Technological Properties of Ancient Wheat Species and Common Wheat Grown Organically Under Mouldboard Ploughing and Shallow Tillage

Abstract

1. Introduction

2. Materials and Methods

2.1. Field Experiment

2.2. Soil and Weather Conditions

2.3. Laboratory Analysis Procedure

- Grain and Flour Analysis. In previously cleaned, representative grain samples, the following parameters were determined in four replicates:

- ➢

- Mass of thousand grains (MTG)—determination consisted of counting 1000 grains and then weighing them; a grain counter (Sadkiewicz Instruments, 2 Startowa Street, 85-744 Bydgoszcz, Poland) and an electronic scale were used for the test [44].

- ➢

- Hectolitre mass (HM)—an SH-type densitometer and electronic balance [44].

- ➢

- Vitreosity (VIT)—a farinotome [44] was used for the analysis, 50 wheat kernels were placed in the farinotome and cut crosswise, the number of vitreous and mealy kernels was counted and converted to %.

- ➢

- Falling number (FN) was determined using the Hagberg–Perten method [45], after prior grinding of the grain on a special hammer mill (type RT 120—Sweden), using an automatic SWD device to determine the value of the falling number (to 7 g of grinded grain placed in a tube, 25 mL of distilled water was added, a viscometer stirrer was mixed and inserted, the whole was placed in a viscometer; after the analysis was completed, the result was read—the time of the viscometer stirrer falling in seconds).

- ➢

- ➢

- The flour yield (FY) and milling efficiency factor (MEF) were also calculated. The flour yield (FY) is the amount of flour obtained from the weight of milled grain expressed as a percentage (a laboratory grain mill type WZ-1 was used).

- Dough Analysis. To determine the rheological properties of the dough, a consistograph connected to a computer was used, on the screen of which a consistographic graph was obtained and the results were read [44]. This device measures and records the resistance that the dough exerts during mixing, allowing properties such as water absorption of flour (WA), dough development time (DDT), dough stability time (DST), and dough softening (DSF) to be determined.

- Bread Evaluation. The value of the direct baking index, which is the volume of bread from 100 g of flour, was obtained after a single-phase baking process [44].

- a—volume of 1 loaf (cm3),

- b—dough yield (weight of dough obtained from 100 g of flour),

- c—the mass (g) of a piece of dough formed for baking [=300 g].

- a—the mass of a piece of dough formed for baking [g].

- b—weight of the baked bread immediately after removing from the oven [g].

- a—the mass of a piece of dough formed for baking [g].

- c—weight of baked, cooled bread after 24 h [g].

- Colour of wheat grain and flour. The colour of the grain and flour of the cereals tested was determined using a CR-410 colorimeter (Konica-Minolta, Tokyo, Japan).

2.4. Statistical Analysis of the Results

3. Results and Discussion

3.1. Physical Parameters of Grain

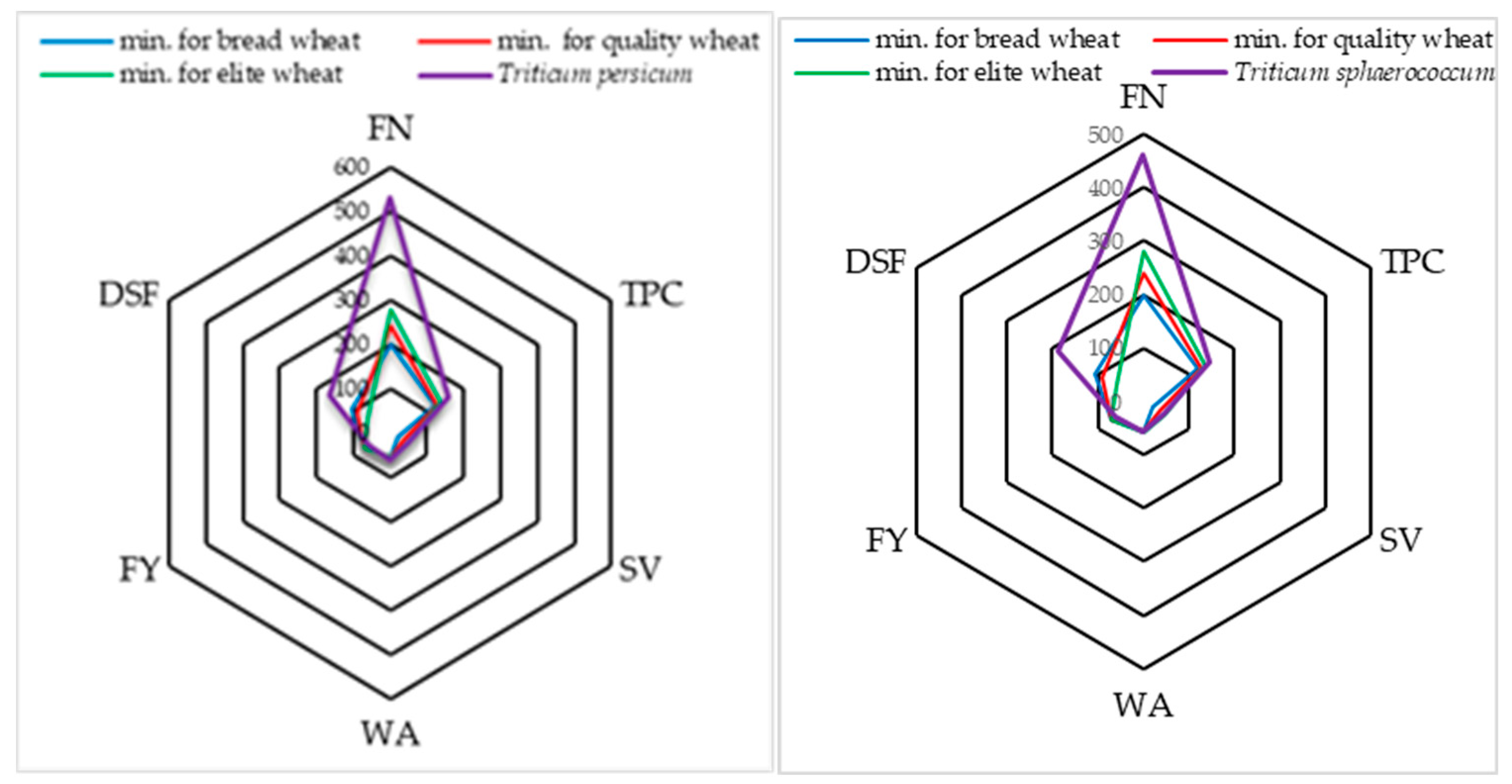

3.2. Technological Parameters of Grain

3.3. Flour Characteristics

3.4. Rheological Features

3.5. Bread Characteristics

3.6. Colour of Wheat Grain and Flour

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jaskulska, I.; Jaskulski, D.; Gałęzewski, L.; Knapowski, T.; Kozera, W.; Wacławowicz, R. Mineral composition and baking value of the winter wheat grain under varied environmental and agronomic conditions. J. Chem. 2018, 2018, 5013825. [Google Scholar] [CrossRef]

- Lacko-Bartošová, M.; Lacko-Bartošová, L.; Konvalina, P.; Matejková, E.; Bieliková, D. Rheological dough properties of organic spelt and emmer wheat for assessment of bread making quality. Zemdirbyste-Agriculture 2021, 108, 279–286. [Google Scholar] [CrossRef]

- Mitura, K.; Cacak-Pietrzak, G.; Feledyn-Szewczyk, B.; Szablewski, T.; Studnicki, M. Yield and grain quality of common wheat (Triticum aestivum L.) depending on the different farming systems (organic vs. integrated vs. conventional). Plants 2023, 12, 1022. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. World Food Situation. 2025. Available online: https://www.fao.org/worldfoodsituation/csdb/en (accessed on 28 November 2024).

- Suchowilska, E.; Wiwart, M.; Krska, R.; Kandler, W. Do Triticum aestivum L. and Triticum spelta L. hybrids constitute a promising source material for quality breeding of new wheat varieties? Agronomy 2020, 10, 43. [Google Scholar] [CrossRef]

- EUROSTAT. Available online: https://ec.europa.eu/eurostat (accessed on 15 November 2022).

- Łaba, S.; Cacak-Pietrzak, G.; Łaba, R.; Sułek, A.; Szczepański, K. Food losses in consumer cereal production in Poland in the context of food security and environmental impact. Agriculture 2022, 12, 665. [Google Scholar] [CrossRef]

- Knapowski, T.; Spychaj-Fabisiak, E.; Kozera, W.; Barczak, B.; Murawska, B. Mineral fertilization and baking value of grain and flour of Triticum aestivum ssp. spelta L. Am. J. Exp. Agric. 2016, 11, 1–11. [Google Scholar] [CrossRef]

- Arzani, A.; Ashraf, M. Cultivated Ancient Wheats (Triticum spp.): A potential source of health-beneficial food products. Compr. Rev. Food Sci. Food Saf. 2017, 16, 477–488. [Google Scholar] [CrossRef]

- Shewry, P.R. Do ancient types of wheat have health benefits compared with modern bread wheat? J. Cereal Sci. 2018, 79, 469–476. [Google Scholar] [CrossRef]

- Geisslitz, S.; Longin, C.F.H.; Scherf, K.A.; Koehler, P. Comparative study on gluten protein composition of ancient (einkorn, emmer and spelt) and modern wheat species (durum and common wheat). Foods 2019, 8, 409. [Google Scholar] [CrossRef]

- Belcar, J.; Sobczyk, A.; Sobolewska, M.; Stankowski, S.; Gorzelany, J. Characteristics of technological properties of grain and flour from ancient varieties of wheat (einkorn, emmer and spelt). Acta Univ. Cibiniensis Ser. E Food Technol. 2020, 24, 269–278. [Google Scholar] [CrossRef]

- Tran, K.; Konvalina, P.; Capouchova, I.; Janovska, D.; Lacko-Bartosova, M.; Kopecky, M.; Tran, P. Comparative study on protein quality and rheological behavior of different wheat species. Agronomy 2020, 10, 1763. [Google Scholar] [CrossRef]

- Kulathunga, J.; Reuhs, B.L.; Zwinger, S.; Simsek, S. Comparative study on kernel quality and chemical composition of ancient and modern wheat species: Einkorn, emmer, spelt and hard red spring wheat. Foods 2021, 10, 761. [Google Scholar] [CrossRef]

- Jorjadze, M.; Berishvili, T.; Shatberashvili, E. The ancient wheats of Georgiaand their traditional use in the southern part of the country. Emir. J. Food Agric. 2014, 26, 192–202. [Google Scholar] [CrossRef]

- Nocente, F.; Galassi, E.; Taddei, F.; Natale, C.; Gazza, L. Ancient caucasian wheats: A contribution for sustainable diets and food diversity. Foods 2022, 11, 1209. [Google Scholar] [CrossRef] [PubMed]

- Szczepanek, M.; Lemańczyk, G.; Nowak, R.; Graczyk, R. Response of Indian dwarf wheat and Persian wheat to sowing density and hydrothermal conditions of the growing seasons. Agriculture 2022, 12, 205. [Google Scholar] [CrossRef]

- Szczepanek, M.; Siwik-Ziomek, A.; Lemańczyk, G.; Lamparski, R.; Graczyk, R. Effect of reduced tillage on soil enzyme activity, pests pressure and productivity of organically grown spring wheat species. Agronomy 2023, 13, 287. [Google Scholar] [CrossRef]

- Andruszczak, S. Reaction of winter spelt cultivars to reduced tillage system and chemical plant protection. Zemdirbyste-Agriculture 2017, 104, 15–22. [Google Scholar] [CrossRef]

- Geisslitz, S.; Wieser, H.; Scherf, K.A.; Koehler, P. Gluten protein composition and aggregation properties as predictors for bread volume of common wheat, spelt, durum wheat, emmer and einkorn. J. Cereal Sci. 2018, 83, 204–212. [Google Scholar] [CrossRef]

- Pandino, G.; Mattiolo, E.; Lombardo, S.; Lombardo, G.M.; Mauromicale, G. Organic cropping system affects grain chemical composition, rheological and agronomic. performance of durum wheat. Agronomy 2020, 10, 46. [Google Scholar] [CrossRef]

- Worthington, V. Nutritional quality of organic versus conventional fruits, vegetables and grains. J. Altern. Complement. Med. 2001, 7, 161–173. [Google Scholar] [CrossRef]

- Bobryk-Mamczarz, A.; Kiełtyka-Dadasiewicz, A.; Rachoń, L. Usefulness of hulled wheats grown in Polish environment for wholegrain pasta-making. Foods 2021, 10, 458. [Google Scholar] [CrossRef]

- Rachoń, L.; Krochmal-Marczak, B.; Cebulak, T. Suitability of common, durum and spelt spring wheat grain for bread production depending on the intensity of production technology. Agron. Sci. 2020, 75, 25–36. (In Polish) [Google Scholar] [CrossRef]

- Devi, U.; Grewal, S.; Yang, C.Y.; Hubbart-Edwards, S.; Scholefield, D.; Ashling, S.; Burridge, A.; King, I.P.; King, J. Development and characterisation of interspecific hybrid lines with genome-wide introgressions from Triticum timopheevii in a hexaploid wheat background. BMC Plant Biol. 2019, 19, 183. [Google Scholar] [CrossRef]

- Zargar, M.; Polityko, P.; Pakina, E.; Bayat, M.; Vandyshev, V.; Kavhiza, N.; Kiselev, E. Productivity, quality and economics of four spring wheat (Triticum aestivum L.) cultivars as affected by three cultivation technologies. Agron. Res. 2018, 16, 2254–2264. [Google Scholar] [CrossRef]

- Sułek, A.; Wyzińska, M.; Cacak-Pietrzak, G. Impact of tillage on yield and quality traits of grains of spring wheat cultivars. In Proceedings of the 2019 18th International Scientific Conference on Engineering for Rural Development, LLU, Jelgava, Latvia, 22–24 May 2019; pp. 600–606. [Google Scholar] [CrossRef]

- Wanic, M.; Denert, M.; Treder, K. Effect of forecrops on the yield and quality of common wheat and spelt wheat grain. J. Elem. 2019, 24, 369–383. [Google Scholar] [CrossRef]

- Bouacha, O.D.; Nouaigui, S.; Rezgui, S. Effects of N and K fertilizers on durum wheat quality in different environments. J. Cereal Sci. 2014, 59, 9–14. [Google Scholar] [CrossRef]

- Dziki, D.; Cacak-Pietrzak, G.; Gawlik-Dziki, U.; Świeca, M.; Miś, A.; Różyło, R.; Jończyk, K. Physicochemical properties and milling characteristics of spring wheat from different farming systems. J. Agric. Sci. Technol. 2017, 19, 1253–1266. Available online: https://jast.modares.ac.ir/article-23-7491-en.html (accessed on 20 August 2025).

- Jańczak-Pieniążek, M.; Buczek, J.; Kaszuba, J.; Szpunar-Krok, E.; Bobrecka-Jamro, D.; Jaworska, G. A Comparative assessment of the baking quality of hybrid and population wheat cultivars. Appl. Sci. 2020, 10, 7104. [Google Scholar] [CrossRef]

- Sułek, A.; Cacak-Pietrzak, G. The influence of production technology on yield selected quality parameters of spring wheat cultivars. Agric. Sci. Crop Sci. Anim. Sci. Res. Rural Dev. 2018, 2, 42–48. [Google Scholar] [CrossRef]

- Gawęda, D.; Haliniarz, M. Grain yield and quality of winter wheat depending on previous crop and tillage system. Agriculture 2021, 11, 133. [Google Scholar] [CrossRef]

- Yousefian, M.; Shahbazi, F.; Hamidian, K. Crop yield and physicochemical properties of wheat grains as affected by tillage systems. Sustainability 2021, 13, 4781. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.C.; Shi, C.; Chen, J.; Zhou, Q.; Xiong, Y. Soil respiration in a triple intercropping system under conservation tillage. Plant Soil Environ. 2015, 61, 378–384. [Google Scholar] [CrossRef]

- Woźniak, A.; Stępniowska, A. Yield and quality of durum wheat grain in different tillage systems. J. Elem. 2017, 22, 817–829. [Google Scholar] [CrossRef]

- Beach, H.M.; Laing, K.W.; Van De Walle, M.; Martin, R.C. The current state and future directions of organic no-till farming with cover crops in Canada, with case study support. Sustainability 2018, 10, 373. [Google Scholar] [CrossRef]

- Fernandez, M.R.; Zentner, R.P.; Schellenberg, M.P.; Leeson, O.A.; Alandenola, O.; McConkey, B.G.; Luce, M. Grain yield and quality of organic crops grown under reduced tillage and diversified sequences. Agron. J. 2019, 111, 793–804. [Google Scholar] [CrossRef]

- Peigné, J.; Casagrande, M.; Payet, V.; David, C.; Sans, F.X.; Blanco-Moreno, J.M.; Cooper, J.; Gascoyne, K.; Antichi, D.; Bàrberi, P.; et al. How organic farmers practice conservation agriculture in Europe. Renew. Agric. Food Syst. 2015, 31, 72–85. [Google Scholar] [CrossRef]

- Woźniak, A. Chemical properties and enzyme activity of soil as affected by tillage system and previous crop. Agriculture 2019, 9, 262. [Google Scholar] [CrossRef]

- Woźniak, A.; Rachoń, L. Effect of tillage systems on the yield and quality of winter wheat grain and soil properties. Agriculture 2020, 10, 405. [Google Scholar] [CrossRef]

- Chiriţă, S.; Rusu, T.; Urdă, C.; Cheţan, F.; Racz, I. Winter wheat yield and quality depending on chemical fertilization, different treatments and tillage systems. AgroLife Sci. J. 2023, 12, 34–39. [Google Scholar] [CrossRef]

- Skrajda-Brdak, M.; Konopka, I.; Tańska, M.; Szczepanek, M.; Sadowski, T.; Rychcik, B. Low molecular phytochemicals of Indian dwarf (Triticum sphaerococcum Percival) and Persian wheat (T. carthlicum Nevski) grain. J. Cereal Sci. 2020, 91, 102887. [Google Scholar] [CrossRef]

- Sadkiewicz, K.; Sadkiewicz, J.; Sadkiewicz, J. Bydgoszcz Apparatus for Testing Grain, Flour and Bread, 2nd ed.; Wydawnictwa Uczelniane Akademii Techniczno-Rolniczej w Bydgoszczy: Bydgoszcz, Poland, 2004; p. 156. (In Polish) [Google Scholar]

- PN-EN ISO 3093:2010; Wheat, Rye and Flour Obtained from Them, Durum Wheat and Semolina—Determination of Falling Number by the Hagberg-Perten Method. Polish Committee for Standardization: Warsaw, Poland, 2010. (In Polish)

- PN-EN-ISO 20483:2014-02; Cereal Grains and Legume Seeds. Determination of Protein Content Using NIR Devices. Polish Committee for Standardization: Warsaw, Poland, 2014. (In Polish)

- PN-EN ISO 5529:2010; Determination of Sedimentation Index—Zeleny’s Test; Determination of Sedimentation Index Values Using NIR Devices. Polish Committee for Standardization: Warsaw, Poland, 2010. (In Polish)

- PN-EN ISO 21415-2:2015-12; Determination of Wet Gluten. Determination of Wet Gluten Using NIR Devices. Polish Committee for Standardization: Warsaw, Poland, 2015. (In Polish)

- PN-EN ISO 2171:2010; Cereal Grains, Legume Seeds and Their Products—Determination of Ash Content; Determination of Ash Content Using NIR Devices. Polish Committee for Standardization: Warsaw, Poland, 2010. (In Polish)

- Lacko-Bartošová, M.; Lacko-Bartošová, L.; Kaur, A.; Moudrý, J. Comparative assessment of agro-morphological and quality traits of ancient wheat cultivars grown under organic farming. Agriculture 2022, 12, 1476. [Google Scholar] [CrossRef]

- Mazzoncini, M.; Antichi, D.; Silvestri, N.; Ciantelli, G.; Sgherri, C. Organically vs conventionally grown winter wheat: Effects on grain yield, technological quality, and on phenolic composition and antioxidant properties of bran and refined flour. Food Chem. 2015, 175, 445–451. [Google Scholar] [CrossRef]

- Sobolewska, M.; Stankowski, S. The influence of farming systems on the technological quality of grain and flour cultivars of winter wheat. Folia Pomer. Univ. Technol. Stetin. Agric. Aliment. Pisc. Zootech. 2017, 3321, 73–82. [Google Scholar] [CrossRef]

- Rachoń, L.; Bobryk-Mamczarz, A.; Kiełtyka-Dadasiewicz, A. Hulled wheat productivity and quality in modern agriculture, against conventional wheat species. Agriculture 2020, 10, 275. [Google Scholar] [CrossRef]

- Borkowska, B.; Banach, D. Assessment of selected physicochemical properties of wheat and rye from the northern and southern region of Poland. Rocz. Nauk. Stow. Ekon. Rol. Agrob. 2018, 20, 18–22. [Google Scholar] [CrossRef]

- PN-R-74107; Cereal Grain—Wheat. Polish Committee for Standardization: Warsaw, Poland, 1997; pp. 1–5. (In Polish)

- Kulathunga, J.; Simsek, S. Dietary fiber variation in ancient and modern wheat species: Einkorn, emmer, spelt and hard red spring wheat. J. Cereal Sci. 2022, 104, 103420. [Google Scholar] [CrossRef]

- Szafrańska, A. Technological value of wheat grain from the 2018 harvest in Poland. Przegl. Zboż. Młyn. 2018, 62, 26–31. (In Polish) [Google Scholar]

- Buczek, J. Quality and productivity of hybrid wheat depending on the tillage practices. Plant Soil Env. 2020, 66, 415–420. [Google Scholar] [CrossRef]

- Podolska, G.; Sułek, A. Wheat grain quality in Poland and the EU. Pam. Puł. 2003, 132, 363–369. (In Polish) [Google Scholar]

- Takač, V.; Tóth, V.; Rakszegi, M.; Mikó, P.; Mikić, S.; Mirosavljević, M. The influence of farming systems, genotype and their interaction on bioactive compound, protein and starch content of bread and spelt wheat. Foods 2022, 11, 4028. [Google Scholar] [CrossRef]

- Longin, C.F.H.; Ziegler, J.; Schweiggert, R.; Koehler, P.; Carle, R.; Würschum, T. Comparative study of hulled (einkorn, emmer, and spelt) and naked wheats (durum and bread wheat): Agronomic performance and quality traits. Crop Sci. 2016, 56, 302–311. [Google Scholar] [CrossRef]

- Wenda-Piesik, A.; Knapowski, T.; Ropińska, P.; Kazek, M. Grain quality of spring wheat cultivars (Triticum aestivum L. Emend. Fiori et Paol.) planted in late autumn and spring. Acta Agrophysica 2017, 24, 601–612. Available online: http://www.acta-agrophysica.org/Issue-4-2017,7234 (accessed on 25 August 2025). (In Polish).

- De Santis, M.A.; Giuliani, M.M.; Giuzio, L.; De Vita, P.; Lovegrove, A.; Shewry, P.R.; Flagella, Z. Differences in gluten protein composition between old and modern durum wheat genotypes in relation to 20th century breeding in Italy. Eur. J. Agric. 2017, 87, 19–29. [Google Scholar] [CrossRef]

- Augspole, I.; Linina, A.; Rutenberga-Ava, A.; Svarta, A.; Strazdina, V. Effect of organic and conventional production systems on the winter wheat grain quality. In Proceedings of the 2019 13th Baltic Conference on Food Science and Technology “Food. Nutrition. Well-Being”, LLU, Jelgava, Latvia, 2–3 May 2019; pp. 93–97. [Google Scholar] [CrossRef]

- Jurga, R. Technological properties of wheat flour and possibilities of their modification. Przeg. Zboż. Młyn. 2014, 58, 7–9. (In Polish) [Google Scholar]

- Rachoń, L.; Bobryk-Mamczarz, A.; Kiełtyka-Dadasiewicz, A. Study on mineral composition of selected wheat species. Przem. Chem. 2019, 98, 1888–1890. [Google Scholar] [CrossRef]

- Rachoń, L.; Bobryk-Mamczarz, A.; Kiełtyka-Dadasiewicz, A. Assessment of the domestic variety Triticum durum ‘SMH87’ as a raw material for pasta production. Agron. Sci. 2021, 76, 5–16. (In Polish) [Google Scholar] [CrossRef]

- Serban, L.R.; Păucean, A.; Man, S.M.; Chis, M.S.; Muresan, V. Ancient wheat species: Biochemical profile and impact on sourdough bread characteristics—A review. Processes 2021, 9, 2008. [Google Scholar] [CrossRef]

- Shewry, P.R. Wheat. J. Exp. Bot. 2009, 60, 1537–1553. [Google Scholar] [CrossRef]

- Sobczyk, A.; Pycia, K.; Jaworska, G. Comparative characteristics of the technological value of grain of old varieties and new types of spelled (Triticum spelta L.) and common wheat grain (Triticum vulgare). Zesz. Probl. Postęp. Nauk. Rol. 2017, 589, 81–91. [Google Scholar] [CrossRef]

- Szwedziak, K.; Polańczyk, E.; Nowaczyk, M. Analysis of quality of selected wheat flour type. Post. Tech. Przetw. Spoż. 2018, 2, 5–8. (In Polish) [Google Scholar]

- Serna-Saldivar, S.O. Cereal Grains: Properties, Processing, and Nutritional Attributes; CRC Press: London, UK, 2016. [Google Scholar] [CrossRef]

- Żuk-Gołaszewska, K.; Majewska, K.; Tyburski, J.; Gołaszewski, J. Physical and technological properties of kernels and flour made from spelt grown in an organic farming system in north-eastern Poland. J. Cereal Sci. 2018, 79, 501–507. [Google Scholar] [CrossRef]

- Zhai, S.; Liu, J.; Xu, D.; Wen, W.; Yan, J.; Zhang, P.; Wan, Y.; Cao, S.; Hao, Y.; Xia, X.; et al. A genome-wide association study reveals a rich genetic architecture of flour color-related traits in bread wheat. Front. Plant Sci. 2018, 9, 1136. [Google Scholar] [CrossRef] [PubMed]

- Banach, J.K.; Majewska, K.; Żuk-Gołaszewska, K. Effect of cultivation system on quality changes in durum wheat grain and flour produced in North-Eastern Europe. PLoS ONE 2021, 16, e0236617. [Google Scholar] [CrossRef] [PubMed]

| Tillage Method | Wheat Species | MTG g | HM kg·hL−1 | VIT % |

|---|---|---|---|---|

| Ploughing | T. sphaerococcum | 25.5 ± 3.9 a | 74.9 ± 1.0 a | 80.2 ± 2.5 a,b |

| T. persicum | 25.6 ± 4.0 a | 73.6 ± 2.3 a | 82.0 ± 8.0 a | |

| T. aestivum | 30.2 ± 6.0 a | 72.9 ± 5.4 a | 75.0 ± 2.9 b | |

| Shallow tillage | T. sphaerococcum | 26.6 ± 2.7 a | 75.4 ± 1.1 a | 76.1 ± 8.8 a |

| T. persicum | 27.4 ± 2.8 a | 74.9 ± 2.7 a | 81.7 ± 11.6 a | |

| T. aestivum | 29.2 ± 6.0 a | 74.3 ± 4.6 a | 76.4 ± 2.96 a | |

| Mean | Ploughing | 27.1 ± 5.1 a | 73.8 ± 3.4 a | 79.1 ± 5.8 a |

| Shallow tillage | 27.7 ± 4.1 a | 74.9 ± 3.1 a | 78.1 ± 8.6 a | |

| T. sphaerococcum | 26.0 ± 3.3 b | 75.1 ± 1.1 a | 78.2 ± 6.6 a,b | |

| T. persicum | 26.5 ± 3.4 a,b | 74.3 ± 2.6 a | 81.8 ± 9.7 a | |

| T. aestivum | 29.7 ± 5.9 a | 73.6 ± 4.9 a | 75.7 ± 2.9 b |

| Tillage Method | Wheat Species | FN s | TPC g·kg−1 | WG % | SV cm3 | SC % |

|---|---|---|---|---|---|---|

| Ploughing | T. sphaerococcum | 449 ± 20 b | 148 ± 10.0 a,b | 36.1 ± 2.6 a | 44.1 ± 6.2 a | 66.6 ± 0.9 a |

| T. persicum | 529 ± 99 a | 156 ± 23.4 a | 38.2 ± 9.3 a | 48.0 ± 13.5 a | 65.3 ± 4.6 a | |

| T. aestivum | 478 ± 25 a,b | 132 ± 6.7 b | 34.9 ± 1.7 a | 53.3 ± 4.6 a | 66.6 ± 2.7 a | |

| Shallow tillage | T. sphaerococcum | 474 ± 80 a | 143 ± 22.3 a | 40.9 ± 8.7 a | 51.1 ± 7.4 a | 65.2 ± 2.95 a |

| T. persicum | 531 ± 116 a | 155 ± 29.5 a | 40.7 ± 11.4 a | 50.7 ± 11.0 a | 64.6 ± 5.0 a | |

| T. aestivum | 491 ± 17 a | 133 ± 5.6 a | 33.8 ± 2.3 a | 47.0 ± 4.5 a | 67.5 ± 2.0 a | |

| Mean | Ploughing | 485 ± 67 a | 145 ± 17.6 a | 36.4 ± 5.6 a | 48.5 ± 9.4 a | 66.2 ± 3.1 a |

| Shallow tillage | 499 ± 92 a | 144 ± 22.7 a | 38.5 ± 8.7 a | 49.6 ± 8.0 a | 65.7 ± 3.6 a | |

| T. sphaerococcum | 462 ± 58 b | 145 ± 17.0 a,b | 38.5 ± 6.7 a | 47.6 ± 7.5 a | 65.9 ± 2.2 a | |

| T. persicum | 530 ± 104 a | 156 ± 25.8 a | 39.4 ± 10.2 a | 49.4 ± 12.0 a | 64.9 ± 4.7 a | |

| T. aestivum | 485 ± 22 a,b | 133 ± 6.0 b | 34.3 ± 2.0 b | 50.1 ± 5.5 a | 67.0 ± 2.3 a |

| Tillage Method | Wheat Species | WGF | TPCF | AC | FY | MEF |

|---|---|---|---|---|---|---|

| % | g·kg−1 | % | ||||

| Ploughing | T sphaerococcum | 31.3 ± 4.9 a | 144 ± 8.2 a,b | 0.85 ± 0.08 a | 62.5 ± 1.1 a | 74.1 ± 7.4 a |

| T. persicum | 33.2 ± 9.4 a | 150 ± 22.1 a | 0.83 ± 0.06 a | 56.3 ± 2.1 b | 68.3 ± 3.9 a | |

| T. aestivum | 29.6 ± 4.2 a | 128 ± 5.4 b | 0.91 ± 0.13 a | 64.2 ± 1.6 a | 72.2 ± 11.0 a | |

| Shallow tillage | T. sphaerococcum | 35.2 ± 6.9 a | 139 ± 22.3 a | 0.88 ± 0.09 a | 61.8 ± 1.9 b | 71.8 ± 6.3 a |

| T. persicum | 35.8 ± 8.6 a | 151 ± 29.0 a | 0.84 ± 0.09 a | 57.1 ± 1.2 c | 68.9 ± 6.8 a | |

| T. aestivum | 29.2 ± 5.5 a | 129 ± 5.4 a | 0.90 ± 0.19 a | 63.7 ± 1,1 a | 73.2 ± 14.6 a | |

| Mean | Ploughing | 31.4 ± 6.5 a | 141 ± 16.5 a | 0.86 ± 0.09 a | 61.0 ± 3.8 a | 71.5 ± 8.0 a |

| Shallow tillage | 33.4 ± 7.5 a | 139 ± 22.4 a | 0.87 ± 0.13 a | 60.9 ± 3.2 a | 71.3 ± 9.8 a | |

| T. sphaerococcum | 33.3 ± 6.1 a | 142 ± 16.5 a,b | 0.86 ± 0.08 a | 62.2 ± 1.6 b | 72.9 ± 6.8 a | |

| T. persicum | 34.5 ± 8.8 a | 150 ± 25.0 a | 0.83 ± 0.07 a | 56.7 ± 1.7 c | 68.6 ± 5.3 a | |

| T. aestivum | 29.4 ± 4.8 b | 128 ± 5.3 b | 0.90 ± 0.16 a | 64.0 ± 1.4 a | 72.7 ± 12.5 a | |

| HM | VIT | FN | TPC | WG | SC | SV | TPCF | WGF | AC | FY | MEF | WA | DDT | DST | DSF | BW | BW24 | BV | BL | TBL | L*G | a*G | b*G | L*F | a*F | b*F | |

| MTG | −0.46 | −0.41 | −0.37 | −0.44 | −0.49 | n.s. | n.s. | −0.45 | −0.65 | 0.89 | n.s. | −0.80 | n.s. | 0.32 | n.s. | −0.32 | n.s. | n.s. | 0.75 | n.s. | n.s. | −0.60 | n.s. | −0.39 | n.s. | n.s. | −0.58 |

| HM | n.s. | −0.27 | n.s. | n.s. | 0.44 | n.s. | n.s. | n.s. | −0.55 | n.s. | 0.55 | 0.33 | −0.36 | −0.41 | n.s. | −0.27 | n.s. | n.s. | 0.35 | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | 0.61 | |

| VIT | n.s. | 0.75 | 0.96 | 0.85 | −0.81 | 0.60 | 0.96 | 0.78 | −0.51 | −0.50 | 0.30 | n.s. | n.s. | n.s. | 0.51 | n.s. | 0.38 | −0.53 | −0.34 | −0.44 | n.s. | n.s. | n.s. | −0.51 | 0.70 | n.s. | |

| FN | −0.27 | 0.75 | 0.78 | 0.80 | −0.78 | 0.48 | 0.78 | 0.67 | −0.41 | −0.45 | n.s. | n.s. | n.s. | 0.42 | 0.40 | 0.35 | 0.49 | −0.47 | −0.46 | −0.46 | 0.32 | n.s. | n.s. | −0.43 | 0.61 | n.s. | |

| TPC | n.s. | 0.96 | 0.78 | 0.90 | −0.87 | 0.62 | 1.00 | 0.83 | −0.48 | −0.58 | n.s. | 0.30 | n.s. | n.s. | 0.60 | n.s. | 0.38 | −0.61 | −0.36 | −0.43 | n.s. | n.s. | n.s. | −0.59 | 0.72 | n.s. | |

| WG | n.s. | 0.85 | 0.80 | 0.90 | −0.88 | 0.69 | 0.90 | 0.91 | −0.53 | −0.40 | 0.36 | n.s. | n.s. | n.s. | 0.66 | n.s. | 0.37 | −0.56 | n.s. | −0.30 | n.s. | n.s. | n.s. | −0.40 | 0.63 | n.s. | |

| SC | 0.44 | −0.81 | −0.78 | −0.87 | −0.88 | −0.70 | −0.87 | −0.69 | n.s. | 0.50 | n.s. | n.s. | n.s. | −0.32 | −0.56 | n.s. | −0.30 | 0.36 | 0.37 | 0.36 | n.s. | n.s. | 0.28 | 0.44 | −0.63 | n.s. | |

| SV | n.s. | 0.60 | 0.48 | 0.62 | 0.69 | −0.70 | 0.60 | 0.65 | n.s. | n.s. | n.s. | n.s. | 0.35 | 0.45 | 0.29 | n.s. | n.s. | n.s. | n.s. | n.s. | −0.30 | n.s. | n.s. | −0.35 | 0.35 | n.s. | |

| TPCF | n.s. | 0.96 | 0.78 | 1.00 | 0.90 | −0.87 | 0.60 | 0.82 | −0.49 | −0.57 | n.s. | n.s. | n.s. | n.s. | 0.63 | n.s. | 0.38 | −0.63 | −0.36 | −0.42 | n.s. | n.s. | n.s. | −0.57 | 0.73 | n.s. | |

| WGF | n.s. | 0.78 | 0.67 | 0.83 | 0.91 | −0.69 | 0.65 | 0.82 | −0.69 | −0.35 | 0.53 | n.s. | n.s. | n.s. | 0.61 | n.s. | 0.38 | −0.55 | n.s. | n.s. | n.s. | n.s. | n.s. | −0.43 | 0.52 | 0.38 | |

| AC | −0.55 | −0.51 | −0.41 | −0.48 | −0.53 | n.s. | n.s. | −0.49 | −0.69 | n.s. | −0.88 | n.s. | n.s. | n.s. | −0.29 | n.s. | −0.29 | 0.68 | n.s. | n.s. | −0.55 | n.s. | −0.32 | n.s. | −0.29 | −0.72 | |

| FY | n.s. | −0.50 | −0.45 | −0.58 | −0.40 | 0.50 | n.s. | −0.57 | −0.35 | n.s. | 0.30 | −0.69 | 0.43 | n.s. | −0.41 | −0.34 | −0.29 | 0.42 | 0.35 | 0.32 | n.s. | n.s. | 0.66 | 0.88 | −0.68 | n.s. | |

| MEF | 0.55 | 0.30 | n.s. | n.s. | 0.36 | n.s. | n.s. | n.s. | 0.53 | −0.88 | 0.30 | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | −0.44 | n.s. | n.s. | 0.48 | n.s. | 0.63 | n.s. | n.s. | 0.69 | |

| WA | 0.33 | n.s | n.s. | 0.30 | n.s. | n.s. | n.s. | 0.29 | n.s. | n.s. | −0.69 | n.s. | −0.51 | −0.33 | 0.40 | n.s. | 0.29 | −0.27 | n.s. | n.s. | n.s. | n.s. | −0.73 | −0.75 | 0.43 | n.s. | |

| DDT | −0.36 | n.s. | n.s. | n.s. | n.s. | n.s. | 0.35 | n.s. | n.s. | n.s. | 0.43 | n.s. | −0.51 | 0.76 | −0.54 | n.s. | n.s. | 0.45 | n.s. | n.s. | n.s. | n.s. | 0.40 | 0.39 | n.s. | n.s. | |

| DST | −0.41 | n.s. | 0.42 | n.s. | n.s. | −0.32 | 0.45 | n.s. | n.s. | n.s. | n.s. | n.s. | −0.33 | 0.76 | −0.42 | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | 0.30 | n.s. | n.s. | n.s. | |

| DSF | n.s. | 0.51 | 0.40 | 0.60 | 0.66 | −0.56 | 0.29 | 0.63 | 0.61 | −0.29 | −0.41 | n.s. | 0.40 | −0.54 | −0.42 | n.s. | 0.28 | −0.50 | n.s. | n.s. | n.s. | n.s. | −0.32 | −0.40 | 0.43 | n.s. | |

| BW | −0.27 | n.s. | 0.35 | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | −0.34 | n.s. | n.s. | n.s. | n.s. | n.s. | 0.79 | n.s. | −0.91 | −0.75 | n.s. | n.s. | n.s. | −0.28 | 0.34 | n.s. | |

| BW24 | n.s. | 0.38 | 0.49 | 0.38 | 0.37 | −0.30 | n.s. | 0.38 | 0.38 | −0.29 | −0.29 | n.s. | 0.29 | n.s. | n.s. | 0.28 | 0.79 | n.s. | −0.73 | −0.84 | n.s. | n.s. | n.s. | −0.29 | 0.44 | 0.32 | |

| BV | n.s. | −0.53 | −0.47 | −0.61 | −0.56 | 0.36 | n.s. | −0.63 | −0.55 | 0.68 | 0.42 | −0.44 | −0.27 | 0.45 | n.s. | −0.50 | n.s. | n.s. | n.s. | n.s. | −0.38 | n.s. | n.s. | 0.40 | −0.44 | n.s. | |

| BL | 0.35 | −0.34 | −0.46 | −0.36 | n.s. | 0.37 | n.s. | −0.36 | n.s. | n.s. | 0.35 | n.s. | n.s. | n.s. | n.s. | n.s. | −0.91 | −0.73 | n.s. | 0.82 | n.s. | n.s. | n.s. | n.s. | −0.47 | n.s. | |

| TBL | n.s. | −0.44 | −0.46 | −0.43 | −0.30 | 0.36 | n.s. | −0.42 | n.s. | n.s. | 0.32 | n.s. | n.s. | n.s. | n.s. | n.s. | −0.75 | −0.84 | n.s. | 0.82 | n.s. | n.s. | n.s. | 0.32 | −0.41 | n.s. | |

| L*G | n.s. | n.s. | 0.32 | n.s. | n.s. | n.s. | −0.30 | n.s. | n.s. | −0.55 | n.s. | 0.48 | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | −0.38 | n.s. | n.s. | n.s. | 0.52 | n.s. | n.s. | 0.66 | |

| a*G | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | |

| b*G | n.s. | n.s. | n.s. | n.s. | n.s. | 0.28 | n.s. | n.s. | n.s. | −0.32 | 0.66 | 0.63 | −0.73 | 0.40 | 0.30 | −0.32 | n.s. | n.s. | n.s. | n.s. | n.s. | 0.52 | n.s. | 0.68 | −0.36 | 0.34 | |

| L*F | n.s. | −0.51 | −0.43 | −0.59 | −0.40 | 0.44 | −0.35 | −0.57 | −0.43 | n.s. | 0.88 | n.s. | −0.75 | 0.39 | n.s. | −0.40 | −0.28 | −0.29 | 0.40 | n.s. | 0.32 | n.s. | n.s. | 0.68 | −0.54 | n.s. | |

| a*F | n.s. | 0.70 | 0.61 | 0.72 | 0.63 | −0.63 | 0.35 | 0.73 | 0.52 | −0.29 | −0.68 | n.s. | 0.43 | n.s. | n.s. | 0.43 | 0.34 | 0.44 | −0.44 | −0.47 | −0.41 | n.s. | n.s. | −0.36 | −0.54 | n.s. | |

| b*F | 0.61 | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | n.s. | 0.38 | −0.72 | n.s. | 0.69 | n.s. | n.s. | n.s. | n.s. | n.s. | 0.32 | n.s. | n.s. | n.s. | 0.66 | n.s. | 0.34 | n.s. | n.s. |

| Tillage Method | Species | WA | DDT | DST | DSF |

|---|---|---|---|---|---|

| % | Min | BU | |||

| Ploughing | T. sphaerococcum | 58.0 ± 4.9 b | 2.69 ± 0.20 b | 1.92 ± 0.65 b | 168.6 ± 34.2 a |

| T. persicum | 62.2 ± 2.9 a | 2.69 ± 0.90 b | 3.04 ± 1.85 a,b | 118.5 ± 32.6 b | |

| T. aestivum | 55.0 ± 1.1 c | 4.40 ± 0.99 a | 4.70 ± 1.55 a | 57.4 ± 13.7 b | |

| Shallow tillage | T. sphaerococcum | 58.4 ± 2.2 b | 2.68 ± 0.18 b | 1.49 ± 0.18 b | 210.3 ± 32.4 a |

| T. persicum | 63.6 ± 4.0 a | 2.23 ± 0.40 b | 2.28 ± 0.90 a,b | 211.2 ± 82.3 a | |

| T. aestivum | 54.2 ± 2.2 c | 4.07 ± 0.83 a | 3.13 ± 1.20 a | 92.8 ± 35.8 b | |

| Mean | Ploughing | 58.4 ± 4.4 a | 3.25 ± 1.11 a | 3.22 ± 1.81 a | 114.8 ± 53.8 b |

| Shallow tillage | 58.7 ± 4.8 a | 2.99 ± 0.95 a | 2.30 ± 1.08 b | 171.4 ± 77.5 a | |

| T. sphaerococcum | 58.2 ± 3.7 b | 2.68 ± 0.18 b | 1.71 ± 0.52 b | 189.4 ± 38.8 a | |

| T. persicum | 62.9 ± 3.5 a | 2.46 ± 0.72 b | 2.66 ± 1.47 b | 164.8 ± 77.2 a | |

| T. aestivum | 54.6 ± 1.7 c | 4.23 ± 0.90 a | 3.92 ± 1.57 a | 75.1 ± 32.0 b | |

| Tillage Method | Wheat Species | BV [cm3] | BW [g] | BW24 [g] | BL [%] | TBL [%] |

|---|---|---|---|---|---|---|

| Ploughing | T. sphaerococcum | 379 ± 28.9 | 266.1 ± 2.7 a | 257.7 ± 2.3 a | 25.2 ± 1.7 a | 29.2 ± 1.3 a |

| T. persicum | 378 ± 21.8 | 268.9 ± 6.0 a | 257.9 ± 4.6 a | 24.2 ± 3.3 a | 29.5 ± 2.7 a | |

| T. aestivum | 438 ± 30.5 | 265.6 ± 6.5 a | 256.1 ± 4.6 a | 25.9 ± 4.2 a | 30.4 ± 2.9 a | |

| Shallow tillage | T. sphaerococcum | 393 ± 50.5 b | 264.0 ± 3.4 b | 255.6 ± 4.3 b | 26.8 ± 2.9 a | 32.7 ± 1.3 a |

| T. persicum | 380 ± 32.7 b | 274.6 ± 2.5 a | 262.7 ± 2.3 a | 21.6 ± 1.2 b | 27.1 ± 2.4 b | |

| T. aestivum | 451 ± 28.7 a | 272.6 ± 1.8 a | 260.6 ± 2.2 a | 23.2 ± 0.7 b | 28.8 ± 1.1 b | |

| Mean | Ploughing | 398 ± 39 a | 266.9 ± 5.4 b | 257.2 ± 3.9 b | 25.1 ± 3.2 a | 29.7 ± 2.4 a |

| Shallow tillage | 408 ± 48 a | 270.4 ± 5.3 a | 259.6 ± 4.3 a | 23.9 ± 2.9 a | 29.5 ± 2.9 a | |

| T. sphaerococcum | 386 ± 40.5 b | 265.0 ± 3.2 b | 256.6 ± 3.6 b | 26.0 ± 2.5 a | 30.9 ± 2.2 a | |

| T. persicum | 379 ± 27.0 b | 271.7 ± 5.3 a | 260.3 ± 4.3 a | 22.9 ± 2.8 b | 28.3 ± 2.8 b | |

| T. aestivum | 444 ± 29.4 a | 269.1 ± 5.8 a | 258.4 ± 4.2 ab | 24.5 ± 3.3 ab | 29.6 ± 2.3 ab |

| Tillage Method | Wheat Species | Grain | Flour | ||||

|---|---|---|---|---|---|---|---|

| L*G | a*G | b*G | L*F | a*F | b*F | ||

| Ploughing | T. sphaerococcum | 50.3 ± 1.30 a | 11.7 ± 0.53 a | 15.0 ± 1.2 a,b | 87.7 ± 0.86 a | 5.4 ± 0.2 b | 7.6 ± 0.9 b |

| T. persicum | 52.1 ± 1.71 a | 11.4 ± 0.35 a | 13.8 ± 1.35 b | 84.6 ± 1.42 b | 6.2 ± 0.67 a | 9.7 ± 0.40 a | |

| T. aestivum | 50.8 ± 2.40 a | 11.3 ± 0.8 a | 15.6 ± 1.6 a | 88.1 ± 0.4 a | 4.9 ± 0.3 b | 9.7 ± 3.3 a | |

| Shallow tillage | T. sphaerococcum | 49.5 ± 0.76 b | 11.58 ± 0.41 a | 14.8 ± 0.70 b | 87.7 ± 0.32 b | 5.10 ± 1.97 a | 7.31 ± 0.75 b |

| T. persicum | 51.5 ± 2.00 a | 11.2 ± 0.24 a | 13.4 ± 0.93 c | 84.4 ± 0.89 c | 6.18 ± 0.55 a | 9.65 ± 0.57 a | |

| T. aestivum | 51.4 ± 1.79 a | 11.6 ± 0.65 a | 15.9 ± 1.04 a | 88.5 ± 0.29 a | 4.83 ± 0.27 a | 9.69 ± 3.40 a | |

| Mean | Ploughing | 51.1 ± 1.93 a | 11.5 ± 0.60 a | 14.8 ± 1.54 a | 86.8 ± 1.83 a | 5.47 ± 0.67 a | 9.00 ± 2.16 a |

| Shallow tillage | 50.8 ± 1.80 a | 11.4 ± 0.48 a | 14.7 ± 1.35 a | 86.9 ± 1.89 a | 5.37 ± 1.29 a | 8.89 ± 2.26 a | |

| T. sphaerococcum | 49.9 ± 1.11 b | 11.65 ± 0.46 a | 14.9 ± 0.94 a | 87.7 ± 0.63 a | 5.23 ± 1.36 b | 7.45 ± 0.80 b | |

| T. persicum | 51.8 ± 1.84 a | 11.3 ± 0.31 a | 13.6 ± 1.15 b | 84.5 ± 1.16 b | 6.17 ± 0.60 a | 9.69 ± 0.48 a | |

| T. aestivum | 51.1 ± 2.05 a,b | 11.4 ± 0.73 a | 15.8 ± 1.33 a | 88.3 ± 0.39 a | 4.87 ± 0.27 b | 9.70 ± 3.24 a | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knapowski, T.; Szczepanek, M.; Kozera, W.; Ducsay, L. Technological Properties of Ancient Wheat Species and Common Wheat Grown Organically Under Mouldboard Ploughing and Shallow Tillage. Agriculture 2025, 15, 1937. https://doi.org/10.3390/agriculture15181937

Knapowski T, Szczepanek M, Kozera W, Ducsay L. Technological Properties of Ancient Wheat Species and Common Wheat Grown Organically Under Mouldboard Ploughing and Shallow Tillage. Agriculture. 2025; 15(18):1937. https://doi.org/10.3390/agriculture15181937

Chicago/Turabian StyleKnapowski, Tomasz, Małgorzata Szczepanek, Wojciech Kozera, and Ladislav Ducsay. 2025. "Technological Properties of Ancient Wheat Species and Common Wheat Grown Organically Under Mouldboard Ploughing and Shallow Tillage" Agriculture 15, no. 18: 1937. https://doi.org/10.3390/agriculture15181937

APA StyleKnapowski, T., Szczepanek, M., Kozera, W., & Ducsay, L. (2025). Technological Properties of Ancient Wheat Species and Common Wheat Grown Organically Under Mouldboard Ploughing and Shallow Tillage. Agriculture, 15(18), 1937. https://doi.org/10.3390/agriculture15181937