1. Introduction

1.1. An Overview of Ripe Fruit Harvesting Methods and Efficiency

Primarily, mechanical harvesting is supposed to significantly reduce harvesting times and costs [

1]. Practically, most of the mechanical citrus harvesting machines are designed to detach the fruit from the tree canopy and have it fall onto a conveyer apparatus or field ground. Citrus harvesting has predominantly relied on three basic methods for removing ripe fruit from citrus trees: (a) excitation of individual tree trunks (trunk shaker), (b) shaking entire tree canopies (canopy shaker), and (c) hand picking (selective harvesting). The two mechanical methods mentioned first are based on transferring vibrations from the harvesting machine to the tree. Harvesting citrus trees using trunk shakers has shown a fruit detachment percentage of up to 80% without damaging the citrus trees. The use of modern technologies to improve citrus production is essential for increasing agricultural profits and reducing citrus farming and harvesting operating costs. In general, mechanical citrus harvesting systems significantly reduce the harvesting costs compared to hand harvesting [

2,

3]. Using a trunk shaker, within the first five seconds, more than 50% of the fruit was removed. Furthermore, the higher vibration amplitude resulted in a maximum displacement of 13.5 cm to the fruits, which could cause a higher damage level of 14 to 74% of the harvested fruits [

4,

5].

Research has also recognized that vibration frequencies impacted harvest yield percentages. For example, Bohannon [

6] designed a citrus fruit harvester using the oscillation of notched rods attached to a single-boom long arm and oscillating at 1000 to 5000 times per minute. Harvesting productivity was between 400 to 500 boxes per day. Additionally, when using a prototype self-propelled canopy shaker with a conveyer belt, Láng [

7] showed that optimal apple detachment was accomplished at oscillations between 4 to 6 Hz. A vertical continuous orange tree canopy shaker using oscillating sticks at frequencies of 4 to 5 Hz led to yields of 71 to 91% of the oranges being detached and dropped onto the machine conveyer. This harvester realized an 83% detachment of the oranges using sticks oscillating at 5 Hz, while 80% of the fruit was detached when the sticks oscillated at 4.7 Hz [

8]. Other mechanical shakers had similar citrus fruit yields: 55 to 95% of the oranges removed from tree canopies by a canopy shaker at 4.5 to 5 Hz, and 84 to 94% of oranges were detached by using a trunk-shaking harvester running at 10 Hz [

9].

Erdoğan et al. [

10] developed an apricot harvester using a long, single hydraulic shaker arm with frequencies of 10 to 20 Hz to furnish oscillations for tree limb shaking. The best apricot detachments required five-second oscillations at 15 Hz. In another vibration frequency study, Loghavi and Mohseni [

11] investigated limb vibrations on lime fruit removal by a beam shaker using three shaking frequencies (5, 7.5, and 10 Hz). All the lime fruits were removed (100%) when the shaker operated at 10 Hz. Torregrosa et al. [

12] investigated orange and mandarin harvesting using a trunk-shaking arm. A frequency of 15 Hz with a shaking time of 4 or 5 s was adequate for optimal fruit removal (an average of 65% of the fruit was removed). Also, to complete the fruit detachment process by the canopy shaker, the configuring of canopy shaking beaters in the middle and lower sections of the canopy shaker with frequencies ranging from 3 to 7.8 Hz resulted in a reduction in damage to the lower and middle tree branches by 25 to 30%; changing the upper beaters of the canopy shaker reduced the branches damage in the upper section of the tree canopy by 40 to 45% [

13].

In another experiment, Liu et al. [

14] conducted a field study on the spread of vibration acceleration along the vibrating branch by different vibrating citrus canopy harvester beaters at vibration frequencies of 2.5 and 5 Hz. The results showed that the vibration acceleration generated by the straight PVC or steel beaters was 1.77 and 1.97 times higher than that of the nylon rods, respectively, and that the steel rods were more effective than either the PVC or nylon rods. Also, a study using a trunk shaker showed that a fruit-mounted accelerometer recorded fruit vibration frequencies between 12 and 18 Hz compared to frequencies around 19 Hz that were measured by an accelerometer mounted on the tree trunk. The importance of applying a chemical abscission agent CMN-Pyrazole (CMNP) to citrus canopies before harvest using a trunk shaker is to reduce the force required to drop the fruit from 120 N with a shaking time of 5 seconds and a frequency of 7 Hz to about 70 N [

5,

15].

An additional consideration associated with mechanical harvesting is fruit damage and the percentage of marketability lost. For example, blackberry canopies were oscillated at frequencies ranging from 5.8 to 7.9 Hz with a thornless blackberry harvester. Unfortunately, this blackberry harvest was not considered successful due to the low yield between 36 and 56% of fruit classified as fresh market quality [

16]. On the other hand, applying the concept of a robotic citrus harvester to detach the orange stems individually, picking the fruits without their stems or damage to fresh market quality, resulted in 84% of the oranges being collected without significant injuries [

17].

1.2. An Overview of the Scientific Method for Extracting Ripe Fruit

Significant progress has been made regarding the scientific study of the practical application of mechanical harvesting based on the concept of shake-to-fruit. Numerous studies have been conducted on the dynamic operating parameters of tree shakers. Castro-García et al. [

18] studied vibrations that were induced by a trunk shaker employed for olive tree harvesting. Using three tri-axial accelerometers (model PCB 356A02) located on various branches and the tree trunk, and by applying specific vibration frequencies in the range of 0 to 256 Hz, the maximum excitation frequency was recorded as 71.5 Hz for large trees and 72.4 Hz for small trees.

A grape harvester experiment in a vineyard used tri-axial accelerometers with a frequency range from 0.1 to 16,500 Hz and an attached amplifier and digital recorder, which were positioned vertically on various grape boughs at different distances. One additional accelerometer setup was placed on top of the trellis wire. The harvester was operated with a ground speed of 2.8 km/h, and applied various beating frequencies of 380, 400, 420, 440, and 460 beats/min. Adequate harvesting results were achieved by applying a beating frequency of 440 beats/min [

19].

Udumala Savary et al. [

20,

21] also conducted studies of vibration forces using low g accelerometers (Freescale MMA7260Q) with a sensitivity of up to ±6 g (NXP Semiconductor Inc., Chandler, AZ, USA) with an XBee-PRO RF module (XBee-PRO DigiMesh

® 2.4 GHz sensor) (Digi International Inc., Hopkins, MN, USA) on a citrus tree canopy that was exposed to mechanical harvesting. The devices were placed on random citrus tree branches and on the citrus fruits so as to study the resistance of citrus fruits to the vibration forces of the mechanical harvester. The examined operating variables were canopy shaker frequencies of 200, 250, and 300 cpm, and the fruit detachment forces (FDF) were calculated from the accelerometers’ sense (three-axial acceleration values) and the fruit and limb weights that were randomly selected. Their studies proposed that the required forces (maximum force) needed for the detachment of the orange fruit were between 22.01 N and 27.20 N. They found that the maximum forces for fruit detachment, depending on the fruit’s location, were recorded as 24.49 N on the tree surface and 23.07 N inside the fruit. Depending on the sizes of citrus trees, the maximum resulting dynamic acceleration values were found to be 136.01 m/s

2 for the large trees with a shaker beater frequency of 250 cpm, and 137.95 m/s

2 for small trees with a beater frequency of 300 cpm.

With the same operating concept, existing olive and blueberry harvesters, as well as the grape harvesting machines, can be modified to adapt to a variety of citrus trees during harvest [

22]. Castro-García et al. [

23] studied dynamic vibrations that were applied to a citrus tree canopy to achieve high fruit detachment efficiency by using an orange canopy shaking machine and a set of tri-axial accelerometers. This study noted that the internal branches of the orange canopy received only 43% of the acceleration of external branches, and that branches should vibrate for a minimum of 5.8 s, at an acceleration of 23.9 m/s

2 to complete the process of fruit detachment.

Liang et al. [

24] studied the automated harvesting of citrus fruits in real-time efficient operations to detect the location of the fruit picking point by using the citrus fruit detection dataset (CFDD) and the citrus branch segmentation dataset (CBSD) algorithms. The results were sufficiently accurate, allowing their results to be utilized for automated harvesting in many agricultural applications for various species of fruit to increase picking productivity and reduce the harvest time.

Optimal tree vibrations were also studied during the mechanical harvesting of walnut trees. Optimal fruit picking can be achieved when the harvester’s operator correctly adjusts each tree’s vibration amplitude and frequency. The results of this study also emphasize the importance of considering a tree’s diameter, height, and canopy shape when determining the optimal vibration frequency for walnut trees [

25].

By operating a citrus harvesting machine, which is based on shaking tree branches, at a frequency of 6 Hz and amplitude of 60 mm, the machine achieved 99.1% fruit detachment and 100% ripe fruit harvest removal [

26]. Shaking beaters are responsible for transferring the mechanical impact of the harvester’s shaking mechanism to the entire tree canopy. The shapes of mechanical shaking beaters also significantly affect fruit detachment and tree damage. Flexible, arc-shaped shaking beaters with a beater vibration frequency of 4.7 Hz and forward speed of 3 km/h have better performance, achieving a higher fruit removal percentage (82.6%), with a 5.36% reduction in tree damage [

27,

28].

Significantly, shaking a citrus tree canopy can also weaken the fruit navel pit, which is the area where the stem of a fruit (i.e., the fruit’s pedicel and calyx) is attached to the canopy. Therefore, the mechanical citrus harvesting, by shaking the canopy, has been the most successful viable solution for harvesting an entire tree canopy and enhancing the quantity picked as well as productivity. Consequently, the primary objective of this article is to clarify the appropriate tree canopy shaking frequency to achieve optimal ripe fruit detachment from tree branches, which could significantly impact the time required for the tree canopy excitation.

2. Materials and Methods

The citrus harvester for these experiments was designed with short adjustable connecting rods, i.e., the reciprocating turnbuckle joints for beater penetration, which have a reciprocating movement horizontally between the machine crankshafts and the vertical beater-pivot shafts. The range of the beaters’ penetration within the tree canopies was modulated by modifying the length of the short connecting rods. Displacement of the shaker’s stroke was modified by adjusting the lengths of the joint turnbuckles. The shaking speeds (synchronized speeds) of the shaking beaters could be changed through manually regulating the speed of the hydraulic motors by adjusting the speed of the harvester’s engines or the two flow control valves of the harvester’s engines. To determine proper machine operations and improve the harvest efficiency of the shaker machine, the first trials (pre-test) were performed on grapefruit trees (Ray Ruby scion), which were dwarfed to less than 10 ft (3.05 m) tall. The grapefruit hedges had been arranged in a space of 8 ft (2.44 m) between the trees and 20 ft (6.10 m) between the rows. Furthermore, the branches of the oranges and grapefruit trees varied significantly. Most of the trees had low-hanging branches reaching to the field soil. Nevertheless, skirting and pruning were conducted on the grapefruit tree’s canopies to adjust the canopy height to be about 8 ft (2.44 m) and the width of nearly 7 ft (2.13 m). The field experiments of the final prototype harvester design were executed on the same Ray Ruby orchard to determine the harvesting machine performance improvements. Before harvesting, the branches of the grapefruit trees were skirted and pruned to set the canopy height and width to nearly the actual size of the internal dimensions of the harvesting machine.

Field testing was accomplished by operating this self-propelled citrus canopy shaker, with which the canopy of the citrus tree was surrounded by the shaker machine beaters (hollow PVC rods). The shaking beaters’ design, i.e., 7 round metal pipes and flexible PVC pipes on each shaker unit, helped to minimize tree canopy damage. The rounded design allowed the trees’ branches to slip up or down when the branches and beaters collided. However, branch splits occurred as a result of the entanglement of inflexible branches in the lower canopies, especially for branches with crotch angles, with the harvester’s lowest beaters. Also, tree canopies with non-uniform (non-concentric) shapes were another source of branch damage, where split branches occurred on one side of the canopies at each trial. Additional development of the citrus harvesting machine included attaching extra beaters (30 inches of a flexible 1-inch (OD) UHMW polyethylene white pipe) to the main beaters (25 inches of curved steel pipe and 30 inches of a flexible 1-inch (OD) UHMW polyethylene white pipe) on the two shakers’ systems of the preliminary shaker design. The result was that the harvester’s shaking beaters delivered more shaking acceleration to the tree canopy. Therefore, the consequence of operating the 26 beaters of the final design at a fixed tunnel width of 69 inches may have been the main cause of the canopies’ damaged branches. Furthermore, the main beaters’ design, i.e., curved metal pipes with attached UHMW polyethylene white pipes, could have helped minimize the damage to the tree canopies. However, some grapefruit canopy splits occurred due to some inflexible branches in the lower tree canopy. The first beater at the bottom of each shaker unit was 28 inches above the ground—exactly where the strong lower branches of the tree canopies (with an approximate diameter of 2.50 inches) were located. According to the harvesting results, 27 trees out of 70 treated trees had a broken crotch branch (large branch) on at least one side of the tree canopy. The broken branch diameters ranged between 0.65 and 2.15 inches. The broken branches were concentrated inside the tree canopies between 26 and 58 inches above the ground. Additionally, 16 trees out of the 70 treated trees had at least one small sub-branch broken on one side of the tree canopy or both sides. Rarely, some tree branches received bark damage.

The harvester initiated a maximum load on the shakers, which transferred sufficient functional load to deflect the tree branches and detach the fruit from the tree (i.e., deliver suitable fruit removal forces to detach fruit without causing broken branches or stems).

Practically, the tree canopy was partially surrounded when the pair of harvester’s shaking beaters forms a “Λ” shape against the tree canopy within the machine’s adjustable tunnel. The beater assemblies were extended into the tree canopies when the canopy shaker passed through the citrus groves, as shown in

Figure 1.

The accelerometer sensor is often utilized for diverse applications where measurements of vibration, acceleration, or shock analysis are required. It is often used with the fast Fourier transform (FFT) algorithm for analyzing the vibration data results (sampled signals), regardless of the variation in the vibration frequency. The measurement of acceleration (motion) can be applied to different spots in the tree canopy (trunks, branches, or fruits) for measuring acceleration in the fruit, which can then be correlated to fruit detachment. The trees were instrumented using Triaxial USB accelerometers, model X16-1C (GCDC), which have an amplitude range of up to ±16 g, sample rates of up to 200 Hz, and weigh 55 g with the associated battery. The accelerometer power was supplied by a detachable AA battery (1.5 V) or a +5 volt PC power supply. For recording field acceleration data, an easily removable 2 GB card was built in (

Figure 2). Fortunately, the GCDC X16-1C Triaxial USB Accelerometer (Gulf Coast Data Concepts, LLC, Waveland, MS, USA) does not require a data acquisition device for transmitting the acceleration data to the portable computer or a special software program (a USB terminal interface was included) [

29].

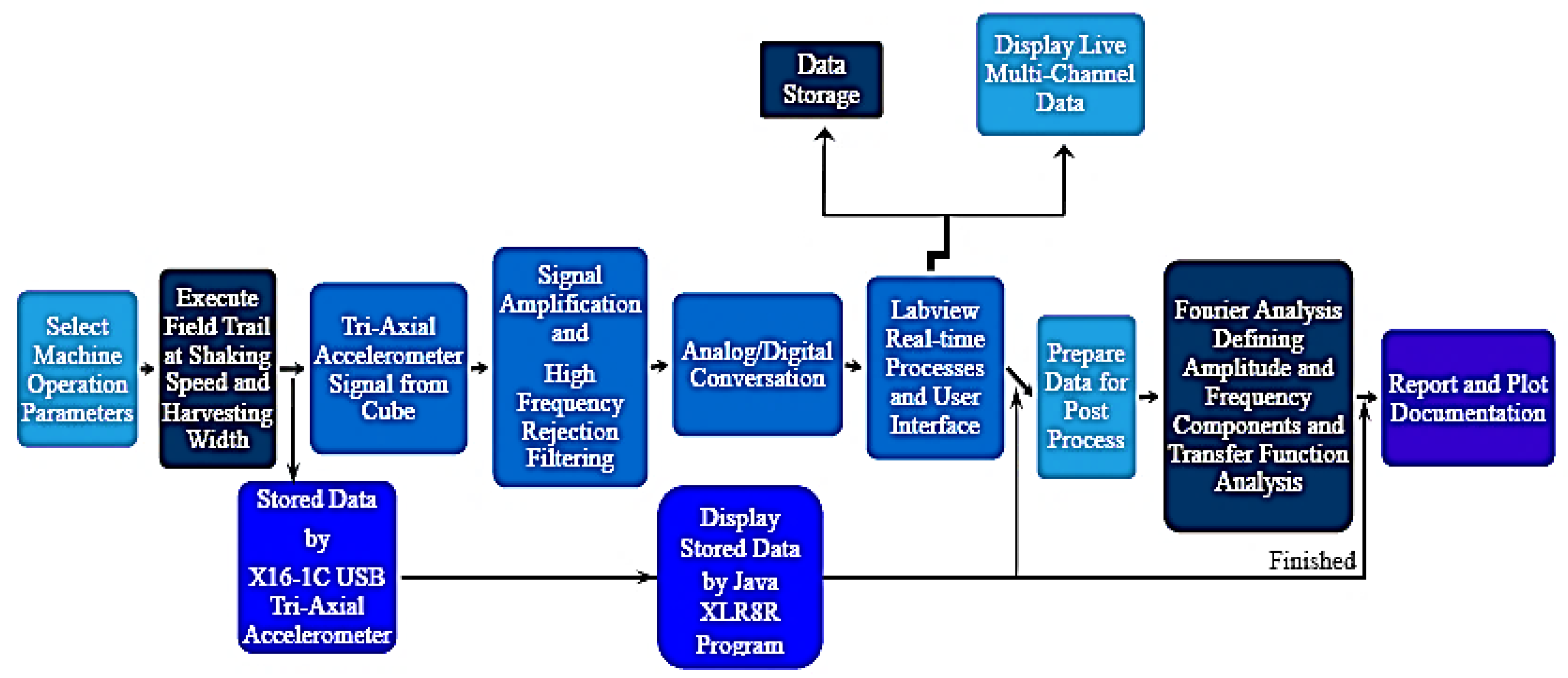

The raw acceleration data (a mixture of time and voltage data) were obtained as a stream of instantly recorded numbers, which were written, viewed, and analyzed through the creation of a text file and

x-,

y-, and

z-axis figures with either Microsoft Excel or WordPad. The test file of the acceleration data, which is actually a built-in application of the XLR8R, is compliant with Java programs (Java (TM) Platform Standard Edition 6.0). Through the XLR8R Java application, the acceleration analysis was shown in graphical plots as a function of time (g force vs. time). Later, the fast Fourier transform (FFT) was utilized as necessary to gather data on the frequency response of the shaking beaters of the harvester or branches of the grapefruit canopy. These data were displayed as a plot of the power spectrum versus the frequency response (the time signal and frequency spectrum graphs). Thus,

Figure 3 illustrates the steps that were required to achieve the acceleration purposes of this study and perform the USB acceleration sensor experiments to extract all the data for the tree branch shaking results.

Before testing began, 15 USB accelerometer sensors (model X16-1C) were randomly placed on various branches at different locations in the canopy of the fruit tree (Ray Ruby grapefruit) and were attached using plastic adhesive tape (

Figure 4). The 15 USB accelerometer sensors were used to estimate the dynamic acceleration (acceleration magnitude) during the harvesting operations.

A rotational speed instrument (digital tachometer) was utilized to obtain the rotational speeds of the shaker’s crankshaft (rpm) and the beater’s rotational speeds (shaking speeds, in/s) during the various harvesting operations. For the precise data analysis of the most important measurements, the practical gravitational accelerations (

ai) on the citrus tree branches for each axis (ith) of the three orthogonal axes coordinates (the

x-,

y-, and

z-axis) from each X16-1C acceleration sensor, were developed using the Java XLR8R program. Subsequently, the resultant of the magnitude of the acceleration data (

aT) based on gravity (g) could be calculated by using the following equation of the root sum squared (RSS) method of acceleration [

21,

30].

Moreover, ANOVA, as well as the General Linear Model (GLM) through the SAS package (2025 SAS© Institute Inc., Cary, NC, USA) at a 90% significance level, were applied to make a decision about the contributive acceleration magnitude that could have a significant impact on the canopy shaker performance for grapefruit detachment.

3. Results and Discussion

Mechanical harvesting is generally employed to shorten the harvesting time and raise field crop harvesting productivity. For citrus harvesting, mechanical harvesting utilizes the generation of a moderate vibration in the tree canopy. Accordingly, the fundamental concept of the canopy shaker is optimally shaking the beaters to impart those oscillations efficiently to the citrus tree canopies, thereby maximizing the harvested fruit yield. Measurements were performed during the operation of the shaking machine in a citrus (grapefruit) field to determine the necessary acceleration of the tree limbs and the harvester’s beaters as a result of the shaking system operations, and an analysis of the acceleration measurements used in this study will be presented in the following sections.

3.1. Demonstrating Shakers’ Penetration into the Grapefruit Tree Canopy

For citrus harvester performance testing, the shaking beaters were placed within the tree canopy. Improvements were made to the original 7 beaters per shaking unit (14 beaters in total), employing 13 beaters per shaking unit (26 beaters in total). However, the intimate engagement between the canopy and shaking beaters was increased by increasing the beater penetration depths. For the beater optimization study, the shaking beaters’ penetration into the grapefruit canopy was regulated by varying the coupling lengths of the turnbuckle linkages, as well as being based on the expectation of having no tree branch load. The lengths of the turnbuckle linkages, which are located between the vertical shaking beaters’ shaft and the vertical operation shaft, are varied and range between 10 and 16 inches in length. When the lengths of the turnbuckle linkages are increased, the result is increased canopy penetration (e.g.,

Table 1). The lowest shaking beater height from the ground was 28 inches, and the height of the top shaking beaters from the ground was 76 inches and 28 inches from the top of the internal tunnel of the harvester machine.

3.2. Distribution of Acceleration Magnitude in the Grapefruit Tree Canopy

Physically, fruits are harvested when the tensile force between the fruit calyx and the peduncle (stem) exceeds the fruit’s adhesion force and, thus, severs the adhesion layer (

Figure 5). The adhesion force is variable according to the fruit’s maturity. Canopy shaking experiments were conducted on grapefruit trees to study the branches’ dynamic behavior (accelerations upon shaking) using a shaking citrus canopy machine. Numerous small acceleration devices (15 USB accelerometer sensors; model X16-1C) were placed on various branches at randomly selected locations in the canopy of a fruit tree (Ray Ruby grapefruit). The resulting distribution of the canopy accelerations was obtained under various operating conditions (e.g., varied beaters’ shaking speeds and the beaters’ penetration into a dense canopy), where the harvester’s tunnel width was maintained at 69 inches. The data configuration was displayed using the Java XLR8R program, which is furnished with an X16-1C sensor, where the magnitude of the acceleration was calculated and stored internally in the X16-1C (i.e., internal calculation and storage). Also, the results of the tree branches’ oscillations during shaking were recorded with a global clock to measure a precise time (milliseconds) and a cluster of three coordinate accelerations (

x,

y, and

z). Subsequently, the acceleration data were found by using the time domain diagram (at the

x-axis, milliseconds) on the

x-,

y-, and

z-axis, which were initially recorded at a sample rate of 50 Hz and a sample size of 30,000 (counts) versus the time domain magnitude of the converted data (at the

y-axis, gravitational acceleration, g). MATLAB

® (MATLAB R2025a, The MathWorks Inc., Natick, MA, USA) contains a variety of panels that enable the development of effective software applications (i.e., code applications) for the basic principles of acceleration and vibration force measurements. Accordingly, the resultants of the three coordinate axes were calculated and displayed (e.g.,

Table 2 and

Table 3), and the figures were generated using the MATLAB

® program.

3.3. Shaking Acceleration Distribution by Diverse Beaters’ Penetration into Dense Grapefruit Canopies

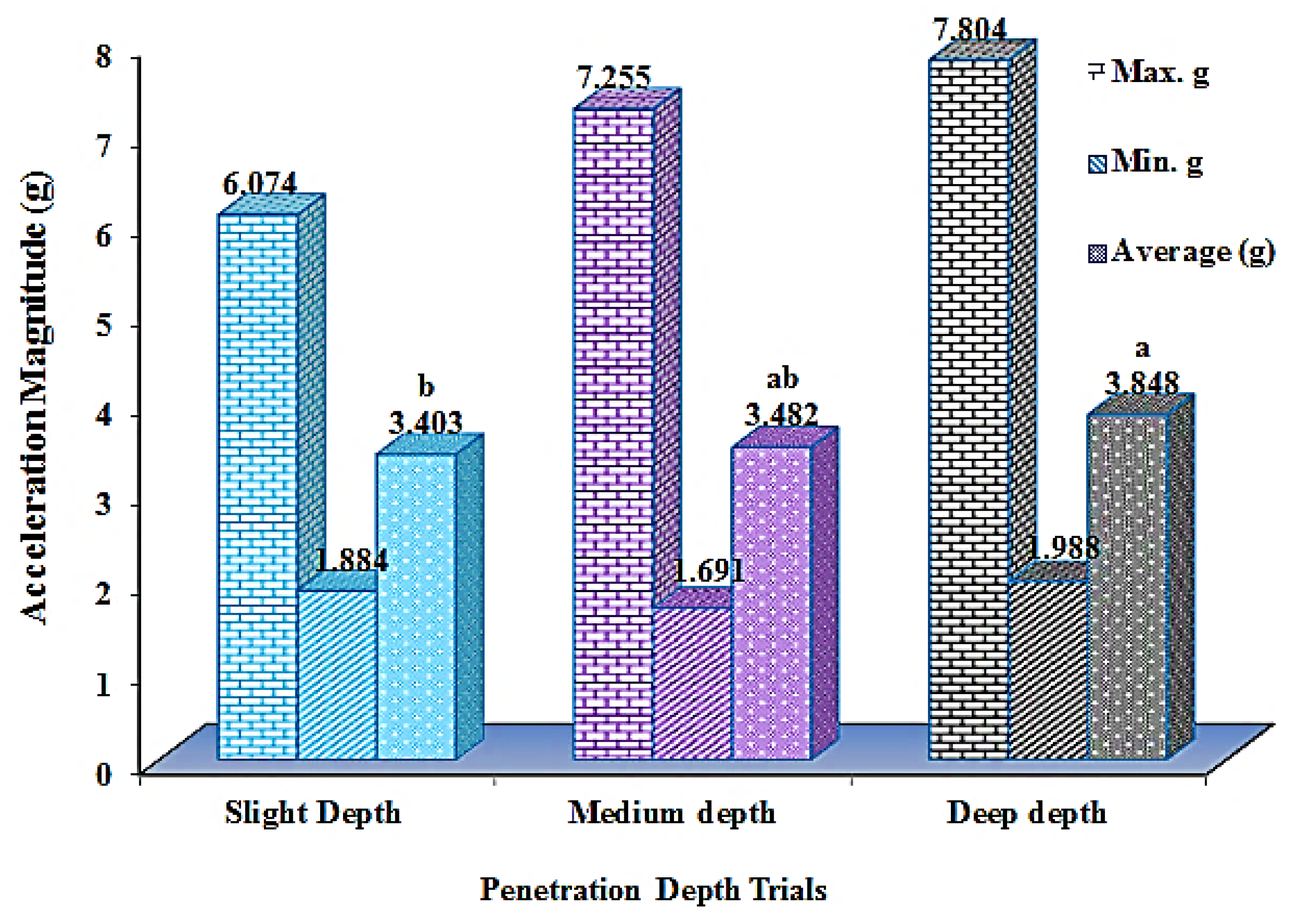

The results in

Table 2 present the time domain magnitudes and averages of the acceleration that were achieved using 14 shaking beaters (i.e., two units on the right and left sides, and seven beaters per shaking unit) and operating the harvester’s beaters at three different tree canopy penetrations (i.e., phases of the beaters’ position of 1, 2, or 3, depending on the harvester turnbuckles’ lengths of 10, 11, or 12 inches) with a constant beater shaking speed of 45.30 in/s and approximately 0.80 mph of the machine in a forward speed. Fifteen sensors were deployed, with all of them in one grapefruit tree canopy. The distribution of the acceleration that resulted from shaking the tree canopy was uneven, with diversity in the magnitudes of acceleration, as shown in the following figures. The branches’ behavior changed along the tree canopy’s cross-section (laterally and vertically). The maximum average magnitude was equal to 7.804 g, which was achieved by increasing the length of the shaker’s turnbuckle joint between the vertical crankshaft and the beaters to 12 inches (i.e., the third phase of the beaters’ penetration depth), which resulted in extending the beaters deeper into the tree canopy. The maximum acceleration magnitude, recorded at the left side of the tree, was achieved by setting the left beaters squad on a maximum turnbuckle length (12 inches), while the minimum average magnitude of 1.691 g was recorded at the top central band of the tree perimeter using 11 inches of turnbuckle length (i.e., the second phase of the beaters’ penetration depth).

Furthermore, as a result of moving the beaters out to the canopy’s perimeter edge, by decreasing the length of each turnbuckle to 10 inches (i.e., the first phase of the beaters’ penetration depth) and running the right beaters squad, a maximum magnitude equal to 6.074 g was recorded at the lower front edge of the tree perimeter. The maximum magnitude gained by increasing the beaters’ penetration to 11 inches (i.e., penetration, second phase), again using the right beaters squad, was 7.255 g, and this was also recorded at the lower front edge of the tree’s perimeter. A maximum magnitude (7.255 g) also resulted from operating the right beaters squad at the lower right side of the tree’s perimeter. In comparison, the minimum magnitude value was 1.691 g, which was recorded at the top central edge of the tree’s perimeter (

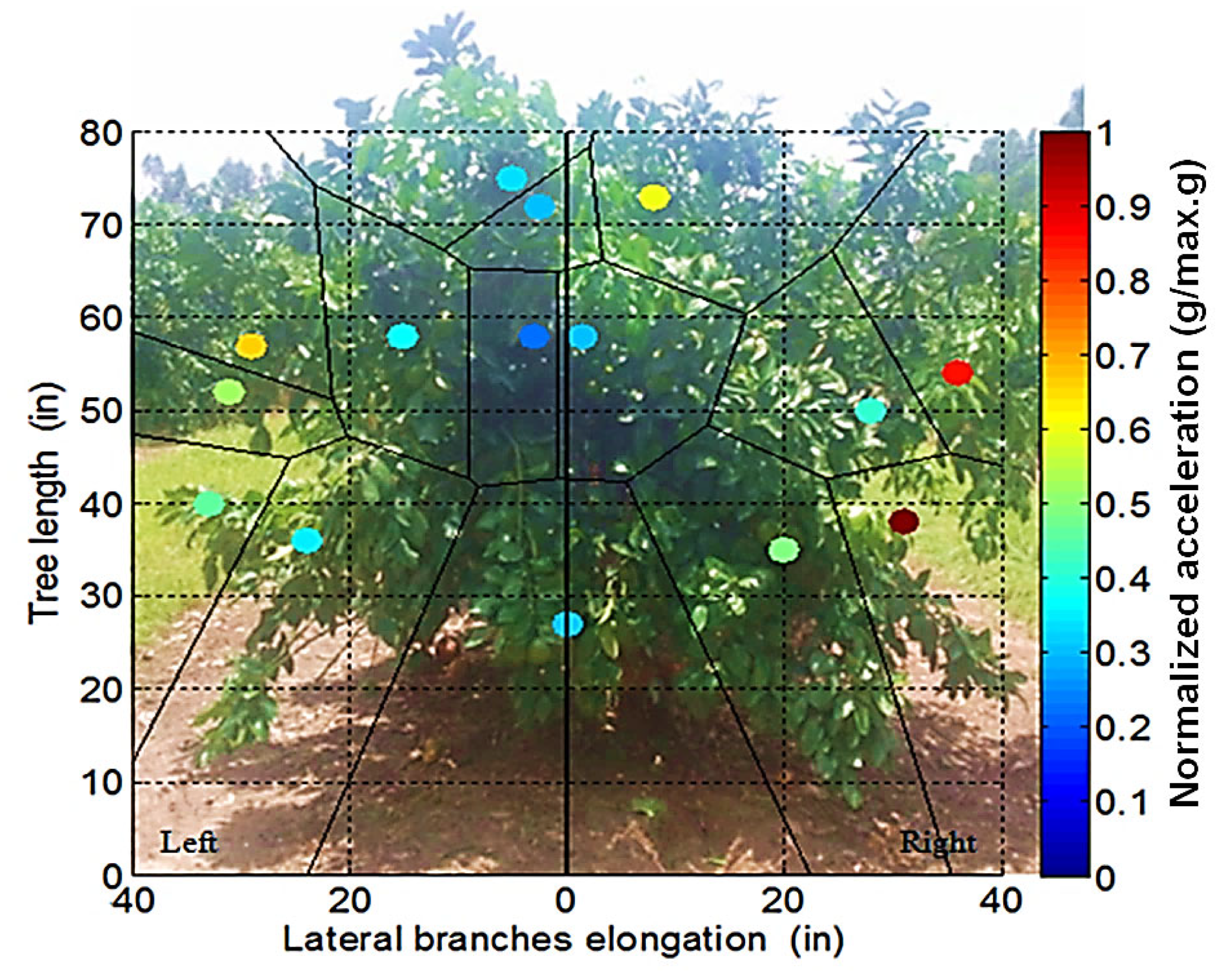

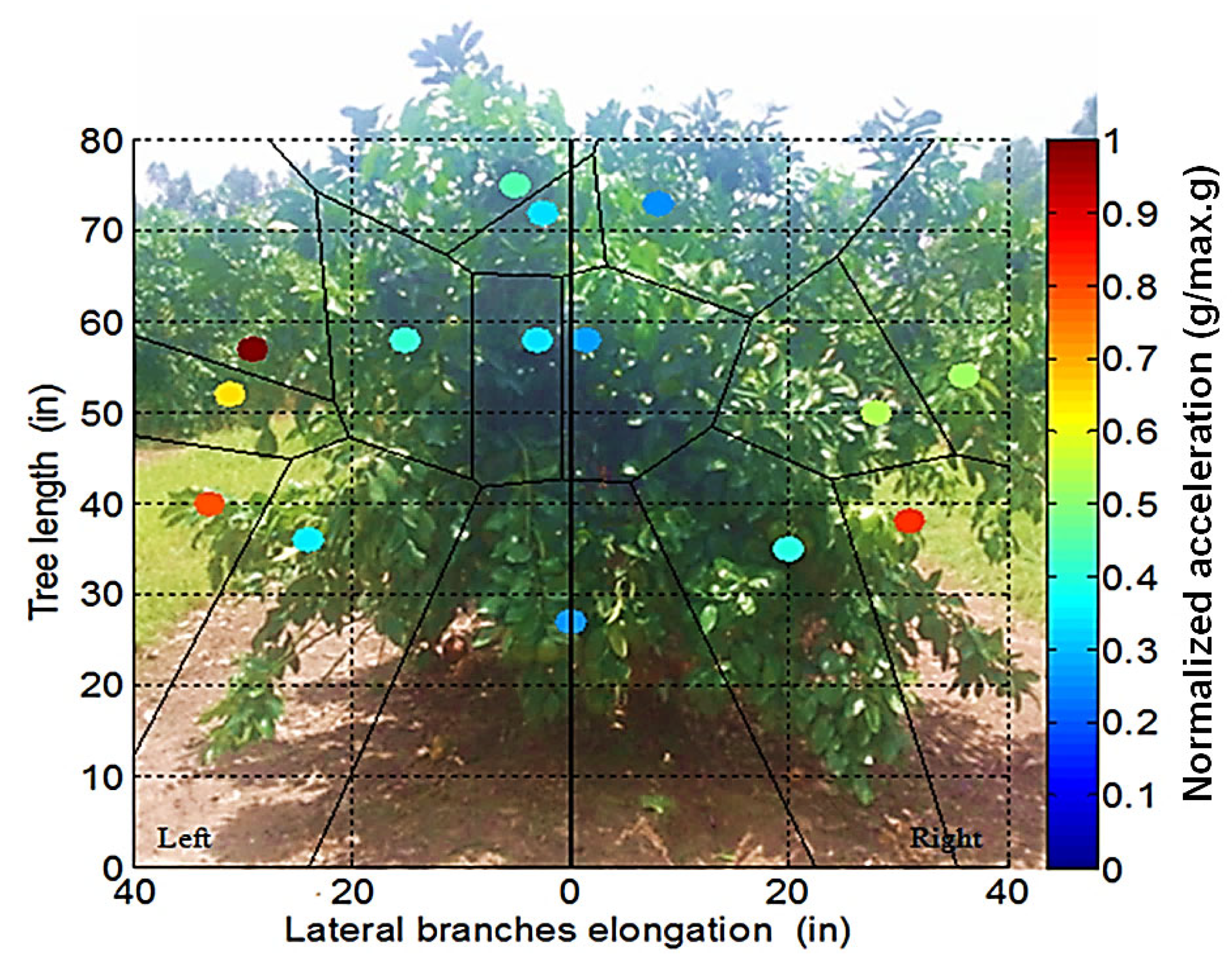

Figure 6).

As shown in

Figure 7,

Figure 8 and

Figure 9, at the top of the tree canopy (sensors 2, 8, and 9), the magnitude increased from 2.740 g to 4.319 g by increasing the beaters’ penetration (i.e., increasing the beaters’ penetration depth from the first phase to the second phase), but decreased to 1.988 g when the depth increased to the third phase of penetration, which was recorded by sensor number 2 under the right beaters’ influence. With the left beaters operating, increasing the harvester’s penetration (increasing the beaters’ penetration depth from the first phase to the third phase) increased the magnitude from 1.910 g to 3.450 g, which was recorded by sensors 8 and 9. Also, the acceleration magnitude value at the central edge of the tree’s perimeter, and parallel to the forward machine speed track, as recorded by sensor number 15 (underneath the canopy and 20 inches rear of the main trunk), increased from 1.971 g to 2.207 g by increasing both beater squads’ depths (the left and right units) from first-phase to second-phase penetration, and again, the magnitude decreased by using the third phase of the beater’s penetration depth. In the lower part of the tree canopy, where sensors 3, 10, 12, and 14 were located on the left and right sides of the tree canopy, the maximum acceleration magnitude was 6.207 g when using the third phase of the beater’s penetration depth for the left side, and it was 7.255 g when using the second phase of the beater’s penetration depth for the right side.

Depending on the sensors’ locations, the acceleration magnitude applied by the shaking beaters under all penetration settings was substantially higher on the lower branches than on the branches at the central top of the tree canopy or the limbs along the central band of the tree canopy (sensor number 15), as referenced in

Table 2. Also, on the lateral branches above 40 inches from the ground, the right side of the tree canopy had a slightly higher acceleration magnitude (an average of 3.930 g) than the left side (an average of 3.520 g) of the tree canopy, while the branches in the center of the tree canopy had a lower acceleration magnitude average for all beaters’ penetration settings. Therefore, in summary, the tree canopy received different shaking magnitudes from the two beater squads (the left and right harvester units).

In general, the average magnitude of the gravitational acceleration (g) ranged from 3.403 g, which was obtained by operating the two shaking beater units on the first phase setting of beater penetration depth, to 3.848 g, which was obtained by operating the shaking beaters on the third phase setting of beater penetration depth. As observed, by increasing the shaking beaters’ penetration into the tree canopy, the average magnitude of acceleration (g) on the trees’ branches increased (

Table 2). Therefore, the overall influence of the beaters’ vibration on the tree branches increased with an increase in the shaking beaters’ penetration displacement. Based on

Table 2, there is a statistically significant (10% level) difference in the influence of beater penetration on branch acceleration between the first and third phases. Otherwise, there are no significant differences at the 10% level of significance between the first and second phases of beater penetration depth or between the second and third phases of beater penetration on the acceleration magnitude of the grapefruit tree branches. Also, there is no further significant difference regarding the effect of both the tree canopy’s sides (3.520 g on the left and 3.930 g on the right) on the acceleration magnitude at the 10% level of significance.

3.4. Shaking Acceleration Distribution Effect by Varying Beaters’ Shaking Speeds

For this experiment, 15 USB accelerometer sensors (model X16-1C) were placed on various branches at different locations on three random tree canopies of grapefruit (Ray Ruby grapefruit), with five sensors placed in each individual grapefruit tree canopy. The results of the acceleration magnitude distribution on the shaking tree canopies were obtained by using various shaking speeds of the harvester’s beaters, as referenced in

Table 3.

The results in

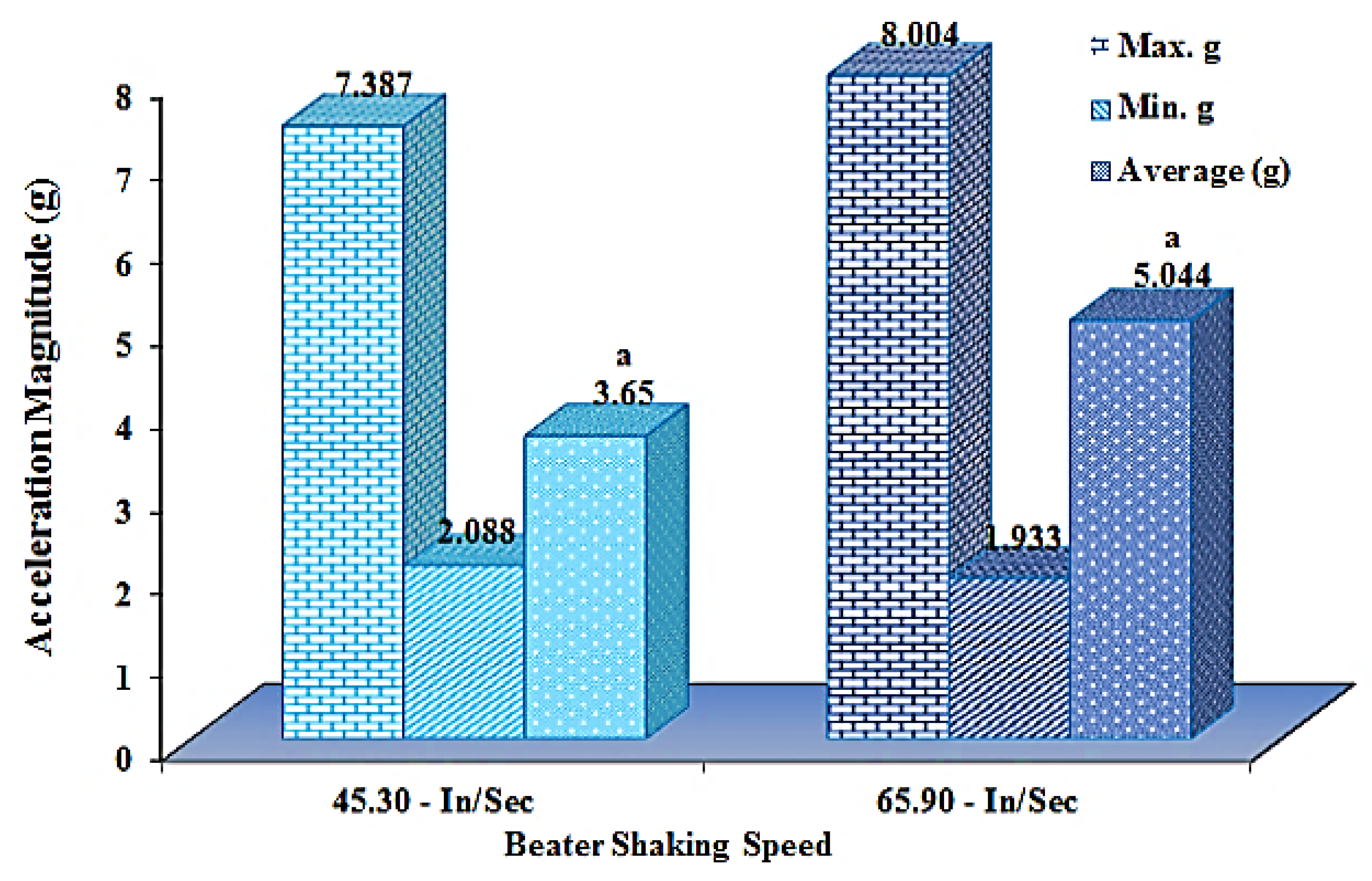

Table 3 show the time domain magnitudes and averages of the acceleration based on gravity that were achieved by operating the shaking beaters at two different shaking speeds (45.30 and 65.90 in/s) while keeping the shaking beaters’ penetration into the grapefruit canopy constant at the previous third phase of depth penetration (12 inches in turnbuckle length) and at approximately 0.80 mph of the harvesting machine’s forward speed. For beater squads operating at an angular velocity of 65.90 in/s, the maximum average of the acceleration magnitude was 8.004 g, gained at the right side of the tree perimeter (sensor number 14), and the minimum average magnitude was 1.933 g, obtained at the central edge of the tree canopy (sensor number 3). For the beater squads operating at an angular velocity of 45.30 in/s, the maximum average acceleration magnitude was 7.387 g and the minimum average magnitude was 2.088 g; both measurements were obtained at the canopy’s right side (

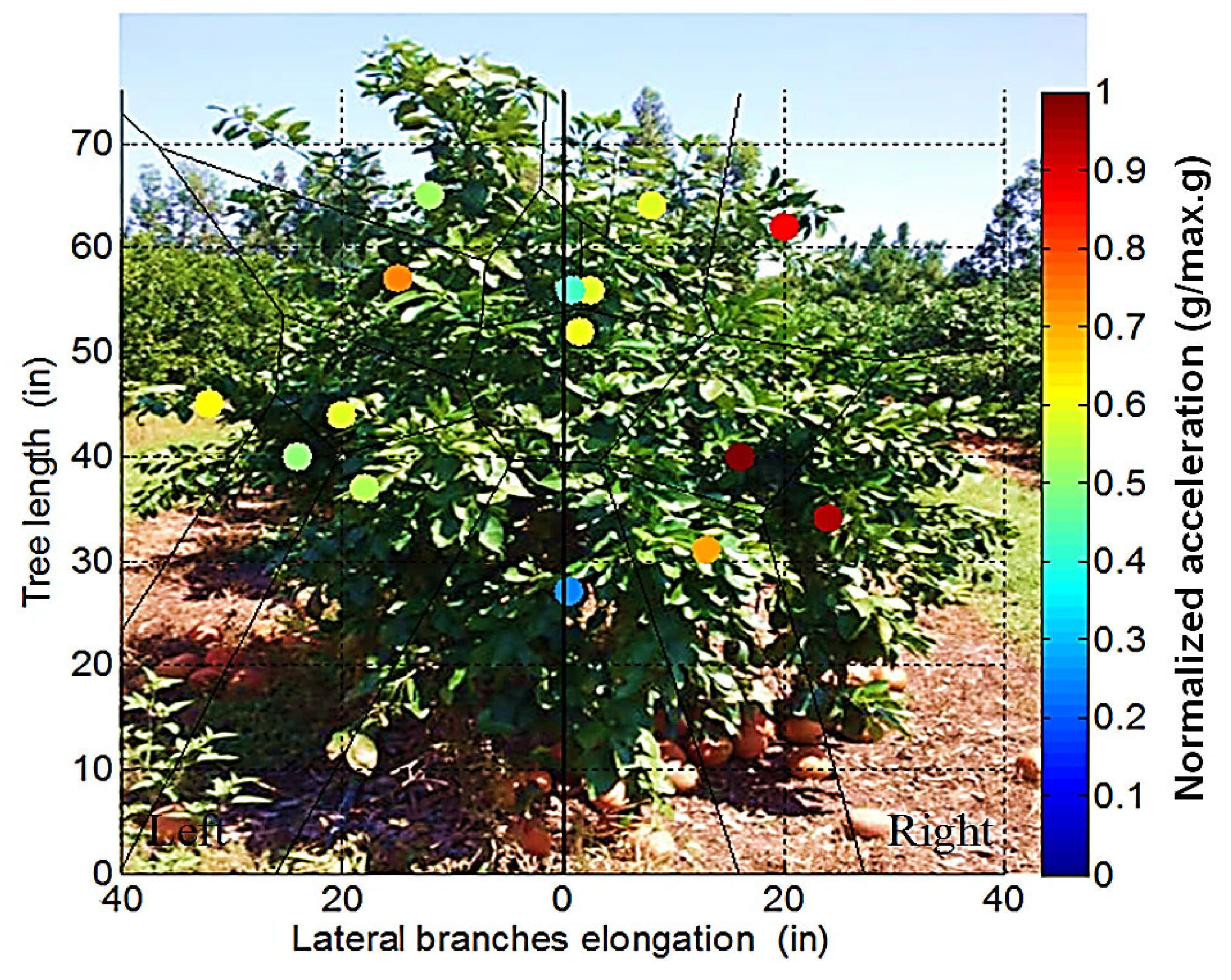

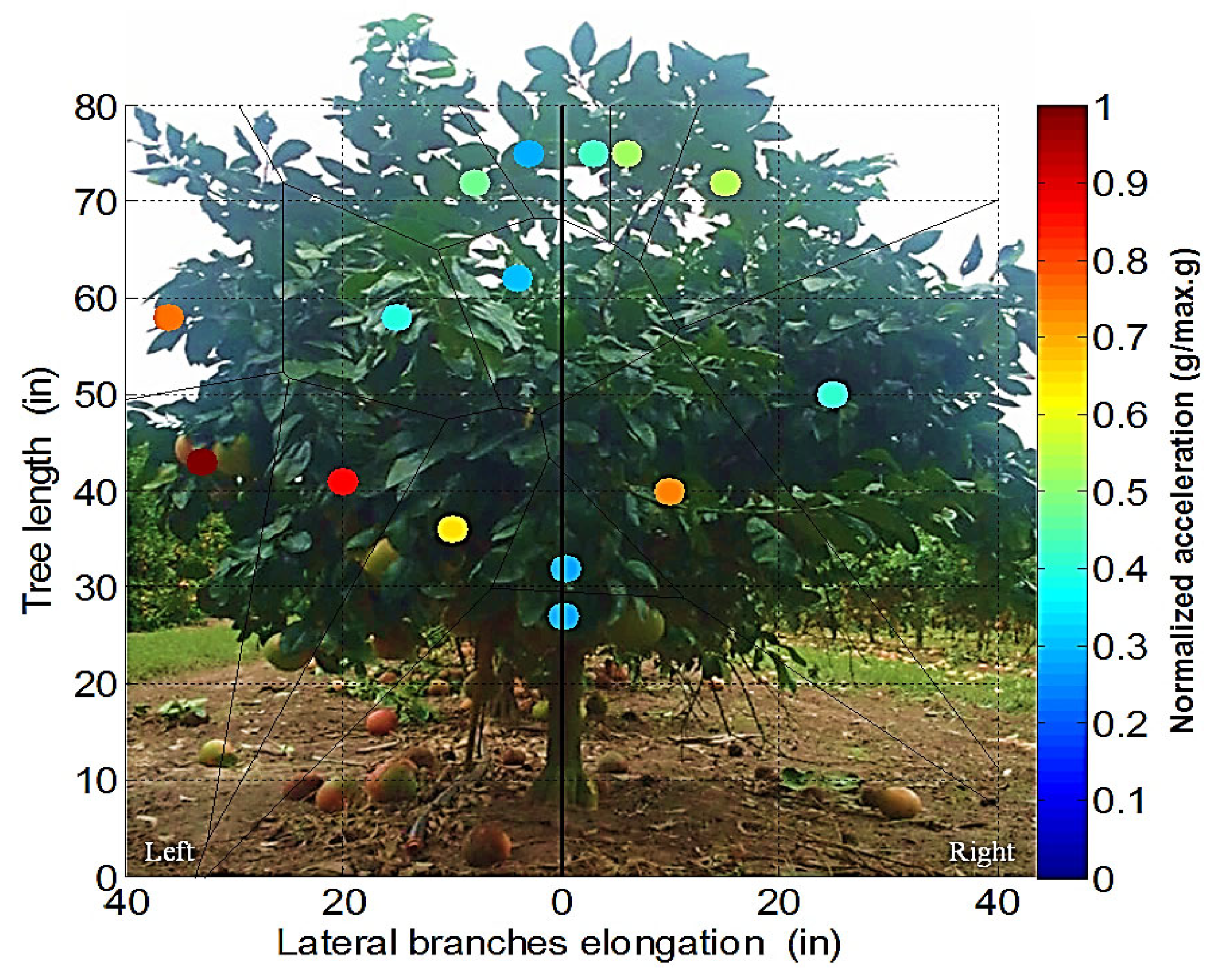

Figure 10).

The distribution of the acceleration from the shaking beaters on the tree canopy was non-uniform, with diversity in the magnitudes of the acceleration (g) occurring, as represented in

Figure 11 and

Figure 12. As previously noted, the tree branch behaviors changed along the tree canopy perimeter (laterally and vertically). On the left side of the tree perimeter, the maximum magnitude was obtained by running the beaters squad on the second shaking speed (65.90 in/s), achieving 5.907 g. In comparison, the lowest beaters’ speed (45.30 in/s) yielded a minimum magnitude of 2.409 g at sensor number 13. At the top of the tree canopy (more than 52 inches from the ground), and under the influence of running the right beater squad, the harvester beaters’ shaking speed increased from 45.30 in/s to 65.90 in/s, resulting in a magnitude increase from 2.286 g to 6.947 g. However, at the top of the canopy, while running the left beaters at the same rate increase, an acceleration magnitude increase from 3.01 g to 5.907 g resulted, as recorded by sensors 2 and 7. At the top central edge of the tree’s perimeter, the acceleration magnitude increased from 2.286 g to 3.425 g by increasing both beater squad speeds. At the central edge of the tree’s perimeter, and parallel to the machine path, which was recorded at sensor number 3 (underneath the tree canopy and 21 inches behind the main trunk), the acceleration magnitude decreased from 2.088 g to 1.933 g with an increase in the beaters’ speed from 45.30 in/s to 65.90 in/s. Measurements were also taken at both the left and right sides of the lower canopy perimeter at heights of 45 inches from the ground and lower. The maximum right side acceleration magnitude average was 8.004 g at a beater speed of 65.90 in/s, and 7.387 g at a beater speed of 45.30 in/s. In contrast, the maximum left side acceleration magnitude average was 4.884 g by a beater speed of 65.90 in/s, and 3.756 g at a beater speed of 45.30 in/s. Accordingly, as shown in

Figure 11 and

Figure 12, a comparison of the results from different sensors’ locations showed that the shaking beaters’ acceleration magnitudes at all shaking settings of beaters was substantially higher at the lower branches in the tree canopy (45 inches from the ground or less) than the acceleration magnitude in branches on the top central part and along the central band of the tree canopy (sensor number 3). It appeared that the lateral branches, which are 45 inches or more from the ground on the left side of the tree canopy, received more acceleration magnitude (4.113 g) than the right side (4.109 g) of the tree canopy. Finally, the branches in the central band of the tree canopy have a low acceleration magnitude average at all beater shaking settings.

In general, the average magnitude of the gravitational acceleration (g) ranged between 3.650 g and 5.044 g when both shaking beaters units (right and left) were operated at 45.30 in/s and 65.90 in/s, respectively. As observed from

Table 3, by increasing the shaking beaters’ speed from 45.30 in/s to 65.90 in/s, the average magnitude of the acceleration (g) on the tree branches will be increased. Hence, the influence of the beaters’ shaking speed on the tree branches is to increase acceleration. Statistically, the small letters, as shown in

Table 3, illustrate that there is no significant difference at the 10% level of significance when considering the influence of the shaking speed of the machine beaters (from the lowest at 45.30 in/s to the highest at 65.90 in/s) on the acceleration magnitude of the tree branches. Similarly, there was no further significant difference between the effects of the two different beaters’ shaking speeds for both tree canopy sides (4.113 g for the left side, and 4.109 g for the right side) on the average amount of acceleration magnitude, with a 10% level of significance.

3.5. Distribution of Acceleration Magnitude on the Harvester’s Shakers

For the acceleration measurement trials of the harvester’s beaters (14 shaking beaters), without resistance loads from the grapefruit tree canopies, six USB accelerometer sensors model X16-1C were placed on the harvester’s beaters at different locations and attached using plastic adhesive tape. There were three sensors attached to three different beaters of each shaker unit (three sensors on the right and three on the left shaking beaters), as shown in

Figure 13. For these trials, the 1/2″ (OD) hollow PVC pipes were replaced with 32-inch-long flexible 1″ (OD) round gray PVC rods. The total length of each single beater was 60 inches, and they were connected to 11.50 inches of turnbuckle length for deep penetration. The first test of these PVC rods revealed that fatigue can occur quickly next to the joining metal sleeve where the steel pipe attaches to the PVC rod. This occurred when using a high shaking speed of more than 101.50 in/s.

As a result, the higher shaking speed, beyond 101.50 in/s, was excluded from the testing. The result of the acceleration magnitude distribution on the shaking beaters was obtained by operating the beaters at two different shaking speeds (69.32 and 101.50 in/s), established by setting the two knobs of the harvester flow control valves at switching points 2.0 and 2.5, respectively, as shown in

Table 4 and

Table 5.

When the individual shakers were operated at a speed of 69.32 in/s, the average magnitude of the acceleration ranged between 5.43 g and 6.65 g. When operating the individual shakers at a shaking speed of 101.50 in/s, the lowest magnitude was 9.18 g, and the highest magnitude was 10.39 g (

Table 4). In general, increasing the shaking beaters’ speed from 69.32 in/s to 101.50 in/s increased the average magnitude of the acceleration (g) on the harvester beaters. However, at the first speed, 69.32 in/s, the right shaker unit gave a higher acceleration magnitude than the left shaker unit. In contrast, at the second speed, 101.50 in/s, the right shaker unit gave an acceleration magnitude less than the left shaker unit, as illustrated in

Table 4. Furthermore, from the statistical analysis, as shown by the small letters in each row in

Table 4, it was found that there is a significant difference between the two shaker units locations (right or left shakers) on the acceleration magnitude at both shaking speeds (69.32 and 101.50 in/s), which was at the 10% level of significance when the two shaker units were operated separately (i.e., the left squad was unengaged, while the right squad was engaged, and the two squads alternated in operation).

While shaking the two machines’ beater units at the same time, the average acceleration magnitude ranged between 5.04 g on the right unit and 5.38 g on the left shaker unit at a shaking speed of 69.32 in/s. Still, there was no significant difference between the right and left shakers’ acceleration magnitude (10 g) at the shaking speed of 101.50 in/s (

Table 5). In general, by increasing the beaters’ shaking speed from 69.32 in/s to 101.50 in/s, the average acceleration magnitude of the two shaker units increased when operating the two shaking beater units simultaneously, as calculated in

Table 5. Statistically, the small letters in

Table 5 show that there are no significant differences at the 10% level of significance for the influence of the shakers’ location (right or left shakers) on the amount of the acceleration magnitude of the shaking beaters when the two shaker units operated simultaneously at different shaking speeds of 69.32 and 101.50 in/s. This diversity in shaking distribution of the harvester’s beaters may have been caused by the fact that either the two flow control valves of the shakers’ relief valves were not adjusted accurately for both harvester units (two crankshafts) so as to be precisely at the same rotational speed, or because the hydraulic circuit that was connected to the right relief valve was longer than the circuit connected to the left relief valve. Therefore, professional harvesting operations are essential to avoid such situations in agricultural machinery designs.

Additional evaluations were performed on the two shakers’ motor performance by measuring the two shaker units’ acceleration magnitudes. The results show that by operating the two shakers’ motors separately, the acceleration magnitudes of both shaker units are equal at 7.91 g. Therefore, the two shakers’ motors (right and left) have no significant differences at the 10% level of significance. On the other hand, when the two shakers’ motors were operated simultaneously (i.e., the left and right squads were engaged in operation simultaneously), the acceleration magnitude of the right shakers’ motor was 7.57 g. The left shakers’ motor offered more acceleration magnitude, equal to 7.69 g; however, these values show no significant differences at a 10% level of significance. The average magnitude that was recorded by running the two shakers’ motors independently was 7.91 g, and synchronized operation was 7.63 g. In general, there is no significant difference between testing the two shakers’ motors individually or together on the acceleration magnitude results. Consequently, from the shaker experiment results, there were no considerable differences between the obtained acceleration magnitudes that resulted from operating the two shaker units either independently or together, which means the two shaker units were functioning adequately as required by the canopy shaker field trials.

3.6. Distribution of Acceleration Magnitude in the Grapefruit Tree Canopy Based on Increasing the Number of Shaking Beaters

Two experiments on the acceleration distribution were conducted on grapefruit trees to evaluate the increase in the number of citrus harvester beaters to 13 beaters on each shaker unit (26 total shaking beaters). Fifteen USB accelerometer sensors (model X16-1C) were placed at various branch locations in a Ray Ruby grapefruit canopy. The same trees were used as those shaken in the primary harvest trials, with the sensors placed at approximately the same locations. The acceleration magnitude data, based on gravity (g) for the X16-1C sensors, were recorded at a sample rate of 50 Hz and a sample size of 30,000 (counts). The results of the distribution of the acceleration during the shaking trials were obtained using a constant beaters’ penetration of deep depth (12 inches of turnbuckle joint length), a high beaters’ shaking speed of 63.74 in/s, a slow machine forward speed, and a harvester’s tunnel width that was fixed at 69 inches.

3.6.1. Shaking Acceleration Distribution on One Grapefruit Canopy Due to Increasing the Number of Shaking Beaters

The results in

Table 6 show the maximum magnitude of the acceleration (g) and the average magnitude of each acceleration period (g) that were gained by operating the harvester’s beaters on one grapefruit tree canopy, where 15 sensors were attached to a grapefruit tree canopy. The harvesting machine ran at an average forward speed of 0.97 mph. The distribution of the acceleration upon shaking operation was non-uniform, with differences in the magnitudes of the acceleration, as shown in

Figure 14. The branches’ behavior changed along the tree canopy’s perimeter (laterally and vertically). The maximum magnitude average was equal to 15.253 g (sensor number 12). The left beaters squad achieved the maximum magnitude on the left side of the grapefruit canopy. In contrast, the maximum magnitude recorded by the right beaters squad on the right side of the grapefruit tree was equal to 11.350 g (sensor number 10). At the top of the tree canopy, the maximum magnitude average was recorded between 4.427 g (caused by the left beaters squad) and an acceleration of 8.138 g, which was caused by the right beaters squad. The minimum magnitude average (4.063 g) was recorded by sensor number 3 at the lower central part of the canopy and near the trunk (

Figure 14). The acceleration had a higher maximum magnitude (15.253 g) at the left and right sides of the tree’s perimeter (40 inches to 65 inches above ground) than at the branches at the central top of the tree canopy (8.138 g). Generally, the comparison results based on the sensors location showed that the acceleration magnitude was substantially higher (an average of 9.792 g) at the lower branches on the tree canopy (from 40 inches to 65 inches from the ground) than the branches at the central top of the tree canopy (an average of 6.867 g) or the limbs along the central band of the tree canopy and trunk (an average of 4.158 g at sensors 3 and 15). Also, the average magnitude of the acceleration (g) increased distinctly when moving from inside the tree canopy to the perimeter of the canopy. This confirms that the canopy acceleration increased as the diameters of the canopy branches decreased from the depth branches close to the main trunk to the diameters that were located exactly at the end of the canopy perimeter (from inside to outside of the canopy periphery).

3.6.2. Acceleration Distribution on Three Harvested Grapefruit Canopies Due to Increasing the Number of the Shaking Beaters

For this experiment, 15 USB accelerometer sensors (model X16-1C) were placed on various branches at different locations on three random citrus tree canopies (Ray Ruby grapefruit), where five sensors were attached to each tree canopy. The results of the acceleration magnitude distribution in the tree canopies were obtained by various shaking speeds of the harvester’s beaters (all 26 shaking beaters), as referenced in

Table 7.

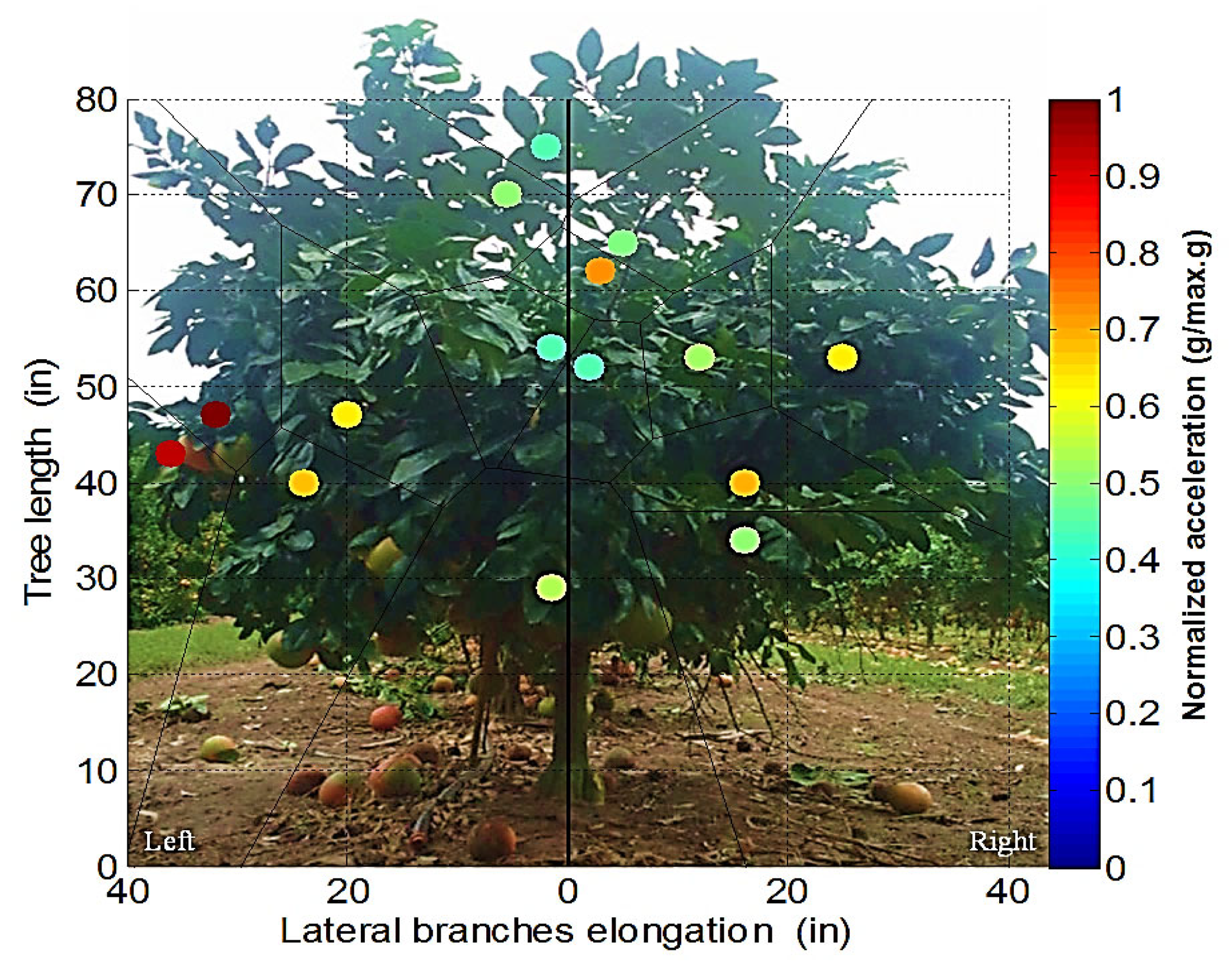

The results in

Table 7 show the average maximum magnitude of the acceleration and the average magnitude of each acceleration period (g) that were achieved by operating the shaking beaters on three different grapefruit canopies. The harvester operating parameters were a 0.85 mph forward speed, a beater penetration depth set as a deep depth (12 inches of turnbuckle joint length), and a beater shaking speed of 63.74 in/s. The distributions of acceleration upon shaking the trees’ canopies were uneven, as shown by the diversity in the magnitudes of the acceleration (g) in

Figure 15. As was observed, the tree branch behavior changed along each tree canopy perimeter (laterally and vertically). The maximum average of the acceleration magnitude was 14.09 g, which was obtained at the left side of the tree perimeter using the left shakers, and the minimum magnitude average was 6.27 g at the right side of the tree perimeter using the right shakers. At the top of the tree canopy (more than 52 inches above the ground), the averages of the maximum magnitude were recorded between 6.27 g and 10.34 g. The averages of the maximum magnitude at the lower tree canopy, that is, less than 52 inches from the ground, were recorded between the values of 7.152 g and 14.09 g. Also, the maximum acceleration magnitude increased from the center of the tree canopy (an average of 6.928 g) to the grapefruit tree perimeter (an average of 9.80 g). The lowest sensor on the grapefruit canopy (sensor number 3, which is 15 inches rear of the main trunk) showed a maximum magnitude of 7.544 g, while the highest sensor (sensor number 7) on the top of the tree canopy showed a maximum acceleration magnitude of 6.367 g. In general, as shown in

Figure 15, the comparison results, depending on the sensor locations, showed that the acceleration magnitude of the shaking beaters was substantially higher at the lower branches on the tree canopy (55 inches from the ground or less) than the branches at the central top of the tree canopy or the limbs on the central band of the tree canopy (sensor 3). At the lateral branches (a height of 40 inches or more from the ground), the left side of the tree canopy had more acceleration magnitude (an average of 9.366 g) than the right side (an average of 8.249 g).

Finally, from the two field experiments of the shaking acceleration effect, the differences in the acceleration magnitude distribution from the left and right shakers (two shaking units, with each unit having 13 beaters) may have occurred due to a failure to maintain the center of the machine harvesting track (it is possible that the main trunk of the grapefruit tree was not centered). Statistically, the total averages of the maximum acceleration magnitude, that are shown in

Figure 16 and

Table 6 and

Table 7, confirmed that there was no significant difference at the 10% level of significance for the influence of the shaking trials, (one tree canopy or various grapefruit trees canopies at a high shaking speed under the harvester’s beaters) on the average amount of acceleration magnitude of the citrus tree’s branches.

3.7. Comparison Results Depending on the Number Optimization of the Shaking Beaters

The number of shakers on both units of the citrus canopy shaking machine was increased from the original 7 beaters per shaking unit (14 beaters in the initial shaking design) to 13 beaters per shaking unit (26 beaters in the final shaking design). It was felt that increasing the number of beaters would have a significant effect on the efficiency of the harvester machine, where more beaters penetrating the tree canopy would equal more engagement with tree branches and fruit. This turned out to be a significant improvement in fruit detachment efficiency.

Comparison results were taken from an experiment using the 15 USB accelerometer sensors that were attached to various branches on three grapefruit trees’ canopies, with five sensors mounted on diverse branches on each canopy. The results of the acceleration magnitude distribution on the tree canopies were obtained by operating the shaking beaters at high shaking speeds of 65.90 in/s for the preliminary design of the shakers (14 shaking beaters) and 63.74 in/s for the final design of the shakers (26 shaking beaters). Furthermore, penetration into three random grapefruit trees canopies was maintained at 12 inches in length of the turnbuckles for the beaters (at a deep depth of the beaters’ penetration), and 69 inches of internal tunnel width for the harvester machine.

Figure 17 shows that the highest acceleration magnitude (14.09 g) was obtained by the final shaker design of 26 beaters, while in contrast, the initial design of the canopy shaker of 14 beaters provided 8.00 g as a maximum magnitude value. Also, the minimum value of the acceleration magnitude by the 26 shaking beaters (6.27 g) was still substantially more than the minimum acceleration magnitude that was obtained by the initial 14 shaking beaters (1.93 g). Evidently, by increasing the number of shakers on each canopy shaker unit from 7 to 13 (14 in total compared to 26 in total), the average of the acceleration magnitude increased from 5.044 g to 8.651 g, as shown in

Figure 17. Statistically, the small letters in

Figure 17 confirm that there is an obvious significant difference, at the 10% level of significance, between the influence of the initial and final canopy shakers’ sets on the average of the maximum acceleration magnitude on the grapefruit tree branches. Thus, more effective shaking beaters of the citrus harvesting machine delivered more shaking acceleration to the tree canopy. Therefore, the consequence of operating 26 shaking beaters in the final shaking shakers design at a fixed shaking tunnel width of 69 inches may have been the primary reason for the improved tree canopy acceleration.

4. Conclusions

In this research study, the acceleration (motion) effectiveness of a citrus harvesting machine, which shakes trees by surrounding the tree canopies with two shaking units, was studied in high-density citrus tree conditions. Operationally, the harvester beaters were thrust into the grapefruit tree canopies to different penetration depths. Primarily, three sets of operating variables were studied during the trials on a field of grapefruit as follows: altered shaking speeds of the machine’s beaters; various positions of the machine’s shaking beaters, i.e., penetration depths into a tree canopy; and increases in the shaking beater number from an initial design of 14 shakers to a final design of 26 shakers. The fruit under this study was the Ray Ruby grapefruit.

During testing with the preliminary design of 14 shakers, an increase in shaking speed, from 40 to 73 in/s, resulted in an increase in detached grapefruit, from 17.90% to 35.77%. On the other hand, with the final design of 26 shakers, an increase in shaking speed, from 56.50 to 73 in/s, increased the percentage of the grapefruit detachment from 73.30% to 79.72%. Moreover, the highest average grapefruit detachment percentage of 93.52% was achieved by the final 26 citrus canopy shakers as a result of interactions between the beaters’ shaking speed of 73 in/s, high machine forward speed of 1.42 mph, and beaters’ position at a turnbuckle length of 16 inches (which was the deepest canopy penetration at phase 5). Furthermore, a percentage of 93.56% was a result of the interactions between the beaters’ shaking speed of 73 in/s, a machine forward speed of 0.62 mph, and a beater turnbuckle length of 16 inches (also the fifth phase of canopy penetration). Operating the final design of 26 beaters with the extra-long beaters provided a grapefruit detachment percentage of 93.29%, which was the result of interactions between the beaters’ shaking speed of 63.74 in/s, a 0.62 mph machine forward speed, and the shaking beaters’ position at a turnbuckle length of 16 inches (the deepest penetration). In general, as it was calculated, the effect of the beaters’ shaking speed on the field performance of the canopy shaking machine showed that an increase in the harvester’s shaking speed increased the fruit detachment performance. Furthermore, operating with the final 26 shakers in trials with different parameters resulted in several 100% detached grapefruit harvests (100% fruit detachment). Additionally, operating this harvesting machine at its higher forward speed, with the preliminary shakers (14 beaters), averaged 4.30 s/tree, and using the final improvement of the shakers to 26 beaters, averaged 3.88 s/tree. Operating at the lower forward speed increased the total shaking time for the preliminary 14 beaters to an average of 6.49 s/tree, and operating at the same speed with 26 beaters increased the shaking time to 8.75 s/tree. Therefore, increasing the harvester’s forward speed reduced the required canopy shaking time and vibration.

As observed from the performance of the preliminary design of 14 shakers on the harvester, the distribution of the shaking vibrations in the tree canopy was uneven, with a large diversity in the magnitudes of the acceleration. Depending on the sensor’s location, by increasing the shaking beaters’ penetration into the grapefruit tree canopy from the slight to deep penetration depth, the average magnitude of the acceleration on the tree’s branches increased from 3.403 to 3.848 g. Also, by increasing the beaters’ shaking speed from 45.30 in/s to 65.90 in/s, the average magnitude of the acceleration (g) on the grapefruit tree’s branches was increased from 3.650 g to 5.044 g. In addition, operating the citrus harvester with the final design of 26 shaking beaters resulted in a varying average magnitude of acceleration (g) on the grapefruit trees’ branches, which varied with the machine’s forward speed changes. Acceleration was 8.080 g when the harvester machine operated at a forward speed of 0.97 mph, a shaker penetration at a deep depth (based on 12 inches of turnbuckle length), and a 63.74 in/s beaters shaking speed. Furthermore, acceleration was 8.651 g when the harvester machine was operated with a forward speed of 0.85 mph, a shaker penetration at a deep depth (based on 12 inches of turnbuckle length), and a 63.74 in/s beaters shaking speed.

The acceleration magnitudes were more evenly distributed in the final trials with 26 shaking beaters. Comparing the results shown in

Table 3, where the average acceleration of 5.044 g was measured while the beaters were moving within the tree canopy (with a load of branches), and

Table 5, where a similar acceleration average of 5.040 g was measured while the shaking beaters were moving freely outside of the tree canopy (i.e., within the harvester tunnel without a load of branches,

Figure 13), the shaking beaters were accommodating branch movement. This is an optimal result, illustrating that the shaking beaters can operate efficiently despite the opposing forces coming from tree branches and can manipulate the canopy to efficiently dislodge fruit.

In conclusion, this study recommends utilizing a self-propelled citrus canopy shaker, which achieved a grapefruit detachment average of 94%, which was occasionally as high as 100% fruit removal, with 37 inches of penetration (the deepest canopy penetration) and a beaters’ shaking speed of 73 in/s. Testing various configurations showed that the acceleration of tree branches by the vibrating shakers is increased by increasing the penetration of the shaking beaters into the grapefruit canopy, as well as increasing the number of shaking beaters, the speed of the shaking beaters, the shaking duration, and reducing the forward speed of the shaking machine. Although there are numerous opportunities for harvest improvement, operational parameters were identified that improved the performance of citrus harvesting and formed the basis for future harvesting trials. These results are very encouraging for the future of high-density citrus mechanical harvesting, and this work has demonstrated concept feasibility, i.e., tree canopy acceleration distribution for a precise collapsing point for fruit picking.

Author Contributions

Conceptualization, N.M.N.A.-D. and T.F.B.; methodology, N.M.N.A.-D., T.F.B. and S.A.A.-H.; software, N.M.N.A.-D.; formal analysis, N.M.N.A.-D., T.F.B. and S.A.A.-H.; validation, N.M.N.A.-D. and T.F.B.; visualization, N.M.N.A.-D. and T.F.B.; investigation, N.M.N.A.-D., T.F.B. and S.A.A.-H.; resources, N.M.N.A.-D. and T.F.B.; data curation, N.M.N.A.-D.; writing—original draft preparation, N.M.N.A.-D., T.F.B. and S.A.A.-H.; supervision, N.M.N.A.-D. and T.F.B.; funding acquisition, N.M.N.A.-D. and T.F.B.; writing—review and editing, N.M.N.A.-D., T.F.B. and S.A.A.-H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ongoing Research Funding Program (ORF), funding number ORF-2025-1397, King Saud University, Riyadh, Saudi Arabia.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to extend their sincere appreciation to the Executive Committee of the ORF Research Support Program, the Ongoing Research Funding Program (ORF), funding number (ORF-2025-1397), at King Saud University, Riyadh, Saudi Arabia, for supporting our work through the Ongoing Research Funding Program (ORF-2025-1397), as well as to the Department of Agricultural and Biological Engineering at University of Florida, Gainesville, FL, USA.

Conflicts of Interest

The authors declare that there are no conflicts of interest in publishing this research paper.

References

- Roka, F.M.; Ehsani, R.J.; Futch, S.H.; Hyman, B.R. Citrus mechanical harvesting systems—Continuous canopy shakers. EDIS 2014, 2014, 2–5. [Google Scholar] [CrossRef]

- Torregrosa, A.; Molina, J.; Pérez, M.; Ortí, E.; Xamaní, P.; Ortiz, C. Mechanical harvesting of ornamental citrus trees in Valencia, Spain. Agronomy 2019, 9, 827. [Google Scholar] [CrossRef]

- Ortiz, C.; Torregrosa, A.; Martínez, J. Evaluation of citriculture mechanisation level in Valencia Region (Spain): Poll results. Agronomy 2022, 12, 1366. [Google Scholar] [CrossRef]

- Ortiz, C.; Torregrosa, A.; Castro-Garcia, S. Comparison of a lightweight experimental shaker and an orchard tractor mounted trunk shaker for fresh market citrus harvesting. Agriculture 2021, 11, 1092. [Google Scholar] [CrossRef]

- Ortiz, C.; Torregrosa, A.; Castro-García, S. Citrus fruit movement assessment related to fruit damage during harvesting with an experimental low-frequency–high-amplitude device. Agronomy 2022, 12, 1337. [Google Scholar] [CrossRef]

- Bohannon, J.D. Mechanical Citrus Fruit Harvester. U.S. Patent 3,485,025, 23 December 1969. [Google Scholar]

- Láng, Z. Lincoln canopy apple harvester using a continuous horizontal shaking method. J. Agric. Eng. Res. 1989, 44, 267–273. [Google Scholar] [CrossRef]

- Peterson, D.L. Mechanical harvester for process oranges. Appl. Eng. Agric. 1998, 14, 455–458. [Google Scholar] [CrossRef]

- Whitney, J.D. Field test results with mechanical harvesting equipment in Florida oranges. Appl. Eng. Agric. 1999, 15, 205–210. [Google Scholar] [CrossRef]

- Erdoğan, D.; Güner, M.; Dursun, E.; Gezer, İ. Mechanical harvesting of apricots. Biosyst. Eng. 2003, 85, 19–28. [Google Scholar] [CrossRef]

- Loghavi, M.; Mohseni, S. The effects of shaking frequency and amplitude on detachment of lime fruit. Iran Agric. Res. 2006, 24–25, 27–38. [Google Scholar]

- Torregrosa, A.; Ortí, E.; Martín, B.; Gil, J.; Ortiz, C. Mechanical harvesting of oranges and mandarins in Spain. Biosyst. Eng. 2009, 104, 18–24. [Google Scholar] [CrossRef]

- Gupta, S.K.; Ehsani, R.; Kim, N. Optimization of a citrus canopy shaker harvesting system: Mechanistic tree damage and fruit detachment models. Trans. ASABE 2016, 59, 761–776. [Google Scholar] [CrossRef]

- Liu, T.H.; Ehsani, R.; Toudeshki, A.; Zou, X.J.; Wang, H.J. Experimental study of vibrational acceleration spread and comparison using three citrus canopy shaker shaking tines. Shock. Vib. 2017, 2017, 9827926. [Google Scholar] [CrossRef]

- Salyani, M.; BenSalem, E.; Whitney, J.D. Spray deposition and abscission efficacy of CMN-Pyrazole in mechanical harvesting of ‘Valencia’ orange. Trans. ASAE 2002, 45, 265–271. [Google Scholar] [CrossRef]

- Peterson, D.L.; Takeda, F. Feasibility of mechanically harvesting fresh market quality eastern thornless blackberry. Appl. Eng. Agric. 2003, 19, 25–30. [Google Scholar] [CrossRef]

- Lee, B.S.; Rosa, U.A.; Cheetancheri, K. End-Effector for Automated Citrus Harvesting; An ASABE Annual International Meeting Presentation; Paper No. 061143; ASABE: St. Joseph, MI, USA, 2006. [Google Scholar]

- Castro-García, S.; Blanco-Roldán, G.L.; Gil-Ribes, J.A.; Agüera-Vega, J. Dynamic analysis of olive trees in intensive orchards under forced vibration. Trees 2008, 22, 795–802. [Google Scholar] [CrossRef]

- Pezzi, F.; Caprara, C. Mechanical grape harvesting: Investigation of the transmission of vibrations. Biosyst. Eng. 2009, 103, 281–286. [Google Scholar] [CrossRef]

- Udumala Savary, S.K.J.; Ehsani, R.; Bora, G.C.; Hebel, M.A. Force distribution on oranges at different locations in the tree harvested with a canopy shaker. Acta Hortic. 2009, 824, 141–146. [Google Scholar] [CrossRef]

- Udumala Savary, S.K.J.; Ehsani, R.; Salyani, M.; Hebel, M.A.; Bora, G.C. Study of force distribution in the citrus tree canopy during harvest using a continuous canopy shaker. Comput. Electron. Agric. 2011, 76, 51–58. [Google Scholar] [CrossRef]

- Ehsani, R.; Khot, L. Over-the-row mechanical harvesting machine for dwarf and young citrus trees. Citrus Ind. 2012, 2012, 10–11. Available online: https://crec.ifas.ufl.edu/media/crecifasufledu/extension/extension-publications/2012/2012_Sept_over_row.pdf (accessed on 12 June 2025).

- Castro-García, S.; Aragon-Rodriguez, F.; Sola-Guirado, R.R.; Serrano, A.J.; Soria-Olivas, E.; Gil-Ribes, J.A. Vibration monitoring of the mechanical harvesting of citrus to improve fruit detachment efficiency. Sensors 2019, 19, 1760. [Google Scholar] [CrossRef]

- Liang, Y.; Jiang, W.; Liu, Y.; Wu, Z.; Zheng, R. Picking-point localization algorithm for citrus fruits based on improved YOLOv8 model. Agriculture 2025, 15, 237. [Google Scholar] [CrossRef]

- Farajijalal, M.; Abedi, A.; Manzo, C.; Kouravand, A.; Maharlooei, M.; Toudeshki, A.; Ehsani, R. Assessing crucial shaking parameters in the mechanical harvesting of Nut trees: A review. Horticulturae 2025, 11, 392. [Google Scholar] [CrossRef]

- Ghonimy, M.; Alzoheiry, A.M.; Abd El Rahman, E.N. Citrus harvesting by vibration action. Misr J. Agric. Eng. 2018, 36, 25–36. [Google Scholar] [CrossRef]

- Pu, Y.; Toudeshki, A.; Ehsani, R.; Yang, F.; Abdulridha, J. Selection and experimental evaluation of shaking rods of canopy shaker to reduce tree damage for citrus mechanical harvesting. Int. J. Agric. Biol. Eng. 2018, 11, 48–54. [Google Scholar] [CrossRef]

- Pu, Y.; Toudeshki, A.; Ehsani, R.; Yang, F.; Abdulridha, J. Design and evaluation of a two-section canopy shaker with variable frequency for mechanical harvesting of citrus. Int. J. Agric. Biol. Eng. 2018, 11, 77–87. [Google Scholar] [CrossRef]

- Gulf Coast Data Concepts. USB Accelerometer Model X16-1C. 2012, p. 14. Available online: http://remotesmart.wdfiles.com/local--files/kiihtyvyys/GCDC_X16-1C_User_Manual.pdf (accessed on 25 August 2025).

- Bedford, A.M.; Fowler, W.L. Statics: Engineering Mechanics; Addison-Wesley Publishing Company, Inc.: Boston, MA, USA, 2008. [Google Scholar]

Figure 1.

Self-propelled vibrating machine for shaking a citrus tree canopy through its harvesting performance.

Figure 1.

Self-propelled vibrating machine for shaking a citrus tree canopy through its harvesting performance.

Figure 2.

The GCDC X16-1C tri-axial USB accelerometer sensor for data gathering [

29].

Figure 2.

The GCDC X16-1C tri-axial USB accelerometer sensor for data gathering [

29].

Figure 3.

An organization diagram of the vital acceleration operations and accelerometer sensor experiment procedures for data collection.

Figure 3.

An organization diagram of the vital acceleration operations and accelerometer sensor experiment procedures for data collection.

Figure 4.

Some X16-1C accelerometer sensors positions, which were randomly placed on citrus tree branches throughout the experiment process.

Figure 4.

Some X16-1C accelerometer sensors positions, which were randomly placed on citrus tree branches throughout the experiment process.

Figure 5.

The target part of the citrus fruit harvesting process where the detachment process takes place.

Figure 5.

The target part of the citrus fruit harvesting process where the detachment process takes place.

Figure 6.

An acceleration magnitude result using 14 shaking beaters on the grapefruit tree canopy by operating the phases of the beaters’ position of 1, 2, or 3, depending on the harvester turnbuckles’ lengths of 10, 11, or 12 inches (the averages, which have been attached with a different letter at the top of each column, have significant differences among them, and are statistically at a 0.90 confidence level).

Figure 6.

An acceleration magnitude result using 14 shaking beaters on the grapefruit tree canopy by operating the phases of the beaters’ position of 1, 2, or 3, depending on the harvester turnbuckles’ lengths of 10, 11, or 12 inches (the averages, which have been attached with a different letter at the top of each column, have significant differences among them, and are statistically at a 0.90 confidence level).

Figure 7.

Acceleration magnitude distributions using 14 shaking beaters in the grapefruit tree canopy by using a slight penetration depth (10 inches of turnbuckle length—front view).

Figure 7.

Acceleration magnitude distributions using 14 shaking beaters in the grapefruit tree canopy by using a slight penetration depth (10 inches of turnbuckle length—front view).

Figure 8.

Acceleration magnitude distributions using 14 shaking beaters in the grapefruit tree canopy by using a moderate penetration depth (11 inches of turnbuckle length—front view).

Figure 8.

Acceleration magnitude distributions using 14 shaking beaters in the grapefruit tree canopy by using a moderate penetration depth (11 inches of turnbuckle length—front view).

Figure 9.

Acceleration magnitude distributions using 14 shaking beaters in the grapefruit tree canopy by using a deep penetration depth (12 inches of turnbuckle length—front view).

Figure 9.

Acceleration magnitude distributions using 14 shaking beaters in the grapefruit tree canopy by using a deep penetration depth (12 inches of turnbuckle length—front view).

Figure 10.

An acceleration magnitude result on the grapefruit tree canopy by operating the machine on two shaking speeds and on phase 3 of the beaters’ position, depending on the harvester turnbuckles’ length, 12 inches (the averages, which have been attached with the same letter at the top of each column, do not have significant differences between them, and are statistically at a 0.90 confidence level).

Figure 10.

An acceleration magnitude result on the grapefruit tree canopy by operating the machine on two shaking speeds and on phase 3 of the beaters’ position, depending on the harvester turnbuckles’ length, 12 inches (the averages, which have been attached with the same letter at the top of each column, do not have significant differences between them, and are statistically at a 0.90 confidence level).

Figure 11.

Acceleration magnitude distribution in the grapefruit tree canopy by the first beaters’ shaking speed (front view).

Figure 11.

Acceleration magnitude distribution in the grapefruit tree canopy by the first beaters’ shaking speed (front view).

Figure 12.

Acceleration magnitude distribution into the grapefruit tree canopy by the second beaters’ shaking speed (front view).

Figure 12.

Acceleration magnitude distribution into the grapefruit tree canopy by the second beaters’ shaking speed (front view).

Figure 13.

A set of 6 acceleration sensors posted on some harvester’s beaters, which are a type of hollow PVC rod.

Figure 13.

A set of 6 acceleration sensors posted on some harvester’s beaters, which are a type of hollow PVC rod.

Figure 14.

Acceleration magnitude distributions in one grapefruit tree canopy by the highest beaters shaking speed (front view).

Figure 14.

Acceleration magnitude distributions in one grapefruit tree canopy by the highest beaters shaking speed (front view).

Figure 15.

Acceleration magnitude distribution into three diverse grapefruit trees canopies by the highest beater shaking speed (front view).

Figure 15.

Acceleration magnitude distribution into three diverse grapefruit trees canopies by the highest beater shaking speed (front view).

Figure 16.

Acceleration magnitude distribution over various grapefruit tree canopy experiments with the highest shaking speed while using 26 shaking beaters (the averages, which have been attached with the same letter at the top of the two columns, do not have significant differences between them, and are statistically at a 0.90 confidence level).

Figure 16.

Acceleration magnitude distribution over various grapefruit tree canopy experiments with the highest shaking speed while using 26 shaking beaters (the averages, which have been attached with the same letter at the top of the two columns, do not have significant differences between them, and are statistically at a 0.90 confidence level).

Figure 17.

An acceleration magnitude result on the grapefruit tree canopy by operating the two shaker sets with a high beater shaking speed (the averages, which have been attached with a different letter at the top of the two columns, have significant differences between them, and are statistically at a 0.90 confidence level).

Figure 17.

An acceleration magnitude result on the grapefruit tree canopy by operating the two shaker sets with a high beater shaking speed (the averages, which have been attached with a different letter at the top of the two columns, have significant differences between them, and are statistically at a 0.90 confidence level).

Table 1.

The shaking beaters’ penetration into the grapefruit canopy to improve fruit picking, which depends on the shakers’ operating phases, by adding 26 more shaking beaters.

Table 1.

The shaking beaters’ penetration into the grapefruit canopy to improve fruit picking, which depends on the shakers’ operating phases, by adding 26 more shaking beaters.

| | The Main Beaters with an Arched Length | The Extra Beaters with a Straight Length |

|---|

| Shaking Beaters’ Crank Position (One Full Cycle) | The Phase of Beaters Penetration Depth | Turnbuckle Joint Lengths for Beaters Penetration (Inches) | Distance Between the Internal Body of the Harvester and a Free End of the Beater (Inches) | Distance Between Free Ends of Two Beaters (Inches) | Distance Between the Internal Body of the Harvester and a Free End of the Beater (Inches) | Distance Between Free Ends of Two Beaters (Inches) |

|---|

| Retraction Position | Deep Canopy Penetration—Phase (3) | 12 | 12 | 45 | 19.50 | 30 |

| Deeper Canopy Penetration—Phase (4) | 15 | 20 | 29 | 23 | 23 |

| Deepest Canopy Penetration—Phase (5) | 16 | 22 | 25 | 24.50 | 20 |

| Extension Position | Deep Canopy Penetration—Phase (3) | 12 | 29 | 11 | 27 | 15 |

| Deeper Canopy Penetration—Phase (4) | 15 | 36 | Interaction was 3 inches | 29 | 11 |

| Deepest Canopy Penetration—Phase (5) | 16 | 37 | Interaction was 5 inches | 30 | 9 |

Table 2.

A precise average magnitude of the acceleration (g) among the tree canopy branches using 14 shaking beaters, depending on the delimited accelerometer sensors locations and the machine operating variables in one tree canopy.

Table 2.

A precise average magnitude of the acceleration (g) among the tree canopy branches using 14 shaking beaters, depending on the delimited accelerometer sensors locations and the machine operating variables in one tree canopy.

| Accel. Sensor No. | Accelerometer Sensors Locations | Branch Dia. at

the Posted Sensor (Inches) | First Trial

(10 Inches of Turnbuckle Linkage)

First Phase of the Beaters Penetration—Slight Depth | Second Trial

(11 Inches of Turnbuckle Linkage)

Second Phase of the Beaters Penetration—Medium Depth | Third Trial

(12 Inches of Turnbuckle Linkage)

Third Phase of the Beaters Penetration—Deep Depth |

|---|

| Into the Tree Canopy | From

Main Trunk

(Inches) | From Ground (Inches) | Avg. of Max. Accel. Mag. (g) | Avg. of Gravi. Accel. (g) | Avg. of Max. Accel. Mag. (g) | Avg. of Gravi. Accel. (g) | Avg. of Max. Accel. Mag. (g) | Avg. of Gravi. Accel. (g) |

|---|

| 1 | Right edge | 36 | 54 | 0.56 | 5.559 | 1.298 | 6.151 | 1.268 | 4.070 | 1.170 |

| 2 | Right edge, Top | 8 | 73 | 0.74 | 2.740 | 0.988 | 4.319 | 0.989 | 1.988 | 0.963 |

| 3 | Right edge, Down | 20 | 35 | 1.19 | 3.782 | 0.996 | 3.516 | 0.973 | 3.130 | 0.992 |

| 4 | Left edge, Top | 29 | 57 | 0.72 | 4.604 | 1.110 | 4.799 | 1.063 | 7.804 | 1.181 |

| 5 | Back edge, Right | 28 | 50 | 0.66 | 3.343 | 1.106 | 2.999 | 1.081 | 4.230 | 1.104 |

| 6 | Central edge, Left, Back | 15 | 58 | 1.25 | 1.884 | 1.045 | 1.691 | 1.030 | 2.588 | 1.044 |

| 7 | Left edge, Front | 31 | 52 | 0.82 | 4.427 | 1.155 | 3.763 | 1.113 | 5.041 | 1.154 |

| 8 | Central edge, Top, Left, Front | 8 | 72 | 0.55 | 1.910 | 1.034 | 2.228 | 1.029 | 2.561 | 1.033 |

| 9 | Central edge, Left, Back | 30 | 75 | 0.68 | 2.823 | 1.089 | 2.464 | 1.075 | 3.450 | 1.095 |

| 10 | Right edge, Front, Down | 31 | 38 | 0.90 | 6.074 | 1.181 | 7.255 | 1.301 | 6.457 | 1.274 |

| 11 | Central edge, Front, Top | 33 | 58 | 0.71 | 2.877 | 1.057 | 2.219 | 1.053 | 2.169 | 1.050 |

| 12 | Left edge | 33 | 40 | 0.63 | 4.070 | 1.236 | 3.348 | 1.163 | 6.207 | 1.264 |

| 13 | Left edge, Top | 15 | 58 | 0.69 | 2.361 | 1.027 | 2.677 | 1.021 | 3.292 | 1.052 |

| 14 | Left edge, Front | 24 | 36 | 0.85 | 2.622 | 1.068 | 2.592 | 1.063 | 2.738 | 1.075 |

| 15 | Central edge, Back, Down, Rear of the main trunk | 20 | 27 | 0.90 | 1.971 | 0.986 | 2.207 | 0.975 | 1.994 | 0.985 |

| Avg. (g) | 3.403 b | 1.092 | 3.482 ab | 1.080 | 3.848 a | 1.096 |

| S.D. (g) | 1.772 | 0.100 | 1.717 | 0.096 | 1.879 | 0.096 |

Table 3.

A precise average magnitude of the acceleration (g) among the tree canopy branches using 14 shaking beaters, depending on the delimited accelerometer sensors locations and the machine operating variables at three different tree canopies.

Table 3.

A precise average magnitude of the acceleration (g) among the tree canopy branches using 14 shaking beaters, depending on the delimited accelerometer sensors locations and the machine operating variables at three different tree canopies.

No.

of Trees | No.

of Accel. Sensors | Accelerometer Sensors Locations | Branch Dia. at

the Posted Sensor (Inches) | First Trial

(Low Beaters Shaking Speed) | Second Trial

(High Beaters Shaking Speed) |

|---|

45.30

(in/s) | 65.90

(in/s) |

|---|

| Into the Tree Canopy | From

Main Trunk

(Inches) | From Ground (Inches) | Avg. of Max. Accel. Mag. (g) | Avg. of Gravi. Accel.

(g) | Avg. of Max. Accel. Mag. (g) | Avg. of Gravi. Accel.

(g) |

|---|

| 1 | 1 | Left edge | 18 | 37 | 1.28 | 2.674 | 1.066 | 4.280 | 1.160 |

| 2 | Left edge, Top | 12 | 65 | 0.74 | 3.470 | 1.011 | 4.216 | 1.074 |

| 3 | Central edge, Back | 21 | 27 | 0.91 | 2.088 | 0.935 | 1.933 | 0.955 |

| 4 | Right edge | 24 | 34 | 1.41 | 7.387 | 1.242 | 7.525 | 1.529 |

| 5 | Right edge Top, Back | 12 | 56 | 0.73 | 3.800 | 1.041 | 4.698 | 1.097 |

| 2 | 6 | Left edge | 32 | 45 | 1.00 | 3.188 | 1.176 | 4.884 | 1.317 |

| 7 | Left edge, Top | 15 | 57 | 0.78 | 3.010 | 1.022 | 5.907 | 1.126 |

| 8 | Right edge, Top, Back | 20 | 62 | 0.57 | 4.320 | 1.229 | 6.947 | 1.411 |

| 9 | Right edge, Down | 13 | 31 | 0.83 | 3.995 | 1.113 | 5.740 | 1.212 |

| 10 | Right edge, Top, Front | 17 | 52 | 0.58 | 2.660 | 1.036 | 4.759 | 1.086 |

| 3 | 11 | Left edge | 20 | 44 | 0.71 | 3.756 | 1.080 | 4.667 | 1.190 |

| 12 | Central edge, Right, Front | 15 | 56 | 0.69 | 2.286 | 0.997 | 3.425 | 1.070 |

| 13 | Left edge, Back | 24 | 40 | 0.87 | 2.409 | 1.037 | 4.024 | 1.194 |

| 14 | Right edge | 16 | 40 | 0.71 | 6.168 | 1.176 | 8.004 | 1.300 |

| 15 | Central edge, Right, Top | 8 | 64 | 0.89 | 3.540 | 1.055 | 4.652 | 1.143 |

| Avg. (g) | 3.650 a | 1.081 | 5.044 a | 1.191 |

| S.D. (g) | 1.708 | 0.091 | 1.883 | 0.156 |

Table 4.

The average magnitude of the acceleration (g) among the harvester’s beaters, depending on operating the two beater units independently at two shaking speeds.

Table 4.

The average magnitude of the acceleration (g) among the harvester’s beaters, depending on operating the two beater units independently at two shaking speeds.

Sensor