The Intelligentization Process of Agricultural Greenhouse: A Review of Control Strategies and Modeling Techniques

Abstract

1. Introduction

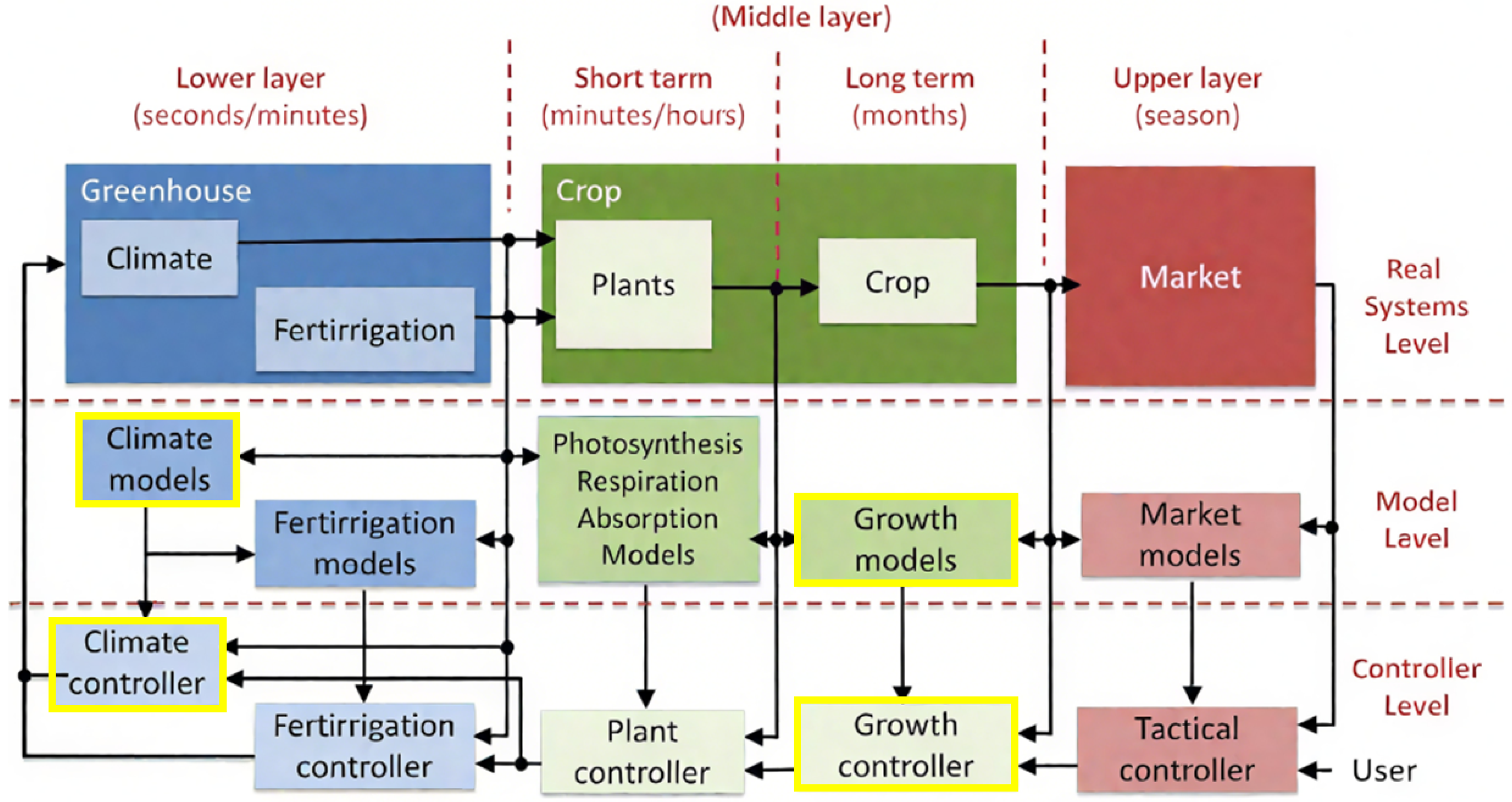

2. Control Techniques in Agricultural Greenhouse Systems

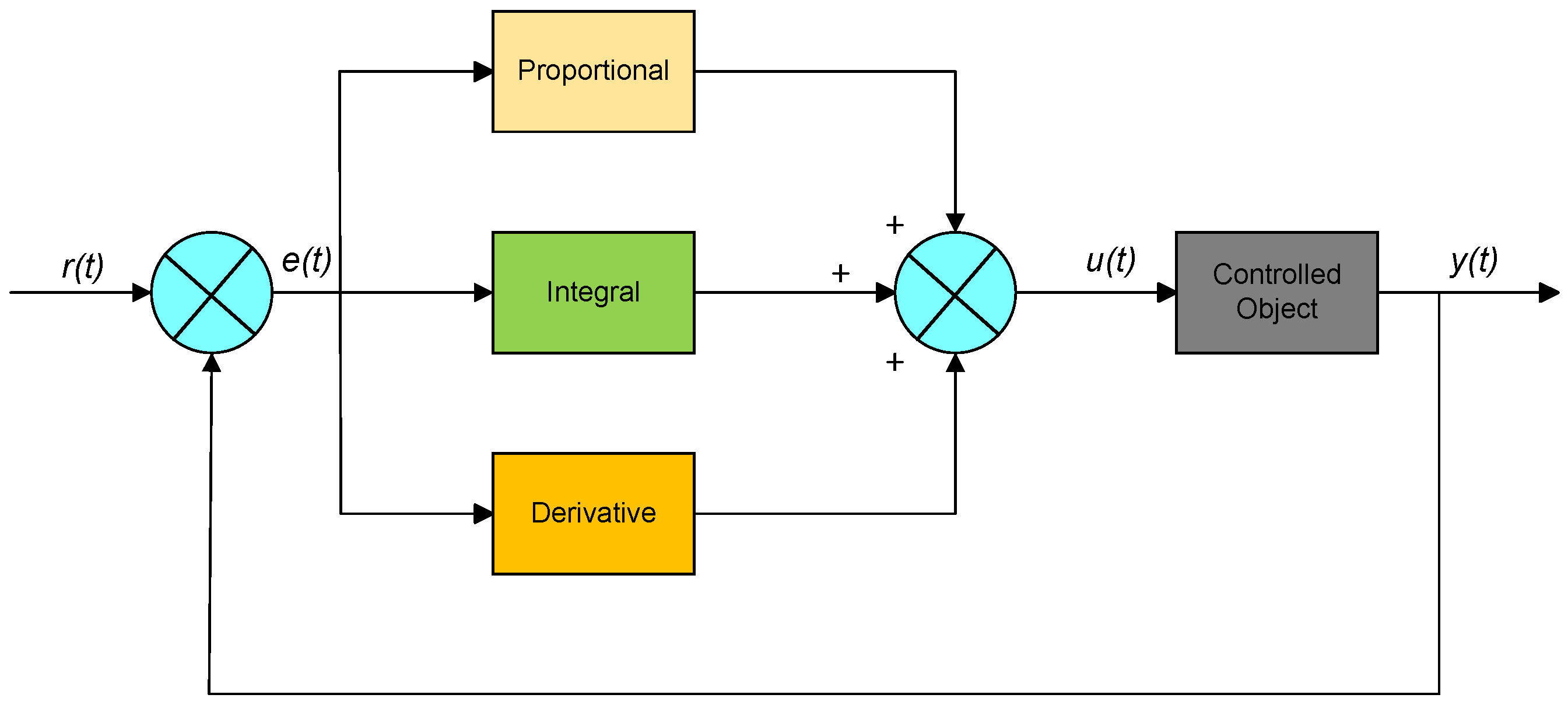

2.1. Conventional Control Techniques

2.1.1. PID Control

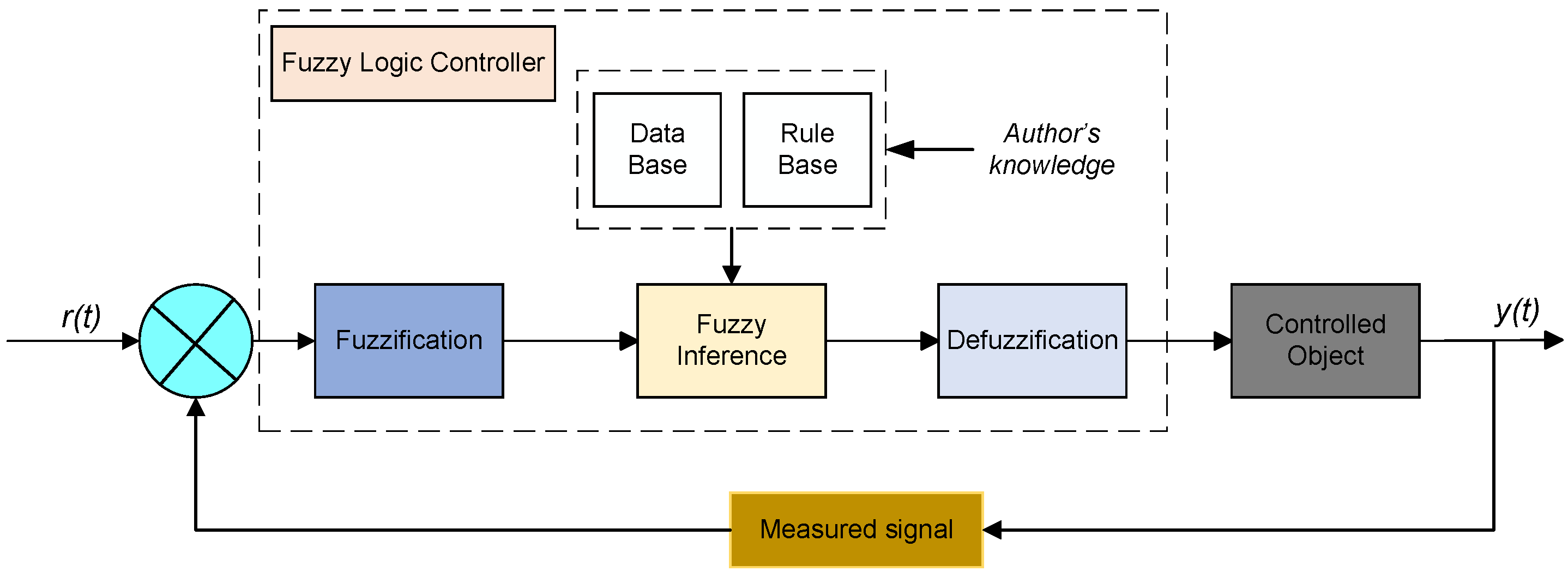

2.1.2. Fuzzy Control

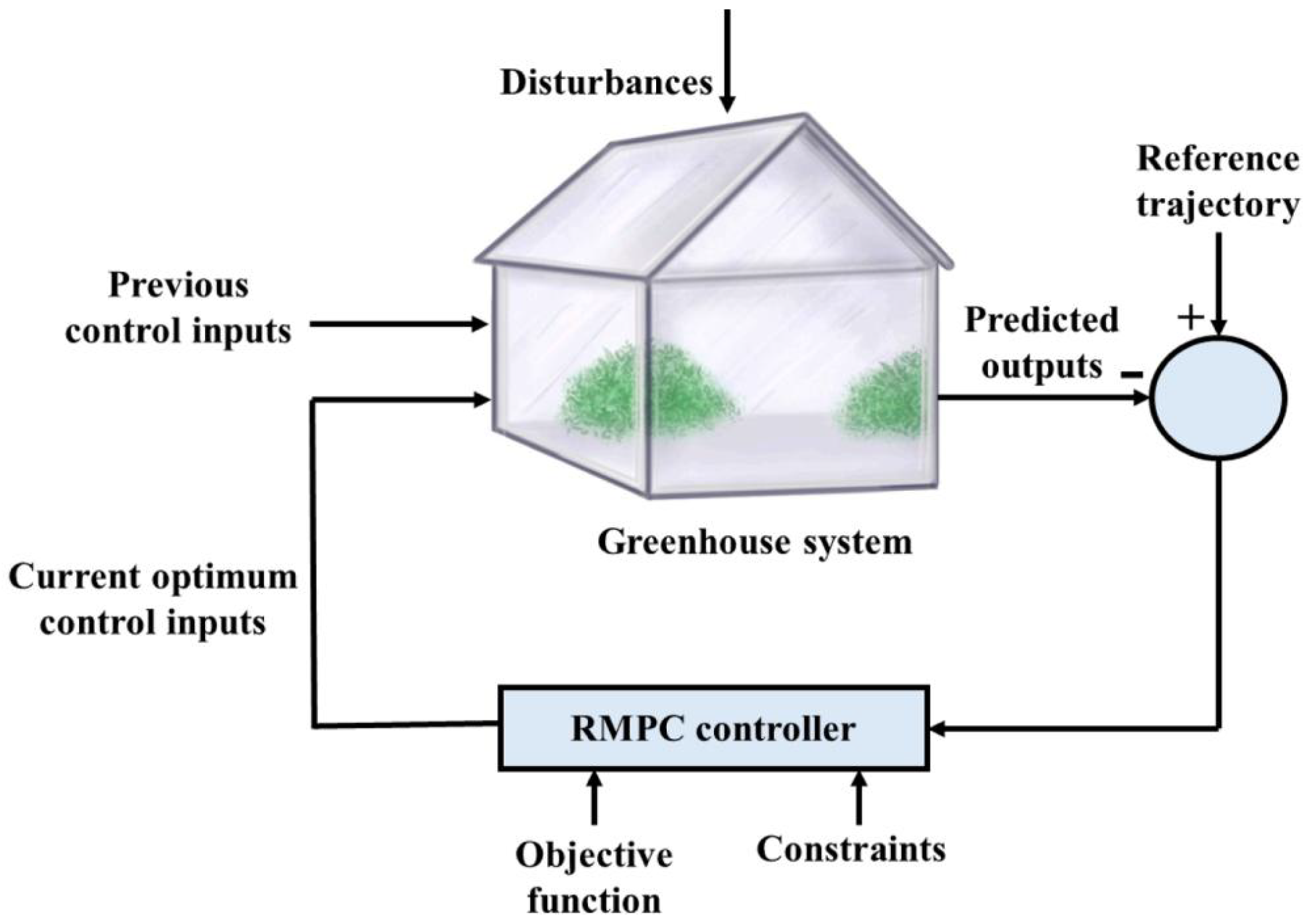

2.1.3. Model Predictive Control

2.2. Intelligent Control Technology

2.2.1. Neural Networks-Based Control

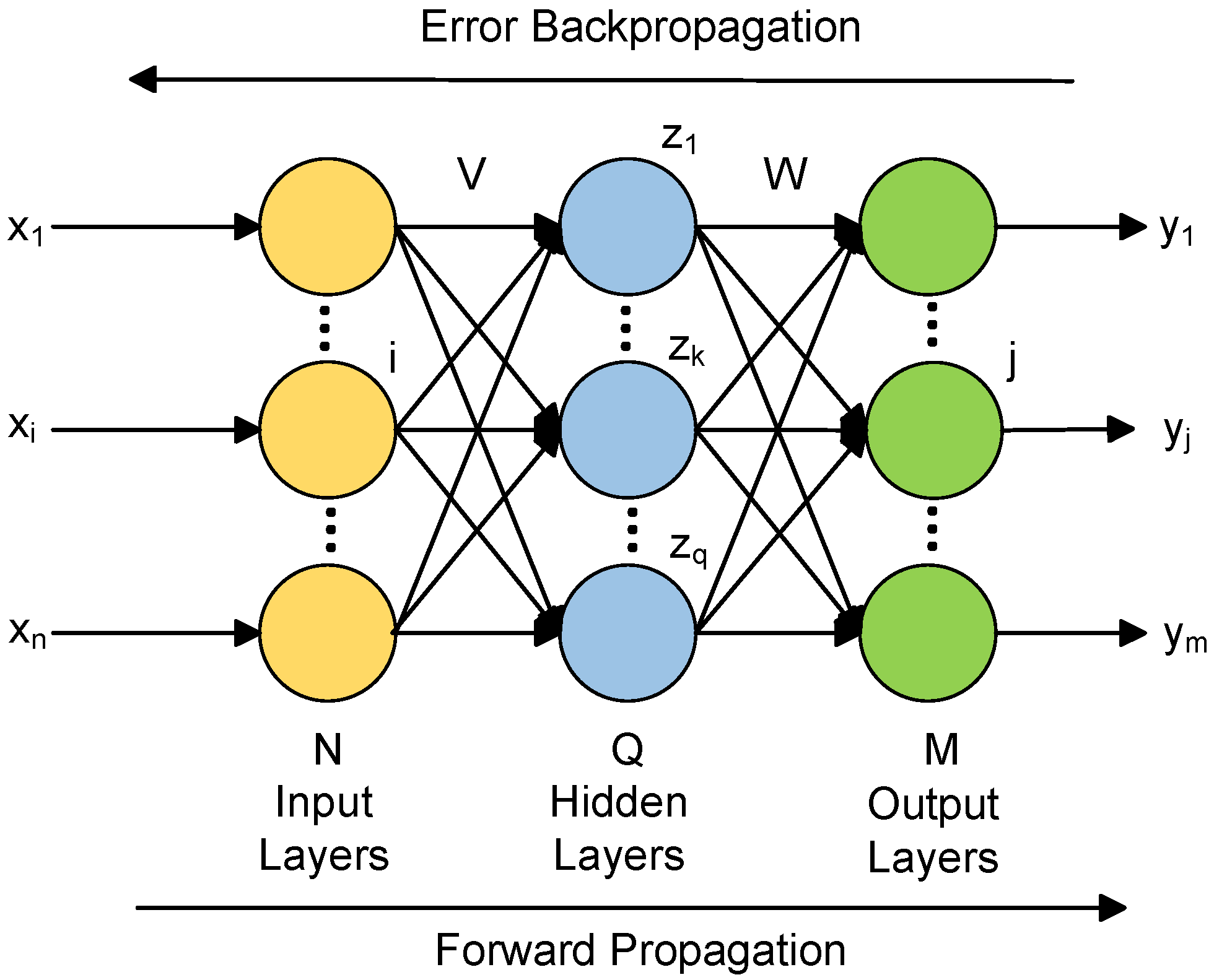

- (1)

- Back Propagation (BP) neural networks

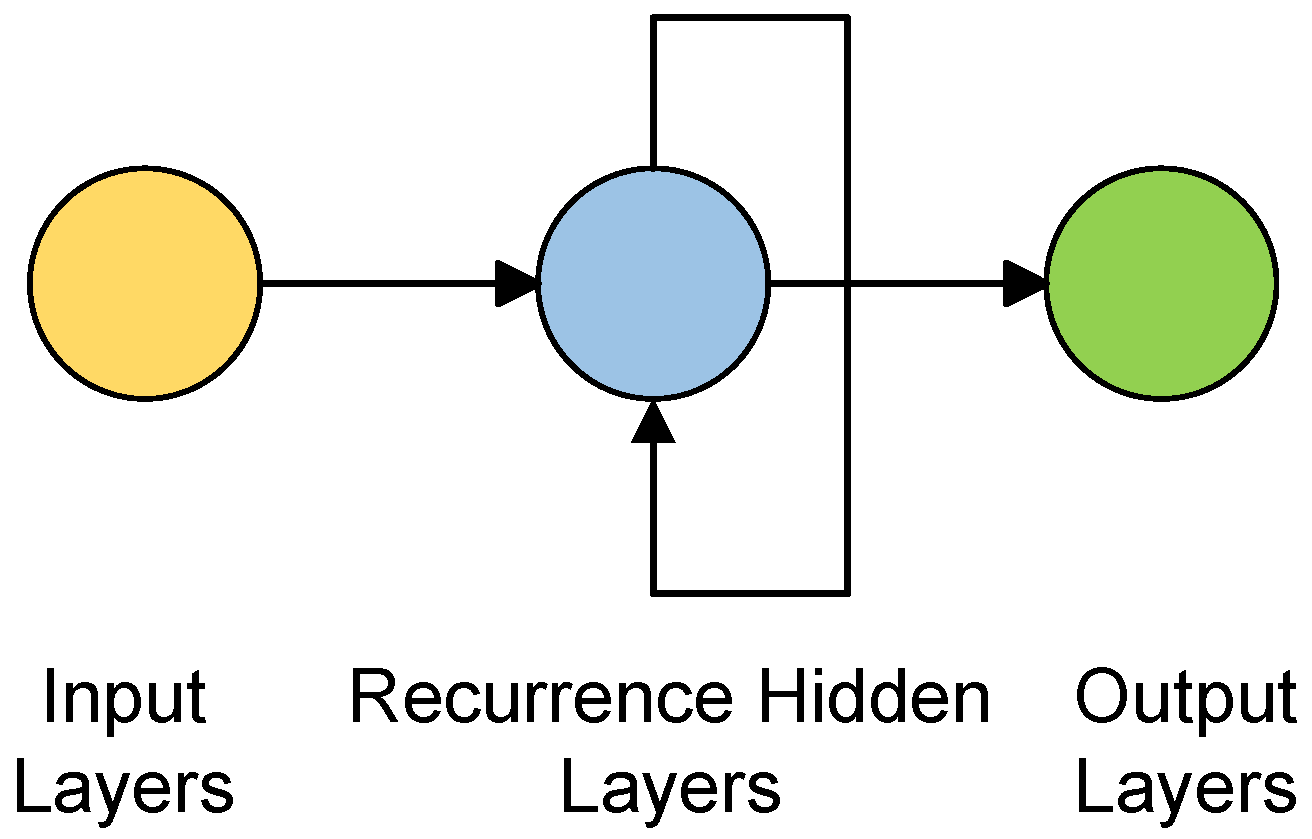

- (2)

- Recurrent neural networks (RNN)

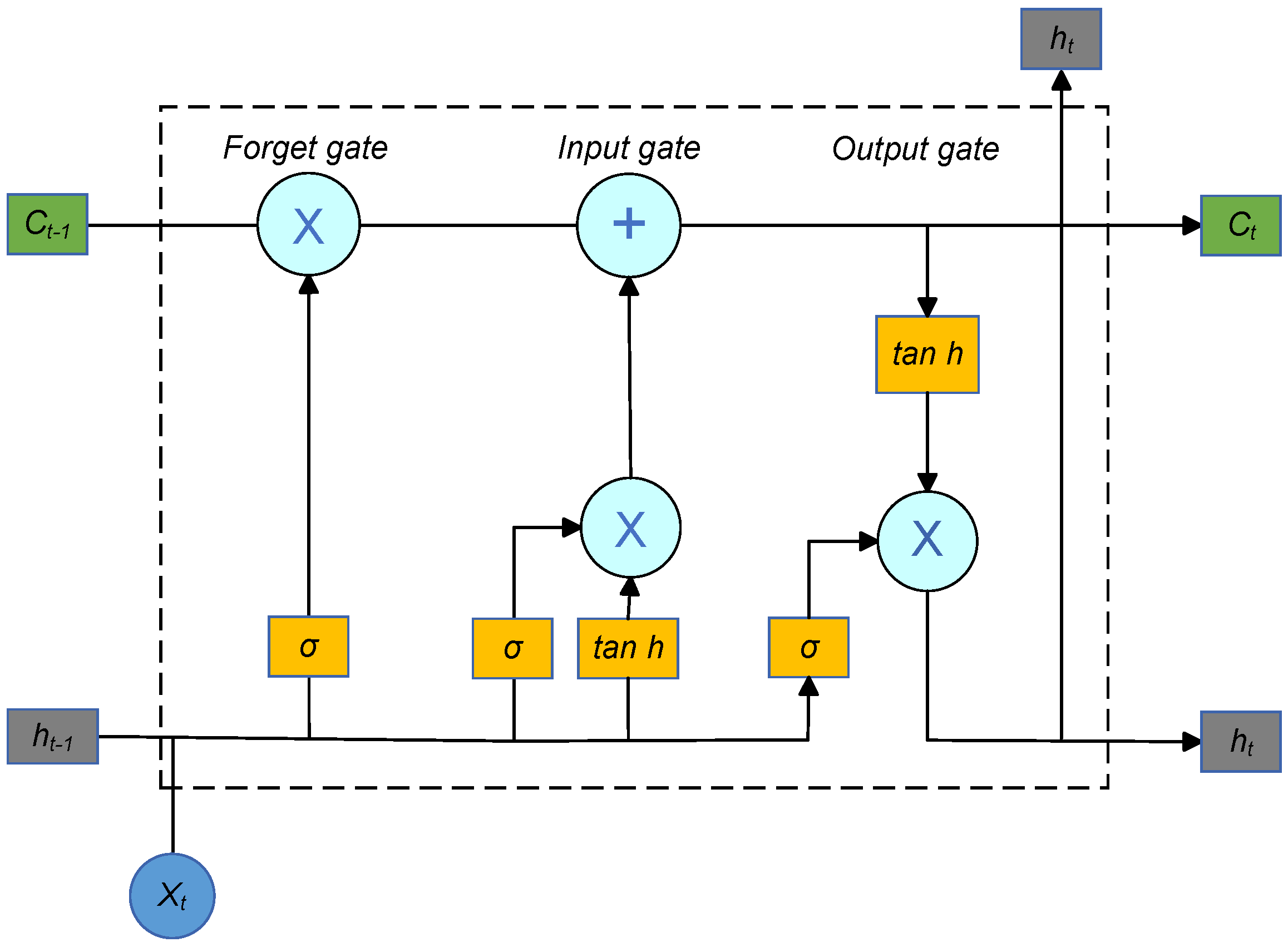

- (3)

- Long short-term memory (LSTM) neural networks

2.2.2. Adaptive Control

2.2.3. Feedback Linearization Control

2.2.4. Event-Based Control

2.2.5. RL-Based Control

3. Intelligent Techniques in Greenhouse System Modeling

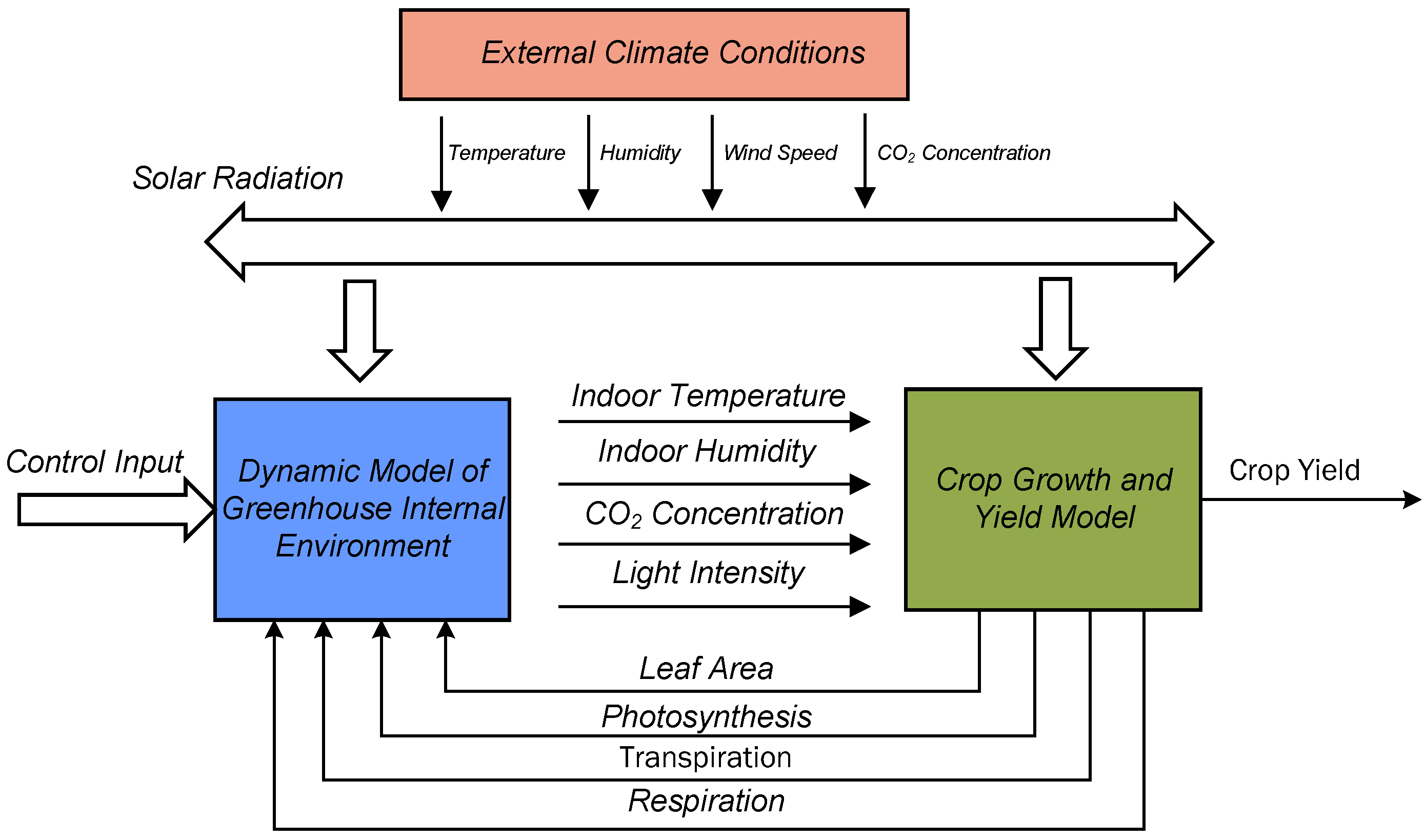

3.1. Greenhouse Environmental Model

3.1.1. Mechanistic Model

3.1.2. CFD Simulation

3.1.3. Data Driven Modeling

3.2. Crop Growth Model

4. Discussion

5. Future Challenges and Development Trends

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maraveas, C. Incorporating artificial intelligence technology in smart greenhouses: Current State of the Art. Appl. Sci. 2022, 13, 14. [Google Scholar] [CrossRef]

- Zhang, M.; Yan, T.; Wang, W.; Jia, X.; Wang, J.; Klemeš, J.J. Energy-saving design and control strategy towards modern sustainable greenhouse: A review. Renew. Sustain. Energy Rev. 2022, 164, 112602. [Google Scholar] [CrossRef]

- ouaham, W.E.; Mouzouna, Y.; Sadik, M. A Literature Review on Smart Greenhouse and AI: Paradigms, Opportunities and Open Issues. In Proceedings of the International Symposium on Ubiquitous Networking, Clermont-Ferrand, France, 1–3 November 2023; Springer: Berlin/Heidelberg, Germany, 2023; pp. 160–173. [Google Scholar] [CrossRef]

- Kaur, A.; Sonawane, V.; Rosha, P. Energy efficiency optimization strategies for greenhouse-based crop cultivation: A review. Can. J. Chem. Eng. 2024, 102, 1051–1065. [Google Scholar] [CrossRef]

- Liu, G.; Zhong, K.; Li, H.; Chen, T.; Wang, Y. A state of art review on time series forecasting with machine learning for environmental parameters in agricultural greenhouses. Inf. Process. Agric. 2024, 11, 143–162. [Google Scholar] [CrossRef]

- Chen, S.; Liu, A.; Tang, F.; Hou, P.; Lu, Y.; Yuan, P. A Review of Environmental Control Strategies and Models for Modern Agricultural Greenhouses. Sensors 2025, 25, 1388. [Google Scholar] [CrossRef]

- Wang, H.; Guo, H.; He, Q.; Pei, Y.; Li, T.; Wang, M. Current Status and Future Perspectives on Greenhouse Environment Control Methods. Agric. Eng. 2025, 15, 45–53. [Google Scholar] [CrossRef]

- Acquah, S.J.; Yan, H.; Zhang, C.; Wang, G.; Zhao, B.; Wu, H.; Zhang, H. Application and evaluation of Stanghellini model in the determination of crop evapotranspiration in a naturally ventilated greenhouse. Int. J. Agric. Biol. Eng. 2018, 11, 95–103. [Google Scholar] [CrossRef]

- Han, L.; Mao, H.; Kumi, F.; Hu, J. Development of a multi-task robotic transplanting workcell for greenhouse seedlings. Appl. Eng. Agric. 2018, 34, 335–342. [Google Scholar] [CrossRef]

- Yan, T.; Zhu, H.; Sun, L.; Wang, X.; Ling, P. Investigation of an experimental laser sensor-guided spray control system for greenhouse variable-rate applications. Trans. ASABE 2019, 62, 899–911. [Google Scholar] [CrossRef]

- Huang, S.; Yan, H.; Zhang, C.; Wang, G.; Acquah, S.J.; Yu, J.; Li, L.; Ma, J.; Darko, R.O. Modeling evapotranspiration for cucumber plants based on the Shuttleworth-Wallace model in a Venlo-type greenhouse. Agric. Water Manag. 2020, 228, 105861. [Google Scholar] [CrossRef]

- Yan, H.; Acquah, S.J.; Zhang, J.; Wang, G.; Zhang, C.; Darko, R.O. Overview of modelling techniques for greenhouse microclimate environment and evapotranspiration. Int. J. Agric. Biol. Eng. 2021, 14, 1–8. [Google Scholar] [CrossRef]

- Rodríguez, F.; Berenguel, M.; Guzmán, J.L.; Ramírez-Arias, A. Modeling and Control of Greenhouse Crop Growth; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Taha, M.F.; Mao, H.; Zhang, Z.; Elmasry, G.; Awad, M.A.; Abdalla, A.; Mousa, S.; Elwakeel, A.E.; Elsherbiny, O. Emerging Technologies for Precision Crop Management towards Agriculture 5.0: A Comprehensive Overview. Agriculture 2025, 15, 582. [Google Scholar] [CrossRef]

- Minorsky, N. Directional stability of automatically steered bodies. J. Am. Soc. Nav. Eng. 1922, 34, 280–309. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, L.; Wang, R.; Xu, X.; Shen, Y.; Liu, Y. Modeling and test on height adjustment system of electrically-controlled air suspension for agricultural vehicles. Int. J. Agric. Biol. Eng. 2016, 9, 40–47. [Google Scholar] [CrossRef]

- Gao, L.; Dai, S.; Xu, X.; Zhou, J.; Li, M. Study on Coupled Temperature and Humidity Control Methods in Greenhouses. Res. Agric. Mech. 2021, 43, 24–30. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, G.; Zhong, G. Intelligent Control System for Temperature and Humidity in Greenhouse Based on PID Algorithm. Digit. Commun. World 2020, 1, 74–75. [Google Scholar]

- Hu, H.; Xu, L.; Wei, R.; Zhu, B. Multi-objective control optimization for greenhouse environment using evolutionary algorithms. Sensors 2011, 11, 5792–5807. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.; Yu, Q.; Zeng, L. Parameter self-tuning PID control for greenhouse climate control problem. IEEE Access 2020, 8, 186157–186171. [Google Scholar] [CrossRef]

- Berenguel, M.; Iborra, C.; Rodríguez, F.; García-Mañas, F.; Guzmán, J.L.; Sánchez-Molina, J.A. Nonlinear PID-based temperature control techniques in greenhouses using natural ventilation. IFAC-PapersOnLine 2024, 58, 454–459. [Google Scholar] [CrossRef]

- Zhang, W.; Tong, J.; Zhang, F.; Zhang, W.; Zhang, J.; Zhang, J.; Zhang, J.; Sun, H.; Northwood, D.O.; Waters, K.E.; et al. Integrated irrigation of water and fertilizer with superior self-correcting fuzzy PID control system. PLoS ONE 2025, 20, e0324448. [Google Scholar] [CrossRef]

- Fu, C.; Ma, X.; Zhang, L. Fuzzy-PID strategy based on PSO optimization for pH control in water and fertilizer integration. IEEE Access 2021, 10, 4471–4482. [Google Scholar] [CrossRef]

- Zhu, F.; Zhang, L.; Hu, X.; Zhao, J.; Meng, Z.; Zheng, Y. Research and design of hybrid optimized backpropagation (BP) neural network PID algorithm for integrated water and fertilizer precision fertilization control system for field crops. Agronomy 2023, 13, 1423. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, B.; Shen, C.; Liu, H.; Huang, J.; Tian, K.; Tang, Z. Review of the field environmental sensing methods based on multi-sensor information fusion technology. Int. J. Agric. Biol. Eng. 2024, 17, 1–13. [Google Scholar] [CrossRef]

- Rasool, G.; Guo, X.; Wang, Z.; Ali, M.U.; Chen, S.; Zhang, S.; Wu, Q.; Ullah, M.S. Coupling fertigation and buried straw layer improves fertilizer use efficiency, fruit yield, and quality of greenhouse tomato. Agric. Water Manag. 2020, 239, 106239. [Google Scholar] [CrossRef]

- Zhu, X.; Chikangaise, P.; Shi, W.; Chen, W.H.; Yuan, S. Review of intelligent sprinkler irrigation technologies for remote autonomous system. Int. J. Agric. Biol. Eng. 2018, 11, 23–30. [Google Scholar] [CrossRef]

- Li, N.; Wang, S.; Li, L.; Chen, Y.; Chen, Q. Research on an Integrated Water-Fertilizer Control System for Greenhouses Based on Fuzzy Adaptive PID. Agric. Technol. 2022, 42, 14–54. [Google Scholar] [CrossRef]

- Yuan, H.; Li, L.; Wang, J.; Wang, H.; NA, S. Design and test of regulation and control equipment for nutrient solution of water and fertilizer integration in greenhouse. Trans. Chin. Soc. Agric. Eng. 2016, 32, 27–32. [Google Scholar]

- Guan, H. Greenhouse environmental monitoring and control system based on improved fuzzy PID and neural network algorithms. J. Intell. Syst. 2025, 34, 20240079. [Google Scholar] [CrossRef]

- Karuppasamy, C.; Kumar, C.S.; Ganesan, R.; Elamparithi, P. Optimizing PID control for maximum power point tracking in photovoltaic systems under variable and partial shading conditions. Renew. Energy 2025, 246, 122930. [Google Scholar] [CrossRef]

- Alfian, E.; Ma’arif, A.; Chotikunnan, P.; Abougarair, A.J. Optimizing Light Intensity with PID Control. Control Syst. Optim. Lett. 2023, 1, 124–131. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Liu, Y.; Hu, P.; Lei, Y.; Liang, M.; Li, B. Closed-Loop Intelligent Lighting for Precision Dimming under Non-Uniform Illuminance and Dynamic Daylight Compensation. Build. Environ. 2025, 281, 113230. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Mamdani, E.H.; Assilian, S. An experiment in linguistic synthesis with a fuzzy logic controller. Int. J. Man-Mach. Stud. 1975, 7, 1–13. [Google Scholar] [CrossRef]

- Chen, J.; Ning, X.; Li, Y.; Yang, G.; Wu, P.; Chen, S. A fuzzy control strategy for the forward speed of a combine harvester based on KDD. Appl. Eng. Agric. 2017, 33, 15–22. [Google Scholar] [CrossRef]

- Azaza, M.; Tanougast, C.; Fabrizio, E.; Mami, A. Smart greenhouse fuzzy logic based control system enhanced with wireless data monitoring. ISA Trans. 2016, 61, 297–307. [Google Scholar] [CrossRef]

- Wang, J.; Xie, N. An Intelligent Temperature Control Strategy for Greenhouse Tomatoes Based on Variable Universe Fuzzy Theory. J. Agric. Sci. Technol. 2018, 20, 71–79. [Google Scholar] [CrossRef]

- El Aoud, M.M.; Maher, M. Intelligent control for a greenhouse climate. Int. J. Adv. Eng. Technol. 2014, 7, 1191. [Google Scholar]

- Su, Y.; Xu, L.; Goodman, E.D. Greenhouse climate fuzzy adaptive control considering energy saving. Int. J. Control Autom. Syst. 2017, 15, 1936–1948. [Google Scholar] [CrossRef]

- Xing, X.; Song, J.; Lin, L. Design of a Greenhouse Intelligent Control System Based on Dual Fuzzy Controllers. N. Hortic. 2018, 1, 62–68. [Google Scholar]

- Wei, Y.; Zhao, J.; Gao, A.; Bai, Y.; Gao, H.; Li, Z. Design of a Fuzzy Expert Control System for Greenhouse Environmental Parameters. J. Jiangsu Agric. Sci. 2021, 49, 183–188. [Google Scholar] [CrossRef]

- Testud, J.; Richalet, J.; Rault, A.; Papon, J. Model predictive heuristic control: Applications to industial processes. Automatica 1978, 14, 413–428. [Google Scholar]

- Rouhani, R.; Mehra, R.K. Model algorithmic control (MAC); basic theoretical properties. Automatica 1982, 18, 401–414. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, L.; Li, Y.; Li, D. Model predictive control and its application in agriculture: A review. Comput. Electron. Agric. 2018, 151, 104–117. [Google Scholar] [CrossRef]

- Mahmood, F.; Govindan, R.; Bermak, A.; Yang, D.; Khadra, C.; Al-Ansari, T. Energy utilization assessment of a semi-closed greenhouse using data-driven model predictive control. J. Clean. Prod. 2021, 324, 129172. [Google Scholar] [CrossRef]

- Chen, L.; Du, S.; He, Y.; Liang, M.; Xu, D. Robust model predictive control for greenhouse temperature based on particle swarm optimization. Inf. Process. Agric. 2018, 5, 329–338. [Google Scholar] [CrossRef]

- Qi, D.; Zhang, K.; Zhao, C.; Li, A.; Song, B.; Li, A. Optimized model predictive control for solar assisted earth air heat exchanger system in greenhouse. Renew. Energy 2024, 228, 120582. [Google Scholar] [CrossRef]

- He, X.; Wang, J.; Guo, S.; Zhang, J.; Wei, B.; Sun, J.; Shu, S. Ventilation optimization of solar greenhouse with removable back walls based on CFD. Comput. Electron. Agric. 2018, 149, 16–25. [Google Scholar] [CrossRef]

- Yu, H.; Chen, Y.; Hassan, S.G.; Li, D. Prediction of the temperature in a Chinese solar greenhouse based on LSSVM optimized by improved PSO. Comput. Electron. Agric. 2016, 122, 94–102. [Google Scholar] [CrossRef]

- El Alaoui, M.; Chahidi, L.O.; Rougui, M.; Mechaqrane, A.; Allal, S. Evaluation of CFD and machine learning methods on predicting greenhouse microclimate parameters with the assessment of seasonality impact on machine learning performance. Sci. Afr. 2023, 19, e01578. [Google Scholar] [CrossRef]

- Mahmood, F.; Govindan, R.; Bermak, A.; Yang, D.; Al-Ansari, T. Data-driven robust model predictive control for greenhouse temperature control and energy utilisation assessment. Appl. Energy 2023, 343, 121190. [Google Scholar] [CrossRef]

- Mahmood, F.; Govindan, R.; Al-Ansari, T. Efficient energy management and temperature control of a high-tech greenhouse using an improved data-driven model predictive control. Energy Convers. Manag. X 2025, 26, 100939. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, P.; Asante, E.A.; Wu, W.; Li, P. Control system of a performance test-bed for frost protection wind machines. Int. J. Agric. Biol. Eng. 2016, 9, 36–43. [Google Scholar] [CrossRef]

- Han, L.; Mo, M.; Ma, H.; Kumi, F.; Mao, H. Design and test of a lateral-approaching and horizontal-pushing transplanting manipulator for greenhouse seedlings. Appl. Eng. Agric. 2023, 39, 325–338. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; Qenawy, M.; Ali, M.; Rostom, M.; Elbeltagi, A.; Salem, A.; Elwakeel, A.E. Optimization of dried garlic physicochemical properties using a self-organizing map and the development of an artificial intelligence prediction model. Sci. Rep. 2025, 15, 3105. [Google Scholar] [CrossRef]

- Bai, J.W.; Xiao, H.W.; Ma, H.L.; Zhou, C.S. Artificial neural network modeling of drying kinetics and color changes of ginkgo biloba seeds during microwave drying process. J. Food Qual. 2018, 2018, 3278595. [Google Scholar] [CrossRef]

- Liu, J.; Abbas, I.; Noor, R.S. Development of deep learning-based variable rate agrochemical spraying system for targeted weeds control in strawberry crop. Agronomy 2021, 11, 1480. [Google Scholar] [CrossRef]

- Wang, Y.; Mao, H.; Zhang, X.; Liu, Y.; Du, X. A rapid detection method for tomato gray mold spores in greenhouse based on microfluidic chip enrichment and lens-less diffraction image processing. Foods 2021, 10, 3011. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Gu, J. Design and research of robot visual servo system based on artificial intelligence. Agro Food Ind. Hi-Tech 2017, 28, 125–128. [Google Scholar]

- Qenawy, M.; Ali, M.; El-Mesery, H.S.; Hu, Z. Analysis and control of hybrid convection-radiation drying systems toward energy saving strategy. J. Food Sci. 2024, 89, 9559–9576. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; Qenawy, M.; Ali, M.; Hu, Z.; Adelusi, O.A.; Njobeh, P.B. Artificial intelligence as a tool for predicting the quality attributes of garlic (Allium sativum L.) slices during continuous infrared-assisted hot air drying. J. Food Sci. 2024, 89, 7693–7712. [Google Scholar] [CrossRef]

- Zhu, W.; Li, J.; Li, L.; Wang, A.; Wei, X.; Mao, H. Nondestructive diagnostics of soluble sugar, total nitrogen and their ratio of tomato leaves in greenhouse by polarized spectra–hyperspectral data fusion. Int. J. Agric. Biol. Eng. 2020, 13, 189–197. [Google Scholar] [CrossRef]

- Castañeda-Miranda, A.; Castaño, V.M. Smart frost control in greenhouses by neural networks models. Comput. Electron. Agric. 2017, 137, 102–114. [Google Scholar] [CrossRef]

- Jiang, D. Greenhouse Temperature Control Technology Based on an Improved BP Neural Network PID Controller. Lab. Res. Explor. 2015, 34, 9–13. [Google Scholar]

- Yuan, J.; Shi, Y.; Jiang, Y.; Jiang, P. Research on an Improved BP Neural Network PID Controller for Greenhouse Environmental Control. Electron. Meas. Technol. 2019, 42, 19–24. [Google Scholar] [CrossRef]

- Li, F.; Fan, Y.; Liang, H. Research on Greenhouse Temperature and Humidity Control Based on an Improved BP Neural Network PID Controller. Comput. Digit. Eng. 2021, 49, 908–913+986. [Google Scholar]

- Yao, X.; Song, X.; Wang, J.; He, D.; Li, W.; Pang, Z. Prediction of Greenhouse Cultivation Environments for Two Tropical Orchid Species in Haikou Based on BP Neural Networks. Henan Agric. Sci. 2018, 47, 155–160. [Google Scholar] [CrossRef]

- Huangfu, L. Greenhouse Temperature Control Technology Based on an Improved B-spline Neural Network-PID Controller. Trans. Chin. Soc. Agric. Mach. 2020, 41, 68–74. [Google Scholar] [CrossRef]

- Aytenfsu, S.A.; Beyene, A.M.; Getaneh, T.H. Controlling the interior of greenhouses using Elman recurrent neural network. In Proceedings of the 2020 Fourth World Conference on Smart Trends in Systems, Security and Sustainability (WorldS4), London, UK, 27–28 July 2020; IEEE: New York, NY, USA, 2020; pp. 32–39. [Google Scholar] [CrossRef]

- Zhang, J.; Shan, H.; Jing, X.; Li, C.; Zhang, C.; Liu, H. Prediction Method of Greenhouse Environmental Factors Based on Elman Neural Network. J. Chin. Agric. Mech. 2021, 42, 203–208. [Google Scholar] [CrossRef]

- Belhaj Salah, L.; Fourati, F. A greenhouse modeling and control using deep neural networks. Appl. Artif. Intell. 2021, 35, 1905–1929. [Google Scholar] [CrossRef]

- Fourati, F.; Chtourou, M. A greenhouse control with feed-forward and recurrent neural networks. Simul. Model. Pract. Theory 2007, 15, 1016–1028. [Google Scholar] [CrossRef]

- Fourati, F. Multiple neural control of a greenhouse. Neurocomputing 2014, 139, 138–144. [Google Scholar] [CrossRef]

- Pan, J.; Liu, P.; Zhang, Y.; Zhang, M.; Liu, C. Research on solar greenhouse temperature and humidity prediction model based on SSA-Elman. J. Chin. Agric. Mech. 2024, 45, 69. [Google Scholar]

- Guesbaya, M.; García-Mañas, F.; Rodríguez, F.; Megherbi, H. A soft sensor to estimate the opening of greenhouse vents based on an LSTM-RNN neural network. Sensors 2023, 23, 1250. [Google Scholar] [CrossRef]

- Liu, Y.; Li, D.; Wan, S.; Wang, F.; Dou, W.; Xu, X.; Li, S.; Ma, R.; Qi, L. A long short-term memory-based model for greenhouse climate prediction. Int. J. Intell. Syst. 2022, 37, 135–151. [Google Scholar] [CrossRef]

- Chen, L.; Pei, X.; Liu, Y. LSTM-Based Prediction of Environmental Variables in Greenhouses. J. Shenyang Ligong Univ. 2018, 37, 13–19. [Google Scholar] [CrossRef]

- Ali, A.; Hassanein, H.S. Wireless sensor network and deep learning for prediction greenhouse environments. In Proceedings of the 2019 International Conference on Smart Applications, Communications and Networking (SmartNets), Sharm El Sheikh, Egypt, 17–19 December 2019; IEEE: New York, NY, USA, 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Jung, D.H.; Kim, H.S.; Jhin, C.; Kim, H.J.; Park, S.H. Time-serial analysis of deep neural network models for prediction of climatic conditions inside a greenhouse. Comput. Electron. Agric. 2020, 173, 105402. [Google Scholar] [CrossRef]

- Gong, L.; Yu, M.; Jiang, S.; Cutsuridis, V.; Pearson, S. Deep learning based prediction on greenhouse crop yield combined TCN and RNN. Sensors 2021, 21, 4537. [Google Scholar] [CrossRef]

- Qiao, X.; Zheng, W.; Zhang, X.; Shan, F.; Wang, M.; Liang, D. Research on a LSTM-GRU-Based Environmental Prediction Method for Solar Greenhouses. J. Jiangsu Agric. Sci. 2022, 50, 211–218. [Google Scholar] [CrossRef]

- Chen, Q.; Hu, X. Design of intelligent control system for agricultural greenhouses based on adaptive improved genetic algorithm for multi-energy supply system. Energy Rep. 2022, 8, 12126–12138. [Google Scholar] [CrossRef]

- Li, Y.; Guo, W.; Wu, J.; Duan, M.; Yang, Y.; Liu, S. Estimation of Greenhouse-Grown Eggplant Evapotranspiration Based on a Crop Coefficient Model. Water 2022, 14, 2959. [Google Scholar] [CrossRef]

- Zeng, S.; Hu, H.; Xu, L.; Li, G. Nonlinear adaptive PID control for greenhouse environment based on RBF network. Sensors 2012, 12, 5328–5348. [Google Scholar] [CrossRef] [PubMed]

- Mansour, M.; Sathyanarayanan, K.K.; Sauerteig, P.; Streif, S. Adaptive robust greenhouse climate control: Combining deep reinforcement learning and economic optimization. Smart Agric. Technol. 2025, 12, 101327. [Google Scholar] [CrossRef]

- Gurban, E.H.; Andreescu, G.D. Employing 2DoF PID controllers to improve greenhouse climate system robustness. In Proceedings of the 2013 International Conference on System Science and Engineering (ICSSE), Budapest, Hungary, 4–6 July 2013; IEEE: New York, NY, USA, 2013; pp. 93–98. [Google Scholar] [CrossRef]

- Qiu, Z.; Wang, X. Environmental parameter control of the greenhouse. In Proceedings of the 2013 Fifth International Conference on Measuring Technology and Mechatronics Automation, Hong Kong, China, 16–17 January 2013; IEEE: New York, NY, USA, 2013; pp. 524–527. [Google Scholar] [CrossRef]

- Chen, L.; Du, S.; Liang, M.; He, Y. Adaptive feedback linearization-based predictive control for greenhouse temperature. IFAC-PapersOnLine 2018, 51, 784–789. [Google Scholar] [CrossRef]

- Miskowicz, M. Sampling of Signals in Energy Domain. In Proceedings of the 2005 IEEE Conference on Emerging Technologies and Factory Automation, Catania, Italy, 19–22 September 2005; IEEE: New York, NY, USA, 2005; Volume 1, pp. 263–266. [Google Scholar] [CrossRef]

- Ferre, J.; Pawlowski, A.; Guzman, J.; Rodriguez, F.; Berenguel, M. A wireless sensor network for greenhouse climate monitoring. In Proceedings of the 2010 Fifth international conference on broadband and biomedical communications, Malaga, Spain, 15–17 December 2010; IEEE: New York, NY, USA, 2010; pp. 1–5. [Google Scholar] [CrossRef]

- Pawlowski, A.; Guzmán, J.L.; Normey-Rico, J.E.; Berenguel, M. A practical approach for generalized predictive control within an event-based framework. Comput. Chem. Eng. 2012, 41, 52–66. [Google Scholar] [CrossRef]

- Pawlowski, A.; Cervin, A.; Guzmán, J.L.; Berenguel, M. Generalized predictive control with actuator deadband for event-based approaches. IEEE Trans. Ind. Inform. 2013, 10, 523–537. [Google Scholar] [CrossRef]

- Pawlowski, A.; Guzmán, J.; Berenguel, M.; Dormido, S.; Fernández, I. Event-based predictive control triggered by input and output deadband conditions. IFAC Proc. Vol. 2014, 47, 8116–8121. [Google Scholar] [CrossRef]

- Wang, L.; He, X.; Luo, D. Deep reinforcement learning for greenhouse climate control. In Proceedings of the 2020 IEEE International Conference on Knowledge Graph (ICKG), Nanjing, China, 9–11 August 2020; IEEE: New York, NY, USA, 2020; pp. 474–480. [Google Scholar] [CrossRef]

- Zhang, W.; Cao, X.; Yao, Y.; An, Z.; Xiao, X.; Luo, D. Robust model-based reinforcement learning for autonomous greenhouse control. In Proceedings of the Asian Conference on Machine Learning, PMLR, Virtual, 17–19 November 2021; pp. 1208–1223. [Google Scholar]

- Ajagekar, A.; Mattson, N.S.; You, F. Energy-efficient ai-based control of semi-closed greenhouses leveraging robust optimization in deep reinforcement learning. Adv. Appl. Energy 2023, 9, 100119. [Google Scholar] [CrossRef]

- Ban, B.; Kim, S. Control of nonlinear, complex and black-boxed greenhouse system with reinforcement learning. In Proceedings of the 2017 International Conference on Information and Communication Technology Convergence (ICTC), Jeju, Republic of Korea, 18–20 October 2017; IEEE: New York, NY, USA, 2017; pp. 913–918. [Google Scholar] [CrossRef]

- Adesanya, M.A.; Obasekore, H.; Rabiu, A.; Na, W.H.; Ogunlowo, Q.O.; Akpenpuun, T.D.; Kim, M.H.; Kim, H.T.; Kang, B.Y.; Lee, H.W. Deep reinforcement learning for PID parameter tuning in greenhouse HVAC system energy Optimization: A TRNSYS-Python cosimulation approach. Expert Syst. Appl. 2024, 252, 124126. [Google Scholar] [CrossRef]

- Yan, H.; Acquah, S.J.; Zhang, C.; Wang, G.; Huang, S.; Zhang, H.; Zhao, B.; Wu, H. Energy partitioning of greenhouse cucumber based on the application of Penman-Monteith and Bulk Transfer models. Agric. Water Manag. 2019, 217, 201–211. [Google Scholar] [CrossRef]

- Bot, G.P. Greenhouse Climate: From Physical Processes to a Dynamic Model; Wageningen University and Research: Wageningen, The Netherlands, 1983. [Google Scholar]

- Van Henten, E. Greenhouse Climate Management: An Optimal Control Approach; Wageningen University and Research: Wageningen, The Netherlands, 1994. [Google Scholar]

- Vanthoor, B.H. A Model-Based Greenhouse Design Method; Wageningen University and Research: Wageningen, The Netherlands, 2011. [Google Scholar]

- van Ooteghem, R.J. Optimal control design for a solar greenhouse. IFAC Proc. Vol. 2010, 43, 304–309. [Google Scholar] [CrossRef]

- Luo, W.; de Zwart, H.F.; DaiI, J.; Wang, X.; Stanghellini, C.; Bu, C. Simulation of greenhouse management in the subtropics, Part I: Model validation and scenario study for the winter season. Biosyst. Eng. 2005, 90, 307–318. [Google Scholar] [CrossRef]

- Herrero, J.; Blasco, X.; Martínez, M.; Ramos, C.; Sanchis, J. Non-linear robust identification of a greenhouse model using multi-objective evolutionary algorithms. Biosyst. Eng. 2007, 98, 335–346. [Google Scholar] [CrossRef]

- Guzmán-Cruz, R.; Castañeda-Miranda, R.; García-Escalante, J.J.; López-Cruz, I.; Lara-Herrera, A.; De la Rosa, J. Calibration of a greenhouse climate model using evolutionary algorithms. Biosyst. Eng. 2009, 104, 135–142. [Google Scholar] [CrossRef]

- Tang, P.; Li, H.; Issaka, Z.; Chen, C. Impact forces on the drive spoon of a large cannon irrigation sprinkler: Simple theory, CFD numerical simulation and validation. Biosyst. Eng. 2017, 159, 1–9. [Google Scholar] [CrossRef]

- Liang, Z.; Xu, L.; De Baerdemaeker, J.; Li, Y.; Saeys, W. Optimisation of a multi-duct cleaning device for rice combine harvesters utilising CFD and experiments. Biosyst. Eng. 2020, 190, 25–40. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, Y.; Wei, W.; Hu, Z.; Li, P. Optimization design of spray cooling fan based on CFD simulation and field experiment for horticultural crops. Agriculture 2021, 11, 566. [Google Scholar] [CrossRef]

- Ni, J.; Dong, J.; Ullah, I.; Mao, H. CFD simulation of sucrose flow field in the stem of greenhouse tomato seedling. Int. J. Agric. Biol. Eng. 2022, 15, 111–115. [Google Scholar] [CrossRef]

- Li, K.; Xue, W.; Mao, H.; Chen, X.; Jiang, H.; Tan, G. Optimizing the 3D distributed climate inside greenhouses using multi-objective optimization algorithms and computer fluid dynamics. Energies 2019, 12, 2873. [Google Scholar] [CrossRef]

- Cunha, J.B.; Couto, C.; Ruano, A. Real-time parameter estimation of dynamic temperature models for greenhouse environmental control. Control Eng. Pract. 1997, 5, 1473–1481. [Google Scholar] [CrossRef]

- Salgado, P.; Cunha, J.B. Greenhouse climate hierarchical fuzzy modelling. Control Eng. Pract. 2005, 13, 613–628. [Google Scholar] [CrossRef]

- Ferreira, P.M.; Faria, E.; Ruano, A. Neural network models in greenhouse air temperature prediction. Neurocomputing 2002, 43, 51–75. [Google Scholar] [CrossRef]

- Suyantohadi, A.; Hariadi, M.; Purnomo, M.; Morimoto, T. Dynamic neural network model for identifying cumulative responses of soybean plant growth based on nitrogen fertilizer compositions. Aust. J. Agric. Eng. 2010, 1, 188–193. [Google Scholar]

- Jung, D.H.; Lee, T.S.; Kim, K.; Park, S.H. A deep learning model to predict evapotranspiration and relative humidity for moisture control in tomato greenhouses. Agronomy 2022, 12, 2169. [Google Scholar] [CrossRef]

- Lin, Y.S.; Fang, S.L.; Kang, L.; Chen, C.C.; Yao, M.H.; Kuo, B.J. Combining recurrent neural network and sigmoid growth models for short-term temperature forecasting and tomato growth prediction in a plastic greenhouse. Horticulturae 2024, 10, 230. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, Z.; Zheng, W.; Li, K. Optimization of indoor temperature sensor layout using proper orthogonal decomposition and Greedy algorithm. In Proceedings of the 2024 43rd Chinese Control Conference (CCC), Kunming, China, 28–31 July 2024; IEEE: New York, NY, USA, 2024; pp. 2028–2033. [Google Scholar] [CrossRef]

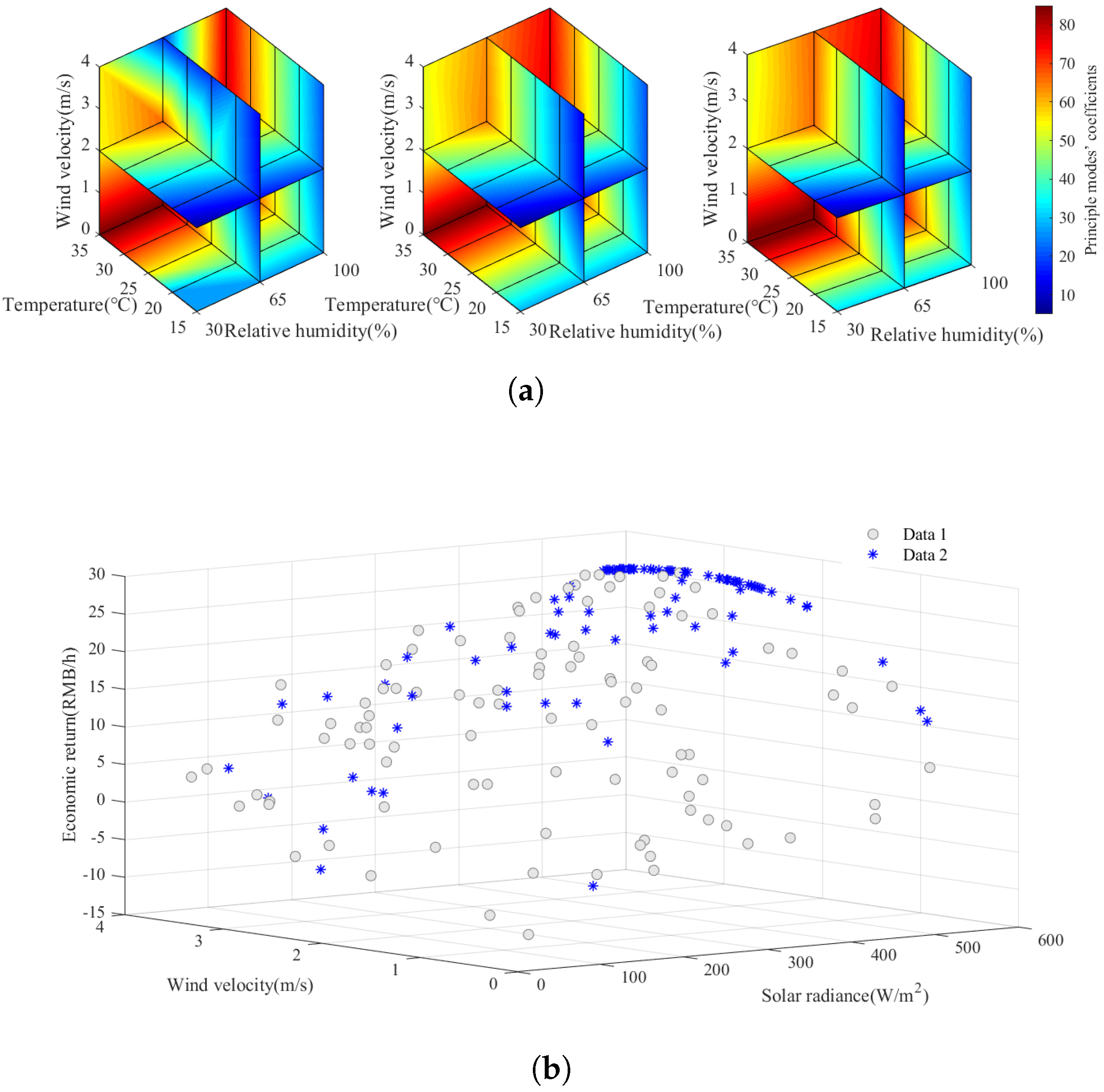

- Li, K.; Sha, Z.; Xue, W.; Chen, X.; Mao, H.; Tan, G. A fast modeling and optimization scheme for greenhouse environmental system using proper orthogonal decomposition and multi-objective genetic algorithm. Comput. Electron. Agric. 2020, 168, 105096. [Google Scholar] [CrossRef]

- Li, K.; Mi, Y.; Zheng, W. An optimal control method for greenhouse climate management considering crop growth’s spatial distribution and energy consumption. Energies 2023, 16, 3925. [Google Scholar] [CrossRef]

- de Wit, C.T. Photosynthesis of Leaf Canopies; Agricultural Research Reports No. 663; PUDOC: Wageningen, The Netherlands, 1965. [Google Scholar]

- de Wit, C.T.; Brouwer, R.; De Vries, F.P. The Simulation of Photosynthetic Systems; Centre for Agricultural Publishing and Documentation: Wageningen, The Netherlands, 1970. [Google Scholar]

- de Wit, C. Simulation of Assimilation, Respiration and Transpiration of Crops; British Ecological Society: London, UK, 1978. [Google Scholar] [CrossRef]

- Penning de Vries, F.W.T.; van Laar, H.H. Simulation of Growth Processes and the Model BACROS. In Simulation of Plant Growth and Crop Production; PUDOC: Wageningen, The Netherlands, 1982; pp. 114–135. [Google Scholar]

- van Keulen, H. Simulation of Water Use and Herbage Growth in Arid Regions; Wageningen University and Research: Wageningen, The Netherlands, 1975. [Google Scholar]

- Ma, B.; Tian, J. A Review of Research on Crop Growth Simulation Models. Water-Sav. Irrig. 2010, 1, 1–5. [Google Scholar]

- Uehara, G.; Tsuji, G. Overview of IBSNAT. In Understanding Options for Agricultural Production; Springer: Berlin/Heidelberg, Germany, 1998; pp. 1–7. [Google Scholar] [CrossRef]

- Ritchie, J.T. Soil water balance and plant water stress. In Understanding Options for Agricultural Production; Springer: Berlin/Heidelberg, Germany, 1998; pp. 41–54. [Google Scholar] [CrossRef]

- Godwin, D.; Singh, U. Nitrogen balance and crop response to nitrogen in upland and lowland cropping systems. In Understanding Options for Agricultural Production; Springer: Berlin/Heidelberg, Germany, 1998; pp. 55–77. [Google Scholar] [CrossRef]

- McCown, R.L.; Hammer, G.L.; Hargreaves, J.N.G.; Holzworth, D.P.; Freebairn, D.M. APSIM: A novel software system for model development, model testing and simulation in agricultural systems research. Agric. Syst. 1996, 50, 255–271. [Google Scholar] [CrossRef]

- Shi, Q.; Pan, Y.; He, B.; Zhu, H.; Liu, D.; Shen, B.; Mao, H. The airflow field characteristics of UAV flight in a greenhouse. Agriculture 2021, 11, 634. [Google Scholar] [CrossRef]

- Ali, H.B.; Bournet, P.E.; Cannavo, P.; Chantoiseau, E. Development of a CFD crop submodel for simulating microclimate and transpiration of ornamental plants grown in a greenhouse under water restriction. Comput. Electron. Agric. 2018, 149, 26–40. [Google Scholar] [CrossRef]

- Nomura, K.; Yasutake, D.; Kaneko, T.; Iwao, T.; Okayasu, T.; Ozaki, Y.; Mori, M.; Kitano, M. Long-term estimation of the canopy photosynthesis of a leafy vegetable based on greenhouse climate conditions and nadir photographs. Sci. Hortic. 2021, 289, 110433. [Google Scholar] [CrossRef]

- Huang, J.; Gómez-Dans, J.L.; Huang, H.; Ma, H.; Wu, Q.; Lewis, P.E.; Liang, S.; Chen, Z.; Xue, J.H.; Wu, Y.; et al. Assimilation of remote sensing into crop growth models: Current status and perspectives. Agric. For. Meteorol. 2019, 276, 107609. [Google Scholar] [CrossRef]

- Zare, H.; Weber, T.K.; Ingwersen, J.; Nowak, W.; Gayler, S.; Streck, T. Combining crop modeling with remote sensing data using a particle filtering technique to produce real-time forecasts of winter wheat yields under uncertain boundary conditions. Remote Sens. 2022, 14, 1360. [Google Scholar] [CrossRef]

- Démoulin, R.; Gastellu-Etchegorry, J.P.; Lefebvre, S.; Briottet, X.; Zhen, Z.; Adeline, K.; Marionneau, M.; Le Dantec, V. Modeling 3D radiative transfer for maize traits retrieval: A growth stage-dependent study on hyperspectral sensitivity to field geometry, soil moisture, and leaf biochemistry. Remote Sens. Environ. 2025, 327, 114784. [Google Scholar] [CrossRef]

- Yan, H.; Deng, S.; Zhang, C.; Wang, G.; Zhao, S.; Li, M.; Liang, S.; Jiang, J.; Zhou, Y. Determination of energy partition of a cucumber grown Venlo-type greenhouse in southeast China. Agric. Water Manag. 2023, 276, 108047. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, G.; Du, X.; Liu, Y.; Wang, B.; Xu, G.; Mao, H. Effects of nutrient solution irrigation quantity and downy mildew infection on growth and physiological traits of greenhouse cucumber. Agronomy 2020, 10, 1921. [Google Scholar] [CrossRef]

- Wang, B.; Bao, R.; Yan, H.; Zheng, H.; Wu, J.; Zhang, C.; Wang, G. Study of evapotranspiration and crop coefficients for eggplant in a Venlo-type greenhouse in South China. Irrig. Drain. 2025, 74, 556–568. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, X.; Sun, S.; Wang, J.; Li, Z.; Guo, Q.; Li, P. Tensile mechanical properties of greenhouse cucumber cane. Int. J. Agric. Biol. Eng. 2016, 9, 1–8. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, M.; Xu, B.; Sun, J.; Mujumdar, A.S. Artificial intelligence assisted technologies for controlling the drying of fruits and vegetables using physical fields: A review. Trends Food Sci. Technol. 2020, 105, 251–260. [Google Scholar] [CrossRef]

- Graefe, J.; Yu, W.; Körner, O. A photosynthetic light acclimation model accounting for the effects of leaf age, chlorophyll content, and intra-leaf radiation transfer. Front. Plant Sci. 2022, 13, 889709. [Google Scholar] [CrossRef]

- Chen, N.; Li, X.; Shi, H.; Hu, Q.; Zhang, Y.; Sun, Y.; Song, F. Simulation of maize crop growth using an improved crop model considering the disintegrated area of biodegradable film. Field Crop. Res. 2021, 272, 108270. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Qin, W.C.; Qiu, B.J.; Xue, X.Y.; Chen, C.; Xu, Z.F.; Zhou, Q.Q. Droplet deposition and control effect of insecticides sprayed with an unmanned aerial vehicle against plant hoppers. Crop Prot. 2016, 85, 79–88. [Google Scholar] [CrossRef]

- Xue, W.; Jia, N.; Zhao, M. Multi-agent deep reinforcement learning based HVAC control for multi-zone buildings considering zone-energy-allocation optimization. Energy Build. 2025, 329, 115241. [Google Scholar] [CrossRef]

| Contents | [1] (2022) | [2] (2022) | [3] (2023) | [4] (2024) | [5] (2024) | [6] (2025) | [7] (2025) |

|---|---|---|---|---|---|---|---|

| Conventional control techniques | × | ||||||

| Neural Network based Control | |||||||

| Reinforcement learning | × | × | × | × | × | × | |

| Data-driven modeling | × | ||||||

| Intelligent Technologies in Greenhouse Environment Modeling | × | × | × | × | |||

| Intelligent Technologies in Crop Growth Modeling | × | × | × | × | × | × |

| Reference | Type of Control | Control Variables | Study Setting | Control Performance |

|---|---|---|---|---|

| Gao et al. [17] | PID | Air temperature/Humidity | Lab | Stabilization time reduced by 73% (T), 50% (H) |

| Bao et al. [18] | PID | Air temperature/Humidity | Field | 80–90% steady accuracy |

| Su et al. [20] | Self-tuning PID | Air temperature/Humidity | Lab | Maintained accuracy, fewer actuator switches |

| Berenguel et al. [21] | PI + feedback linearization | Sim. + Lab | Stable under ±10% disturbances | |

| Su et al. [20] | Adaptive PID | Lab | Accuracy +35%, energy −23% | |

| Zhang et al. [22]; | ||||

| Fu et al. [23]; Zhu et al. [24] | PID | Water/Nutrients | Field | Widely applied in fertigation |

| Li et al. [28] | Fuzzy adaptive PID | Water/Nutrients | Sim. | Real-time dosing adjustment |

| Yuan et al. [29] | PID | Water/Nutrients | Field | Soil error ±2%, nutrient error ±5% |

| Guan et al. [30] | PID | Light/Shading rate | Field | Applied in shading/lighting |

| Azaza et al. [37] | Fuzzy (dynamic) | Multiple variables | Sim. | Energy −22%, water-use +33% |

| Wang et al. [38] | Variable-universe fuzzy | Air temperature | Lab | Overshoot −75%, energy −10% |

| El Aoud et al. [39] | Fuzzy adaptive (GD) | Air temperature/Humidity | Sim. | Reduced rule complexity, better tracking |

| Su et al. [40] | Fuzzy adaptive composite | Lab | Accuracy +35%, energy −23% | |

| Xing et al. [41] | Dual fuzzy | Air temperature | Lab | Accuracy ±0.5 °C vs. ±1.2 °C (PID) |

| Chen et al. [47] | MPC | Air temperature | Sim. + Lab | High-precision tracking, robust |

| Qi et al. [48] | MPC | Air temperature | Sim. + Field | Accuracy +10.6%, violations −29.7% |

| Mahmood et al. [52] | Robust MPC | Air temperature | Sim. | RMSE 0.29–0.31 °C |

| Mahmood et al. [53] | Dual-layer data-driven MPC | Air temperature | Sim. + Field | MAE 0.09 °C (winter), energy −13.3% (summer) |

| Reference | Study Setting | Dataset Size/Duration | Train/Test Split |

|---|---|---|---|

| BP Neural Networks | |||

| Castaneda et al. [64] | Field | 2880 samples (10-min)/1 year (summer & winter) | 70/30 split |

| Dingguo [65] | Sim. | 600 samples (Not reported interval)/Not reported duration | Not reported |

| Jianping et al. [66] | Sim. | Not reported | Not reported |

| Feng et al. [67] | Sim. + Field | Not reported/1 day | 70/30 split |

| Xinxin et al. [68] | Field | 438 samples (10-min)/multi-season (Oncidium); 371 samples (10-min)/multi-season (Phalaenopsis) | 78/22 split |

| Liqun [69] | Sim. | 600 samples (0.01 s)/Not reported duration | Not reported |

| Recurrent Neural Networks (RNN) | |||

| Aytenfsu et al. [70] | Field | 18,000 samples (5-min)/10 days | 75/25 split |

| Zhang et al. [71] | Field | 2880 samples (3-min)/5 days | 2400/480 split |

| Belhaj Salah et al. [72] | Sim. | 1440 samples (1-min)/1 day | 50/50 split |

| Fourati et al. [74] | Field | 1440 samples (1-min)/1 day | Not reported |

| Pan et al. [75] | Field | 3500 samples (30-min)/93 days | 80/20 split |

| Long Short-Term Memory (LSTM) | |||

| Chen et al. [78] | Field | 2880 samples (10-min)/1 year | 70/30 split |

| Ali et al. [79] | Sim. | 600 samples (Not reported interval)/Not reported duration | Not reported |

| Jung et al. [80] | Sim. + Field | Not reported/1 day (12 h) | 70/30 split |

| Gong et al. [81] | Field | Not reported/1 year | 70/30 split |

| Qiao et al. [82] | Sim. | 600 samples (0.01s)/Not reported duration | Not reported |

| Reference | Method | Control Variables | Performance |

|---|---|---|---|

| BP Neural Networks | |||

| Castaneda et al. [64] | BP | Air temperature | Error reduced >50% vs. ARX |

| Dingguo [65] | BP-PSO-PID | Air temperature | Faster response, less overshoot |

| Jianping et al. [66] | GA-PSO-BP | Air temperature | Shorter adjustment time |

| Feng et al. [67] | BP-PID | Air temperature/Humidity | Stable T/H, lower fluctuation |

| Xinxin et al. [68] | BP | Air temperature/Humidity | RMSE ±1.4 °C, 5% H |

| Liqun [69] | B-BP | Air temperature/Humidity/ | Better overshoot, faster response |

| RNN | |||

| Aytenfsu et al. [70] | Elman NN | Air temperature/Humidity | Accurate short-term prediction |

| Zhang et al. [71] | Elman NN | Air temperature/Humidity/ | = 0.99 for T |

| Belhaj Salah et al. [72] | Elman+MLP | Air temperature/Humidity/ | Improved stability |

| Fourati et al. [74] | Elman+FFNN | Air temperature/Humidity | Better tracking |

| Pan et al. [75] | SSA-Elman | Air temperature/Humidity | RMSE 0.59 (T), 2.53 (H) |

| LSTM | |||

| Chen et al. [78] | LSTM | Air temperature/Humidity/ | Outperformed RNN/GRU |

| Ali et al. [79] | LSTM-RNN | Air temperature | RMSE = 0.069 (12 h) |

| Jung et al. [80] | LSTM | Multiple variables | Stronger long-horizon accuracy |

| Gong et al. [81] | LSTM+TCN | Multiple variables | RMSE ≈ 30% lower |

| Qiao et al. [82] | LSTM-GRU+Kalman | Air temperature | 94% within ±0.5 °C |

| Reinforcement Learning | |||

| Wang et al. [95] | DDPG | Multiple variables | Higher cucumber yield |

| Zhang et al. [96] | Model-based RL | Air temperature/Humidity | 57% energy saving |

| Ajagekar et al. [97] | RO-DRL | Air temperature/Humidity/ | Robust, energy efficient |

| Ban et al. [98] | Actor-Critic | Multiple variables | >20× stability gain |

| Adesanya et al. [99] | DQN-PID | Air temperature/Humidity | Optimized PID, energy saving |

| Reference | Method | Control Variables | Study Setting | Performance |

|---|---|---|---|---|

| Adaptive Control | ||||

| Chen [83] | GA-based adaptive | Air temperature/Humidity/ | Sim. | Improved robustness under uncertainties |

| Li et al. [84] | Fuzzy adaptive PID | Water/Nutrients | Field | Real-time tuning, precise regulation |

| Zeng et al. [85] | RBF NN adaptive PID | Air temperature/Humidity | Sim. | Online Jacobian estimation, higher stability |

| Mansour et al. [86] | Hierarchical adaptive (MPC+DRL) | Multiple variables | Sim. | Robust to faults/weather, improved adaptability |

| Feedback Linearization | ||||

| Gurban et al. [87]; Zengshuai et al. [88] | Feedback linearization | Multiple variables | Sim. | Enabled linear design for nonlinear dynamics |

| Chen et al. [89] | FL + UKF + MPC | Air temperature | Sim. | ±1.0 °C tracking accuracy, optimized energy |

| Event-Based Control | ||||

| Ferre et al. [91]; Pawlowski et al. [92,93,94] | Event-driven WSN sampling | Air temperature/Humidity/ | Field/Sim. | >80% fewer updates, energy saving, longer actuator life |

| Type | References | Key Features | Limitations |

|---|---|---|---|

| Mechanistic models | [103,104,105,106,107] | Thermodynamic and physiological basis; dynamic equations; calibration by evolutionary algorithms. | Require many parameters; difficult calibration; heavy computation. |

| CFD simulation | [49,108,109,110,111,112] | Spatial distribution of airflow, temperature, ; ventilation and transport analysis. | Very high computation; not suitable for real-time. |

| Data-driven models | [5,51,80,114,116,117,118] | No prior knowledge; ANN, fuzzy logic, LSTM, CNN-LSTM; accurate prediction. | Depend on data; weak generalization; ignore spatial effects. |

| Model reduction | [119,120,121] | POD from CFD; fast response; combined with crop models. | Approximation errors; need prior CFD data. |

| Model Type | References | Key Features | Limitations |

|---|---|---|---|

| Fuzzy models | [114] | Nonlinear mapping; better than ARX. | Rule design subjective. |

| ANN | [51,115,116] | Accurate climate prediction; faster than CFD. | Data-dependent; weak generalization. |

| LSTM/RNN | [5,80,117] | Capture dynamics; LSTM outperforms RNN/GRU; CNN-LSTM improves humidity prediction. | Long-horizon decay; data hungry. |

| Hybrid | [118] | LSTM-Sigmoid + growth models; accurate with fewer sensors. | Higher complexity; low interpretability. |

| SVM | [51] | High accuracy; efficient vs CFD. | Sensitive to kernel; no spatial info. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Shi, J.; Hu, C.; Xue, W. The Intelligentization Process of Agricultural Greenhouse: A Review of Control Strategies and Modeling Techniques. Agriculture 2025, 15, 2135. https://doi.org/10.3390/agriculture15202135

Li K, Shi J, Hu C, Xue W. The Intelligentization Process of Agricultural Greenhouse: A Review of Control Strategies and Modeling Techniques. Agriculture. 2025; 15(20):2135. https://doi.org/10.3390/agriculture15202135

Chicago/Turabian StyleLi, Kangji, Jialu Shi, Chenglei Hu, and Wenping Xue. 2025. "The Intelligentization Process of Agricultural Greenhouse: A Review of Control Strategies and Modeling Techniques" Agriculture 15, no. 20: 2135. https://doi.org/10.3390/agriculture15202135

APA StyleLi, K., Shi, J., Hu, C., & Xue, W. (2025). The Intelligentization Process of Agricultural Greenhouse: A Review of Control Strategies and Modeling Techniques. Agriculture, 15(20), 2135. https://doi.org/10.3390/agriculture15202135