Comparative Analysis of Static Rollover Stability Between Conventional and Electric Tractor

Abstract

1. Introduction

2. Materials and Methods

2.1. Modeling of Electric and Conventional Tractor

2.2. Placement of Powertrain Components in Each Model

2.3. Mathematical Modeling of Static Tipping and Deviation Calculation

2.4. Simulation Framework for Rollover Stability Analysis

2.5. Validation of the Simulation Model

3. Results

3.1. Observation of Initial Wheel Lift-Off and Rollover Onset

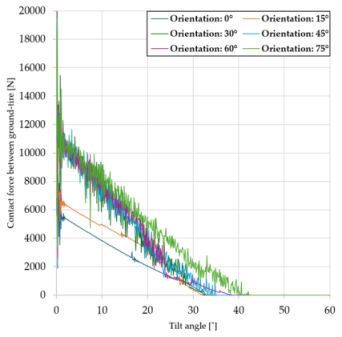

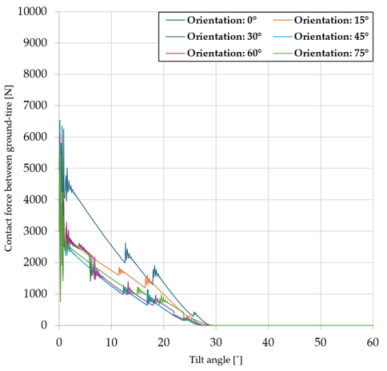

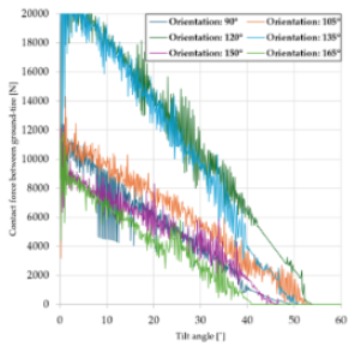

3.2. Variation in First Ground Contact Loss According to Vehicle Orientation and Structural Type

3.3. Comparison of Directional Rollover Stability

3.4. Rollover Angle Error Analysis Between Electric and Internal Combustion Tractors

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.C.; Chen, L.W.; Chang, M.Y. A design of an unmanned electric tractor platform. Agriculture 2022, 12, 112. [Google Scholar] [CrossRef]

- Chowdhury, M.; Islam, M.N.; Iqbal, M.Z.; Islam, S.; Lee, D.H.; Kim, D.G.; Chung, S.O. Analysis of overturning and vibration during field operation of a tractor-mounted 4-row radish collector toward ensuring user safety. Machines 2020, 8, 77. [Google Scholar] [CrossRef]

- Reński, A. Investigation of the influence of the centre of gravity position on the course of vehicle rollover. In Proceedings of the 24th International Technical Conference on the Enhanced Safety of Vehicles (ESV), Gothenburg, Sweden, 8–11 June 2015; National Highway Traffic Safety Administration: Gothenburg, Sweden, 2015; pp. 8–11. [Google Scholar]

- Togaev, A.; Shermukhamedov, A. Tractor rollover accidents: A review of factors and safety measures. E3S Web Conf. 2023, 449, 09011. [Google Scholar] [CrossRef]

- Scolaro, E.; Beligoj, M.; Estevez, M.P.; Alberti, L.; Renzi, M.; Mattetti, M. Electrification of agricultural machinery: A review. IEEE Access 2021, 9, 164520–164541. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A.; Martelli, S.; Martini, V. Trends and future perspective of electrification in agricultural tractor-implement applications. Energies 2023, 16, 6601. [Google Scholar] [CrossRef]

- Troncon, D.; Alberti, L. Case of study of the electrification of a tractor: Electric motor performance requirements and design. Energies 2020, 13, 2197. [Google Scholar] [CrossRef]

- Chan, C.C. The state of the art of electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 704–718. [Google Scholar] [CrossRef]

- Kim, Y.K.; Kim, Y.K.; Kim, Y.R.; Hong, C.H.; Lee, M.I. Development of a 22 kW IPMSM drive inverter for electric tractor. In Proceedings of the KIPE Conference, Jeju, Republic of Korea, 5–7 July 2012; The Korean Institute of Power Electronics: Seoul, Republic of Korea, 2012; pp. 478–479. [Google Scholar]

- Baek, S.Y.; Baek, S.M.; Jeon, H.H.; Kim, W.S.; Kim, Y.S.; Sim, T.Y.; Kim, Y.J. Traction performance evaluation of the electric all-wheel-drive tractor. Sensors 2022, 22, 785. [Google Scholar] [CrossRef]

- Korea Institute for Industrial Economics & Trade (KIET). Expansion of Future Vehicle Technologies into the Agricultural Machinery Industry; Industrial Trends, No. 98; KIET: Sejong, Republic of Korea, 2022. [Google Scholar]

- Gao, H.; Xue, J. Modeling and economic assessment of electric transformation of agricultural tractors fueled with diesel. Sustain. Energy Technol. Assess. 2020, 39, 100697. [Google Scholar] [CrossRef]

- Wen, C.K.; Ren, W.; Zhu, Q.Z.; Zhao, C.J.; Luo, Z.H.; Zhang, S.L.; Meng, Z.J. Reducing operation emissions and improving work efficiency using a pure electric wheel drive tractor. Engineering 2024, 37, 230–245. [Google Scholar] [CrossRef]

- Choi, K.H.; Kim, S.M.; Hong, S. Analysis of static stability by modified mathematical model for asymmetric tractor-harvester system: Changes in lateral overturning angle by movement of center of gravity coordinates. J. Biosyst. Eng. 2017, 42, 127–135. [Google Scholar] [CrossRef]

- Watanabe, M.; Sakai, K. Impact dynamics model for a nonlinear bouncing tractor during inclined passage. Biosyst. Eng. 2019, 182, 84–94. [Google Scholar] [CrossRef]

- Son, J.; Kim, Y.; Kang, S.; Ha, Y. Enhancing safety through optimal placement of components in hydrogen tractor: Rollover angle analysis. Agriculture 2024, 14, 315. [Google Scholar] [CrossRef]

- Wang, M.; Ning, P.; Su, K.; Yoshinori, G.; Wang, W.; Cui, Y.; Cui, G. Slip-draft embedded control system by adaptively adjusting the battery position for electric tractors. Int. J. Agric. Biol. Eng. 2023, 16, 155–164. [Google Scholar] [CrossRef]

- Lee, D.; Yoo, H.J.; Shin, M.; Oh, J.; Shim, S.B. Analysis of overturning stability of small off-road vehicle. J. Biosyst. Eng. 2023, 48, 309–318. [Google Scholar] [CrossRef]

- Jang, M.K.; Hwang, S.J.; Kim, J.H.; Nam, J.S. Overturning and rollover characteristics of a tractor through dynamic simulations: Effect of slope angle and obstacles on a hard surface. Biosyst. Eng. 2022, 219, 11–24. [Google Scholar] [CrossRef]

- Xie, B.; Wang, S.; Wu, X.; Wen, C.; Zhang, S.; Zhao, X. Design and hardware-in-the-loop test of a coupled drive system for electric tractor. Biosyst. Eng. 2022, 216, 165–185. [Google Scholar] [CrossRef]

- Lajunen, A. Simulation of energy efficiency and performance of electrified powertrains in agricultural tractors. In Proceedings of the 2022 IEEE Vehicle Power and Propulsion Conference (VPPC), Merced, CA, USA, 1–4 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Łyp-Wrońska, K.; Gdowska, K.; Paciolla, F. Sustainability evaluation of hybrid agriculture-tractor powertrains. Sustainability 2024, 16, 1184. [Google Scholar] [CrossRef]

- Deng, X.; Sun, H.; Lu, Z.; Cheng, Z.; An, Y.; Chen, H. Research on dynamic analysis and experimental study of the distributed drive electric tractor. Agriculture 2022, 13, 40. [Google Scholar] [CrossRef]

- Guzzomi, A.L. A revised kineto-static model for Phase I tractor rollover. Biosyst. Eng. 2012, 113, 65–75. [Google Scholar] [CrossRef]

- Hunter, A.G.M. A review of research into machine stability on slopes. Saf. Sci. 1993, 16, 325–339. [Google Scholar] [CrossRef]

- Jiang, H.; Xu, G.; Zeng, W.; Gao, F.; Tang, X. Design and lateral stability analysis of an attitude adjustment tractor for moving on side slopes. Appl. Sci. 2024, 14, 2220. [Google Scholar] [CrossRef]

- RDA (Rural Development Administration). Korean Agricultural Machinery Testing Standards—Tractor. Available online: https://www.law.go.kr/admRulLsInfoP.do?admRulId=69848&efYd=0 (accessed on 5 August 2025).

- Organisation for Economic Co-Operation and Development (OECD). OECD Standard Codes for the Official Testing of Agricultural and Forestry Tractors; OECD Publishing: Paris, France, 2025; Available online: https://www.oecd.org/agriculture/tractors/ (accessed on 24 September 2025).

- ISO 5700:2025; Tractors for Agriculture and Forestry—Roll-Over Protective Structures (ROPS)—Static Test Method and Acceptance Conditions. International Organization for Standardization (ISO): Geneva, Switzerland, 2025.

- Lee, N.G.; Kim, Y.J.; Baek, S.M.; Moon, S.P.; Park, S.U.; Choi, Y.S.; Choi, C.H. Analysis of traction performance for agricultural tractor according to soil condition. J. Drive Control 2020, 17, 133–140. [Google Scholar] [CrossRef]

- Matache, M.G.; Cristea, M.; Găgeanu, I.; Zapciu, A.; Tudor, E.; Carpus, E.; Popa, L.D. Small power electric tractor performance during ploughing works. INMATEH Agric. Eng. 2020, 60, 123–128. [Google Scholar] [CrossRef]

| Parameters | Electric Tractor | Conventional Tractor |

|---|---|---|

| Length [mm] | 3840 | 3920 |

| Width [mm] | 1880 | 1940 |

| Height [mm] | 2415 | 2710 |

| Mass [kg] | 2800 | 3065 |

| Rated power [kW(ps)] | 55 (75) | 55 (75) |

| Minimum ground clearance [mm] | 493 | 450 |

| Wheelbase [mm] | 2143 | 2200 |

| Parameters | Battery | Engine |

|---|---|---|

| Length [mm] | 514.9 | 1352.3 |

| Width [mm] | 630.0 | 1003.0 |

| Height [mm] | 783.7 | 1487.5 |

| Mass [kg] | 500.0 | 461.0 |

| Parameters | Front-Mounted | Center-Mounted | Conventional |

|---|---|---|---|

| X coordinate [mm] | −86.22 | −15.06 | −11.14 |

| Y coordinate [mm] | 913.63 | 893.84 | 906.00 |

| Z coordinate [mm] | 1253.14 | 773.23 | 868.99 |

| Category | Front-Mounted | Son et al. | Validation Model |

|---|---|---|---|

| Specifications | Mass (kg) | 5100 | 5100 |

| Center of Gravity [mm] | (1355.72, 66, 1356.59) | (1355.72, 66, 1356.59) | |

| Conditions | Dynamic Friction Coefficient | 1.2 | 1.2 |

| Stiffness Coefficient [N/mm3] | 105 | 105 | |

| Damping Coefficient [N·s/mm] | 10 | 10 | |

| Result | Rollover Angle [°] | 35.89 | 37.92 |

| Orientation | Front-Mounted | Center-Mounted | Conventional |

|---|---|---|---|

| 0–75 |  |  |  |

| 90–165 |  |  |  |

| 180–255 |  |  |  |

| 270–345 |  |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Kang, S.; Han, Y.; Son, J.; Ha, Y. Comparative Analysis of Static Rollover Stability Between Conventional and Electric Tractor. Agriculture 2025, 15, 2099. https://doi.org/10.3390/agriculture15192099

Lee J, Kang S, Han Y, Son J, Ha Y. Comparative Analysis of Static Rollover Stability Between Conventional and Electric Tractor. Agriculture. 2025; 15(19):2099. https://doi.org/10.3390/agriculture15192099

Chicago/Turabian StyleLee, Juhee, Seokho Kang, Yujin Han, Jinho Son, and Yushin Ha. 2025. "Comparative Analysis of Static Rollover Stability Between Conventional and Electric Tractor" Agriculture 15, no. 19: 2099. https://doi.org/10.3390/agriculture15192099

APA StyleLee, J., Kang, S., Han, Y., Son, J., & Ha, Y. (2025). Comparative Analysis of Static Rollover Stability Between Conventional and Electric Tractor. Agriculture, 15(19), 2099. https://doi.org/10.3390/agriculture15192099