Dynamic Water and Fertilizer Management Strategy for Greenhouse Tomato Based on Morphological Characteristics

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Site and Plant Material

2.2. Nutrient Solution Composition

2.3. Greenhouse Environmental Monitoring and Plant Growth Measurements

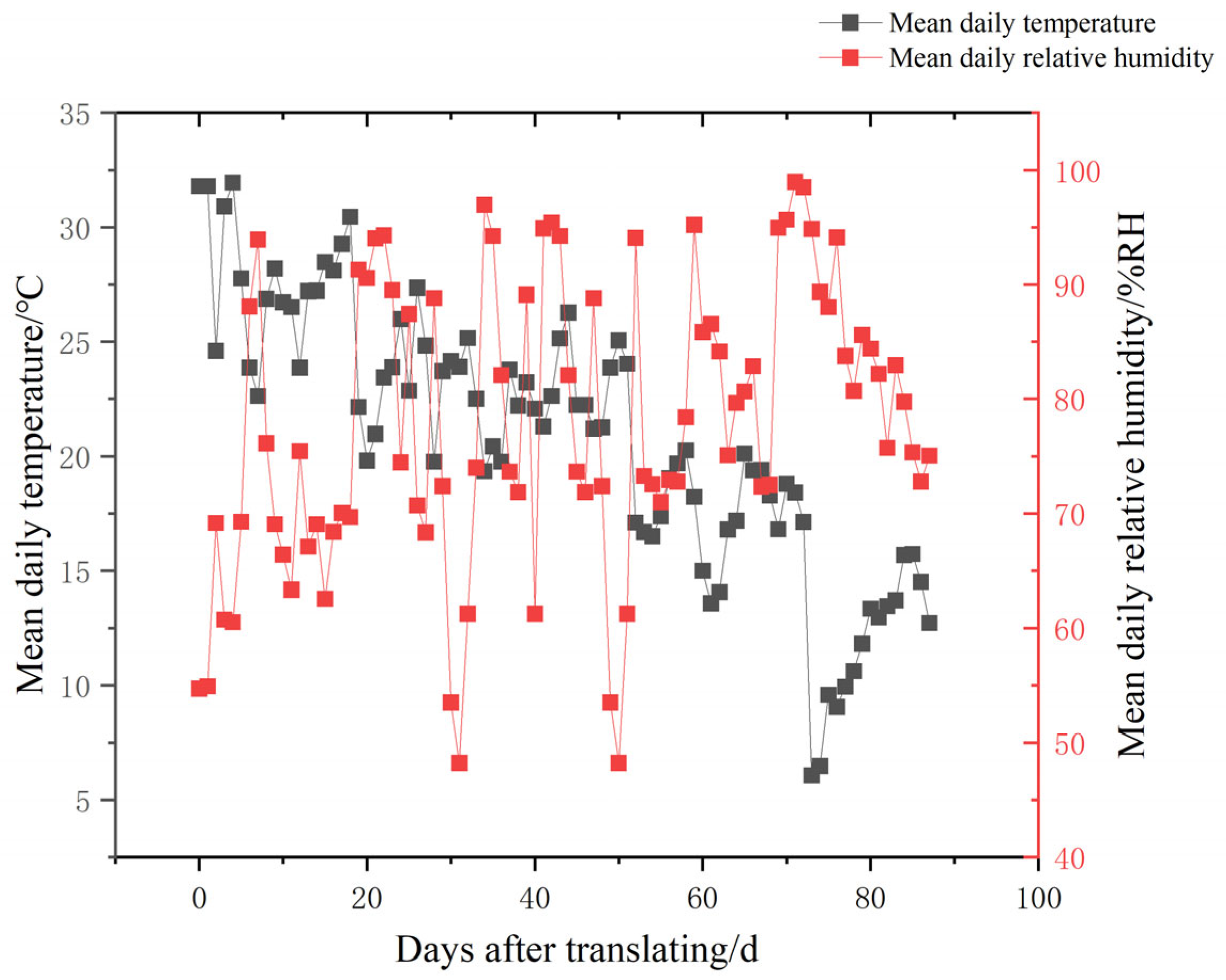

2.3.1. Environmental Data Acquisition

2.3.2. Plant Height and Stem Diameter Measurements

2.3.3. Growth Rate Calculations

2.4. Determination of Reference Irrigation and Fertilization Amounts

2.4.1. Reference Irrigation Evapotranspiration

2.4.2. Reference Irrigation Amount Calculation

2.4.3. Crop Coefficient Adjustment for Potted Tomato Plants

2.4.4. Fertilization Amount Calculation

2.5. Prediction of Plant Height and Stem Diameter

2.5.1. Plant Height Prediction

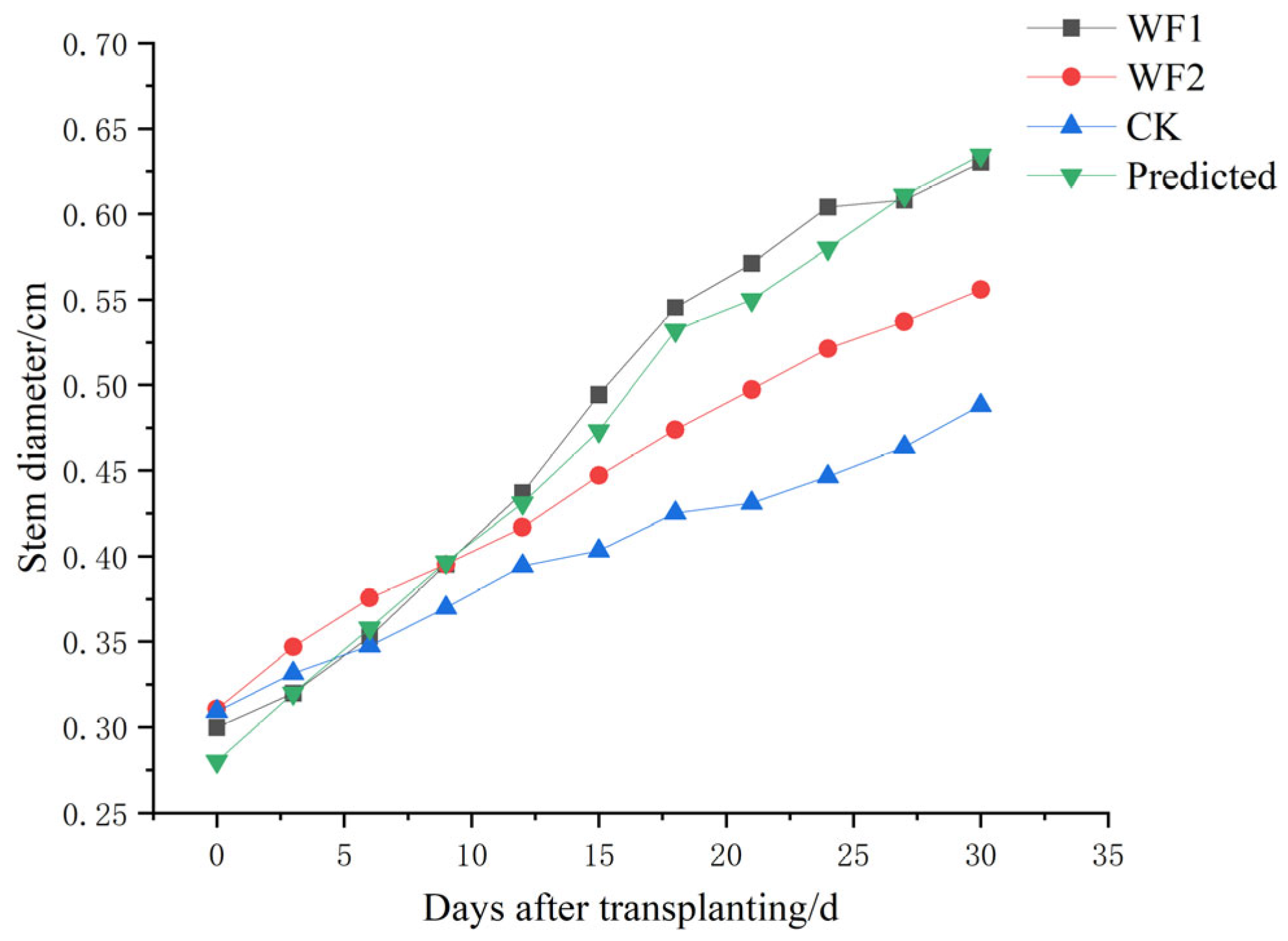

2.5.2. Stem Diameter Prediction

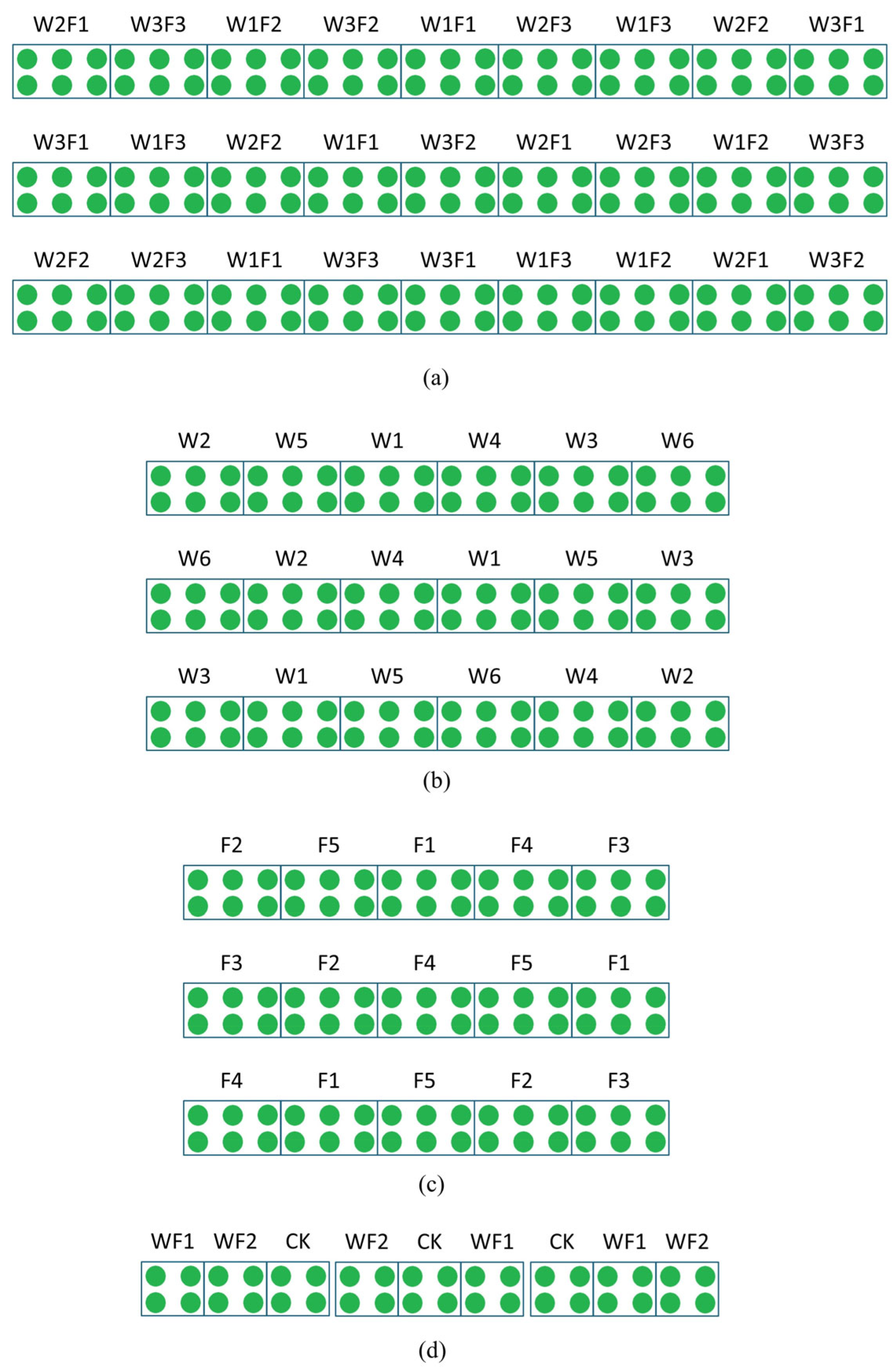

2.6. Experimental Design and Treatments

2.6.1. Transplanting and Crop Management

2.6.2. Water–Fertilizer Interaction Experiment

2.6.3. Irrigation and Fertilization Response Experiment

- Irrigation response

- Fertilization response

2.6.4. Model Validation Experiment

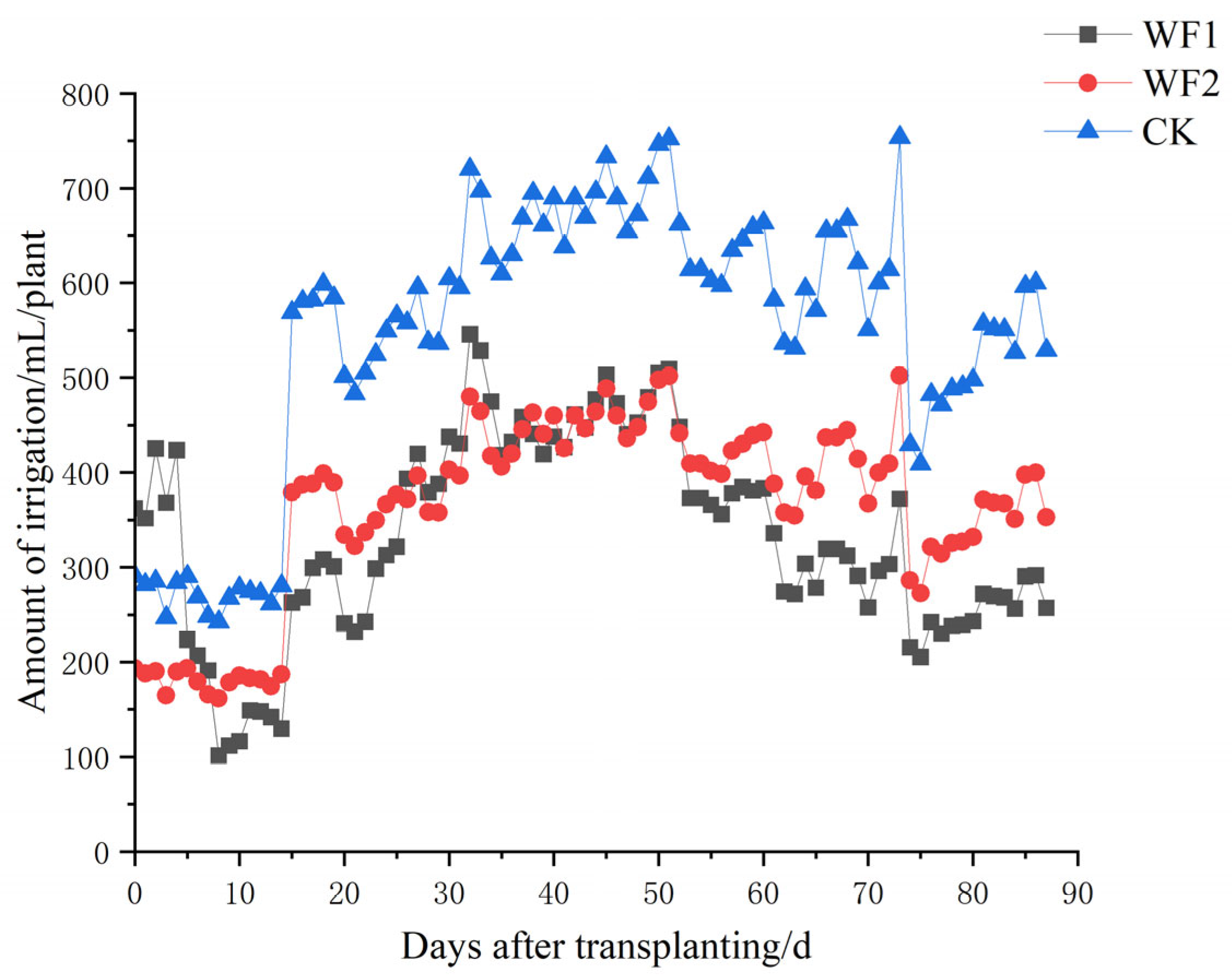

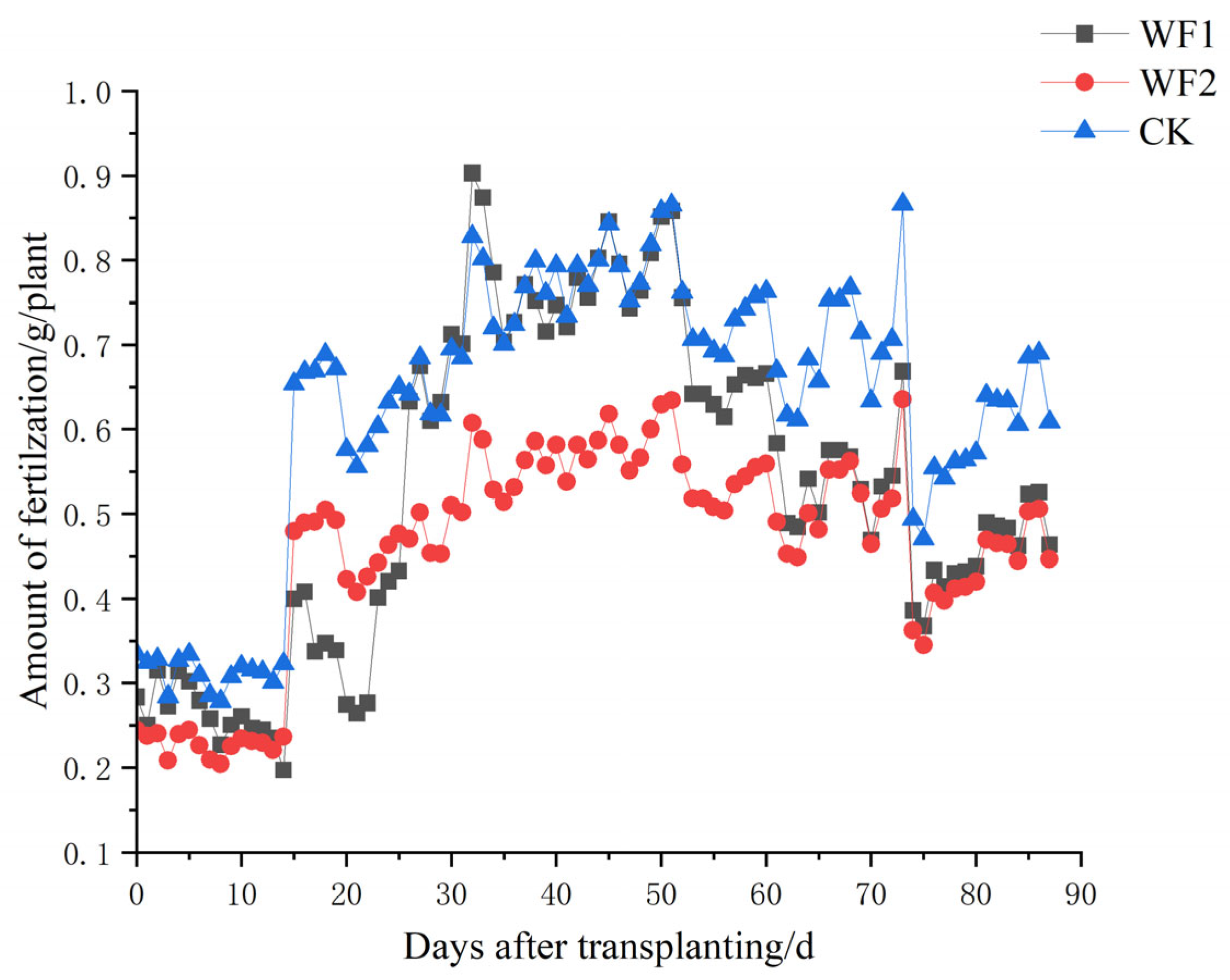

- WF1 (dynamic model): The irrigation and fertilization amounts were dynamically determined using Equations (23)–(26) based on real-time measurements of plant height and stem diameter.

- WF2 (fixed regime): This treatment involved a fixed irrigation and fertilization regime based on the optimal combination determined in Section 3.1. Specifically, the irrigation amount was fixed at 80% throughout the experiment, and the fertilization amount was fixed at 110% . Water was applied via a drip irrigation system, with one emitter per plant.

- CK (control): These plants were grown under a fertigation regime designed to represent conventional practices for greenhouse tomato production in the region, characterized by ample water and nutrient supply. Specifically, the irrigation amount for the CK treatment was set to 120% , and the fertilization amount was set to 120% . Water was applied via a drip irrigation system, with one emitter per plant.

2.7. Irrigation and Fertigation System Details

2.7.1. Water Source and Quality

2.7.2. Fertigation System

2.7.3. Irrigation System

2.8. Data Analysis

3. Results

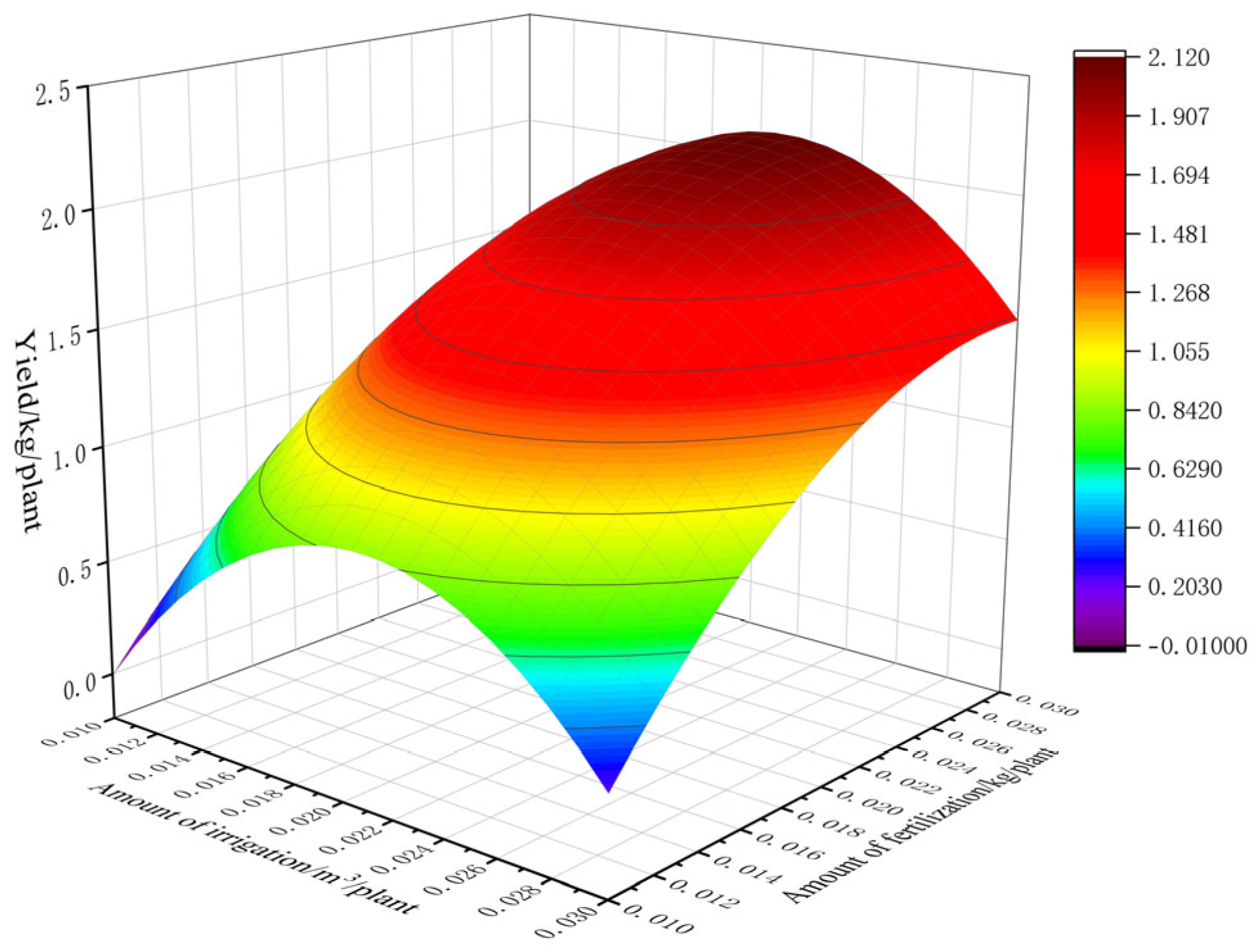

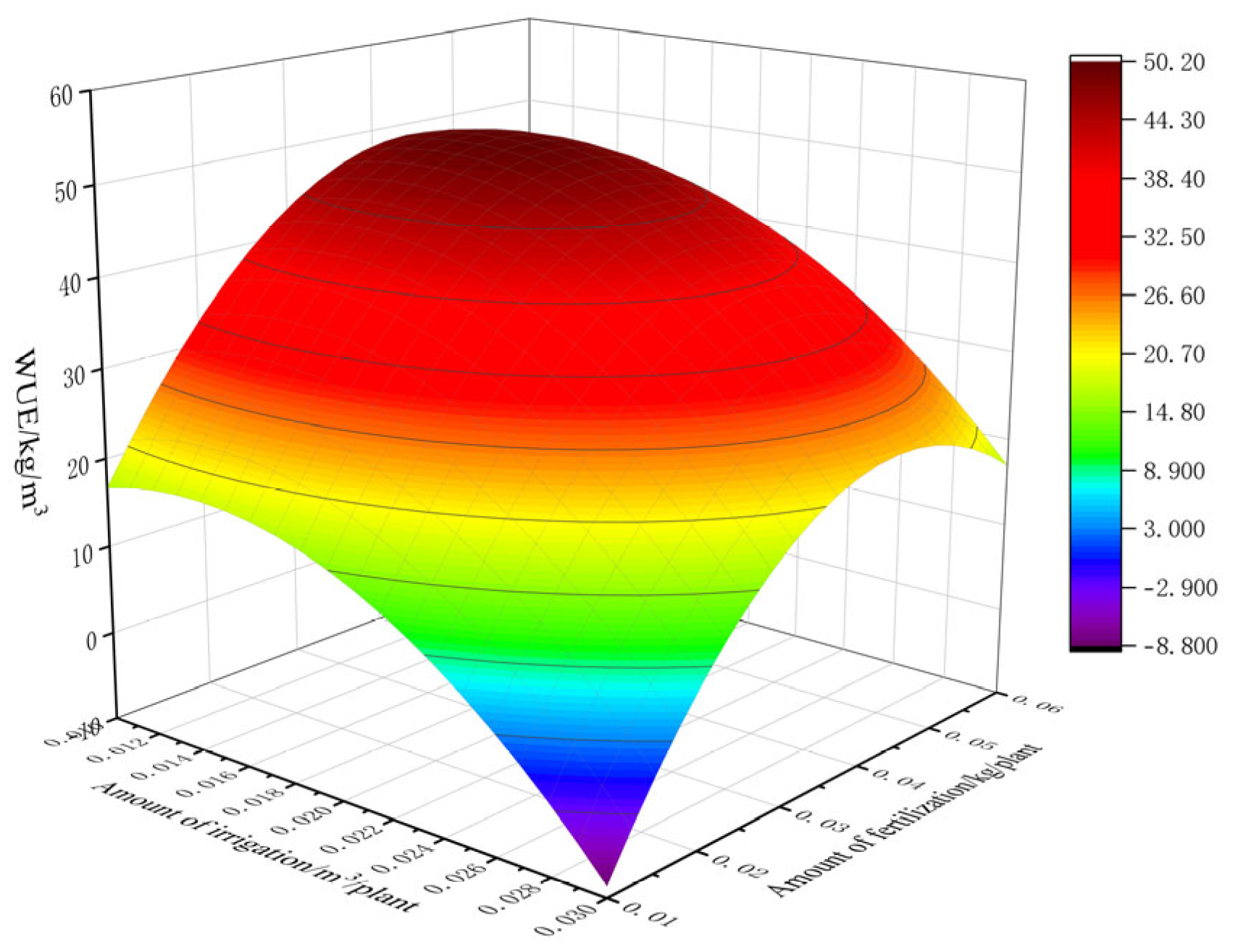

3.1. Coupling Effects of Water and Fertilizer on Fruit Yield and WUE

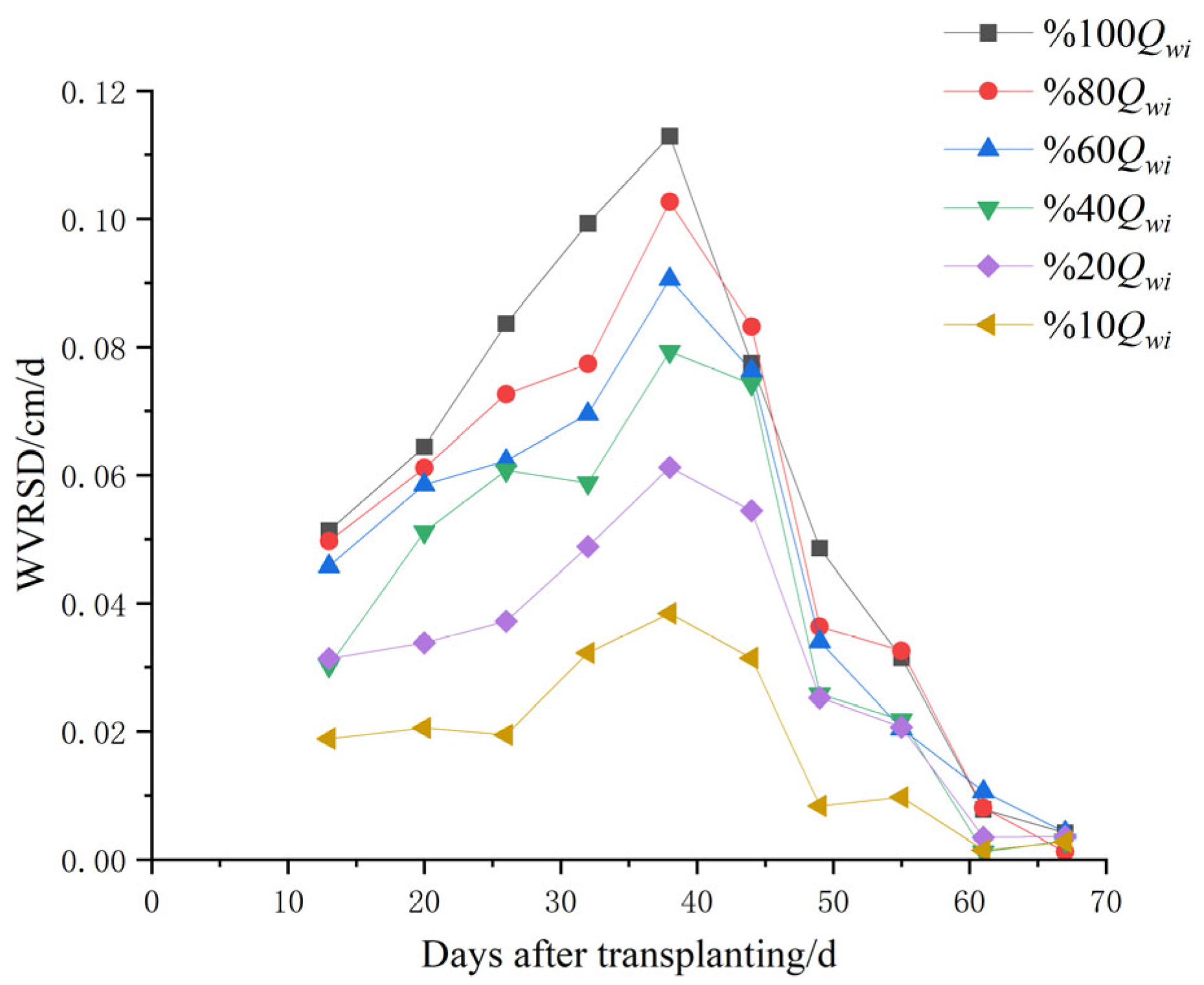

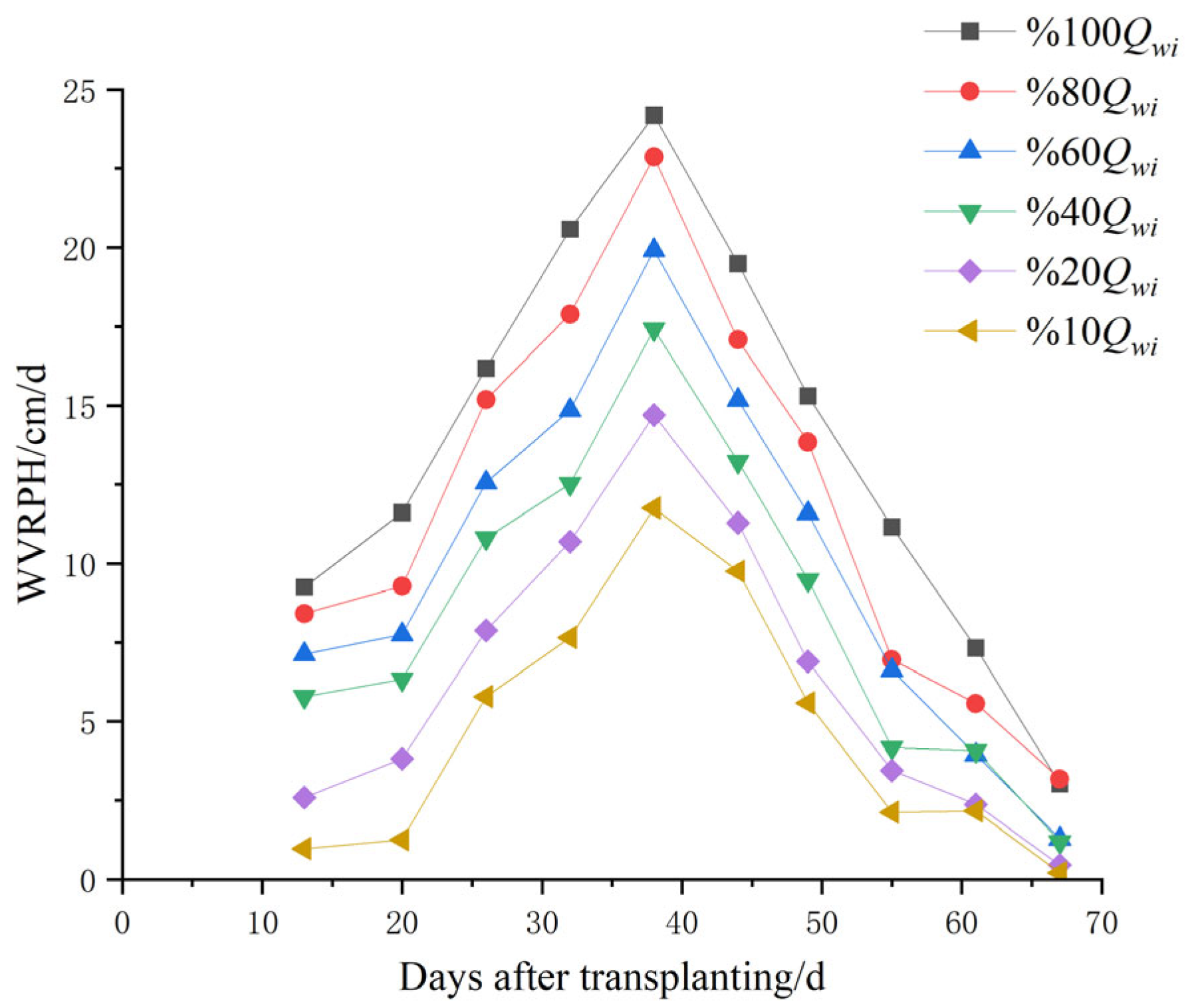

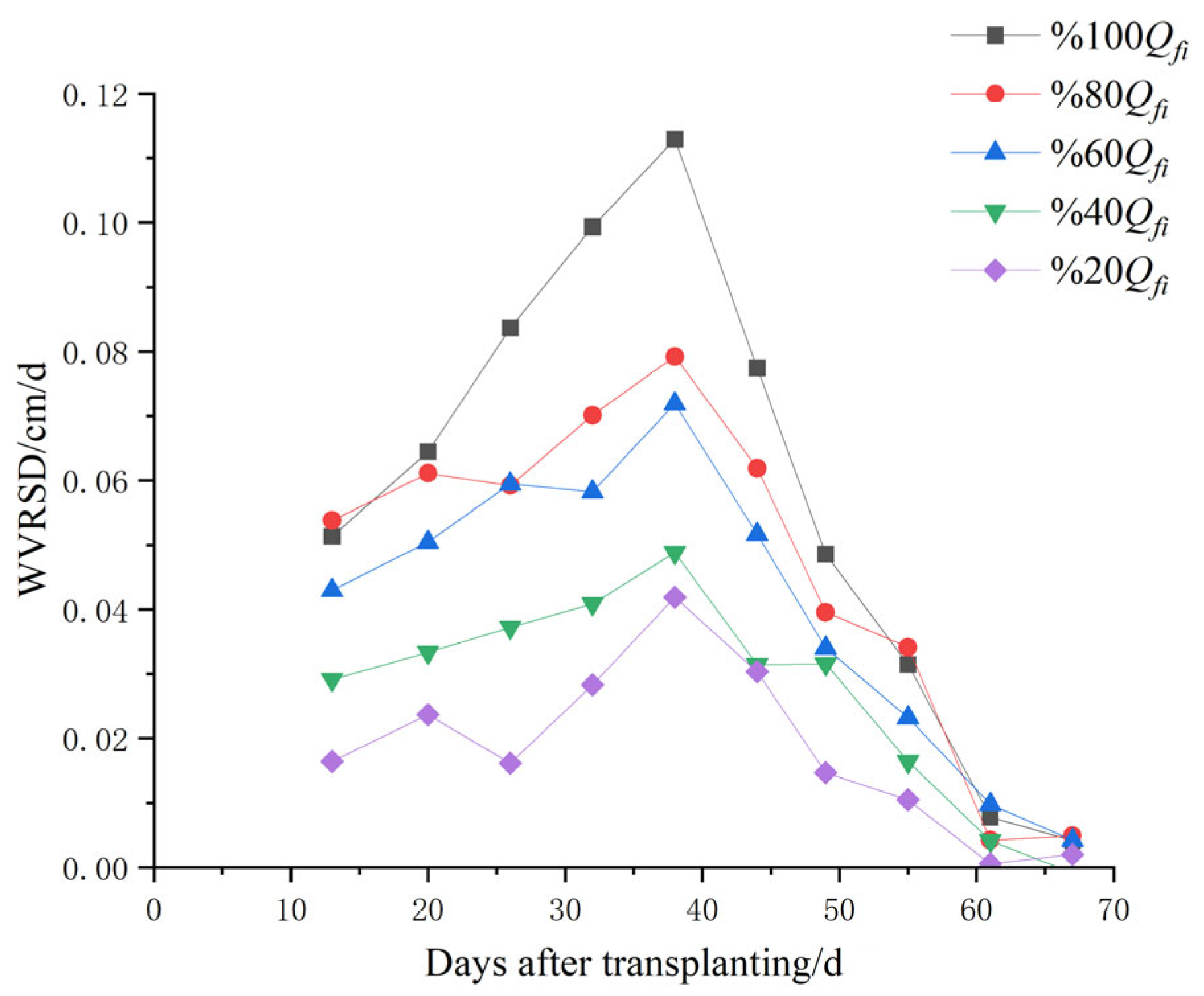

3.2. Effects of Irrigation Amount Change on Stem Diameter and Plant Height

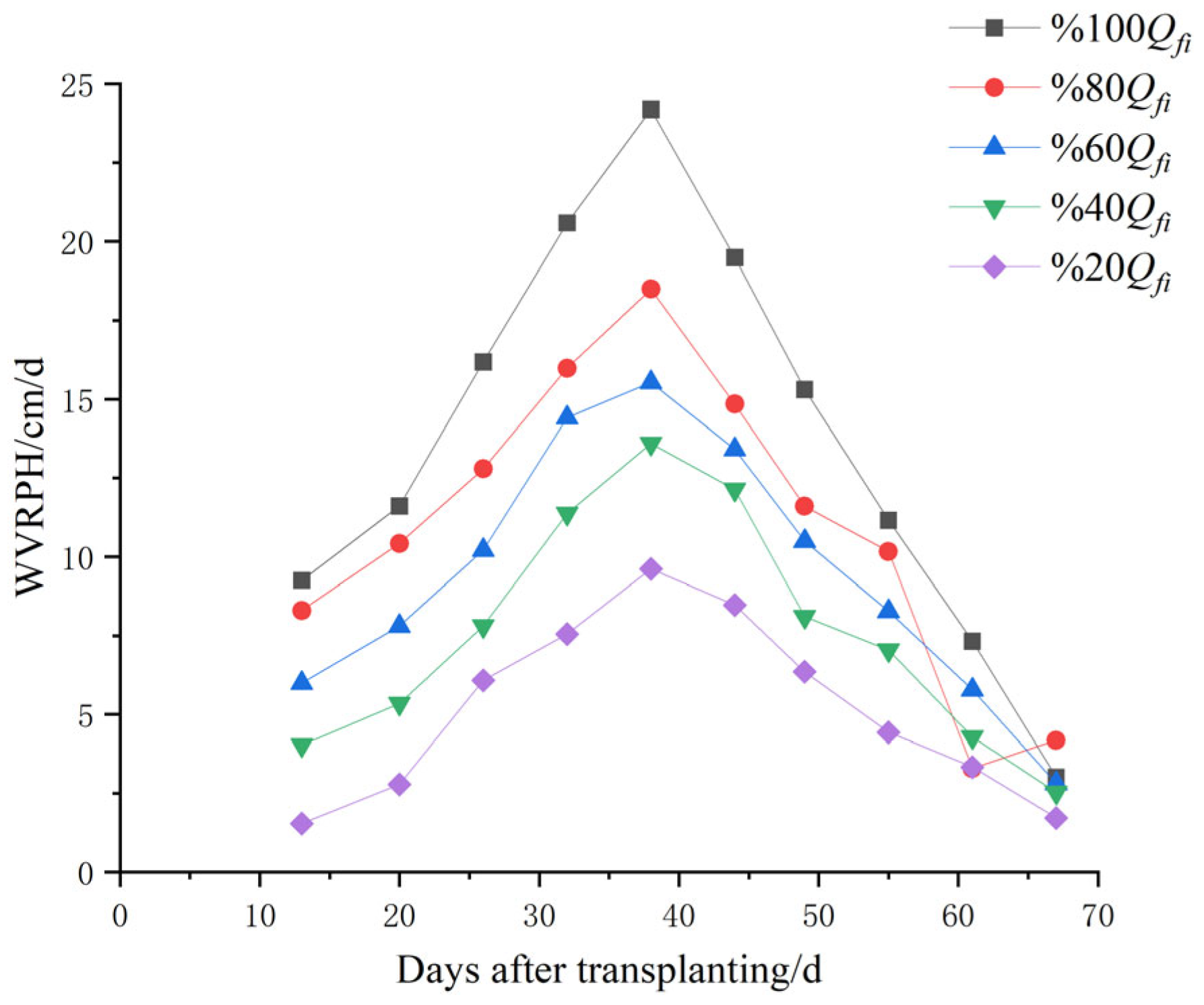

3.3. Effects of Fertilization Change on Stem Diameter and Plant Height

3.4. Dynamic Water and Fertilizer Management Strategy

4. Discussion

4.1. Interactive Effects of Water and Fertilizer on Yield and WUE

4.2. Morphological Responses as Indicators for Precision Management

4.3. Model Validation and Effectiveness of the Dynamic Management Strategy

4.4. Limitations and Future Directions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, Y.; Duan, L.; Zhong, H.; Cai, H.; Xu, J.; Li, Z. Effects of irrigation-fertilization-aeration coupling on yield and quality of greenhouse tomatoes. Agric. Water Manag. 2024, 299, 108893. [Google Scholar] [CrossRef]

- Zhang, J.; Xiang, L.; Liu, Y.; Jing, D.; Zhang, L.; Liu, Y.; Li, W.; Wang, X.; Li, T.; Li, J. Optimizing irrigation schedules of greenhouse tomato based on a comprehensive evaluation model. Agric. Water Manag. 2024, 295, 108741. [Google Scholar] [CrossRef]

- Ullah, I.; Mao, H.; Rasool, G.; Gao, H.; Javed, Q.; Sarwar, A.; Khan, M.I. Effect of deficit irrigation and reduced N fertilization on plant growth, root morphology and water use efficiency of tomato grown in soilless culture. Agronomy 2021, 11, 228. [Google Scholar] [CrossRef]

- Zhang, C.; Lia, X.; Yan, H.; Ullaha, I.; Zuo, Z.; Li, L.; Yu, J. Effects of irrigation quantity and biochar on soil physical properties, growth characteristics, yield and quality of greenhouse tomato. Agric. Water Manag. 2020, 241, 106263. [Google Scholar] [CrossRef]

- Li, Z.; Xu, B.; Du, T.; Ma, Y.; Tian, X.; Wang, F.; Wang, W. Excessive nitrogen fertilization favors the colonization, survival, and development of Sogatella furcifera via bottom-up effects. Plants 2021, 10, 875. [Google Scholar] [CrossRef]

- Shabbir, A.; Mao, H.; Ullah, I.; Buttar, N.A.; Ajmal, M.; Solangi, K.A. Improving water use efficiency by optimizing the root distribution patterns under varying drip emitter density and drought stress for cherry tomato. Agronomy 2021, 11, 3. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Du, Y.; Chen, Q. Optimization of an aerated fertilizer irrigation application scheme for tomato photosynthesis, yield and quality in Xi’an, China. Sci. Hortic. 2024, 338, 113743. [Google Scholar] [CrossRef]

- Yue, W.; Liu, L.; Chen, S.; Bai, Y.; Li, N. Effects of water and nitrogen coupling on growth, yield and quality of greenhouse tomato. Water 2022, 14, 3665. [Google Scholar] [CrossRef]

- Wang, L.; Uri, Y.; Yasuor, H.; Ning, S.; Tan, J.; Ben-Gal, A. Simulating water and potassium uptake of greenhouse tomato as a function of salinity stress. Irrig. Sci. 2022, 40, 873–884. [Google Scholar] [CrossRef]

- Sun, Y.; Duan, L.; Zhong, H.; Cai, H.; Wang, X. Response mechanism of soil greenhouse gas emission and yield of greenhouse tomato to water-fertilizer-air coupling. Trans. Chin. Soc. Agric. Eng. 2024, 55, 312–322. [Google Scholar] [CrossRef]

- Shabbir, A.; Mao, H.; Ullah, I.; Buttar, N.A.; Ajmal, M.; Lakhiar, I.A. Effects of drip irrigation emitter density with various irrigation levels on physiological parameters, root, yield, and quality of cherry tomato. Agronomy 2020, 10, 1685. [Google Scholar] [CrossRef]

- Veerachamy, R.; Ramar, R.; Balaji, S.; Sharmila, L. Autonomous application controls on smart irrigation. Comput. Electr. Eng. 2022, 100, 107855. [Google Scholar] [CrossRef]

- Cantore, V.; Lechkar, O.; Karabulut, E.; Sellami, M.H.; Albrizio, R.; Boari, F.; Stellacci, A.M.; Todorovic, M. Combined effect of deficit irrigation and strobilurin application on yield, fruit quality and water use efficiency of “cherry” tomato (Solanum lycopersicum L.). Agric. Water Manag. 2016, 167, 53–61. [Google Scholar] [CrossRef]

- Szabó, A.; Széles, A.; Illés, Á.; Bojtor, C.; Mousavi, S.M.N.; Radócz, L.; Nagy, J. Effect of different nitrogen supply on maize emergence dynamics, evaluation of yield parameters of different hybrids in long-term field experiments. Agronomy 2022, 12, 284. [Google Scholar] [CrossRef]

- Zhang, M.; Xiao, N.; Li, Y.; Li, Y.; Zhang, D.; Xu, Z.; Zhang, Z. Growth and fruit yields of greenhouse tomato under the integrated water and fertilizer by moistube irrigation. Agronomy 2022, 12, 1630. [Google Scholar] [CrossRef]

- Farid, M.; Anshori, M.F.; Rossi, R.; Haring, F.; Mantja, K.; Dirpan, A.; Larekeng, S.H.; Mustafa, M.; Adnan, A.; Tahara, S.A.M.; et al. Combining image-based phenotyping and multivariate analysis to estimate fruit fresh weight in segregation lines of lowland tomatoes. Agronomy 2024, 14, 338. [Google Scholar] [CrossRef]

- Li, R.; Bai, J.; Li, D.; Ren, X.; He, D.; Du, R.; Feng, Z.; Zhang, Z. Water and fertilizer decision model for synergistic optimization of yield, quality and efficiency of cherry tomato based on combination evaluation. Comput. Electron. Agric. 2024, 224, 109224. [Google Scholar] [CrossRef]

- Liang, Z.; Liu, X.; Xiong, J.; Xiao, J. Water allocation and integrative management of precision irrigation: A systematic review. Water 2020, 12, 3135. [Google Scholar] [CrossRef]

- Zhao, F.; Yoshida, H.; Goto, E.; Hikosaka, S. Development of an automatic irrigation method using an image-based irrigation system for high-quality tomato production. Agronomy 2022, 12, 106. [Google Scholar] [CrossRef]

- Georgieva, T.; Veleva, P.; Atanassova, S.; Daskalov, P. Indirect determination of basic tomato quality parameters using color digital images. Eng. Proc. 2024, 70, 24. [Google Scholar] [CrossRef]

- Sai, K.; Sood, N.; Saini, I. Time series data modelling for classification of drought in tomato plants. Theor. Exp. Plant Physiol. 2023, 35, 379–394. [Google Scholar] [CrossRef]

- Labrador, R.H.; Masot, R.; Alcaniz, M.; Baigts, D.; Soto, J.; Martinez-Manez, R.; Garcia-Breijo, E.; Gil, L.; Barat, J.M. Prediction of NaCl, nitrate and nitrite contents in minced meat by using a voltammetric electronic tongue and an impedimetric sensor. Food Chem. 2010, 122, 864–870. [Google Scholar] [CrossRef]

- Silva, P.C.; Ferreira, A.F.A.; Araújo, E.S.; Net, J.V.B.; Costa, A.R.d.; Fernandes, L.d.S.; Martins, A.A.S.; Cândido, R.d.S.; Jardim, A.M.d.R.F.; Pandorfi, H.; et al. Cherry tomato crop management under irrigation levels: Morphometric characteristics and their relationship with fruit production and quality. Gesunde Pflanz. 2022, 75, 1277–1288. [Google Scholar] [CrossRef]

- Olagunju, S.O.; Sosanya, O.S.; Oguntade, O.A.; Adewusi, K.M.; Soremi, P.A.S.; Joda, A.O.; Nassir, A.L. Effect of NPK fertiliser on upper and basal stem diameters and implication on growth habit of tomato. J. Saudi Soc. Agric. Sci. 2024, 23, 55–66. [Google Scholar] [CrossRef]

- Bwambale, E.; Abagale, F.K.; Anornu, G.K. Model-based smart irrigation control strategy and its effect on water use efficiency in tomato production. Cogent Eng. 2023, 10, 2259217. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; He, G. Vegetable Soilless Cultivation Practical Technology; China Agricultural University: Beijing, China, 2000. [Google Scholar]

- Yun, Y.; Sheng, W. Prediction of stem diameter variations based on principal component regression. Trans. Chin. Soc. Agric. Eng. 2015, 46, 306–314. [Google Scholar] [CrossRef]

- Ding, J.; Peng, S.; Xu, J.; Jiao, X.; Luo, Y. Calculation method for reference crop evaportranspiration based on temperature data. J. Hohai Univ. 2007, 35, 633–637. [Google Scholar]

- Harel, D.; Sofer, M.; Broner, M.; Zohar, D.; Gantz, S. Growth-stage-specific kc of greenhouse tomato plants grown in semi-arid mediterranean region. J. Agric. Sci. 2014, 6, 132–142. [Google Scholar] [CrossRef]

- Qi, W.; Zhang, Z.; Zou, Z.; He, C.; Sun, Z. Research of tomato’s growth rule based on accumulation temperature in greenhouse. J. Hua Zhong Agric. Univ. 2004, 35, 53–57. [Google Scholar]

- Wang, X.; Meng, Z.; Duan, A.; Liu, Z. Mechanism and methodology for monitoring tomato water content based on stem diameter variation. Trans. Chin. Soc. Agric. Eng. 2010, 26, 107–113. [Google Scholar] [CrossRef]

- Ma, X.; Yang, Y.; Tan, Z.; Cheng, Y.; Wang, T.; Yang, L.; He, T.; Liang, S. Climate-smart drip irrigation with fertilizer coupling strategies to improve tomato yield, quality, resources use efficiency and mitigate greenhouse gases emissions. Land 2024, 13, 1872. [Google Scholar] [CrossRef]

- Zeineldin, F.I.; Turk, K.G.B.; Elmulthum, N.A. Modified surface drip irrigation and hydraulic barrier impacts on soil moisture and water productivity for tomatoes in a greenhouse. Water 2024, 16, 2926. [Google Scholar] [CrossRef]

- Sun, L.; Li, B.; Yao, M.; Mao, L.; Zhao, M.; Niu, H.; Xu, Z.; Wang, T.; Wang, J. Simulation of soil water movement and root uptake under mulched drip irrigation of greenhouse tomatoes. Water 2023, 15, 1282. [Google Scholar] [CrossRef]

- Sharma, S.P.; Leskovar, D.I.; Crosby, K.M.; Volder, A.; Ibrahim, A.M.H. Root growth, yield, and fruit quality responses of reticulatus and inodorus melons (Cucumis melo L.) to deficit subsurface drip irrigation. Agric. Water Manag. 2014, 136, 75–85. [Google Scholar] [CrossRef]

- Wang, D.; Kang, Y.; Wan, S. Effect of soil matric potential on tomato yield and water use under drip irrigation condition. Agric. Water Manag. 2007, 87, 180–186. [Google Scholar] [CrossRef]

- Patanèa, C.; Tringalia, S.; Sortino, O. Effects of deficit irrigation on biomass, yield, water productivity and fruit quality of processing tomato under semi-arid Mediterranean climate conditions. Sci. Hortic. 2011, 129, 590–596. [Google Scholar] [CrossRef]

- Zhao, D.; Reddy, K.R.; Kakani, V.G.; Reddy, V.R. Nitrogen deficiency effects on plant growth, leaf photosynthesis, and hyperspectral reflectance properties of sorghum. Eur. J. Agron. 2005, 22, 391–403. [Google Scholar] [CrossRef]

- De Swaef, T.; De Schepper, V.; Vandegehuchte, M.W.; Steppe, K. Stem diameter variations as a versatile research tool in ecophysiology. Tree Physiol. 2015, 35, 1047–1061. [Google Scholar] [CrossRef]

- Wang, X.; Meng, Z.; Chang, X.; Deng, Z.; Li, Y.; Lv, M. Determination of a suitable indicator of tomato water content based on stem diameter variation. Sci. Hortic. 2017, 215, 142–148. [Google Scholar] [CrossRef]

- Viégas, I.d.J.M.; Cordeiro, R.A.M.; de Almeida, G.M.; Silva, D.A.S.; da Silva, B.C.; Okumura, R.S.; da Silva Júnior, M.L.; da Silva, S.P.; de Freitas, J.M.N. Growth and visual symptoms of nutrients deficiency in mangosteens (Garcinia mangostana L.). Am. J. Plant Sci. 2018, 9, 1014–1028. [Google Scholar] [CrossRef]

- Heiba, Y.; Nasr, M.; Fujii, M.; Mohamed, A.E.; Ibrahim, M.G. Improving irrigation schemes using sustainable development goals (SDGs)-related indicators: A case study of tomato production in pot-scale experimentation. Environ. Dev. Sustain. 2024, 26, 17721–17747. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, J.; Yan, S.; Si, W.; Liu, R.; Yang, J.; Qiu, Z.; Fan, J.; Zhang, F. Changing drip fertigation strategy to decrease greenhouse agroecosystem soil nitrate residue and improve tomato production in Northwest of China. J. Soil Sci. Plant Nutr. 2024, 24, 4565–4580. [Google Scholar] [CrossRef]

- Jain, P.; Huber, A.E.; Rockwell, F.E.; Sen, S.; Holbrook, N.M.; Stroock, A.D. New approaches to dissect leaf hydraulics reveal large gradients in living tissues of tomato leaves. New Phytol. 2024, 242, 453–465. [Google Scholar] [CrossRef]

- Liu, X.; Ali, S.; Yang, L.; He, T.; Pang, G.; Shaik, M.R.; Assal, M.E.; Hussain, S.A.; Khan, M.N. Optimized irrigation practices with fertilizer utilization strategies to improve photo-fluorescence efficiency, vascular bundles and maize production in semi-arid regions. Heliyon 2024, 10, e39222. [Google Scholar] [CrossRef]

| Treatment Level | Yield (kg/Plant) | WUE (kg/m3) |

|---|---|---|

| W1F1 | 1.8592 | 28.57 |

| W1F2 | 1.9261 | 29.59 |

| W1F3 | 1.3983 | 21.49 |

| W2F1 | 1.9949 | 38.32 |

| W2F2 | 1.7585 | 33.77 |

| W2F3 | 1.1899 | 22.85 |

| W3F1 | 1.6866 | 32.19 |

| W3F2 | 1.3332 | 28.99 |

| W3F3 | 1.0344 | 26.49 |

| Significance test (F value) | ||

| Irrigation factor | 45.205 * | 15.014 ** |

| Fertilization factor | 16.760 ** | 0.351 |

| Coupling effect of irrigation and fertilization | 0.534 | 1.633 |

| Irrigation Amount Change | Seedling Stage | Flowering Stage | ||

|---|---|---|---|---|

| WVRSD | WVRPH | WVRSD | WVRPH | |

| +20% | +0.0025 | +1.5889 | +0.0144 | +1.6704 |

| 0% | 0 | 0 | 0 | 0 |

| −20% | −0.0032 | −1.4056 | −0.0101 | −2.8667 |

| −40% | −0.0147 | −2.7833 | −0.0179 | −5.0704 |

| −60% | −0.0228 | −5.6444 | −0.0351 | −7.5593 |

| −70% | −0.0357 | −7.7278 | −0.0542 | −10.2482 |

| Source of Variance | R | p | |

|---|---|---|---|

| Seedling stage | WVRSD regression model | 0.950 | 0.004 * |

| WVRPH regression model | 0.980 | 0.001 * | |

| Flowering stage | WVRSD regression model | 0.975 | 0.001 * |

| WVRPH regression model | 0.992 | 0.000 * | |

| Fertilizer Amount Change | Seedling Stage | Flowering Stage | ||

|---|---|---|---|---|

| WVRSD | WVRPH | WVRSD | WVRPH | |

| +40% | +0.0112 | +3.5333 | +0.0354 | +6.9333 |

| +20% | +0.0107 | +2.4611 | +0.0063 | +2.3667 |

| 0 | 0 | 0 | 0 | 0 |

| −20% | −0.0155 | −2.2167 | −0.0209 | −2.4667 |

| −40% | −0.0267 | −4.7444 | −0.0344 | −5.637 |

| Source of Variance | R | p | |

|---|---|---|---|

| Seedling stage | WVRSD regression model | 0.968 | 0.007 * |

| WVRPH regression model | 0.992 | 0.001 * | |

| Flowering stage | WVRSD regression model | 0.994 | 0.001 * |

| WVRPH regression model | 0.992 | 0.007 * | |

| Treatment | Yield (kg/Plant) | WUE (kg/m3) | Economic Benefit (RMB/Plant) |

|---|---|---|---|

| WF1 | 2.362 | 38.21 | 31.38 |

| WF2 | 2.199 | 35.55 | 29.84 |

| CK | 2.014 | 21.71 | 24.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuo, Z.; Lü, T.; Sun, J.; Peng, H.; Yang, D.; Song, J.; Ma, G.; Mao, H. Dynamic Water and Fertilizer Management Strategy for Greenhouse Tomato Based on Morphological Characteristics. Agriculture 2025, 15, 304. https://doi.org/10.3390/agriculture15030304

Zuo Z, Lü T, Sun J, Peng H, Yang D, Song J, Ma G, Mao H. Dynamic Water and Fertilizer Management Strategy for Greenhouse Tomato Based on Morphological Characteristics. Agriculture. 2025; 15(3):304. https://doi.org/10.3390/agriculture15030304

Chicago/Turabian StyleZuo, Zhiyu, Tianyuan Lü, Jicheng Sun, Haitao Peng, Deyong Yang, Jinxiu Song, Guoxin Ma, and Hanping Mao. 2025. "Dynamic Water and Fertilizer Management Strategy for Greenhouse Tomato Based on Morphological Characteristics" Agriculture 15, no. 3: 304. https://doi.org/10.3390/agriculture15030304

APA StyleZuo, Z., Lü, T., Sun, J., Peng, H., Yang, D., Song, J., Ma, G., & Mao, H. (2025). Dynamic Water and Fertilizer Management Strategy for Greenhouse Tomato Based on Morphological Characteristics. Agriculture, 15(3), 304. https://doi.org/10.3390/agriculture15030304