Considering the unique geographical location and ecological environment of Inner Mongolia, and with the primary goal of restoring degraded grassland ecology, we selected natural agropyron seeds, which are suitable for growth in arid and semi-arid regions, as the research subject. The choice of materials for agropyron seed pelletization focused on factors such as seed formation, bonding, compressive strength, and seed water absorption and cracking behavior. For the pelletization formulation, soybean flour was chosen as the solid binding agent, while diatomaceous earth was used as the filler, with a soybean flour to diatomaceous earth ratio of 3:7. This mixture, combined with water, was applied to the seed surface to form the pelletization coating. Given the requirements for grass seed broadcasting, a heavy pelletization coating approach was adopted, with a seed-to-powder mass ratio of 1:3 [

23,

24].

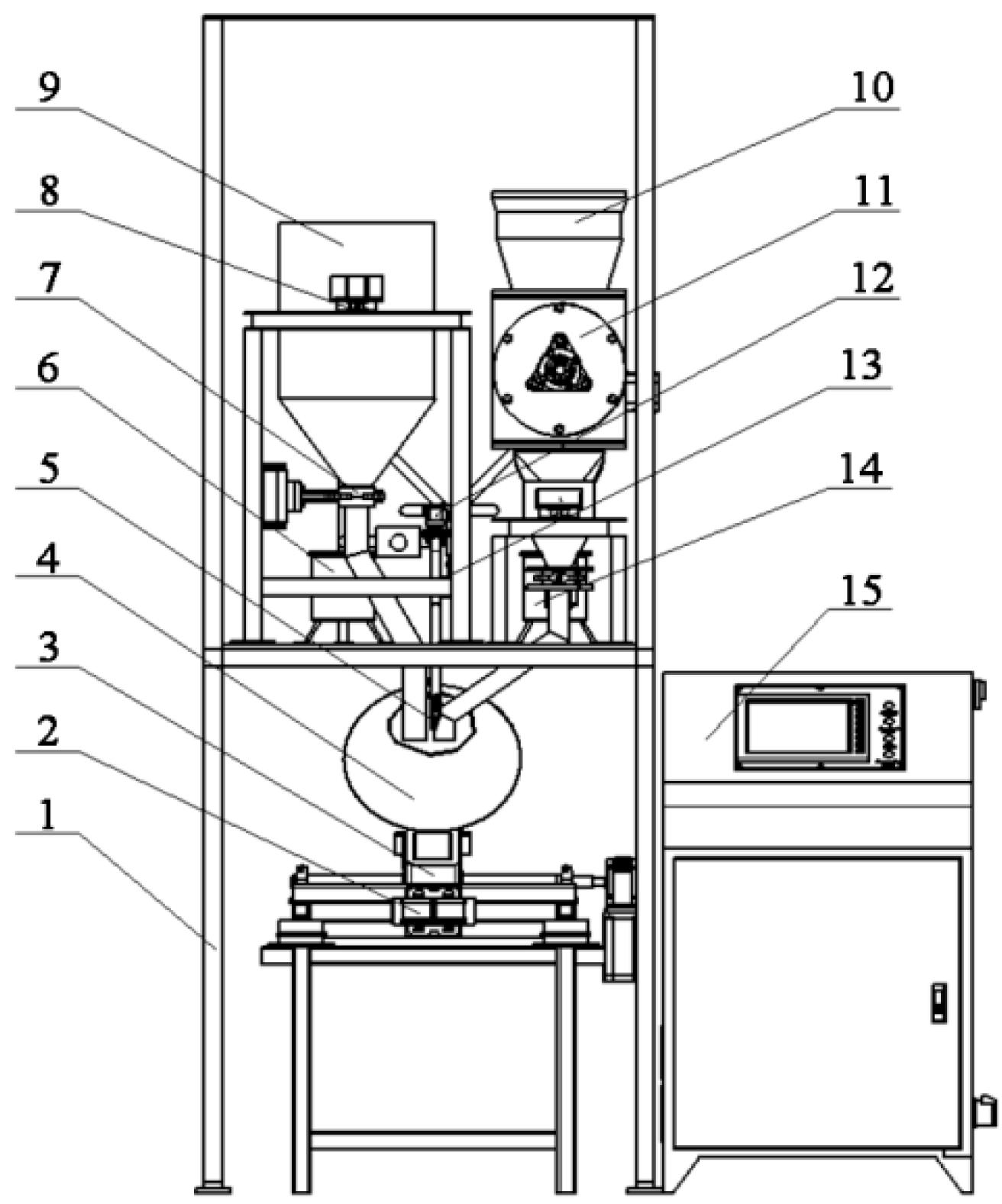

2.1. The Overall Structure and Working Principle of the Pelletization Coating Machine

The experimental setup primarily consists of a seed supply system, a powder supply system, a liquid supply system, a pelletization device, a vibration system, and a control system, among others. The overall structure is illustrated in

Figure 1. Preliminary experimental studies have shown that the vibration field can effectively address issues such as low pellet qualification rates and low compressive strength in traditional inclined pan pelletizing coating machines. Based on the structure of the inclined pan pelletizer, the vibration field was introduced into the machine. The upper part of the machine mainly consists of the feeding system, including the seed, powder, and liquid supply systems, while the lower part is dedicated to the pelletizing device and the overall control system of the machine.

Prior to initiating the pellet granulation coating process, a preliminary screening of the seeds is conducted to select seeds with consistent size and quality, serving as the foundation for the granulation process. The seeds are placed in the seed storage drum, the pelletizing powder is stored in the powder storage drum, and the binder is loaded into the liquid storage drum. Once the control system is activated, the seeds are fed into the pelletizing coating pot through the feeding device. Next, the binder is sprayed into the pelletizing coating pot in the form of a mist. Once the seed surfaces are moistened, the fillers and other powders required for the pelletization process are introduced into the pot in a specific ratio relative to the seeds. The forage seeds, within the coating pot, undergo both rotational and vibrational movements driven by centrifugal forces and the interaction of friction and shear forces. In this dynamic environment, the seed–powder mixture experiences diffusion-like motion between its inner and outer layers due to vibrational forces and collisions. As a result, the pelletized coating powder adheres uniformly to the surface of the seeds throughout the process. The supply of liquid and powder is performed iteratively, in a precise and controlled manner, until the desired seed weight gain ratio is achieved, indicating the completion of the pelletization process.

2.3. Theoretical Analysis of Pelletization and Coating Process for Forage Seeds

In the forage seed pill granulation coating process, both the seed and powder are initially introduced into the coating pot for thorough mixing. Subsequently, the binder is sprayed into the pot through nozzles, where it contacts the particles and adheres to their surfaces. This interaction creates liquid bridges among the particles, and at the contact points between seed and powder particles, a bonding force facilitates their fusion. Aggregation of particles occurs when the adhesive force exceeds the maximum rebound force during collisions, resulting in the formation of larger aggregated particles.

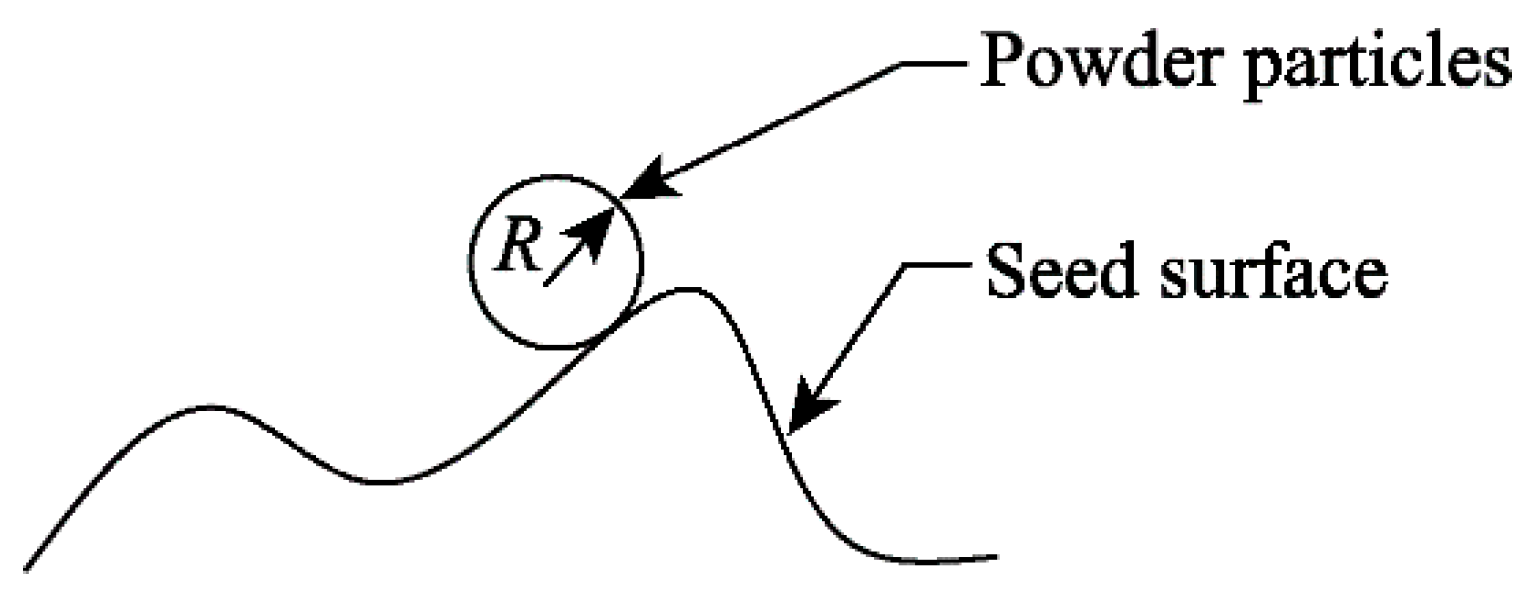

During the mixing process of seeds and pelletizing powder, the significantly smaller diameter of the powder particles compared to the seeds means that the seed particles can be approximated as having an infinitely large diameter and being without elasticity, similar to a flat plane. This interaction is illustrated in

Figure 3. Therefore, when powder particles with velocity v collide with the seed surface, they adhere to the Hertzian elastic contact theory model.

According to the Hertz elastic contact theory, the penetration depth

δ of the powder particles when subjected to the impact force

P onto the seed particles is given by:

where

;

;

E1,

v1 and

E2,

v2 are the modulus of elasticity and Poisson’s ratio of the powder and seed,

R1,

R2 are the radii of the powder particles and seed particles, respectively, in mm.

From Equation (1), the impact force

P when the powder particles collide with the seed particles can be determined as follows:

It is understood through Newton’s second law:

By integrating the equation above from 0 to

t, we obtain:

where

Vt=0 is the initial velocity of the powder particles impacting the seed, m/s, take the value of 0 at the maximum value of the velocity of the powder hitting the seed particle. Therefore, the maximum intrusion depth

δmax and the maximum load

Pmax between the seed and the powder can be expressed as follows:

where

v represents the relative velocity of the powder and seed particles at the point of impact, m/s.

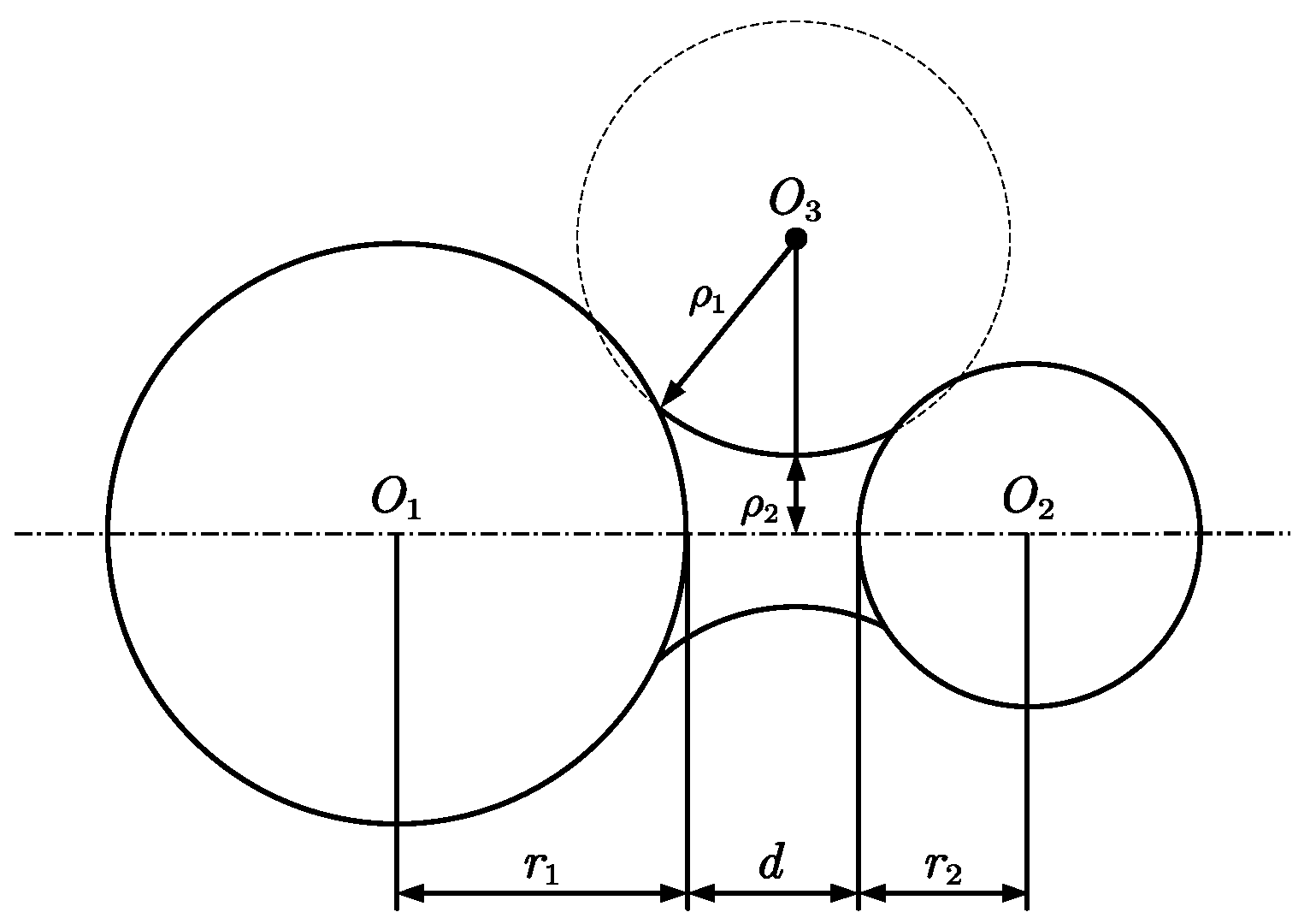

When the powder and seed particles are thoroughly mixed and the binder is sprayed into the coating pot, the binder moistens the surface of the seed particles, causing both the seed and powder particles to become wet particles. Consequently, the Hertz model should be refined to a wet particle model that incorporates a liquid bridge force, as illustrated in

Figure 4. In this figure, the radii of the seed particles and powder particles are denoted as

r1 and

r2, respectively, while the distance between the two particles is represented by

d. The formula for calculating the liquid bridge force

Fy between the wet seed and powder particles is expressed as follows:

where

γ the surface tension of the liquid between the two wet particles, N/m;

ρ1,

ρ2 are the first and second radii of curvature of the liquid bridge between the wet particles, m, respectively;

μ is the viscosity of the adhesive, Pa·s;

Vn,ij is the relative normal velocity of the two particles before collision, m/s.

The formation of particle aggregates among multiple particles is influenced by inter-particle forces, leading to an increase in particle size. The agglomeration characteristics between seed and powder particles are related to the qualification rate of the pelletized coating of forage seeds. This rate depends on the quantity and distribution of powder particles in the region surrounding the seed particles. If the distribution of powder particles around the seed is uniform, the pelletization qualification rate is high. However, if there are no powder particles around the seed, the multi-seed rate in the pelletized coating increases, and the aggregation of powder particles can result in a higher non-seed rate. To explore the mechanism of seed pelletization coating and understand the mixing and agglomeration characteristics between seed and powder particles during the coating process, the coefficient of variation is used as an evaluation parameter to measure the degree of mixing between seed and powder particles. A smaller coefficient of variation indicates a more uniform distribution of powder particles around the seed. The coefficient of variation is obtained through discrete element simulation experiments.

2.5. Single-Factor Testing

To determine the impact of the operating parameters of the pill granulation coating machine on the single-seed pilling pass rate, single-factor experiments were conducted on the following parameters: coating pot rotation speed, tilt angle, vibration frequency, vibration amplitude, and vibration direction. In the single-factor experiments, the ranges of the parameters were selected based on preliminary tests [

13]. The design of these experiments is shown in

Table 2, while the results of both the pilling coating tests and simulation experiments are presented in

Figure 6. The coefficient of variation reflects the simulation results, whereas the pilling pass rate represents the outcomes of the physical experiments in the single-factor analysis.

To further validate the practical applicability of the discrete element simulation method and to optimize the working parameters for the pelletizing coating of agropyron seeds, additional experiments were conducted. Several factors influence the degree of uniform mixing between seeds and powder. To identify the parameters that significantly impact the pelletizing coating process, the

Cv was used as the response variable. Parameters with substantial effects were identified using the Plackett–Burman test. The experimental design involved using high and low levels for the five test parameters listed in

Table 3. The Plackett–Burman test efficiently screened and identified parameters with notable effects on the pelletizing coating process.