Evaluation of Environmental Quality in Northern Winter Fattening Pig Houses Based on AHP-EWM

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Site and Experimental Design

2.2. Test Equipment

2.3. AHP-EWM Comprehensive Evaluation

2.3.1. AHP Evaluation of Subjective Weights

2.3.2. EWM Objective Weight Evaluation

2.3.3. Comprehensive Weight

3. Results and Discussion

3.1. Construction of the Environmental Comfort Evaluation Weight Set

3.1.1. Construction of the Evaluation Index System

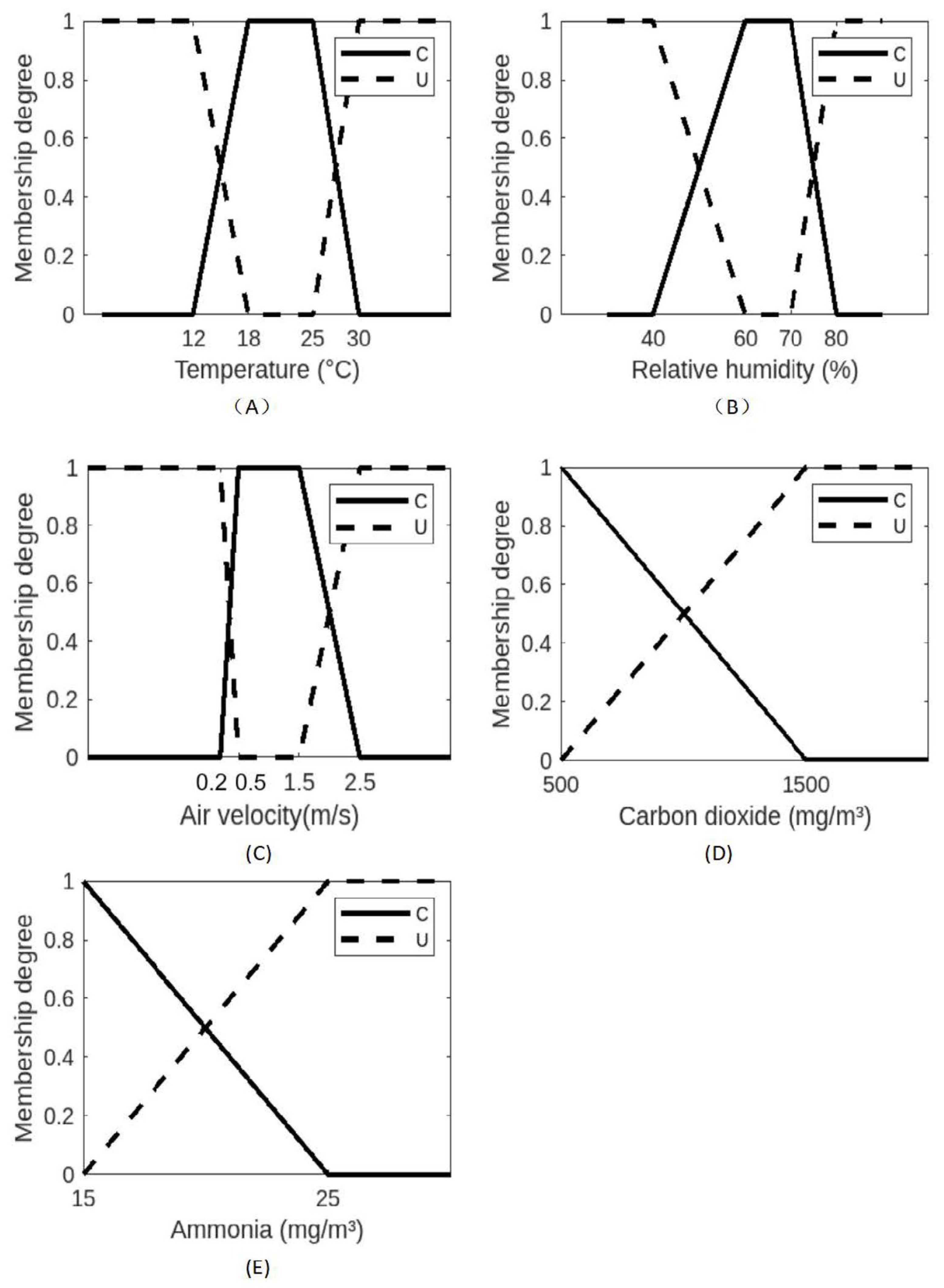

3.1.2. Membership Function Determination

3.1.3. Determination of Comprehensive Weights Using AHP-EWM

3.2. Radar Chart Analysis of Pigsty Environmental Assessment

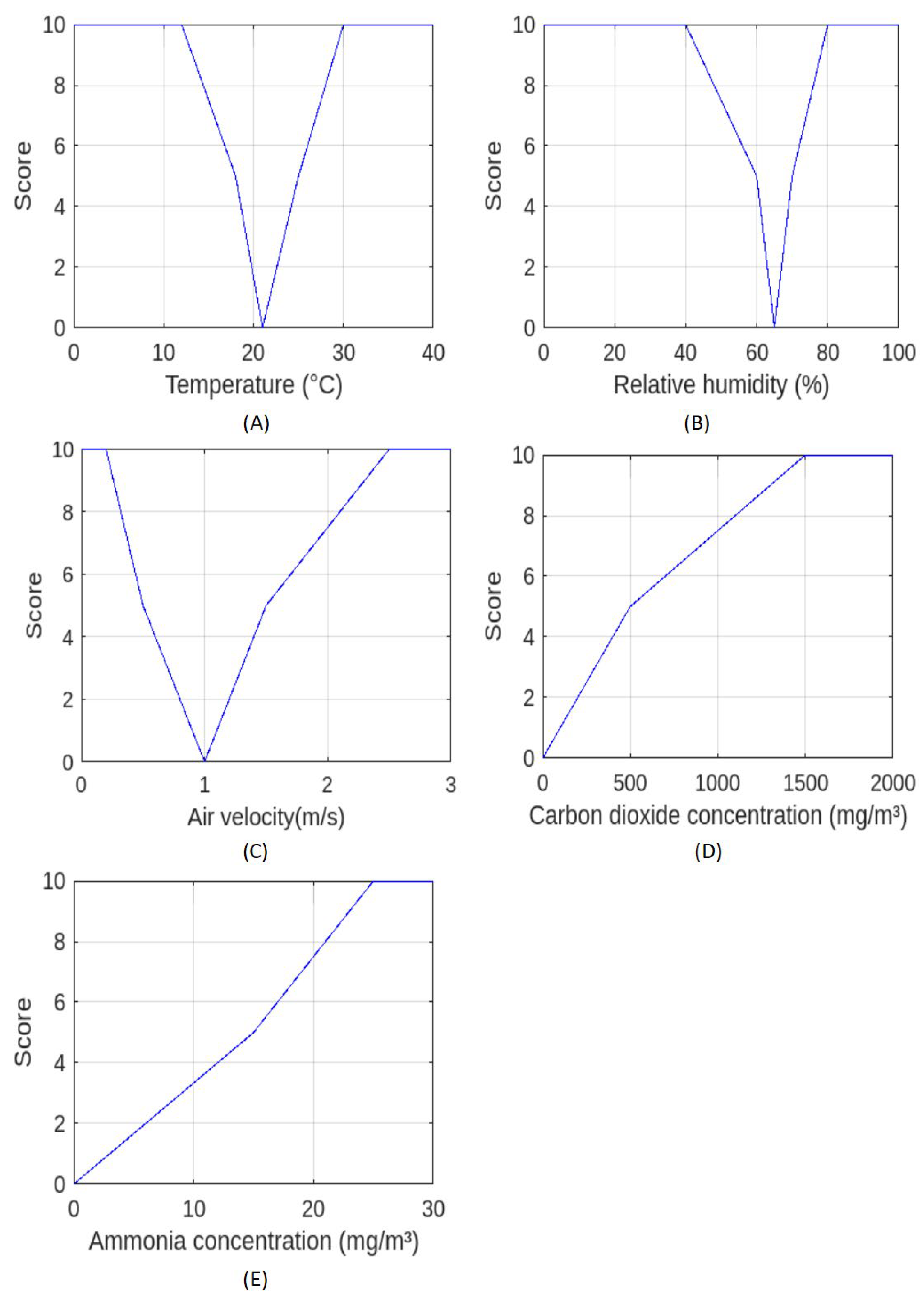

3.2.1. Environmental Factor Data Scoring Conversion

3.2.2. Construction of Radar Charts

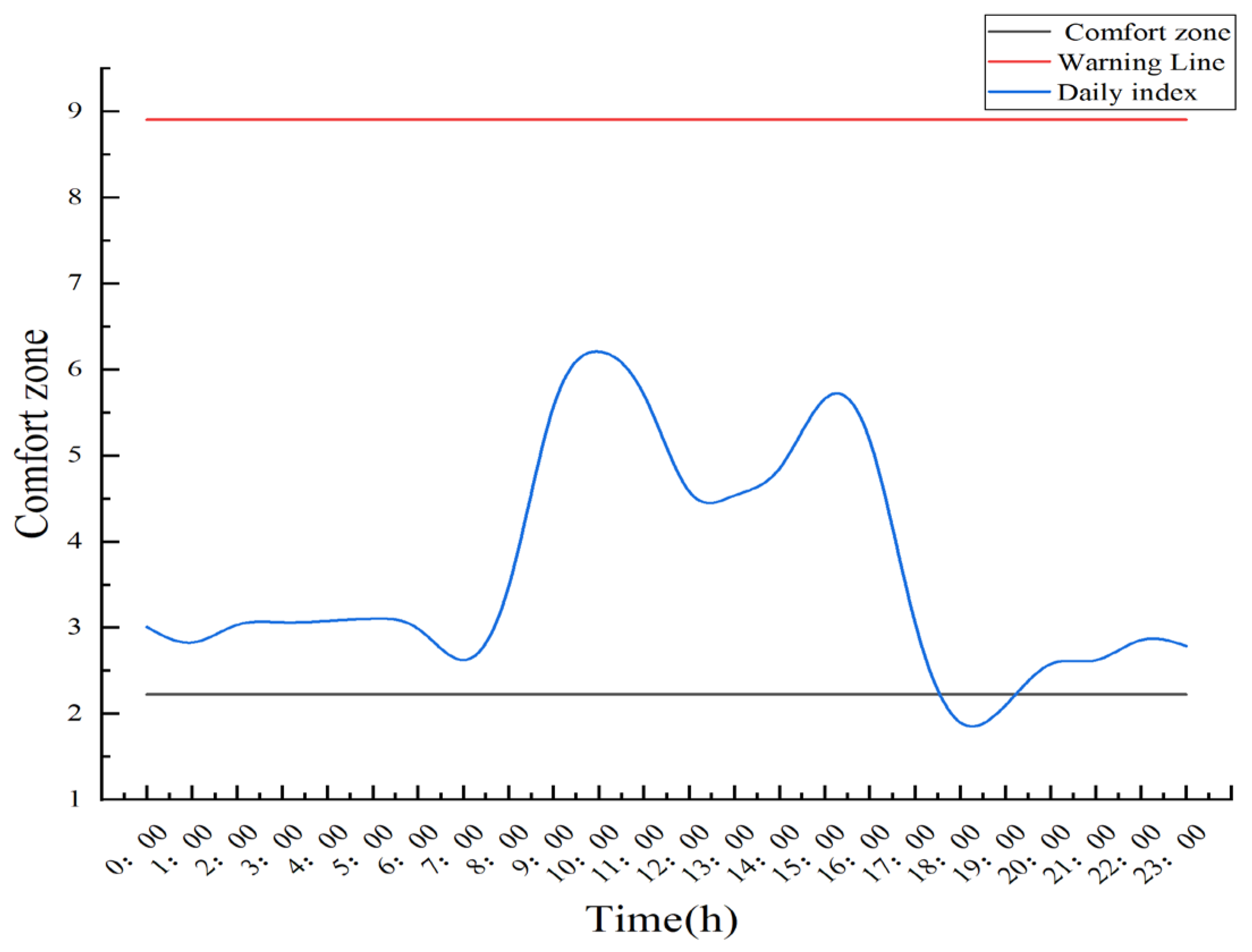

3.3. Environmental Comfort Assessment Model Verification Analysis

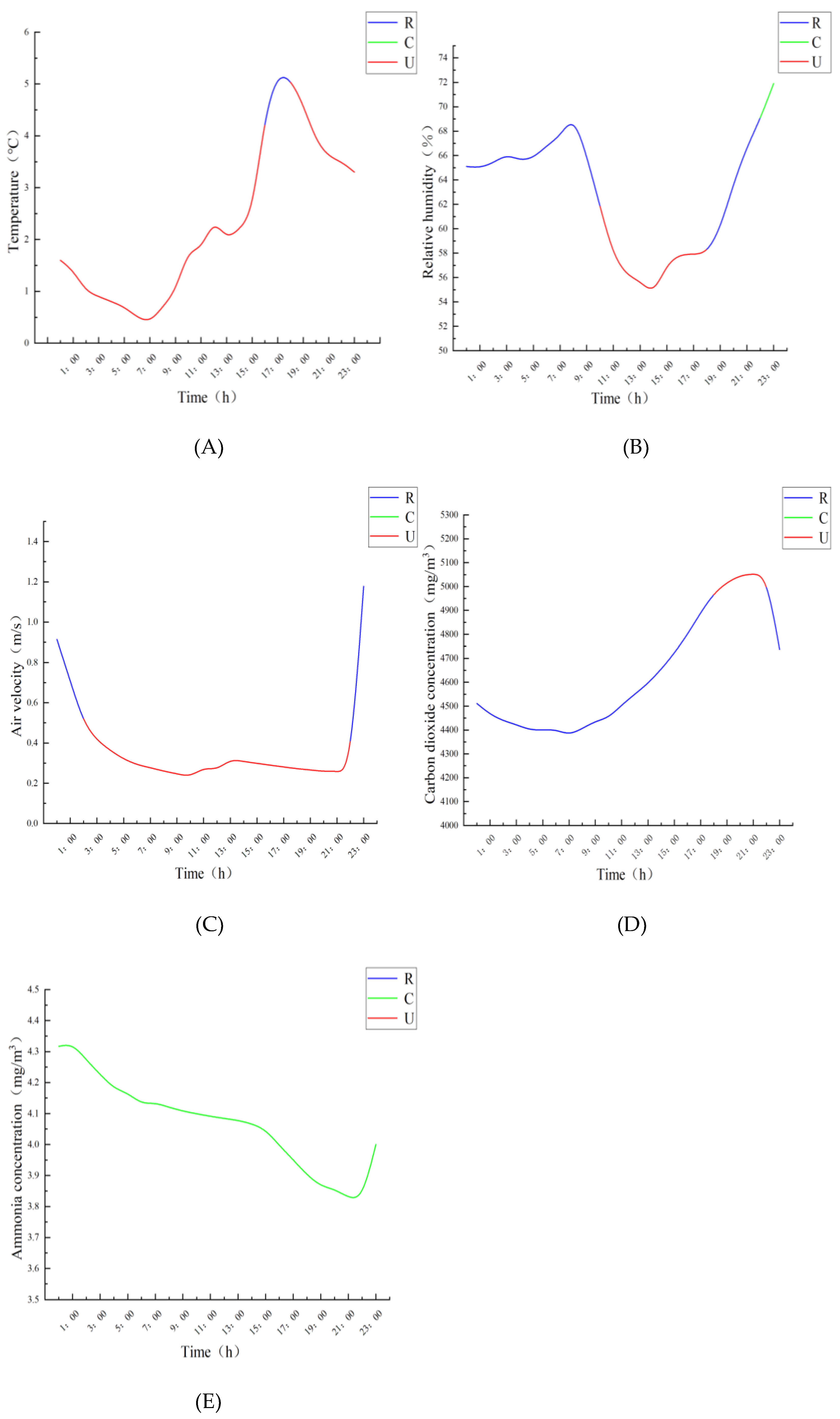

3.3.1. Analysis of Diurnal Variation in Environmental Comfort Evaluation Indicators

3.3.2. Single-Factor Environmental Indicator Trends

4. Conclusions

- (1)

- Comprehensive Weighting Evaluation: By employing the AHP-EWM comprehensive evaluation, the combined weights of the environmental factors were determined as {0.4777, 0.2293, 0.1533, 0.0862, 0.0535}.

- (2)

- Comfort Index Visualization: Normalized scoring of the combined weights enabled the derivation of environmental comfort metrics. Using radar chart visualization, the comfort indices were quantified as 2.236 (comfort zone) and 8.934 (relatively comfortable zone), providing intuitive spatial–temporal representations of the environmental conditions.

- (3)

- Multi-Factor Sensitivity Analysis: Comparative analysis revealed that the multi-factor comfort index exhibited higher sensitivity to environmental dynamics than the single-factor evaluations, offering a more comprehensive and accurate assessment of pigsty conditions. Under extreme climatic scenarios, the model identified periods of suboptimal environmental quality, necessitating targeted adjustments to ventilation and thermal regulation strategies to mitigate adverse impacts on swine productivity and economic returns.

- (4)

- Weight assignments must undergo region-specific calibration based on the local climatic conditions and geographical contexts to ensure practical relevance. Consequently, adaptive recalibration and optimization of weights are imperative during implementation. Furthermore, sensor configurations and environmental monitoring protocols should be tailored to specific operational requirements across diverse farming practices and pigsty architectures, thereby enhancing the scientific validity and reliability of evaluations. Transient environmental dynamics, such as abrupt fluctuations in temperature and relative humidity during the activation of evaporative cooling systems, significantly impact indoor comfort levels. Future research should prioritize the integration of advanced computational technologies (e.g., IoT-enabled real-time monitoring platforms) and automated control systems to achieve dynamic environmental management. This integration will improve the temporal resolution and sensitivity of evaluation frameworks, addressing critical gaps in transient response capabilities—a key focus for next-generation precision livestock farming innovations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peng, H. Current Status and Development Trends of Modern Pig Farming. Today Anim. Husb. Vet. 2020, 36, 73–106. [Google Scholar]

- Tu, K.K. Analysis of Influencing Factors and Research on Simulation Countermeasures of Pig Cycle in China. Master’s Thesis, Nanchang University, Nanchang, China, 2023. [Google Scholar]

- Yeo, U.H.; Lee, S.Y.; Park, S.J.; Kim, J.-G.; Jetong, D.-Y.; Decano-Valentin, C.S.; Kim, R.-W.; Lee, I.-B. Determination of the optimal location and the number of sensors for efficient heating, ventilation, and air conditioning system operation in a mechanically ventilated pig house. Biosyst. Eng. 2023, 229, 1–17. [Google Scholar] [CrossRef]

- Shin, H.; Lee, S.; Kim, J.; Park, D.-H.; Jo, S.-K.; Kwak, Y. Applicability evaluation of a temperature humidity index-controlled ventilation system in livestock using a building energy simulation model. Case Stud. Therm. Eng. 2024, 5735, 104335. [Google Scholar] [CrossRef]

- Zang, J.; Ye, S.; Xu, Z.; Wang, J.; Liu, W.; Bai, Y.; Yong, C.; Zou, X.; Zhang, W. Prediction model of carbon dioxide concentration in pig house based on deep learning. Atmosphere 2022, 13, 1130. [Google Scholar] [CrossRef]

- Chi, Y.; Guo, Y.J.; Feng, H.; Feng, H.; Li, H.; Zheng, Y. Environmental quality evaluation method for swine gestation barns based on multi-source information fusion. Trans. Chin. Soc. Agric. Eng. 2022, 38, 212–221. [Google Scholar]

- Choi, H.L.; Han, S.H.; Albright, L.D.; Chang, W.K. The correlation between thermal and noxious gas environments, pig productivity and behavioral responses of growing pigs. Int. J. Environ. Res. Public Health 2011, 8, 3514–3527. [Google Scholar] [CrossRef]

- Arango, T.; Besteiro, R.; Ortega, J.A.; Castro, Á.; Rodríguez, M.R.; Fernández, M.D. Linear models for the prediction of animal zone ammonia in a weaned piglet building. Agronomy 2021, 11, 1927. [Google Scholar] [CrossRef]

- Witt, J.; Krieter, J.; Schröder, K.; Büttner, K.; Hölzel, C.; Krugmann, K.; Czycholl, I. Comparison of three different measuring devices of ammonia and evaluation of their suitability to assess animal welfare in pigs. Livest. Sci. 2024, 279, 105372. [Google Scholar] [CrossRef]

- Yu, P.; Zhu, W.H. Analysis of Site Selection and Planning Layout for Large-Scale Pig Farms. Today Anim. Husb. Vet. 2022, 38, 61–64. [Google Scholar]

- Anthony, T.R.; Yang, A.Y.; Peters, T.M. Assessment of interventions to improve air quality in a livestock building. J. Agric. Saf. Health 2017, 23, 247–263. [Google Scholar] [CrossRef]

- Zhu, J.M.; Sun, B.; Pu, S.H.; Pan, X.; Xu, S.; Hu, B.; Qi, R. Prediction model of temperature and humidity in pig barn based on multi-environmental factors analysis. J. South China Agric. Univ. 2024, 45, 709–721. [Google Scholar]

- Shin, H.; Kwak, Y.; Jo, S.K.; Kim, S.-H.; Huh, J.-H. Applicability evaluation of a demand-controlled ventilation system in livestock. Comput. Electron. Agric. 2022, 196, 106907. [Google Scholar] [CrossRef] [PubMed]

- Buoio, E.; Cialini, C.; Costa, A. Air Quality Assessment in Pig Farming: The Italian Classyfarm. Animals 2023, 13, 2297. [Google Scholar] [CrossRef]

- Chen, C.; Liu, X.Q.; Liu, C.J.; Chang, R.M. Optimization of Evaluation and Prediction Model of Environmental Comfort in Lactating Sow House. Trans. Chin. Soc. Agric. Mach. 2020, 51, 311–319. [Google Scholar]

- Ruckli, A.K.; Hörtenhuber, S.J.; Ferrari, P.; Guy, J.; Helmerichs, J.; Hoste, R.; Hubbard, C.; Kasperczyk, N.; Leeb, C.; Malak-Rawlikowska, A.; et al. Integrative sustainability analysis of European pig farms: Development of a multi-criteria assessment tool. Sustainability 2022, 14, 5988. [Google Scholar] [CrossRef]

- Zapf, R.; Schultheiß, U.; Schubbert, A.; Daniel, G.; Kornel, C.; Solveig, M.; Jan, B.; Ute, K. Evaluation of animal welfare in on-farm self-assessments–development of a reference framework with target and alarm values based on a Delphi survey. Landtechnik 2023, 78, 125–138. [Google Scholar]

- Chen, C.; Liu, X.; Duan, W.; Liu, C. Assessment of the environmental comfort of lactating sows via improved analytic hierarchy process and fuzzy comprehensive evaluation. Int. J. Agric. Biol. Eng. 2022, 15, 58–67. [Google Scholar] [CrossRef]

- Zhou, Z.J. Risk Assessment of Harmless Treatment Projects for Dead Livestock and Poultry Based on the Analytic Hierarchy Process (AHP) Method. Master’s Thesis, Beijing University of Technology, Beijing, China, 2020. [Google Scholar]

- Putra, D.W.T.; Punggara, A.A. Comparison analysis of simple additive weighting (SAW) and weigthed product (WP) in decision support systems. MATEC Web Conf. EDP Sci. 2018, 215, 01003. [Google Scholar] [CrossRef]

- Zhu, Y.; Tian, D.; Yan, F. Effectiveness of entropy weight method in decision-making. Math. Probl. Eng. 2020, 2020, 3564835. [Google Scholar] [CrossRef]

- Li, Z.; Luo, Z.; Wang, Y.; Fan, G.; Zhang, J. Suitability evaluation system for the shallow geothermal energy implementation in region by Entropy Weight Method and TOPSIS method. Renew. Energ. 2022, 184, 564–576. [Google Scholar] [CrossRef]

- Qi, J.; Zhang, Y.; Zhang, J.; Chen, Y.; Wu, C.; Duan, C.; Cheng, Z.; Pan, Z. Research on the evaluation of geological environment carrying capacity based on the AHP-CRITIC empowerment method. Land 2022, 11, 1196. [Google Scholar] [CrossRef]

- Jin, C.; Shu, Y.; Han, Z.; Chen, Q.; He, J.; Wang, S. Lightning disaster risk zoning in Jiangsu province of China based on the analytic hierarchy process and entropy weight method. Front. Environ. Sci. 2022, 10, 943000. [Google Scholar] [CrossRef]

- Xie, J.; Liu, B.; He, L.; Zhong, W.; Zhao, H.; Yang, X.; Mai, T. Quantitative evaluation of the adaptability of the shield machine based on the analytic hierarchy process (AHP) and fuzzy analytic hierarchy process (FAHP). Adv. Civ. Eng. 2022, 2022, 3268150. [Google Scholar] [CrossRef]

- Chen, Z. Port logistics function evaluation model based on entropy weight TOPSIS method. Discret. Dyn. Nat. Soc. 2022, 2022, 5006900. [Google Scholar] [CrossRef]

- Panchal, S.; Shrivastava, A.K. Landslide hazard assessment using analytic hierarchy process (AHP): A case study of National Highway 5 in India. Ain Shams Eng. J. 2022, 13, 101626. [Google Scholar] [CrossRef]

- Bi, K.; Xu, Q.; Ji, Z.Q.; Zhao, X.W.; Lu, Z.H. Construction and empirical analysis of DNA storage scheme evaluation model based on analytic hierarchy process. Chin. J. Bioinform. 2024, 3–24. [Google Scholar]

- Saaty, T.L. Modeling unstructured decision problems—The theory of analytical hierarchies. Math. Comput. Simulat. 1978, 20, 147–158. [Google Scholar] [CrossRef]

- Yin, P.; Cheng, J.; Peng, M. Analyzing the passenger flow of urban rail transit stations by using entropy weight-grey correlation model: A case study of Shanghai in China. Mathematics 2022, 10, 3506. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, X.; Guo, Y. Comprehensive Evaluation of the Implementation Effect of Commercial Street Quality Improvement Based on AHP-Entropy Weight Method—Taking Hefei Shuanggang Old Street as an Example. Land 2022, 11, 2091. [Google Scholar] [CrossRef]

- Wen, Z. Evaluation of Heterogeneity in Tectonically Deformed Coal Reservoirs Based on the Analytic Hierarchy Process-Entropy Weight Method Coupling Model: A Case Study. ACS Omega 2023, 8, 36700–36709. [Google Scholar] [CrossRef]

- Shi, D.; Guo, Y.; Gu, X.; Feng, G.; Xu, Y.; Sun, S. Evaluation of the ventilation system in an LNG cargo tank construction platform (CTCP) by the AHP-entropy weight method. In Building Simulation; Tsinghua University Press: Beijing, China, 2022; pp. 1–18. [Google Scholar]

- Deng, Q.Q. Comprehensive Evaluation of Ecological Environment Quality in Chongqing Based on Entropy Method and AHP. Master’s Thesis, Southwest University, Chongqing, China, 2022. [Google Scholar]

- Mun, H.S.; Dilawar, M.A.; Gil Jeong, M.; Rathnayake, D.; Won, J.S.; Park, K.W.; Lee, S.R.; Ryu, S.B.; Yang, C.J. Effect of a Heating system using a ground source geothermal heat pump on production performance, energy-saving and housing environment of pigs. Animals 2020, 10, 2075. [Google Scholar] [CrossRef] [PubMed]

- Huynh, T.T.T.; Aarnink, A.J.A.; Verstegen, M.W.A.; Gerrits, W.J.; Heetkamp, M.J.; Kemp, B.; Canh, T.T. Effects of increasing temperatures on physiological changes in pigs at different relative humidities. J. Anim. Sci. 2005, 83, 1385–1396. [Google Scholar] [CrossRef]

- Tang, S.; Yin, C.; Xie, J.; Jiao, J.; Chen, L.; Liu, L.; Zhang, S.; Zhang, H. Aerial ammonia exposure induces the perturbation of the interorgan ammonia disposal and branched-chain amino acid catabolism in growing pigs. Anim. Nutr. 2021, 7, 947–958. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, A.; Chen, Y.; Bao, J.; Xing, H. Intestinal barrier dysfunction induced by ammonia exposure in pigs in vivo and in vitro: The protective role of L-selenomethionine. Ecotoxicol. Environ. Safe 2022, 248, 114325. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Yang, Q.; Tao, Y.; Shi, L.; Tu, J.; Wang, Y. A review of ventilation and cooling systems for large-scale pig farms. Sustain. Cities Soc. 2023, 89, 104372. [Google Scholar] [CrossRef]

- Wen, P.; Li, L.; Xue, H.; Jia, Y.; Gao, L.; Li, R.; Huo, L. Comprehensive evaluation method of the poultry house indoor environment based on gray relation analysis and analytic hierarchy process. Poult. Sci. 2022, 101, 101587. [Google Scholar] [CrossRef]

- Chen, C.; Shen, C.; Duan, W. Air quality monitoring of sow houses with the fuzzy comprehensive evaluation method. Agron. J. 2023, 115, 2694–2707. [Google Scholar] [CrossRef]

- Liang, S.T.; Hong, H. Fuzzy Comprehensive Evaluation on Surface Water Quality. Site Investig. Sci. Technol. 2019, 5, 49–53. [Google Scholar]

- Dong, H.; Zhang, G.; Yan, M.; Tian, Y. Soil environmental quality in Nanling commodity grain base based on equal intercept transformation radar chart. Sci. Rep. 2021, 11, 10460. [Google Scholar] [CrossRef]

- Yang, R.X. Application of Radar Chart Method to the Karst Tunnel in Complex Geology. Mod. Tunn. Technol. 2020, 57, 125–129. [Google Scholar]

- Peng, W. Improved radar chart for lighting system scheme selection. Appl. Opt. 2022, 61, 5619–5625. [Google Scholar] [CrossRef] [PubMed]

- Xie, Q.; Ni, J.Q.; Su, Z. Fuzzy comprehensive evaluation of multiple environmental factors for swine building assessment and control. J. Hazard. Mater 2017, 340, 463–471. [Google Scholar] [CrossRef] [PubMed]

- Xie, Q.; Li, J.L.; Cao, S.L.; Guo, Y.H.; Liu, H.G.; Zheng, P.; Liu, W.Y.; Yu, H.M. Comprehensive Evaluation Method of Pig House Environment Based on Time Series Sequences. Trans. Chin. Soc. Agric. Mach. 2024, 55, 430–440. [Google Scholar]

| Location | Composition |

|---|---|

| Roof | 40 mm × 60 mm × 4 mm square steel frame + 100 mm polystyrene board + 1 mm color steel plate |

| Ceiling | 30 mm × 30 mm × 2 mm L-shaped angle steel frame + 50 mm polystyrene board + 1 mm double-layer color steel plate |

| Exterior wall | External 100 mm polystyrene board + internal 240 mm brick concrete wall |

| Ground | 150 mm thick concrete, compacted |

| Door | 1.8 m wide, 2.0 m high inward-opening double wooden door, with cotton thermal insulation curtain |

| Window | Plastic steel frame, double glazing |

| Name | Range | Resolution | Precision |

|---|---|---|---|

| Ambient temperature sensor | −40 °C~+80 °C | 0.1 °C | ±0.4 °C |

| Ambient humidity sensor | 0~100% RH | 0.1% | ±3% RH |

| NH3 sensor | 0~100 ppm | 1 ppm | ±8% |

| CO2 sensor | 0~10,000 ppm | 1 ppm | ±(45 ppm + 5% F·S) |

| Air velocity sensor | 0~60 m/s | 0.01 m/s | ±(0.2 m/s ± 0.02·v) (v is the air velocity) |

| Scale | Meaning |

|---|---|

| 1 | Indicates that the importance of the two indicators is the same |

| 3 | Indicates that one indicator is slightly more important than the other |

| 5 | Indicates that one indicator is significantly more important than the other |

| 7 | Indicates that one indicator is strongly more important than the other |

| 9 | Indicates that one indicator is extremely more important than the other |

| 2, 4, 6, 8 | The medians of the adjacent judgments mentioned above |

| The reciprocal of the scale. | If Indicator i is compared to Indicator j and the result is aij, then, when comparing Indicator j to Indicator i, the result is 1/aij |

| Environmental Factors | Temperature | Relative Humidity | Air Velocity | CO2 Concentration | NH3 Concentration |

|---|---|---|---|---|---|

| Temperature | 1 | 4 | 2 | 5 | 5 |

| Relative Humidity | 1/4 | 1 | 2 | 2 | 3 |

| Air Velocity | 1/2 | 1/2 | 1 | 3 | 3 |

| CO2 Concentration | 1/5 | 1/2 | 1/3 | 1 | 2 |

| NH3 Concentration | 1/5 | 1/3 | 1/3 | 1/2 | 1 |

| Comment Set | Factor Set | ||||

|---|---|---|---|---|---|

| Temperature (℃) | Relative Humidity (%) | Air Velocity (m/s) | CO2 Concentration (mg/m3) | NH3 Concentration (mg/m3) | |

| C | 18~25 | 60~70 | 0.5~1.5 | <1500 | <15 |

| R | 5~18 or 25~30 | 40~60 or 60~80 | 0.2~0.5 or 1.5~2.5 | 1500~4000 | 15~25 |

| U | >30 or <5 | >70 or <60 | >2.5 or <0.2 | >4000 | >25 |

| Sampling Time | Temperature Status | Relative Humidity Status | Air Velocity Status | CO2 Concentration Status | NH3 Concentration Status | Comprehensive Status |

|---|---|---|---|---|---|---|

| 0:00 | U | C | C | R | C | R |

| 1:00 | U | R | C | R | C | R |

| 2:00 | U | C | R | R | C | R |

| 3:00 | U | C | R | R | C | R |

| 4:00 | U | C | R | R | C | R |

| 5:00 | U | C | R | R | C | R |

| 6:00 | U | C | R | R | C | R |

| 7:00 | U | C | R | R | C | R |

| 8:00 | U | C | R | R | C | R |

| 9:00 | U | C | R | R | C | R |

| 10:00 | R | R | U | R | C | R |

| 11:00 | R | R | R | R | C | R |

| 12:00 | C | R | U | R | C | R |

| 13:00 | R | R | R | R | C | R |

| 14:00 | R | R | R | R | C | R |

| 15:00 | C | R | R | R | C | R |

| 16:00 | C | R | R | R | C | R |

| 17:00 | C | R | R | R | C | R |

| 18:00 | C | R | R | R | C | C |

| 19:00 | C | R | U | U | C | C |

| 20:00 | C | C | U | U | C | R |

| 21:00 | C | C | U | U | C | R |

| 22:00 | C | C | U | U | C | R |

| 23:00 | C | C | C | R | C | R |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Li, T.; Jing, T.; Wang, Z.; Zhong, T.; Zhou, L.; Jiang, H. Evaluation of Environmental Quality in Northern Winter Fattening Pig Houses Based on AHP-EWM. Agriculture 2025, 15, 584. https://doi.org/10.3390/agriculture15060584

Li J, Li T, Jing T, Wang Z, Zhong T, Zhou L, Jiang H. Evaluation of Environmental Quality in Northern Winter Fattening Pig Houses Based on AHP-EWM. Agriculture. 2025; 15(6):584. https://doi.org/10.3390/agriculture15060584

Chicago/Turabian StyleLi, Jinsheng, Tianhao Li, Tingting Jing, Zhi Wang, Tianhao Zhong, Lina Zhou, and Hailong Jiang. 2025. "Evaluation of Environmental Quality in Northern Winter Fattening Pig Houses Based on AHP-EWM" Agriculture 15, no. 6: 584. https://doi.org/10.3390/agriculture15060584

APA StyleLi, J., Li, T., Jing, T., Wang, Z., Zhong, T., Zhou, L., & Jiang, H. (2025). Evaluation of Environmental Quality in Northern Winter Fattening Pig Houses Based on AHP-EWM. Agriculture, 15(6), 584. https://doi.org/10.3390/agriculture15060584