Experiment and Calibration of Finite Element Parameters of Pineapple Based on Cohesive Zone Model

Abstract

1. Introduction

2. Test Materials and Methods

2.1. Material Collection

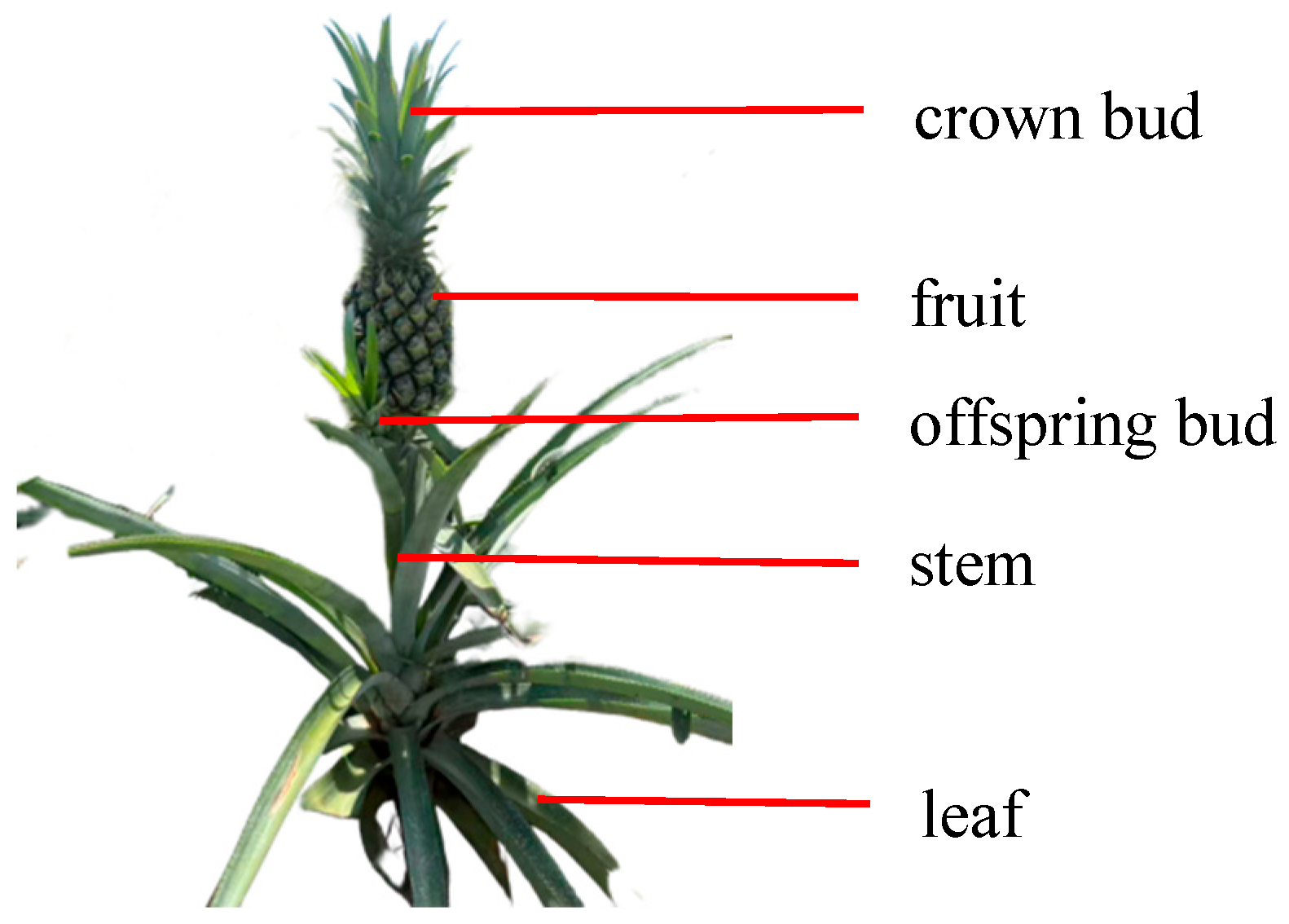

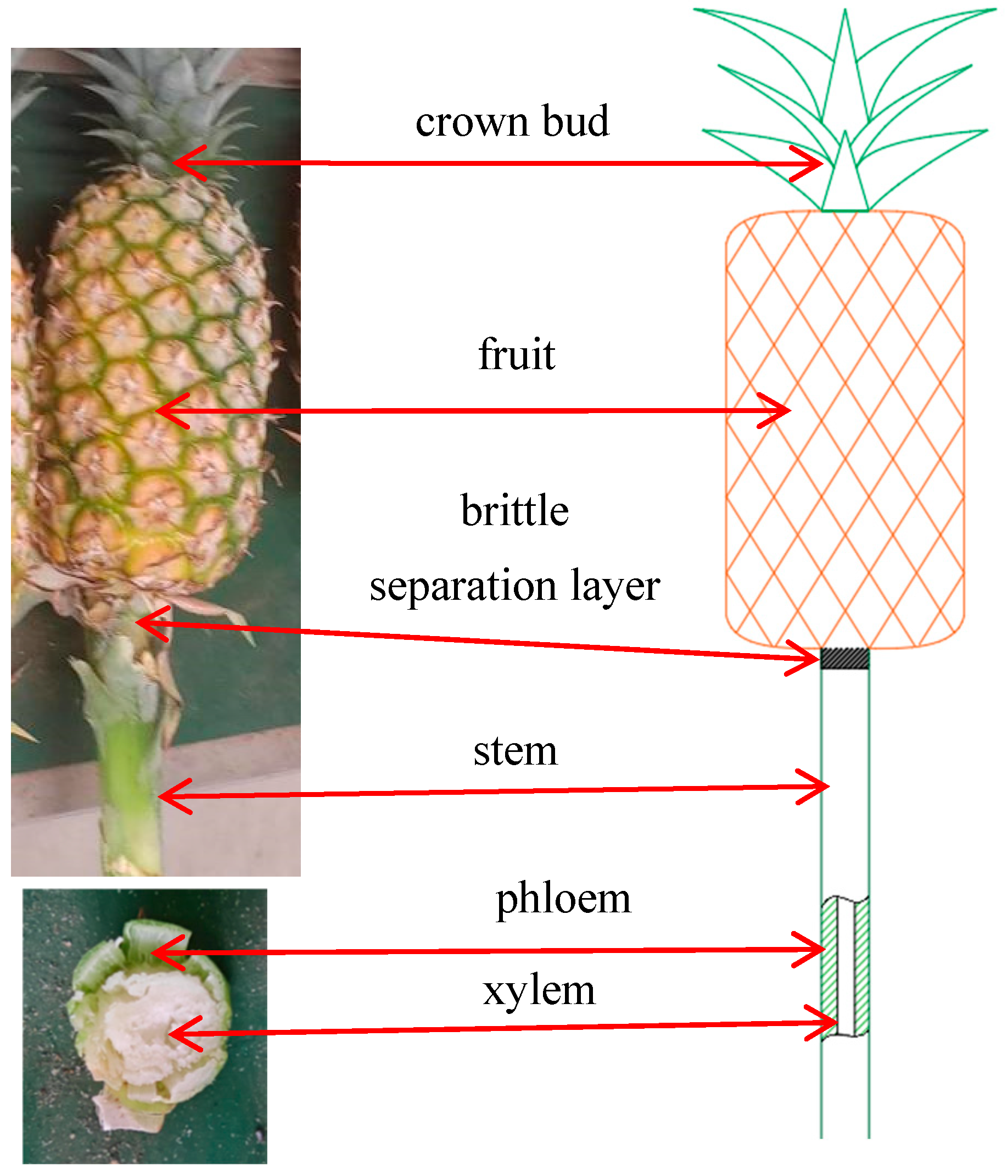

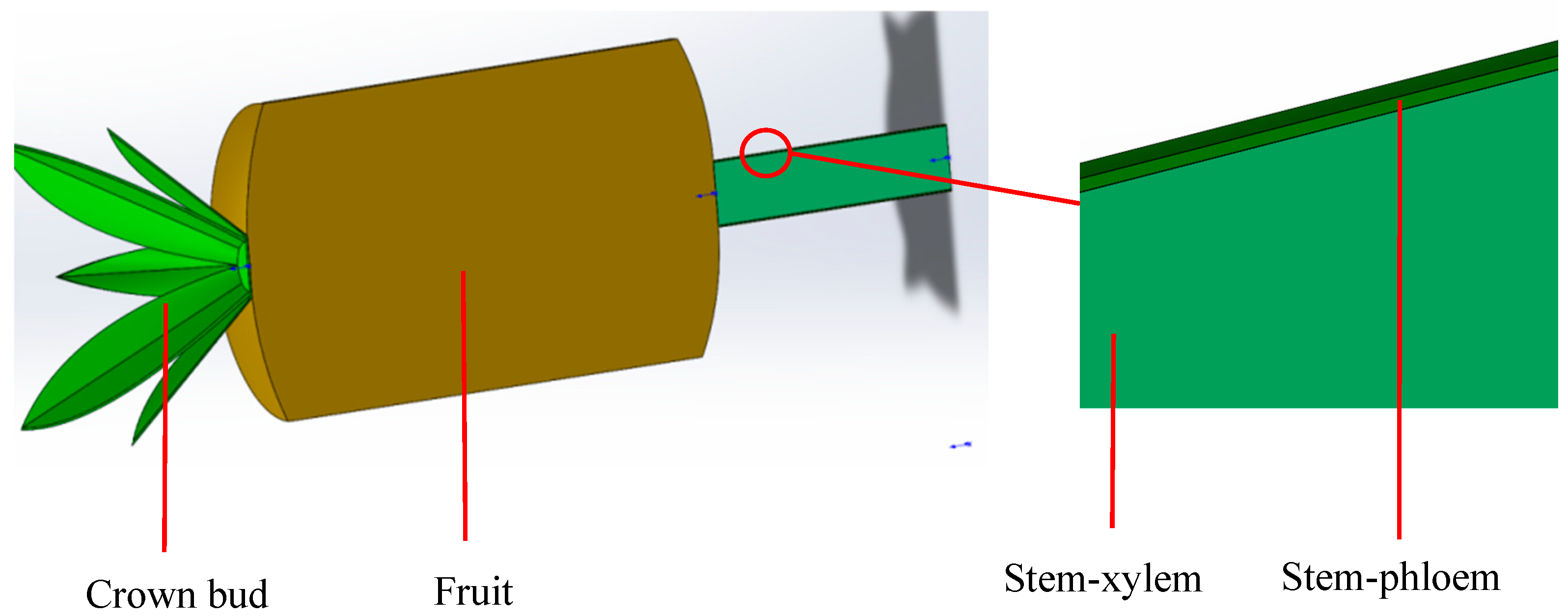

2.2. Analysis of Structure Composition of Pineapple

2.3. Pineapple Fruit Mechanical Properties Parameters

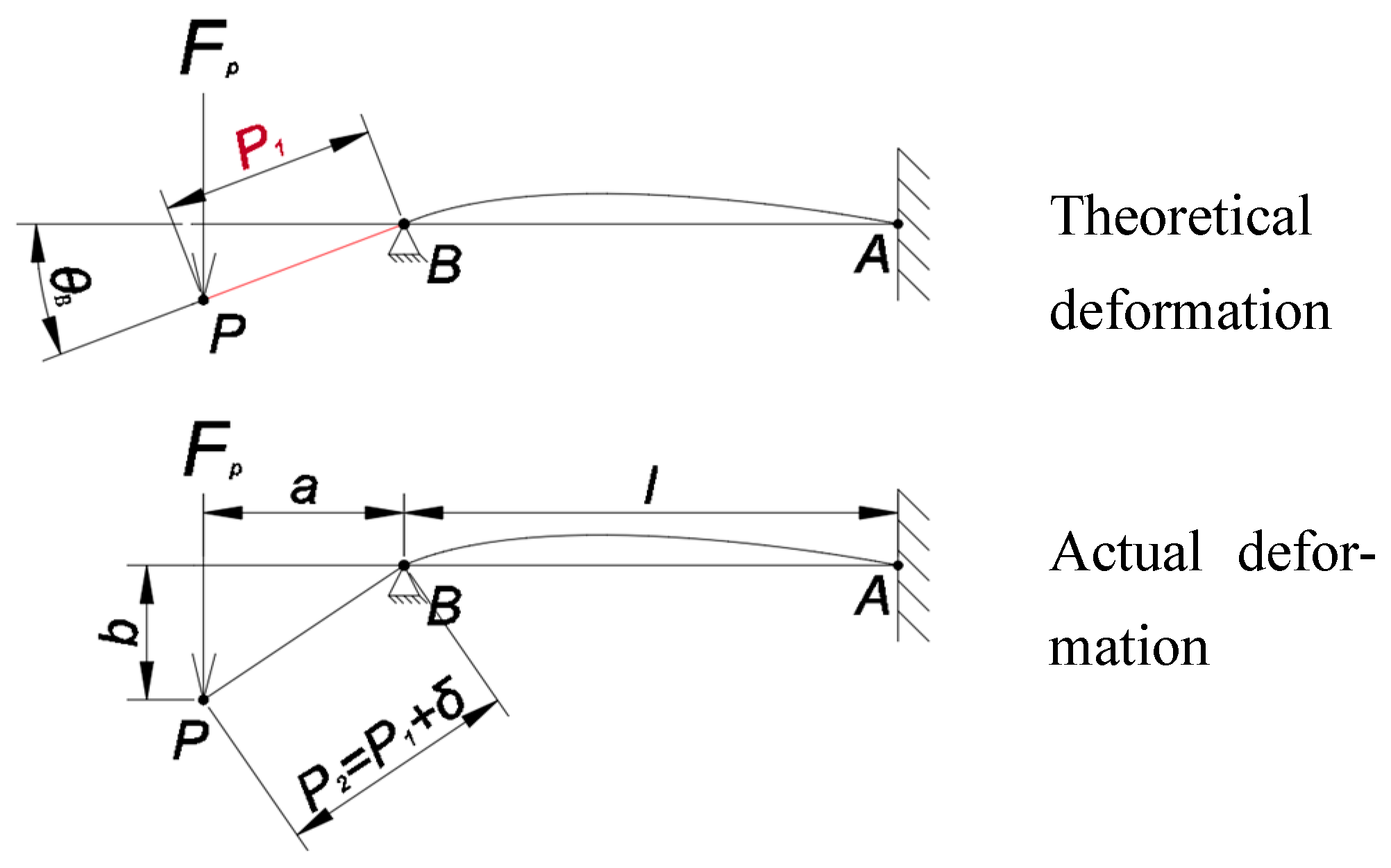

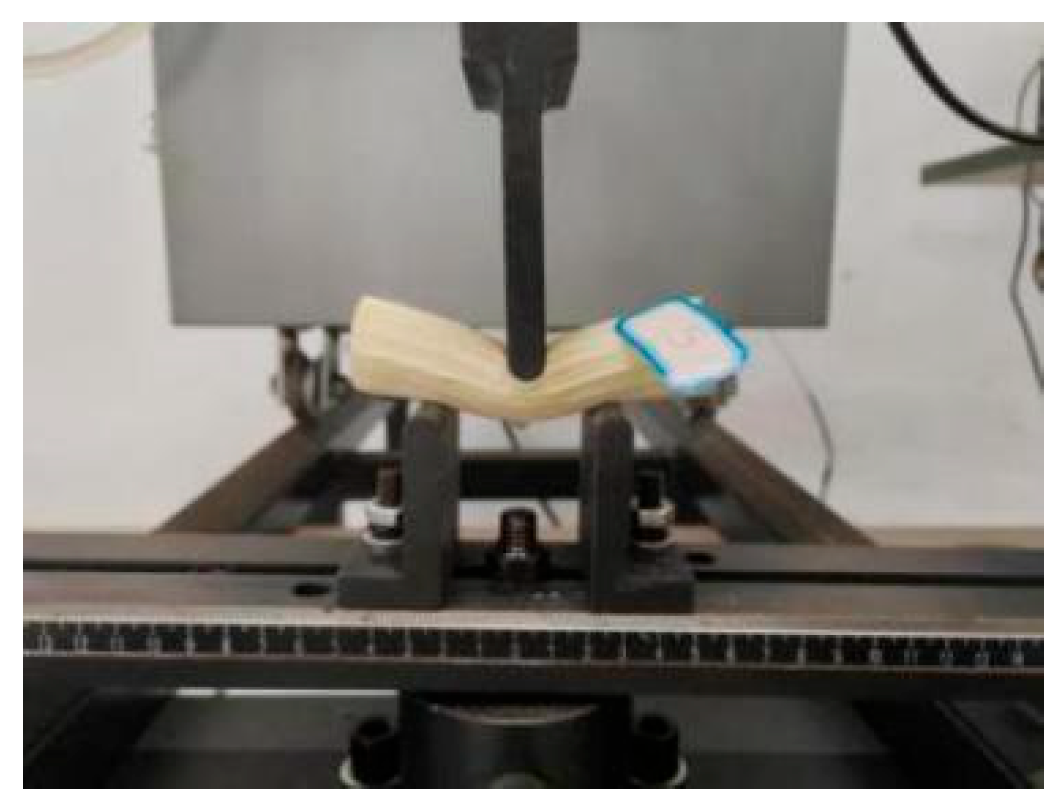

2.4. Physical Parameters of Brittle Separation Layer

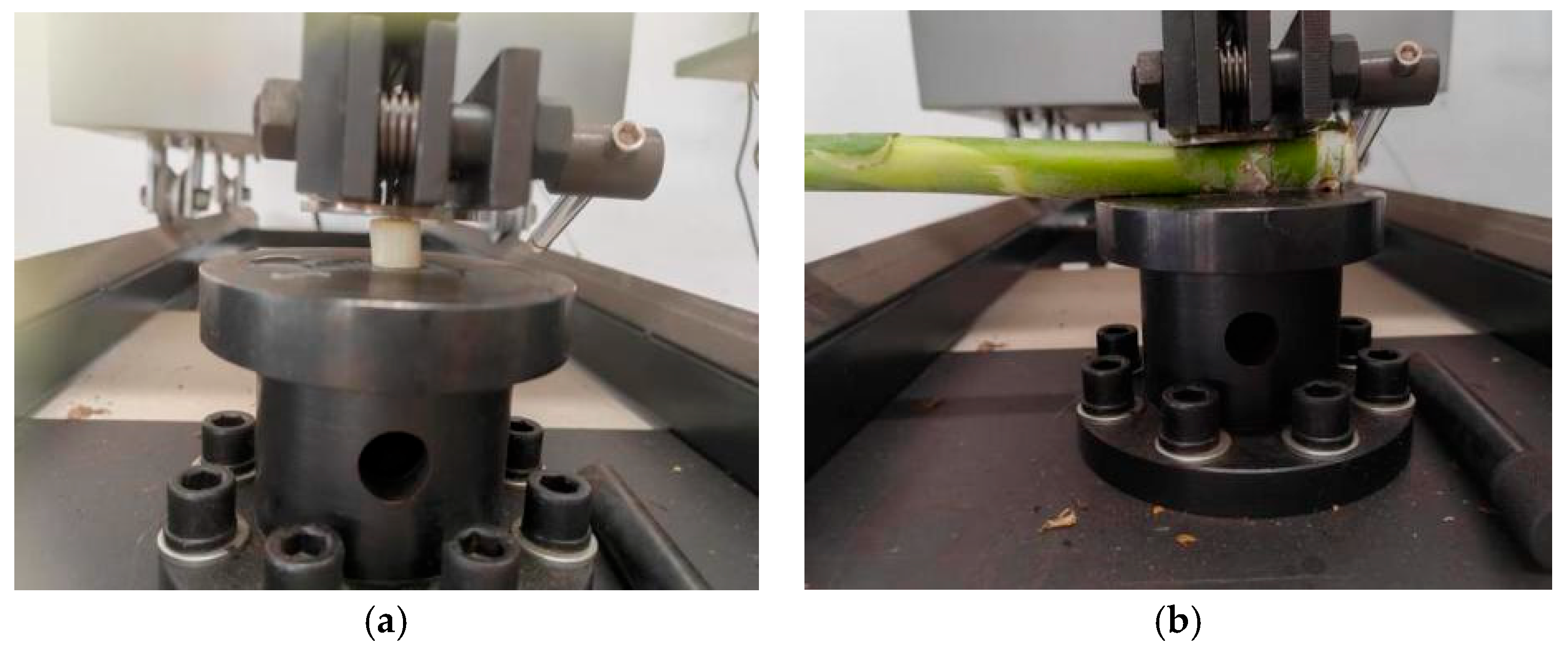

2.5. Mechanical Characteristic Parameters of Stem

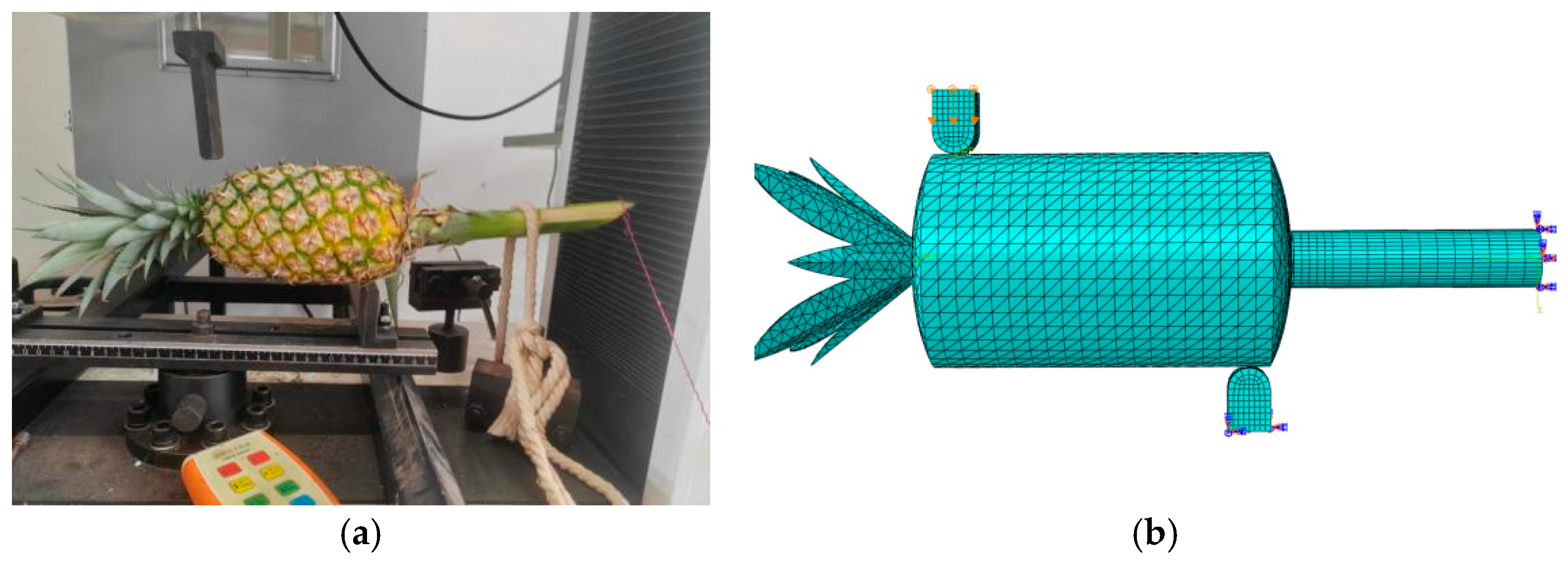

2.6. Establishment and Verification of the Finite Element Model of Pineapple

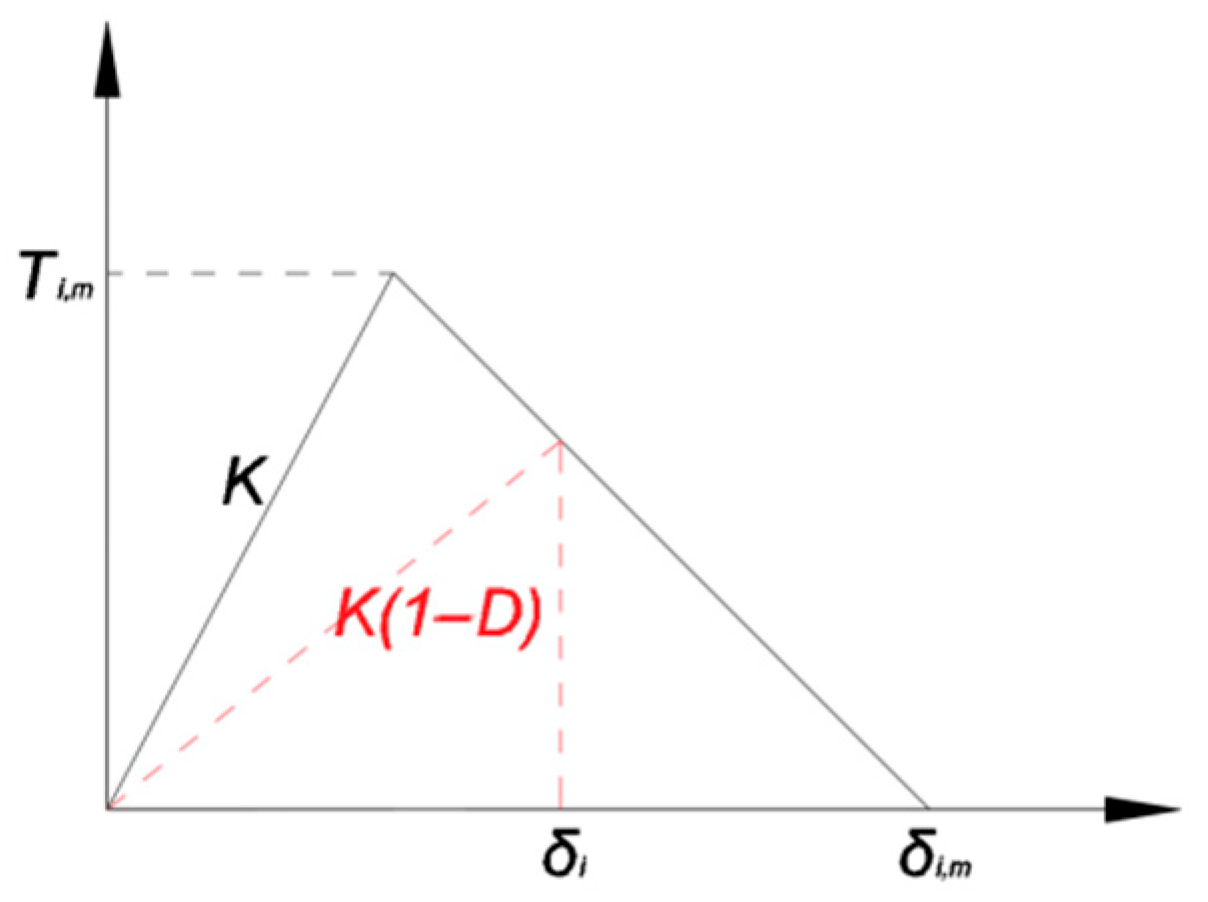

2.6.1. Establishment of Finite Element Model

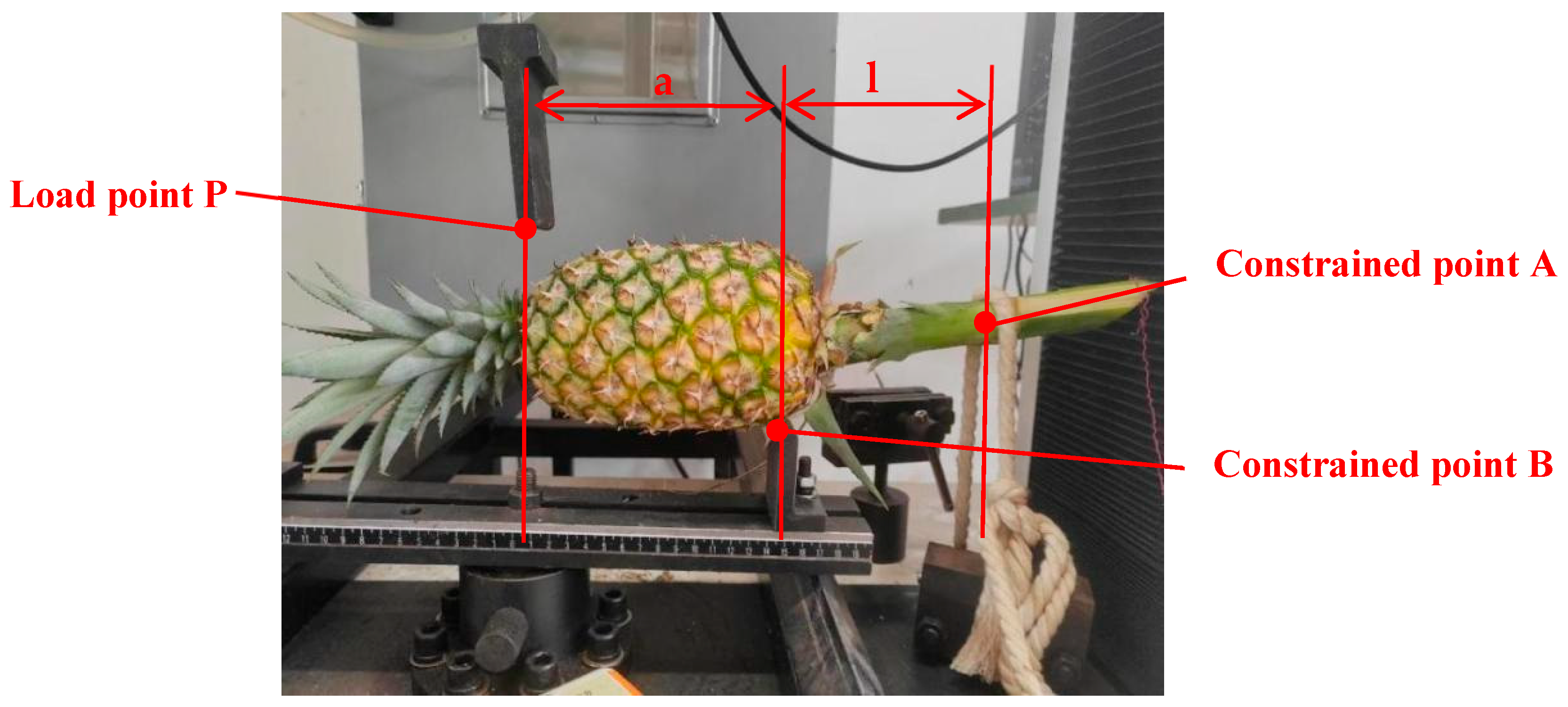

2.6.2. Validation Test of Finite Element Model

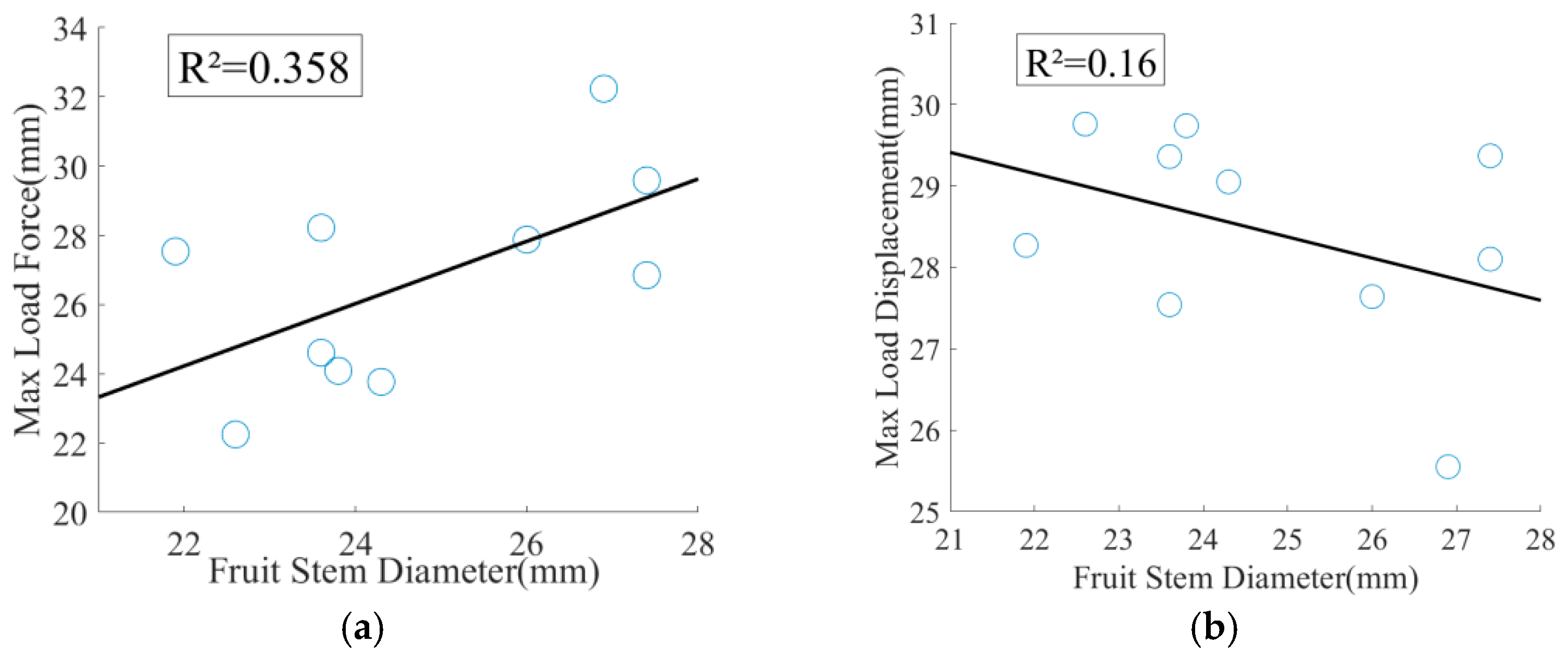

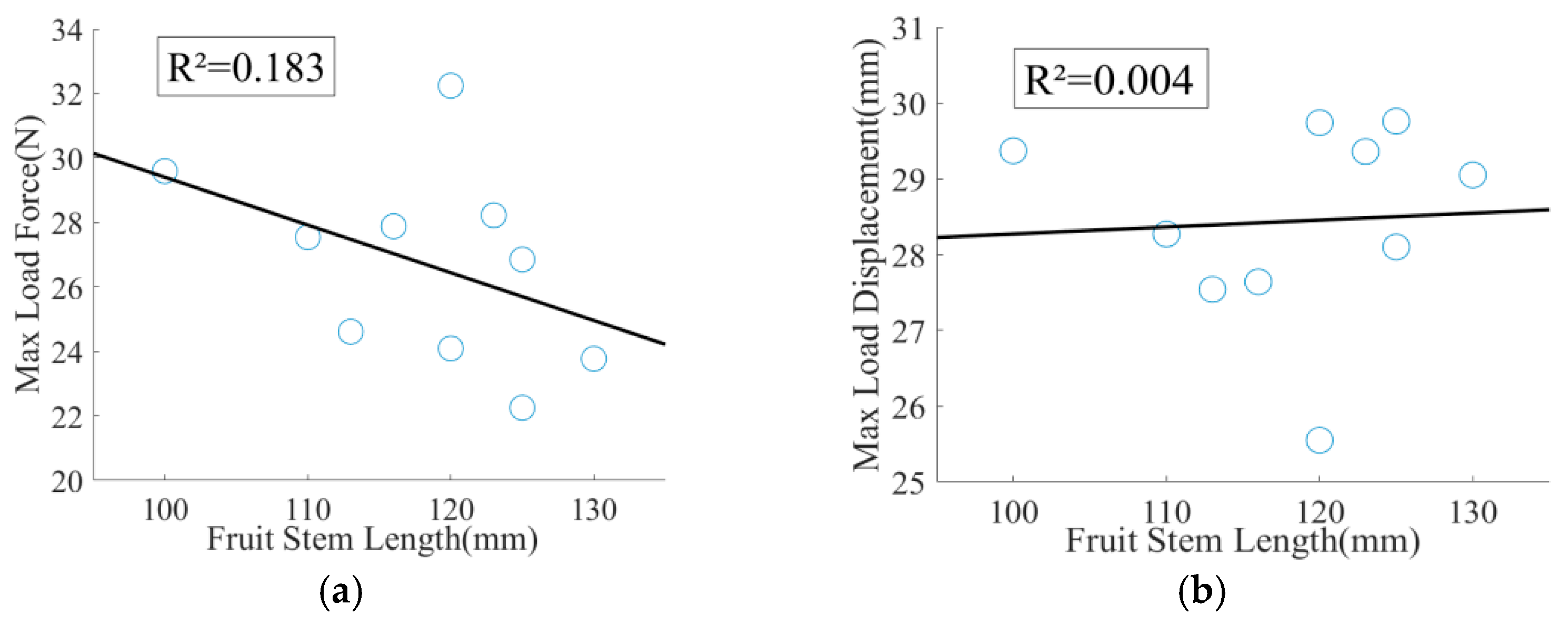

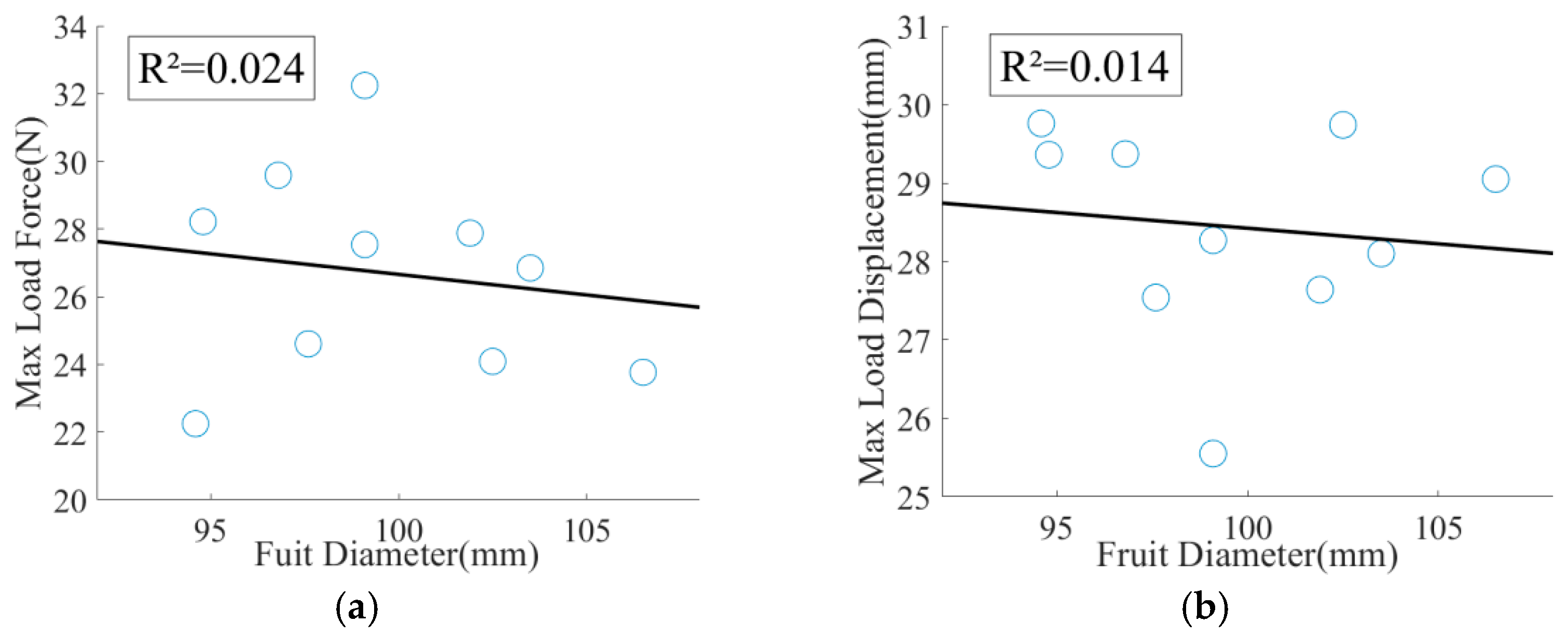

3. Result and Discussion

3.1. Parameters of Each Component in the Finite Element Model

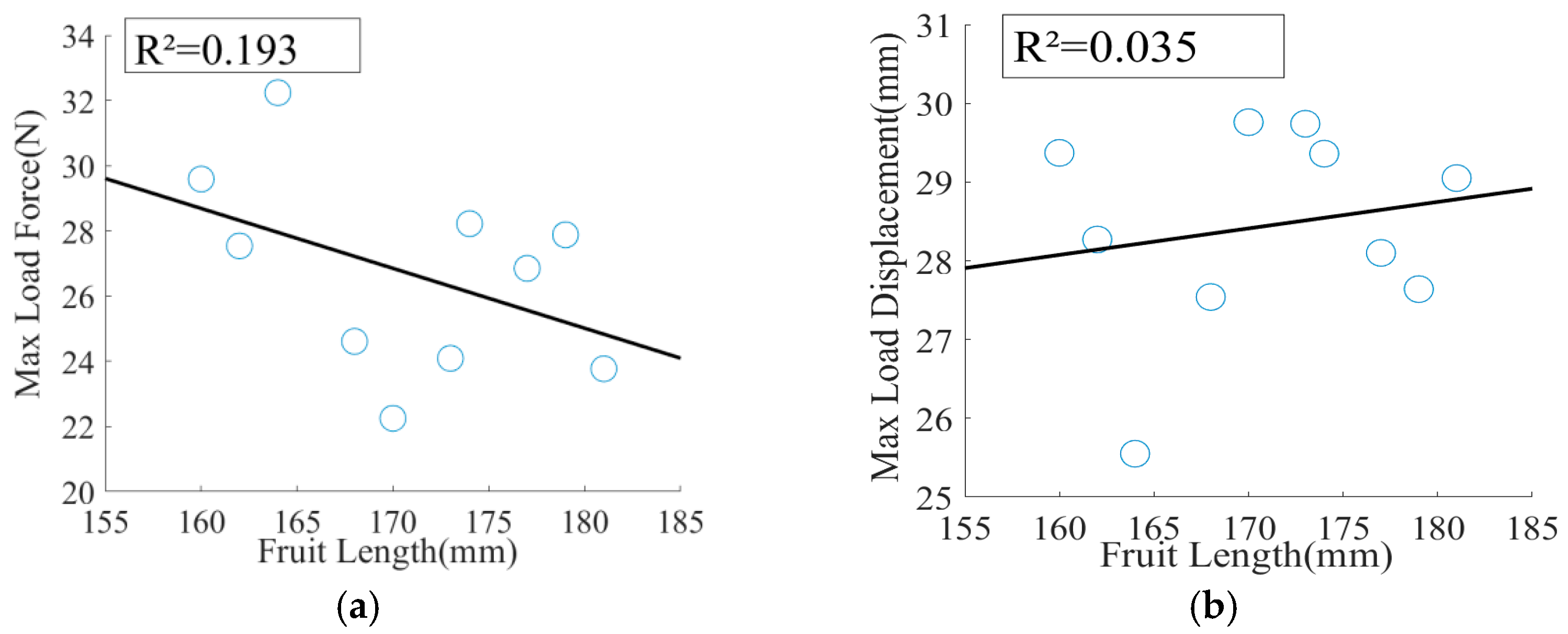

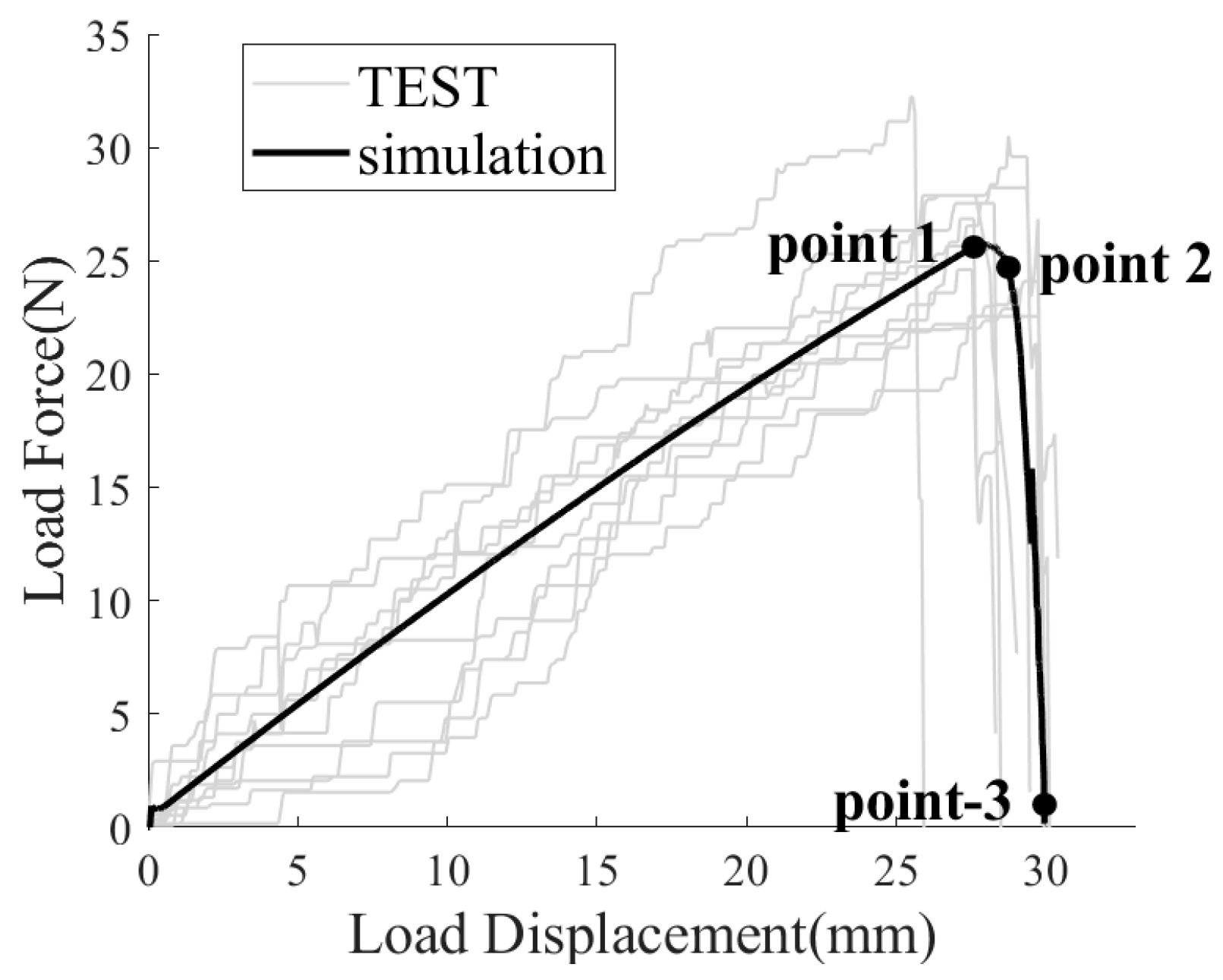

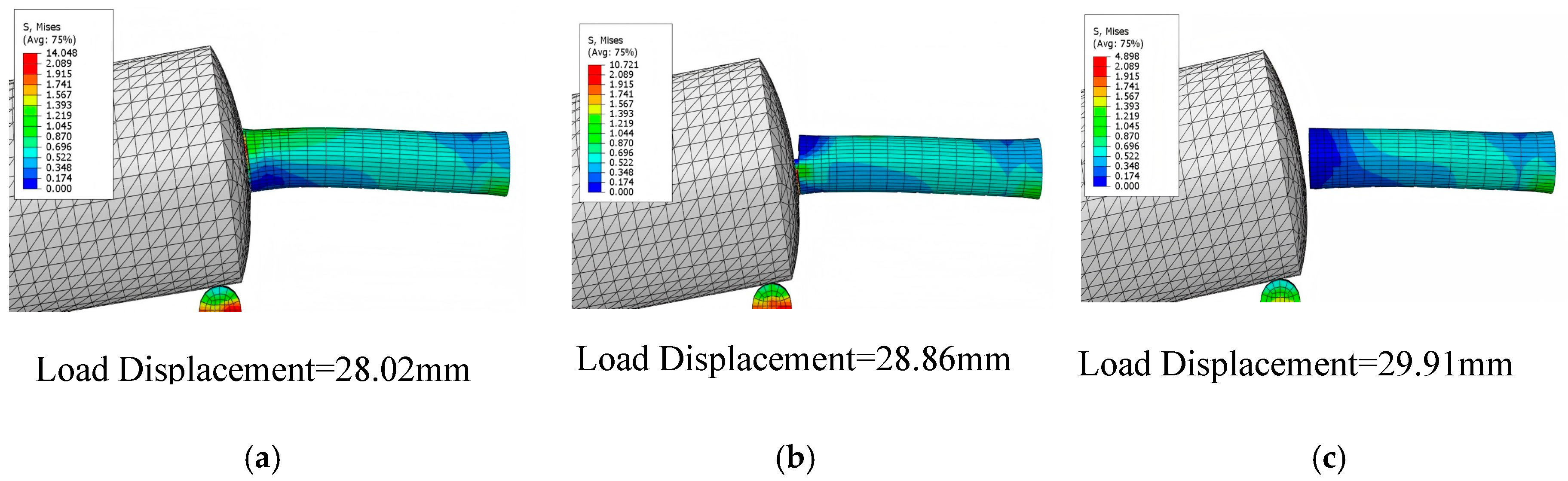

3.2. Experimental Results by Comparison

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Major Topical Fruits Market Review Preliminary Results. 2024. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 23 August 2025).

- Chen, P.; Yan, B.; Deng, G.; Li, G.; Cui, Z.; Zheng, S.; He, F.; Li, L.; Wang, X.; Zhou, S.; et al. Pose detection and localization of pineapple fruit picking based on improved litehrnet. Front. Plant Sci. 2025, 16, 1577312. [Google Scholar] [CrossRef]

- Li, J.; Li, C.; Luo, X.; Chen, C.L.; Chen, W. Real-time pineapple detection for agricultural robot via lightweight YOLOV7-Tiny Model. Procedia Comput. Sci. 2023, 226, 92–98. [Google Scholar] [CrossRef]

- He, D.; Zhang, L.; Li, X.; Li, P.; Wang, T. Design of automatic pineapple harvesting machine based on binocular machine vision. J. Anhui Agric. Sci. 2019, 47, 207–210. [Google Scholar]

- Lin, G.; Wu, Z.; Yan, M.; Liang, R.; Wu, Y.; Yan, F.; Wu, T.; Deng, G.; Yao, J.; Zhang, Y. Design and Testing of a Multi-arm Pineapple Picking Robot Based on Machine Vision. Mech. Electr. Eng. Technol. 2023, 52, 141–144+154. [Google Scholar]

- Guo, A.F.; Li, J.; Guo, L.Q.; Jiang, T.; Zhao, Y.P. Structural design and analysis of an automatic pineapple picking and collecting straddle machine. J. Phys. Conf. Ser. 2021, 1777, 012029. [Google Scholar] [CrossRef]

- Liu, T.; Liu, W.; Zeng, T.; Qi, L.; Zhao, W.; Cheng, Y.; Zhang, D. Working principle and design of the multi-flexible fingered roller pineapple harvesting mechanism. Trans. Chin. Soc. Agric. Eng. 2022, 38, 21–26. [Google Scholar]

- Liu, T.; Cheng, Y.; Li, J.; Chen, S.; Lai, J.; Liu, Y.; Qi, L.; Yang, X. Feeding-type harvesting mechanism with the rotational lever for pineapple fruit. Trans. Chin. Soc. Agric. Eng. 2023, 39, 27–38. [Google Scholar]

- Wang, H.; Chen, Z.; Zhang, X.; Sun, H.; Zou, H.; Yu, Z.; Wang, C.; Li, H. Design and Experimental Study of Differential Speed Comb Type Pineapple Harvesting Machine. J. Agric. Mech. Res. 2024, 46, 115–120+127. [Google Scholar] [CrossRef]

- Fu, M.; Li, C.; Zheng, Z. Design and analysis of semi-automatic screw type pineapple picking-collecting machine. Chin. J. Eng. Des. 2020, 27, 487–497. [Google Scholar]

- Zulkifli, N.; Hashim, N.; Harith, H.; Mohamad Shukery, M.F. Finite element modelling for Fruit Stress Analysis—A Review. Trends Food Sci. Technol. 2019, 97, 29–37. [Google Scholar] [CrossRef]

- Li, M.; He, L.; Yue, D.; Wang, B.; Li, J. Fracture mechanism and separation conditions of pineapple fruit-stem and calibration of physical characteristic parameters. Int. J. Agric. Biol. Eng. 2023, 16, 248–259. [Google Scholar] [CrossRef]

- Xue, Z.; Zhang, X.; Chen, R. Experimental Study on Morphology and Mechanical Properties of Pineapple. J. Agric. Mech. Res. 2024, 46, 170–174. [Google Scholar] [CrossRef]

- Carter, J.; Hoffman, J.; Fjeldsted, B.; Ogilvie, G.; Cook, D.D. Measurement of maize stalk shear moduli. Plant Methods 2024, 20, 152. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Jiang, F.; Zhang, J.; Zhang, H.; Wang, X.; Yang, Z. Twelve Elastic Constant Values of Larch Forest. J. Northwest For. Univ. 2015, 30, 227–231. [Google Scholar]

- Li, J.; He, P.; Wang, Y.; Zhang, D.; Zheng, W.; He, J. Determination of Mechanical Property of Goldenpassion Fruit Vine. J. Agric. Mech. Res. 2023, 45, 181–190. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, B.; Li, X.; Sheng, C.; Tian, K.; Huang, J. Experimental Study on Mechanical Properties of Fresh Corn Straw. J. Agric. Mech. Res. 2018, 40, 171–175+180. [Google Scholar] [CrossRef]

- Al-Zube, L.; Sun, W.; Robertson, D.; Cook, D. The elastic modulus for maize stems. Plant Methods 2018, 14, 11. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Luo, G.; Ehsani, R.; Toudeshki, A.; Zou, X.; Wang, H. Simulation study on the effects of tine-shaking frequency and penetrating depth on fruit detachment for citrus canopy-shaker harvesting. Comput. Electron. Agric. 2018, 148, 54–62. [Google Scholar] [CrossRef]

- Shi, N. Peeling Method of Cotton Stalk and Development of Rubbing Peeling Machine. Ph.D. Thesis, Northwest A & F University, Xianyang, China, 2018. [Google Scholar]

- Hu, G. Key Technology of Apple Harvest Using Combing Brushing. Master’s Thesis, Northwest A & F University, Xianyang, China, 2020. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, P.; Jiao, H.; Wang, P.; Wang, L.; Li, C.; Qi, N. Construction of constitutive model and parameter determination of green Sichuan Pepper (Zanthoxylum armatum) branches. Biosyst. Eng. 2023, 227, 147–160. [Google Scholar] [CrossRef]

- Ji, W.; Qian, Z.; Xu, B.; Chen, G.; Zhao, D. Apple Viscoelastic Complex Model for bruise damage analysis in constant velocity grasping by Gripper. Comput. Electron. Agric. 2019, 162, 907–920. [Google Scholar] [CrossRef]

- Li, Z.; Li, P.; Yang, H.; Liu, J. Internal mechanical damage prediction in tomato compression using multiscale finite element models. J. Food Eng. 2013, 116, 639–647. [Google Scholar] [CrossRef]

- Yousefi, S.; Farsi, H.; Kheiralipour, K. Drop test of Pear Fruit: Experimental measurement and finite element modelling. Biosyst. Eng. 2016, 147, 17–25. [Google Scholar] [CrossRef]

- Bu, L.; Chen, C.; Hu, G.; Zhou, J.; Sugirbay, A.; Chen, J. Investigating the dynamic behavior of an Apple branch-stem-fruit model using experimental and simulation analysis. Comput. Electron. Agric. 2021, 186, 106–224. [Google Scholar] [CrossRef]

- Sheng, C.; Li, X.; Tian, K.; Zhang, B.; Huang, J.; Chen, Q. Experimental analysis on mechanical model of ramie stalk. Trans. Chin. Soc. Agric. Eng. 2015, 31, 26–33. [Google Scholar]

- Malachanne, E.; Jebli, M.; Jamin, F.; Garcia-Diaz, E.; El Youssoufi, M.-S. A cohesive zone model for the characterization of adhesion between cement paste and aggregates. Constr. Build. Mater. 2018, 193, 64–71. [Google Scholar] [CrossRef]

- She, Y.; Dai, Y.; Zhang, L.; Li, L. Construction and verification of parameters based on wire rope cohesion model. Coal Eng. 2024, 56, 172–178. [Google Scholar]

- Ezzine, M.C.; Amiri, A.; Tarfaoui, M. Experimental and numerical investigation of the fracture behavior of adhesive shear tests single lap joints. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 382. [Google Scholar] [CrossRef]

- Turon, A.; Dávila, C.G.; Camanho, P.P.; Costa, J. An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models. Eng. Fract. Mech. 2007, 74, 1665–1682. [Google Scholar] [CrossRef]

| Number | Stem Diameter (mm) | Stem Length (mm) | Fruit Diameter (mm) | Fruit Length (mm) | Maximum Load Force (N) | Maximum Load Displacement (mm) |

|---|---|---|---|---|---|---|

| 1 | 21.9 | 110 | 99.1 | 162 | 27.54 | 28.27 |

| 2 | 27.4 | 100 | 96.8 | 160 | 29.59 | 29.37 |

| 3 | 22.6 | 125 | 94.6 | 170 | 22.25 | 29.76 |

| 4 | 23.8 | 120 | 102.5 | 173 | 24.09 | 29.74 |

| 5 | 24.3 | 130 | 106.5 | 181 | 23.77 | 29.05 |

| 6 | 26 | 116 | 101.9 | 179 | 27.88 | 27.64 |

| 7 | 23.6 | 113 | 97.6 | 168 | 24.61 | 27.54 |

| 8 | 27.4 | 125 | 103.5 | 177 | 26.85 | 28.1 |

| 9 | 23.6 | 123 | 94.8 | 174 | 28.22 | 29.36 |

| 10 | 26.9 | 120 | 99.1 | 164 | 32.24 | 25.55 |

| Component | Elastic Modulus (MPa) | Shear Modulus (MPa) | Poisson’s Ratio | Density (kg·m−3) | Fruit Length (mm) | Fruit Diameter (mm) |

|---|---|---|---|---|---|---|

| Fruit | 2.45 | 0.94 | 0.3 | 950.5 | 180 | 100 |

| Component | Interface Stiffness Kt (N·mm−3) | Maximum Traction Stress Strength (MPa) | Maximum Displacement (mm) |

|---|---|---|---|

| Brittle separation layer | 10,000 | 1.809 | 2.208 |

| Component | Stem-Xylem | Stem-Phloem |

|---|---|---|

| Anisotropic surface shear modulus Gr (MPa) | 5.706 | 6.02 |

| Isotropic surface shear modulus Gxy (MPa) | 1.103 | 1.111 |

| Radial elastic modulus Er (MPa) | 2.867 | 2.889 |

| Axial elastic modulus Ez (MPa) | 8.764 | 15.594 |

| Anisotropic surface Poisson’s ratio r | 0.4 | 0.2 |

| Isotropic surface Poisson’s ratio xy | 0.3 | 0.3 |

| Density (kg·m−3) | 313.4 | 313.4 |

| Diameter/thickness (mm) | 22.2 | 0.5 |

| Length (mm) | 120 | 120 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, D.; He, F.; Zhang, Q.; Deng, G.; Li, G.; Cui, Z.; Chen, P.; Li, J. Experiment and Calibration of Finite Element Parameters of Pineapple Based on Cohesive Zone Model. Agriculture 2025, 15, 2422. https://doi.org/10.3390/agriculture15232422

Pan D, He F, Zhang Q, Deng G, Li G, Cui Z, Chen P, Li J. Experiment and Calibration of Finite Element Parameters of Pineapple Based on Cohesive Zone Model. Agriculture. 2025; 15(23):2422. https://doi.org/10.3390/agriculture15232422

Chicago/Turabian StylePan, Dexuan, Fengguang He, Qin Zhang, Ganran Deng, Guojie Li, Zhende Cui, Pinlan Chen, and Jiehao Li. 2025. "Experiment and Calibration of Finite Element Parameters of Pineapple Based on Cohesive Zone Model" Agriculture 15, no. 23: 2422. https://doi.org/10.3390/agriculture15232422

APA StylePan, D., He, F., Zhang, Q., Deng, G., Li, G., Cui, Z., Chen, P., & Li, J. (2025). Experiment and Calibration of Finite Element Parameters of Pineapple Based on Cohesive Zone Model. Agriculture, 15(23), 2422. https://doi.org/10.3390/agriculture15232422