Abstract

This study evaluates the application of circular economy principles in the wine sector through a demonstrative case developed within the LIFE Climawin project. The initiative focuses on the local valorization of vineyard residues by producing biochar from vine pruning and using it to enrich compost derived from winemaking by-products and sheep manure. The combined application of these soil amendments aims to improve soil structure, enhance carbon sequestration, and reduce reliance on synthetic fertilizers. A systemic evaluation was conducted using the Ecocanvas methodology—a conceptual framework for mapping circular business models across environmental, economic, and social dimensions. The analysis integrated a targeted literature review, examination of technical data, direct field observations of composting and biochar production, and semi-structured interviews with key stakeholders. Results indicate multiple benefits from localized residue valorization, including improved compost quality, reduced greenhouse gas emissions, potential contributions to long-term soil health, and enhanced resource efficiency. The analysis also highlights economic opportunities, such as reduced dependency on external inputs, and social value creation through local stakeholder engagement. Furthermore, the study identifies factors that enable or constrain the replication and scaling of this model. These findings contribute to frameworks for advancing circular, economically viable, and socially inclusive climate-resilient agricultural systems.

1. Introduction

Intensive agricultural activity has, in recent decades, increased pressure on ecosystems, accelerating soil degradation, the loss of organic matter, and rising emissions of pollutants. This problem is particularly acute in sectors such as viticulture, which generate large volumes of lignocellulose waste and depend on specific climatic conditions to sustain productivity [1]. Inadequate management of these residues not only poses environmental risks but also constitutes the loss of resources that could be locally valorized through circular strategies [2,3].

The circular economy provides a framework for transforming organic residues into regenerative assets. Pyrolysis of pruning residues produces biochar, a material with high stability, substantial carbon sequestration potential, and beneficial soil properties, including high porosity and energy content [4]. When incorporated into compost derived from agricultural sources—such as sheep manure or wine industry by-products—biochar further enhances soil quality and functions as a long-term carbon sink [2].

Despite promising advances, the recent literature indicates that a gap still exists between conceptual models and their practical application in the wine sector. In a systematic review of both the scientific and gray literature, [5] highlighted the urgent need to develop viable strategies for wine waste valorization that integrate technical, managerial, and organizational aspects. Their findings suggest that bridging this gap requires empirical case studies that demonstrate how circular economy principles can be concretely applied in wineries. This study seeks to respond to that challenge.

In Mediterranean regions, where viticulture is an economic and environmental pillar, these practices are gaining particular importance. According to the author of [1], the valorization of waste in the wine sector not only reduces the carbon footprint and production costs but also improves resilience to climatic and economic factors. The authors of [3] complement this perspective by demonstrating, through life cycle analysis, that the conversion of pruning residues into solid or liquid biofuels can close production cycles based on circular economy principles.

In this context, the European LIFE Climawin project is framed, aimed at mitigating climate change in the wine sector through the implementation of sustainable practices in vineyards and wineries. Among its actions, it proposes a local strategy for the valorization of viticultural residues based on the integration of pruning waste pyrolysis into the composting process of agricultural and livestock by-products. This combined approach seeks to apply biochar-enhanced compost to the soil in order to improve its quality, increase carbon sequestration, and reduce dependence on external inputs.

To evaluate the broader implications of this strategy, beyond its technical performance, the study applies the Ecocanvas methodology—a conceptual tool specifically developed to map circular business models across environmental, economic, and social dimensions [6]. Consistent with the authors [7], Ecocanvas adapts the business model canvas to a sustainability focus, embedding environmental challenges into strategic planning. This framework, recently validated as a decision-making instrument to support agricultural organizations in developing context-specific sustainable value propositions by the authors of [8], offers a structured basis for integrating sustainability into business model design.

In this case, Ecocanvas is used to systematically analyze the circular strategy piloted at Bosque de Matasnos—a winery located in a semi-natural landscape in northern Spain and serving as a demonstrative site for the LIFE Climawin project. The model involves the local production and application of biochar-enhanced compost derived from pruning residues, winemaking by-products, and livestock manure, with the goal of improving soil health, enhancing carbon sequestration, and reducing dependence on external inputs.

The application of Ecocanvas enables a structured visualization of resource flows, stakeholder relationships, and value creation mechanisms within this regenerative model. It serves both as a diagnostic and strategic tool, identifying the key actors, inputs, and outputs involved, as well as the environmental and social impacts generated by the intervention. Complementary to this, a targeted PESTEL analysis was conducted to account for relevant political, economic, and regulatory factors shaping the viability of the model.

This study evaluates biochar-enhanced compost not merely as an agronomic amendment, but as a circular economy intervention in viticulture. Unlike previous works focused primarily on technical performance, our contribution lies in analyzing its environmental, social, and economic potential through the Ecocanvas framework. The main objective is to assess the pilot implementation of this circular strategy within the LIFE Climawin project and to explore its role in regenerative and circular viticulture. Specifically, the study (i) characterizes the composting process and establishes key performance indicators (KPIs), (ii) integrates agronomic and contextual data into a systemic analysis of Ecocanvas building blocks, and (iii) identifies opportunities for circular business model innovation aligned with the European Green Deal and the Sustainable Development Goals (SDGs). In doing so, the research bridges the gap between theory and practice in circular economy applications, providing a replicable and scalable model for sustainable soil management in Mediterranean vineyards.

The article is organized into six main sections. Following this introduction, Section 2 presents the theoretical frameworks regarding the circular economy in agriculture and the properties of biochar. Section 3 describes the materials and methods used. Section 4 reports the results of applying the ECOCANVAS methodology to the biochar-enhanced compost measure. Section 5 provides the discussion, and Section 6 concludes with the main findings and implications for replication.

2. Theoretical Framework

2.1. Circular Economy in the Wine Sector

The transition from linear to circular models is a key transformation in the food industry, with the wine sector being particularly relevant due to its economic, social, and environmental importance [9]. Unlike the traditional extract–produce–consume–dispose approach, the circular economy seeks to regenerate resources, extend material life, and revalorize waste as new inputs [10,11].

Wine production generates by-products like grape pomace, lees, and stems, rich in bioactive compounds, which can be used in the food, cosmetics, energy, and pharmaceutical sectors [12]. This industrial symbiosis allows these residues to become valuable resources, closing production cycles [13].

Studies using Life Cycle Assessment (LCA) and Life Cycle Costing (LCC) show that circular strategies—such as bottle reuse—can reduce greenhouse gas emissions by up to 90% and lower costs by up to 63% in small wineries [14]. Combining LCA with circular economy tools also helps identify environmental hotspots, support eco-design, promote nutrient recovery, and increase renewable energy use [15,16].

However, implementation is still limited. Many initiatives focus only on waste reduction or recycling and often neglect areas like soil management, biodiversity, and agrochemical use [17]. The author in [5] highlights the need for integrated strategies that address technical, managerial, and systemic aspects.

The “10R” framework—rethink, reduce, reuse, repair, restore, remanufacture, recycle, recover, regenerate, and redesign—offers a useful lens for evaluating circular practices. Research in wineries in northwestern Italy shows that by-product reuse is common, but there is still room to redesign processes, extend product life, and reduce inputs [18].

In this context, the circular economy is not just about managing waste, but about redefining how viticulture relates to the environment. It involves moving toward regenerative, resilient, and socially responsible systems through cultural change, collaboration, and long-term sustainability planning. Within this approach, regenerative practices allow for the revalorization of agricultural residues while improving soil health, biodiversity, and climate resilience.

2.2. Biochar-Enhanced Compost: Scientific Evidence and Benefits in Vineyards

Soil health is critical to vineyard productivity and ecosystem integrity, especially in Mediterranean regions facing degradation from intensive tillage, agrochemical use, and climate change [19,20]. Agrochemical inputs alone contribute up to 37% of viticultural GHG emissions [21]. In this context, improving soil fertility, biological activity, and resilience is essential.

The application of organic amendments—particularly biochar, compost, or their combination—offers a key agroecological solution aligned with circular economy principles [22,23,24,25]. Biochar, produced by pyrolysis of pruning residues or forestry biomass, enhances soil structure, water retention, and carbon sequestration [26,27]. Mediterranean studies report improved drought resilience and up to 45% higher water retention without negative ecological effects [28,29,30].

Compost from sheep manure, grape pomace, and winery by-products provides nutrients, microbial diversity, and stabilized organic matter [31]. Grape pomace and other winery by-products contribute substantial amounts of organic matter, nitrogen, potassium, minerals, and bioactive phenolic compounds. Their typical composition includes approximately 50–60% dietary fiber, 10–15% protein, and around 5% minerals, alongside diverse polyphenols with recognized bioactivity [32,33,34,35]. These characteristics make them valuable inputs for composting processes, enhancing nutrient availability while also enriching composts with secondary metabolites that may influence soil microbial activity.

Several studies report successful experiences in valorizing grape pomace and winery residues through composting and vermicomposting. For instance, the co-composting of pomace with stalks or manures has been shown to accelerate compost maturation and improve nutrient profiles, producing organic amendments suitable for vineyard application [36,37,38]. Vermicomposting has also emerged as a promising strategy, yielding stabilized products that increase soil organic carbon and total nitrogen stocks while enhancing microbial activity [39,40]. Field trials confirm that the application of grape pomace-derived composts can improve soil fertility, water-holding capacity, and vine performance, ultimately contributing to grape quality and vineyard resilience.

When combined with biochar, synergistic effects improve nutrient retention, reduce losses, and enhance compost quality [41,42,43]. Research confirms that biochar-enhanced compost boosts soil carbon by 11–17% [44], increases microbial activity, and supports pathogen suppression and fungal diversity [45,46]. Several studies also show that this mixture improves carbon stability, enhances mineralization efficiency, increases water-holding capacity, and promotes the development of functional microbial communities [47]. Life cycle assessments show reduced environmental impacts—global warming, acidification, eutrophication—compared to mineral fertilization [48].

These results position biochar-enhanced compost as more than just a soil amendment. It constitutes a strategic agronomic intervention aligned with circular economy principles, enabling the transformation of locally available residues—such as vine pruning, livestock manure, and winery by-products—into regenerative inputs that enhance soil fertility and carbon retention. Particularly in Mediterranean regions facing intensifying drought and degradation, this practice offers a viable, context-sensitive solution aligned with the European Green Deal and the Common Agricultural Policy. Beyond its technical efficacy, its adoption supports the environmental positioning of wineries in sustainability-oriented markets and strengthens the resilience of agroecosystems. However, scaling its use requires overcoming barriers such as initial costs, knowledge gaps, and regulatory uncertainties related to biochar. Therefore, its integration should be evaluated not only in agronomic terms, but within a broader systemic framework that includes institutional support, stakeholder collaboration, and long-term sustainability planning. When embedded in enabling policies and supported by training and cooperative networks, this circular strategy can become a replicable model for climate-resilient viticulture in drought-prone areas and beyond.

2.3. The Ecocanvas Methodology for the Analysis of Circular Models

The use of biochar-enhanced compost in viticulture represents a regenerative and circular strategy that requires evaluation beyond agronomic and environmental metrics, extending into the transformation of business models. In this context, Ecocanvas emerges as a relevant methodological tool for visualizing, designing, and evaluating circular models adapted to real-world organizational challenges.

The Ecocanvas draws inspiration from the Business Model Canvas [49], but integrates critical circular economy principles—such as resource reuse, industrial symbiosis, eco-design, and ecosystem regeneration—into its structure [6]. More than a business activity template, the Ecocanvas enables organizations to develop value propositions that reflect systemic interactions, long-term implications, and the transformation of waste into regenerative inputs.

Its versatility has been demonstrated in multiple sectors. In small and medium-sized wineries, for instance, Ecocanvas has been used to align production processes with circularity principles [6]. In other industries, it has supported decision-making in SMEs by integrating sustainability and digitalization [8], and has guided functional beverage production [50], clean tech entrepreneurship [7], and inclusive business model innovation through the Triple Helix approach.

This expanding body of literature confirms the strategic value of Ecocanvas as both a diagnostic and design tool for sustainability-oriented innovation. However, its potential to analyze concrete agroecological interventions—such as circular soil amendments in viticulture—remains underexplored. By applying the Ecocanvas framework to the implementation of biochar-enhanced compost in a Mediterranean winery, this study contributes to bridging that methodological gap and highlights the relevance of this tool for advancing regenerative transitions in agri-food systems.

3. Materials and Methods

3.1. Case Study

This study applied the Ecocanvas methodological framework as a systemic tool to assess a circular mitigation measure developed within the LIFE Climawin project at the Bosque de Matasnos winery, located near Peñaranda de Duero (Burgos, Spain), on the northern edge of the Ribera del Duero appellation in Castilla y León. The estate comprises 74 ha of vineyard, 80 ha of forest and 50 ha of cereal, legume, and oilseed crops used for both animal feed and soil regeneration, complemented by livestock and beekeeping activities. Within this diversified agroecosystem, the intervention focused on producing and applying biochar-enhanced compost from locally available residues, such as woody forest residues and vine pruning waste for biochar production, and sheep manure together with winery by-products for composting. The objective was to holistically analyze the environmental, social, and economic implications of this circular practice.

The winery is situated at approximately 950 m above sea level (41°45′ N, 3°28′ W) and is exposed to a continental Mediterranean climate characterized by cold winters, hot summers, and pronounced diurnal temperature variation. Average annual precipitation is 500–600 mm, and the mean annual temperature is 11–12 °C, with summer maxima frequently above 30 °C. The soils are predominantly sandy-loam to loam, moderately calcareous, slightly alkaline, and low in organic matter. These conditions, typical of Mediterranean vineyards, increase vulnerability to drought and soil degradation, making biochar-enhanced compost particularly suitable for improving soil carbon content, fertility, water retention, and resilience.

The methodological approach combined empirical and qualitative inputs. The project’s technical partner generated the agronomic data from the composting process under real operating conditions. Our research, in turn, focused on the environmental, social, and economic dimensions of the intervention, adopting a systemic perspective. Activities included participation in technical work sessions, field visits to vineyards and processing facilities, and semi-structured interviews with key stakeholders. This collaborative design ensured that experimental results were embedded in a broader systemic assessment of impacts, value creation mechanisms, and circular synergies through the Ecocanvas framework.

Biochar used in this study was obtained through two different approaches, depending on the project phase. In Phase I (2023–2024), commercial biochar derived from holm oak pruning and barrel residues was supplied by a local producer, using the traditional earth-covered pit method of slow pyrolysis (>600 °C). In Phase II (2024–2025), currently in progress, the winery has begun producing its own biochar on-site with the same earth-pit method, using vineyard pruning residues together with forest biomass from the estate as feedstock.

3.2. Methodological Structure and Operational Tools of Ecocanvas

Table 1 summarizes the Ecocanvas methodology, outlining the correspondence between its seven operational stages, the specific instruments applied, and the business model blocks primarily addressed. This schematic overview, adapted from [6], provides a comprehensive reference for the full scope of the framework. It facilitates a quick understanding of its systemic logic before presenting its application to the pilot case.

Table 1.

Correspondence between methodological stages, tools, and Ecocanvas blocks.

While [6] originally introduced Ecocanvas and structured its operational stages, the framework has since been consolidated as a strategic tool for redesigning business models toward regenerative and circular approaches. It integrates twelve interlinked building blocks—grouped into three functional dimensions (value proposition, operational model, and circularity/impact)—with fifteen practical tools deployed through seven sequential stages (A–G). Unlike linear approaches such as the Business Model Canvas, Ecocanvas incorporates instruments for anticipating environmental and social impacts, mapping circular value chains, and fostering systemic innovation.

It is important to note, however, that Ecocanvas is not a rigid methodology [6]. The stages and tools can be adapted to different research contexts, and results may be structured according to the most suitable narrative for each study. This flexibility makes it possible to highlight those components most relevant to the case while preserving analytical rigor.

Several recent adaptations of Canvas-based frameworks further demonstrate the robustness and adaptability of this family of tools. These include the Responsible Business Model Canvas [51], the Circular Business Model Value Dimension Canvas [52], the Circular Business Ecosystem Model Canvas [53], and applications of Eco-Canvas in energy transition [54] and low-carbon tourism [55]. Together, these studies validate the use of Canvas-derived frameworks for analyzing sustainability and circular economy strategies.

In the present study, Ecocanvas serves as the overarching framework for assessing and redesigning a circular business model in the wine sector. Its specific application to the biochar-enhanced compost strategy developed within the LIFE Climawin project is detailed in Section 3.3. By embedding this intervention in Ecocanvas, the analysis goes beyond technical performance to highlight stakeholder interactions, enabling conditions, and opportunities for replication and scaling within circular viticulture.

3.3. Practical Application of Ecocanvas in the Pilot Case: Bosque de Matasnos Winery

The Ecocanvas framework was applied in a modular manner, focusing on those stages and building blocks for which robust empirical and qualitative evidence was available. This section describes the methodological procedure adopted under real vineyard conditions. The sequence of presentation in the results has been adapted for clarity: the agronomic outcomes and key performance indicators (KPIs) derived from the composting process are first reported in Section 4.1, while the systemic analysis based on Ecocanvas is developed in Section 4.2, following the order of its building blocks.

The procedure began with a strategic diagnosis to identify the main needs and challenges associated with waste management, soil fertility, and climate-related pressures. These challenges were contextualized through a PESTEL analysis, which examined political, economic, social, technological, environmental, and legal factors. The PESTEL was not treated as a stand-alone block, but as a transversal tool informing the subsequent elements of the Ecocanvas.

Building on this foundation, the framework guided the design of the unique circular value proposition, which was directly linked to the customer segments most sensitive to regenerative and sustainability-oriented practices. The key resources sustaining this model were then identified, followed by the configuration of the circular value chain and the mapping of stakeholder relationships that enable implementation.

The framework also incorporated environmental foresight and impact, and social foresight and impact, allowing for the anticipation of outcomes in terms of greenhouse gas mitigation, soil regeneration, local employment, and community engagement.

Finally, the market and economic dimensions were considered. Communication and sales were analyzed to understand how the value proposition could be transmitted and monetized, while the cost structure and revenue streams captured the economic viability of the strategy. All components were then integrated into the circular business model and innovation, explicitly aligned with the Sustainable Development Goals (SDGs).

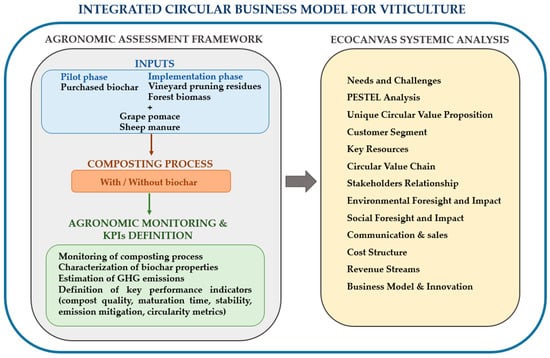

Figure 1 summarizes the methodological workflow applied in this study. The agronomic assessment framework, based on composting with and without biochar, provided key performance indicators (Section 4.1), which were subsequently integrated into the Ecocanvas systemic analysis (Section 4.2).

Figure 1.

Methodological workflow.

This diagram illustrates how empirical agronomic data, stakeholder input, and contextual analysis were embedded into the Ecocanvas framework to construct a circular business model for viticulture.

4. Results of Applying the Ecocanvas Methodology to the Biochar-Enhanced Compost Measure

This section presents the results of the pilot implementation of the biochar-enhanced compost strategy at Bosque de Matasnos. The analysis is structured in two parts: Section 4.1 reports agronomic outcomes and key performance indicators (KPIs), providing quantitative evidence on compost quality, nutrient dynamics, and greenhouse gas mitigation. Section 4.2 then applies the Ecocanvas framework to integrate these results with stakeholder input and contextual factors into a circular business model analysis, highlighting opportunities for circular innovation and alignment with the Sustainable Development Goals (SDGs).

4.1. Agronomic Results and Key Performance Indicators (KPIs)

Phase I (2023–2024) of the LIFE Climawin project tested the use of biochar-enhanced compost at the Bosque de Matasnos winery. As described in Section 3.1, this first phase used commercial biochar produced from holm oak pruning and barrel residues by slow pyrolysis (>600 °C). Phase II will transition to on-site biochar production from vineyard and forest residues, thus closing the circular loop at the farm level by valorizing local biomass and reducing dependence on external inputs.

The pilot experiment began on 16 November 2023 with the establishment of two composting piles under controlled field conditions: a control pile with standard compost (without biochar) and an experimental pile amended with biochar at 20% by volume. Each pile contained approximately 15 metric tons of material, composed of 83% fresh sheep manure with bedding (70 t) and 17% winemaking by-products, mainly grape marc and sorting residues (14.5 t). The composting process lasted until 16 April 2024, during which key parameters were systematically monitored, including temperature, moisture, pH, electrical conductivity, total organic carbon (TOC), nitrogen fractions (ammonium and nitrate), phosphate content, and biological maturity assessed through the germination index of Lepidium sativum. Table 2 summarizes the main physicochemical results of the composting process for both treatments, comparing values for pH, electrical conductivity, carbon and nitrogen content, essential nutrients, and compost maturity indicators.

Table 2.

Quality parameters of the compost at the end of the process.

The physicochemical characterization of the compost and biochar was carried out using standardized and widely recognized methods to ensure the reliability of the results. For the compost, moisture content was determined gravimetrically, organic matter by loss-on-ignition at 550 °C, and pH and electrical conductivity in a 1:10 aqueous extract [56]. Nitrogen fractions were analyzed as ammonium (NH4+) using Berthelot’s reaction [57], and nitrate (NO3−) by HPLC, together with phosphate quantification. Total organic carbon (TOC) and total nitrogen (TN) were measured by elemental analysis (LECO CHNS-932), while biological maturity was assessed through the germination index of Lepidium sativum seeds following [58], using ten replicates per sample. Representative samples were obtained by mixing five subsamples from each pile, and the values are reported as means ± standard deviation.

As shown in Table 2, the incorporation of biochar into the composting process resulted in higher organic carbon and nitrogen content, increased nitrate availability, and a reduction in ammonium concentration. The treatment with biochar also accelerated compost maturation (shortening the time to stability by about 25 days) and did not show signs of phytotoxicity, as indicated by stable germination index values. Table 3 presents the properties of the biochar used in Phase I, which showed high organic carbon content, alkaline pH, and low electrical conductivity—characteristics consistent with biochars produced from woody feedstocks by slow pyrolysis at temperatures >600 °C. These properties explain its role in improving compost stability, reducing nitrogen losses, and enhancing microbial activity during the process.

Table 3.

Physicochemical properties of the biochar used.

In addition to improving compost quality, the incorporation of biochar noticeably reduced greenhouse gas emissions during the process. CH4 and CO2-eq emissions were estimated using the factors proposed by the authors in [59], adapted to the specific conditions and scale of the project. Table 4 indicates the emission values observed during composting.

Table 4.

Emission mitigation during composting.

Following the composting process, both treatments—standard compost and biochar-enhanced compost—were applied in March 2024 to vineyard plots at Bosque de Matasnos within a planned, multi-phase field assessment. This sequential design, aligned with the LIFE Climawin methodology, allows clear attribution of effects by first isolating the composting stage (Phase I, presented here) and its direct process-related impacts, before integrating post-application soil and vine dynamics (Phase II, March 2024–June 2025), currently under scientific monitoring. This second phase also incorporates a new composting trial using biochar produced on-site from vineyard and forest residues, advancing towards greater circularity and eliminating transport-related emissions. Results from Phase II will be reported in subsequent publications, providing comparative insights into composting efficiency, soil performance, and climate mitigation potential over the full cycle.

To synthesize the results and support their integration into the Ecocanvas-based analysis, Table 5 presents a selection of Key Performance Indicators (KPIs) derived from Phase I of the pilot project.

Table 5.

Environmental and Operational KPIs from the Composting Stage (Phase I).

These indicators reflect the main environmental, operational, and resource efficiency impacts formally documented during the composting process—including greenhouse gas mitigation, improved compost stability, reduced maturation time, and circularity-related benefits such as responsible biomass sourcing (e.g., PEFC certification). Potential qualitative contributions, such as rural employment generation, are also noted. In line with the sequential design of the study, KPIs reported at this stage correspond exclusively to the composting phase, prior to the integration of post-application soil and vine metrics currently being monitored in Phase II. This phased approach ensures that the performance of the biochar-enhanced compost is rigorously characterized before linking it to field-level outcomes. These indicators provide the quantitative foundation for the systemic business model analysis presented in the following section.

4.2. Ecocanvas-Based Systemic Analysis and Circular Business Model

The Ecocanvas framework was applied to provide an integrated representation of the circular model based on the production of biochar-enhanced compost at the Bosque de Matasnos winery. This representation encompasses all twelve building blocks of the tool, showing their interrelations, resource flows, and value-creation mechanisms within the system.

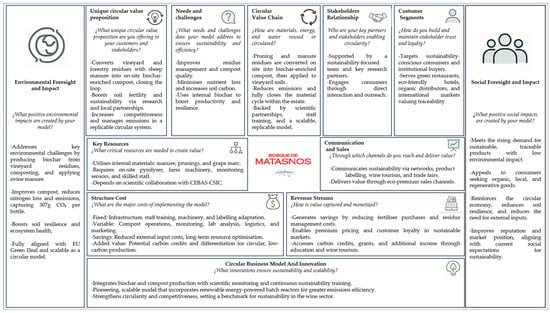

Figure 2 displays the complete Ecocanvas developed for this case, offering an overall view of the model’s structure and operational logic, integrating environmental, economic, and social dimensions.

Figure 2.

Ecocanvas applied to the circular biochar-enhanced compost strategy at Bosque de Matasnos winery (LIFE Climawin framework).

Beyond illustrating the internal consistency of the model, the Ecocanvas also highlights its potential scalability, replicability, and alignment with EU policy objectives on climate mitigation and circular economy. In this sense, the framework not only visualizes the business strategy but also generalizes the lessons learned into a transferable tool for other wineries and agri-food systems seeking to integrate biochar into circular business models.

4.2.1. Needs and Challenges

The implementation of the circular model at Bosque de Matasnos was driven by a key operational need: to improve the management and valorization of organic waste generated on the estate, including pruning residues, grape pomace, stems, forest biomass, and sheep manure. Although composting was already practiced as a basic regenerative strategy, opportunities were identified to enhance both the agronomic performance of the compost and its environmental impact.

The main challenge was to increase composting efficiency—particularly in terms of nutrient retention, maturation time, and carbon stabilization—while simultaneously reducing emissions and dependence on external inputs. To address this, the LIFE Climawin project introduced biochar as a compost enhancer, aiming to improve compost quality and contribute to climate mitigation.

This innovation enables the winery to move towards a more autonomous and resilient production model. By integrating biochar into its composting system, the operation aligns more closely with the principles of the circular economy and regenerative agriculture, while reinforcing compliance with sustainability standards and performance targets demanded by environmentally conscious markets.

These challenges and priorities provide the foundation for the systemic assessment presented in the following sections, beginning with a contextual PESTEL analysis.

4.2.2. PESTEL Analysis

To understand the systemic context in which the Bosque de Matasnos circular model is implemented, a PESTEL analysis was conducted to identify the political, economic, social, technological, environmental, and legal factors influencing the adoption of regenerative practices. This tool highlights both the incentives and constraints of the operating environment, as well as the strategic opportunities that support the model’s viability and replicability. Table 6 shows a structured summary of these factors, serving as a foundation for a deeper examination of the most relevant environmental and social impacts of the case.

Table 6.

PESTEL Analysis.

Overall, the PESTEL analysis shows that the Bosque de Matasnos model benefits from a favorable political and social environment, reinforced by strong consumer demand and institutional support for circular practices. At the same time, technological and legal aspects represent the main challenges, particularly regarding scalability, quality assurance, and compliance with increasingly stringent regulations. By situating the model within this systemic context, it becomes clear that its long-term viability depends not only on agronomic performance but also on the ability to navigate regulatory frameworks, leverage policy incentives, and strengthen technological capacity.

Building on this comprehensive contextual analysis, the next section details the strategic resources and capacities available to Bosque de Matasnos, which support the development of an integrated circular value proposition.

4.2.3. Unique Circular Value Proposition

The circular value proposition developed at Bosque de Matasnos is defined by its capacity to integrate agricultural, livestock, and forest residues into a regenerative production model that operates entirely within the estate. By transforming internally generated biomass—such as vine prunings, sheep manure, and winemaking by-products—into biochar-enhanced compost, the winery closes material loops and aligns production with principles of circularity, low-impact farming, and ecological restoration.

This integrated approach redefines waste as a strategic asset, embedding environmental innovation directly into the core of the winery’s business model. Rather than relying on fragmented or external sustainability measures, the intervention consolidates value creation across environmental, operational, and reputational dimensions. The practice of producing regenerative soil amendments on-site reinforces both input autonomy and authenticity—critical attributes in high-value wine markets increasingly shaped by sustainability expectations.

Moreover, the model links environmental stewardship with market differentiation, allowing the winery to communicate a transparent, science-backed narrative of circularity. This narrative not only enhances consumer trust but also positions the winery as a reference for scalable regenerative practices in Mediterranean viticulture.

4.2.4. Customer Segment

The market segment targeted by Bosque de Matasnos is composed primarily of environmentally conscious consumers who place a high value on traceability, production ethics, and product authenticity. This profile is especially relevant in the premium and estate wine segment, where sustainability credentials and transparent communication of production practices are becoming decisive drivers of differentiation.

In addition to individual consumers, the winery engages with strategic intermediaries such as organic-certified restaurants, boutique hotels, and specialized wine distributors. These actors not only provide access to niche markets but also act as multipliers of the sustainability narrative, using environmental performance and circular sourcing as differentiation tools in competitive contexts.

Wine tourism also plays a complementary role in reinforcing brand perception. On-site visits allow consumers to experience the winery’s environmental practices firsthand, which strengthens customer loyalty and encourages informal dissemination of the sustainability message through experiential narratives.

By responding to these market expectations, the circular model enhances the winery’s commercial positioning while contributing to broader shifts in consumption patterns toward climate-resilient and ethically produced goods. Understanding and addressing the preferences of these consumer segments is therefore not only key to the model’s economic viability but also to its scalability and replication across other wine-producing regions.

4.2.5. Key Resources

The implementation of the circular model at Bosque de Matasnos is supported by a set of strategic resources that enable the operation of the biochar-enhanced composting system. These include renewable organic inputs, basic agricultural infrastructure, technical monitoring tools, and specialized human capital—all of which contribute to the model’s functionality, credibility, and replicability.

From a material standpoint, the winery secures a steady internal supply of organic matter derived from viticultural operations (e.g., pruning residues), integrated sheep farming (manure), forest biomass, and winemaking by-products (grape pomace and stems). These inputs provide the nitrogen-carbon balance required for composting, ensuring resource circularity and reducing dependency on external inputs.

Basic agricultural equipment, such as a tractor with a front loader, facilitates on-site material handling, while composting is carried out in static piles within a designated outdoor area. Technical monitoring includes routine measurements of temperature, pH, and moisture, complemented by laboratory analyses to guarantee compost quality and compliance with environmental standards.

The human dimension is equally critical. Trained personnel oversee composting operations, biochar handling, and quality control, while scientific collaboration with institutions such as CEBAS-CSIC enhances methodological rigor and process validation. Administrative resources further support traceability and regulatory compliance, enabling access to sustainability certifications and eco-labeling schemes.

Together, these physical, technical, and organizational resources form the operational backbone of the winery’s circular value proposition. Beyond sustaining the internal closed-loop system, they demonstrate how locally available assets can be leveraged to build regenerative value chains, offering replicable lessons for other agri-food businesses seeking circular economy transitions.

4.2.6. Circular Value Chain

The circular value chain implemented at Bosque de Matasnos is structured around the closed-loop transformation of on-site organic residues into regenerative soil amendments. This vertically integrated model involves the systematic collection, processing, and reintegration of vineyard pruning, forest biomass, and sheep manure through a combined composting and biochar production system.

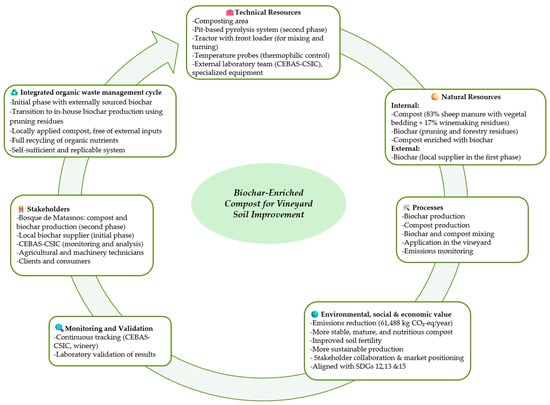

Figure 3 illustrates the operational flow of this circular value chain, detailing how internal resources are managed from origin to application. Each stage—residue collection, biochar integration, composting, and vineyard application—is carried out within the estate, minimizing external inputs and emissions, while maximizing traceability and resource efficiency.

Figure 3.

Process flow diagram of the circular value chain for the biochar-enhanced compost strategy at Bosque de Matasnos.

Rather than relying on fragmented or outsourced inputs, the winery has developed a self-contained system that captures both environmental and agronomic value. This structure enhances operational autonomy, ensures alignment with regenerative agriculture principles, and consolidates circularity as a central axis of production strategy.

The design and functionality of this value chain also enable robust monitoring and continuous improvement, supported by scientific validation in partnership with CEBAS-CSIC. This integration of operational control and empirical feedback strengthens the model’s potential for replication in similar viticultural contexts.

As shown in Figure 3, this flowchart offers a visual synthesis that complements the narrative, making the systemic logic of the circular model more tangible. The circular value chain at Bosque de Matasnos integrates natural and technical resources, operational processes, stakeholder engagement, and monitoring mechanisms into a coherent system. Such a design not only delivers environmental and agronomic benefits on-site but also demonstrates the replicability of a low-input, circular approach to vineyard management. By combining operational autonomy with scientific validation, the model stands as a transferable reference for other wineries and agricultural enterprises seeking to align with EU climate targets and the Sustainable Development Goals.

4.2.7. Stakeholders Relationship

The successful implementation of the circular model at Bosque de Matasnos is sustained by a robust ecosystem of stakeholders, encompassing internal commitment, scientific collaboration, institutional support, and active consumer engagement. These relationships form a strategic network of influence and cooperation that not only strengthens the daily operation of the model but also enhances its credibility, scalability, and long-term viability.

At the heart of the model lies Bosque de Matasnos, the winery itself, which acts as the central coordinating actor and primary driver of the circular strategy. Its owner plays an inspirational and operational leadership role, translating a vision of sustainability into concrete, replicable actions. Direct engagement with visitors strengthens the narrative of authenticity, linking technical practices with experiential learning.

The agricultural and technical personnel form another pillar of this internal ecosystem. They are responsible for the implementation of composting and biochar production, ensuring process integrity and direct execution of the regenerative practices. The direct involvement of agricultural staff ensures operational control and facilitates continuous improvement, supported by systematic monitoring and evaluation.

A defining feature of the model is the integration of a sheep farming system within the estate, which supplies the manure used in composting. This synergy between viticulture and livestock reinforces the closed-loop design of the circular strategy, enhancing nutrient cycling and on-farm resource efficiency—key pillars of regenerative agroecology and the circular bioeconomy.

Additionally, input and machinery suppliers (e.g., for pyrolysis and composting systems) provide critical technological infrastructure and act as potential strategic partners in the system’s technical evolution.

A fundamental external partner is CEBAS-CSIC, the Spanish public research institute that provides scientific and methodological support, from impact validation to continuous improvement of agronomic practices. This partnership reinforces the technical credibility and empirical grounding of the model.

The project also benefits from institutional support through the LIFE Climawin initiative and other public entities connected to the Common Agricultural Policy (CAP) and Next Generation EU funds. These actors offer financial, regulatory, and political backing, essential for scaling and institutional alignment. Although their influence is indirect, it is structurally significant.

From a market perspective, consumers—particularly within the premium organic segment—play a decisive role. These are highly informed customers who value traceability, low carbon footprint, authenticity, and regenerative narratives. Their demand strengthens the winery’s positioning in sustainability-driven market niches, while their loyalty generates economic and reputational capital.

Lastly, the model’s outreach potential is amplified through interaction with sectoral networks and peer wineries, which represent potential replicators of the system. These stakeholders could play a vital role in scaling the approach to the industry level, fostering a collective transition toward regenerative viticulture.

To better understand the stakeholder ecosystem, Table 7 summarizes the primary actors involved, their roles, and their influence within the circular strategy:

Table 7.

Stakeholders’ ecosystem.

Overall, the stakeholder ecosystem at Bosque de Matasnos demonstrates that the successful deployment of a circular model relies on a multi-actor configuration that combines internal commitment, scientific validation, institutional support, and consumer engagement. This interconnected network not only sustains the case study but also provides a transferable blueprint for advancing circular and regenerative transitions in the wider wine sector.

Building on the stakeholder ecosystem, the analysis now turns to the environmental foresight and measurable impacts of the model, which represent a critical dimension of its long-term sustainability.

4.2.8. Environmental Foresight and Impact

The circular model implemented at Bosque de Matasnos demonstrates strong alignment with broader European environmental policy frameworks and long-term sustainability goals. By valorizing organic residues locally and reducing reliance on external inputs, the winery contributes to several core objectives of the European Green Deal, the EU Soil Strategy for 2030, and the Circular Economy Action Plan, including nutrient recycling, sustainable land use, and climate-smart agriculture.

The use of biochar-enhanced composting supports soil regeneration, enhances resource efficiency, and contributes to greenhouse gas mitigation. These outcomes, as previously summarized in the KPI framework (Section 4.1), highlight the systemic environmental benefits of the model beyond individual practices or stages.

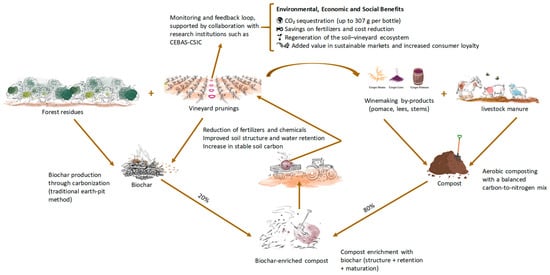

Figure 4 provides a systems-based overview of the environmental flows and impacts associated with the intervention. This case illustrates how localized circular interventions can serve as effective mechanisms for operationalizing high-level environmental targets within the agricultural sector. The combination of empirical validation, institutional support, and territorial integration reinforces its replicability and relevance for Mediterranean viticulture.

Figure 4.

Transversal mapping of systemic environmental impacts, resource flows, and policy alignments.

Overall, the environmental foresight embedded in the Bosque de Matasnos model demonstrates how localized circular practices can be scaled to contribute to systemic policy goals. Beyond its immediate climate and soil benefits, the case illustrates a replicable pathway for aligning farm-level operations with the broader transition toward sustainable, low-carbon, and regenerative agri-food systems.

4.2.9. Social Foresight and Impact

From a social perspective, the adoption of regenerative viticulture practices at Bosque de Matasnos reflects a broader shift in societal expectations regarding sustainability, traceability, and environmental responsibility. Increasing consumer awareness—amplified by public discourse, media coverage, and digital communication platforms—has led to growing demand for agricultural products that demonstrate authenticity, transparency, and a reduced environmental footprint. This trend is an increasingly decisive factor in premium wine markets, where sustainability credentials are becoming central to differentiation.

Verified indicators of environmental performance (e.g., GHG reduction, carbon sequestration) provide evidence suitable for third-party certification schemes and compliance with institutional sustainability requirements. Beyond their technical significance, these indicators also translate into social legitimacy by reinforcing consumer trust and strengthening the winery’s credibility with regulators and certifiers. Such results may also offer competitive advantages, as buyers increasingly value verified sustainability performance when making purchasing decisions.

At the territorial level, the circular strategy generates direct social benefits by stimulating the local economy through increased agricultural activity, the creation of specialized employment, and the promotion of skills related to sustainable farming practices. The internal reuse of biomass and localized biochar production contribute to a circular economy based on endogenous resources, supporting productive autonomy and reducing dependency on external inputs.

In terms of public health and well-being, the transition toward regenerative practices—such as the application of biochar-enhanced compost—reduces reliance on chemical inputs and promotes more ecologically sound production systems. These efforts are consistent with increasing societal demand for food systems that prioritize health, environmental protection, and long-term sustainability.

Overall, the social foresight integrated into the Bosque de Matasnos model demonstrates how environmental performance, consumer trust, and local benefits can be mutually reinforcing. By coupling measurable ecological outcomes with tangible social value, the model provides a pathway for strengthening the legitimacy and scalability of regenerative viticulture across Mediterranean wine regions.

4.2.10. Communication and Sales

The communication and sales strategy at Bosque de Matasnos translates its circular production model into commercial value by emphasizing sustainability credentials and transparent traceability in its messaging. Rather than relying solely on conventional marketing, the winery integrates scientific credibility and operational transparency, reinforcing the alignment between environmental performance and product differentiation.

A multichannel approach is employed, combining digital platforms—such as the winery’s website and social media—with on-site activities including guided tours and educational workshops. These channels not only inform but also amplify the circular narrative, fostering trust and emotional engagement among consumers and key opinion leaders in sustainability-oriented markets.

On the sales side, the model focuses on specialized distribution channels that value environmental innovation: gourmet retailers, organic-certified restaurants, curated e-commerce platforms, and international distributors with a sustainability agenda. Participation in trade fairs and European sustainability forums further supports brand visibility and positioning.

Overall, communication and sales practices are structured to reinforce the winery’s circular value proposition, allowing it to respond to evolving market expectations while leveraging environmental credentials as a core asset for competitiveness and loyalty. More broadly, this approach illustrates how effective communication strategies can accelerate the market uptake of circular innovations in the wine sector.

4.2.11. Cost Structure

The circular strategy at Bosque de Matasnos entails a cost structure that combines fixed investments, variable operating expenses, and strategic outlays linked to market positioning.

Fixed costs include the acquisition or adaptation of infrastructure for biochar production, composting facilities (pile areas, turning and storage equipment), staff training, and scientific coordination. Depreciation of agricultural machinery (tractors, loaders, sensors) is also considered, as well as the update of labeling to communicate environmental performance.

Variable costs encompass recurrent composting operations—pile management, turning, and field application—together with laboratory analyses (temperature, pH, nutrient content, and carbon and nitrogen fractions). Additional expenditures are related to marketing, communication, participation in trade fairs, and strengthening the winery’s profile as a benchmark in regenerative agriculture.

Unlike conventional production systems, Bosque de Matasnos does not incur costs for external fertilizers, since the estate itself generates the necessary resources. This optimization reduces dependency on external inputs and translates into medium- and long-term economic benefits.

Finally, the circular model creates opportunities for indirect returns, including the potential monetization of emission reductions through carbon credits and climate incentives (e.g., CAP and European programs). These opportunities are not accounted for as immediate cost savings but represent potential sources of income, which are further developed in the following section on revenue streams.

4.2.12. Revenue Streams

While biochar-enhanced compost does not yield immediate direct income, it strengthens economic sustainability through complementary revenue mechanisms. Internal production of enriched compost reduces input costs and avoids conventional waste management expenses, resulting in operational savings.

These internal efficiencies also support product differentiation and reinforce positioning in premium and sustainability-oriented market segments, where attributes such as circular traceability, environmental certifications, and regenerative narratives enable premium pricing and foster consumer loyalty.

Beyond savings, the model creates opportunities for diversified revenues through the commercialization of surplus compost to local farmers, participation in carbon credit markets, access to climate finance mechanisms, and the attainment of sustainability certifications that attract investment and improve eligibility for grants and awards. In addition, educational wine tourism and events focused on the circular economy generate complementary income while deepening visitor engagement and strengthening long-term customer relationships.

4.2.13. Circular Business Model and Innovation

The circular business model implemented at Bosque de Matasnos is distinguished by its systemic incorporation of regenerative practices into the winery’s operational, organizational, and market structures. Rather than relying on isolated sustainability actions, the model embeds circularity as a guiding principle across value creation, resource management, stakeholder engagement, and communication strategies.

Its most distinctive innovation lies not in a single technological breakthrough, but in the orchestration of internal resources, scientific validation, institutional support, and territorial embedding to create a fully functional, closed-loop system. This structure enhances operational autonomy, reduces environmental externalities, and ensures alignment with evolving regulatory and market expectations.

The adaptability of the model is further reinforced through ongoing collaboration with research institutions (e.g., CEBAS–CSIC), capacity-building for technical staff, and traceability mechanisms that connect production practices to environmental outcomes. These elements collectively contribute to its replicability in other viticultural contexts, particularly in Mediterranean regions seeking to reconcile climate adaptation with economic and ecological resilience.

Critically, the business model aligns with multiple Sustainable Development Goals (SDGs), including those related to responsible consumption, soil regeneration, rural employment, and climate action (see Table 8).

Table 8.

Contribution of the circular business model to selected SDGs.

Rather than treating sustainability as an add-on, the Bosque de Matasnos model integrates environmental innovation into its core economic logic, demonstrating that regenerative viticulture can be both commercially viable and systemically transformative. In doing so, it provides a transferable roadmap for the wine sector, showing how circular business models can reconcile competitiveness with ecological resilience in Mediterranean and other climate-sensitive regions.

5. Discussion

At Bosque de Matasnos, the composting of residues from vineyard, winery, and livestock operations was already a consolidated practice, consistent with recommendations for enhancing soil fertility and nutrient efficiency [31]. The pursuit of greater input autonomy led to the incorporation of biochar—initially supplied by local producers and later manufactured on the estate from PEFC-certified forest biomass.

The direct application of biochar to soil presents certain limitations, including the potential presence of undesirable compounds generated during pyrolysis and the temporary immobilization of nutrients [27,60]. Integrating biochar into composting mitigates these risks by enhancing nutrient retention, stimulating microbial activity, and accelerating stabilization [41]. Recent studies show that the co-composting of biochar improves nutrient retention, microbial activity, and the final quality of the compost [61,62,63].

Our pilot results corroborate this evidence: methane emissions during composting were reduced by 75%, organic carbon increased by 84% relative to the control, nitrogen availability improved, and compost maturity was reached 25 days earlier. These findings are consistent with reports from Mediterranean contexts [27,61] and align with the positive impacts of biochar co-composting described in other cropping systems [63].

Beyond these physicochemical benefits, wider effects such as increased soil organic carbon, improved water retention, enhanced microbial biodiversity, and reduced reliance on synthetic fertilizers are widely documented in the literature [41,60,61]. Given that the winery meets comparable technical and management conditions, these outcomes are expected to materialize in vineyard soils; ongoing monitoring of Phase II (2024–2025) will validate these projections.

The application of Ecocanvas provided an additional layer of insight, extending the analysis from a purely agronomic assessment to a systemic business model perspective. By mapping resource flows across vineyard, winery, and livestock subsystems, the tool highlighted synergies such as the dual valorization of pruning residues and winemaking by-products. It also clarified relationships with scientific partners (CEBAS–CSIC), technology providers, and certification bodies, thereby reinforcing stakeholder engagement and knowledge exchange.

Compared with traditional analytical tools such as life cycle assessment (LCA), Ecocanvas proved useful as an accessible and participatory framework that facilitated dialogue between technical staff, managers, and external collaborators [6]. However, its qualitative orientation requires complementing with quantitative methods to strengthen credibility in communication with policymakers and sustainability-driven consumers, both of whom increasingly demand verified performance metrics.

The exercise also revealed enabling factors for replication—such as the availability of local biomass, pre-existing composting infrastructure, and market positioning in premium segments—as well as potential constraints, including the need to consolidate stable demand for value-added products and to evaluate long-term agronomic impacts. Addressing these conditions will be critical to scaling the model across Mediterranean viticulture.

Overall, the integration of biochar-enhanced composting with the systemic perspective of Ecocanvas demonstrates how circular economy practices can generate simultaneous environmental benefits (emission reductions, improved compost quality, greater resource efficiency), economic advantages (cost savings, market differentiation, premium positioning), and social value (rural employment, community collaboration). This integrated approach not only strengthens the winery’s alignment with EU policy frameworks such as the European Green Deal and the EU Soil Strategy 2030, but also offers a transferable model for advancing climate-resilient and market-oriented circular agriculture.

6. Conclusions

This study evaluated the implementation of a biochar-enhanced compost strategy within a Mediterranean winery, combining agronomic performance indicators with a systemic business model analysis through the Ecocanvas methodology. The research addressed three objectives formulated in the introduction: (i) to characterize the composting process and establish key performance indicators (KPIs), (ii) to integrate agronomic and contextual data into a systemic Ecocanvas assessment, and (iii) to identify opportunities for circular business model innovation aligned with EU sustainability goals.

The results obtained during Phase I demonstrate the technical effectiveness of the intervention. Compared with the control, biochar-enhanced composting reduced methane emissions and generated significant improvements in compost quality, including higher organic carbon and nitrogen availability as well as shorter maturation times. These outcomes confirm the potential of biochar-enhanced compost as a robust agroecological practice under Mediterranean conditions, with a measurable contribution to lowering the carbon footprint of wine production.

Beyond technical performance, the systemic application of Ecocanvas provided a structured framework for representing resource flows, stakeholder relationships, and value creation mechanisms. This enabled the visualization of synergies, co-benefits, and strategic opportunities that transcend conventional agronomic assessments. The model at Bosque de Matasnos illustrates how locally driven business initiatives, supported by research collaboration and institutional alignment, can embed circular economy principles into viticulture in ways that are both territorially grounded and market relevant.

Several limitations must nonetheless be acknowledged. The agronomic effects of biochar-enhanced compost on vineyard soils remain under evaluation, limiting the assessment of long-term performance. No detailed economic analysis has yet been conducted to determine return on investment under different market scenarios, and the social benefits—such as rural employment and knowledge transfer—have so far been qualitatively described rather than quantified.

Future research should therefore expand monitoring to include soil and crop responses, compare outcomes against conventional fertilization regimes, and apply integrated tools such as life cycle assessment (LCA) and life cycle costing (LCC). It will also be important to assess the potential integration of this model into carbon credit schemes and climate finance instruments.

Despite these limitations, the case demonstrates that sustainability in viticulture can be approached not as a collection of isolated practices but as a comprehensive circular business model. By linking environmental, economic, and social dimensions through the use of Ecocanvas, the Bosque de Matasnos experience provides a replicable and scalable pathway toward regenerative, climate-smart viticulture in Mediterranean and other climate-sensitive regions.

Author Contributions

Conceptualization, A.A.-R. and N.G.-C.; methodology, A.A.-R. and P.G.; formal analysis, A.A.-R. and P.G.; investigation, A.A.-R. and P.G.; data curation, A.A.-R.; writing—original draft, A.A.-R. and P.G.; writing—review and editing, A.A.-R. and P.G.; supervision, N.G.-C.; resources, N.G.-C.; project administration, N.G.-C.; funding acquisition, P.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union through the LIFE Programme, under the LIFE Climawin project [101113948-LIFE22-CCM-ES-CLIMAWIN]. The Article Processing Charges (APC) were covered by the project S41_23R: Métodos Estadísticos No Paramétricos y Bayesianos sobre Datos Sesgados (Government of Aragón, Research Reference Group).

Data Availability Statement

Data are available on request from the corresponding author.

Acknowledgments

The authors wish to thank the Bosque de Matasnos winery for its collaboration, and the scientific partner CEBAS–CSIC for its valuable contributions to the project (see [64], a deliverable from the LIFE CLIMAWIN Project containing all the technical data incorporated in this work).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Provenzano, M.; Pacchera, F.; Silvestri, C.; Ruggieri, A. From Vineyard to Value: A Circular Economy Approach to Viticulture Waste. Resources 2024, 13, 172. [Google Scholar] [CrossRef]

- Mujtaba, G.; Hayat, R.; Hussain, Q.; Ahmed, M. Physio-Chemical Characterization of Biochar, Compost and Co-Composted Biochar Derived from Green Waste. Sustainability 2021, 13, 4628. [Google Scholar] [CrossRef]

- Kovacs, E.; Hoaghia, M.A.; Senila, L.; Scurtu, D.A.; Varaticeanu, C.; Roman, C.; Dumitras, D.E. Life Cycle Assessment of Biofuels Production Processes in Viticulture in the Context of Circular Economy. Agronomy 2022, 12, 1320. [Google Scholar] [CrossRef]

- Liu, X.; Ren, X.; Dong, J.; Wang, B.; Gao, J.; Wang, R.; Yao, J.; Cao, W. Preparation and Physicochemical Properties of Biochar from the Pyrolysis of Pruning Waste of Typical Fruit Tree in North China. BioResources 2023, 18, 8536–8556. [Google Scholar] [CrossRef]

- Abbate, S.; Centobelli, P.; Di Gregorio, M. Wine Waste Valorisation: Crushing the Research Domain. Rev. Manag. Sci. 2025, 19, 963–998. [Google Scholar] [CrossRef]

- Daou, A.; Mallat, C.; Chammas, G.; Cerantola, N.; Kayed, S.; Saliba, N.A. The Ecocanvas as a Business Model Canvas for a Circular Economy. J. Clean. Prod. 2020, 258, 120938. [Google Scholar] [CrossRef]

- Ririh, K.R.; Sundana, S.; Kusumawati, A.; Ningtyas, D.R. The Development of the Triple-Helix Role Model on the Development of a Cleantech Startup Ecocanvas Based on Green Innovation & Technology Adoption. Barometer 2022, 7, 107–116. [Google Scholar] [CrossRef]

- Bálint, L.P.; Várallyai, L.; Botos, S. Evaluation of Data-Driven Sustainability Potential at SMEs Using an Altered Ecocanvas Model. Economies 2025, 13, 49. [Google Scholar] [CrossRef]

- Rajković, M.B.; Popović, M.D.; Milinčić, D.; Zdravković, M. Circular Economy in Food Industry. Zast. Mater. 2020, 61, 229–250. [Google Scholar] [CrossRef]

- Matrapazi, V.K.; Zabaniotou, A. Experimental and Feasibility Study of Spent Coffee Grounds Upscaling via Pyrolysis towards Proposing an Eco-Social Innovation Circular Economy Solution. Sci. Total Environ. 2020, 718, 137316. [Google Scholar] [CrossRef]

- Dora, M.; Biswas, S.; Choudhary, S.; Nayak, R.; Irani, Z. A System-Wide Interdisciplinary Conceptual Framework for Food Loss and Waste Mitigation Strategies in the Supply Chain. Ind. Mark. Manag. 2021, 93, 492–508. [Google Scholar] [CrossRef]

- Kounani, A.; Sotiropoulou, E.; Seleventi, M. Implementing Circular Economy in Wineries: The Case of Greece. In Proceedings of the 17th International Conference on Environmental Science and Technology, Athens, Greece, 1–4 September 2021. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. Current Options for the Valorization of Food Manufacturing Waste: A Review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef]

- Mura, R.; Vicentini, F.; Botti, L.M.; Chiriacò, M.V. Achieving the Circular Economy Through Environmental Policies: Packaging Strategies for More Sustainable Business Models in the Wine Industry. Bus. Strategy Environ. 2024, 33, 1497–1514. [Google Scholar] [CrossRef]

- García-García, J.; García-Castellanos, B.; García García, B. Economic and Environmental Assessment of the Wine Chain in Southeastern Spain. Agronomy 2023, 13, 1478. [Google Scholar] [CrossRef]

- Marques, C.; Güneş, S.; Vilela, A.; Gomes, R. Life-Cycle Assessment in Agri-Food Systems and the Wine Industry—A Circular Economy Perspective. Foods 2025, 14, 1553. [Google Scholar] [CrossRef]

- Berardi, P.C.; Dias, J.M. How Has the Wine Sector Incorporated the Premises of Circular Economy? J. Environ. Sci. Eng. B 2019, 8, 108–117. [Google Scholar] [CrossRef]

- Destefanis, R.; Cela, N.; Torri, L.; Fassio, F. Systemic Approach Applied to the “R” Paradigm of the Circular Economy: A Critical Reading of the Winemaking Process Through Case Studies from Northwest Italy. Sustainability 2024, 16, 8960. [Google Scholar] [CrossRef]

- Prosdocimi, M.; Jordán, A.; Tarolli, P.; Keesstra, S.D.; Novara, A.; Cerdà, A. The Immediate Effectiveness of Barley Straw Mulch in Reducing Soil Erodibility and Surface Runoff in Mediterranean Vineyards. Sci. Total. Environ. 2016, 547, 323–330. [Google Scholar] [CrossRef]

- O’Brien, F.; Nesbitt, A.; Sykes, R.; Kemp, B. Regenerative Viticulture and Climate Change Resilience. OENO One 2025, 59, e8089. [Google Scholar] [CrossRef]

- Ghiglieno, I.; Simonetto, A.; Facciano, L.; Tonni, M.; Donna, P.; Valenti, L.; Gilioli, G. Comparing the Carbon Footprint of Conventional and Organic Vineyards in Northern Italy. Sustainability 2023, 15, 5252. [Google Scholar] [CrossRef]

- Igalavithana, A.D.; Mandal, S.; Niazi, N.K.; Vithanage, M.; Parikh, S.J.; Mukome, F.N.; Rizwan, M.; Oleszczuk, P.; Al-Wabel, M.; Bolan, N.; et al. Advances and Future Directions of Biochar Characterization Methods and Applications. Crit. Rev. Environ. Sci. Technol. 2017, 47, 2275–2330. [Google Scholar] [CrossRef]

- Giagnoni, L.; Maienza, A.; Baronti, S.; Vaccari, F.P.; Genesio, L.; Taiti, C.; Martellini, T.; Scodellini, R.; Cincinelli, A.; Costa, C.; et al. Long-Term Soil Biological Fertility, Volatile Organic Compounds and Chemical Properties in a Vineyard Soil after Biochar Amendment. Geoderma 2019, 344, 127–136. [Google Scholar] [CrossRef]

- Sirohi, R.; Tarafdar, A.; Singh, S.; Negi, T.; Gaur, V.K.; Gnansounou, E.; Bhartiraja, B. Green Processing and Biotechnological Potential of Grape Pomace: Current Trends and Opportunities for Sustainable Biorefinery. Bioresour. Technol. 2020, 314, 123771. [Google Scholar] [CrossRef]

- Cataldo, E.; Fucile, M.; Mattii, G.B. A Review: Soil Management, Sustainable Strategies and Approaches to Improve the Quality of Modern Viticulture. Agronomy 2021, 11, 2359. [Google Scholar] [CrossRef]

- Thakur, A.; Kumar, A.; Somya, A. Forestry and Agricultural Residues-Based Wastes: Fundamentals, Classification, Properties, and Applications. In Biomass Wastes for Sustainable Industrial Applications; CRC Press: Boca Raton, FL, USA, 2025; pp. 95–139. [Google Scholar]

- Baronti, S.; Vaccari, F.P.; Miglietta, F.; Calzolari, C.; Lugato, E.; Orlandini, S.; Pini, R.; Zulian, C.; Genesio, L. Impact of Biochar Application on Plant Water Relations in Vitis vinifera (L.). Eur. J. Agron. 2014, 53, 38–44. [Google Scholar] [CrossRef]

- Genesio, L.; Miglietta, F.; Baronti, S.; Vaccari, F.P. Biochar Increases Vineyard Productivity Without Affecting Grape Quality: Results from a Four Years Field Experiment in Tuscany. Agric. Ecosyst. Environ. 2015, 201, 20–25. [Google Scholar] [CrossRef]

- Rombolà, A.G.; Meredith, W.; Snape, C.E.; Baronti, S.; Genesio, L.; Vaccari, F.P.; Miglietta, F.; Fabbri, D. Fate of Soil Organic Carbon and Polycyclic Aromatic Hydrocarbons in a Vineyard Soil Treated with Biochar. Environ. Sci. Technol. 2015, 49, 11037–11044. [Google Scholar] [CrossRef]

- Maienza, A.; Baronti, S.; Cincinelli, A.; Martellini, T.; Grisolia, A.; Miglietta, F.; Renella, G.; Stazi, S.R.; Vaccari, F.P.; Genesio, L. Biochar Improves the Fertility of a Mediterranean Vineyard without Toxic Impact on the Microbial Community. Agron. Sustain. Dev. 2017, 37, 45. [Google Scholar] [CrossRef]

- Azim, K.; Soudi, B.; Boukhari, S.; Perissol, C.; Roussos, S.; Alami, I.T. Composting Parameters and Compost Quality: A Literature Review. Org. Agric. 2018, 8, 141–158. [Google Scholar] [CrossRef]

- Caponio, G.R.; Minervini, F.; Tamma, G.; Gambacorta, G.; De Angelis, M. Promising application of grape pomace and its agri-food valorization: Source of bioactive molecules with beneficial effects. Sustainability 2023, 15, 9075. [Google Scholar] [CrossRef]

- Karastergiou, A.; Gancel, A.L.; Jourdes, M.; Teissedre, P.L. Valorization of grape pomace: A review of phenolic composition, bioactivity, and therapeutic potential. Antioxidants 2024, 13, 1131. [Google Scholar] [CrossRef]

- Constantin, O.E.; Stoica, F.; Rațu, R.N.; Stănciuc, N.; Bahrim, G.E.; Râpeanu, G. Bioactive components, applications, extractions, and health benefits of winery by-products from a circular bioeconomy perspective: A review. Antioxidants 2024, 13, 100. [Google Scholar] [CrossRef]

- Lopes, J.D.C.; Madureira, J.; Margaça, F.M.; Cabo Verde, S. Grape pomace: A review of its bioactive phenolic compounds, health benefits, and applications. Molecules 2025, 30, 362. [Google Scholar] [CrossRef]

- Ferrari, V.; Taffarel, S.R.; Espinosa-Fuentes, E.; Oliveira, M.L.; Saikia, B.K.; Oliveira, L.F. Chemical evaluation of by-products of the grape industry as potential agricultural fertilizers. J. Clean. Prod. 2019, 208, 297–306. [Google Scholar] [CrossRef]

- Gómez-Brandón, M.; Lores, M.; Insam, H.; Domínguez, J. Strategies for recycling and valorization of grape marc. Crit. Rev. Biotechnol. 2019, 39, 437–450. [Google Scholar] [CrossRef]

- Perra, M.; Cuena-Lombraña, A.; Bacchetta, G.; Manca, M.L.; Manconi, M.; Maroun, R.G.; De Gioannis, G. Combining different approaches for grape pomace valorization: Polyphenols extraction and composting of the exhausted biomass. Sustainability 2022, 14, 10690. [Google Scholar] [CrossRef]

- Gabur, G.D.; Teodosiu, C.; Fighir, D.; Cotea, V.V.; Gabur, I. From waste to value in circular economy: Valorizing grape pomace waste through vermicomposting. Agriculture 2024, 14, 1529. [Google Scholar] [CrossRef]

- Nascimento-Gonçalves, E.; Azevedo, T.; Lopes, H.; Sousa, J.R.; Oliveira, P.A.; Roboredo, M.; Morais, M.C. Vermicomposting as a valorization solution to the winery sector by-products. Agronomy 2024, 14, 1111. [Google Scholar] [CrossRef]

- Sánchez-Monedero, M.A.; Cayuela, M.L.; Sánchez-García, M.; Vandecasteele, B.; D’Hose, T.; López, G.; Martínez-Gaitán, C.; Kuikman, P.J.; Sinicco, T.; Mondini, C. Agronomic Evaluation of Biochar, Compost and Biochar-Blended Compost across Different Cropping Systems: Perspective from the European Project FERTIPLUS. Agronomy 2019, 9, 225. [Google Scholar] [CrossRef]

- Ronga, D.; Francia, E.; Allesina, G.; Pedrazzi, S.; Zaccardelli, M.; Pane, C.; Tava, A.; Bignami, C. Valorization of Vineyard By-Products to Obtain Composted Digestate and Biochar Suitable for Nursery Grapevine (Vitis vinifera L.). Prod. Agron. 2019, 9, 420. [Google Scholar] [CrossRef]

- Garau, M.; Pinna, M.V.; Nieddu, M.; Castaldi, P.; Garau, G. Mixing Compost and Biochar Can Enhance the Chemical and Biological Recovery of Soils Contaminated by Potentially Toxic Elements. Plants 2024, 13, 284. [Google Scholar] [CrossRef] [PubMed]

- Sharifi, M.; Hajiaghaei-Kamrani, M. Biochar–Compost Mixture and Cover Crop Effects on Soil Carbon and Nitrogen Dynamics, Yield, and Fruit Quality in an Irrigated Vineyard. Can. J. Soil Sci. 2023, 103, 200–212. [Google Scholar] [CrossRef]

- Bello, A.; Wang, B.; Zhao, Y.; Yang, W.; Ogundeji, A.; Deng, L.; Egbeagu, U.U.; Yu, S.; Zhao, L.; Li, D.; et al. Composted Biochar Affects Structural Dynamics, Function and Co-Occurrence Network Patterns of Fungi Community. Sci. Total Environ. 2021, 775, 145672. [Google Scholar] [CrossRef] [PubMed]

- Zahra, M.B.; Fayyaz, B.; Aftab, Z.E.H.; Haider, M.S. Mitigation of Degraded Soils by Using Biochar and Compost: A Systematic Review. J. Soil Sci. Plant Nutr. 2021, 21, 2856–2873. [Google Scholar] [CrossRef]

- Sánchez-Monedero, M.A.; Cayuela, M.L.; Roig, A.; Jindo, K.; Mondini, C.; Bolan, N. Role of Biochar as an Additive in Organic Waste Composting. Bioresour. Technol. 2018, 247, 1155–1164. [Google Scholar] [CrossRef]

- Oldfield, T.L.; Sikirica, N.; Mondini, C.; López, G.; Kuikman, P.J.; Holden, N.M. Biochar, Compost and Biochar–Compost Blend as Options to Recover Nutrients and Sequester Carbon. J. Environ. Manag. 2018, 218, 465–476. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar]

- Alfarizi, M.; Sari, R.K. Micro Business Study of Traditional Health Drink Products “Telang limao bangkak” (Green Business Canvas Study “Ecocanvas”). Food Sci. Tech. J. 2021, 3, 127. [Google Scholar] [CrossRef]

- Pepin, M.; Tremblay, M.; Audebrand, L.K.; Chassé, S. The responsible business model canvas: Designing and assessing a sustainable business modeling tool for students and start-up entrepreneurs. Int. J. Sustain. High. Educ. 2024, 25, 514–538. [Google Scholar] [CrossRef]

- Islam, M.T.; Iyer-Raniga, U. Circular business model value dimension canvas: Tool redesign for innovation and validation through an Australian case study. Sustainability 2023, 15, 11553. [Google Scholar] [CrossRef]