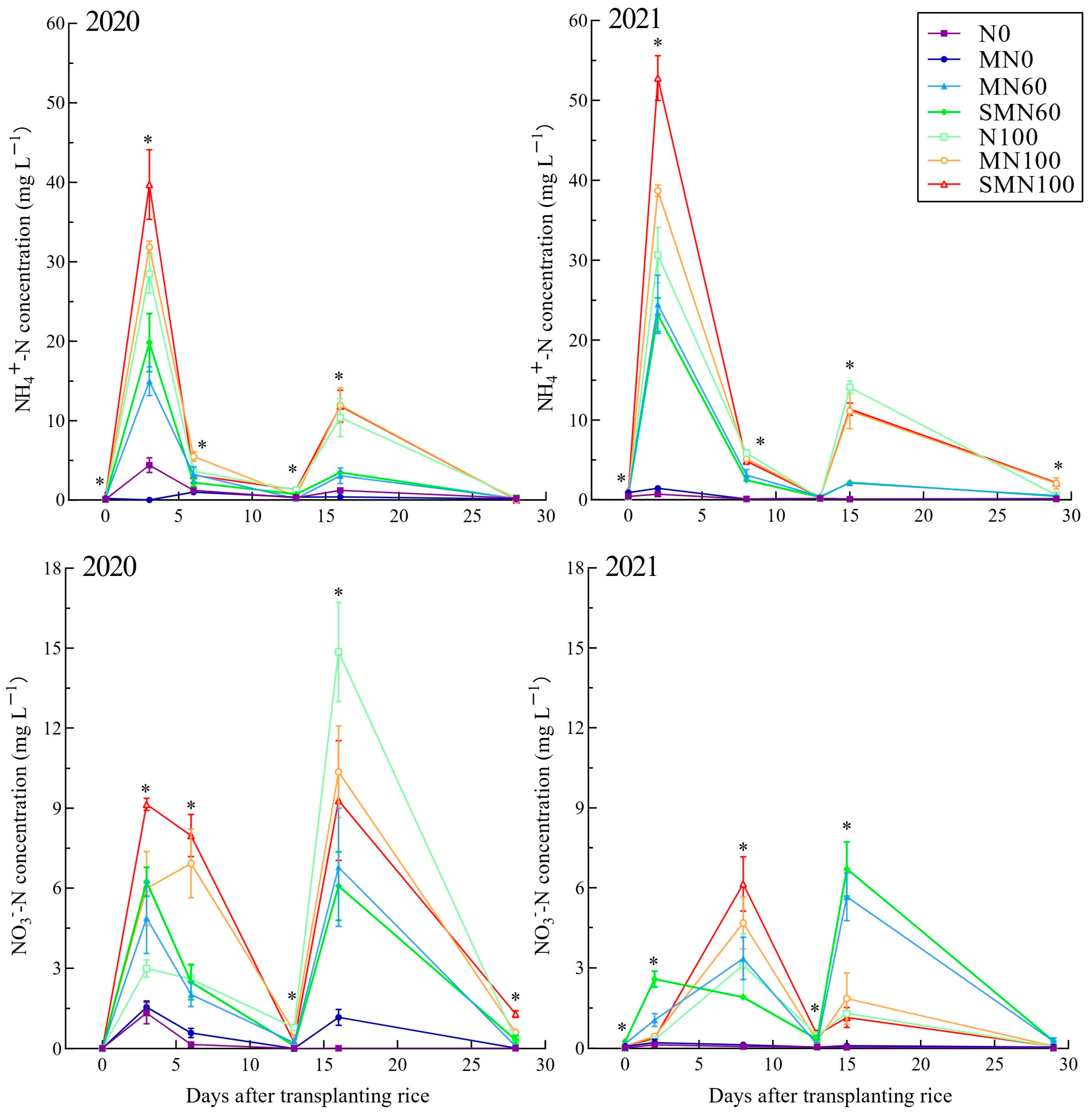

Inorganic N in the surface water can be directly absorbed by rice and represent the primary source of N loss from paddy field [

28]. When N was applied at 60% of the conventional rate, the NH

4+-N concentrations in the surface water with CMV alone and in combination with rice straw were lower than that under N100. This indicates that the 40% N fertilizer replacement reduced the risk of N loss, especially at 2–3 days after N fertilizer application. The changes in NO

3−-N concentration in the surface water generally lagged behind changes in NH

4+-N [

29]. The first peak of NO

3−-N concentration occurred at 2 and 8 DAT in 2020 and 2021, respectively, which might be related to the sampling time. The first sampling date after initial fertilizer application in 2021 was one day earlier than that in 2020, probably resulting in the missed peak of NO

3−-N concentration. Chu et al. [

30] and Ai et al. [

31] showed that an increased N application rate could enhance nitrification and soil NO

3−-N content. Therefore, the high N input is one of the key factors causing N loss from the paddy field. In the present study, especially in 2020, a 40% N fertilizer replacement reduced the NO

3−-N concentrations in the surface water, thus reducing the potential for N loss through leaching and runoff.