Performance Evaluation of a UAV-Based Graded Precision Spraying System: Analysis of Spray Accuracy, Response Errors, and Field Efficacy

Abstract

1. Introduction

- (1)

- Field flight accuracy assessment—evaluate the UAV’s flight precision and trajectory stability under real-world agricultural conditions;

- (2)

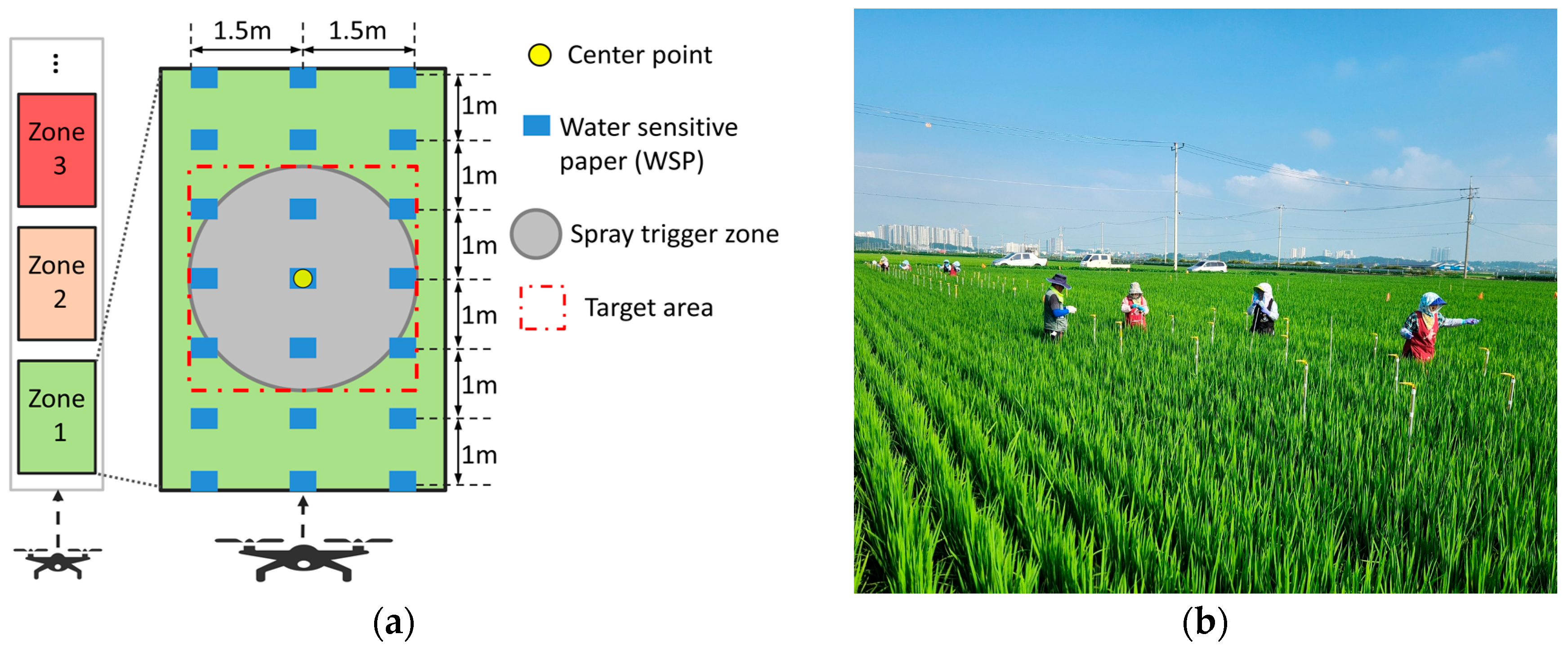

- Spraying effectiveness evaluation—analyze spray uniformity and deposition efficiency in field trials using water-sensitive paper (WSP);

- (3)

- Fertilizer application experiment—implement graded fertilizer spraying with the proposed precision UAV system and assess its impact on rice yield;

- (4)

- Correlation analysis of spraying and harvest outcomes—investigate the relationships between spraying levels and various harvest indicators to quantify the system’s agronomic benefits.

2. Materials and Methods

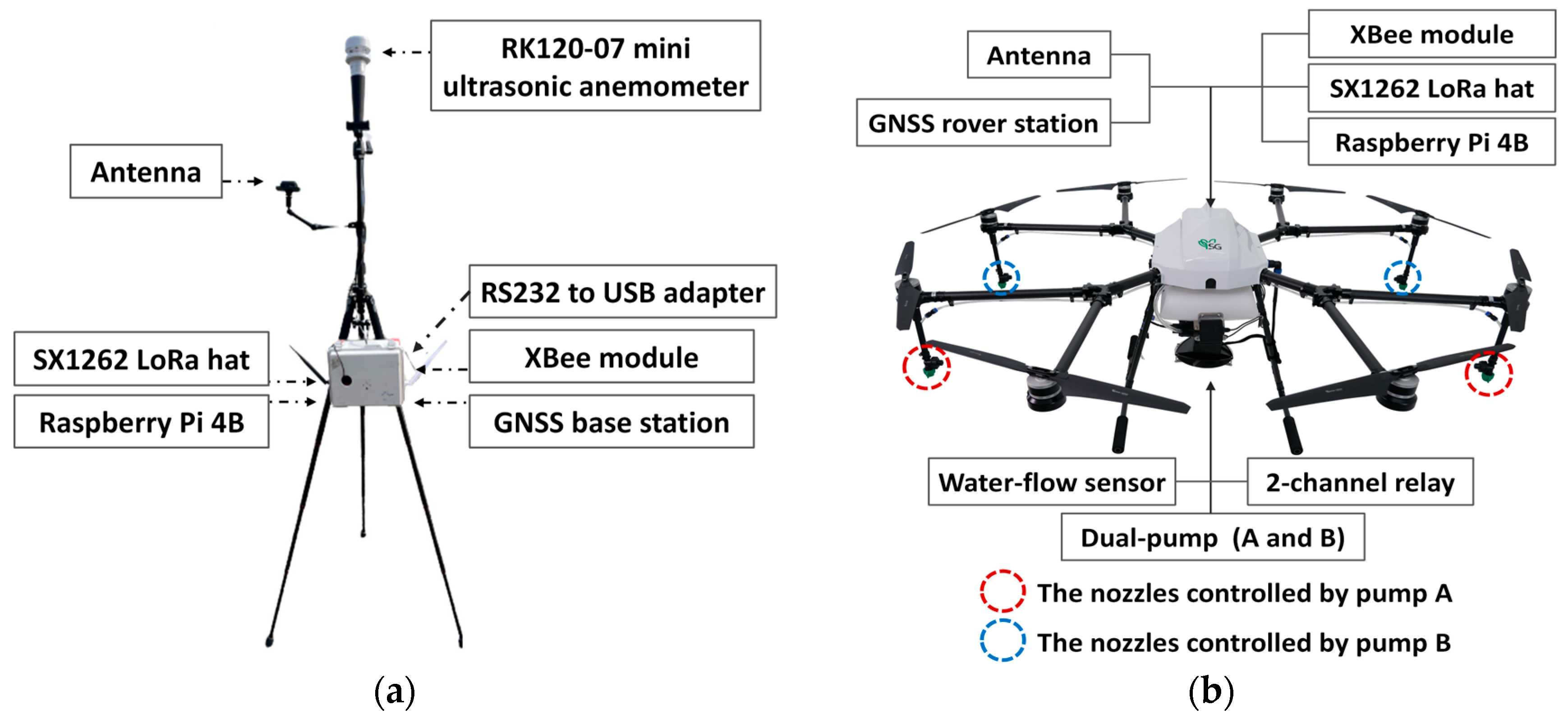

2.1. Hardware Design of the Automatic UAV-Based Spraying System

2.1.1. System Components and Architecture

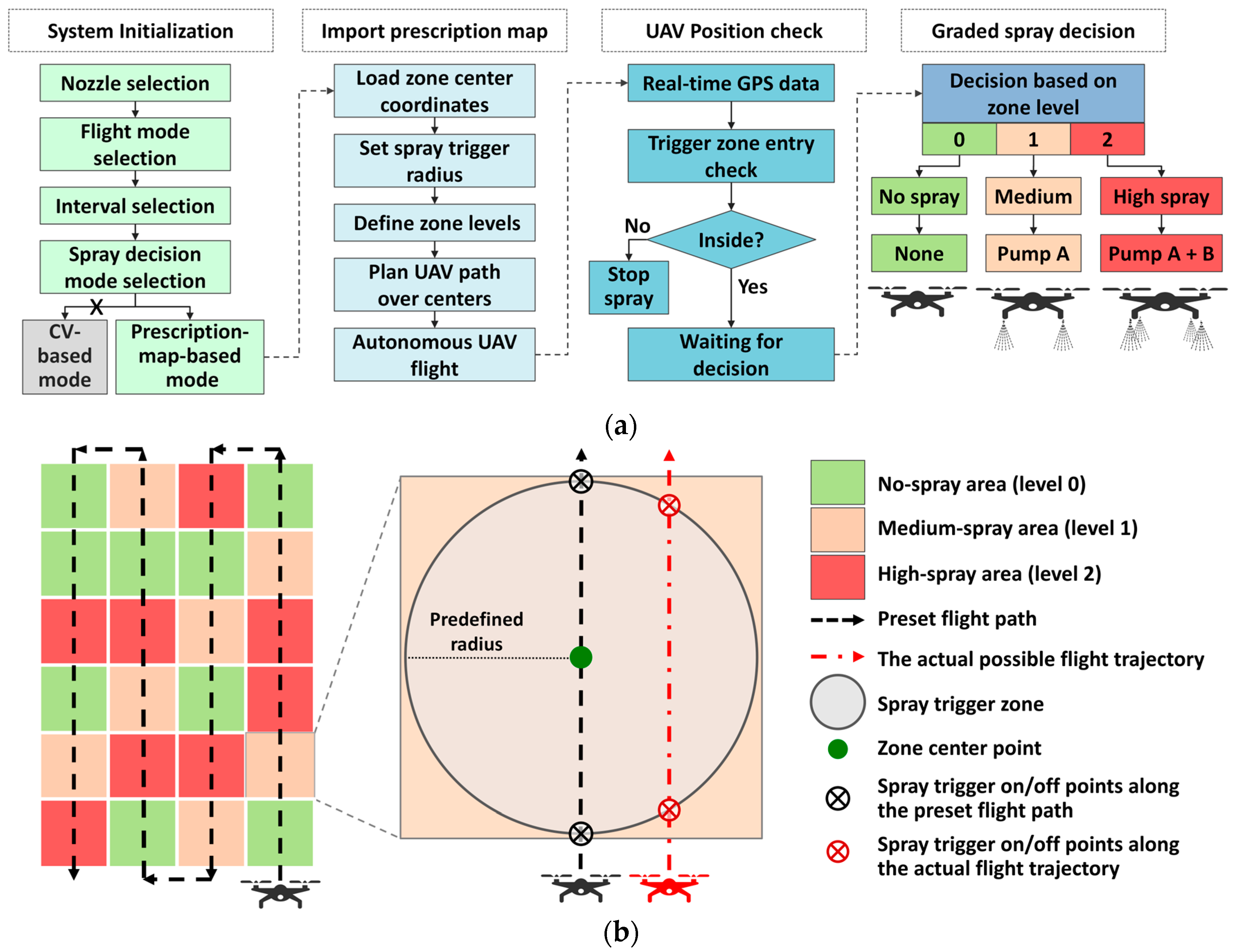

2.1.2. System Operation Principle

2.2. Experimental Methodology and Design

2.2.1. Experimental Site and Layout

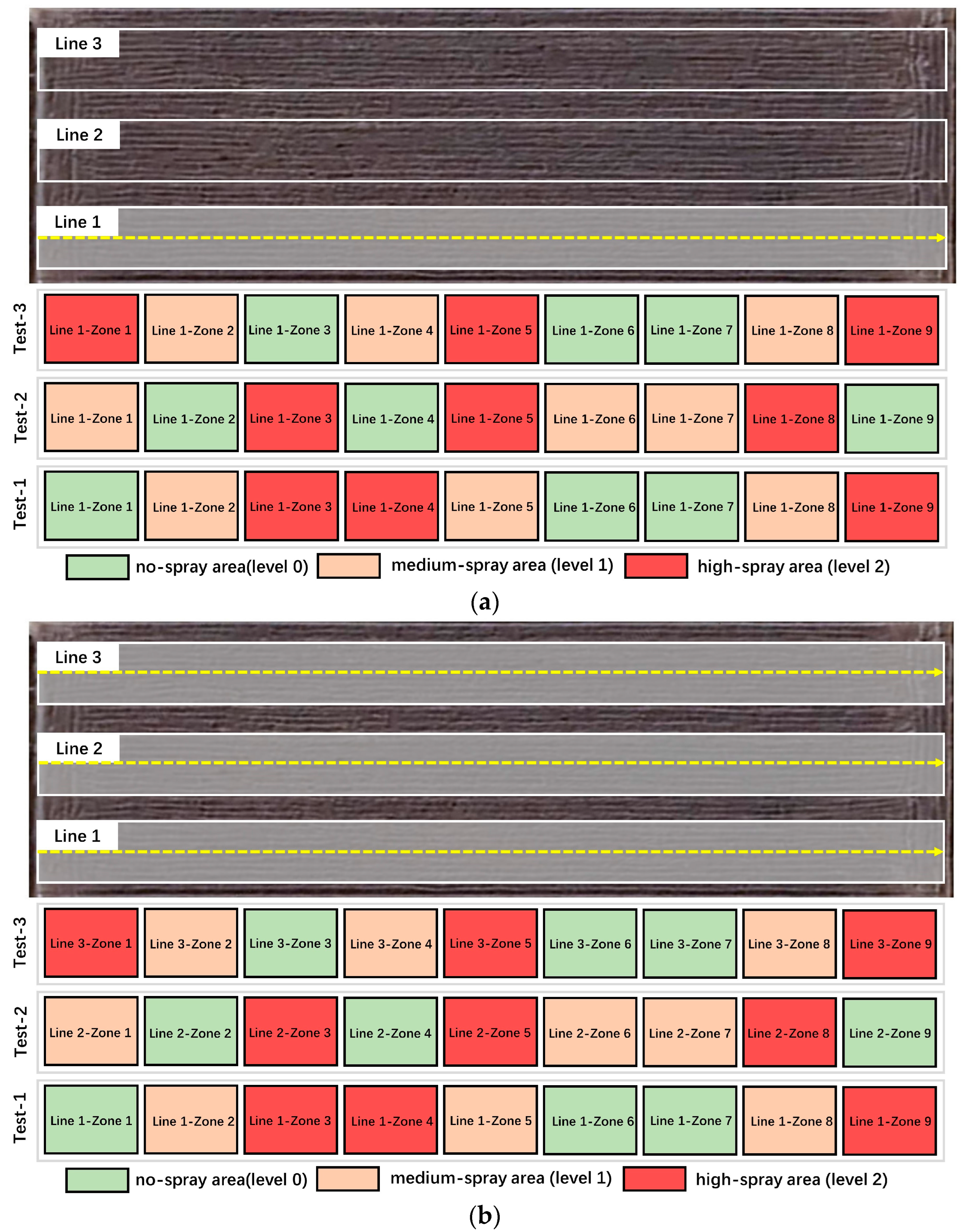

2.2.2. Flight Plan and Spraying Experiments

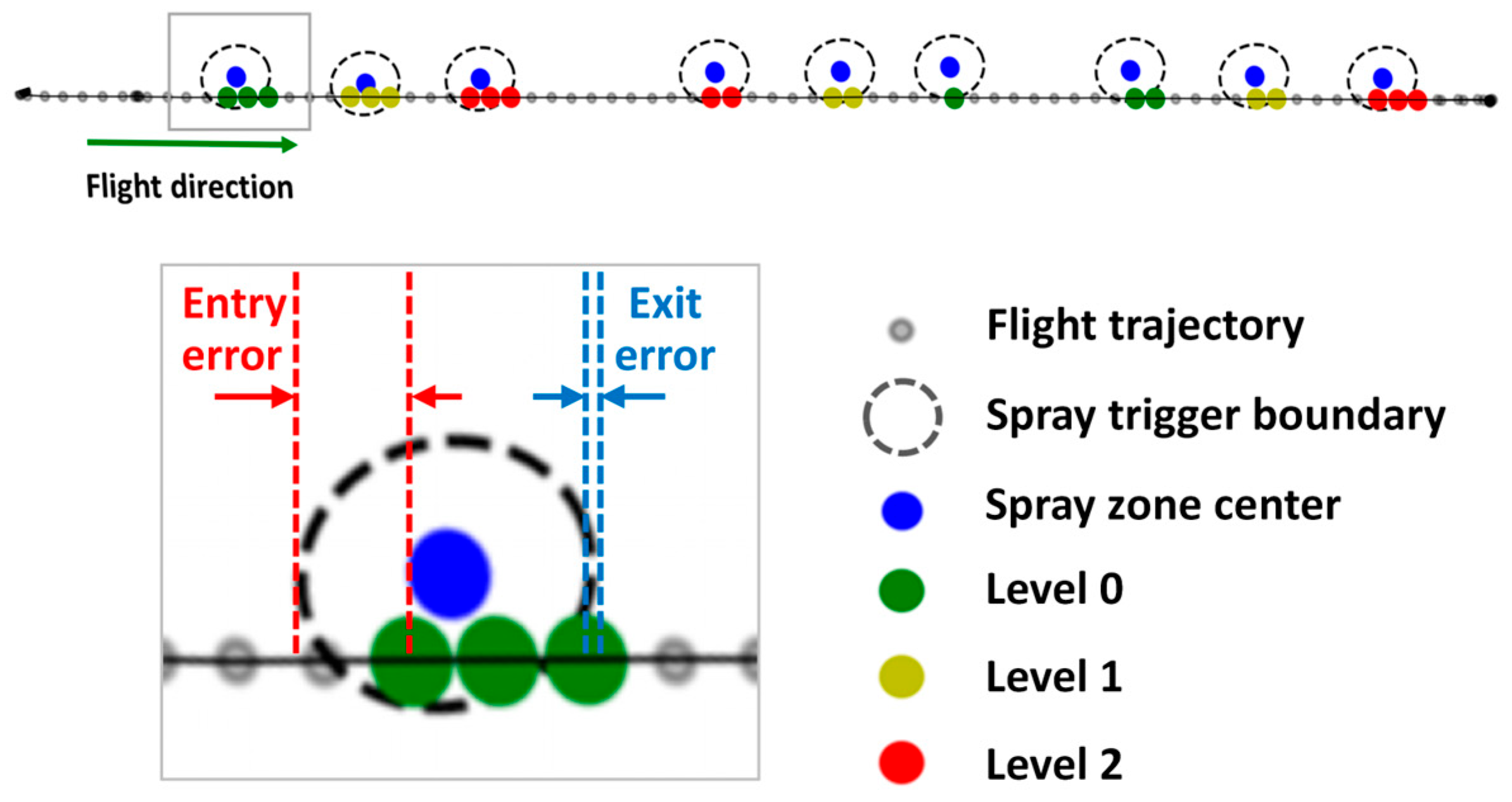

2.3. Experimental Method for Spray Error Analysis

2.3.1. WSP Placement and Droplet Deposition Analysis

2.3.2. Comprehensive Statistical Analysis of Spraying Errors

2.4. Experimental Analysis of Spraying System Response Errors

2.5. Analysis of Fertilizer Spraying Effectiveness

2.5.1. Evaluation Metrics for Post-Fertilization Rice Harvest

2.5.2. Correlation Analysis of Rice Harvest After Fertilization

3. Results

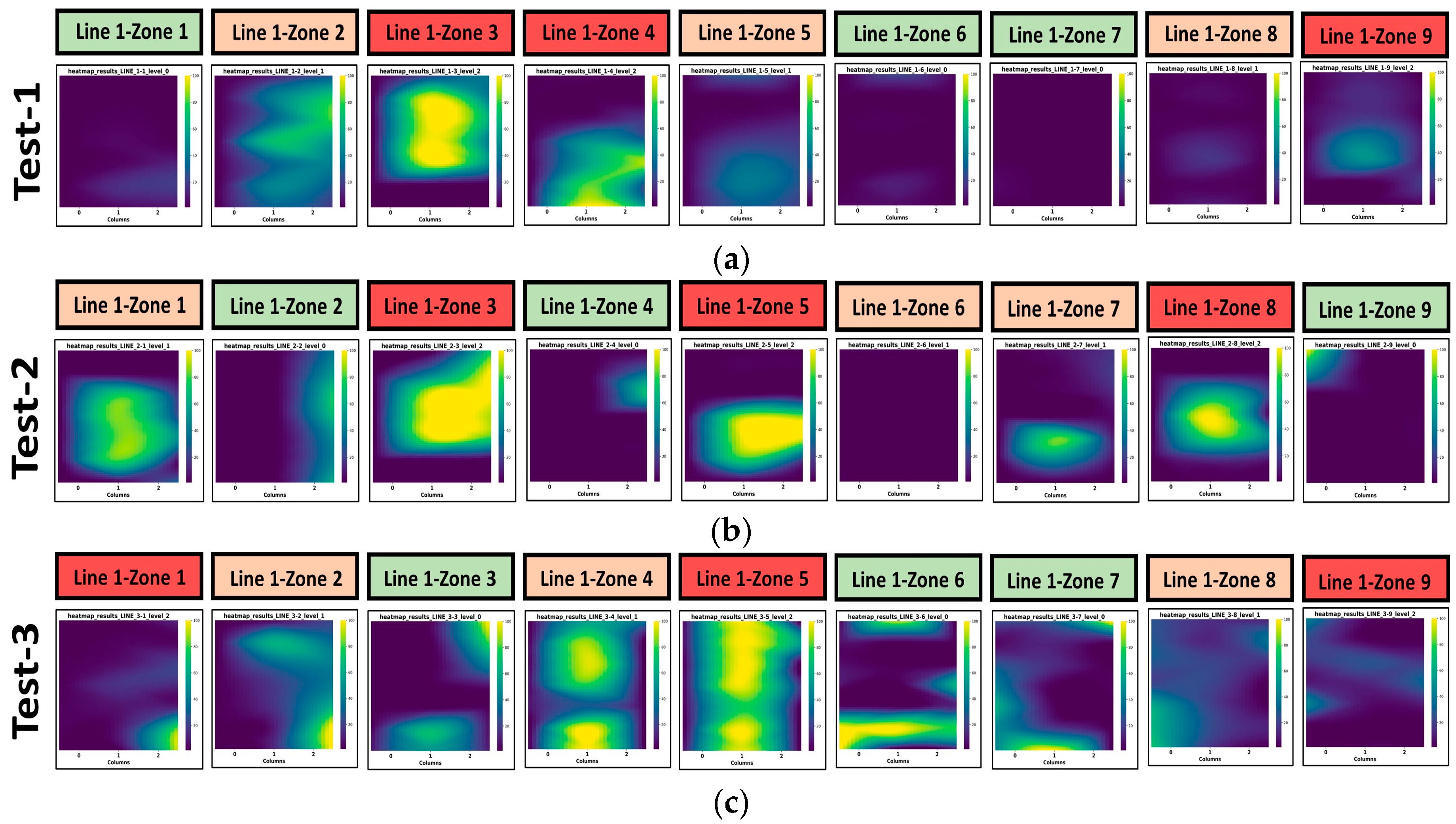

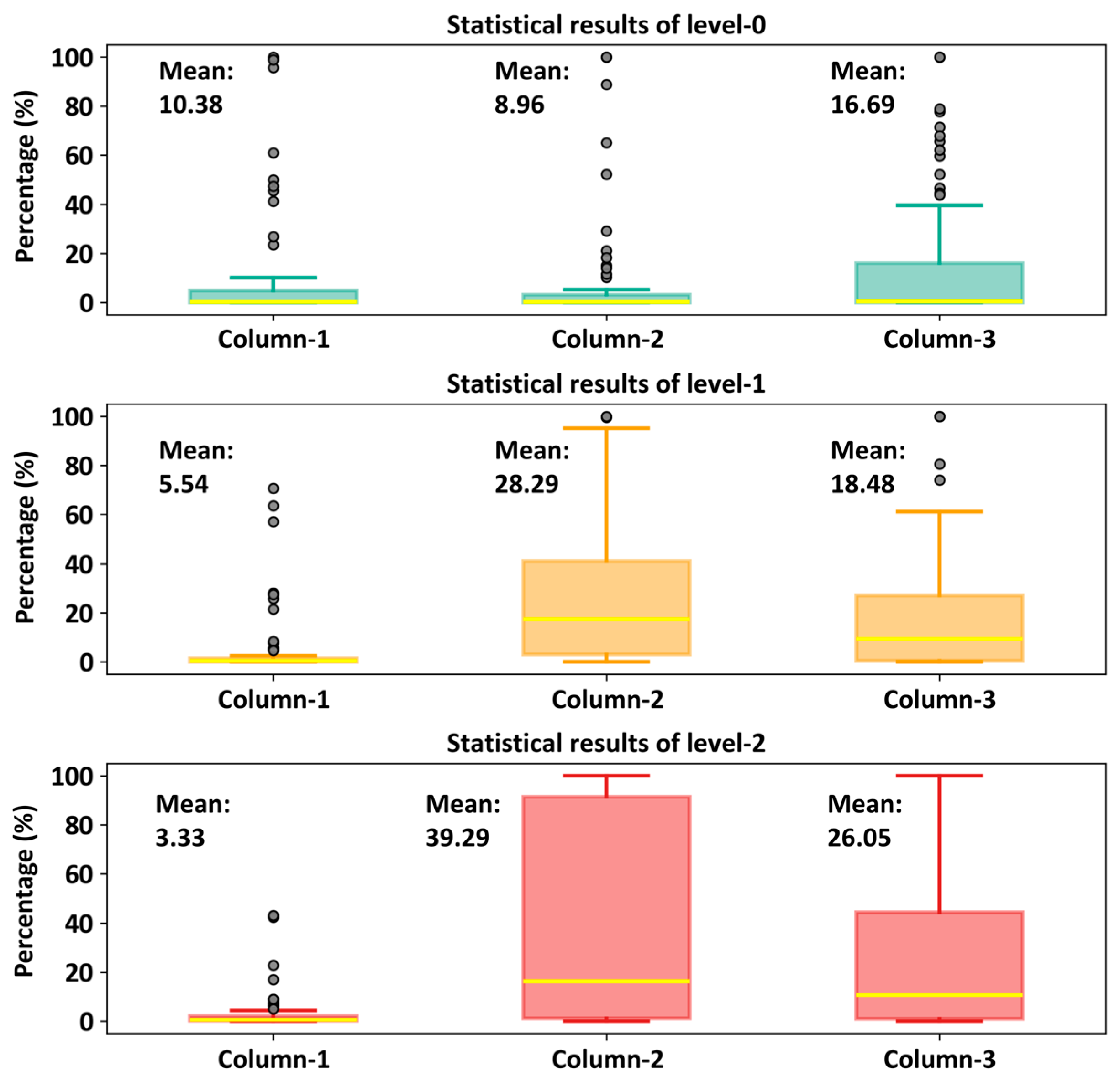

3.1. Analysis of Spray Errors and Distribution Patterns

3.1.1. Characterization of Droplet Deposition Patterns Under Different Spray Levels

3.1.2. Comprehensive Statistical Analysis of Spraying Performance Across All Regions

- (1)

- Non-uniform deposition: Across the three tests, droplet distribution was concentrated in certain regions instead of being evenly dispersed.

- (2)

- Inconsistent coverage in medium-spray zones: Coverage gaps and irregularities were frequently observed, likely due to wind effects or flight path deviations.

- (3)

- Unintended droplet dispersion in no-spray areas: Trace deposition outside designated spray zones suggests minor spray drift.

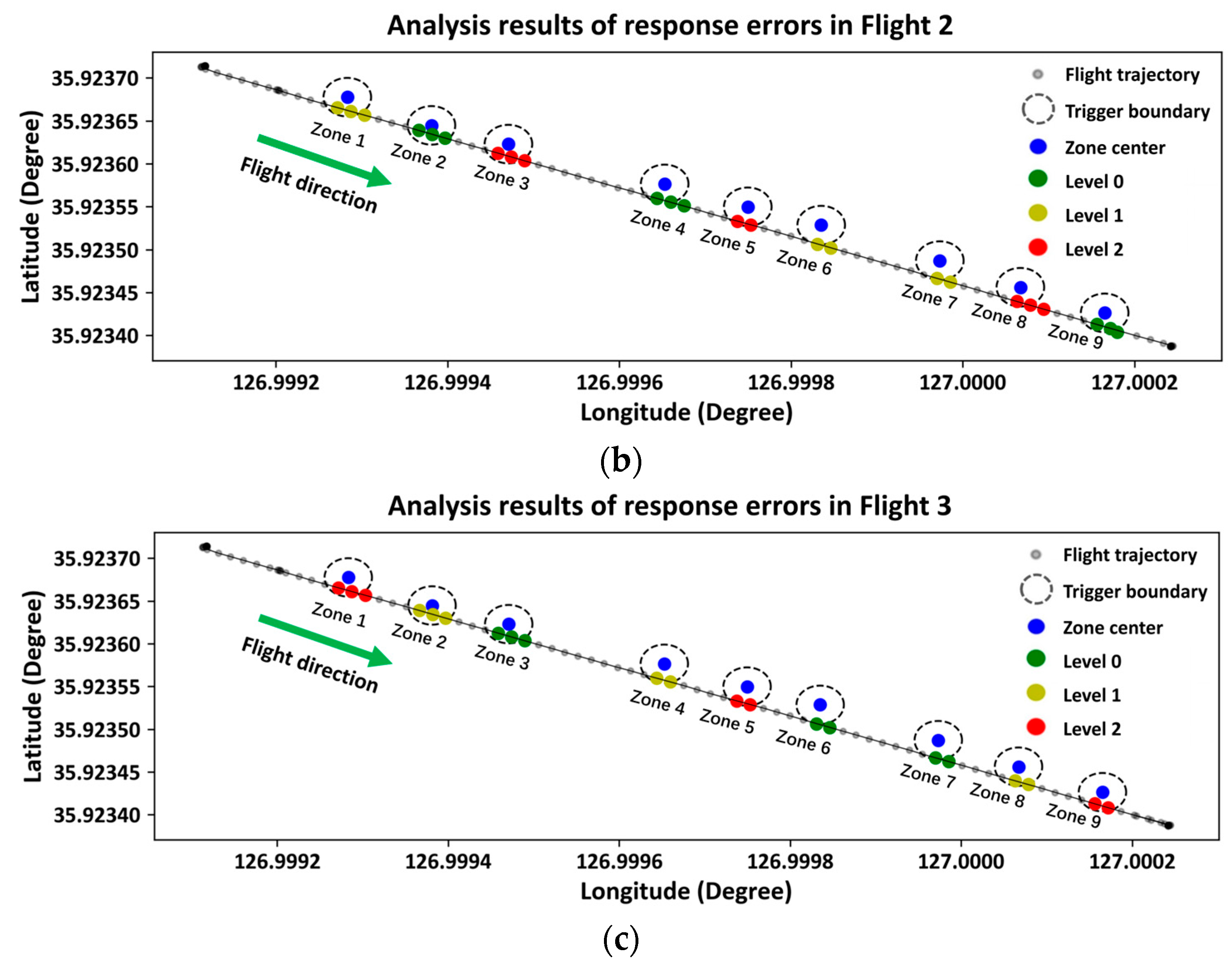

3.2. Comprehensive Analysis of Spraying System Response Errors

3.3. Correlation Analysis of Post-Fertilization Rice Harvest Outcomes

3.3.1. Analysis of Harvest Metrics

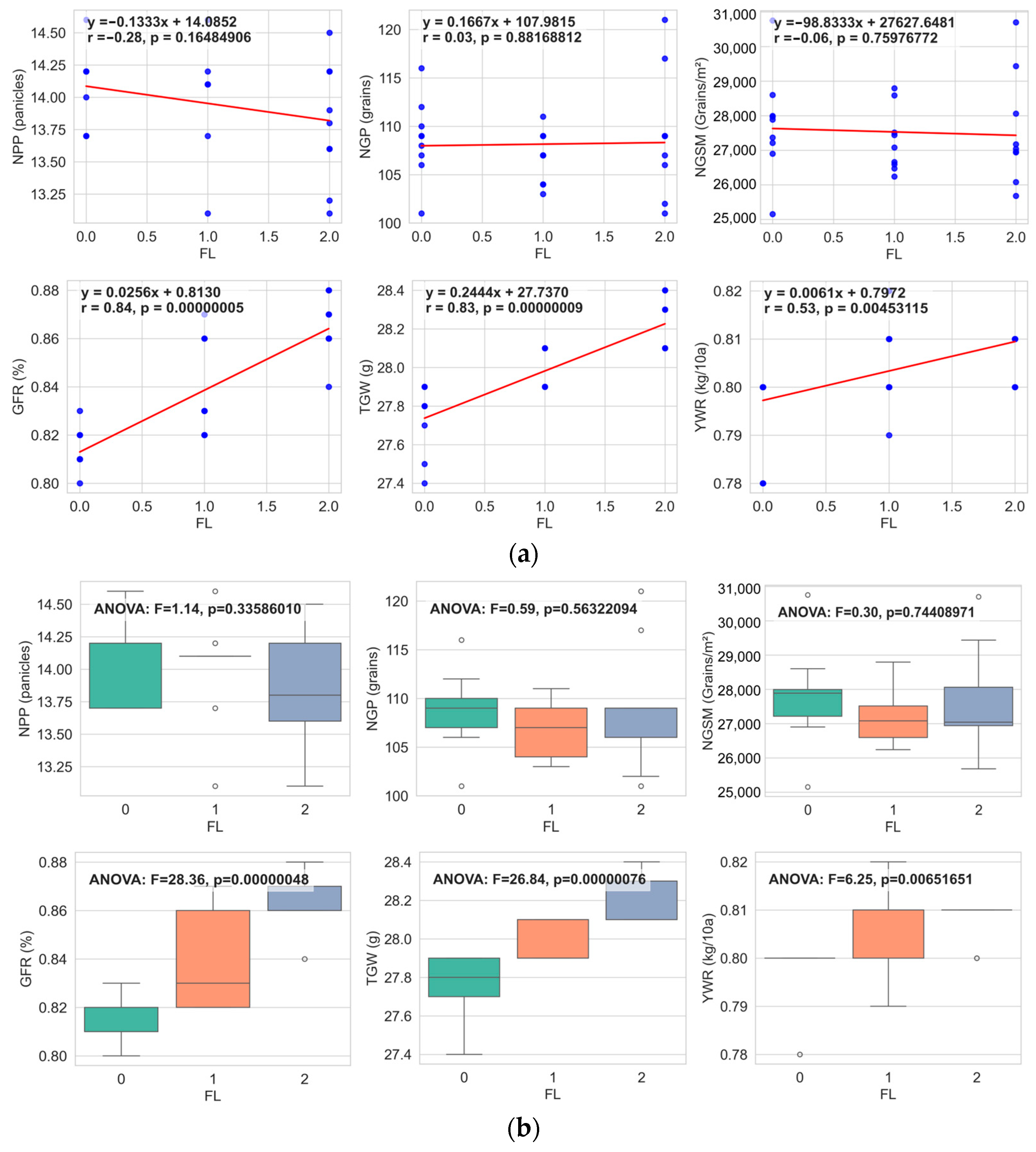

3.3.2. Correlation Analysis Between Fertilizer Application Rate and Harvest Outcomes

4. Discussion

- (1)

- Higher-performance embedded platforms: Replacing the RPI with a more powerful unit would reduce computational latency and enhance the accuracy of real-time spraying decisions.

- (2)

- Higher GNSS sampling frequency: Increasing the GNSS sampling rate to 5 Hz or higher, along with short-term trajectory corrections using inertial measurement unit sensors, would help compensate for UAV path deviations [25].

- (3)

- Wind-resistant control mechanisms: A real-time wind-adaptive spraying model that adjusts spray parameters based on wind speed and direction would improve spray uniformity [26].

- (4)

- (5)

- Airflow sensor integration: Incorporating real-time airflow sensors into the system would further strengthen spraying strategies, improving droplet stability in varying environmental conditions.

- (1)

- Increasing PWM resolution: Expanding the number of PWM levels from 3 to 5 or 10 would enable more refined adjustments to spray levels [30].

- (2)

- AI-driven dynamic spray adjustments: Integrating real-time AI-based predictions could enable automated fine-tuning of spray levels based on crop conditions and environmental factors [31].

- (3)

- Exploring pressure-regulated spray technologies: Combining variable-pressure spraying with prescription maps could further enhance spraying efficiency and reduce agrochemical waste.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, X.; Shu, L.; Chen, J.; Ferrag, M.A.; Wu, J.; Nurellari, E.; Huang, K. A Survey on Smart Agriculture: Development Modes, Technologies, and Security and Privacy Challenges. IEEE/CAA J. Autom. Sin. 2021, 8, 273–302. [Google Scholar] [CrossRef]

- Da Silveira, F.; Lermen, F.H.; Amaral, F.G. An overview of agriculture 4.0 development: Systematic review of descriptions, technologies, barriers, advantages, and disadvantages. Comput. Electron. Agric. 2021, 189, 106405. [Google Scholar] [CrossRef]

- Shaikh, F.K.; Karim, S.; Zeadally, S.; Nebhen, J. Recent Trends in Internet-of-Things-Enabled Sensor Technologies for Smart Agriculture. IEEE Internet Things J. 2022, 9, 23583–23598. [Google Scholar] [CrossRef]

- Shaikh, T.A.; Mir, W.A.; Rasool, T.; Sofi, S. Machine Learning for Smart Agriculture and Precision Farming: Towards Making the Fields Talk. Arch. Comput. Methods Eng. 2022, 29, 4557–4597. [Google Scholar] [CrossRef]

- Adli, H.K.; Remli, M.A.; Wan Salihin Wong, K.N.S.; Ismail, N.A.; González-Briones, A.; Corchado, J.M.; Mohamad, M.S. Recent Advancements and Challenges of AIoT Application in Smart Agriculture: A Review. Sensors 2023, 23, 3752. [Google Scholar] [CrossRef]

- García-Munguía, A.; Guerra-Ávila, P.L.; Islas-Ojeda, E.; Flores-Sánchez, J.L.; Vázquez-Martínez, O.; García-Munguía, A.M.; García-Munguía, O. A Review of Drone Technology and Operation Processes in Agricultural Crop Spraying. Drones 2024, 8, 674. [Google Scholar] [CrossRef]

- Elmeseiry, N.; Alshaer, N.; Ismail, T. A detailed survey and future directions of unmanned aerial vehicles (uavs) with potential applications. Aerospace 2021, 8, 363. [Google Scholar] [CrossRef]

- Huang, J.; Du, B.; Zhang, Y.; Quan, Q.; Wang, B.; Mu, L. A Pesticide Spraying Mission Allocation and Path Planning with Multicopters. IEEE Trans. Aerosp. Electron. Syst. 2024, 60, 2277–2291. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Y.; Xue, X.; Liu, X.; Liu, X. Optimal spraying task assignment problem in crop protection with multi-UAV systems and its order irrelevant enumeration solution. Biosyst. Eng. 2022, 214, 177–192. [Google Scholar] [CrossRef]

- Chen, S.; Lan, Y.; Zhou, Z.; Ouyang, F.; Wang, G.; Huang, X.; Cheng, S. Effect of droplet size parameters on droplet deposition and drift of aerial spraying by using plant protection UAV. Agronomy 2020, 10, 195. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, Y.; Du, H. An integrated framework for UAV-based precision plant protection in complex terrain: The ACHAGA solution for multi-tea fields. Front. Plant Sci. 2024, 15, 1440234. [Google Scholar] [CrossRef]

- Guebsi, R.; Mami, S.; Chokmani, K. Drones in Precision Agriculture: A Comprehensive Review of Applications, Technologies, and Challenges. Drones 2024, 8, 686. [Google Scholar] [CrossRef]

- Xu, J.; Liu, C.; Shao, J.; Xue, Y.; Li, Y. Collaborative orchard pesticide spraying routing problem with multi-vehicles supported multi-UAVs. J. Clean. Prod. 2024, 458, 142429. [Google Scholar] [CrossRef]

- Yallappa, D.; Kavitha, R.; Surendrakumar, A.; Suthakar, B.; Mohan Kumar, A.P.; Kannan, B.; Kalarani, M.K. Improving agricultural spraying with multi-rotor drones: A technical study on operational parameter optimization. Front. Nutr. 2024, 11, 1487074. [Google Scholar] [CrossRef] [PubMed]

- Liao, J.; Zang, Y.; Luo, X.; Zhou, Z.; Lan, Y.; Zang, Y.; Gu, X.; Xu, W.; Hewitt, A.J. Optimization of variables for maximizing efficacy and efficiency in aerial spray application to cotton using unmanned aerial systems. Int. J. Agric. Biol. Eng. 2019, 12, 10–17. [Google Scholar] [CrossRef]

- Shi, X.; Du, Y.; Liu, X.; Liu, C.; Hou, Q.; Chen, L.; Yong, R.; Ma, J.; Yang, D.; Yuan, H.; et al. Optimizing UAV spray parameters to improve precise control of tobacco pests at different growth stages. Pest Manag. Sci. 2024, 80, 5809–5819. [Google Scholar] [CrossRef]

- Wongsuk, S.; Qi, P.; Wang, C.; Zeng, A.; Sun, F.; Yu, F.; Zhao, X.; Xiongkui, H. Spray performance and control efficacy against pests in paddy rice by UAV-based pesticide application: Effects of atomization, UAV configuration and flight velocity. Pest Manag. Sci. 2024, 80, 2072–2084. [Google Scholar] [CrossRef] [PubMed]

- Shan, C.; Xue, C.; Zhang, L.; Song, C.; Kaousar, R.; Wang, G.; Lan, Y. Effects of different spray parameters of plant protection UAV on the deposition characteristics of droplets in apple trees. Crop Prot. 2024, 184, 106835. [Google Scholar] [CrossRef]

- Luo, S.; Wen, S.; Zhang, L.; Lan, Y.; Chen, X. Extraction of crop canopy features and decision-making for variable spraying based on unmanned aerial vehicle LiDAR data. Comput. Electron. Agric. 2024, 224, 109197. [Google Scholar] [CrossRef]

- Cavalaris, C.; Tagarakis, A.C.; Kateris, D.; Bochtis, D. Cost Analysis of Using UAV Sprayers for Olive Fruit Fly Control. AgriEngineering 2023, 5, 1925–1942. [Google Scholar] [CrossRef]

- Shahrooz, M.; Talaeizadeh, A.; Alasty, A. Agricultural Spraying Drones: Advantages and Disadvantages. In Proceedings of the 2020 Virtual Symposium in Plant Omics Sciences (OMICAS), Bogotá, Colombia, 23–27 November 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Lan, Y.; Thomson, S.J.; Huang, Y.; Hoffmann, W.C.; Zhang, H. Current status and future directions of precision aerial application for site-specific crop management in the USA. Comput. Electron. Agric. 2010, 74, 34–38. [Google Scholar] [CrossRef]

- Hanif, A.S.; Han, X.; Yu, S.H.; Han, C.; Baek, S.W.; Lee, C.G.; Lee, D.H.; Kang, Y.H. Modeling of the control logic of a UASS based on coefficient of variation spraying distribution analysis in an indoor flight simulator. Front. Plant Sci. 2023, 14, 1235548. [Google Scholar] [CrossRef]

- Wang, P.; Saiful Hanif, A.; Yu, S.-H.; Lee, C.-G.; Ho Kang, Y.; Lee, D.-H.; Han, X. Development of an autonomous drone spraying control system based on the coefficient of variation of spray distribution. Comput. Electron. Agric. 2024, 227, 109529. [Google Scholar] [CrossRef]

- Toscano, F.; Fiorentino, C.; Capece, N.; Erra, U.; Travascia, D.; Scopa, A.; Drosos, M.; D’Antonio, P. Unmanned Aerial Vehicle for Precision Agriculture: A Review. IEEE Access 2024, 12, 69188–69205. [Google Scholar] [CrossRef]

- Li, W.; Wu, B. Computational fluid dynamics investigation of pesticide spraying by agricultural drones. Comput. Electron. Agric. 2024, 227, 109506. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, T.; Song, C.; Yu, X.; Shan, C.; Gu, H.; Lan, Y. Evaluation of Spray Drift of Plant Protection Drone Nozzles Based on Wind Tunnel Test. Agriculture 2023, 13, 628. [Google Scholar] [CrossRef]

- Kim, S.K.; Ahmad, H.; Moon, J.W.; Jung, S.Y. Nozzle with a Feedback Channel for Agricultural Drones. Appl. Sci. 2021, 11, 2138. [Google Scholar] [CrossRef]

- Aminjan, K.K.; Sedaghat, M.; Heidari, M.; Khashehchi, M.; Mohammadzadeh, K.; Salahinezhad, M.; Bina, R. Numerical investigation of the impact of fuel temperature on spray characteristics in a pressure-swirl atomizer with spiral path. Exp. Comput. Multiph. Flow 2024, 6, 428–445. [Google Scholar] [CrossRef]

- Li, X.J.; Liang, Z.; Yang, G.; Lin, T.; Liu, B. Assessing the Severity of Verticillium Wilt in Cotton Fields and Constructing Pesticide Application Prescription Maps Using Unmanned Aerial Vehicle (UAV) Multispectral Images. Drones 2024, 8, 176. [Google Scholar] [CrossRef]

- Taseer, A.; Han, X. Advancements in variable rate spraying for precise spray requirements in precision agriculture using Unmanned aerial spraying Systems: A review. Comput. Electron. Agric. 2024, 219, 108841. [Google Scholar] [CrossRef]

- Lee, D.-H.; Seong, B.-G.; Baek, S.-Y.; Lee, C.-G.; Kang, Y.-H.; Han, X.; Yu, S.-H. Coverage Estimation of Droplets Sprayed on Water-Sensitive Papers Based on Domain-Adaptive Segmentation. Drones 2024, 8, 670. [Google Scholar] [CrossRef]

| Experimental Indicator | Unit |

|---|---|

| Fertilization levels (FL) | 0, 1, 2 |

| Number of panicles per plant (NPP) | Panicles |

| Number of grains per panicle (NGP) | Grains |

| Number of grains per square meter (NGSM) | Grains/m2 |

| Grain-filling rate (GFR) | % |

| Thousand-grain weight (TGW) | g |

| Yield of white rice (YWR) | kg/10a |

| Column 1 (%) | Column 2 (%) | Column 3 (%) | Average (%) | |

|---|---|---|---|---|

| Level 0 | 0.03–4.90 | 0.025–3.18 | 0.07–16.11 | 0.04–8.06 |

| Level 1 | 0.06–1.53 | 2.985–40.95 | 0.35–27.13 | 1.13–23.20 |

| Level 2 | 0.25–2.14 | 1.125–91.36 | 0.88–44.34 | 0.75–45.94 |

| Zone | 1st Entry Error (m) | 1st Exit Error (m) | 2nd Entry Error (m) | 2nd Exit Error (m) | 3rd Entry Error (m) | 3rd Exit Error (m) |

|---|---|---|---|---|---|---|

| 1 | 0.5992 | 1.1949 | 0.5992 | 1.1949 | 0.5992 | 1.1949 |

| 2 | 0.0897 | 0.5735 | 0.0897 | 0.5735 | 0.0897 | 0.5735 |

| 3 | 0.4960 | 0.9989 | 0.4960 | 0.9989 | 0.4960 | 0.9989 |

| 4 | 1.0657 | −0.1504 | 1.0657 | 1.6190 | 1.0657 | −0.1504 |

| 5 | 0.7048 | −0.5262 | 0.7048 | −0.5262 | 0.7048 | −0.5262 |

| 6 | 1.3358 | −1.3358 | 1.3358 | 0.4339 | 1.3358 | 0.4339 |

| 7 | 1.2361 | 0.5108 | 1.2361 | 0.5108 | 1.2361 | 0.5108 |

| 8 | 1.4238 | 0.3307 | 1.4238 | 2.0803 | 1.4238 | 0.3307 |

| 9 | 0.9515 | 1.4191 | 0.9515 | 0.6589 | 0.9405 | −0.3084 |

| Average | 0.8781 | 0.7823 | 0.8781 | 0.9552 | 0.8768 | 0.5586 |

| Sample | FL | NPP (Panicles) | NGP (Grains) | NGSM (Grains/m2) | GFR | YWR (kg/10a) | TGW (g) |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 13.7 | 109 | 27,214 | 0.82 | 447 | 27.4 |

| 2 | 0 | 13.7 | 108 | 26,902 | 0.81 | 473 | 27.9 |

| 3 | 0 | 13.7 | 101 | 25,153 | 0.81 | 439 | 27.5 |

| 4 | 0 | 14.2 | 108 | 27,884 | 0.80 | 495 | 27.9 |

| 5 | 0 | 14.0 | 112 | 28,602 | 0.81 | 440 | 27.4 |

| 6 | 0 | 14.6 | 116 | 30,756 | 0.81 | 505 | 27.8 |

| 7 | 0 | 14.0 | 110 | 27,990 | 0.83 | 526 | 28.0 |

| 8 | 0 | 14.2 | 106 | 27,367 | 0.80 | 496 | 27.7 |

| 9 | 0 | 14.4 | 107 | 27,973 | 0.82 | 500 | 27.9 |

| 10 | 1 | 14.2 | 103 | 26,593 | 0.86 | 522 | 28.1 |

| 11 | 1 | 13.0 | 111 | 26,236 | 0.87 | 521 | 28.2 |

| 12 | 1 | 14.0 | 104 | 26,473 | 0.82 | 493 | 27.9 |

| 13 | 1 | 14.1 | 104 | 26,662 | 0.83 | 487 | 28.1 |

| 14 | 1 | 14.4 | 109 | 28,580 | 0.81 | 533 | 27.9 |

| 15 | 1 | 13.7 | 109 | 27,151 | 0.82 | 507 | 27.9 |

| 16 | 1 | 14.8 | 107 | 28,793 | 0.84 | 561 | 28.1 |

| 17 | 1 | 14.6 | 102 | 27,076 | 0.83 | 512 | 27.9 |

| 18 | 1 | 14.1 | 107 | 27,441 | 0.86 | 543 | 28.1 |

| 19 | 2 | 14.2 | 101 | 26,076 | 0.87 | 520 | 28.4 |

| 20 | 2 | 13.2 | 107 | 25,680 | 0.87 | 509 | 28.3 |

| 21 | 2 | 14.0 | 121 | 30,703 | 0.86 | 624 | 28.2 |

| 22 | 2 | 13.9 | 107 | 27,042 | 0.88 | 547 | 28.2 |

| 23 | 2 | 13.6 | 109 | 26,953 | 0.82 | 506 | 28.1 |

| 24 | 2 | 14.1 | 106 | 27,175 | 0.87 | 542 | 28.1 |

| 25 | 2 | 14.2 | 109 | 28,059 | 0.86 | 561 | 28.2 |

| 26 | 2 | 13.8 | 117 | 29,434 | 0.84 | 561 | 28.3 |

| 27 | 2 | 14.5 | 102 | 26,940 | 0.86 | 536 | 28.4 |

| Avg. 1 (FL = 0) | 14.1 | 109 | 27,760 | 0.81 | 480 | 27.7 | |

| Avg. 2 (FL = 1) | 14.1 | 106 | 27,223 | 0.84 | 520 | 28.0 | |

| Avg. 3 (FL = 2) | 13.9 | 109 | 27,563 | 0.86 | 545 | 28.2 | |

| Pearson Correlation | ANOVA | |||

|---|---|---|---|---|

| Pearson r | p-Value | F-Statistic | p-Value | |

| FL-NPP | −0.27512999 | 0.16484906 | 1.14219919 | 0.33586010 |

| FL-NGP | 0.03005817 | 0.88168812 | 0.58803707 | 0.56322094 |

| FL-NGSM | −0.06171256 | 0.75976772 | 0.29926440 | 0.74408971 |

| FL-GFR | 0.83798114 *** | 0.00000005 *** | 28.35714286 *** | 0.00000048 *** |

| FL-TGW | 0.83013943 *** | 0.00000009 *** | 26.83870968 *** | 0.00000076 *** |

| FL-YWR | 0.52923775 ** | 0.00453115 ** | 6.25352113 ** | 0.00651651 ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, Y.; Yu, S.-H.; Lee, C.-G.; Wang, P.; Kang, Y.-H.; Lee, D.-H.; Han, X. Performance Evaluation of a UAV-Based Graded Precision Spraying System: Analysis of Spray Accuracy, Response Errors, and Field Efficacy. Agriculture 2025, 15, 2070. https://doi.org/10.3390/agriculture15192070

Lyu Y, Yu S-H, Lee C-G, Wang P, Kang Y-H, Lee D-H, Han X. Performance Evaluation of a UAV-Based Graded Precision Spraying System: Analysis of Spray Accuracy, Response Errors, and Field Efficacy. Agriculture. 2025; 15(19):2070. https://doi.org/10.3390/agriculture15192070

Chicago/Turabian StyleLyu, Yang, Seung-Hwa Yu, Chun-Gu Lee, Pingan Wang, Yeong-Ho Kang, Dae-Hyun Lee, and Xiongzhe Han. 2025. "Performance Evaluation of a UAV-Based Graded Precision Spraying System: Analysis of Spray Accuracy, Response Errors, and Field Efficacy" Agriculture 15, no. 19: 2070. https://doi.org/10.3390/agriculture15192070

APA StyleLyu, Y., Yu, S.-H., Lee, C.-G., Wang, P., Kang, Y.-H., Lee, D.-H., & Han, X. (2025). Performance Evaluation of a UAV-Based Graded Precision Spraying System: Analysis of Spray Accuracy, Response Errors, and Field Efficacy. Agriculture, 15(19), 2070. https://doi.org/10.3390/agriculture15192070