1. Introduction

Wet clutches are key components in the transmission systems of heavy-duty tractors, responsible for power transmission and smooth shifting [

1]. Their core elements, the wet clutch friction pairs, endure high loads, significant relative velocities, and intense thermal shock during frequent engagement and disengagement cycles [

2]. The tribological characteristics of these pairs are paramount, as they directly govern the clutch’s torque capacity, operational lifespan, and the reliability of the entire machine [

3].

Researchers have carried out numerous studies on clearance lubrication and friction characteristics to cope with the complex mechanical and thermal loads that wet clutch friction pairs encounter during operation. For example, Zhang et al. [

4] employed a modified Reynolds equation with an elastic contact model to numerically simulate how material parameters affect the thermal characteristics of the friction pair and ATF during engagement. Regarding surface structures, Jang et al. [

5] built a mathematical model of the heat generation and transfer process to investigate the influence of various groove patterns and their structural parameters on the clutch’s thermal behavior. Kong et al. [

6] analyzed convective cooling and temperature distribution for waffle and radial-arc groove designs using a CFD–thermal coupled analysis. Furthermore, Xie et al. [

7] modeled the oil film flow field considering the friction plate grooves to numerically determine their impact on oil film velocity and pressure. Zhou et al. [

8] proposed a semi-Y labyrinth seal (SYLS) to reduce leakage and enhance the stability of centrifugal pump. Compared to the traditional interlocking labyrinth seal (ILS) structure, the leakage of the SYLS was reduced significantly. Yang et al. [

9] used a model based on the Reynolds equation, average flow model, and Greenwood model and friction test based on SAE#2 testing machine to study the COF of different groove types. The results showed that waffling groove or double arc groove are suitable for the friction plate of the wet clutch. This body of work highlights the positive effect of optimizing friction parameters to improve clutch performance. Indeed, optimizing the design of the wet clutch friction pair to achieve a stable COF while managing frictional heat is crucial for ensuring stable torque transmission and minimizing thermal damage [

1]. While these studies mainly focused on designing macroscopic grooves on the friction pair, the impact of surface micro-texture is equally significant.

Surface micro-texturing technology, which involves fabricating micro-scale dimples or grooves with specific geometries on a frictional surface, has been proven to be an effective way to improve tribological performance [

10]. Fesanghary et al. [

11] used mathematical optimization methods to obtain the optimum periodic surface grooves (elongated “heart-like” shape for small aspect ratios, and spiral shape for high aspect ratios) with the highest load-carrying capacity (LCC) in parallel flat surface bearings. Agrawal et al. [

12] deals with the performance of micro-grooved hole-entry hybrid spherical thrust bearing (HSTB) considering Non-Newtonian behavior of the lubricant. The result showed that the performance of the hole-entry hybrid spherical thrust bearing was enhanced by the micro-grooves and was affected by the geometry of the micro-groove. Through a series of pioneering studies, Etsion proved that Laser Surface Texturing (LST) technology can significantly improve the performance of mechanical seals [

13], journal bearings [

14], piston rings [

15,

16], and cylinder liners [

17].

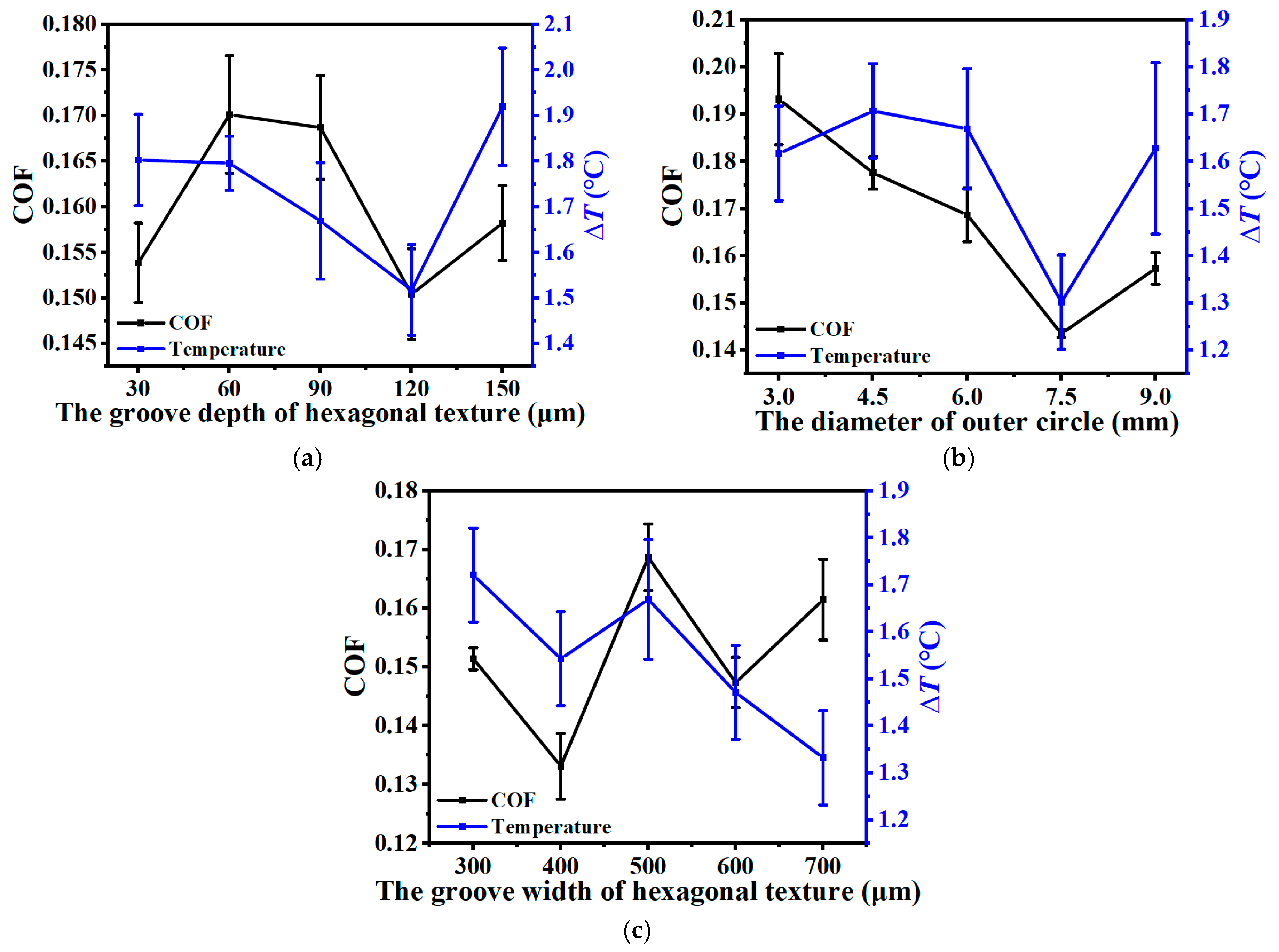

However, surface micro-textures come in various forms, and determining the appropriate micro-texture pattern and optimizing its structural parameters is key to enhancing the overall performance of the friction pair. Chen et al. [

18] studied the influence of the structural parameters of hexagonal grooves on the wet friction characteristics on glass and compared them with square, rhombic, and triangular patterns, demonstrating the high-friction advantage of the hexagonal structure. Iturri et al. [

19] prepared hexagonal specimens from PDMS material with different aspect ratios and found that, compared to untextured specimens, the hexagonal specimens showed significantly improved tribological performance on both wetted and non-wetted surfaces. Liu et al. [

20] introduced hexagonal micro-textures to the friction pair formed between the stator and rotor of a screw pump, which enhanced the oil film load-carrying capacity of the friction pair.

The research above indicates that introducing hexagonal textures on a wet friction surface can improve its tribological performance. However, exploring the coupled effects of micro-texture geometric parameters and operating conditions on friction performance is a complex, multi-variable, and non-linear problem. Traditional numerical and experimental methods are often limited to specific conditions and cannot capture the full complexity of these interactions [

21,

22]. Here, the rise of data-driven methods, particularly machine learning, offers a powerful alternative [

23]. By creating data-driven surrogate models, researchers have successfully predicted complex frictional behaviors in cam-followers [

24], calibrated dynamic models of piezoelectric drives [

25], and improved torque simulation accuracy in wet clutches [

26]. Such approaches enable the efficient prediction of system performance across a wide range of parameter combinations [

27].

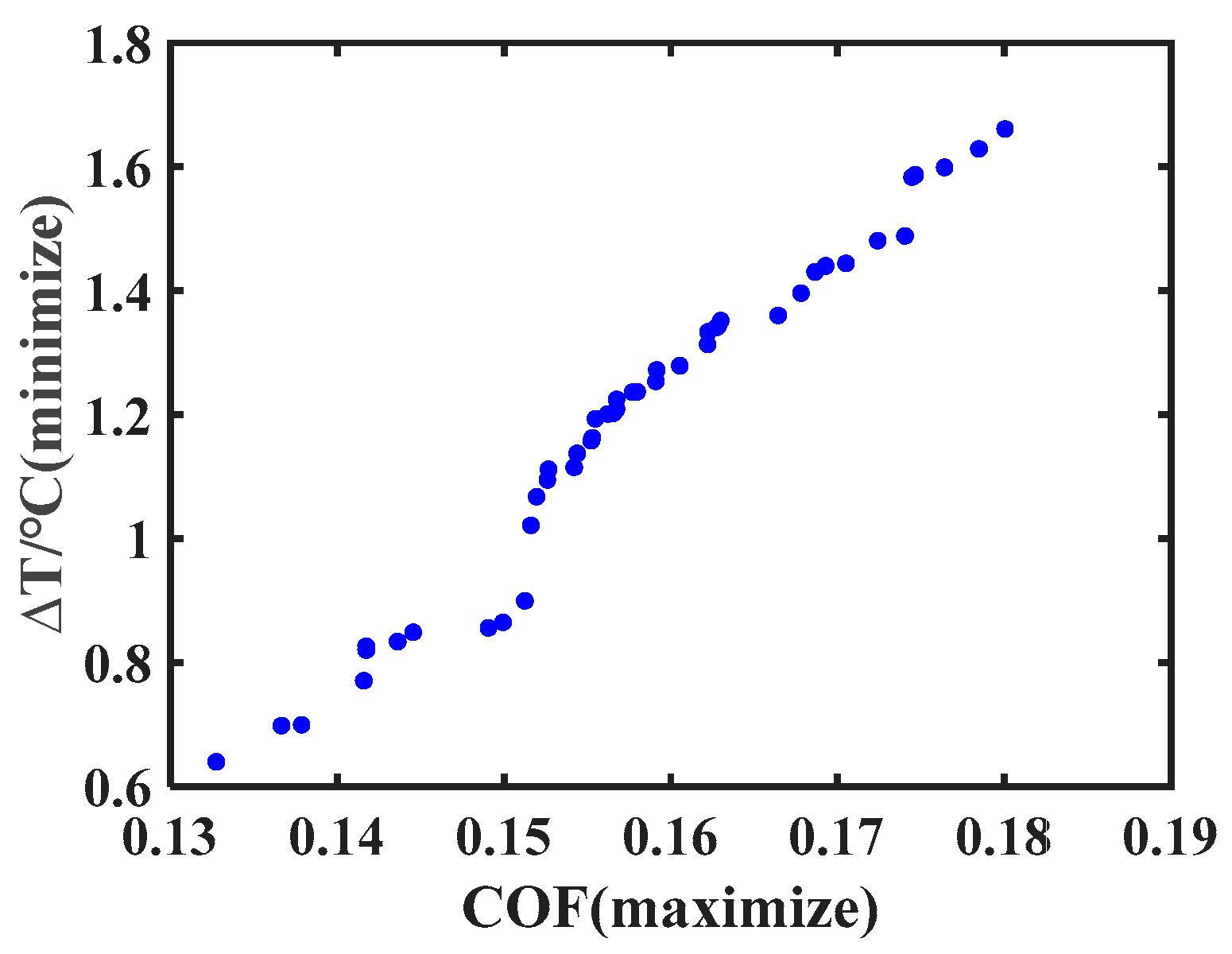

Simultaneously, to ensure the wet clutch can transmit stable torque with minimal thermal damage, the parameter optimization of the friction pair requires a trade-off between the conflicting objectives of coefficient of friction (COF) and temperature rise (

). This is a classic Multi-Objective Optimization (MOP) problem [

28]. While various evolutionary algorithms, such as the NSGA-II, are applied to such engineering trade-offs [

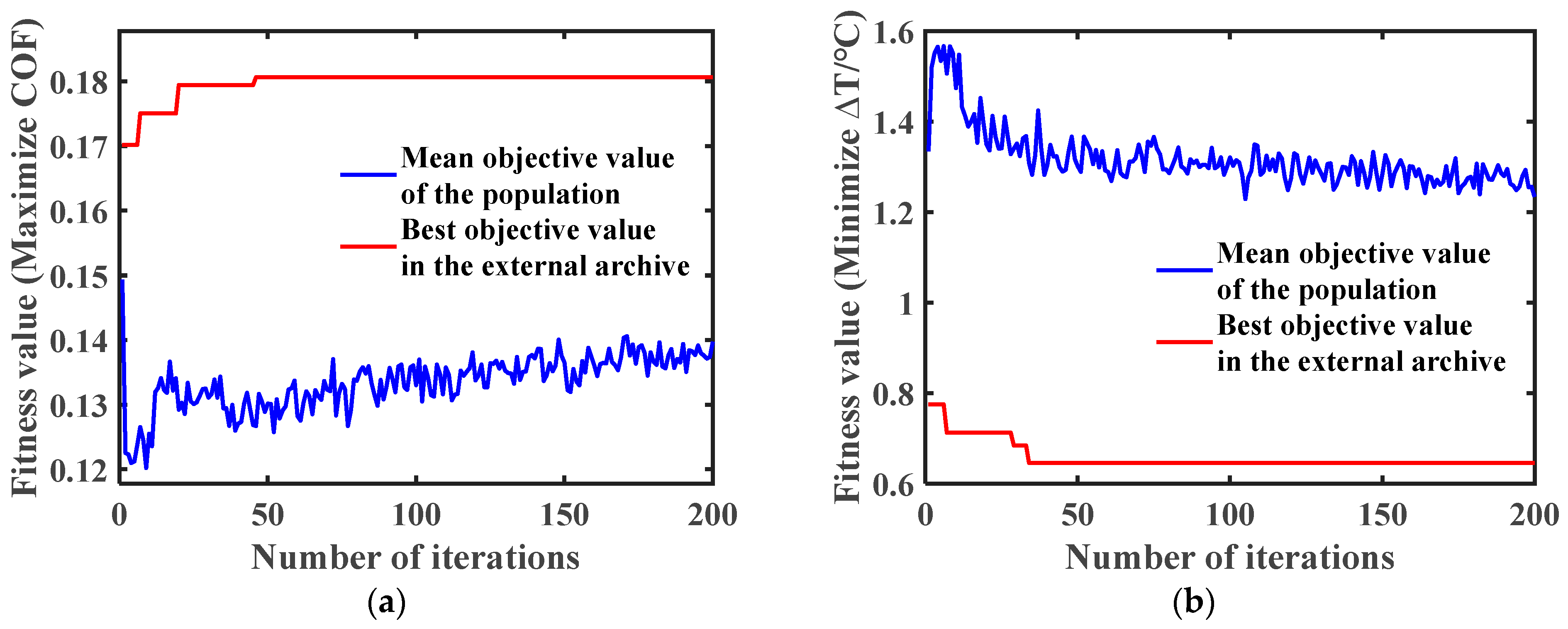

29], the swarm intelligence-based Multi-Objective Particle Swarm Optimization (MOPSO) algorithm was selected for this study due to its distinct advantages [

30,

31,

32]. Compared to other methods, MOPSO generally exhibits faster convergence [

33]—a critical feature when integrated with the GPR surrogate model used in this work. Furthermore, by effectively balancing global search (Exploration) and local refinement (Exploitation), MOPSO efficiently navigates complex, high-dimensional search spaces and avoids being trapped in local optima [

34]. These characteristics make it an ideal fit for this complex, data-driven tribological optimization that involves exploring the coupled effects of multiple variables.

However, previous research has typically optimized structural parameters for a single, fixed operating condition. In recent years, several studies have begun to recognize the necessity of incorporating operating conditions into the decision space. For example, Kong et al. [

35] explicitly examined the influence of rotational speed, clearance, and eccentricity on the optimal texture design in the topology optimization of textured journal bearings. Similarly, Zhang et al. [

36] compared optimal groove distributions under different speeds and eccentricities. These results collectively highlight the strong coupling between geometry and operating conditions; nevertheless, most of these efforts still adopt a “scenario-by-scenario” analysis rather than a unified optimization. This approach is insufficient for applications like heavy-duty power-shift tractors, where different wet clutches encounter variable sliding conditions. An optimization design that neglects operating parameters fails to achieve optimal tribological performance for the wet clutch friction pair under specific working conditions. To overcome this limitation, it is necessary to include both structural and operating parameters as decision variables in a synchronous optimization. Hingawe et al. [

37] proposed a multi-objective framework for a square-textured parallel slider, in which sliding velocity was introduced together with texture density and aspect ratio, yielding a Pareto front between load-carrying capacity enhancement and friction reduction based on response surface methodology and gray relational analysis. Abbas and Metwalli [

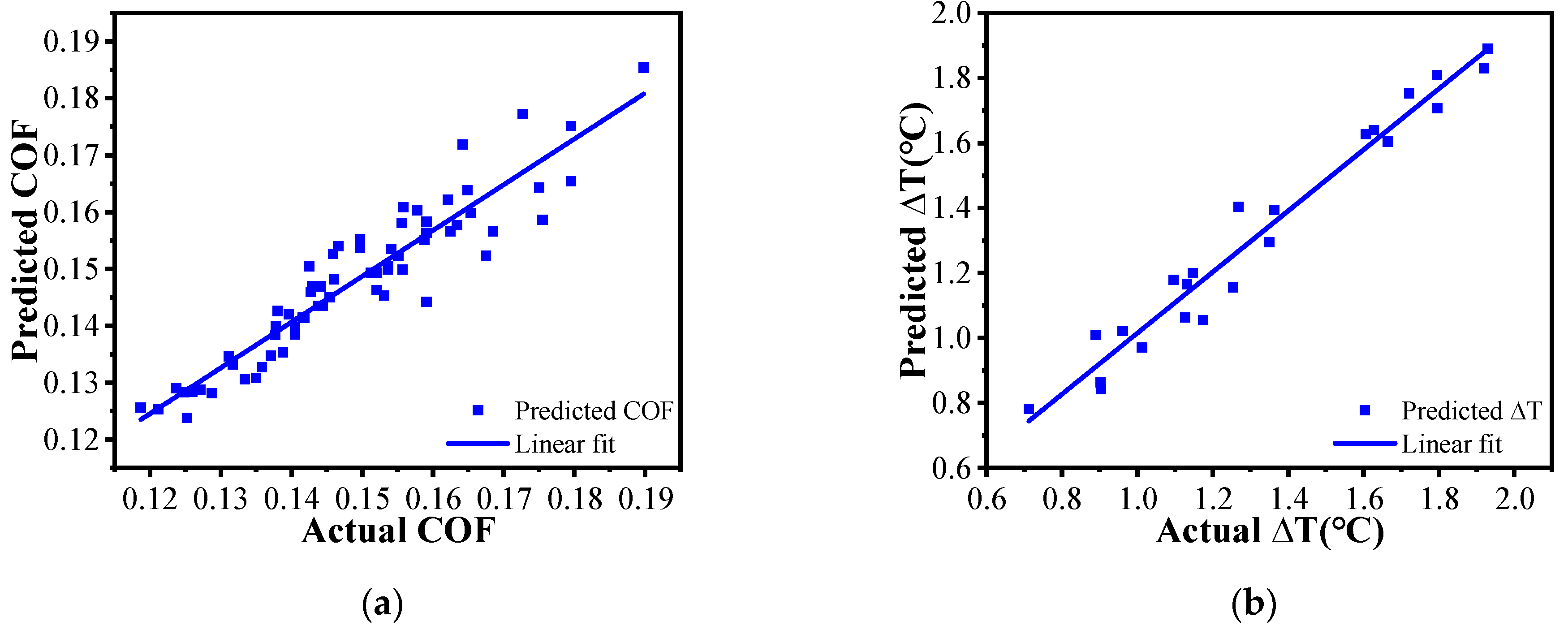

38] extended this idea to rolling element bearings under elastohydrodynamic lubrication (EHL) by formulating a joint decision space of geometry and operating conditions, and used a hybrid NSGA-II with supervised machine learning to obtain a Pareto front validated by industrial case studies. Collectively, these studies confirm that integrating both structural and operating parameters can generate more comprehensive Pareto fronts and improve the reliability of optimization outcomes. However, in the field of wet clutch friction pairs, such unified optimization has rarely been reported. GPR provides a high-precision surrogate model capable of capturing complex non-linear relations from limited experimental data [

39], while MOPSO is known for its faster convergence and efficiency in high-dimensional spaces. By integrating these two methods, the present study addresses the above limitation and establishes a framework for synchronously optimizing micro-texture geometry and operating parameters of wet clutch friction pairs.

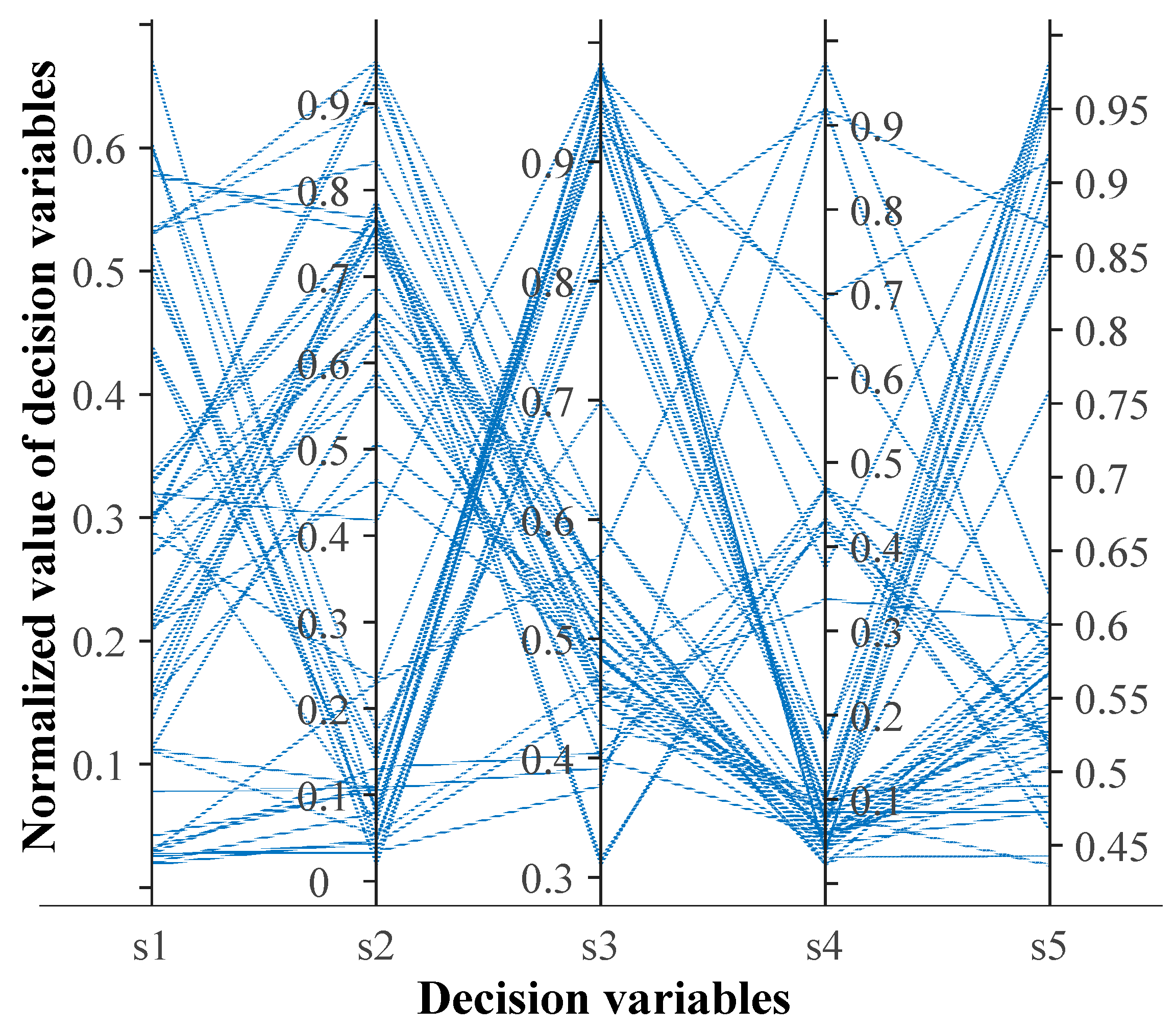

This paper proposes to simulate the friction experiments of wet clutch friction pairs using pin-on-disk tests and to incorporate operating parameters themselves as decision variables into a multi-objective optimization model. The objective is no longer to find a single optimal solution, but rather to provide optimal design schemes for the surface micro-texture geometric parameters of wet clutch friction pairs under different sliding friction states. This approach proposes an integrated framework that combines experimental data, machine learning, and multi-objective optimization. Firstly, a high-precision surrogate model is constructed from the experimental data using Gaussian Process Regression (GPR). Subsequently, the Multi-Objective Particle Swarm Optimization (MOPSO) algorithm is employed to obtain the optimal solution set based on the GPR model. Finally, this yields representative optimal solutions for the micro-textures of clutch friction pairs under two different sliding friction states. This study provides a new method for enhancing the tribological performance and reducing the damage of the wet clutch friction pairs in heavy-duty power-shift tractors.