Seed Potato Quality Assurance in Ethiopia: System Analysis and Considerations on Quality Declared Assurance Practices

Abstract

1. Introduction

- (1)

- What type of seed quality assurance mechanisms (informal, quality declared, certified) are under implementation in Ethiopia?

- (2)

- How does the current seed quality assurance system operate in terms of reliability, accessibility, and quality standards to deliver quality seed potato?

2. Methods

2.1. Description of Seed Regulatory Laboratories

2.2. Data Collection

2.3. Literature Review

2.4. Seed Regulatory Laboratory Managers and Technician Interviews

2.5. Analytical Framework

3. Results

3.1. Seed Quality Assurance Practices in Ethiopia

3.2. Human Resource Capacity and Gender Disaggregation

3.3. Physical Infrastructure, Logistics, and Seed Testing Facilities

3.4. Challenges for Effective Seed Quality Assurance in Ethiopia

4. Discussion

4.1. Seed Quality Assurance Mechanisms in Ethiopia

4.2. Seed Quality Assurance Standards in Ethiopia

4.3. Implications for Integrated Seed Sector Development

- Focus on developing high-yield, disease-resistant seed varieties that are well suited to local conditions.

- Maintaining updated, accessible, and specialized catalogues for crop varieties and agricultural inputs is crucial. This enables inspectors to easily verify the authenticity and quality of seeds during inspections.

- Seed inspectors, regulatory agencies, and other stakeholders should receive regular training on the latest quality assurance practices, seed health, and pest management techniques to ensure informed decision-making.

- Improve extension services to effectively disseminate knowledge about quality assurance, seed management, and innovative practices to farmers.

- Ensure that policies facilitate seed access, distribution, and regulation while also safeguarding farmers’ rights.

- Foster collaboration between the government, private sector, the industry, and NGOs to drive investment and innovation in potato seed systems.

- Establishing a national institutional framework or model to integrate these components into a cohesive system.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- NAIP (National Agricultural Investment Plan). National Agricultural Investment Plan 2021–2030; Federal Democratic Republic of Ethiopia, Ministry of Agriculture: Addis Ababa, Ethiopia, 2022; 105p, Available online: https://citizenengagement.nepad.org/pdf/20231005145754.pdf (accessed on 20 March 2024).

- Mellor, J.W.; Dorosh, P. Agriculture and the Economic Transformation of Ethiopia. Ethiop. Strategy Support Program 2 Work. Pap. 2010, 10, 45. [Google Scholar]

- Worldometer. 2024. Available online: https://www.worldometers.info/world-population/ethiopia-population/ (accessed on 3 January 2024).

- Seid, E.; Tessema, L. Evaluation of tuber quality, yield and yield related traits of potato (Solanum tuberosum L.) genotypes at Holetta, Central Ethiopia. CABI Agric. Biosci. 2024, 5, 99. [Google Scholar] [CrossRef]

- ESS (Ethiopian Statistics Service). Report on area, production and farm management. practice of Belg season crops for private peasant holdings. In Agricultural Sample Survey, Statistical Bulletin, 578; ESS (Ethiopian Statistics Service): Addis Ababa, Ethiopia, 2022; p. 146. [Google Scholar]

- Setegn, G.; Kakuhenzire, R.; Solomon, R.; Chindi, A.; Lemlem, T.M.; Haileab, K.; Wudneh, G. Analysis for Developing a Sustainable Seed Potato Value Chain in Oromia. Region, Ethiopia; Working Paper; International Potato Center (CIP): Lima, Peru, 2024; 90p. [Google Scholar] [CrossRef]

- Tessema, L.; Negash, W.; Kakuhenzire, R.; Alemu, G.B.; Hussen, E.S.; Fentie, M.E. Seed health trade-offs in adopting quality declared seed in potato farming systems. Crop Sci. 2023, 64, 1340–1348. [Google Scholar] [CrossRef]

- Diriba, G. Agricultural and Rural Transformation in Ethiopia: Obstacles, Triggers and Reform Considerations; Policy Working Paper 01/2020; Ethiopian Economics Association (EEA): Addis Ababa, Ethiopia, 2020; Available online: https://www.ajol.info/index.php/eje/article/view/207582 (accessed on 2 January 2023).

- Yigezu, W.G. The challenges and prospects of Ethiopian agriculture. Cogent Food Agric. 2021, 7, 1923619. [Google Scholar] [CrossRef]

- Hirpa, A.; Meuwissen, M.P.; Tesfaye, A.; Lommen, W.J.; Oude Lansink, A.; Tsegaye, A.; Struik, P.C. Analysis of seed potato systems in Ethiopia. Am. J. Potato Res. 2010, 87, 537–552. [Google Scholar] [CrossRef]

- Hirpa, A.; Meuwissen, M.P.M.; Lommen, W.J.M.; Lansink, A.O.; Tsegaye, A.; Struik, P.C. Improving seed potato quality in Ethiopia: A value chain perspective. In Quality and Innovation in Food Chains; Wageningen Academic: Wageningen, The Netherlands, 2016; pp. 101–118. [Google Scholar] [CrossRef]

- Etherton, B.A.; Sula, A.I.P.; Mouafo-Tchinda, R.A.; Kakuhenzire, R.; Kassaye, H.A.; Asfaw, F.; Kosmakos, V.S.; McCoy, R.W.; Xing, Y.; Yao, J.; et al. Translating Ethiopian potato seed networks: Identifying strategic intervention points for managing bacterial wilt and other diseases. Agric. Syst. 2025, 222, 104167. [Google Scholar] [CrossRef]

- Tarekegn, K.; Mogiso, M. Assessment of improved crop seed utilization status in selected districts of Southwestern Ethiopia. Cogent Food Agric. 2020, 6, 1816252. [Google Scholar] [CrossRef]

- Demo, P.; Lemaga, B.; Kakuhenzire, R.; Schulz, S.; Borus, D.; Barker, I.; Woldegiorgis, G.; Parker, M.L.; Schulte-Geldermann, E. Strategies to improve seed potato quality and supply in Sub-Saharan Africa: Experience from interventions in five countries. In Potato and Sweet Potato in Africa: Transforming the Value Chains for Food and Nutrition Security; CABI: Oxford, UK, 2015; pp. 155–167. [Google Scholar] [CrossRef]

- Tadesse, Y.; Almekinders, C.J.M.; Schulte, R.P.O.; Struik, P.C. Potatoes and livelihoods in Chencha, southern Ethiopia. NJAS-Wagening. J. Life Sci. 2019, 88, 105–111. [Google Scholar] [CrossRef]

- Wubet, G.K.; Zemedu, L.; Tegegne, B. Value chain analysis of potato in Farta District of south Gondar zone, Amhara national state of Ethiopia. Heliyon 2022, 8, e09142. [Google Scholar] [CrossRef] [PubMed]

- Haug, R.; Hella, J.P.; Mulesa, T.H.; Kakwera, M.N.; Westengen, O.T. Seed systems development to navigate multiple expectations in Ethiopia, Malawi and Tanzania. World Dev. Sustain. 2023, 3, 100092. [Google Scholar] [CrossRef]

- Mulesa, T.H.; Dalle, S.P.; Makate, C.; Haug, R.; Westengen, O.T. Pluralistic seed system development: A path to seed security? Agronomy 2021, 11, 372. [Google Scholar] [CrossRef]

- Schulz, S.; Woldegiorgis, G.; Hailariam, G.; Abdurahman, A.; van de Haar, J.; Shiferaw, W. Sustainable seed potato production in Ethiopia: From farm-saved to quality declared seed. In Proceedings of the National Workshop on Seed Potato Tuber Production and Dissemination: Experiences, Challenges and Prospects, Bahir Dar, Ethiopia, 12–14 March 2012; Woldegiorgis, G., Schulz, S., Berihun, B., Eds.; Ethiopian Institute of Agricultural Research and Amhara Regional Agricultural Research Institute: Addis Ababa, Ethiopia, 2013; pp. 60–71. Available online: https://hdl.handle.net/10568/57048 (accessed on 25 June 2023).

- Kansiime, M.K.; Bundi, M.; Nicodemus, J.; Marandu, D.; Njau, S.S.; Kessy, R.F.; Williams, F.; Karanja, D.; Tambo, J.A.; Romney, D. Assessing sustainability factors of farmer seed production: A case of the Good Seed Initiative project in Tanzania. Agric. Food Secur. 2021, 10, 15. [Google Scholar] [CrossRef]

- Nigussie, M.; Kalsa, K.; Ayana, A.; Alemu, D.; Hassena, M.; Zeray, T.; Adam, A.; Mengistu, A. Status of Seed Quality Control and Assurance in Ethiopia: Required Measures for Improved Performance; Technical Report; Ethiopian Institute of Agricultural Research: Addis Ababa, Ethiopia, 2020. [Google Scholar] [CrossRef]

- Alemu, D.; Bishaw, Z.; Zeray, T.; Ayana, A.; Hassena, M.; Sisay, D.T.; Kalsa, K.K. National Seed Sector Coordination in Ethiopia: Status, Challenges, and Way Forward. 2023. Available online: https://www.researchgate.net/publication/377395995 (accessed on 15 April 2024).

- Getnet, M.; Teshome, A.; Snel, H.; Alemu, D. Potato seed System in Ethiopia: Challenges, Opportunities, and Leverage Points; SWRE-RAISE-FS-23-025; Stichting Wageningen Research Ethiopia: Addis Ababa, Ethiopia, 2023. [Google Scholar]

- Etherton, B.A.; Choudhury, R.A.; Alcala Briseno, R.I.; Mouafo-Tchinda, R.A.; Plex Sula, A.I.; Choudhury, M.; Adhikari, A.; Lei, S.L.; Kraisitudomsook, N.; Buritica, J.R.; et al. Disaster plant pathology: Smart solutions for threats to global plant health from natural and human-driven disasters. Phytopathology 2024, 114, 855–868. [Google Scholar] [CrossRef]

- Benson, T.; Spielman, D.; Kassa, L. Direct Seed Marketing Program in Ethiopia in 2013: An Operational Evaluation to Guide Seed-Sector Reform. IFPRI Discuss. Pap. 2014, 1350, 68. Available online: https://www.researchgate.net/publication/272300332 (accessed on 20 January 2024). [CrossRef]

- Wimalasekera, R. Role of Seed Quality in Improving Crop Yields. In Crop Production and Global Environmental Issues; Hakeem, K., Ed.; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Bentley, J.W.; Andrade-Piedra, J.; Demo, P.; Dzomeku, B.; Jacobsen, K.; Kikulwe, E.; Kromann, P.; Kumar, P.L.; McEwan, M.; Mudege, N.; et al. Understanding root, tuber, and banana seed systems and coordination breakdown: A multistakeholder framework. J. Crop Improv. 2018, 32, 599–621. [Google Scholar] [CrossRef]

- Tessema, L.; Kakuhenzire, R.; McEwan, M. Latent Bacterial Wilt and Viral Infection Burden in the Seed Potato System in Ethiopia: Policy Implications for Seed Potato. Policy Brief 02. International Potato Centre. 2023. Available online: https://hdl.handle.net/10568/132185 (accessed on 1 April 2024).

- Spielman, D.J.; Gatto, M.; Wossen, T.; McEwan, M.; Abdoulaye, T.; Maredia, M.K.; Hareau, H. Regulatory Options to Improve Seed Systems for Vegetatively Propagated Crops in Developing Countries. IFPRI Discuss. Pap. 2021, 2029, 55. [Google Scholar]

- Tadesse, Y.; Almekinders, C.J.M.; Griffin, D.; Struik, P.C. Collective Production and Marketing of Quality Potato Seed: Experiences from Two Cooperatives in Chencha, Ethiopia. Forum Dev. Stud. 2020, 47, 139–156. [Google Scholar] [CrossRef]

- Tafesse, S.; Lie, R.; van Mierlo, B.; Struik, P.C.; Lemaga, B.; Leeuwis, C. Analysis of a monitoring system for bacterial wilt management by seed potato cooperativs in Ethiopia: Challenges and future direction. Sustainability 2020, 12, 3580. [Google Scholar] [CrossRef]

- Weiss, B.D.; Mays, M.Z.; Martz, W.; Castro, K.M.; DeWalt, D.A.; Pignone, M.P.; Hale, F.A. Quick assessment of literacy in primary care: The newest vital sign. Ann. Fam. Med. 2005, 3, 514–522. [Google Scholar] [CrossRef]

- Maroya, N.; Balogum, M.; Aighewi, B.; Mignouna, D.B.; Kumar, P.L.; Asiedu, R. Transforming yam seed system in West Africa. In Root, Tuber and Banana Food System Innovations; Thiele, G., Friedmann, M., Campos, H., Polar, V., Bentley, J.M., Eds.; Springer: Cham, Switzerland, 2022; pp. 421–452. [Google Scholar] [CrossRef]

- Sulle, E.; Pointer, R.; Kumar, L.; McEwan, M. Inventory of Novel Approaches to Seed Quality Assurance Mechanisms for Vegetatively Propagated Crops (VPCs) in Seven African Countries; International Institute of Tropical Agriculture (IITA); International Potato Center (CIP): Lima, Peru, 2022; 48p. [Google Scholar] [CrossRef]

- ISSD. Effective Seed Quality Assurance: ISSD Africa Synthesis Paper, 2017–2. 20p. Available online: https://www.kit.nl/wp-content/uploads/2018/08/Effective-seed-quality-assurance.pdf (accessed on 23 December 2023).

- Kuhlmann, K.A.; Francis, T.; Thomas, I.; Schreinemachers, P. Laws and regulations enabling and restricting Africa’s vegetable seed sector. Int. J. Agric. Sustain. 2023, 21, 2210005. [Google Scholar] [CrossRef]

- Misra, M.K.; Harries, A.; Dadlani, M. Role of Seed Certification in Quality Assurance. In Seed Science and Technology; Dadlani, M., Yadava, D.K., Eds.; Springer: Singapore, 2023. [Google Scholar] [CrossRef]

- Almekinders CJ, M.; Walsh, S.; Jacobsen, K.S.; Andrade-Piedra, J.L.; McEwan, M.A.; de Haan, S.; Kumar, L.; Staver, C. Why interventions in the seed systems of roots, tubers and bananas crops do not reach their full potential. Food Secur. 2019, 11, 23–42. [Google Scholar] [CrossRef]

- Kuhlmann, K.; Dey, B. Using regulatory flexibility to address market informality in seed systems: A global study. Agronomy 2021, 11, 377. [Google Scholar] [CrossRef]

| Inspection Stage | Yes/No | Reasons |

|---|---|---|

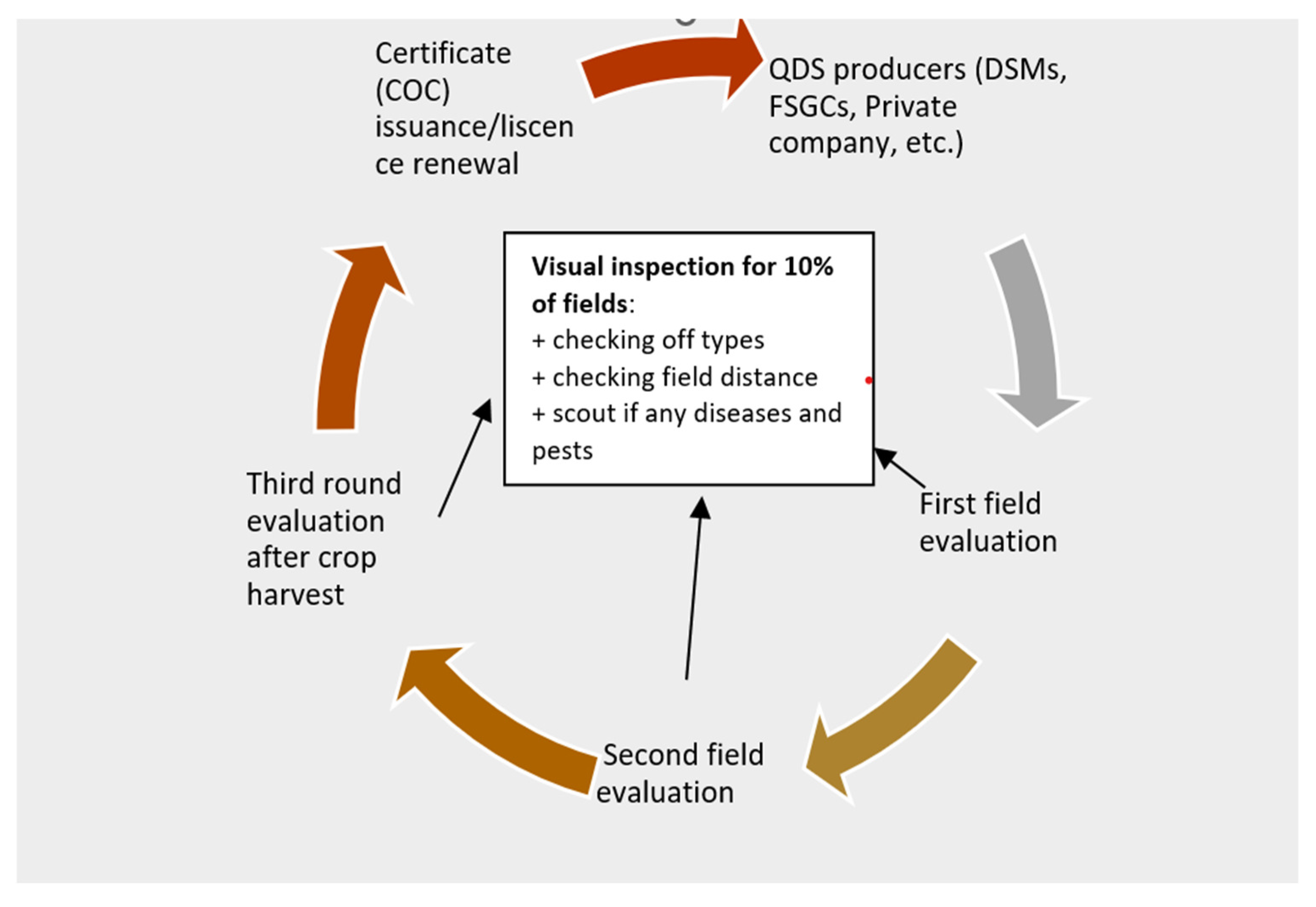

| Early vegetative (30–50 days after planting) | Yes | To check crop emergence status, isolation distance, and varietal purity |

| Flowering (55–70 days) | Yes | To check off types, insect pests, bacterial diseases, viruses, etc. |

| Postharvest (in store) | Yes | To assess seed quality, disease presence, mechanical damage, cracking, storage conditions |

| Human Resource | Male | Female | Total | Percent |

|---|---|---|---|---|

| Zonal laboratory managers | 5 | 0 | 5 | 3.6 |

| Seed testing managers | 1 | 0 | 1 | 0.7 |

| Seed testing lab technicians | 10 | 7 | 17 | 12.3 |

| Field seed inspectors | 18 | 5 | 23 | 16.7 |

| Certification officers | 0 | 1 | 1 | 0.7 |

| Seed quality controllers | 5 | 2 | 7 | 5.1 |

| Product quality inspectors | 2 | 0 | 2 | 1.4 |

| Plant pathologist (B.Sc.) | 1 | 1 | 2 | 1.4 |

| Human resource managers | 3 | 2 | 5 | 3.6 |

| Estate managers | 2 | 0 | 2 | 1.4 |

| Planning and evaluation | 4 | 0 | 4 | 3.0 |

| Procurement assistants | 8 | 12 | 20 | 14.5 |

| Financial inspection and audit | 1 | 2 | 3 | 2.2 |

| Support staff | 6 | 6 | 12 | 8.7 |

| Records officers | 3 | 2 | 5 | 3.6 |

| ICT assistants | 1 | 0 | 1 | 0.7 |

| Security guards | 10 | 4 | 14 | 10.1 |

| Drivers | 10 | 0 | 10 | 7.3 |

| Secretaries | 1 | 3 | 4 | 3.0 |

| Total | 91 (65.9) | 47 (34.1) | 138 | 100 |

| Equipment | Bonga | Welkite | Durame | Shashemene | Ambo | National |

|---|---|---|---|---|---|---|

| Refrigerators | 1 | 2 | 2 | 1 | 2 | 0 |

| Deep freezers | 0 | 1 | 0 | 1 | 1 | 2 |

| Oven dries | 2 | 2 (1) | 2 | 5 | 1 | 2 |

| Seed counters | 2 (1) | 2 (2) | 2 | 3 (2) | 0 | 0 |

| Microscopes | 2 | 4 (2) | 2 (1) | 1 | 2 (1) | 2 |

| Seed potato graders | 0 | 0 | 0 | 0 | 0 | 0 |

| PCR machines | 0 | 0 | 0 | 0 | 0 | 1 |

| Centrifuge machine | 0 | 1 | 0 | 0 | 0 | 0 |

| Shaker/incubators | 1 | 2 | 0 | 3 | 2 (1) | 0 |

| ELISA plate reader | 0 | 0 | 0 | 0 | 0 | 0 |

| BW-ELISA kits | 0 | 0 | 0 | 0 | 0 | 0 |

| BW & viruses pocket testing kits | 1 | 1 | 1 | 3 | 1 | 0 |

| Magnifying lens | 0 | 0 | 2 | 2 | 0 | 0 |

| Analytical balances | 0 | 2 | 3 | 2 (1) | 1 | 0 |

| Moisture testers | 0 | 1 | 1 | 2 | 1 | 0 |

| Autoclaves | 1 | 1 (1) | 0 | 1 | 1 (1) | 0 |

| Laminar flow hoods | 1 | 1 | 0 | 0 | 1 | 0 |

| Growth chambers | 0 | 2 (2) | 0 | 1 | 0 | 0 |

| Grinding machine | 0 | 2 (1) | 0 | 2 (1) | 0 | 0 |

| Logistics | Bonga | Welkite | Durame | Shashemene | Ambo | National |

|---|---|---|---|---|---|---|

| Own building | Yes | Yes | Yes | Yes | No | No |

| Vehicle (N) | 2 (1) | 3 (2) | 3 (1) | 2 (1) | 2 (1) | 0 |

| Computer | 9 (2) | 15 (5) | 10 | 13 (3) | 14 (2) | 1 |

| Printer | 6 | 6 | 5 (1) | 2 | 6 (2) | 1 |

| Photocopier | 1 | 1 | 1 | 1 | 1 | 1 |

| Scanner | 0 | 0 | 0 | 1 | 2 | 0 |

| LCD projector | 0 | 0 | 0 | 0 | 1 | 0 |

| Element of Seed Quality Assurance | Challenges Observed |

|---|---|

| Organization of the seed regulatory authority |

|

| Rules and standards |

|

| Data collection for seed quality assurance |

|

| Decision-making by zonal seed regulatory bodies |

|

| Enforcement of rules compliance with QDS standards |

|

| Communication across seed regulatory authority |

|

| Resource for seed quality assurance |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tessema, L.; Kakuhenzire, R.; McEwan, M.A. Seed Potato Quality Assurance in Ethiopia: System Analysis and Considerations on Quality Declared Assurance Practices. Agriculture 2025, 15, 517. https://doi.org/10.3390/agriculture15050517

Tessema L, Kakuhenzire R, McEwan MA. Seed Potato Quality Assurance in Ethiopia: System Analysis and Considerations on Quality Declared Assurance Practices. Agriculture. 2025; 15(5):517. https://doi.org/10.3390/agriculture15050517

Chicago/Turabian StyleTessema, Lemma, Rogers Kakuhenzire, and Margaret A. McEwan. 2025. "Seed Potato Quality Assurance in Ethiopia: System Analysis and Considerations on Quality Declared Assurance Practices" Agriculture 15, no. 5: 517. https://doi.org/10.3390/agriculture15050517

APA StyleTessema, L., Kakuhenzire, R., & McEwan, M. A. (2025). Seed Potato Quality Assurance in Ethiopia: System Analysis and Considerations on Quality Declared Assurance Practices. Agriculture, 15(5), 517. https://doi.org/10.3390/agriculture15050517