The Potential of Green Hydrogen and Power-to-X to Decarbonize the Fertilizer Industry in Jordan

Abstract

1. Introduction

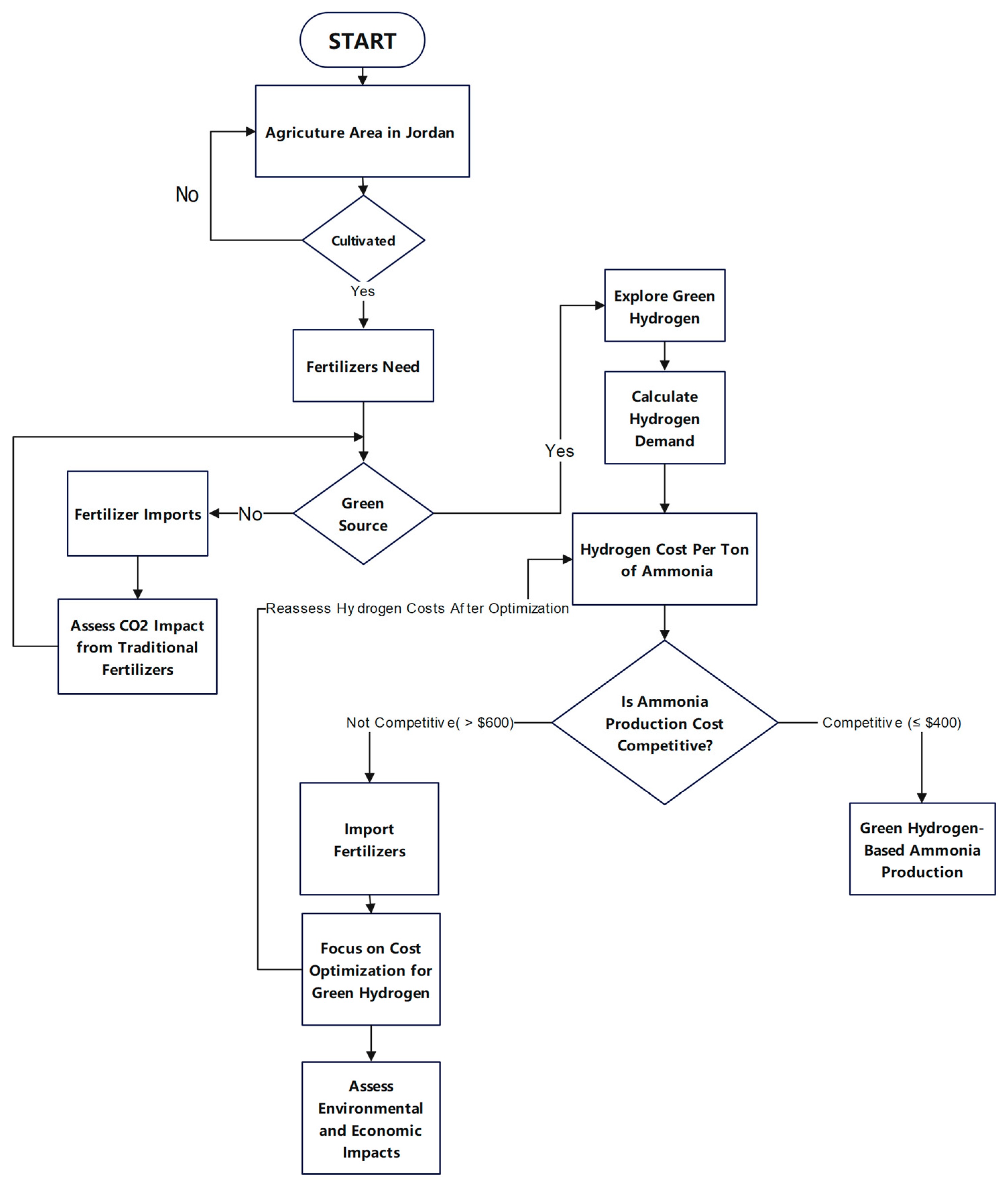

2. Materials and Methods

- Hydrogen price: Varying between USD 3/kg and USD 7/kg.

- Urea price: Global market prices for urea fluctuate, with a range of 450 USD/ton to 600 USD/ton.

- Urea import quantity: Derived from historical trends and projected rates.

3. Results and Discussion

- Neutral scenario: Assumed that the land area would remain constant from 2023 until 2050.

- Optimistic Scenario: Assumed an annual increase of 2% in the land area for the same period.

- Pessimistic Scenario: Estimated a 2% annual decrease in the land area for the same period.

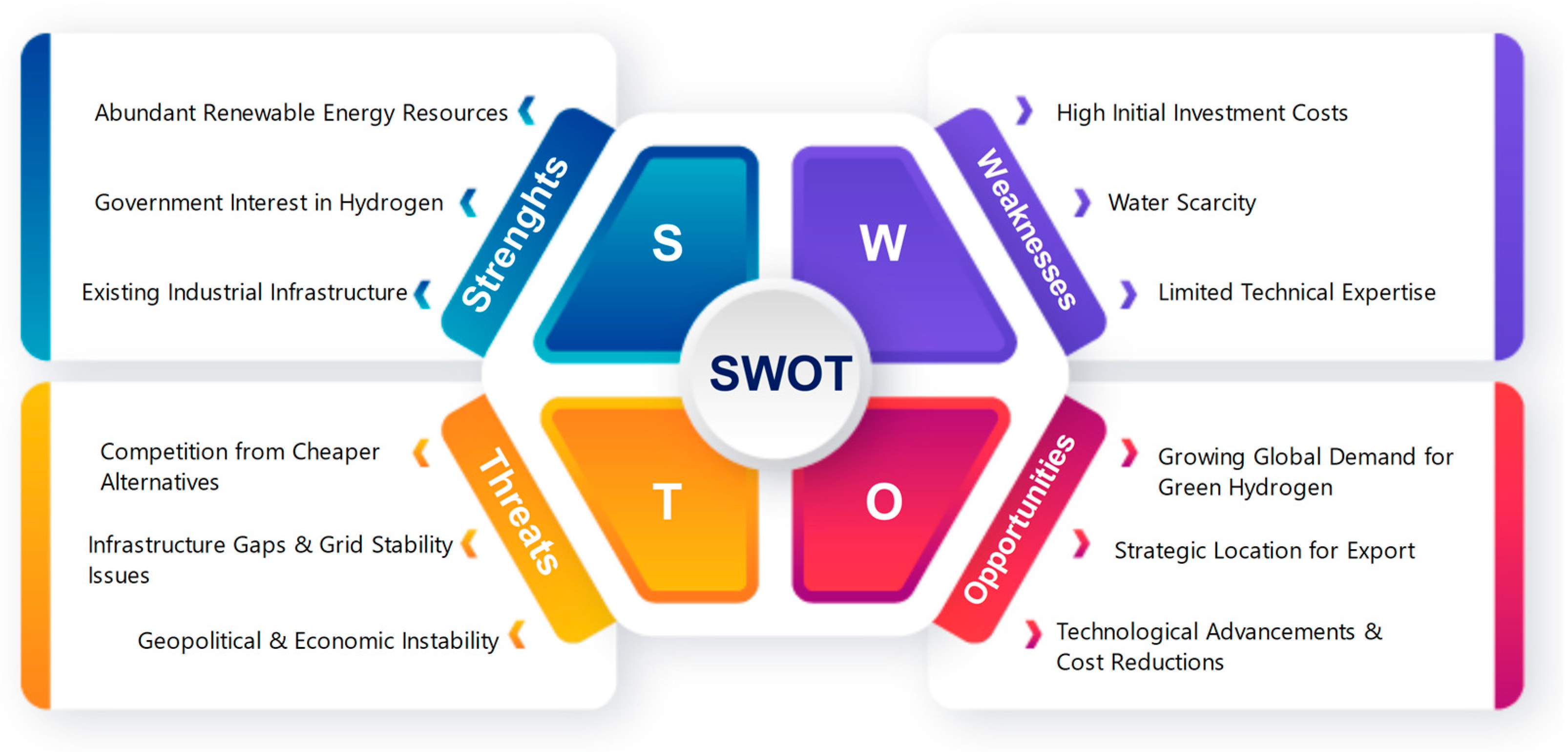

4. SWOT Analysis

5. Conclusions

6. Limitations and Future Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhanumathi, S.; Vineeth, M.; Rohit, N. Crop yield prediction and efficient use of fertilizers. In Proceedings of the 2019 International Conference on Communication and Signal Processing (ICCSP), Brighton, UK, 12–17 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 0769–0773. [Google Scholar]

- Lim, J.; Fernández, C.A.; Lee, S.W.; Hatzell, M.C. Ammonia and nitric acid demands for fertilizer use in 2050. ACS Energy Lett. 2021, 6, 3676–3685. [Google Scholar] [CrossRef]

- Daramola, D.A.; Hatzell, M.C. Energy demand of nitrogen and phosphorus based fertilizers and approaches to circularity. ACS Energy Lett. 2023, 8, 1493–1501. [Google Scholar] [CrossRef]

- Oliveira, A.M.; Beswick, R.R.; Yan, Y. A green hydrogen economy for a renewable energy society. Curr. Opin. Chem. Eng. 2021, 33, 100701. [Google Scholar] [CrossRef]

- Ozturk, M.; Dincer, I. A comprehensive review on power-to-gas with hydrogen options for cleaner applications. Int. J. Hydrogen Energy 2021, 46, 31511–31522. [Google Scholar] [CrossRef]

- Genovese, M.; Schlüter, A.; Scionti, E.; Piraino, F.; Corigliano, O.; Fragiacomo, P. Power-to-hydrogen and hydrogen-to-X energy systems for the industry of the future in Europe. Int. J. Hydrogen Energy 2023, 48, 16545–16568. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. Renewable Energy Benefits Leveraging Local Capacity for Concentrated Solar Power. Irena. 2025. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2025/Jan/IRENA_Renewable_energy_benefits_leveraging_capacity_CSP_2025.pdf (accessed on 31 January 2025).

- International Energy Agency. Net Zero by 2050: A Roadmap for the Global Energy Sector-Event-IEA. 2021. Available online: https://iea.blob.core.windows.net/assets/deebef5d-0c34-4539-9d0c-10b13d840027/NetZeroby2050-ARoadmapfortheGlobalEnergySector_CORR.pdf (accessed on 31 January 2025).

- Li, Y.; Taghizadeh-Hesary, F. Energy Prices and the Economic Feasibility of Using Hydrogen Energy for Road Transport in the People’s Republic of China; (No. 1185); ADBI Working Paper Series; Asian Development Bank Institute: Mandaluyong, Philippines, 2020. [Google Scholar]

- Risco-Bravo, A.; Varela, C.; Bartels, J.; Zondervan, E. From green hydrogen to electricity: A review on recent advances, challenges, and opportunities on power-to-hydrogen-to-power systems. Renew. Sustain. Energy Rev. 2024, 189, 113930. [Google Scholar] [CrossRef]

- Coleman, D.; Kopp, M.; Wagner, T.; Scheppat, B. The value chain of green hydrogen for fuel cell buses—A case study for the Rhine-Main area in Germany. Int. J. Hydrogen Energy 2020, 45, 5122–5133. [Google Scholar] [CrossRef]

- Pagani, G.; Hajimolana, Y.; Acar, C. Green hydrogen for ammonia production—A case for the Netherlands. Int. J. Hydrogen Energy 2024, 52, 418–432. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Emissions Gap Report 2024|UNEP-UN Environment Programme. 2024. Available online: https://www.unep.org/resources/emissions-gap-report-2024 (accessed on 2 February 2025).

- Ahrens, F.; Land, J.; Krumdieck, S. Decarbonization of nitrogen fertilizer: A transition engineering desk study for agriculture in Germany. Sustainability 2022, 14, 8564. [Google Scholar] [CrossRef]

- Pradhan, B.B.; Limmeechokchai, B.; Chaichaloempreecha, A.; Rajbhandari, S. Role of green hydrogen in the decarbonization of the energy system in Thailand. Energy Strategy Rev. 2024, 51, 101311. [Google Scholar] [CrossRef]

- Seck, G.S.; Hache, E.; Sabathier, J.; Guedes, F.; Reigstad, G.A.; Straus, J.; Wolfgang, O.; Ouassou, J.A.; Askeland, M.; Hjorth, I.; et al. Hydrogen and the decarbonization of the energy system in europe in 2050: A detailed model-based analysis. Renew. Sustain. Energy Rev. 2022, 167, 112779. [Google Scholar] [CrossRef]

- Maestre, V.M.; Ortiz, A.; Ortiz, I. Challenges and prospects of renewable hydrogen-based strategies for full decarbonization of stationary power applications. Renew. Sustain. Energy Rev. 2021, 152, 111628. [Google Scholar] [CrossRef]

- Bartlett, J.; Krupnick, A. Decarbonized hydrogen in the US power and industrial sectors: Identifying and incentivizing opportunities to lower emissions. Resour. Future 2020, 20–25. [Google Scholar]

- Khatiwada, D.; Vasudevan, R.A.; Santos, B.H. Decarbonization of natural gas systems in the EU–costs, barriers, and constraints of hydrogen production with a case study in Portugal. Renew. Sustain. Energy Rev. 2022, 168, 112775. [Google Scholar] [CrossRef]

- Adekola, K.; Ghafoori, S.; Dechamp, F.; Prada, A. Electricity supply configurations for green hydrogen hubs: A European case study on decarbonizing urban transport. Int. J. Hydrogen Energy 2024, 85, 539–559. [Google Scholar] [CrossRef]

- Inal, O.B.; Zincir, B.; Dere, C. Hydrogen as maritime transportation fuel: A pathway for decarbonization. In Greener and Scalable E-fuels for Decarbonization of Transport; Springer: Singapore, 2021; pp. 67–110. [Google Scholar]

- Kurien, C.; Mittal, M. Utilization of green ammonia as a hydrogen energy carrier for decarbonization in spark ignition engines. Int. J. Hydrogen Energy 2023, 48, 28803–28823. [Google Scholar] [CrossRef]

- Rinaldi, A.; Syla, A.; Patel, M.K.; Parra, D. Optimal pathways for the decarbonisation of the transport sector: Trade-offs between battery and hydrogen technologies using a whole energy system perspective. Clean. Prod. Lett. 2023, 5, 100044. [Google Scholar] [CrossRef]

- Kazi, M.K.; Eljack, F.; El-Halwagi, M.M.; Haouari, M. Green hydrogen for industrial sector decarbonization: Costs and impacts on hydrogen economy in qatar. Comput. Chem. Eng. 2021, 145, 107144. [Google Scholar] [CrossRef]

- Zaiter, I.; Ramadan, M.; Bouabid, A.; El-Fadel, M.; Mezher, T. Potential utilization of hydrogen in the UAE’s industrial sector. Energy 2023, 280, 128108. [Google Scholar] [CrossRef]

- Nikhil, P.; Prakash, G.B.; Kavyasri, K.; Sivasankar, P. Analysis on CO2 emissions, green hydrogen requirement and geo-storage potential of hydrogen for decarbonization of industrial operations in southeastern coast of India. Int. J. Hydrogen Energy 2024, 52, 1507–1521. [Google Scholar] [CrossRef]

- Muhsen, H.; Al-Mahmodi, M.; Tarawneh, R.; Alkhraibat, A.; Al-Halhouli, A.A. The potential of green hydrogen and power-to-X utilization in Jordanian Industries: Opportunities and future prospects. Energies 2023, 17, 213. [Google Scholar] [CrossRef]

- Doucet, F.; Jürgens, L.; Barkow, H.; Schütte, C.; Neubauer, N.; von Düsterlho, E.; Schäfers, H. Decarbonization of the Industry–Demand and Cost Comparison of Green Hydrogen in Germany. In Proceedings of the 2023 19th International Conference on the European Energy Market (EEM), Lappeenranta, Finland, 6–8 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Nurdiawati, A.; Urban, F. Decarbonising the refinery sector: A socio-technical analysis of advanced biofuels, green hydrogen and carbon capture and storage developments in Sweden. Energy Res. Soc. Sci. 2022, 84, 102358. [Google Scholar] [CrossRef]

- Moradpoor, I.; Syri, S.; Santasalo-Aarnio, A. Green hydrogen production for oil refining—Finnish case. Renew. Sustain. Energy Rev. 2023, 175, 113159. [Google Scholar] [CrossRef]

- Manna, J.; Jha, P.; Sarkhel, R.; Banerjee, C.; Tripathi, A.K.; Nouni, M.R. Opportunities for green hydrogen production in petroleum refining and ammonia synthesis industries in India. Int. J. Hydrogen Energy 2021, 46, 38212–38231. [Google Scholar] [CrossRef]

- Badakhsh, A.; Bhagavathy, S.M. Caveats of green hydrogen for decarbonisation of heating in buildings. Appl. Energy 2024, 353, 122152. [Google Scholar] [CrossRef]

- Segawa, Y.; Endo, N.; Shimoda, E.; Yamane, T. Assessment of hydrogen storage capacity required for decarbonization: A case study using off-site green hydrogen for buildings. Int. J. Hydrogen Energy 2024, 94, 1046–1055. [Google Scholar] [CrossRef]

- Röben, F.; Kicherer, N.; Jürgens, L.; Decher, S.; Schäfers, H.; von Düsterlho, J.E. Decarbonization of the heating sector in hamburg grid constraints, efficiency and costs of green hydrogen vs. heat pumps. In In Proceedings of the 2022 18th International Conference on the European Energy Market (EEM), Ljubljana, Slovenia, 13–15 September 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Okeke, I.J.; Kamath, D.; Nimbalkar, S.U.; Cresko, J. The Role of Low-Carbon Fuels and Carbon Capture in Decarbonizing the US Clinker Manufacturing for Cement Production: CO2 Emissions Reduction Potentials. Energies 2024, 17, 5233. [Google Scholar] [CrossRef]

- Cormos, C.C. Decarbonization options for cement production process: A techno-economic and environmental evaluation. Fuel 2022, 320, 123907. [Google Scholar] [CrossRef]

- Bhaskar, A.; Abhishek, R.; Assadi, M.; Somehesaraei, H.N. Decarbonizing primary steel production: Techno-economic assessment of a hydrogen based green steel production plant in Norway. J. Clean. Prod. 2022, 350, 131339. [Google Scholar] [CrossRef]

- Johnson, S.; Deng, L.; Gençer, E. Environmental and economic evaluation of decarbonization strategies for the Indian steel industry. Energy Convers. Manag. 2023, 293, 117511. [Google Scholar] [CrossRef]

- Arpino, F.; Canale, C.; Cortellessa, G.; Dell’Isola, M.; Ficco, G.; Grossi, G.; Moretti, L. Green hydrogen for energy storage and natural gas system decarbonization: An Italian case study. Int. J. Hydrogen Energy 2024, 49, 586–600. [Google Scholar] [CrossRef]

- Bhaskar, A.; Assadi, M.; Somehsaraei, H.N. Decarbonization of the Iron and Steel Industry with Direct Reduction of 643 Iron Ore with Green Hydrogen. Energies 2020, 13, 758. [Google Scholar] [CrossRef]

- AlZahrani, A.A.; Zamfirescu, C.; El-Emam, R.S. Analysis of a Solar-Assisted Crude Oil Refinery System with Onsite Green Hydrogen Generation: A Case Study. Arab. J. Sci. Eng. 2024, 50, 2557–2571. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Emissions Due to Agriculture—Global, Regional and Country Trends 2000–2018. FAO. 2021. Available online: https://openknowledge.fao.org/items/08e67acd-1791-4486-ba41-2b52a075b432 (accessed on 3 February 2025).

- Statista. Agriculture Emissions Worldwide—Statistics & Facts. Statista. 2024. Available online: https://www.statista.com/topics/10348/agriculture-emissions-worldwide/#topicOverview (accessed on 29 December 2024).

- International Fertilizer Association. Fertilizers and Agriculture’s Carbon Footprint. IFA. 2022. Available online: https://www.fertilizer.org/key-priorities/fertilizer-use/fertilizers-agricultures-carbon-footprint/ (accessed on 29 December 2024).

- International Energy Agency. The Role of Low-Carbon Fuels in the Clean Energy Transitions of the Power Sector. IEA. 2021. Available online: https://www.iea.org/reports/the-role-of-low-carbon-fuels-in-the-clean-energy-transitions-of-the-power-sector (accessed on 26 December 2024).

- Bora, N.; Singh, A.K.; Pal, P.; Sahoo, U.K.; Seth, D.; Rathore, D.; Bhadra, S.; Sevda, S.; Venkatramanan, V.; Prasad, S.; et al. Green ammonia production: Process technologies and challenges. Fuel 2024, 369, 131808. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. The Future of Food and Agriculture Drivers and Triggers for Transformation. FAO. 2022. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/002ef5c5-3501-413f-b226-c87da30a7a29/content (accessed on 15 January 2025).

- Nadarajan, S.; Sukumaran, S. Chemistry and toxicology behind chemical fertilizers. In Controlled Release Fertilizers for Sustainable Agriculture; Academic Press: Cambridge, MA, USA, 2021; pp. 195–229. [Google Scholar]

- Kusin, F.M.; Akhir NI, M.; Mohamat-Yusuff, F.; Awang, M. The impact of nitrogen fertilizer use on greenhouse gas emissions in an oil palm plantation associated with land use change. Atmósfera 2015, 28, 243–250. [Google Scholar] [CrossRef]

- Green Economy. Our Energy Future: Green Ammonia. Green Economy. 2025. Available online: https://www.greenintelligence.org.uk/news-and-resources/insights/our-energy-future-green-ammonia/ (accessed on 27 December 2024).

- Higher Population Council. Jordan—Recent Demographic Indicators (April 2024). HPC. 2024. Available online: https://www.hpc.org.jo/sites/default/files/jordan_demographic_indicators_sheet_2024.pdf (accessed on 31 December 2024).

- International Trade Administration. Jordan Country Commercial Guide. ITA. 2024. Available online: https://www.trade.gov/country-commercial-guides/jordan-agricultural-sectors (accessed on 31 December 2024).

- Al-Addous, M.; Bdour, M.; Alnaief, M.; Rabaiah, S.; Schweimanns, N. Water resources in Jordan: A review of current challenges and future opportunities. Water 2023, 15, 3729. [Google Scholar] [CrossRef]

- Ministry of Environment. Agriculture Sector—Green Growth National Action Plan 2021–2025. MoEnv. 2020. Available online: https://www.moenv.gov.jo/ebv4.0/root_storage/ar/eb_list_page/20022_jordan_agriculture_v06_rc_web-0.pdf (accessed on 1 January 2025).

- O’Brien, T.; Bui NT, N.; Frasheri, E.; Garcia, F.; Protzer, E.; Villasmil, R.; Hausmann, R. What Will It Take for Jordan to Grow? CID Faculty Working Paper Series. 022.411; Harvard University: Cambridge, MA, USA, 2022. [Google Scholar]

- Al-Karablieh, E.; Salman, A. Water Resources, Use and Management in Jordan. A Focus on Groundwater; IWMI Project Publication–Groundwater Governance in the Arab World–Taking Stock and Addressing the Challenges; International Water Management Institute (IWMI): Colombo, Sri Lanka, 2016. [Google Scholar]

- Ministry of Agriculture. Agriculture in Numbers—Annual Reports. MoA. 2025. Available online: https://www.moa.gov.jo/AR/List/__%D8%A7%D9%84%D8%B2%D8%B1%D8%A7%D8%B9%D8%A9_%D8%A8%D8%A7%D9%84%D8%A3%D8%B1%D9%82%D8%A7%D9%85 (accessed on 1 January 2025).

- Al-Alayani, H.; Utilizing Ammonia’s Value Chain in Jordan. Jordan News. 2023. Available online: https://www.jordannews.jo/Section-36/Opinion/Utilizing-amonia-s-value-chain-in-jordan-30897 (accessed on 2 January 2025).

- Fertilizers Europe. Types of Fertilizers. Fertilizers Europe. 2023. Available online: https://www.fertilizerseurope.com/fertilizers-in-europe/types-of-fertilizer/ (accessed on 2 January 2025).

- Teagasc—The Agriculture and Food Development Authority. Fertiliser Types. Teagasc. 2017. Available online: https://www.teagasc.ie/crops/soil--soil-fertility/fertiliser-types/ (accessed on 2 January 2025).

- International Fertilizer Association. Consumption. IFASTAT. 2025. Available online: https://www.ifastat.org/databases/plant-nutrition (accessed on 2 January 2025).

- World Bank Group. Fertilizer Consumption (% of Fertilizer Production)—Jordan. WBG. 2025. Available online: https://data.worldbank.org/indicator/AG.CON.FERT.PT.ZS?end=2022&locations=JO&start=1973&view=chart (accessed on 3 January 2025).

- World Integrated Trade Solution. Jordan Mineral or Chemical Fertilizers with Nitrogen, Imports by Country in 2023. WITS. 2023. Available online: https://wits.worldbank.org/trade/comtrade/en/country/JOR/year/2023/tradeflow/Imports/partner/ALL/product/310520 (accessed on 3 January 2025).

- Volza. Fertilizer Imports in Jordan—Market Size & Demand Based on Import Trade Data. Volza. 2025. Available online: https://www.volza.com/p/fertilizer/import/import-in-jordan/ (accessed on 4 January 2025).

- Alrwashdeh, S.S.; Alsaraireh, F.M.; Saraireh, M.A. Solar radiation map of Jordan governorates. Int. J. Eng. Technol. 2018, 7, 1664–1667. [Google Scholar] [CrossRef]

- Jordan Wind Project Company. Tafilah Energy Farm. JWPC. 2025. Available online: https://jordanwind.com/ (accessed on 4 January 2025).

- International Renewable Energy Agency. Renewable Energy & Energy Efficiency (Law No. 13). IEA. 2021. Available online: https://www.iea.org/policies/5348-renewable-energy-energy-efficiency-law-no-13 (accessed on 5 January 2025).

- Hassan, Q.; Algburi, S.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. Green hydrogen: A pathway to a sustainable energy future. Int. J. Hydrogen Energy 2024, 50, 310–333. [Google Scholar] [CrossRef]

- ToAgriculture. Watermelon Fertilizer Application for 1 Hectare: Dos and Don’ts. 2025. Available online: https://toagriculture.com/watermelon-fertilizer-application-for-1-hectare/#:~:text=Calculating%20the%20correct%20amount%20of%20fertilizer%3A&text=Generally%2C%20for%201%20hectare%20of,applications%20throughout%20the%20growing%20season (accessed on 6 January 2025).

- Hochmuth, G.J.; Hanlon, E.A. IFAS Standardized Fertilization Recommendations for Vegetable Crops; University of Florida, Cooperative Extension Service, Institute of Food and Agricultural Sciences: Gainesville, FL, USA, 1995. [Google Scholar]

- Shrestha, S.; Dhakal, M.; Sapkota, S.; Gautam, I.P.; Pandey, S.; Shrestha, Y. Evaluation of Zucchini (Cucurbita pepo L.) genotypes for spring season production in the mid–hills of Nepal. Nepal J. Sci. Technol. 2021, 20, 73–81. [Google Scholar] [CrossRef]

- Hensleigh, P. Evaluation of Fava Bean Lines Under Irrigated and Dryland Conditions at the Bridger, Montana Plant Materials Center. United States Department of Agriculture. Available online: https://www.nrcs.$a.gov/plantmaterials/mtpmcsr13297.pdf (accessed on 5 January 2025).

- Garlic Seed. How to Fertilize Your Garlic Properly. 2025. Available online: https://garlicseed.ca/blogs/growing-garlic/how-to-fertilize-your-garlic (accessed on 5 January 2025).

- Shafeek, M.R.; Shaheen, A.M.; Abd El-Samad, E.H.; Rizk, F.A.; Abd El-Al, F.S. Response of growth, yield and fruit quality of cantaloupe plants (Cucumis melo L.) to organic and mineral fertilization. Middle East J. Appl. Sci. 2015, 5, 76–82. [Google Scholar]

- Lelei, D.; Nabwile, E.; Onyango, O.J. Effect of harvesting stages and nitrogen on seed quality and yield of jute mallow (Corchorus olitorius L.). Int. J. Hortic. Sci. Technol. 2020, 7. [Google Scholar]

- Davis, J.G.; Brick, M.A. Fertilizing Dry Beans; Colorado State University Extension: Fort Collins, CO, USA, 2009. [Google Scholar]

- North Dakota State University. Field Pea Production. NDSU. 2021. Available online: https://www.ndsu.edu/agriculture/sites/default/files/2021-12/a1166.pdf (accessed on 6 January 2025).

- Grains Research and Development Corporation. Chickpea—Section 5: Nutrition and Fertiliser. GRDC. 2017. Available online: https://grdc.com.au/__data/assets/pdf_file/0030/369444/GrowNote-Chickpea-West-5-Nutrition.pdf (accessed on 6 January 2025).

- Horticultural Development Company. Nitrogen Recommendations for Optimizing Yield and Quality of Baby Leaf Lettuce. HDC. 2014. Available online: https://projectbluearchive.blob.core.windows.net/media/Default/Imported%20Publication%20Docs/16_14%20Nitrogen%20recommendations%20for%20optimising%20yield%20and%20quality%20of%20baby%20lettuce.pdf (accessed on 7 January 2025).

- Wahocho, N.A.; Wahocho, S.A.; Memon, N.; Leghari, M.H.; Baloch, Q.B. Growth and yield response of turnip to various nitrogen application rates. Pak. J. Agric. Agric. Eng. Vet. Sci. 2016, 32, 143–149. [Google Scholar]

- TNAU Agritech. Fertilizer Schedule. Available online: https://agritech.tnau.ac.in/horticulture/ferti_schedule.pdf (accessed on 7 January 2025).

- Roy, R.N.; Finck, A.; Blair, G.J.; Tandon HL, S. Nutrient management guidelines for some major field crops. Plant Nutrition for Food Security. A Guide for Integrated Nutrient Management; FAO: Rome, Italy, 2006; pp. 235–349. [Google Scholar]

- Gebregergis, Z.; Sibhatu, F.B.; Teame, G. Optimizing N fertilizer use for sesame under rain fed and irrigation conditions in Northern Ethiopia. Oil Crop. Sci. 2023, 8, 252–258. [Google Scholar] [CrossRef]

- AgriFarming. Best Fertilizer for Barley: Organic, NPK, Requirements, When and How to Apply. 2025. Available online: https://www.agrifarming.in/best-fertilizer-for-barley-organic-npk-requirements-when-and-how-to-apply (accessed on 8 January 2025).

- Gerwig, J.; Gelderman, R.; Fertilizer Recommendations Guide. South Dakota State University. 2005. Available online: https://www.nrcs.$a.gov/sites/default/files/2023-06/EC750_2023.pdf (accessed on 8 January 2025).

- Conaghan, P.; Clavin, D. Red Clover—Agronomy and Management. Available online: https://www.teagasc.ie/media/website/publications/2017/6-Red-clover-agronomy-and-management.pdf (accessed on 9 January 2025).

- New Jersey Agricultural Experiment Station. Soil Fertility Recommendations for Producing Grass Hay. 2025. Available online: https://njaes.rutgers.edu/fs1295/ (accessed on 9 January 2025).

- Corn Agronomy. Broomcorn. 1990. Available online: https://corn.aae.wisc.edu/Crops/Broomcorn.aspx (accessed on 10 January 2025).

- Alberta Pulse Growers. Lentil—Fertility. 2025. Available online: https://albertapulse.com/lentil-seeding/lentil-fertility/ (accessed on 10 January 2025).

- Haifa Group. A Complete Fertilization Program for Olive Trees. 2025. Available online: https://www.haifa-group.com/complete-fertilization-program-olive-trees (accessed on 10 January 2025).

- Haifa Group. Fertilization of Pomelo Trees in Tropical Climate. 2025. Available online: https://www.haifa-group.com/fertilization-pomelo-trees-tropical-climate (accessed on 10 January 2025).

- Haifa Group. Nutritional Recommendations for Citrus. Available online: https://www.haifa-group.com/files/Guides/Citrus.pdf (accessed on 11 January 2025).

- Zekri, M.; Schumann, A.W.; Vashisth, T.; Kadyampakeni, D.M.; Morgan, K.T.; Boman, B.; Shahid, M.A.; Obreza, T.A. 2024–2025 Florida Citrus Production Guide: Fertilizer Application Methods; EDIS: Gainesville, FL, USA, 2024. [Google Scholar]

- Wen, S.; Cui, N.; Gong, D.; Xing, L.; Wu, Z.; Zhang, Y.; Wang, Z.; Wang, J. Optimizing nitrogen fertilizer application for achieving high yield with low environmental risks in apple orchard. Agric. Water Manag. 2023, 289, 108501. [Google Scholar] [CrossRef]

- Muhammad, S.; Sanden, B.L.; Saa, S.; Lampinen, B.D.; Smart, D.R.; Shackel, K.A.; DeJong, T.M.; Brown, P.H. Optimization of nitrogen and potassium nutrition to improve yield and yield parameters of irrigated almond (Prunus dulcis (Mill.) DA webb). Sci. Hortic. 2018, 228, 204–212. [Google Scholar] [CrossRef]

- Guo, C.; Wang, X.; Li, Y.; He, X.; Zhang, W.; Wang, J.; Shi, X.; Chen, X.; Zhang, Y. Carbon footprint analyses and potential carbon emission reduction in China’s major peach orchards. Sustainability 2018, 10, 2908. [Google Scholar] [CrossRef]

- Yan, X.; Ye, D.; Tang, Y.; Muneer, M.A.; Christie, P.; Tou, C.; Xu, W.; Shen, B.; Xu, J.; Zhang, J. Potential mitigation of environmental impacts of intensive plum production in southeast China with maintenance of high yields: Evaluation using life cycle assessment. Front. Plant Sci. 2023, 14, 1158591. [Google Scholar] [CrossRef]

- Mohit, M.; Verma, M.L.; Thakur, J. Effect of different nitrogenous fertilizers on Fruit Quality and Yield of apricot (Prunus armeniaca L.). J. Pharmacogn. Phytochem 2017, 6, 217–220. [Google Scholar]

- Rutkowski, K.; Łysiak, G.P.; Zydlik, Z. Effect of nitrogen fertilization in the sour cherry orchard on soil enzymatic activities, microbial population, and fruit quality. Agriculture 2022, 12, 2069. [Google Scholar] [CrossRef]

- Brunetto, G.; Sete, P.B.; Marcio Norberto, P.; Daiane Welter, P.; Thábata Silva Viana, I.; Paulo Andrade, M. The Fate of Soil-Applied Nitrogen in the Fig Tree. Horticulturae 2024, 10, 609. [Google Scholar] [CrossRef]

- Ayars, J.E.; Phene, C.J.; Phene, R.C.; Gao, S.; Wang, D.; Day, K.R.; Makus, D.J. Determining pomegranate water and nitrogen requirements with drip irrigation. Agric. Water Manag. 2017, 187, 11–23. [Google Scholar] [CrossRef]

- Khan, J.; Sajid, M. Effect of Nitrogen Doses and Timing on Fruit Quality of Guava in Winter. Sarhad J. Agric. 2024, 40, 848–857. [Google Scholar] [CrossRef]

- Klein, P. Land preparation planting operation fertilization requirements Chapter 6. In Date Palm Cultivation. FAO Plant Production and Protection; Zaid, A., Ed.; FAO: Rome, Italy, 2002; Volume 156. [Google Scholar]

- Magalhães, R.M.F.; Edvan, R.L.; Ratke, R.F.; de Oliveira, M.E.; Carvalho, C.D.M.; Araújo, J.S.; Araújo, D.D.C.; do Nascimento, R.R. Efficiency of fertilization with coated urea in the cultivation of cactus pear under rainfed conditions in Brazilian savannah. J. Agric. Sci. 2021, 159, 426–436. [Google Scholar] [CrossRef]

- Polat, A.A. Loquat production in Turkey: Problems and solutions. Eur. J. Plant Sci. Biotechnol. 2007, 1, 187–199. [Google Scholar]

- Glenk, G.; Reichelstein, S. Economics of converting renewable power to hydrogen. Nat. Energy 2019, 4, 216–222. [Google Scholar] [CrossRef]

- Bhandari, R.; Trudewind, C.A.; Zapp, P. Life cycle assessment of hydrogen production via electrolysis–a review. J. Clean. Prod. 2014, 85, 151–163. [Google Scholar] [CrossRef]

- Staffell, I.; Scamman, D.; Abad, A.V.; Balcombe, P.; Dodds, P.E.; Ekins, P.; Shah, N.; Ward, K.R. The role of hydrogen and fuel cells in the global energy system. Energy Environ. Sci. 2019, 12, 463–491. [Google Scholar] [CrossRef]

- Hydrogen Council. Path to Hydrogen Competitiveness: A Cost Perspective. 2020. Available online: https://hydrogencouncil.com/wp-content/uploads/2020/01/Path-to-Hydrogen-Competitiveness_Full-Study-1.pdf (accessed on 12 January 2025).

- European Commission. A Hydrogen Strategy for a Climate Neutral Europe. 2020. Available online: https://energy.ec.europa.eu/system/files/2020-07/hydrogen_strategy_0.pdf (accessed on 12 January 2025).

- Bicer, Y.; Dincer, I. Clean fuel options with hydrogen for sea transportation: A life cycle approach. Int. J. Hydrogen Energy 2018, 43, 1179–1193. [Google Scholar] [CrossRef]

| Scenario | Urea Price (USD/ton) | Hydrogen Price (USD/kg) | Description |

|---|---|---|---|

| Best case | 600 | 3 | Low hydrogen price and high urea price |

| Baseline | 525 | 5 | Midpoint values for both prices |

| Worst case | 450 | 7 | High hydrogen price and low urea price |

| Category | Total Need of Ammonia—2023 (ton) |

|---|---|

| Vegetables | 10,471.42711 |

| Grains | 6887.553799 |

| Olives | 30.4635075 |

| Citrus | 2270.66563 |

| Fruits | 5035.439602 |

| Greenhouse | 2382.156283 |

| Total Ammonia—2023 (ton) | 27,077.70593 |

| CO2 Current | 48,739.87067 |

| CO2 Green | 0 |

| Reduction % | 100% |

| Savings | 48,739.87067 |

| Cost of Urea Imports | ||

|---|---|---|

| Scenario | Price per ton (USD) | Total Cost (USD) |

| Best Case | 600 | 8,394,822.68 |

| Baseline | 525 | 7,345,469.84 |

| Worst Case | 450 | 6,296,117.01 |

| Cost of Green Hydrogen Production | ||

|---|---|---|

| Scenario | Price per kg (USD) | Total Cost |

| Best Case | 3 | 30,366,173.88 |

| Baseline | 5 | 50,610,289.80 |

| Worst Case | 7 | 70,854,405.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhsen, H.; Hamida, F.; Tarawneh, R. The Potential of Green Hydrogen and Power-to-X to Decarbonize the Fertilizer Industry in Jordan. Agriculture 2025, 15, 608. https://doi.org/10.3390/agriculture15060608

Muhsen H, Hamida F, Tarawneh R. The Potential of Green Hydrogen and Power-to-X to Decarbonize the Fertilizer Industry in Jordan. Agriculture. 2025; 15(6):608. https://doi.org/10.3390/agriculture15060608

Chicago/Turabian StyleMuhsen, Hani, Farah Hamida, and Rashed Tarawneh. 2025. "The Potential of Green Hydrogen and Power-to-X to Decarbonize the Fertilizer Industry in Jordan" Agriculture 15, no. 6: 608. https://doi.org/10.3390/agriculture15060608

APA StyleMuhsen, H., Hamida, F., & Tarawneh, R. (2025). The Potential of Green Hydrogen and Power-to-X to Decarbonize the Fertilizer Industry in Jordan. Agriculture, 15(6), 608. https://doi.org/10.3390/agriculture15060608