CFD Analysis of Irradiance and Its Distribution in a Photovoltaic Greenhouse

Abstract

1. Introduction

2. Materials and Methods

2.1. Numerical Simulations

- 1.

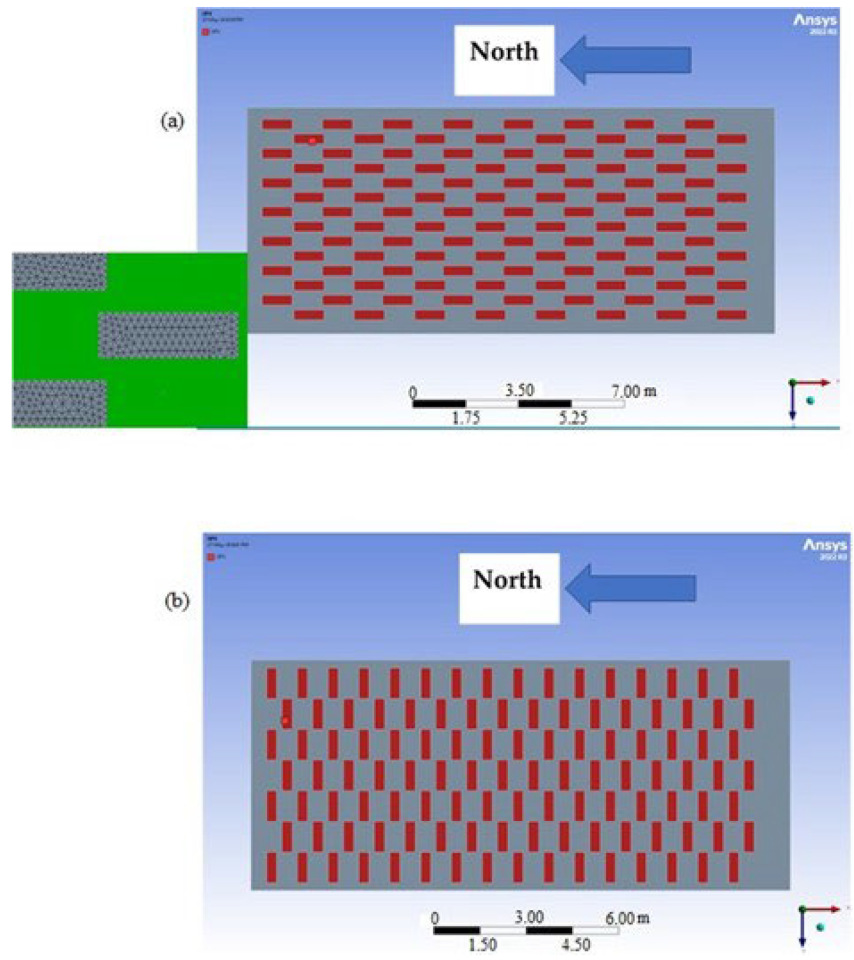

- Checkerboard patterns

- -

- Checkerboard with north–south strips (NSC) and checkerboard with east–west strips (EWC) (Figure 2).

- -

- Each checkerboard element measured 0.33 m × 1.05 m.

- -

- The distance between adjacent elements in the north–south direction was 1.05 m.

- 2.

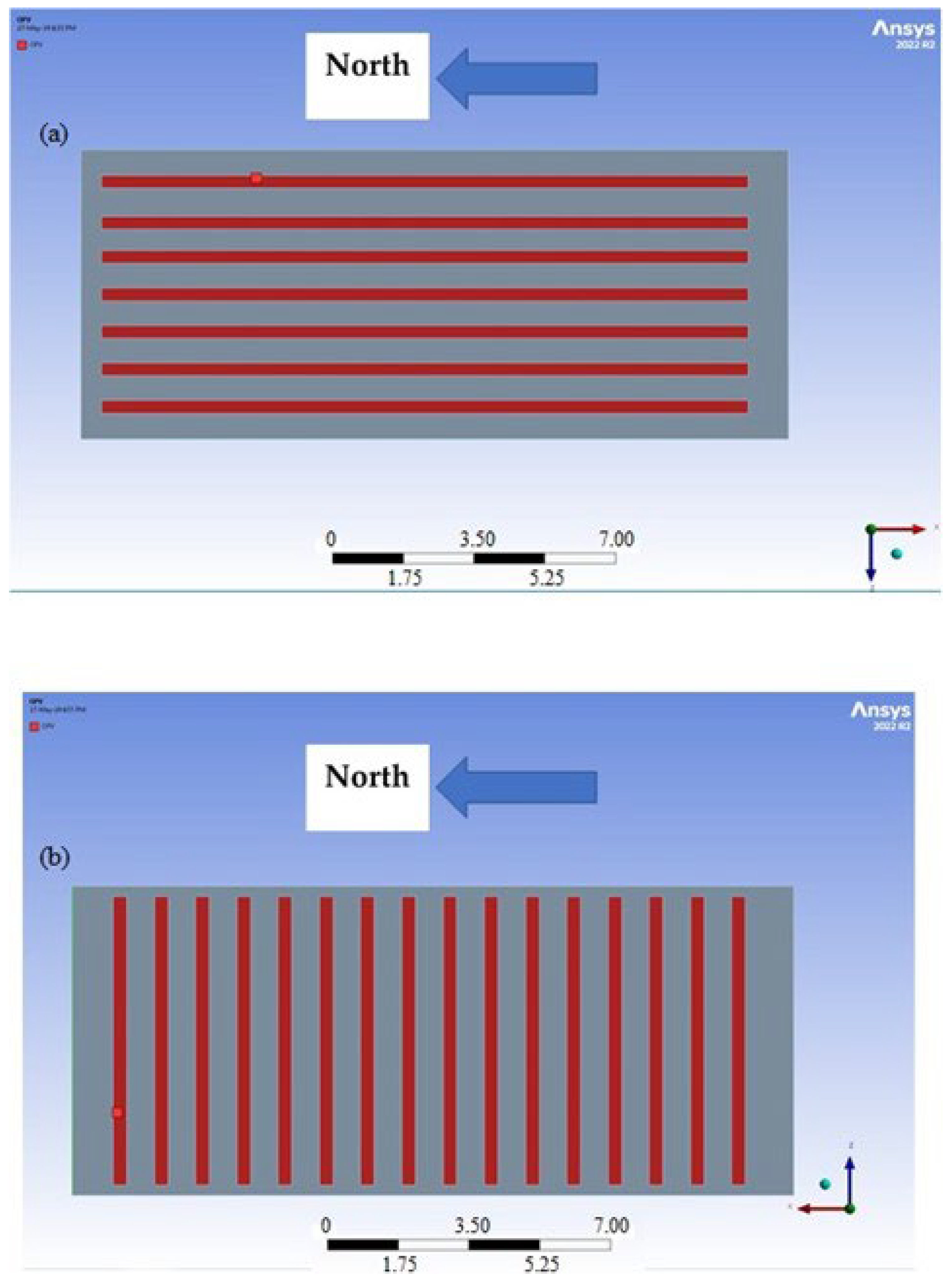

- Straight-line patterns

- -

- North–south straight-line (NSL) and east–west straight-line (EWL) (Figure 3).

- 3.

- Pitched roof arrangement

- -

- North–south straight-line OPV arrangement in a greenhouse with a pitched roof (NSLP).

2.2. Uniformity of the MAVR Distribution

3. Results and Discussion

3.1. Validation Stage

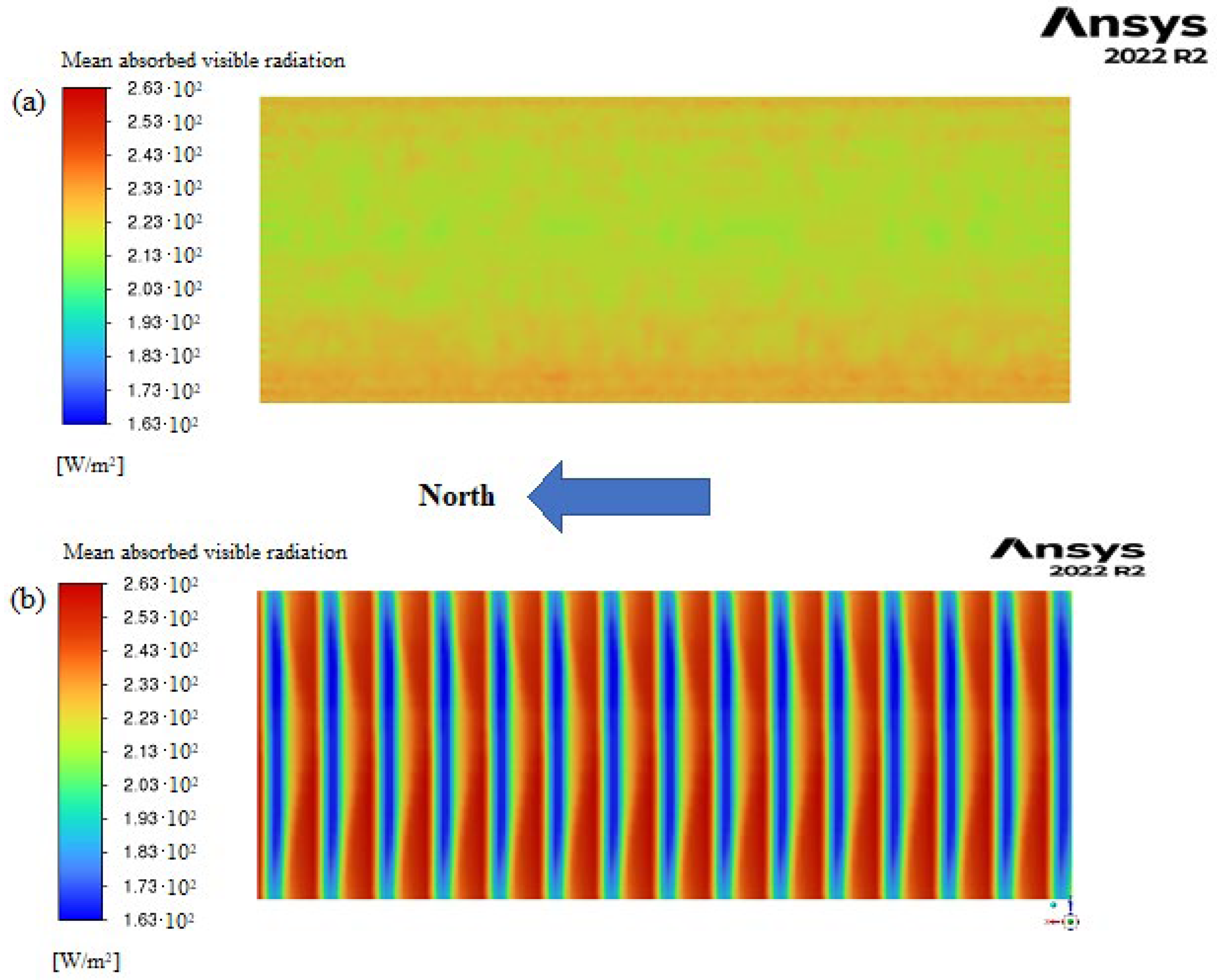

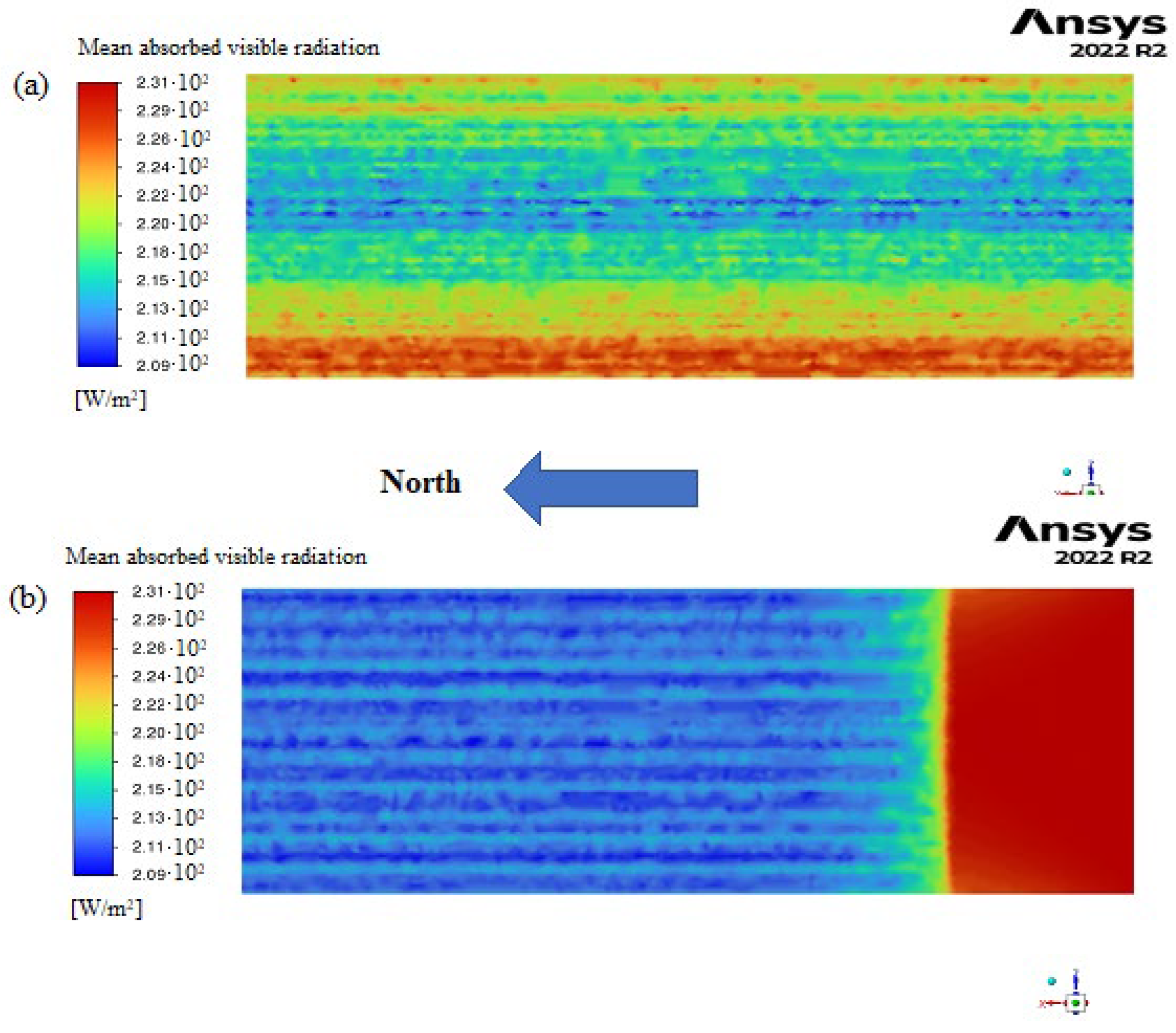

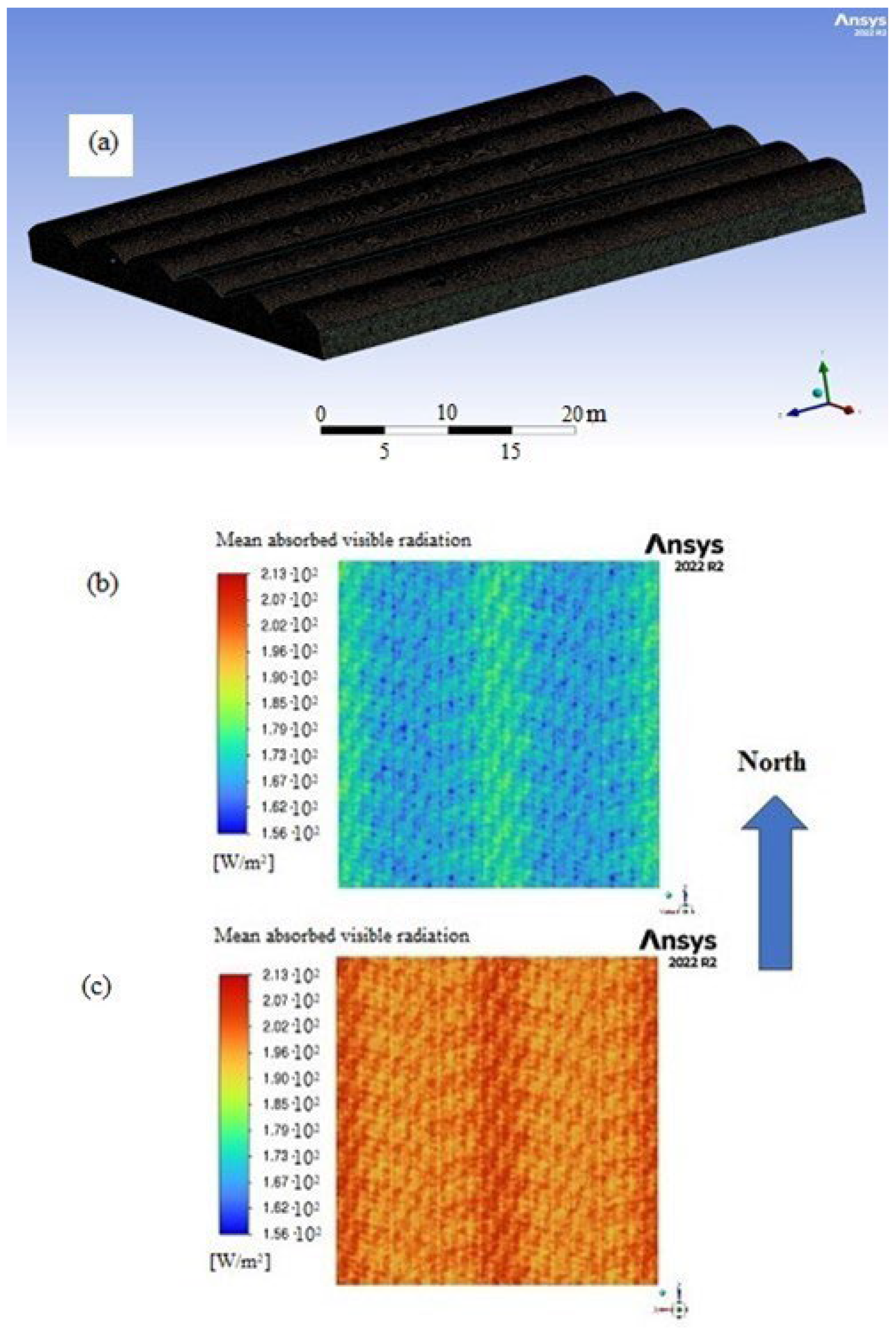

3.2. Simulations of a Tunnel Greenhouse with OPV Modules—the 21 June Case

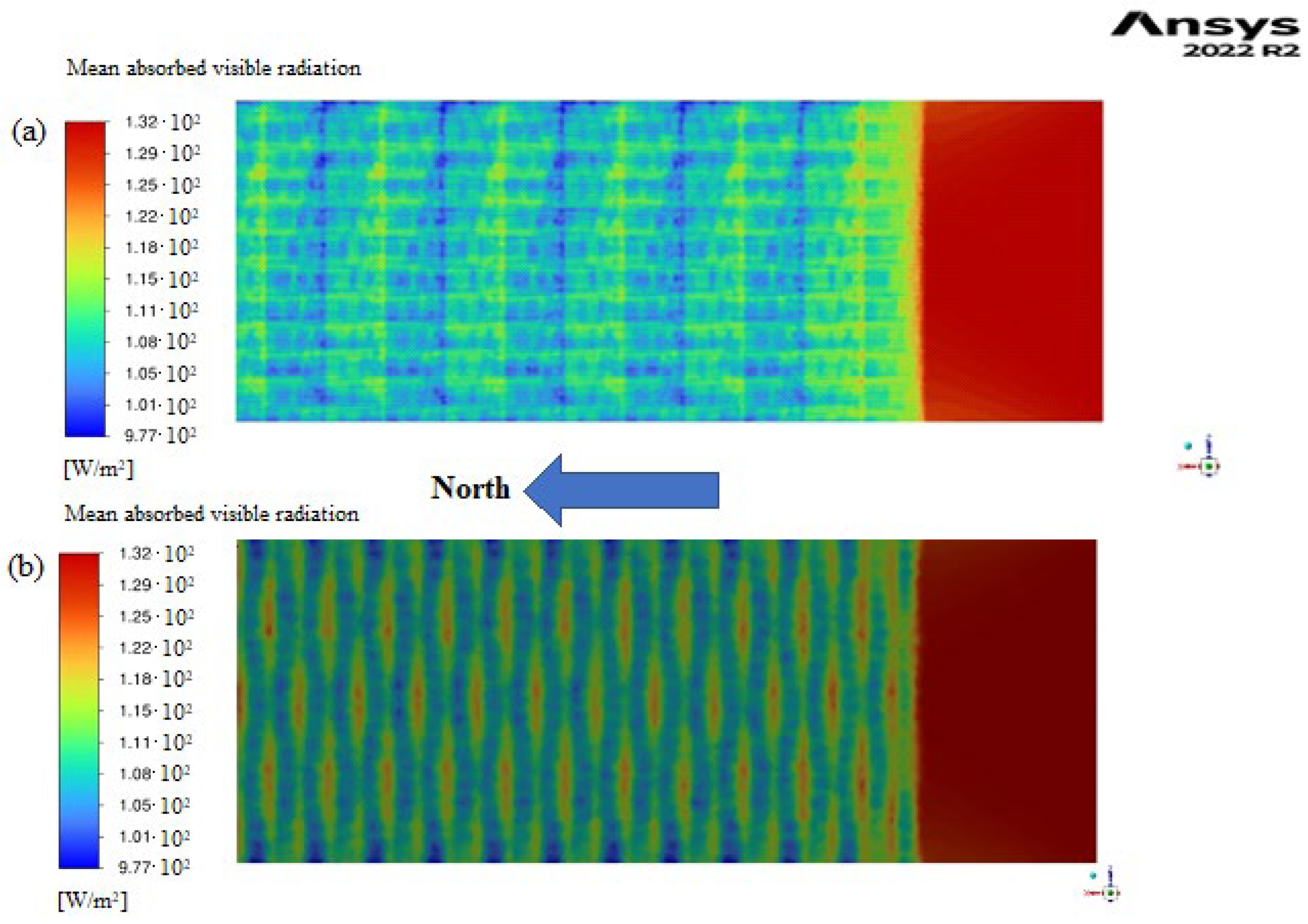

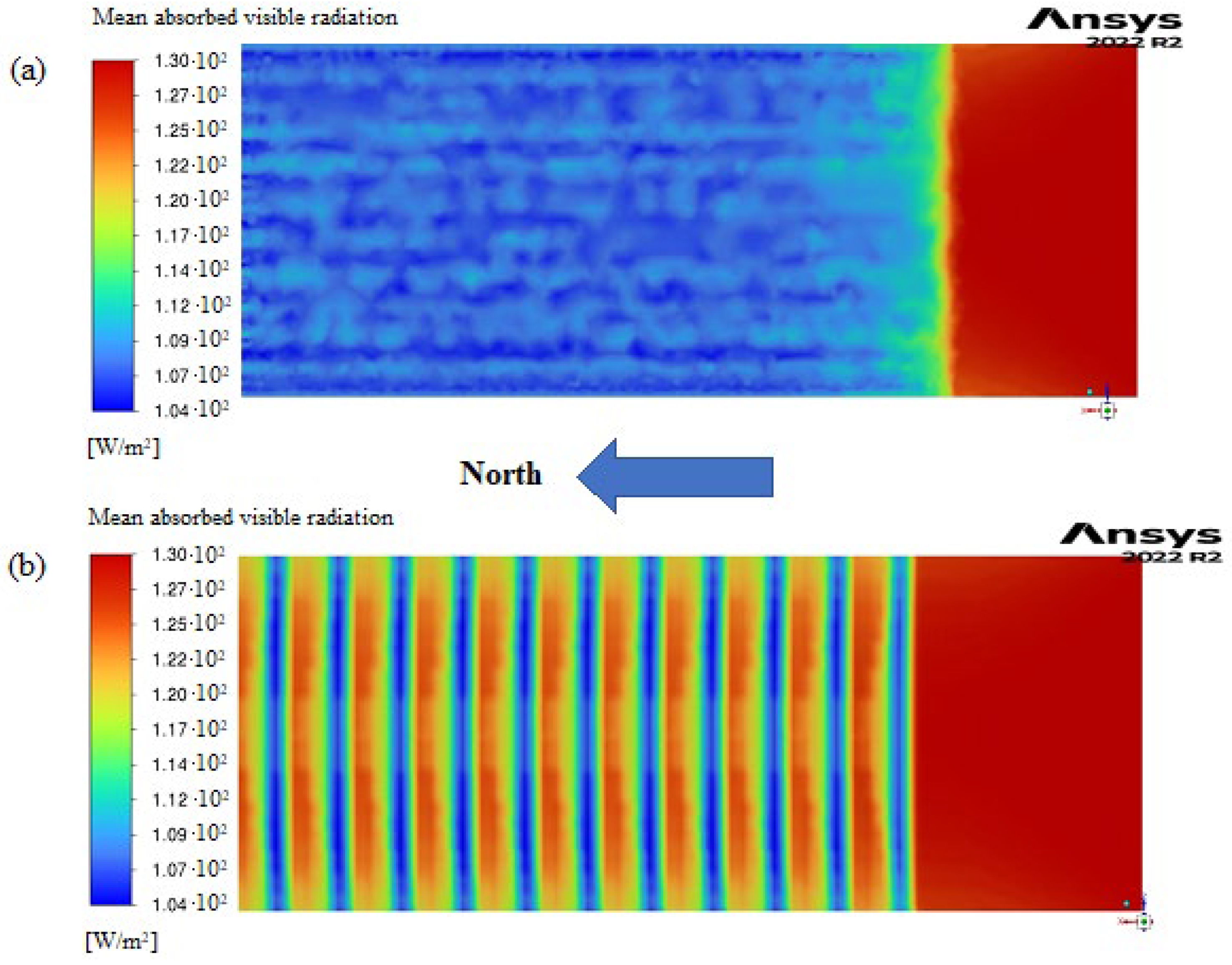

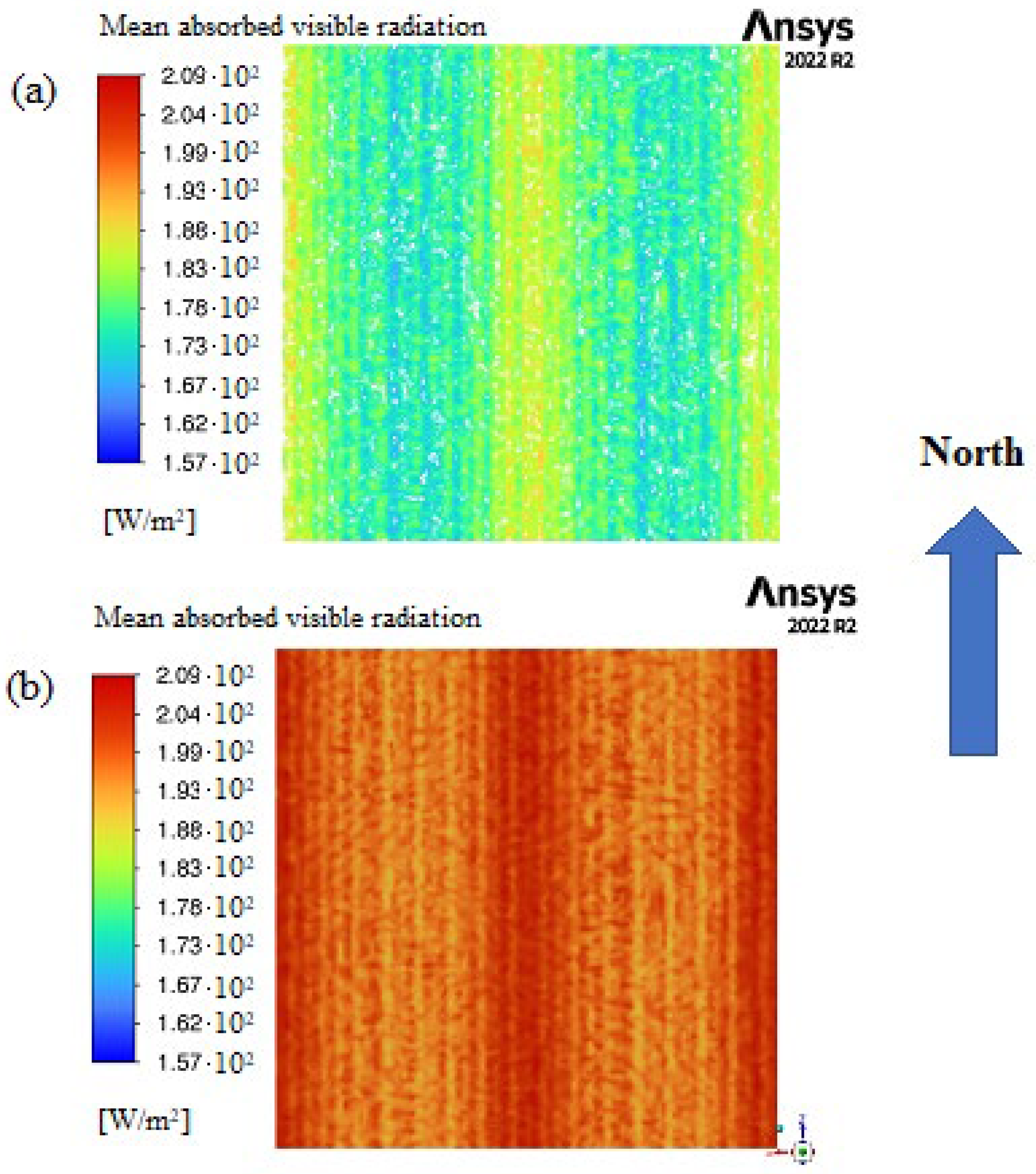

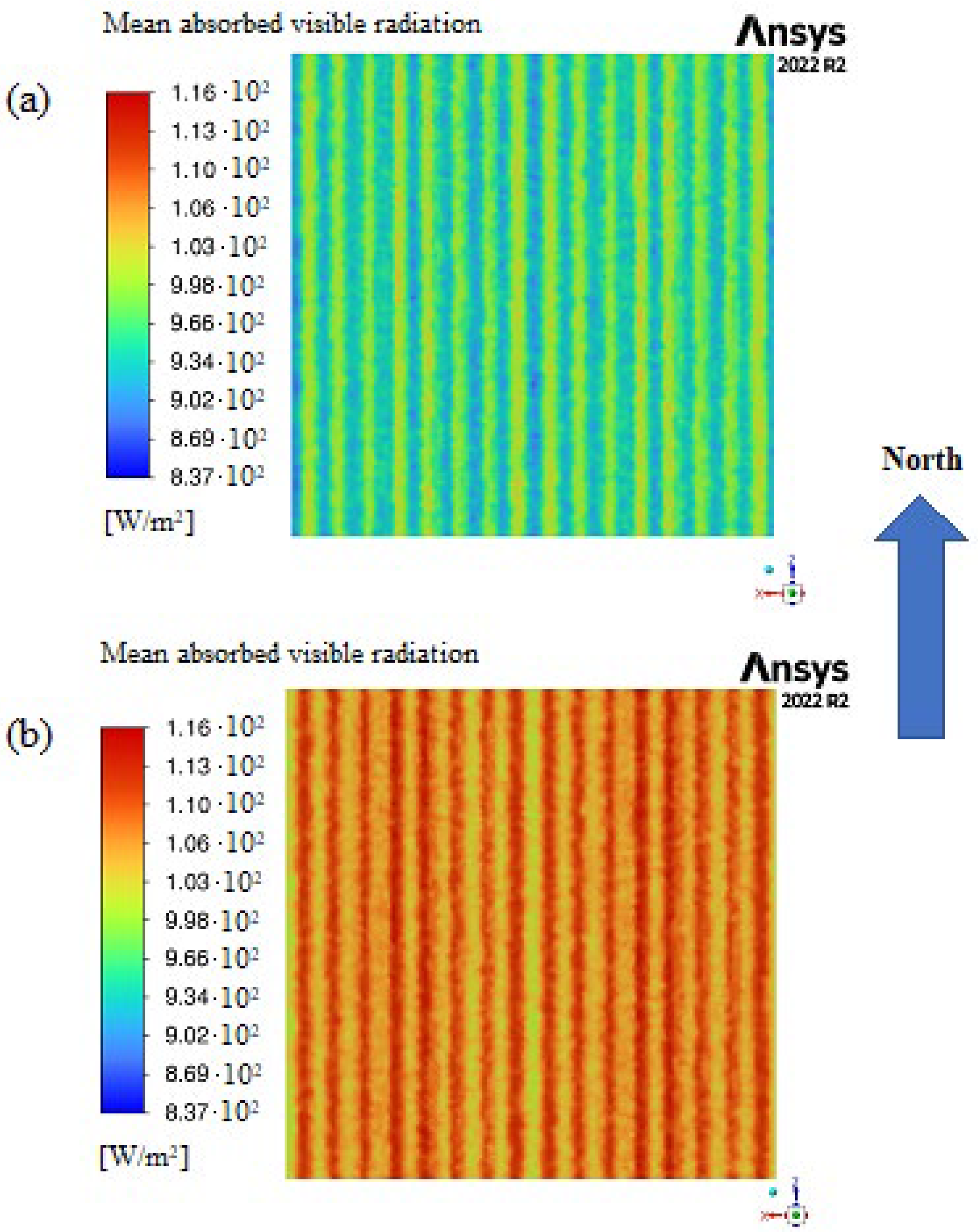

3.3. Simulations of a Mono-Span Greenhouse with OPV Modules—the 21 December Case

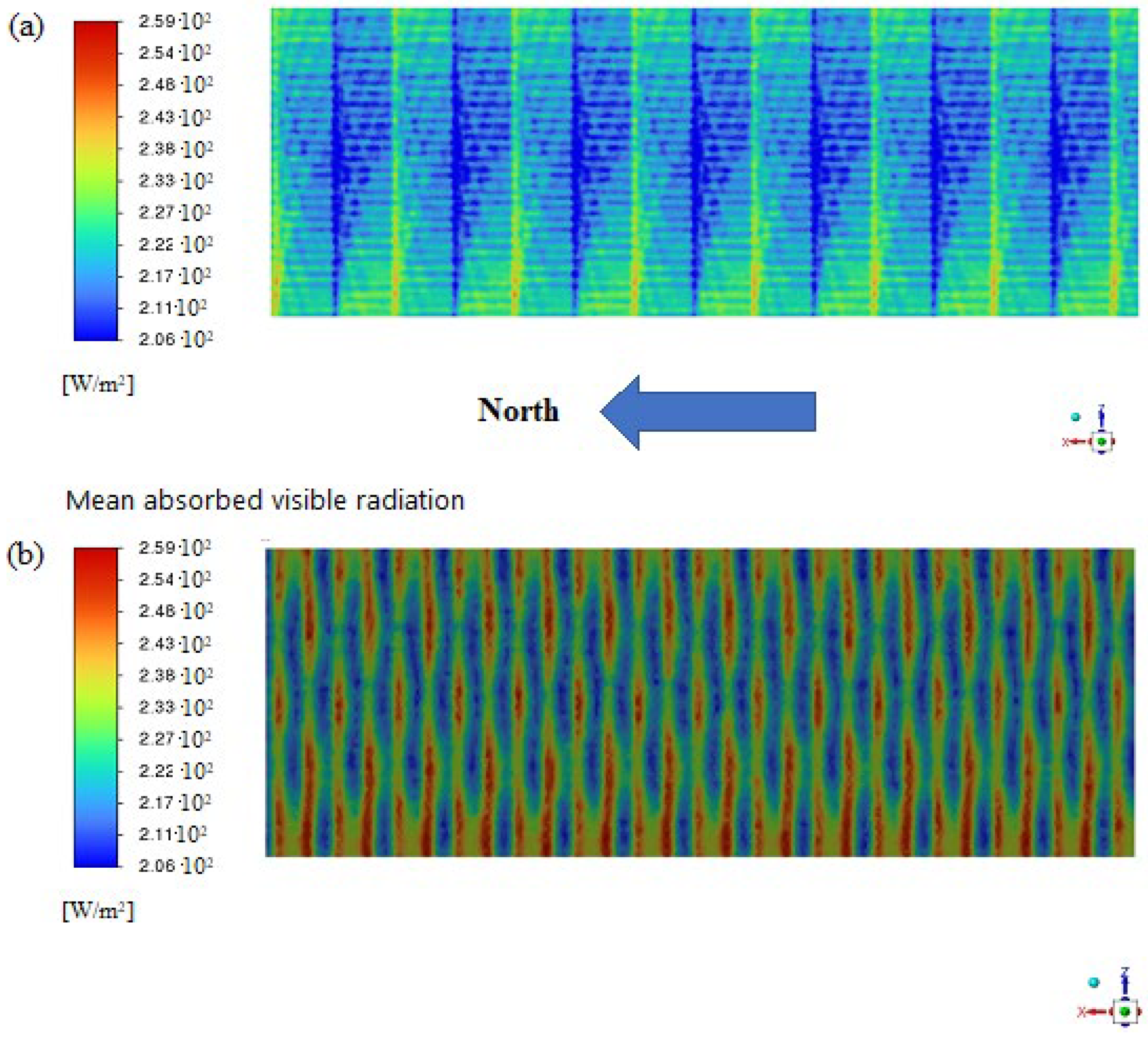

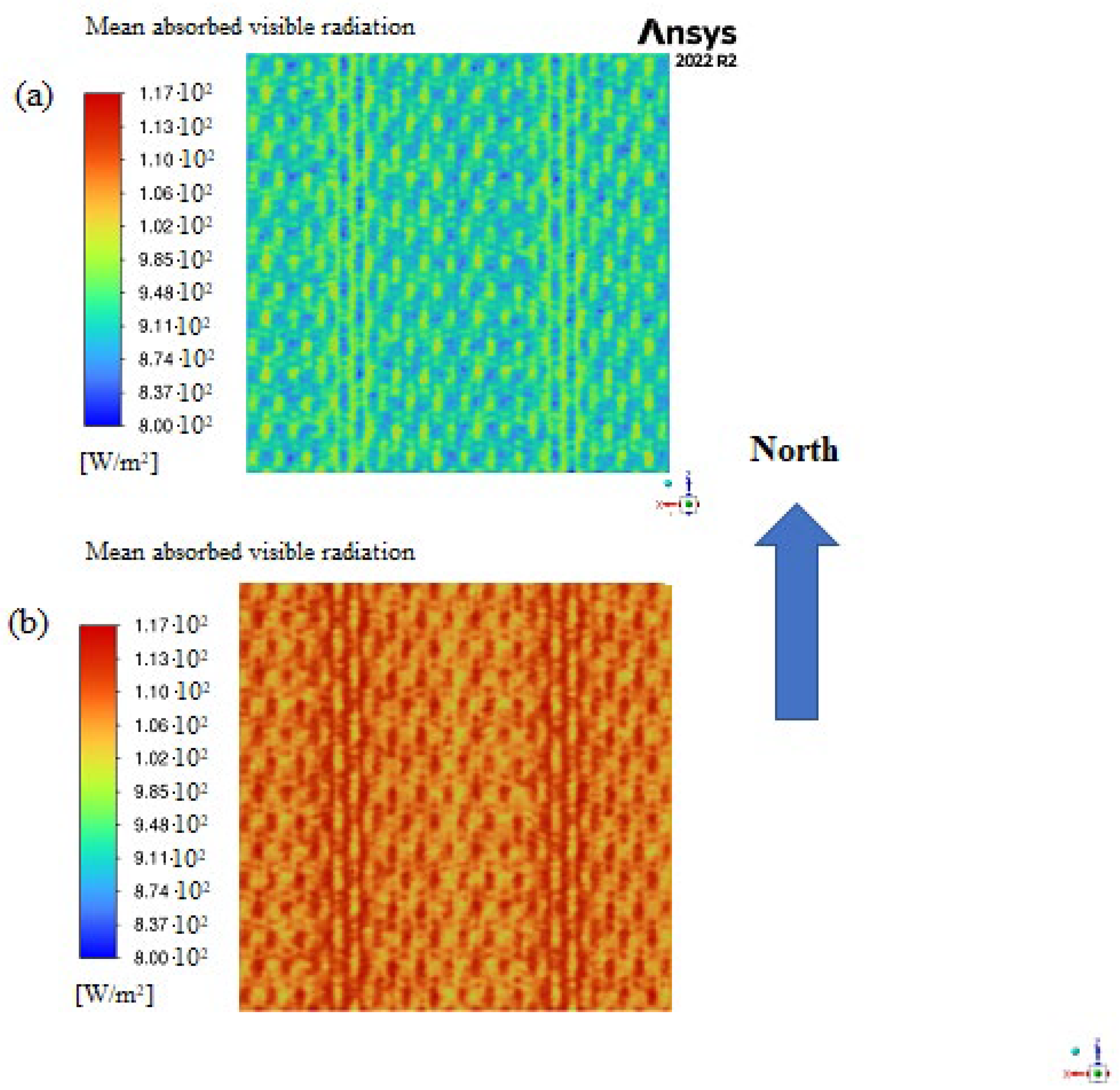

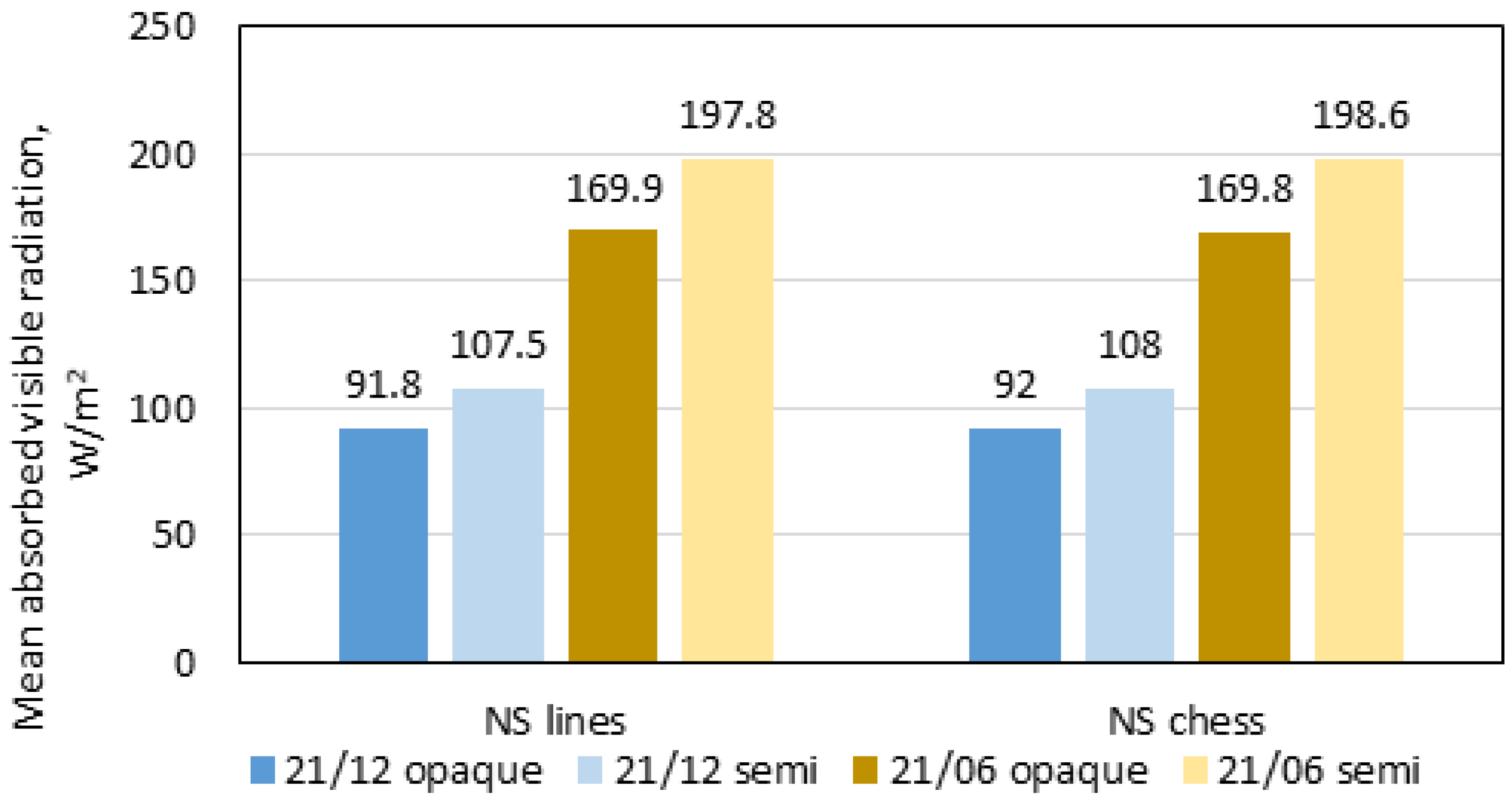

3.4. Simulations of a Multi-Span Greenhouse with Opaque and Semi-Transparent Modules: NSC Layout

3.5. Simulations of a Multi-Span Greenhouse with Opaque and Semi-Transparent Modules: NSL Layout

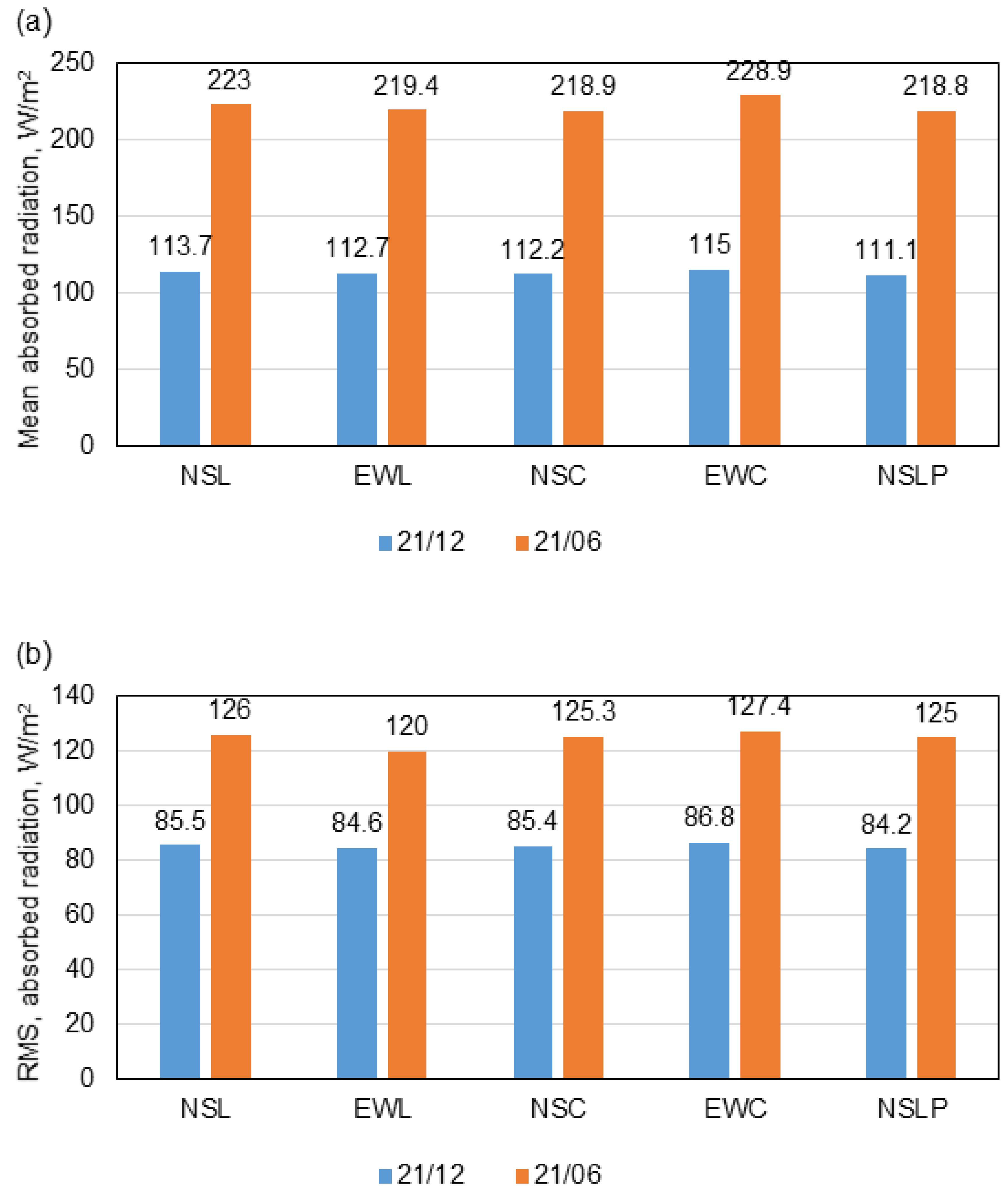

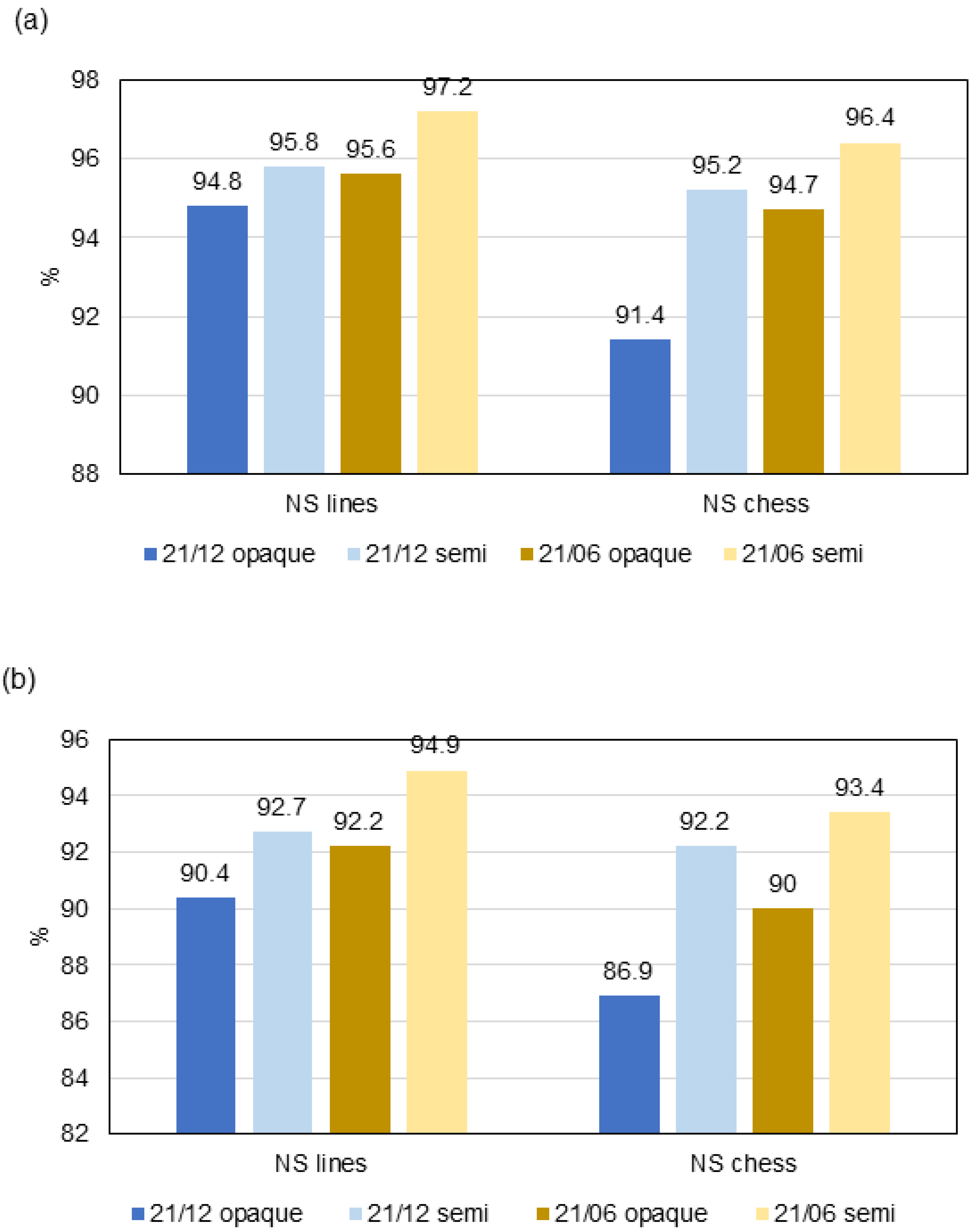

3.6. Uniformity of the MAVR Distribution

3.7. The Potential of Energy Production

4. Conclusions

- (1)

- Opaque NS straight-line strips (NSL) resulted in a slightly more homogeneous mean absorbed visible radiation (MAVR) distribution at ground level than the NS checkerboard layout (NSC). The difference in MAVR homogeneity between semi-transparent NSL and NSC was negligible.

- (2)

- East–west semi-transparent straight-line strips (EWL) resulted in the worst MAVR distribution.

- (3)

- Visible radiation distribution in summer was better than in winter.

- (4)

- MAVR values in a large multi-span greenhouse were lower than in a mono-span tunnel greenhouse.

- (5)

- MAVR values were higher under a semi-transparent PV than under an opaque material, as expected.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CFD | Computational fluid dynamics |

| EW | East–west |

| EWC | Checkerboard with east–west strips |

| EWL | East–west straight-line strips |

| IR | Infra-red |

| MAVR | Mean absorbed visible radiation |

| NS | North–south |

| NSC | Checkerboard with north–south strips |

| NSL | North–south straight-line strips |

| NSLP | North–south straight-line strips in a greenhouse with a pitched roof |

| OPV | Organic photovoltaic |

| PAR | Photosynthetically active radiation |

| PPFD | Photosynthetic photon flux density |

| PV | Photovoltaic |

References

- Yano, A.; Furue, A.; Kadowaki, M.; Tanaka, T.; Hiraki, E.; Miyamoto, M.; Ishizu, F.; Noda, S. Electrical energy generated by photovoltaic modules mounted inside the roof of a north-south oriented greenhouse. Biosyst. Eng. 2009, 103, 228–238. [Google Scholar] [CrossRef]

- Kadowaki, M.; Yano, A.; Ishizu, F.; Tanaka, T.; Noda, S. Effects of greenhouse photovoltaic array shading on Welsh onion growth. Biosyst. Eng. 2012, 111, 290–297. [Google Scholar] [CrossRef]

- Cossu, M.; Murgia, L.; Ledda, L.; Deligios, P.A.; Sirigu, A.; Chessa, F.; Pazzona, A. Solar radiation distribution inside a greenhouse with south-oriented photovoltaic roofs and effects on crop productivity. Appl. Energy 2014, 133, 89–100. [Google Scholar] [CrossRef]

- Marucci, A.; Cappuccini, A. Dynamic photovoltaic greenhouse: Energy efficiency in clear sky conditions. Appl. Energy 2016, 170, 362–376. [Google Scholar] [CrossRef]

- Trypanagnostopoulos, G.; Kavga, A.; Souliotis, M.; Tripanagnostopoulos, Y. Greenhouse performance results for roof installed photovoltaics. Renew. Energy 2017, 111, 724–731. [Google Scholar] [CrossRef]

- Okada, K.; Yehia, I.; Teitel, M.; Kacira, M. Crop production and energy generation in a greenhouse integrated with semi-transparent organic photovoltaic film. Acta Hortic. 2018, 1227, 231–239. [Google Scholar] [CrossRef]

- Ezzaeri, K.; Fatnassi, H.; Bouharroud, R.; Gourdo, L.; Bazgaou, A.; Wifaya, A.; Demrati, H.; Bekkaoui, A.; Aharoune, A.; Poncet, C.; et al. The effect of photovoltaic panels on the microclimate and on the tomato production under photovoltaic Canarian greenhouses. Sol. Energy 2018, 173, 1126–1134. [Google Scholar] [CrossRef]

- Friman-Peretz, M.; Ozer, S.; Levi, A.; Magadley, E.; Yehia, I.; Geoola, F.; Gantz, S.; Brikman, R.; Levy, A.; Kacira, M.; et al. Energy partitioning and spatial variability of air temperature, VPD and radiation in a greenhouse tunnel shaded by semi-transparent organic PV modules. Sol. Energy 2021, 220, 578–589. [Google Scholar] [CrossRef]

- Friman-Peretz, M.; Ozer, S.; Geoola, F.; Magadley, E.; Yehia, I.; Levi, A.; Brikman, R.; Gantz, S.; Levy, A.; Kacira, M.; et al. Microclimate and crop performance in a tunnel greenhouse shaded by organic photovoltaic modules—Comparison with conventional shaded and unshaded tunnels. Biosyst. Eng. 2020, 197, 12–31. [Google Scholar] [CrossRef]

- Friman-Peretz, M.; Geoola, F.; Yehia, I.; Ozer, S.; Levi, A.; Magadley, E.; Brikman, R.; Rosenfeld, L.; Levy, A.; Kacira, M.; et al. Testing organic photovoltaic modules for application as greenhouse cover or shading element. Biosyst. Eng. 2019, 184, 24–36. [Google Scholar] [CrossRef]

- Ben-Amara, H.; Bouadila, S.; Fatnassi, H.; Arici, M.; Guizani, A.A. Climate assessment of greenhouse equipped with south-oriented PV roofs: An experimental and computational fluid dynamics study. Sustain. Energy Technol. Assess. 2021, 45, 101100. [Google Scholar] [CrossRef]

- Ghaffarpour, Z.; Fakhroleslam, M.; Amidpour, M. Calculation of energy consumption, tomato yield, and electricity generation in a PV-integrated greenhouse with different solar panels configuration. Renew. Energy 2024, 229, 120723. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Li, M.; Yin, F. The integration of semitransparent photovoltaics on greenhouse roof for energy and plant production. Renew. Energy 2018, 121, 377–388. [Google Scholar] [CrossRef]

- Ezzaeri, K.; Fatnassi, H.; Wifaya, A.; Bazgaou, A.; Aharoune, A.; Poncet, C.; Bekkaoui, A.; Bouirden, L. Performance of photovoltaic canarian greenhouse: A comparison study between summer and winter seasons. Sol. Energy 2020, 198, 275–282. [Google Scholar] [CrossRef]

- Cossu, M.; Cossu, A.; Deligios, P.A.; Ledda, L.; Li, Z.; Fatnassi, H.; Poncet, C.; Yano, A. Assessment and comparison of the solar radiation distribution inside the main commercial photovoltaic greenhouse types in Europe. Renew. Sustain. Energy Rev. 2018, 94, 822–834. [Google Scholar] [CrossRef]

- Cossu, M.; Yano, A.; Solinas, S.; Deligios, P.A.; Tiloca, M.T.; Cossu, A.; Ledda, L. Agricultural sustainability estimation of the European photovoltaic greenhouses. Eur. J. Agron. 2020, 118, 126074. [Google Scholar] [CrossRef]

- Waller, R.; Kacira, M.; Magadley, E.; Teitel, M.; Yehia, I. Semi-transparent organic photovoltaics applied as greenhouse shade for spring and summer tomato production in arid climate. Agronomy 2021, 11, 1152. [Google Scholar] [CrossRef]

- Yano, A.; Kadowaki, M.; Furue, A.; Tamaki, N.; Tanaka, T.; Hiraki, E.; Kato, Y.; Ishizu, F.; Noda, S. Shading and electrical features of a photovoltaic array mounted inside the roof of an east-west oriented greenhouse. Biosyst. Eng. 2010, 106, 367–377. [Google Scholar] [CrossRef]

- Fatnassi, H.; Poncet, C.; Bazzano, M.M.; Brun, R.; Bertin, N. A numerical simulation of the photovoltaic greenhouse microclimate. Sol. Energy 2015, 120, 575–584. [Google Scholar] [CrossRef]

- Lu, L.; Ya’acob, M.E.; Anuar, M.S.; Mohtar, M.N. Comprehensive review on the application of inorganic and organic photovoltaics as greenhouse shading materials. Sustain. Energy Technol. Assess. 2022, 52, 102077. [Google Scholar] [CrossRef]

- Gorjian, S.; Bousi, E.; Ozdemir, O.E.; Trommsdorff, M.; Kumar, N.M.; Anand, A.; Kant, K.; Chopra, S.S. Progress and challenges of crop production and electricity generation in agrivoltaic systems using semi-transparent photovoltaic technology. Renew. Sustain. Energy Rev. 2022, 158, 112126. [Google Scholar] [CrossRef]

- Mabindisa, R.; Tambwe, K.; Mciteka, L.; Ross, N. Organic nanostructured materials for sustainable applications in next generation solar cells. Appl. Sci. 2021, 11, 11324. [Google Scholar] [CrossRef]

- Meitzner, R.; Schubert, U.S.; Hoppe, H. Agrivoltaics the perfect fit for the future of organic photovoltaics. Adv. Energy Mater. 2020, 11, 2002551. [Google Scholar] [CrossRef]

- Chalkias, D.A.; Charalampopoulos, G.; Andreopoulou, A.K.; Karavioti, A.; Stathatos, E. Spectral engineering of semi-transparent dye-sensitized solar cells using new triphenylamine-based dyes and an iodine-free electrolyte for greenhouse-oriented applications. J. Power Sources 2021, 496, 229842. [Google Scholar] [CrossRef]

- Jean, J.; Brown, P.R.; Jaffe, R.L.; Buonassisi, T.; Bulović, V. Pathways for solar photovoltaics. Energy Environ. Sci. 2015, 8, 1200–1219. [Google Scholar] [CrossRef]

- Chalkias, D.A.; Stathatos, E. The Emergence of Agrivoltaics, Current Status, Challenges and Future Opportunities; Springer: Berlin/Heidelberg, Germany, 2024; ISBN 978-3-031-48861-0. [Google Scholar] [CrossRef]

- Castellano, S.; Santamaria, P.; Serio, F. Solar radiation distribution inside a monospan greenhouse with the roof entirely covered by photovoltaic panels. J. Agric. Eng. 2016, 47, 1–6. [Google Scholar] [CrossRef]

- Chen, J.; Xu, F.; Ding, B.; Wu, N.; Shen, Z.; Zhang, L. Performance analysis of radiation and electricity yield in a photovoltaic panel integrated greenhouse using the radiation and thermal models. Comput. Electron. Agric. 2019, 164, 104904. [Google Scholar] [CrossRef]

- Torrente, C.J.; Reca, J.; L’opez-Luque, R.; Martínez, J.; Casares, F.J. Simulation model to analyze the spatial distribution of solar radiation in agrivoltaic Mediterranean greenhouses and its effect on crop water needs. Appl. Energy 2024, 353, 122050. [Google Scholar] [CrossRef]

- Baxevanou, C.; Fidaros, D.K.; Katsoulas, N.; Mekeridis, E.; Varlamis, C.; Zachariadis, A.; Logothetidis, S. Simulation of Radiation and Crop Activity in a Greenhouse Covered with Semitransparent Organic Photovoltaics. Appl. Sci. 2020, 10, 2550. [Google Scholar] [CrossRef]

- ANSYS. Fluent Theory Guide; Technology Drive: Canonsburg, PA, USA, 2013; p. 275. [Google Scholar]

- Franco, J.E.; Rodríguez-Arroyo, J.A.; Ortiz, I.M.; Sánchez-Soto, P.J.; Garzón, E.; Lao, M.T. Chemical, radiometric and mechanical characterization of commercial polymeric films for greenhouse applications. Materials 2022, 15, 5532. [Google Scholar] [CrossRef]

- Goerner, F.L.; Duong, T.; Stafford, R.J.; Clarke, G.D. A comparison of five standard methods for evaluating image intensity uniformity in partially parallel imaging MRI. Med. Phys. 2013, 40, 082302. [Google Scholar] [CrossRef] [PubMed]

- Teitel, M.; Grimberg, R.; Ozer, S.; Vitoshkin, H.; Yehia, I.; Magadley, E.; Levi, A.; Ziffer, E.; Gantz, S.; Levy, A. Effects of organic photovoltaic modules installed inside greenhouses on microclimate and plants. Biosyst. Eng. 2023, 232, 81–96. [Google Scholar] [CrossRef]

- Marcelis, L.F.M.; Broekhuijsen, A.G.M.; Meinen, E.; Nijs, E.M.F.M.; Raaphorst, M.G.M. Quantification of the growth response to light quantity of greenhouse grown crops. Acta Hortic. 2006, 711, 97–104. [Google Scholar] [CrossRef]

- Moretti, S.; Marucci, A. A Photovoltaic Greenhouse with Variable Shading for the Optimization of Agricultural and Energy Production. Energies 2019, 12, 2589. [Google Scholar] [CrossRef]

- Basu, R.; Gumpert, F.; Lohbreier, J.; Morin, P.-O.; Vohra, V.; Liu, Y.; Zhou, Y.; Brabec, C.J.; Egelhaaf, H.-J.; Distler, A. Large-area organic photovoltaic modules with 14.5% certified world record efficiency. Joule 2024, 8, 970–978. [Google Scholar] [CrossRef]

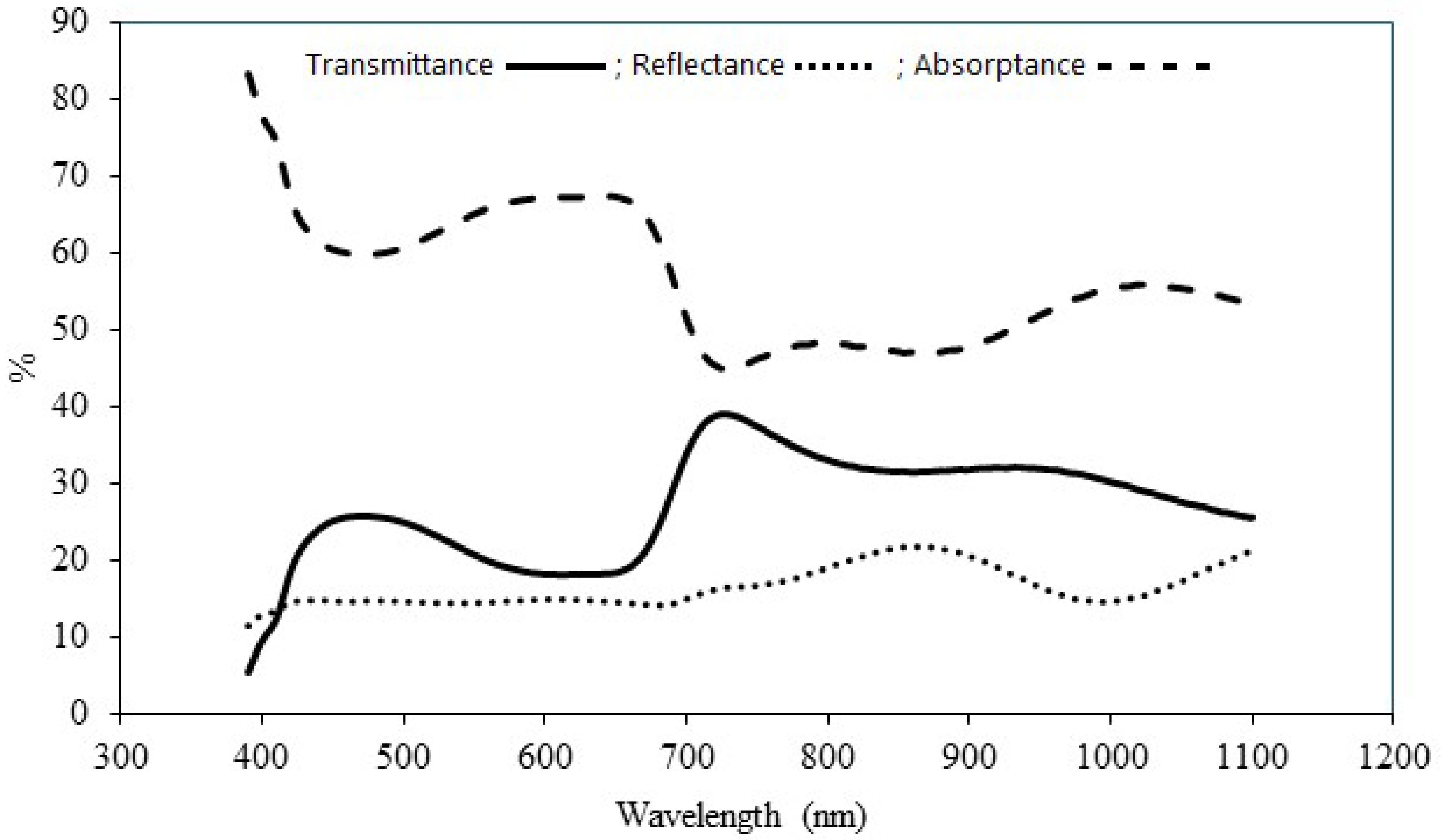

| Polyethylene | OPV Module | |

|---|---|---|

| absorptivity | 0.10 | 0.61 |

| transmissivity | 0.76 | 0.24 |

| reflectivity | 0.14 | 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teitel, M.; Ozer, S.; Vitoshkin, H. CFD Analysis of Irradiance and Its Distribution in a Photovoltaic Greenhouse. Agriculture 2025, 15, 1867. https://doi.org/10.3390/agriculture15171867

Teitel M, Ozer S, Vitoshkin H. CFD Analysis of Irradiance and Its Distribution in a Photovoltaic Greenhouse. Agriculture. 2025; 15(17):1867. https://doi.org/10.3390/agriculture15171867

Chicago/Turabian StyleTeitel, Meir, Shay Ozer, and Helena Vitoshkin. 2025. "CFD Analysis of Irradiance and Its Distribution in a Photovoltaic Greenhouse" Agriculture 15, no. 17: 1867. https://doi.org/10.3390/agriculture15171867

APA StyleTeitel, M., Ozer, S., & Vitoshkin, H. (2025). CFD Analysis of Irradiance and Its Distribution in a Photovoltaic Greenhouse. Agriculture, 15(17), 1867. https://doi.org/10.3390/agriculture15171867